Cair Euromatic Automation is a leading manufacturer, exporter and supplier of motorized valves.

Don't wanna be here? Send us removal request.

Text

How Smart Valves are Transforming the Water Supply Industry

Smart valves are advanced, sensor-integrated control devices designed to optimize fluid flow, pressure, and temperature across critical industrial systems. Equipped with real-time monitoring, remote actuation, and predictive diagnostics, smart valves go beyond traditional valve functions—enabling automated decision-making and seamless integration with SCADA, DCS, and IIoT platforms.

0 notes

Text

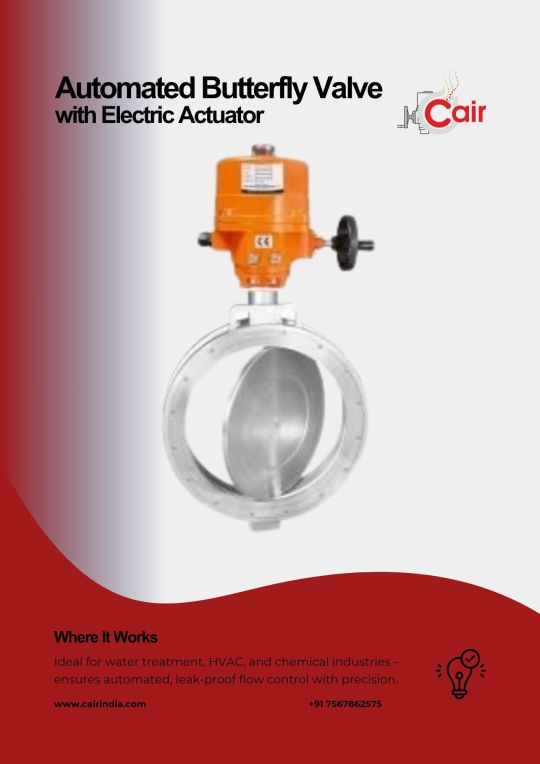

motorised butterfly valve

A motorised butterfly valve is an automated flow control device designed for reliable and efficient regulation of liquids, gases, and slurries in industrial piping systems. Featuring a rotating disc operated by an electric actuator, it provides precise on/off or modulating control with minimal torque and fast response times. Ideal for applications requiring remote operation and process automation, this valve ensures durability, low maintenance, and seamless integration into control systems.

0 notes

Text

Top Benefits of Using Electric Ball Valves in Automation Systems

Advancing Flow Control in the Age of Automation

As industries across the globe continue to digitize and automate, the demand for reliable, responsive, and energy-efficient components has never been higher. One such component at the heart of many modern automated systems is the electric ball valve. Offering precise control over fluid flow with minimal human intervention, electric ball valves are rapidly becoming the go-to solution for process engineers, facility managers, and automation integrators.

These valves are not just about opening or closing pipelines—they play a vital role in enabling intelligent, programmable fluid control across diverse industries. From HVAC systems and water treatment plants to chemical processing units and smart irrigation, electric ball valves provide the seamless integration, efficiency, and performance that today’s industrial applications demand.

What Is an Electric Ball Valve?

An electric ball valve is a motor-operated valve that uses an electric actuator to rotate a ball with a bore, controlling the flow of liquids or gases. Unlike manually operated or pneumatic valves, electric ball valves offer precise, programmable movement, enabling remote operation and full integration into industrial automation networks such as SCADA, PLC, or DCS systems.

Core Components Include:

Valve Body: Typically made of stainless steel, brass, or PVC depending on the application.

Rotating Ball: The central element that regulates flow.

Electric Actuator: Motorized device that controls valve position (on/off or modulating).

Seals and Seats: Provide leak-proof operation under pressure.

Key Benefits of Electric Ball Valves in Automation Systems

1. Precise and Remote Flow Control

One of the greatest advantages of electric ball valves is their precision. These valves allow for accurate modulation and on/off control from remote control centers or programmable systems. Whether it’s adjusting fluid levels in a mixing tank or managing coolant flow in a high-performance process line, electric ball valves deliver fine-tuned control with repeatable accuracy.

2. Reduced Manual Labor and Human Error

In industrial operations, manual valve adjustments introduce the risk of error, inconsistency, and delay. With electric ball valves, these challenges are eliminated. The valves respond to electrical signals instantly, executing commands accurately without the need for manual intervention—especially valuable in hard-to-access or hazardous environments.

3. Seamless Integration with Automation Networks

Electric ball valves are easily integrated into programmable logic controllers (PLCs), distributed control systems (DCS), and industrial Internet of Things (IIoT) setups. This integration allows for real-time monitoring, diagnostics, and system optimization, enabling industries to react swiftly to process changes and data insights.

4. Energy Efficiency and Low Operating Costs

Unlike pneumatic valves that rely on continuous compressed air supply, electric ball valves consume energy only when actuated. This energy-on-demand functionality translates to lower operating costs, especially in systems with infrequent valve cycling. Additionally, electric actuators generally have fewer moving parts than pneumatic systems, reducing long-term maintenance.

5. Durable and Reliable for Harsh Environments

With proper IP-rated enclosures and high-quality materials, electric ball valves can be configured for use in extreme environments—be it high-temperature chemical lines, outdoor irrigation systems, or corrosive marine applications. Their robust design ensures reliable operation even in demanding conditions.

Applications Across Key Industries

Thanks to their versatility and precision, electric ball valves are widely used across various industrial sectors:

HVAC Systems: For automated heating and cooling flow control based on temperature feedback loops.

Water Treatment: Used to manage inlet/outlet flow, dosing chemicals, or distributing clean water with exact timing.

Food and Beverage: Provides sanitary control in automated mixing, CIP (clean-in-place), and filling operations.

Pharmaceuticals: Ensures sterile, leak-proof operation for cleanroom fluid handling.

Agriculture and Irrigation: Enables smart irrigation systems with remote control and time-based scheduling.

Choosing the Right Electric Ball Valve

Selecting the correct electric ball valve involves considering several key parameters:

Media type and pressure rating

Actuation time and power supply (AC or DC)

On/off or modulating control

Enclosure ratings (IP65, IP67, etc.)

Valve body and seat material compatibility

Working with a knowledgeable supplier ensures that the valve selected aligns with your system’s operating environment and automation needs.

