Don't wanna be here? Send us removal request.

Text

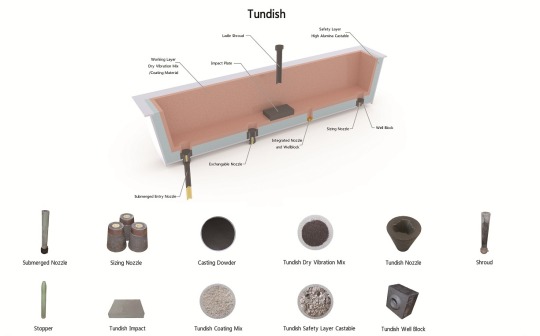

What are the difference between tundish nozzles and ladle nozzles in steel making

This article explains the difference between ladle nozzle and tundish nozzle. Learn about the difference between ladle furnace andtundish furnace. Welcome to know more about refractory nozzle and other kinds of refractory products.

The different between tundish nozzles and ladle nozzles

Tundish nozzle and ladle nozzle are important components in the process of steelmaking, but they serve different purposes. Tundish is used in the continuous casting process to distribute molten steel into the mold, while the ladle is used for transporting and pouring molten steel from the furnace to the tundish.

Refractory nozzles including a so-called long nozzle, an upper nozzle, a lower nozzle, and an immersion nozzle made from high-alumina refractory material, graphite powder, silica powder and other minor constitutents wherein a major part of the high-alumina refractory material.

This article relates to nozzles used around the ladle and the tundish in a steel manufacturing plant and made from specially processed refractories, and more particularly, it relates to those used in so-called continuous casting.

Tundish Nozzle Composition

Tundish Nozzles are an integral part of Continuous Steel Casting process. These products are instrumental in controlling the flow of Molten Steel from Tundish to Continuous Casting. Long casting sequence time. Controlled casting speed.

Tundish Nozzles usually comprise a zirconia inner nozzle (often referred to as a “zirconia insert”) with a lower grade outer body such as Alumina, Zircon or Bauxite.

Ladle Nozzle Composition

Ladle-nozzle – a type of refractory products used in the process of non-stop casting of steel. They are part of the components of refractories to a steel casting slide gate. They are an integral replaceable part of the nest block.

Ladle nozzle is composed of upper and lower sliding plates and 4 refractory bricks for the upper and lower nozzles. The pouring of each ladle of molten steel must pass through the upper and lower sliding plates and the upper and lower nozzles, so they are very strict.

Tundish Nozzles are an integral part of Continuous Steel Casting process. These products are instrumental in controlling the flow of Molten Steel from Tundish to Continuous Casting. These are highly suitable for open casting.

Tundish Nozzle & Ladle Nozzle

What is the difference between tundish and ladle?

(1) The tundish nozzle is smaller than the ladle nozzle and is easy to be blocked by cooling.

(2) The height of molten steel in the tundish is used to adjust and control the flow of molten steel in the tundish into the mold.

(3) The tundish allows a reservoir of metal to feed the casting machine while ladles are switched, thus acting as a buffer of hot metal, as well as smoothing out flow, regulating metal feed to the moulds and cleaning the metal.

What is Ladle furnace?

In steel: The ladle. An open-topped cylindrical container made of heavy steel plates and lined with refractory, the ladle is used for holding and transporting liquid steel.

The main purpose of the Ladle is to raise steel temperature and to control the chemical composition between tapping and casting, removing and/or modifying inclusions and acting as a buffer in melt shop logistics.

In the process of steelmaking, once the steel is made in the basic oxygen furnace, arc furnace or induction furnace, it is transferred into the ladle for further refining, chemistry adjustment, inclusion modifications, etc.All these treatments are carried out in the ladle. Additional heat is required to carry out these operations. Hence the ladle is provided with a heat source which heats the liquid metal and compensates thermal losses. Thus the furnace in which the quality of liquid steel is improved by refining and heating is called a ladle refining furnace (LRF). Our offer consists of a wide range of safe and reliable refractories ranging from slide gate to nozzle to nozzle changers and purging plug systems.

What is Tundish Furnace?

The tundish is a container of large dimensions that receives the steel from the ladle prior to its introduction into the continuous casting machine.

Tundish are highly responsible facilities within the casting process of molten steel, because they are subjected to high temperatures continuously and failure of them involves not only the production sequence, but also the safety of the plant.

The tundish is made from extremely durable materials which are capable of coping with the high heat of molten metals. The equipment is usually lined with a material with low conductivity, and may be fitted with a nozzle to control the flow of molten metal. In other designs, the pour is controlled by hand or by machine. Controlling the pour is important to avoid casting a piece with flaws such as cracks and bubbles, and to accommodate the needs of different metals.

