Don't wanna be here? Send us removal request.

Text

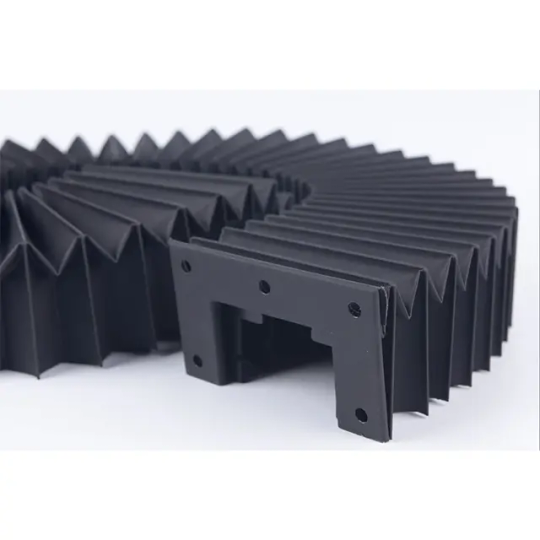

Bellow Cover Manufacturer Excellence: Craftsmanship and Custom Design

There is a great and ever-growing demand for custom-engineered components in the automotive, aerospace, machinery, and medical device industries. Bellows and bellow covers are some of those critical components that accomplish the functions of protection for sensitive parts, vibration absorption, and prolongation of system performance. Custom Rubber Bellows, as a bellow cover manufacturer, became synonymous with the best workmanship, modern design, and customer satisfaction.

The years of manufacturing experience as a wholesale bellows manufacturer have made them a renowned company for serving industries worldwide with uniform quality and unparalleled flexibility

Bellows Manufacturer: Engineering Versatility

As an internationally committed designer and Bellow cover manufacturer, companies like Custom Rubber Bellows mainly introduce innovations with rubber, silicone, and elastomeric bellows used across various industries. The application of rubber bellows includes covering automotive fuel systems and assemblies for aerospace, medical devices, and heavy machinery. Their true versatility stems from engineering flexibility that matches the science with an array of custom shapes, thicknesses, and sizes to satisfy any uniquely defined application. Thus, they comprise more than a bellows manufacturer; they solve problems by ensuring that these solutions for their products meet the dual requirements of functionality and safety.

Wholesale Bellow Manufacturer: Serving Global Industries

As the demand for higher bulk orders and large-scale supply, Custom Rubber Bellows has also become a wholesale bellow manufacturer. Their large manufacturing capacity enables them to supply bulk quantities without compromise on quality. So, consistent standard, cost-effective, and timely delivery are enjoyed by clients all across the globe. The company ensures that the same high quality happens whether it is a small custom project or a large industrial supply by marrying scalability with craft. This combination of quality and efficiency proves their place as a wholesale bellow manufacturer of trust.

Silicone Bellows: Flexibility Meets Durability

Besides a large variety of products for combination flexibility and durability, silicone bellows stand out as one of the more preferred solutions for many applications for their unique characteristics. They are very resistant to extreme temperatures and remain effective under both extremes of hot and cold conditions without becoming inflexible. Food processing industries, pharmaceuticals, and cleanroom operations greatly rely on silicone bellows to be contamination-free, protecting sensitive systems from dust, moisture, and vibrations.

Custom Rubber Bellows is the reputed and most trusted bellow cover manufacturing company that has been manufacturing FDA-grade silicone bellows, completely non-toxic, safe, and built to last. All construction materials are sourced from reputed suppliers who use approved quality materials conforming to higher standards of regulation, and thus rendering them suitable for use in applications where health and safety risks are imperative.

Also, silicone bellows can be custom-manufactured to make up shapes, sizes, and wall thicknesses specific to the industry's demands. The company raising the standards of the proficient manufacturer of bellows is also trusted all over the globe due to the reliability and adaptive service unmatched by it.

Flange Bellows: Strength in Connection

Flange bellows are the specialty products custom rubber bellow manufacturers make, engineered to bring in added security into the connection and a superior sealing performance. These bellows are often in their most crucial element for industries whose lives will depend on high-pressure regulation and leak-proof performance. The applications in chemical processing, hydraulic systems, and aerospace equipment are often dependent on flange bellows to ensure safety and efficiency in extremely strenuous working conditions.

As the leading bellow manufacturer in the wholesale market, the organization ensures production of each flange bellow using strengthened materials qualified to resist high pressure, corrosive fluids, and temperature fluctuations. The dimensions, shapes, and compounds are available in customized forms for system-specific requirements.

Each product goes through a meticulous design, prototyping, and testing process before it can be said that the solution offered is beyond expectations. With such precision and strength as its hallmarks, Custom Rubber Bellows enjoys an enviable reputation not only as a flange bellows specialist but also as a global reference in bellow cover manufacture for demanding industries.

Craftsmanship and Custom Design Approach

Custom Rubber Bellows is able to distinguish itself afresh through craftsmanship coupled with a design-since-its-conception attitude. All projects begin with discussions between engineers and customers to ascertain the critical functional needs of the application.

A customer-oriented perspective allows the company to weigh in on what materials, design configurations, and performance specifications are appropriate for the intended use. This involves newer prototyping, proper selection of materials, and thorough testing under real-world service conditions. Transforming modern designs into handcrafted manufacturing processes combines silicone bellows and flange bellows that constantly outperform all the out-of-date alternatives with modern molding techniques.

The focus on customization ensures that the credibility of manufactured items is derived from specific challenges other than generic challenges found across industries. They could either be serving some niche industries as a bellow cover manufacturer or be simultaneously serving some other big industries as a wholesale bellow manufacturer. But they will always pursue excellence through quality, flexibility, and innovation.

Applications Across Industries

Bellows and covers are highly diverse products and have found application in the following areas:

• Automotive Industry - Automotive OEMs mainly apply silicone bellows in their engine systems, where such elasticity may be required to withstand adverse high temperature and continuous vibration conditions.

• Flange Bellows are also used by Aerospace Companies in safety critical applications, where measurement accuracy, strength, and overall leak-free performance are paramount to mission success.

• Heavy-Duty Machinery - Covers designed by a careful bellow cover manufacturer or supplier have a very robust design and aptly cater to dust, moisture, and contaminant protection.

• Medical Devices - In the medical Industry, precision components are of huge importance. Manufacturing companies like Custom Rubber Bellows are trusted to produce precision components for such industry that support life-saving devices and ensure their reliable performance. Cross-industry exposure is subject to adaptation and invention by the company to meet the various sector-specific requirements.

Conclusion

As demand in the industry increases every day, it must never be compromised when it comes to accuracy, sturdiness, and personalization in bellows and covers. Custom Rubber Bellows has earned its reputation as one of the leading manufacturers of bellow covers, providing practical solutions owing to their expertise. Being a leader as a bellow manufacturer and wholesale bellow manufacturer, along with their expertise in the niche of silicone bellows and flange bellows, shows their versatility and commitment to excellence. While continuing to focus on function and style, they know how to be a partner in trust for industries across the globe by ensuring that critical systems remain safe, sound, and working.

CTA-

Partner with Custom Rubber Bellows today for durable, precision-engineered silicone and flange bellows that meet your industry’s toughest demands—request your quote now!

Call- (647) 294-5240

Email- [email protected]

0 notes

Text

Custom Rubber Bellows and Expansion Joints Molded Solutions by Top Manufacturer

Made with an integral flexible sealing that makes possible the high performance and durability of a system, custom rubber bellows and bellows expansion joints are widely used in many applications across a number of industries. These specialized products help absorb vibrations, accommodate thermal expansion and contraction, and provide protection for delicate equipment against harsh environmental conditions.