One such trusted provider is Cair Euro, known for its advanced range of electric ball valves engineered for industrial-grade performance. Their valves combine durable construction with intelligent actuation, making them a preferred choice for businesses seeking automation-ready flow control solutions.

Conclusion: Powering the Future of Automated Fluid Control

As industries continue to push for smarter, more responsive systems, the electric ball valve stands out as a practical, efficient, and dependable solution. Its blend of accuracy, energy efficiency, and remote control capability makes it indispensable for modern automation strategies.

By incorporating electric ball valves into your system architecture, you not only reduce operational complexity but also future-proof your infrastructure for evolving demands. Whether managing chemical flow, maintaining climate control, or streamlining water distribution, these valves deliver unmatched value and control.

0 notes

Text

Leading Ball Valve Manufacturer

We are a trusted ball valve manufacturer offering high-performance flow control solutions for industrial applications.

0 notes

Text

Cair Euromatic offers Electric Actuator Butterfly Valves, also known as Motorised Butterfly Valves. Our Motorized Butterfly Valves come with the most advanced features and performance.

0 notes

Text

Automated Butterfly Valve with Electric Actuator

Discover the benefits and applications of motorized butterfly valves for precise and automated flow control in HVAC, water treatment, and industrial systems.

0 notes

Text

Powerful Control with Compact Design – Electric Actuator

Experience powerful and precise control with this compact electric actuators, engineered for reliable performance in industrial automation and valve operations.

0 notes

Text

Choosing the Right UPVC Ball Valve: Key Factors for Maximum Efficiency

When it comes to fluid control systems, selecting the proper UPVC ball valve is crucial for ensuring optimal performance, durability, and cost-effectiveness. At Cair Euromatic, we understand that the right valve choice can significantly impact your system's efficiency and maintenance requirements. This comprehensive guide outlines the essential factors to consider when selecting a UPVC ball valve

for your specific application.

Understanding UPVC Ball Valves

UPVC (Unplasticized Polyvinyl Chloride) ball valves have become increasingly popular across various industries due to their excellent chemical resistance, lightweight construction, and affordability. Unlike metal valves, UPVC valves won't corrode when exposed to harsh chemicals, making them ideal for water treatment plants, chemical processing, irrigation systems, and industrial applications.

Key Selection Factors

1. Valve Size and Flow Capacity

The first consideration should always be proper sizing. A valve that's too small will restrict flow and increase pressure drop, while an oversized valve may lead to poor control and higher costs. Measure your pipe diameter accurately and choose a valve with matching specifications. For optimal flow, consider full-port designs that minimize resistance.

2. Pressure and Temperature Ratings

Every UPVC ball valve has specific pressure (PN) and temperature ratings. Standard valves typically handle temperatures between 0°C to 60°C and pressures up to 16 bar. For higher temperature applications, CPVC or reinforced valves may be necessary. Always select a valve rated for at least 20% above your system's maximum operating pressure.

3. Connection Types

The right connection method ensures secure installation and easy maintenance:

Threaded connections (BSP/NPT) for simple installation and removal

Socket weld for permanent, leak-proof joints

Flanged ends for high-pressure industrial systems

Union connections when frequent disassembly is required

4. Chemical Compatibility

While UPVC resists many corrosive substances, always verify compatibility with your specific fluids. These valves work exceptionally well with:

Water and wastewater

Acids and alkalis

Chlorinated water

Many industrial chemicals

Avoid using them with hydrocarbons, strong solvents, or extremely hot fluids beyond their temperature rating.

5. Operation Mechanism

Consider how the valve will be operated:

Manual ball valves with handles are cost-effective for accessible locations

Lever-operated valves allow quick shut-off in emergencies

Automated valves with electric/pneumatic actuators suit remote or automated systems

Quality and Certification

Always look for valves that meet international standards like ISO 9001, ASTM, or DIN. These certifications ensure the valves have undergone rigorous testing for performance and safety. For potable water applications, NSF or WRAS certification is essential.

Maintenance and Longevity

Proper maintenance extends valve life significantly:

Conduct regular inspections for leaks or wear

Clean valves periodically to prevent debris buildup

Lubricate seals when necessary

Avoid over-tightening during installation

Why Choose Cair Euromatic?

At Cair Euromatic, we specialize in high-performance UPVC ball valves designed for reliability and efficiency. Our products offer: ✔ Excellent chemical resistance ✔ Precise flow control ✔ Durable construction ✔ Competitive pricing

With years of industry experience, our technical team can help you select the perfect valve for your specific requirements, ensuring optimal system performance and minimal downtime.

Final Recommendations

Choosing the right UPVC ball valve involves careful consideration of:

System pressure and temperature requirements

Fluid compatibility

Installation and maintenance needs

Operational preferences

By focusing on these factors and selecting quality valves from reputable manufacturers like Cair Euromatic, you can achieve maximum efficiency and longevity in your fluid control systems.

For complex applications or specialized requirements, our experts are always available to provide personalized recommendations and technical support. Invest in the right UPVC ball valve today and experience the difference in performance and reliability.

0 notes

Text

The Future of Motion Control: Why Electric Actuators Lead the Way

In the evolving landscape of industrial automation, motion control plays a pivotal role in ensuring efficiency, precision, and reliability. Among the various technologies available, electric actuators have emerged as the leading choice for industries seeking superior performance and sustainability. With advancements in automation, manufacturers are increasingly shifting toward electric solutions that offer unparalleled benefits over traditional pneumatic and hydraulic systems.

Understanding the Role of Electric Actuators

In electric actuators, electrical energy is converted into mechanical motion. They are widely used in industries such as manufacturing, automotive, aerospace, robotics, and medical equipment, where precision control and high efficiency are essential. Unlike hydraulic or pneumatic actuators, which rely on fluid power, electric actuators operate with direct electrical input, eliminating the need for complex support systems.

Key Advantages of Electric Actuators

1. Precision and Control

One of the most significant advantages of electric actuators is their precise control over motion. They allow for accurate positioning, speed regulation, and force control, making them ideal for high-precision applications in industries such as robotics and semiconductor manufacturing.

2. Energy Efficiency

Compared to pneumatic and hydraulic systems, electric actuators consume significantly less energy. They eliminate the need for air compressors or hydraulic pumps, which often lead to energy losses. By reducing power consumption, electric actuators contribute to lower operational costs and improved sustainability.