More details about Ladle Nozzle & Tundish Nozzle

Which is the connector pipe between tundish and steel ladle?

In steel making, the shroud tube creates a connection between the ladle and tundish of the continuous casting plant allowing molten metal to flow between the two.

What is nozzle and diffuser?

A nozzle is a device which accelerates fluid. During this process, velocity of fluid increases with decreasing pressure. A diffuser is a device which slows down fluid. That means velocity of fluid decreases with increasing pressure.

What are the different types of tundish nozzles?

Different kind of tundish nozzles include, Alumina, Alumina Carbon, Zirconia Alumina Nozzles, which are manufactured for single to multiple casting application.

What is a tundish nozzle used for?

Tundish Nozzles are an integral part of Continuous Steel Casting process. These products are instrumental in controlling the flow of Molten Steel from Tundish to Continuous Casting. These are highly suitable for open casting.

What is a ladle nozzle used for?

Ladle-nozzle – a type of refractory products used in the process of non-stop casting of steel. They are part of the components of refractories to a steel casting slide gate. They are an integral replaceable part of the nest block.

In general, Learn more about the differences between ladle nozzle and tundish nozzle by reading this article. What's more, Get an in-depth look at the difference between ladle furnace and tundish furnace. If you are interested in refractory nozzle and other refractory products, welcome to view our factory to know more.

Article Source: What are the difference between tundish nozzles and ladle nozzles in steel making Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

Ladle Nozzle for sale

0 notes

Text

How to manufacture high alumina cement

This article introduces the advantages and disadvantages of high alumina bricks. Read this article to learn about the application areas and product features of high alumina brick. What's more, You can know more details about difference between High Alumina Cement and Ordinary Portland Cement.

High Alumina Cement (HAC), sometimes known as calcium aluminate cement (CAC) or aluminous cement, is composed of calcium aluminates, unlike Portland cement which is composed of calcium silicates. It is manufactured from limestone or chalk and bauxite (Special clay having extremely high alumina content).

High Alumina Cement including lime, they are ground into cement clinkers in a process called fusing or sintering. Its popularity rose when the properties of this cement such as rapid strength gain and easy to manufacture were found out and widely used for precast concreting. High alumina cement is mostly used to manufacture structural concrete such as pre-cast beams.

High Alumina Cement

The process of manufacture of High Alumina Cement

The process of manufacture of High Alumina Cement is different compared to that of ordinary portland cement. Bauxite and lime are used as the raw material. The raw materials are mixed in the required proportion and grinded into small fragments of 100 mm. These lumps are fed in kiln and heated up-to their fusion point which is 1600°C. The molten material fall down on the steel plate and it is send to cool down in rotary kiln. These clinkers are then grounded finely in tube mills unto the fineness not less than 2250 cm2/gram is achieved.

High alumina cement is manufactured by sintering or fusing a mixture in suitable proportions, of alumina and calcareous materials and grinding the resultant product to a fine powder.

There are two main elements used to make high alumina cements limestone and bauxite. These two ingredients were charged into the furnace.

The furnace is fired with pulverized coal or oil with a hot air blast. The fusion process in the furnace generally takes place at a temperature of about 1550-1600°C.

The cement is maintained in a liquid state in the furnace. Then after the molten cement is filled in molds and cooled.

These castings are known as pigs. After cooking this molten cement it looks like a dark, fine gey compact rock resembling the structure and hardness of basalt rock. The pigs of fused cement, after cooling are crushed and then ground in tube mills to a fineness of about 3000 sq. cm/gm.

The complete process of High Alumina Cement production step by step:

At first, use the chemicals Bauxite and lime as raw materials and crush them both into small proportions. Each lump must be less than 100 mm in size.

1.Put these small fragments in a furnace

2.Now maintain the temperature of heat between 1500-to-1600-degree C.

3.The melted material fell on the steel plate

4.Wait for the molten material to little cool down

5.Place this molten material into vessel

6.This form of cement will now look like a rock after cooling down and turns into a light grey colour

7.We will now break this cement rock into small chunks

8.Every chunk must be crushed till it turn to a fined powder form of cement

9.In last we will go through separation or filtration process by the use of separating funnel and magnetic separators to separate metallic iron and other impurities from the cement

10.This refined powder or form of cement is High Alumina cement.

Advantages of High Alumina Cement

The advantages of High Alumina Cement are as follows,

1.Due to the more setting time, time for mixing and placing is more.

2.The resistance for the chemical action is good.

3.Can withstand high temperature.

4.Frost action is low as the heat evolved is more during setting.

5.High alumina cement is very reactive and has very high compressive strength.

6.High resistant to fire.

Disadvantages of High Alumina Cement

The disadvantages of high alumina cement are as follows,

1.As the heat required for the manufacture of this cement is more, the manufacturing cost of this cement is high.