A profound rubber bellow supplier, Custom Rubber Bellows, has proudly established itself as one of the most accomplished manufacturers and suppliers in the industry for premium-grade small rubber bellows meant to meet the rigorous demands of diversified industrial sectors.

The highly efficient and durable rubber bellows comply with international production standards. They are capable of surviving the most hostile of operating conditions, promising a lifetime performance. With modern manufacturing and stringent quality control procedures, the company manufactures highly efficient, perfectly functional, and durably functional rubber bellows.

Understanding Rubber Bellows Expansion Joints:

Small rubber bellows are extremely flexible and highly pliable, accordion-like structures made of elastomeric materials such as EPDM, neoprene, silicone, or nitrile rubber. Small rubber bellows have found an application in automobiles, aerospace, medicine, and industries where the demand for endurance and flexibility is high.

Bellows expansion joints are specialized flexible couplings within a piping system that are employed for their specific purpose of absorbing movements caused by thermal expansion, varying pressure, or mechanical vibrations. These joints, in principle, take the stresses out of the pipelines and so limit the possibility for leakage or structural damage. At Custom Rubber Bellows, we manufacture bellows expansion joints with precision to provide prolonged service even in challenging environments.

Why Choose Custom Molded Rubber Bellows?

Custom Rubber Bellows, a pioneer in manufacturing rubber bellows, boasts a variety of molded rubber bellows that have a lot to offer in terms of performance. Each rubber bellow is manufactured based on specific requirements to suit the performance features of that application. Whether small rubber bellows for fragile machines or big bellows expansion joints for industrial pipelines, custom manufacturing guarantees the best fit.

The choice of rubber compounds depends on the application, with EPDM possessing properties of excellent weather and ozone resistance, neoprene possessing oil and chemical resistance, silicone being more suited to high temperatures, and nitrile (NBR) to fuel and petroleum-based fluids.

Rubber bellows, cast by bulk rubber bellow supplier, withstand extreme heat, rapid pressure changes, and aggressive atmospheres. Flexible and resilient, they're almost impossible to wear out within their life cycle. Rubber bellows also serve purposes such as absorbing vibrations and noise in the mechanical apparatus, increasing operational efficiency, and reducing maintenance costs. Small sizes of rubber bellows work where many of them serve as protective coverings for sensitive parts to be salvaged from dirt, rumblers, moisture, and other chemical contaminants that could ruin the functionality of such parts.

Applications of Rubber Bellows and Expansion Joints:

An experienced rubber bellow manufacturer designs products for reliable performance under the most daunting conditions. The solutions thus provided embody some advanced material science along with precision manufacturing to manufacture components that will prolong equipment life while reducing maintenance interventions.

Automotive Sector

In the automotive sector, our rubber bellows also do their job as a primary defence mechanism for the concerned vehicle system. Rubber bellow supplier manufactures specialized bellows for the suspension system that provide protection to the CV joints and shock absorbers from road debris while giving way for flexibility. For the exhaust systems, we manufacture hot expansion joints that take up thermal movement and vibration. Precision molded bellows for steering systems, protect sensitive components from contaminants while allowing the full range of motion.

Aerospace Defense

The aerospace and defense industries require components that meet the most stringent performance standards for each component. Our hydraulic system bellows maintains sealing integrity through extreme pressure fluctuations during flight operations. Molded rubber bellows in engine compartments use special high-temperature materials that resist degradation in jet engine environments. We manufacture corrosion-resistant bellows for landing gear systems to protect critical mechanisms from severe environmental conditions.

Medical Equipment

Precision and reliability are paramount in critical medical applications where our components play vital roles. The manufacturers of Custom Rubber Bellows manufacture medical-grade silicone bellows for ventilators that maintain airtight seals in life-support systems. The pump system below is designed for accurate fluid delivery in dialysis and infusion equipment. For robotic surgical tools, ultra-clean molded rubber bellows to allow for smooth, contamination-free movement during minimally invasive procedures are supplied.

Industrial Machinery

Industrial applications require a rugged solution that can withstand harsh operating conditions. Our expansion joints for pumps and compressors help minimize vibration transmission and related pipe stress. Bellows for HVAC systems work thermally in the movement of ducting while sealing airtight. For chemical processing equipment, we manufacture bellows from specialized compounds that resist aggressive fluids and corrosive environments.

These include material options such as EPDM, Nitrile, Neoprene, and Viton®, so we can perform a solution tailored to specific chemical requirements for resistance and long life.

Marine and Offshore Applications

Marine environments are subjected to unique challenges which our specialized bellows are engineered to overcome. Leading suppliers supply seawater-resistant expansion joints for shipboard piping systems that withstand constant exposure to saltwater. Components on the offshore platform are made from marine-grade materials that resist corrosion in the harshest conditions.

Custom Rubber Bellows – Your Trusted Rubber Bellow Manufacturer

Leading rubber bellow manufacturer producing mainly modern manufacturing techniques for precision, consistency, and high-performance molded rubber bellows for various industries. Other features include fast design verification and production through rapid prototyping and short lead times. Custom Rubber Bellows has a wide reach distribution that serves not only US customers but also clients worldwide. Small rubber bellows can be used for precision equipment, even for heavy-duty bellows expansion joints for industrial applications. Joining hands with a reputable rubber bellow manufacturer guarantees high quality and performance.

Conclusion

Custom Rubber Bellows gives high-performance moldable rubber bellows and expansion joints, customized for various industries. These products absorb vibrations, control thermal expansion, and protect sensitive components. With state-of-the-art manufacturing and strict quality protocol, we are present in the automotive, aerospace, medical, industrial, and marine fields, providing durable and flexible goods resistant to harsh conditions to ensure reliability and performance for a long time in all applications. For tailored solutions that meet your exact requirements, get in touch with customrubberbellows.com, call +1647) 294-5240 or email [email protected].

#Custom Rubber Bellows #Small rubber bellows #bellows expansion joints #Rubber bellow supplier #molded rubber bellows

0 notes

Text

Everything You Need to Know About Small Rubber Bellows and Expansion Joints

Tight spaces demand smart parts like small rubber bellows for protection. They fill in holes or protect tools against dust, heat, or vibration. They will be in pumps, cars, HVAC systems, and test labs. They flex easily, retain their shapes and seal fluid/air leakage. They accept wear without cracking or tearing.

Each unit should be compatible to eliminate breakdown or leak paths. They aid in smooth movements of joints, even in gravel or crowded areas. These bellows exclude dust and allow free movement of the part. Seal and shape control are a big factor in use.

It is possible to ask your rubber bellow manufacturer whether they cut to shape or mold. Some are circular, and some are cone or oval-shaped to fit joint angles. They are great with heavy tools as well as delicate laboratory equipment. Having the reliability below implies fewer failures in parts and fewer downtimes in the system.

What Are Small Rubber Bellows?

They are small, flexible covers used in narrow joint systems. These bellows help block dirt, moisture, and unwanted air leaks. Most units are made of durable rubber or synthetic elastomers. They fit well in valves, meters, vents, and handheld tools. A good rubber bellow manufacturer tests for durability and sealing ability. They are perfect for spots that face low movement or strain.

Unlike metal parts, rubber bellows won’t rust or wear easily. Their main role is to protect and extend the device’s life. Companies design each unit to flex slightly without cracking or tearing. They prevent minor gaps from turning into major leak issues quickly. There are devices like vacuum pumps that often rely on them for smooth operation.

You’ll see them around cable joints, actuators, or small pipe ends. Some are molded precisely for odd shapes and custom spaces. Manufacturers use different rubbers based on temperature or load needs. Bellows work well where frequent bending or twisting is expected. They are found in medical tools, auto parts, and lab systems.