3. Low Maintenance and Long Lifespan

Traditional motion control systems require frequent maintenance due to fluid leaks, contamination, and mechanical wear. In contrast, electric actuators have fewer moving parts, resulting in lower maintenance requirements and a longer service life. The result is reduced downtime and increased productivity

4. Environmental Sustainability

With growing concerns about environmental impact, industries are prioritizing greener alternatives. Electric actuators do not require hydraulic fluids or compressed air, minimizing the risk of leaks, emissions, and contamination. This makes them an eco-friendly choice for companies striving to meet sustainability goals.

5. Compact and Lightweight Design

The compact design of electric actuators allows for easy integration into various applications, even where space is limited. Their lightweight nature makes them suitable for portable and mobile systems, enhancing flexibility in automation processes.

Applications of Electric Actuators

1. Industrial Automation

From conveyor systems to robotic arms, electric actuators are integral to modern industrial automation. They enable smooth and precise movement in assembly lines, material handling, and packaging systems, enhancing efficiency and accuracy.

2. Automotive and Aerospace

In the automotive industry, electric actuators are used in electronic throttle control, adaptive headlights, and active suspension systems. Aerospace applications include aircraft control surfaces, seat adjustments, and cargo handling mechanisms, where reliability is critical.

3. Medical Equipment

Electric actuation technology plays a vital role in medical devices such as surgical tables, imaging systems, and prosthetic limbs. The precision and quiet operation of electric actuators make them ideal for applications requiring controlled movement in healthcare settings.

4. Renewable Energy

Wind and solar energy systems benefit from electric actuators for panel positioning and turbine blade adjustments. Their ability to withstand harsh environmental conditions ensures optimal performance in renewable energy applications.

Cair Euro: A Trusted Name in Electric Actuation Technology

As industries continue to embrace automation, choosing a reliable motion control solution is crucial. Cair Euro is a leading provider of electric actuators, delivering high-performance solutions tailored to diverse industrial needs. With a commitment to innovation and quality, Cair Euro ensures that businesses achieve superior efficiency, reliability, and sustainability in their operations.

The Future of Motion Control with Electric Actuators

The shift toward electric actuators is accelerating as industries recognize their advantages over conventional motion control technologies. With advancements in smart automation, Internet of Things (IoT) integration, and artificial intelligence-driven control systems, electric actuators are set to revolutionize the future of motion control.

Companies looking to enhance their automation processes must invest in high-quality electric actuators that offer precise performance, energy efficiency, and long-term reliability. As technology continues to evolve, Cair Euro remains at the forefront, providing cutting-edge solutions that drive industrial innovation.

Conclusion

The future of motion control is undoubtedly moving toward electric actuators due to their superior precision, energy efficiency, and sustainability. As industries seek smarter and more reliable automation solutions, the demand for electric actuation technology will continue to rise. With Cair Euro leading the way in innovation and excellence, businesses can confidently transition to advanced motion control solutions that enhance productivity and operational efficiency.

0 notes

Text

Valve Manufacturer Guide: How to Select the Best for Your Industry

In industrial processes, valves are critical components that ensure the smooth flow and regulation of liquids, gases, and slurries across various systems. Whether you’re in the oil and gas, water treatment, power generation, or chemical industry, selecting the right valve manufacturer in India is essential for operational efficiency and safety. Choosing a trusted and experienced manufacturer can lead to better valve performance, lower operational costs, and enhanced safety standards.

If you’re looking for reliable valve solutions, Cair Euro is a leading valve manufacturer in India that specializes in delivering high-quality valves designed to meet the needs of diverse industries. This guide explores the essential factors you need to consider when selecting the best valve manufacturer to ensure you’re making the right investment.

Understanding the Role of Industrial Valves

Industrial valves are devices that control the flow of fluids or gases within pipelines. They regulate, direct, or control the movement of substances such as water, air, steam, or chemicals. By adjusting the flow, controlling the pressure, or even completely shutting off supply, valves play a crucial role in preventing system failures, ensuring efficiency, and maintaining safety in industries.

Valves are used in many industrial sectors, and their functionality can vary depending on the type of system and the materials being handled. From simple on/off controls to complex systems that require precise flow regulation, valves are indispensable to the industrial world.

How to Choose the Right Valve Manufacturer in India

Choosing the right valve manufacturer in India is essential to ensure the durability, efficiency, and performance of your systems. Several factors come into play when selecting the best manufacturer for your specific needs. Let’s break down these factors:

1. Product Quality and Durability

The material quality and manufacturing processes used by a valve manufacturer in India are crucial for the reliability and durability of the valves. Valves that are built from high-quality materials such as stainless steel, brass, or carbon steel can withstand extreme conditions like high pressure, temperature fluctuations, and corrosive environments.

At Cair Euro, valves are manufactured using only the highest quality materials that adhere to strict industrial standards. This ensures that every valve is durable and built to last under challenging operational conditions.

2. Expertise and Experience

The manufacturer’s experience in the industry plays a significant role in determining the quality of their valves. A company with years of experience is more likely to offer innovative solutions and tailor products to meet industry-specific needs. Experienced manufacturers also have a better understanding of the challenges faced by industries and can provide valves that are more efficient and effective.

Cair Euro, as a leading valve manufacturer in India, brings extensive experience and expertise to the table. The company has successfully served multiple industries, from oil and gas to water treatment, providing customized valve solutions to suit different operational needs.

3. Customization Options

Not all industrial operations are the same, and one-size-fits-all solutions often don’t provide the best results. A reliable valve manufacturer in India should be able to offer customization options to meet the specific needs of your industry. Whether it’s a custom size, material, or valve design, the manufacturer should work with you to create a solution that fits your exact requirements.

Cair Euro specializes in offering customized valves, ensuring that each product is designed to match your system’s unique specifications, thereby enhancing efficiency and performance.

4. Certifications and Compliance with Industry Standards

When selecting a valve manufacturer, it’s important to check whether they comply with industry standards and hold relevant certifications. Certifications like ISO 9001, ASME, API, and CE mark indicate that the manufacturer’s valves meet the required safety, quality, and environmental standards.

Cair Euro meets all necessary industry certifications, ensuring that their valves adhere to global standards for quality, safety, and performance.