The size and shape vary based on joint angle and motion. Flexibility matters most when choosing bellows for any moving zone. Pressure resistance and sealing range also guide the right material choice. A trusted small rubber bellows provider will offer test reports and specs. The low-load areas benefit the most from compact bellow designs today.

The quality makes all the difference in performance and part lifespan. The companies keep refining shapes to match new machinery and tight spaces.

Why Use Bellows Expansion Joint?

They absorb pipe shifts caused by heat, flow, or system pressure. This helps protect bolts, seals, and nearby pipe ends from strain. These joints keep systems stable during fast temperature or pressure changes. A well-made bellows expansion joint reduces noise and shaking during operations. They’re common in ducts carrying steam, gas, air, or exhaust gases.

Many companies prefer them for tough jobs that need both strength and flexibility. The shape allows a slight stretch without breaking the pipe path. The unit is tested to handle a wide range of flow rates. Expansion joints lower the risk of breaks in HVAC and boiler lines. They also prevent cracks where pipes meet rigid supports or corners.

Many engineers pick them when piping runs long distances or spans floors. They help move loads safely without stiff pipe stress or misalignment. Their use keeps maintenance costs low and system safety high long term. A tested bellows expansion joint performs well even in high-heat conditions. They resist wear caused by heat cycles, sharp bends, or fast flow.

The material choice depends on the fluid type, system size, and working heat range. They give more life to joints while keeping the flow steady.

Pick the Right Molded Rubber Bellows

These bellows are formed to exact shapes for better part sealing. A tight fit means no leaks, even in high-stress zones. You can pick U, S, cone, or rounded bellow shapes easily. Each shape suits different joint angles, strokes, and system needs. A trusted rubber bellow supplier will guide size and shape matching.

You must check the inner and outer diameters before choosing. The stroke length and wall thickness also matter in tight fits. The molded types flex smoothly and last longer in wear-heavy areas. They suit pumps, valves, and moving seals exposed to rough conditions. The companies test them under load to check crack or tear risks.

You can pick material based on oil contact, heat level, and movement style. Nitrile works for oil; silicone fits high-heat or medical spaces. Neoprene is strong for general use and has light chemical resistance. A custom bellow prevents bellow failure during pressure spikes or sharp turns. Every unit of molded rubber bellows must match function, not just size.

The fit should allow full motion without stretch or collapse risks. The reliable companies provide guides or drawings for better part matching. The right choice saves repair costs and improves the full system life.

How to Choose a Rubber Bellow Manufacturer?

You check if the company follows ISO and full QC processes. They should use digital tools to test leaks, fit, and strength. You must ask if they mold in-house or send parts out. The in-house work gives better control and faster changes if needed. A trusted company must show test pieces or sample part runs.

Strong mold skills are key for tight parts like small rubber bellows. You can ask about low-volume orders, not just big bulk batches. This shows they handle both custom and large-scale client needs. A good firm explains its full flow from design to final test. It helps if they share past work or client industries served.

Materials used should match heat, oil, or stretch needs clearly. Some firms offer only basic types, so confirm before the final deal. They must be able to make round, oval, or cone shapes. You’ll want smooth edges, clean lines, and flexible yet tough rubber. If you need a bellows expansion joint, ask about the pressure range. You can look for clarity in quotes and no hidden extra charges later.

Conclusion

The firms test for crack points, heat limits, and stretch life too. A trusted rubber bellow supplier gives full data, not just product names. They help match the right bellow to your load and job. Bellows may look simple, but good ones make big systems last.

Contact us more to know about the products. Get in touch to know the quote!

0 notes

Text

Rubber Bellows And Boots Leading Custom Rubber Bellow Manufactures

Bellows and boots are used to protect parts while allowing movement. They seal off joints, shafts, or ends that deal with stress or motion. These flexible parts are key in systems that face dust, heat, or vibration. A trusted rubber bellow manufacturer understands how shape, material, and function work together.

These components stop moisture, dirt, and chemicals from reaching sensitive machine areas. Their flexibility supports expansion, compression, or rotation without cracking or leaking over time. The custom bellows and boots handle harsh conditions, odd shapes, and unique stress patterns. Their role may be small, but it’s critical in ensuring long-term, safe operation.

What Are Rubber Bellows & Boots?

Rubber boots and bellows are elastic rubber components used to shield moving parts. They serve a significant function in guarding joints against outside harm. Bellows expand and shrink, while boots typically enclose joints or open ends. They are commonly used in machinery, automotive components, and industrial machines. These covers preserve movement without allowing moisture or dirt to enter.

Materials such as EPDM, nitrile, neoprene, or silicone rubber are applied for strength. There is a different rubber for a different environment based on heat, chemicals, or pressure. A rubber bellow manufacturer chooses materials according to your industry and project requirements. The components make the parts last longer when they are exposed to the elements.

Some equipment in dusty or wet conditions depends on these to remain operational. They minimize wear, rust, or friction-induced failure. A custom rubber bellow manufacturer also makes odd shapes or motion paths.

Quick Applications

Seals and protects shafts

Shields against fluid and dust

Accommodates part motion

Employed in high-heat installations

Provides sealing and insulation

Rubber bellows and boots keep things running smoothly by halting outside dangers. They're diminutive yet important protection units for a broad variety of industries.

Why Customisation Is Critical for These Products?

Customisation is important since common parts never quite fit actual equipment requirements. Modern machines have irregular shapes, with cramped areas and awkward corners. An improper fit can create gaps that result in leaks or component failure.

Tolerances mean a great deal when pressure, motion, or fluid is present. The rubber bellows and boot have to fit the precise specifications to function effectively. A rubber bellows boot made for a pump may not work on an engine. Customization avoids such misapplication and minimizes system damage or downtime.

Precision is what industries require for safety, performance, and long-term reliability. The custom parts provide more precise motion control, better seals, and longer lifespan. Material selection also hinges on temperature range, movement type, and chemical exposure. OEMs use customized parts for optimal system integration.

It makes a difference when working with heat, oil, or pressure. A custom molded rubber bellows perfectly fits your part and performs as it does under actual conditions.

Why Does It Matters?

Fits machine size precisely

Accommodates special stress points

Functions with abrasive media

Prevents friction and tearing

Increases long-term reliability

These bellows or boots minimize failure risks in complex configurations.

Where Are Rubber Bellows & Boots Used?

Rubber boots and bellows are used in a number of high-demand industries nowadays. In the automobile industry, they seal CV joints, steering parts, and suspension seals. They prevent dirt and water from entering while providing easy movement and flexibility.

Medical equipment also depends on these components for joint movement and cleanroom protection. A rubber bellow manufacturer needs to be precise to achieve safety and hygiene standards. In aerospace, they suppress vibration, protect sensors, and prevent fluid damage in confined areas.

Trains and sea configurations employ them as seals for electrical boxes and hatch covers. Such conditions require durable, weather-resistant sealing. A reliable rubber bellow manufacturer knows how each application requires various specs and tolerances. Boots and bellows play a key role in safeguarding core systems and minimizing wear.

Types of Rubber Bellows

There are many rubber bellows to meet different movement and sealing requirements. These are suitable for particular types of motion, pressures, or exposure to the environment. A custom rubber bellow manufacturer chooses the appropriate style based on your application and equipment configuration.

Convoluted Bellows

They collapse and expand readily, accommodating axial motion and vibration easily. They are used where motion is stable and pressure is moderate.

Molded Bellows

This is for accuracy, shaped bellows accommodate unusual spaces and quirky machine bends. They provide leak-tight sealing where off-the-shelf bells fail to seal reliably.

Fabric-Reinforced Bellows

Reinforced styles support heavy-duty pressure and high stress without rupturing. These are best for industrial or high-impact areas with repeated pressure fluctuations.