5. Technical Support and After-Sales Service

Good technical support and after-sales service are vital when working with a valve manufacturer. Whether it’s installation guidance, troubleshooting, or ongoing maintenance, reliable support can save time, reduce costs, and prevent downtime.

Cair Euro provides exceptional after-sales service, ensuring that customers receive the necessary technical assistance and maintenance support throughout the lifecycle of the valves.

Key Industries That Rely on Valve Manufacturers in India

Several industries rely heavily on valves for smooth operations. Here are some sectors where valves are indispensable:

Oil and Gas Industry: Valves regulate the flow of oil, gas, and chemicals, ensuring smooth and safe operations.

Water Treatment: Valves play a critical role in regulating water flow and maintaining the pressure within treatment plants.

Power Generation: In power plants, valves help control steam flow, ensuring efficient energy production.

Chemical Processing: Specialized valves are essential for managing hazardous chemicals and maintaining safety standards.

Each of these industries requires high-performance valves that meet stringent safety and operational standards, and Cair Euro is equipped to provide solutions for all these sectors.

Why Cair Euro Stands Out as a Leading Valve Manufacturer in India

Cair Euro is a trusted name in the valve manufacturing industry in India. Their commitment to producing high-quality, durable, and efficient valves makes them the preferred choice for many industries. With a focus on innovation, customization, and customer satisfaction, Cair Euro provides valves that help businesses optimize their operations while ensuring safety and compliance with industry regulations.

They offer an extensive range of valves suitable for various applications, including ball valves, gate valves, check valves, and more. The company’s experienced engineers and state-of-the-art manufacturing processes ensure that every product meets the highest standards.

Conclusion

Selecting the right valve manufacturer in India can have a significant impact on the performance, safety, and efficiency of your operations. Factors like product quality, experience, customization options, and after-sales service should all play a key role in your decision-making process.Cair Euro, with its years of expertise, high-quality manufacturing standards, and commitment to customer satisfaction, is an excellent choice for industries looking for reliable and durable valve solutions.

0 notes

Text

A New Approach to Optimizing Fluid Control in Modern Systems with Butterfly Valves

Effective fluid management is essential for industries such as water treatment, chemical processing, HVAC, and oil and gas. As operational demands increase, companies are seeking reliable and responsive methods to control the flow of fluids. Butterfly valves offer a practical solution that combines simplicity, durability, and efficiency. This article explores innovative methods for optimizing fluid control with butterfly valves and highlights the essential role played by a butterfly valve manufacturer. In particular, we spotlight Cair Euro—a leading butterfly valve manufacturer and supplier—as an example of excellence in the industry.

Understanding the Role of Butterfly Valves

Butterfly valves operate on a straightforward principle. At their core, these valves feature a circular disc that rotates on a central shaft. When the disc is aligned parallel to the flow, it permits fluid to pass with minimal resistance. Conversely, when the disc rotates to a perpendicular position, it restricts or completely stops the fluid flow. This design allows for rapid adjustment of the flow rate and helps minimize pressure drops. The compact design and fewer moving parts reduce maintenance requirements, leading to lower operating costs and improved system reliability.

The versatility of butterfly valves makes them particularly suited for applications requiring quick and precise adjustments. Their ease of installation and operation means they can be integrated into various systems without extensive modifications. This adaptability is one of the key reasons why industries continue to rely on butterfly valves for effective fluid control.

Embracing Advanced Materials and Integrated Automation

Recent developments in materials science have significantly enhanced the performance of butterfly valves. Many modern valves are manufactured using high-grade stainless steel, reinforced plastics, and specialized composites. These materials provide improved resistance to corrosion, extreme temperatures, and chemically aggressive environments. The result is a valve that not only lasts longer but also maintains consistent performance even under demanding conditions. The use of advanced materials directly contributes to reduced maintenance intervals and lower long-term operational costs.

In addition to material advancements, the integration of automation technology has transformed how butterfly valves function. Modern butterfly valves often incorporate sensors and electronic actuators that enable real-time monitoring and precise control. This smart integration allows operators to adjust the valve remotely and optimize performance based on instantaneous system requirements. Continuous data collection through these sensors facilitates predictive maintenance, helping to identify potential issues before they escalate into serious problems. The combination of advanced materials and automation thus ensures a more efficient and reliable fluid control process.

The Crucial Role of a Butterfly Valve Manufacturer

A dedicated butterfly valve manufacturer is key to driving innovation and ensuring product quality in the fluid control sector. Such a manufacturer not only produces the valves but also invests heavily in research and development, quality assurance, and customer support. The role of a butterfly valve manufacturer encompasses several critical responsibilities:

Research and Development: A forward-thinking butterfly valve manufacturer continuously explores new designs and materials. By investing in R&D, the manufacturer can develop valves that meet evolving industry demands while improving performance and durability. The focus on innovation helps in creating products that can adapt to future challenges in fluid management.

Quality Assurance: Ensuring that every valve meets rigorous industry standards is essential. A butterfly valve manufacturer implements strict quality control measures throughout the production process. Comprehensive testing and inspection ensure that each valve can perform reliably under a range of conditions, which is vital for maintaining safety and operational efficiency.

Customization: Every industrial application comes with its own set of challenges. Recognizing this, a butterfly valve manufacturer works closely with clients to tailor valve solutions that meet specific operational requirements. Customization not only enhances system performance but also ensures that the valve integrates seamlessly with existing processes.

After-Sales Support: The commitment of a butterfly valve manufacturer extends beyond the point of sale. Providing robust after-sales support, including technical guidance, installation assistance, and ongoing maintenance, is critical to ensuring the long-term success of the valve. This level of support helps clients maximize the value and efficiency of their fluid control systems.

Cair Euro: A Leading Butterfly Valve Manufacturer

Cair Euro stands out as a prime example of excellence in the field of butterfly valve manufacturing. Renowned for its commitment to innovation, quality, and customer service, Cair Euro has built a reputation as one of the leading butterfly valve manufacturers in the industry.

What Sets Cair Euro Apart?

Innovative Engineering:Cair Euro invests significantly in research and development to produce advanced valve designs that leverage the latest in material science and automation technology. Their engineering team is dedicated to creating valves that deliver reliable performance, even in the most challenging environments.

Tailored Solutions:Understanding that every industrial process is unique, Cair Euro offers customized valve solutions. Their approach involves close collaboration with clients to ensure that the valve design aligns perfectly with specific operational needs. This bespoke service ensures that the final product enhances system efficiency and reduces downtime.

Uncompromising Quality:Quality is at the forefront of Cair Euro’s manufacturing philosophy. Every butterfly valve produced undergoes rigorous testing to confirm its durability and reliability. This commitment to high standards helps minimize the risk of system failures and contributes to long-term cost savings for customers.

Dedicated Customer Support:Cair Euro is not just a supplier; it is a partner in fluid control solutions. The company provides exceptional after-sales support, offering technical advice, installation assistance, and ongoing maintenance services. This comprehensive support network ensures that clients can operate their systems with confidence, knowing that expert help is always available when needed.

Enhancing System Performance Through Advanced Design

The integration of advanced materials and automation into butterfly valve design not only enhances the valve’s durability but also improves overall system performance. Modern butterfly valves are engineered to reduce energy losses by minimizing pressure drops, resulting in significant cost savings over time. Their compact design allows for easy retrofitting into existing pipelines, offering a practical upgrade for systems seeking to improve fluid control capabilities.

As industries increasingly focus on efficiency and environmental sustainability, the evolution of butterfly valve technology is expected to play a pivotal role. The ongoing trend towards smart, connected systems—where real-time data drives dynamic adjustments—will continue to shape the future of fluid control. In this context, a proactive butterfly valve manufacturer will remain essential for delivering the innovations that underpin this progress.

A Vision for the Future of Fluid Control

Environmental considerations and energy efficiency are becoming ever more critical in industrial operations. The latest butterfly valve designs incorporate eco-friendly materials and energy-saving features, contributing to a reduced environmental footprint. Future advancements are likely to include further integration of smart technologies, such as IoT-enabled monitoring systems, which will enhance control precision and predictive maintenance capabilities.

As the landscape of industrial operations evolves, the role of a dedicated butterfly valve manufacturer will only grow in importance. By continuing to push the boundaries of innovation, quality, and customer service, leading companies like Cair Euro will help drive the industry toward more efficient, reliable, and sustainable fluid control solutions.

Conclusion

Optimizing fluid control with butterfly valves represents a significant advancement in managing complex industrial systems. The strategic integration of advanced materials, automation, and customized engineering delivers a robust solution for precise and reliable fluid management. A dedicated butterfly valve manufacturer plays a crucial role in this evolution by ensuring that every valve is designed to meet rigorous standards and tailored to specific applications.

Cair Euro exemplifies the excellence that defines a leading butterfly valve manufacturer. Through innovative engineering, customized solutions, uncompromising quality, and dedicated customer support, Cair Euro continues to set new benchmarks in the industry. As technological advancements and environmental considerations shape the future, the innovations in butterfly valve design will be instrumental in driving efficient, sustainable, and reliable industrial processes.

0 notes

Text

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes

Text

Learn about multiple types of industrial valves and their distinct benefits.

Industrial valves play an essential role in regulating the flow of liquids, gases, and other substances within various systems. These valves are critical components in industries such as oil and gas, water treatment, manufacturing, and chemical processing, among others. Understanding the different types of industrial valves and their specific functions is crucial for choosing the right valve for your system. In this article, we will explore the most common types of industrial valves, their unique benefits, and the general purpose and function of a valve manufacturer.

The General Purpose and Function of Industrial Valves

Industrial valves are mechanical devices used to control the flow of fluids within a pipeline or system. The primary purpose of a valve is to regulate, direct, or control the flow of fluids, whether it’s by stopping, starting, or throttling the flow. These valves can be operated manually, automatically, or remotely, depending on the specific requirements of the application.

A valve manufacturer designs and manufactures these essential components, ensuring that they meet the required standards and specifications. The role of a valve manufacturer is critical because they are responsible for producing reliable, durable, and safe valves that can handle extreme conditions like high pressures, temperatures, and corrosive environments. When looking for a valve manufacturer, it's important to consider factors like the company's experience, product range, and commitment to quality.

Cair Euro is one such leading valve manufacturer and supplier. With years of experience, Cair Euro provides high-quality valves that cater to a variety of industrial applications. Their products include a wide range of valve types, each designed to meet specific operational needs.

1. Gate Valves

Gate valves are one of the most commonly used types of industrial valves. These valves are primarily used to control the flow of liquids and gases in a pipeline. The gate valve consists of a wedge-shaped gate that moves up and down to open or close the flow path. When fully open, gate valves have minimal pressure drop, making them ideal for applications where the flow needs to be fully stopped or fully opened.

Benefits of Gate Valves:

Full Flow Capability: When fully opened, gate valves allow the flow to pass with minimal resistance.

High Durability: Made from high-quality materials, gate valves are highly durable and can withstand harsh conditions.

Reliable Performance: Gate valves are known for their long service life and low maintenance needs.

2. Ball Valves

Ball valves are widely used for their ability to start, stop, and regulate the flow of a variety of fluids. These valves feature a spherical ball with a hole in the middle, which rotates to allow or stop the flow. When the ball is aligned with the pipeline, the valve is open, and when it is turned 90 degrees, the flow is stopped.

Benefits of Ball Valves:

Quick Operation: Ball valves can be quickly opened or closed with a simple quarter-turn.

Leakage Prevention: The design of the ball valve ensures tight sealing, reducing the chances of leakage.

Versatility: Ball valves can be used for both high and low-pressure applications, making them versatile for various industrial processes.

3. Globe Valves

Globe valves are commonly used for regulating or throttling the flow of fluids. Unlike gate valves, which are designed for on/off control, globe valves are used to adjust the flow rate by regulating the position of the valve plug inside the valve body. They are often used in systems where flow needs to be carefully controlled.

Benefits of Globe Valves:

Precise Flow Control: Globe valves provide better control over flow rates than gate valves.

Compact Design: They are more compact than other valve types, making them suitable for applications where space is limited.

Stable Performance: Globe valves offer stable and reliable performance, even in challenging conditions.

4. Butterfly Valves

Butterfly valves are a popular choice in systems that require a lightweight and compact valve. These valves consist of a disc that rotates to regulate the flow. Butterfly valves are especially suitable for large pipes and systems where a fast shutoff is needed. They are often used in industries like water treatment, food processing, and HVAC.

Benefits of Butterfly Valves:

Space-Efficient Design: Due to their compact size, butterfly valves are ideal for systems where space is limited.