Slip-On Boots

Slip-on types are versatile and designed to seal up irregular shapes or ends. Such a rubber bellows boot can easily seal moving or rotating sections.

How to Choose the Right Manufacturer?

Quality endorsements such as ISO attest that they have processes that adhere to rigorous international manufacturing standards. You can inquire about in-house tooling and molding to provide greater control.

Companies that have full facilities produce higher precision and quicker turnaround of projects. You may also inquire about their experience in your particular industry to prevent design or material errors early.

A manufacturer producing custom molded rubber bellows for the industry might not be appropriate to medical requirements. You sift through their previous work and make sure they grasp your performance and environmental issues. Always verify lead time, pricing model, and minimum order quantities in advance.

You order a sample of their product before a full run. This will test the fit, finish, and functionality of their work. You can request references from clients to check long-term reliability and communication quality.

A company that provides both prototyping and high-volume runs provides flexibility. The custom molded rubber bellows manufacturers should be able to scale up or down as per the project size and need.

Conclusion

Custom bellows and boots should complement your system's motion and sealing requirements. Be sure to verify dimensions such as size, media exposure, and heat tolerance before ordering. A good rubber bellow manufacturer will help you through design, fit, and material selection.

In-house manufacturers with direct experience in doing things in-house tend to have improved quality control. Compare lead times, clarity of pricing, and custom run support always. Get the best results through straightforward communication and long-term cooperation from the beginning.

Protect your equipment with custom-designed rubber bellows and boots by the industry leader. Our innovative solutions provide better sealing, flexibility, and durability for any application. Call us today for professional advice and a free quote on your custom rubber bellows.

0 notes

Text

Custom & Wholesale Industrial Bellows Molded, Stitched, Rack & Pinion Bellows Manufacturer

These bellows are necessary additives in many industries due to its super flexibleness, toughness, shock and noise absorbance. Consequently, there has been a worldwide surge in the demand of the very good molded rubber bellows manufacturers. It’s crucial; therefore, in order to selectively choose producers of pinnacle-notch products.

Key producers in the enterprise point out the importance of best and precision. They ornament their repertoire with specially produced rubber bellows that advocate to individual characters’ wishes of their clients. These agencies have the technical knowledge and sophisticated equipment to form the bellows under controlled conditions for consistent thickness and reliability of performance.

The top grade molded rubber bellows manufacturers from the enterprises use top rate-grade materials such as nitrile, EPDM, Silicone and so forth; which are greatly resistant to high stress, heat and unstable chemicals. They conform to global standards hence the credibility and dependability of their merchandise in various deployments such as car, construction and heavy-responsibility machineries.

When you make a selection of professional these bellows manufacturers then you are guaranteed of impeccable excellence, unparalleled performance and sparkling customer support. When working together with enterprise specialists, customers may rely on improved performance of their machines and equipment, hence a higher output and productivity.

The masterpiece creations of the molded rubber bellows manufacturers play an integral role in maintaining different industries moving. Their passion and skill are central in making them deliver dependable and strong products to the groups around the world.

Discover the Best: Exceptional Wholesale Bellows Manufacturers

In the heart of business packages, a vital yet unsung hero flourishes – bellows. They are critical components that make a contribution to the easy waft of operations throughout various industries. As the call for excellent bellows continues to bounce, it becomes imperative to collaborate with dependable wholesale bellows producers.

These manufacturers have an in-intensity understanding of the intricacies of diverse enterprise wishes. They are geared up to provide pinnacle-notch bellows designed to bear even in intense conditions. Wholesale bellow manufacturer prioritize using excessive-grade substances to ensure durability even as retaining the power of the products.

Partnering with relied on wholesale bellow manufacturers assures an inflow of first-rate products designed for performance and sturdiness. Today, with modern-day technology at their fingertips, these manufacturers are capable of delivering exceptional accuracy in their merchandise. In addition, they offer aggressive fees which make it an economical solution for companies.

Opting to paintings with bellow manufacturers brings alongside the promise of superior customer support, on-time delivery, and most significantly, products that comply with the best industry standards. Boost your commercial enterprise productiveness and operational performance via integrating elite excellent bellows from dependable wholesale producers.

Unleashing the Magic of Custom Industrial Bellows

Understanding the dynamics of various industries and their particular requirements is key to harnessing most fulfilling functionality in operations. At the heart of this lies a charming era - custom business bellows.

Industrial bellows might seem insignificant at the start look; however they play an vital position in various sectors. From the chemical enterprise to the sector of aerospace, they ensure greater productiveness and optimize operational efficiency.

Custom industrial bellows offer numerous benefits. Their underlying gain lies in their adaptability, tailor-made to deal with everyday industrial rigors and individualized specifications. Built to undergo excessive tiers of stress and temperatures, they decrease danger while facilitating smooth workflow.

Moreover, the ability of the fabric selected for those bellows typically metal or rubber substantially amplifies their application. The sturdiness and versatility custom bellows offer are unequalled, making them an invaluable industrial asset.

So, whether or not you are into manufacturing, automation, or semiconductor industries, custom business bellows are a game-changer. They contribute to streamlining operations and selling more secure working situations. So, pass ahead and embrace the energy of custom business bellows, the unsung heroes of commercial capability. After all, it's the little matters that make the huge photograph ideal!

Unraveling the Mysteries: The Importance of Rack and Pinion Bellows

When it comes to the sector of automotive components, rack and pinion bellows might not right now take hold of the headlines, but their function is no less critical. These additives play a pivotal role in retaining the toughness of your car's guidance device.

These bellows are rubber boots that guard the rack and pinion steering mechanism from adverse environmental elements like dirt, debris, water, and other contaminants. These components function as a shield, preventing premature wearing out of the rack and pinion system and therefore ensuring the driving experience stays clean and secure.

While they might appear insignificant due to their size, the absence of operative rack and pinion bellows can invite useless hassles and exponentially higher repair fees. Just like other car components, those bellows require timely inspection and maintenance. Damaged or tired bellows need to get replaced right now to save you from infection of the steerage device and to keep away from further headaches.

These bellows personify the adage of small but effective. They are indeed unsung heroes of the car world whose importance can't be overstated in ensuring an automobile's most advantageous performance.

Unraveling the Mystique of Stitched Bellows

Within the area of machine dynamics, the function of stitched bellows serves as an unsung hero. Due to their brilliant flexibility, stitched bellows are often used as protective measures inside moving components of equipment, making sure both performance and toughness.

Fabricated from excessive-grade substances like neoprene, nylon, or silicone-covered fibers, those bellows provide terrific flexibility, resistance to warmness, chemical substances, and moisture. Additionally, their design permits them to guard both linear and rotating actions from dangerous particles and environmental degradation.

These bellows exhibit a high-quality trait of customization. Depending upon the specific requirements, consisting of the working surroundings, length, form, and motion constraints, the bellows may be custom made to ensure most suitable performance. This guarantees a tailor-made safety which can stand the trials of diverse packages.

However, it's the stitching that absolutely amplifies their performance. Firmly stitched with a high-strength thread, these bellows own scalability which complements their durability and adaptability even below severe situations.

The adoption of stitched bellows inside industries is an economical answer that ensures the easy operation of machinery. Their fantastic versatility and sturdiness lead them to a crucial part of both simple machines and complicated commercial operations. Ignoring their functionality may want to cause steeply-priced upkeep and untimely shutdowns. Embracing stitched bellows is certainly a step closer to efficient and fee-effective commercial practices.

Conclusion

Bellows' flexibility, durability, stress resistance, and noise absorption make them vital additions in a variety of industries. The need for premium molded rubber bellows producers, who employ premium materials including silicone, EPDM, and nitrile, is rising globally.