Cost-Effective: These valves are generally more affordable compared to other valve types, making them cost-effective for large systems.

Quick Operation: Butterfly valves can be opened or closed quickly, providing fast control over fluid flow.

5. Check Valves

Check valves are designed to prevent backflow in a piping system. These valves allow fluid to flow in one direction only and automatically close if the flow reverses. Check valves are crucial in preventing damage to pumps and other equipment caused by backflow, which can lead to operational failures.

Benefits of Check Valves:

Prevents Backflow: The primary function of check valves is to prevent backflow, protecting the integrity of the system.

Automatic Operation: These valves automatically close when the flow reverses, requiring no manual intervention.

Versatility: Check valves can be used in a wide range of applications, including water systems, oil pipelines, and chemical plants.

6. Pressure Relief Valves

Pressure relief valves are safety valves designed to protect systems from overpressure conditions. These valves open automatically when the pressure within the system exceeds a set limit, allowing excess pressure to be released. This prevents equipment from being damaged due to high pressure.

Benefits of Pressure Relief Valves:

Safety: Pressure relief valves are essential for protecting systems from dangerous overpressure conditions.

Prevent Damage: By releasing excess pressure, these valves prevent damage to pipes, pumps, and other components.

Reliable Performance: Pressure relief valves are designed to open and close quickly, providing fast protection when needed.

Conclusion

Industrial valves are critical components in the smooth operation of many industries. Whether you need to control flow, prevent backflow, or protect against overpressure, there’s a valve type specifically designed to meet your needs. From gate valves and ball valves to check valves and pressure relief valves, each valve type offers distinct advantages depending on the application.

Choosing the right valve manufacturer is equally important, as the quality of the valve can significantly impact the performance of the entire system. Cair Euro stands out as a leading valve manufacturer, offering high-quality valves for a wide range of industrial applications. With a reputation for reliability and innovation, Cair Euro provides the expertise and solutions you need to ensure your systems run smoothly and efficiently.

By understanding the different types of valves and their benefits, you can make informed decisions that will enhance the performance and safety of your industrial operations.

1 note

·

View note

Text

How to Maintain Butterfly Valves in Critical Applications

Butterfly valves are vital components in different industrial systems owing to their efficiency, compact design, and ability to control fluid flow. These valves are particularly significant in critical applications, such as water treatment, chemical processing, and power generation, where their failure can lead to severe disruptions. Proper maintenance is necessary to maintain their dependability and performance. This article provides a detailed guide to maintaining butterfly valves and emphasizes the importance of partnering with a reliable butterfly valve manufacturer in India.

Understanding Butterfly Valves in Critical Applications

Butterfly valves function by using a rotating disc to control the flow of liquids or gases within a pipeline. Their versatility allows them to handle diverse conditions, such as high pressure, extreme temperatures, and corrosive environments. However, critical applications often subject these valves to harsh operating conditions, making regular maintenance essential to prevent malfunctions.

Key Maintenance Practices for Butterfly Valves

1. Routine Inspections

Routine checks are the cornerstone of proper valve maintenance. Regularly check for:

The valve body and disc show signs of wear and corrosion.

Leaks or irregularities in the valve's operation.

Accumulated debris that may hinder performance.

Early detection of issues can prevent minor problems from escalating into costly repairs or downtime.

2. Thorough Cleaning

Butterfly valves often encounter contaminants such as sediment, scale, or chemical residues. Cleaning the valve components ensures unobstructed operation.

Use soft brushes and non-corrosive cleaning agents to remove buildup.

Rinse and dry the components thoroughly to avoid introducing moisture that could lead to corrosion.

Partnering with a reputable butterfly valve manufacturer in India ensures access to maintenance guidelines tailored to the valve’s material and application.

3. Lubrication of Moving Parts

Smooth operation depends on well-lubricated moving parts, particularly the stem and bearings. To ensure proper lubrication:

Make use of the premium lubricants that the valve manufacturer recommends.

Apply lubricant sparingly to avoid attracting dust or debris.

This method reduces wear and guarantees that the valve runs with minimum resistance.

4. Monitoring Seal Integrity

The valve’s seal is critical in maintaining a leak-proof operation. Over time, seals can degrade due to temperature fluctuations, chemical exposure, or physical wear. Regularly inspect the seals for:

Cracks, deformation, or hardening.

Signs of leaks or reduced performance.

Replace damaged seals immediately to prevent system inefficiencies. Working with a trusted butterfly valve manufacturer in India ensures access to high-quality replacement seals that match your valve specifications.

5. Avoid Over-Tightening Bolts

During installation or maintenance, over-tightening bolts can distort the valve body or components, leading to misalignment or damage. To avoid this:

Use a torque wrench to tighten bolts uniformly.

Follow the manufacturer’s torque recommendations for optimal performance.

Proper assembly techniques ensure that the valve operates as designed.

The Role of Manufacturers in Butterfly Valve Maintenance

Reliable maintenance starts with choosing high-quality butterfly valves. A trusted butterfly valve manufacturer in India, such as Cair Euro, provides products engineered for durability and performance. Manufacturers like these also offer maintenance resources, including detailed manuals and customer support, to help industries maintain their valves efficiently.

Additionally, manufacturers often supply spare parts and provide training to ensure seamless maintenance, reducing downtime and enhancing system reliability.

Preventive Maintenance: A Long-Term Solution

Preventive maintenance involves proactive measures to keep butterfly valves in peak condition. This approach includes:

Scheduling periodic performance tests to identify potential issues.

Keeping detailed maintenance records to track valve performance over time.

Replacing worn-out components promptly to avoid unexpected failures.

Preventive maintenance reduces operational risks and extends the lifespan of butterfly valves, making it a cost-effective strategy for critical applications.

Addressing Environmental and Operational Challenges

Critical applications often expose butterfly valves to challenging conditions such as corrosive substances, high temperatures, or abrasive particles. To maintain valve integrity:

Select valves with materials and coatings resistant to the specific operating environment.

Install filtration systems to reduce debris in the flow stream.

Choosing the right valve for the application is a crucial step, and partnering with a reliable butterfly valve manufacturer in India ensures you have access to specialized products tailored to your needs.

Importance of Skilled Personnel

Maintenance tasks should always be carried out by trained personnel familiar with butterfly valve operations. Skilled technicians can:

Identify subtle signs of wear or damage that may be overlooked.