Discover a wide array of custom bellows with Custom Rubber Bellows, designed to fit your regional and industry-specific requirements. We partner with key stakeholders to assess your ROI and guarantee maximum value from your investment. Our service offerings include advanced customization and business-enhancing features. To get started or to speak with our team, contact us at [email protected] or (647) 294-5240.

#Molded rubber bellows manufacturers#wholesale bellow manufacturer#custom industrial bellows#rack and pinion bellows#stitched bellows

0 notes

Text

Industrial Rubber Bellows & Dust Boots Molded, Stitched & Hydraulic Cylinder Protection

Deep in the crux of numerous machines, there lies a resilient performer, the rubber bellows dust boot. Far from auxiliary, this issue is essential for relying on machinery operation across industries, ensuring toughness and most fulfilling performance.

Everything from automobiles to business equipment hinges on the fitness of this thing. These boots confer complete protection from a number of negative factors which include dust, dirt, moisture, and cruel factors which can compromise mechanism integrity.

Rubber bellows dust boot are wonderful for his or her splendid flexibility and sturdiness, essential inside the face of steady motion and shifting hundreds. Made of high-electricity rubber, they uphold their shape and characteristic no matter this steady barrage, even under variable temperature and strain.

Remarkably, they may be tailor-made to match various design specs, serving sectors as numerous as transport, electronics, and household home equipment, to pharmaceutical and food & beverage, maintaining their ubiquity and software.

What makes these unassuming additives extra promising is their price-effective nature. They offer a prolonged thin lifespan, coupled with reduced maintenance and substitute charges, contributing substantially to general price-efficiency.

In the world of equipment wherein dirt can also appear a trivial foe, the common-or-garden rubber bellows dust boot emerges as an unsung hero, status shield steadfastly, making sure performance and capability are by no means compromised. Indeed, a testimony to necessity being the mother of all innovations.

Unveiling the Versatility of Molded Rubber Bellows

In the considerable realm of industrial programs, a secret titan has been subtly appearing miracles meet Molded Rubber Bellows. This unsung hero is excellent in guarding machinery against contaminants like dust, water, and different particles, thereby gambling a critical role in extending the existence expectancy of equipment.

These bellows flexibly accommodate multiple mechanical motions, consisting of axial, angular, and lateral, without restraining their effectiveness. They possess the power to resist intense temperatures, strain situations, and probably damaging chemicals – all the way to rubber's inherent houses of resilience and strength.

Tailor-made to perfection, the manufacturing of those bellows leverages advanced rubber molding technology. This versatility in layout allows it to cater to a big selection of industries such as car, aerospace, clinical, and greater. These bellows may be molded into almost any conceivable form and size to align with unique programs, making sure a snug healthy and highest quality overall performance.

It's excessive time we recognized and applauded the invaluable contribution of these low-profile, excessive-appearing molded rubber bellows in the direction of safeguarding and enhancing our machinery's operational efficiency. Their awesome combination of flexibility, power, and adaptability really lead them to the titans of industrial componentry.

Unveiling the Silent Protectors: The Power of Stitched Fabric Bellows

Bellows, a technological marvel even inside the current age, are essential components in various machines and instruments. Among those, especially noteworthy, are the stitched fabric bellows. These bellows encapsulate unfaltering sturdiness coupled with flexibility, presenting a number movement and safety capability beyond the reach of conventional substances.

Seemingly mundane, those silent protectors are the unsung heroes of several commercial operations. They uphold the command in packages consisting of dirt and dust safety, stress alleviation, and cost-effective retrofitting for scrolling and shifting components. And despite these heavy-duty performing, their design flexibility contains equipment of all styles and sizes with style to spare.

These stitched-up saviors, expertly made from excellent substances, bear severe situations like dirt, warmness, oil, and water, defending the extra sensitive elements of the machine. The robust production means longer device existence and reduced protection, leading to a typical discount in operational expenses.

In a world pushed by performance and innovation, the stitched material below is a brand of both. Superlative in performance and comparatively cheap, they're no longer simply additives; they are quintessential commercial companions, making sure smooth and sustained functionality, day in and day trip.

Next time you spot a gadget working perfectly, take into account, it is viable due to those reliable little wonders- stitched material bellows.

Transformative Flexibility: The Pivotal Role of Industrial Bellows Manufacturers

In nowadays rapid-paced commercial areas, the significance of business bellows cannot be overstated. Renowned for his or her resilience and flexibility, those device components play a critical position in ensuring the seamless operation of devices in numerous industries. Industrial Bellows Manufacturers are unsung heroes, dutifully controlling thermal growth, constraining vibration, and containing pressure.

Industrial bellows producers are at the heart of this business revolution. They epitomize innovation, regularly pushing obstacles in bellow design to maximize performance and minimize machine downtimes. An adept manufacturer does not just produce resilient bellows; they engineer custom answers precisely tailored to meet every client's precise operational needs.

Their sturdy manufacturing practices result in wonderful, long-lasting bellows that may withstand the rigors of different applications, from vehicles to HVAC systems. Furthermore, they're dedicated to continuous development, incorporating the present day technological advances in their manufacturing techniques.

Partnerships with those manufacturers are a strategic advantage for companies. They provide huge manufacturing talents, in-intensity technical information, and unwavering dedication to satisfactory. In this period in which system efficiency notably influences a company's backside line, the choice of a business bellows producer subjects surprisingly.

In the stop, a fantastic industrial bellows producer transforms businesses, optimizing operation structures and promoting industrial growth. As the economic quarter evolves, their role will stay pivotal, forging the future one bellow at a time.

Unveiling the Might of Hydraulic Cylinder Bellows: Enhancing Machine Efficacy

When thinking about the impeccable functioning of machines, hydraulic cylinder bellows stand as unsung heroes ensuring the seamless overall performance of diverse business packages. These bellows, generally made from sturdy, bendy substances, are immensely critical to enhancing the existence expectancy of the hydraulic cylinder.

Under the continuous motional pressure, the hydraulic cylinders would possibly face contamination from dirt, debris, and different foreign particles. The bellow shields the piston rod from these perilous factors, boosting operational efficiency and decreasing the chance of frequent maintenance and replacements, for this reason, amplifying productiveness.

The marked flexibility of the hydraulic cylinder bellows permits them to endure the shifting piston rod without cracking or tearing. Concurrently, the long lasting materials of these bellows, together with rubber or polyurethane, offer advanced resistance in opposition to various environmental situations.

Their design contains the dimensional variability of hydraulic cylinders, permitting custom sizes to enhance the bellow's compatibility, therefore, optimizing the machine's overall performance. As an essential device, their ease of installation eliminates the want for unique equipment or widespread downtime.

Undoubtedly, hydraulic cylinder bellows quietly revolutionize the core equipment operations even as appreciably decreasing upkeep fees. Investing in these important additives guarantees the maximization of equipment lifespan and ushers the enterprise into a brand new generation of optimum performance.

Conclusion

Rubber bellows dust boots, which offer protection against dust, grime, wetness, and other hazardous elements, are crucial for the operation of machinery in a variety of sectors. These high-electricity rubber boots, which are used in the transportation, electronics, home appliance, pharmaceutical, and food and beverage industries, may be tailored to meet a variety of design requirements.

Custom Rubber Bellows offers a wide range of bellows with personalized customization services, tailored to meet your specific regional needs. We collaborate with all key stakeholders to evaluate your return on investment, ensuring you get the most value from your resources. Additionally, we provide enhanced customization features and services designed to boost your business performance. To schedule a consultation or get in touch, contact us at [email protected] or (647) 294-5240.

#rubber bellows dust boot#molded rubber bellows#Stitched Fabric Bellows#industrial bellows manufacturer#hydraulic cylinder bellows

0 notes

Text

Custom Molded & Stitched Rubber Bellows Precision Bellows Boots Manufacture

Bellows, particularly molded sorts, maintain an unheard of role in dynamic engineering systems. Considered the unsung champions of the industrial era, molded bellows are more than meets the eye.

These gadgets come to existence as key components in numerous applications spanning throughout sectors like medical, aerospace, semiconductor, and UHV environments. Their fulfillment rests on a simple yet elegant layout, a one-piece, seamless synthetic rubber or plastic product with flexible convolutions.

Molded bellows supply notable resilience and flexibility, vital for soaking up vibration, noise, and thermal enlargement. To upload - their electricity for compensating alignment errors is outstanding, supplying a buffer to defend crucial components and amplify system lifestyles.

Furthermore, such bellows can brag with an unusually high level of flexibleness of design and selection of materials. This allows engineers to fine-tune them as per the particular needs of an application for optimized performance and efficiency.

With its inherent properties of flexibility, sturdiness, and flexibility, the molded bellows are robust answers to maintaining running suavity in many spheres. Their silent contribution towards our existing infrastructures tells a lot about how invaluable they are in industrial dynamics.

Unlocking the Magic of Custom Molded Rubber Bellows

The global of business and industrial mechanics is replete with improvements, and custom molded rubber bellows stand out as a shining instance. These part flats, which are mostly employed as protective covers, are, among others, important in every mechanical system in a significant manner.

These rubber bellows provide a state of pliability and sealing abilities that is unmatched. Customization ensures best compatibility with particular equipment and improves functionality and durability.

They may be designed to accommodate complicated motion sorts, thereby assembling numerous commercial necessities for unique packages, together with car, aerospace, scientific, oil and fuel, and greater.

Their inherent resilience to excessive temperatures, pressure, oil, and other harsh conditions is remarkable, promising superior performance and safety. Moreover, these rubber bellows are value-powerful, imparting tremendous financial savings on capability maintenance and alternative charges.

The authentic price of these rubber bellows lies in their capacity to be tailor-made for unique applications, permitting superior device performance and reliability. Hence, investing in excessive-grade, custom molded rubber bellows can show to be a pivotal choice that appreciably enhances operational performance?

Unlock the magic of those important additives, and harness their capacity to drive your business’s fulfillment to new heights.

Mastering the Craft as a Custom-Stitched Bellows Manufacturer

To project into the engineering domain is a strategic bounce for enterprise specialists; however, the area of interest of custom stitched bellows manufacturers is an art of precision, persistence, and professionalism. Bellows discover a huge spectrum of usage in programs that variety from cameras to heavy industry devices. Being a custom, stitched bellows producer entails no longer best exhausting craftsmanship but additionally a complete expertise of consumer’s necessities.

Our expertise in production bellows encompasses neoprene, silicone, aluminized fiberglass, and other green materials. This versatility allows us to cater to a variety of industries, confronting challenges with progressive answers.

The essence of our approach is rooted in the custom element. Every bellows element created is specific to the application it serves. Custom tasks project us to push limitations, study, and enhance. The system is not a simple assembly line manufacturing. It includes an in-intensity evaluation of the design, careful selection of materials, precision at some stage in assembly, and rigorous inspection to make certain great.

Indeed, a testimony of price for the knowledge in handling complex designs is a stitched bellows, specifically. The sewing wants to be long-lasting, durable, and firmly distinguished in order to ensure durability and to reduce the maintenance needs.

As a frontier of this dynamic world, we commit to maintain our promise of nice, innovation, and purchaser satisfaction in this changing world of industries. Let us provide the excellence that rings in all our custom bellows stitches.

Artistry in Flexibility: Unlocking the Potential of Custom Rubber Bellows

In the problematic world of industrial mechanisms, custom rubber bellows sit majestically on the core, silently orchestrating the flawless functionality of numerous structures. As unsung workhorses, those reticent additives often pass ignored, but they keep the strength to revolutionize a couple of core applications.

These bellows are flexible elements used extensively across medical, car, and aerospace sectors, exhibiting top notch flexibility, adaptability, and sturdiness. Their expansive reach also extends to govern systems, optical devices, and cargo cells.

The phenomenal flexibility, resistance to warmth, oils, acids, and salts makes these rubber bellows a wonder element throughout numerous sectors. They effectively accommodate lateral, torsional, and axial motion, safeguarding intricate elements from the invasion of dust, dirt, and moisture, ensuring long existence and green performance of these systems.

What unit’s bellows apart is the capacity to mildew them into bespoke designs to cater to a numerous palette of industrial wishes? Experts can design these components to articulate complex movements exactly – expanding the horizons of what is potential in various commercial spheres.

These bellows affords now not only a defensive masking however a bridge to progressive packages. They are the unsung heroes at the back of the seamless capability of diverse structures, underlining the importance of crafting excellence in every element.

Rubber Bellows Boot: The Unsung Hero of Machinery

Rubber bellows boot, also referred to as a bendy joint or a growth joint, is an essential yet extensively disregarded component in a variety of commercial machinery. This unsung hero inside the realm of machinery commonly functions as a protective detail, growing a barrier towards dirt, dust, and environmental factors that would doubtlessly harm touchy transferring elements.

Composed of a flexible material, the rubber bellow boot can face up to excessive-warmness levels, withstand abrasion, and fight dangerous chemical substances factors instrumental in elongating the operational existence of machinery and maintaining foremost overall performance degrees.

Shaped like a folded accordion, this piece of equipment expands and compresses to take in surprise and isolate vibration, preventing disruptive noises that might in any other case imply mechanical misery. The terrific flexibility offered by way of a rubber bellow boot is what allows such effective sound deadening and vibration reduction, thereby curtailing potential gadget put on and tear.

While the position of the boot may additionally seem minor primarily based on its size, its contributions toward the overall capability and lifespan of the machinery are gigantic. The humble bellows boot may just be the knight in shining armor your equipment needs.

Conclusion

In dynamic engineering systems, especially in industries like medicine, aircraft, semiconductors, and UHV conditions, bellows, especially molded ones, are essential. They provide exceptional alignment compensation, robustness, and flexibility, guaranteeing peak performance and effectiveness.

At Custom Rubber Bellows, we provide a diverse selection of bellows with customization options to match your local requirements. Our team actively engages with relevant stakeholders to analyze ROI, helping you maximize the value of your investment. We also offer advanced customization and unique features to support and grow your enterprise. Reach out today at [email protected] or call (647) 294-5240 to book an appointment.

#molded-bellows#custom-molded-rubber-bellows#stitched-bellows-manufacturer#custom-rubber-bellows#rubber-bellows-boot

0 notes

Text

Custom Made Bellows: Durable Solutions for Industrial Applications

Custom bellows are integral parts in varied industrial uses. They offer enduring and flexible ways to shield machinery. This ensures smooth operation. Specialized goods are crafted to absorb vibrations. They can handle expansion due to heat. They also stop pollution. Industry sectors such as manufacturing and medical equipment rely on these.

Understanding Custom Made Bellows

Custom-Made Bellows - What are They?

Customised bellows are flexible enclosures. They can expand and contract while keeping their structure. They take on multiple functions. They act as seals to stop dust and moisture. They absorb vibrations from machinery. They also facilitate movement between connected parts. Customisation lets you make targeted solutions. These meet specific needs. This is crucial in industries valuing precision and reliability.

Why Pick Custom Made Bellows?

Primary strength of custom bellows is their adaptability. Unlike standard bellows there can be misfits in all applications. Tailored answers can be crafted to exact sizes, materials and performance traits. This guarantees good function. It's in exclusive settings. Like high heat in production or sterile conditions in clinics.