Properly execute maintenance procedures without risking valve integrity.

Regular training for maintenance teams and collaboration with manufacturers like Cair Euro ensures that the workforce is equipped to handle valve maintenance effectively.

Conclusion

Maintaining butterfly valves in critical applications is essential for ensuring reliable performance and minimizing operational risks. Routine inspections, proper cleaning, lubrication, and timely component replacements are integral to maintaining these valves. Partnering with a trusted butterfly valve manufacturer in India, such as Cair Euro, guarantees access to durable valves, expert guidance, and high-quality spare parts.

By investing in quality valves and adopting a proactive maintenance approach, industries can ensure uninterrupted operations and long-term cost savings. Butterfly valves, when properly maintained, serve as a cornerstone for efficient and reliable industrial processes.

0 notes

Text

The Benefits of Using Multi Turn Electric Actuators in Valve Control

In the ever-evolving world of industrial automation, the importance of reliable and efficient valve control cannot be overstated.

Valves are critical components in a wide range of industries, including oil and gas, water treatment, chemical processing, and power generation.

To ensure optimal performance and safety, these valves need precise control.

They offer a myriad of benefits that can significantly improve the efficiency and reliability of valve control systems.

In this article, we will explore the advantages of using multi turn electric actuators in valve control, with a focus on their role in industrial settings.

What are Multi Turn Electric Actuators?

Before diving into the benefits, it’s important to understand what multi turn electric actuators are.

These devices are a type of electric actuator specifically designed to operate valves that require multiple turns to open or close fully.

Multi-turn actuators convert electrical energy into mechanical torque, enabling them to precisely control the position of a valve.

They are commonly used with gate, globe, and other types of multi-turn valves, making them indispensable in various industrial applications.

Key Benefits of Multi Turn Electric Actuators in Valve Control

Precision and Accuracy

One of the primary benefits of using multi turn electric actuators is the high level of precision and accuracy they offer in valve control.

Unlike manual or pneumatic actuators, electric actuators can be programmed to achieve specific positions with exceptional accuracy.

This precision is crucial in applications where exact flow rates or pressures need to be maintained.

By providing consistent and repeatable valve positioning, multi turn electric actuators help ensure optimal process control and prevent costly errors.

Automation and Remote Operation

In today’s fast-paced industrial environment, automation is key to improving efficiency and reducing operational costs.

Multi turn electric actuators facilitate automation by enabling remote operation of valves.

This means that valves can be controlled from a central control room or even from off-site locations.

Remote operation not only enhances convenience but also improves safety by allowing operators to control valves in hazardous or hard-to-reach areas without having to be physically present.

Energy Efficiency

Multi turn electric actuators are known for their energy efficiency. Unlike pneumatic actuators that rely on compressed air systems, electric actuators use electricity directly, which can be more efficient and cost-effective.

Additionally, electric actuators consume power only when they are operating, as opposed to pneumatic systems that may continuously consume air.

This reduced energy consumption can lead to significant cost savings over time, especially in large-scale industrial operations.

Enhanced Safety

Safety is a top priority in industrial settings, and multi turn electric actuators contribute to safer operations.

Their precise control minimizes the risk of over-pressurization or leakage, which can lead to accidents or equipment damage.

Moreover, the ability to automate and remotely operate valves reduces the need for manual intervention, thereby decreasing the exposure of workers to potentially hazardous environments.

Reliability and Durability

Multi turn electric actuators are designed for reliability and long-term durability.

They are built to withstand harsh industrial conditions, including extreme temperatures, corrosive environments, and high vibration levels.

This robustness ensures that they provide consistent performance over extended periods, reducing the need for frequent maintenance and minimizing downtime.

Reliable valve control is essential for maintaining continuous operations and preventing disruptions in critical processes.

Flexibility and Adaptability

Another advantage of multi turn electric actuator is their flexibility and adaptability.

They can be easily integrated into existing control systems and customized to meet specific application requirements.

Whether it’s adjusting torque settings, programming specific valve positions, or integrating with advanced control systems, multi turn electric actuators offer a high degree of adaptability.

This makes them suitable for a wide range of applications, from simple on/off control to complex modulating operations.

Environmental Friendliness

In an era where environmental concerns are increasingly important, multi turn electric actuators offer a greener alternative to pneumatic actuators.

By eliminating the need for compressed air systems, they reduce the overall energy consumption of industrial facilities.

Additionally, electric actuators do not produce emissions, making them an environmentally friendly choice for companies looking to reduce their carbon footprint.

Conclusion

The use of multi turn electric actuators in valve control offers numerous benefits, including precision, automation, energy efficiency, safety, reliability, flexibility, and environmental friendliness.

These advantages make them an ideal choice for industries that rely on accurate and efficient valve control. As technology continues to advance, the role of multi turn electric actuators in enhancing industrial automation will only become more significant.

For businesses in Ahmedabad looking to improve their valve control systems, consider partnering with industry experts.

Cair Euromatic offers cutting-edge multi turn electric actuators designed to meet the demands of modern industrial applications, ensuring superior performance and reliability.

By investing in multi turn electric actuators, companies can not only enhance their operational efficiency but also contribute to a safer and more sustainable future.

0 notes

Text

Top Advantages of Using Electric Actuator Globe Control Valves in Your Facility

In the ever-evolving world of industrial automation, the demand for precision and efficiency has never been higher.

One of the key components in achieving this precision is the use of electric actuator globe control valves.

These valves play a crucial role in regulating the flow of fluids, gases, and other materials within various industrial processes.

In this article, we will explore the top advantages of using electric actuator globe control valves in your facility, with a focus on their importance, functionality, and how they can enhance operational efficiency.

What Are Electric Actuator Globe Control Valves?

Electric actuator globe control valves are specialized valves that use an electric actuator to control the flow of fluids through a pipe.

These valves are characterized by their globe-shaped body and the way they regulate flow by moving a plug or disc against the flow path.

The actuator is responsible for moving the valve stem, which in turn adjusts the flow rate.

By leveraging electric power, these valves offer precise control, making them ideal for applications requiring accurate regulation of flow and pressure.

Top Advantages of Using Electric Actuator Globe Control Valves

Precise Flow Control

One of the most significant advantages of electric actuator globe control valves is their ability to provide precise flow control.