Applications Across Industries

1. Manufacturing: Manufacturing settings benefit from custom bellows. These guard moving pieces from grit and refuse. They also absorb vibrations. Those could lead to machine breakdown. They're often vital in CNC machines. Automated systems need them. Precision is a must.

2. Medical Equipment: The medical world leans on custom bellows. They use them for gadgets like MRI machines and surgery tables. It's an industry with strict cleanliness requirements. These bellows must stand up to many pressures, movements.

3. Oil and Gas: In the oil and gas industry custom bellows play a crucial role. They protect equipment from tough weather. They can handle high pressures and corrosive things. These ensure the life of crucial components.

Kinds of Custom-Made Bellows

Neoprene Bellows: Neoprene bellows are popular. This is due to the excellent resistance to oils. They're resistant to chemicals and harsh weather. The bellows provide effective sealing capabilities. They also absorb vibrations. They can be used in a variety of industrial applications. These bellows are durable and ensure long-lasting performance. This is even true in challenging environments.

Stitched Fabric Bellows: Stitched fabric bellows are a cost-effective solution. This solution is usually for applications requiring flexibility and durability. Bellows can be customized in terms of size and shape. They can match specific operational needs. These bellows are especially useful in certain environments. Here, traditional molded bellows might not be feasible. It could be due to space constraints or budget limitations.

The Role of Bellow Cover Manufacturers

Manufacturers of bellow covers play a critical role. They are vital in the creation of custom bellows. This is done by making sure that the bellow meets the right material choice. They understand the design specifications. They then deliver. The final product should meet strict criteria. It is for the intended purpose.

Selecting a manufacturer of bellows is crucial. Their experience is one factor to consider. They should have a good track record in the industry. They should also offer customized solutions. A good manufacturer will work with clients closely. They work to understand their needs. The final goal is to deliver the right performance.

Benefits of Using Custom-Made Bellows

Enhanced Durability: Bellows custom made from high-quality materials. These materials are designed for specific applications. The bellows have a longer service life versus standard options.

Improved Performance: Bellows custom made by addressing unique challenges. These challenges belong to different industries. Bellows enhance overall efficiency of machinery and equipment.

Cost-Effectiveness: At first the investment may be higher. It is higher than off-the-shelf solutions. Yet, longevity and reliability of custom-made bellows can lead to cost savings. These savings come over time.

Flexibility: Ability to customize size, shape and material is a benefit. It means businesses can find solutions. The solutions fit their exact requirements without compromise.

Conclusion

Custom made bellows are key to many industrial uses. They last long providing durable solutions. These solutions enhance machine performance. Machines also get protected from diverse environmental factors. Products include neoprene bellows. Stitched fabric designs also fit here. These items offer custom solutions. They can meet the modern industry's diverse needs.

Businesses hunt for methods to boost efficiency. They work to minimize downtime. Their investment in quality custom bellows is needed. This is particularly so when the bellows come from reputable manufacturers. Benefits and applications of these products need to be understood. It helps companies make educated choices. Decisions that link back to their operational goals.

Considering a custom approach to your industrial needs? Seek out experienced bellow cover manufacturers. They can help you. They can guide through the selection process. The right materials. The right designs. Help is available for your specific applications.

Right custom bellows improve machinery operation. It helps ensure smooth operation. Plus, it extends lifespan. A gain that is substantial.

0 notes

Text

Rack and Pinion Boots and Rubber Bellow Seals: A Guide for Industrial Uses

Rubber bellow seal are important portions of the economic puzzle, regularly disregarded however vital in maintaining your machinery's functionality. With their accelerated usage in industrial equipment, it's critical to understand their middle cost.

Promoting Efficiency and Longevity: These seals play a critical position in preventing leaks in equipment, mainly to expand performance and toughness of the system. The rubber bellow seal helps reduce renovation time which improves workplace productivity.

These flexible temperature range limits of rubber bellow seals enable their use within numerous industrial sectors. The rubber bellow shows resistance to extreme temperatures in both heating and refrigeration systems.

Cost-Effective Machinery Solution: These bellow seals are a cost-powerful choice for industries. Not best do they promote toughness of the system, however in addition they lower the general costs related to upkeep and replacement.

The rubber bellow seal isn't always merely a chunk of rubber, but a strategic funding closer to machinery capability. Infusing it into the economic equipment promotes performance, saves prices and extends the lifespan of structures typical. Understand

ding and appreciating its role can considerably beautify the general performance and profitability of your industry. It’s excessive time that we pay attention to those small but notably influential aspects of the industrial global.

A Stitch in Time: Behind the Top-notch Stitched Bellows Manufacturer

The craftsmanship in the back of stitched bellows actually merges the prowess of cloth technology knowledge with engineering precision. The industry’s standout leaders, stitched bellows manufacturers, do not now simply churn out products; they devise solutions allowing industries.

Precision Engineering: The quality of a stitched bellow hinges on precision. From the initial fabric selection to the very last sewing, every step includes meticulous attention to detail. Renowned manufacturers leverage superior era and skilled manpower to keep unwavering precision, making high-quality, long lasting products each time.

A stitched bellow depends on precise engineering principles for achieving its high level of quality. Both fabric choice and final sewing perform under close examination to achieve exact details at every step throughout manufacturing. The leading manufacturing firms combine advanced technologies with qualified personnel to maintain absolute precision for delivering excellent long-lasting products every time.

Modern manufacturing has brought forward customized solutions as its key development. Their target customers from different industries including aerospace and automotive and medical fields receive entirely customized bellows solutions which meet their specific requirements.

Stitched bellows producers aren't sincere producers; they may be innovators, technicians, and answer vendors. Their information and ahead-questioning approach keep to empower commercial efficiency globally, reflecting not only their dedication to fine but also their position as critical partners in progress. The future will best see similar improvements in this discipline, as they remain centered on perfecting their merchandise.

Unveiling the Mystery of Rack and Pinion Boot

Your automobile steering system entirely relies on the frequently overlooked but essential rack and pinion boot which you should pay close attention to. Even though often overlooked the rack and pinion boot serves as an essential component which assists your automobile to maintain its ease of use and durability.

Protection against Contaminants: These boot safeguards the tools mechanisms from dust, debris, and other road shrapnel. Without it, these risks ought to penetrate and cause enormous damage in your vehicle's guidance machine, mainly too expensive upkeep or replacements.

Maintenance of Lubrication: The boot offers steady lubrication to the steering gear, making sure clean operation and assuaging the excessive wear and tear which can result in costly mechanical screw ups.

Scheduling regular inspections of your boot to detect early signs of damage will help extend your vehicle's steering system durability until it becomes more effective.

The pinion boot maintains your car from experiencing walking issues so never overlook its essential function. Proper maintenance stands as the key factor which determines how long your vehicle survives.

Diving Deep into the World of Industrial Rubber Bellows

In the industrial international, rubber bellows play a massive role intently related to efficiency, safety, and production optimization. Precisely crafted, those flexible connectors are unified into numerous structures making them relatively quintessential.

Cutting-Edge Technologies: Predominantly featured in sectors like automobile, plumbing, and production, rubber bellows harness superior technologies. They are designed to take in warmness, noise, and vibration, offering a seamless operational experience. Their design configurations are marvels of precision, adjusting to system movements and misalignments without impairing overall performance.

Excellent Durability: Industrial rubber bellows boast durability and sturdy pleasantness. With excessive resistance to harsh environments, stress variance, chemical reactions, they provide lengthy-status providers, curtailing maintenance and alternative prices.

Broad Functionality: These rubber bellows demonstrate wide functionality. They expertly facilitate axial, lateral, and angular moves in interconnected systems, in tandem with sealing houses to save you leaks. Additionally, bellows additionally act as protecting sleeves, shielding machinery components from abrasive elements.