These valves can make fine adjustments to the flow rate, allowing for accurate regulation of process variables such as pressure, temperature, and fluid levels.

This precision is crucial in industries like chemical processing, pharmaceuticals, and food and beverage, where maintaining exact process conditions is essential for product quality and safety.

Automation and Remote Operation

Electric actuator globe control valves are easily integrated into automated systems, allowing for remote operation and monitoring.

This capability is invaluable in modern industrial settings where automation is key to improving efficiency and reducing labor costs.

Operators can control valve positions and monitor system performance from a central control room, minimizing the need for manual intervention and enabling quick responses to changes in process conditions.

Enhanced Safety

Safety is a top priority in any industrial facility, and electric actuator globe control valve contribute to safer operations.

The ability to remotely control and automate valve operations reduces the need for personnel to manually adjust valves in potentially hazardous environments.

Additionally, these valves can be equipped with fail-safe features that automatically close or open the valve in the event of a power failure or system malfunction, preventing accidents and protecting both personnel and equipment.

Energy Efficiency

Electric actuator globe control valves are known for their energy efficiency.

Unlike pneumatic or hydraulic actuators, which require a continuous supply of compressed air or fluid, electric actuators only consume power when adjusting the valve position.

This reduced energy consumption not only lowers operating costs but also contributes to a facility's overall energy efficiency, making these valves an environmentally friendly choice.

Low Maintenance Requirements

Electric actuator globe control valves typically have fewer moving parts than their pneumatic or hydraulic counterparts, resulting in lower maintenance requirements.

The simplicity of electric actuators means there is less wear and tear, reducing the likelihood of breakdowns and the need for frequent repairs.

This reliability translates to reduced downtime, ensuring continuous operation and productivity in your facility.

Versatility in Applications

Another significant advantage of electric actuator globe control valves is their versatility.

These valves can be used in a wide range of applications, from controlling steam and water flow in power plants to regulating chemical flows in manufacturing processes.

They are suitable for both high-pressure and low-pressure applications and can handle various fluid types, including corrosive and abrasive substances.

Improved Process Efficiency

By providing accurate and reliable control over fluid flow, electric actuator globe control valves help optimize process efficiency.

Consistent and precise regulation ensures that processes operate within their desired parameters, reducing the risk of deviations that could lead to product quality issues or equipment damage.

This improved efficiency not only enhances product quality but also maximizes the use of resources, leading to cost savings.

Integration with Advanced Control Systems

Modern industrial facilities often rely on sophisticated control systems to manage operations.

Electric actuator globe control valves can seamlessly integrate with these systems, allowing for advanced control strategies and real-time monitoring.

This integration enables facilities to implement predictive maintenance, optimize process performance, and quickly adapt to changing production demands, further enhancing operational efficiency.

Conclusion

Electric actuator globe control valves offer a multitude of advantages for industrial facilities, ranging from precise flow control and automation to enhanced safety and energy efficiency.

Their versatility and reliability make them an excellent choice for a wide variety of applications, ensuring optimal process performance and productivity.

By investing in electric actuator globe control valves, facilities can achieve greater operational efficiency, reduce maintenance costs, and enhance overall safety.

For businesses in Ahmedabad looking to take advantage of these benefits, consider partnering with Cair Euromatic, a trusted name in valve technology.

Embrace the power of electric actuator globe control valves to elevate your facility's performance and stay ahead in the competitive industrial landscape.

0 notes

Text

Optimizing Your System with Premium Damper Valves: Cair Euromation

In the intricate network of modern HVAC systems, damper valves stand as pivotal components, regulating airflow with precision. The efficiency and performance of an entire system can be significantly impacted by the quality and functionality of these valves. This is where Cair Euromation, a leading damper valve supplier, steps in to elevate your system's capabilities.

The Crucial Role of Damper Valves

Damper valves are essential for controlling airflow within ductwork systems. They regulate the volume of air passing through various branches, ensuring optimal temperature distribution and energy efficiency. Whether it's a residential, commercial, or industrial setting, the right damper valve can make a substantial difference in comfort, energy consumption, and overall system performance.

Cair Euromation: Your Trusted Damper Valve Supplier

Cair Euromation has established itself as a premier damper valve supplier, renowned for its commitment to quality, innovation, and customer satisfaction. With a comprehensive range of damper valves tailored to diverse applications, we offer solutions that meet the specific needs of our clients.

Our expertise lies in:

Precision engineering: Our damper valves are meticulously designed and manufactured to ensure accurate airflow control and durability.

Material selection: We employ high-quality materials that are resistant to corrosion, wear, and temperature extremes, guaranteeing long-lasting performance.

Customization: We understand that every system is unique. Our team works closely with clients to develop customized damper valve solutions that perfectly align with their requirements.

Technical support: Our experienced engineers provide comprehensive technical support throughout the selection, installation, and maintenance process.

Benefits of Choosing Cair Euromation Damper Valves

Opting for Cair Euromation damper valves translates into numerous advantages:

Enhanced energy efficiency: Our valves are designed to minimize air leakage, reducing energy consumption and lowering operating costs.

Improved indoor air quality: By optimizing airflow distribution, our damper valves contribute to healthier indoor environments.

Reduced noise levels: Our products are engineered to minimize noise transmission, creating quieter and more comfortable spaces.

Extended system lifespan: The durability and reliability of our damper valves prolong the overall lifespan of your HVAC system.

Expert support: Our dedicated team is always available to assist you with any questions or concerns.

Applications of Cair Euromation Damper Valves

Our damper valves find applications across a wide range of industries and sectors:

Residential: Creating comfortable living spaces with efficient heating and cooling.

Commercial: Ensuring optimal indoor air quality and energy efficiency in offices, retail spaces, and hospitality establishments.

Industrial: Controlling airflow in demanding environments such as manufacturing plants, data centers, and cleanrooms.

HVAC systems: Integrating seamlessly into various HVAC systems to optimize performance.

Partnering with Cair Euromation

At Cair Euromation, we are committed to building long-term partnerships with our clients. Our dedication to quality, innovation, and customer satisfaction sets us apart as a leading damper valve supplier.

By choosing Cair Euromation, you are investing in a product that not only enhances your system's performance but also contributes to a sustainable future.

Contact us today to discuss your specific requirements and discover how our damper valves can elevate your system to new heights.

0 notes