These rubber bellows are unsung heroes in numerous business mechanisms. By bolstering structures with multiplied capability, sturdiness, and price efficiency, they play a pivotal part within the seamless orchestration of varied business approaches. Their significance cannot be underscored enough – an exquisite testimony to the breakthroughs of modern industrial design.

Conclusion

Rubber bellow seals, which are frequently disregarded yet essential in many sectors, are essential to preserving the operation of machinery. By avoiding leaks, cutting down on reconstruction time, and lowering maintenance expenses, they increase efficacy, durability, and cost-effectiveness. Manufacturers of stitched bellows guarantee high-quality, long-lasting goods by fusing engineering accuracy with their understanding of textile technology.

Discover superior-fine bellows with Custom Rubber Bellows, presenting lots of customizable answers designed to fit your particular programs. Our crew collaborates with all stakeholders to assess performance, ensuring you get the first-rate fee on your funding. We offer specialized customization alternatives, including unique capabilities that enhance durability and performance. With expert steering and high-precision production, we ensure pinnacle-tier solutions tailor-made on your commercial enterprise needs.

For extra info or to schedule a consultation, contact [email protected] or name (647) 294-5240 today!

0 notes

Text

Exploring Stitched Fabric Bellows and Custom Covers: Insights from Top Manufacturer

Manufacturing industries have begun a substantial transformation through an innovative system which brings both customization and unique developments. The transformation of industrial processes brings Custom Industrial Bellows as specially designed mechanical devices that bring revolution to industry sectors while improving methods.

Each bellow goes through customized engineering according to operational needs that enhances system functioning as a whole. Industrial bellows identify with diverse operational applications which range from moisture and dust sealing to temperature control and pressure-related duties and many more.

The use of advanced fabrication methods aligns with best materials selection to custom industrial bellows that deliver superior resistant performance during tough operational environments. These components have an essential protective role because they shield valuable machinery components from capacity put on and tear.

These custom business bellows represent a great long-term value proposition because they enhance machinery durability while decreasing maintenance expenses and operational interruptions. Investing in these resourceful devices leads organizations to achieve substantial returns on investment at their conclusion phase.

The custom industrial bellows stand as a proof of manufacturing industry innovation power. These components redefine operational procedures as they make new standards that will determine operational performance and product productivity which represents today's economic evolution. Selecting customized bellows represents both an essential business move which also protects your company operations from future changes.

Revolutionizing Safety & Efficiency with Stitched Fabric Bellows

Fabric bellows, long a staple feature of numerous business equipment, are actually gaining renewed interest for his or her versatility and sturdiness. Although several varieties of bellows exist, the focal point of our discussion these days is on Stitched Fabric Bellows a cutting-edge innovation in machine protection and efficiency.

Enhanced Machine Protection: The primary function of a stitched material bellows is to offer advanced safety to machines. By protecting inclined elements from dust, dirt, or external damage, those bellows boom the lifespan of the equipment significantly.

The ability to adapt is what gives stitched material bellows their renowned status because they are versatile and flexible. The products can suit into different machinery arrays because they maintain their performance capabilities even when manufacturers build them with specific shapes and dimensions.

The bellows provide price efficiency that produces instant operational financial benefits. The material's durability system minimizes the necessity for replacement parts thus cutting down maintenance expenses as well as downtime needs.

Stitched material bellows, with their mixture of safety, adaptability, and price efficiency, stand as a wonderful innovation within the industrial zone. Incorporating them now not the simplest ensures durability of important machinery elements, but also enhances operational efficiency, making them a critical detail in the latest commercial scenario.

Sculpting Quality Coverings: The Mastery of Bellow Cover Manufacturer

Bellow cover manufacturers are the unsung heroes in the accomplice of your machinery and industrial device. Producing defensive covers of unequalled satisfaction, they're the shields that keep the optimum operation of your gadgets.

Unraveling the Secret of Durability: Bellow covers are not simply designed; they're precisely crafted. With the producer's loyal awareness on sturdiness, you could trust that your system’s maximum sensitive components are protected from harmful debris, corrosion, and physical effect. This full-size durability guarantees the productivity of your equipment for a substantially longer duration, paying dividends for your investment.

Customizable For Every Need: The aptitude of these manufacturers to create custom-suit products sets them aside. Their extensive understanding within the sector lets in them accommodate varying sizes and configurations, adhering to the specifications of even the most complicated equipment.

Committed to Excellence: With big attention to element, bellow cover producers have constructed a long lasting reputation for his or her dedication to greatness. Each bellow cowl undergoes a rigorous fine assessment process to attest its credibility and patience.

In an era in which machinery is critical to every industry, the position of the bellow cowl producer is pivotal. Their commitment to first-class, interest in detail, and the capacity to satisfy unique customer requirements put them on the map of vital members in our increasingly mechanized world.

Decoding the Wide Range of Rubber Bellows: A Comprehensive Rubber bellows catalogue

The rubber bellows enterprise is a specialized niche, however, know-how the components provided in the catalogue are essential for selecting the precise elements for equipment. If you are searching to replace or procure new rubber bellows, this weblog is adapted for you!

Diverse Applications: These catalogue gives an array of product designs crucial to numerous fields which include automobile, railway, and construction. Each application has specific available dimensions, coatings and strain scores, all detailed within the catalogue.

Superior Material Quality: The catalogue shows a collection of great rubber bellows made from materials like Nitrile, Natural Rubber, EPDM and Silicone. These guarantee sturdiness, flexibility, and resistance to environmental extremes, thereby enhancing the durability of your gadget.

Customization and Innovation: The catalogue no longer handiest showcases widespread services but also opens up possibilities for custom designed answers. Innovations, just like the advent of excessive-temperature bellows or bellows with integrated restrict rods, make the catalogue a should-see for progressive device builders.

Navigating through a complete rubber bellows catalogue might first of all appear daunting, but information the underlying info is vital for making an knowledgeable choice. The catalogue permits professionals to discover the exceptional-fit rubber bellows that satisfies their machinery necessities while ensuring durability, performance, and value-effectiveness.

Conclusion

Custom Industrial Bellows' exceptional endurance to challenging operating conditions is intended to transform production processes. These bellows are necessary for a number of tasks, including temperature regulation, sealing against moisture and dust, and tasks involving pressure. By increasing the longevity of machinery and lowering maintenance costs and downtime, they provide long-term value propositions. Because of their affordability, durability, and adaptability, stitched fabric bellows are becoming more and more popular. Manufacturers of bellow covers are essential to preserving the best possible performance of industrial equipment and machinery.

Custom Rubber Bellows provides expertly crafted bellows with complete customization services, making sure they meet your actual specs. Our group works carefully with all stakeholders to maximize price, overall performance, and return on funding. With improved customization options, we combine modern features that raise durability, flexibility, and performance. Whether for industrial or commercial use, our solutions are designed to fulfill the highest standards of best and precision.

Reach out these days at [email protected] or call (647)294-5240 to book an appointment.

0 notes

Text

Custom Rubber Bellows: What to Look for in a Wholesale Manufacturer

Understand the advanced role of custom rubber bellows that bring transformation across automotive industries and scientific applications and aeronautics and many other sectors.

These rubber bellows demonstrate extraordinary durability because of their resistance. Custom rubber bellows endure tough environmental conditions that combine temperature changes along with pressure variances and chemical corrosives so they provide extended service life. The extended lifespan of these rubber bellows reduces expenses by decreasing the need for future system replacements or changes.

The custom rubber bellows offer exceptional flexibility as their main distinctive feature because of their adaptable nature. The natural flex in rubber elements enables them to handle movement types such as rotation and vibration and alignment while supporting various business and industrial and family machines.