2.As the fineness is kept not less than 2250 cm2/gram, which is very fine. Care to be taken that it doesn't come in contact with human eye or mouth.

3.As the heat evolution while setting is high, it cannot be used in mass concreting works.

High Alumina Cement Raw Materials

Raw MaterialPercentage

Bauxite40 %

Lime40 %

Iron oxide15 %

Ferric oxide, silica, magnesiaLittle

High Alumina Cement Applications:

1.It is frequently utilized in sewer infrastructure and maritime building because of its quick hardening and strength properties.

2.Refractory concretes that need higher strength at very high temperatures, also use this cement.

3.High alumina cement is also used in refractory concretes where it requires more strength at very high temperature.

4. In construction concretes, where rapid strength development is required, even at low temperatures.

5. As a protective liner against microbial corrosion such as in sewer infrastructure

6. As a component in blended cement formulations, for various properties such as ultra-rapid strength development and controlled expansion are required.

7. In sewer networks for their high resistance to biogenic sulfide corrosion.

Characteristics of High Alumina Cement:

1.This cement is excellent resistance to chemical attacks.

2.There is a pH problem.

3.It is used to construct water and sewage pipes, factory drains, coastal constructions, and manufacturing chimneys due to its strong resistance to chemical corrosion.

4.There is a high refractive index in the cement issue.

5.It is highly resistant to sulfuric acid.

6.This cement’s rapid cementing property.

7.Due to its ability to establish a ceramic bond at high temperatures, it serves as a bonding agent when added to refractory castable.

Hydration of High Alumina Cement:

The important reaction during the setting of the high alumina cement (HAC) is the formation of monocalcium aluminate decahydrate (CAH10), dicalcium aluminate octahydrate (C2AH8), and alumina gel (Ahn).

These aluminates provide high strength to HAC concrete but they are metastable and at normal temperature convert gradually to tricalcium alumina hexahydrate (C3AH6) and gibbsite which are more stable.

Difference between High Alumina Cement and Ordinary Portland Cement

As compared to ordinary portland cement, high alumina cement has the following differences:

High Alumina CementOrdinary Portland Cement

High alumina content about 40 %

Higher resistance to sulphate attackOPC is not much resistant to sulphate attack

Calcium hydroxide is absent in the hydrated products of high alumina cementCalcium hydroxide and CSH gel are the main hydration products of OPC

No free lime is produced after setting and hardening even at high temperaturesAt high temperatures, Ca(OH)

2

decomposes producing free lime

Absence of free lime does not make HAC unsound when exposed to moisture or waterFree lime makes OPC unsound when exposed to moisture

Used for making refractory lining in furnacesUsed for normal construction purposes

More details about High Alumina Cement:

What is high alumina cement used for?

Generally, this refractory product is widely used in sewer infrastructure and marine construction. Besides, it is also used in refractory concretes for furnaces, boilers, kilns, and chimneys. This is due to its strength to withstand very high temperatures with proven durability.

Why is high alumina cement not allowed to be used structurally?

High alumina cement possesses properties like high early strength, rapid hardening even at low temperature, and durability to sulphate attack. But the conversion of HAC has made it unfit for structural use due to gradual strength loss.

Which raw material is used for high alumina cement?

High alumina cement is manufactured by fusing together a mixture of 40% bauxite , 40% lime and 15% iron oxide and ferric oxide, 5% silica, magnesia etc.

What is another name for high alumina cement?

aluminous cement

Calcium aluminate cements are cements consisting predominantly of hydraulic calcium aluminates. Alternative names are "aluminous cement", "high-alumina cement", and "Ciment fondu" in French. They are used in a number of small-scale, specialized applications.

How high alumina cement is made?

High Alumina Cement is manufactured by grinding the clinkers of alumina and calcareous material such as lime by fusing or sintering process. This cement is also known as calcium aluminum cement.

By reading this article, have In-depth understanding of the advantages and disadvantages of high alumina bricks. If you are interested in other refractory products or other furnace solutions, welcome to contact us anytime.

Article Source: How to manufacture high alumina cement Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

The Development of Refractory Ramming Mass

The ramming mass refers to ramming (manual or mechanical) method of construction, and hardened in the heating effect is higher than normal temperature under the unshaped refractory materials.

By refractory aggregate, with certain gradation of powder, binder, additive water or other liquid after mixing.According to the material classification with high alumina, clay, magnesite, dolomite, zirconium and silicon carbide carbon refractory ramming material.

Refractory Ramming Mass Function:

ramming material is made of silicon carbide, graphite, electric calcined anthracite as raw material, mixed with a variety of ultra-fine powder additives, fused cement or composite resin as the binder made of bulk cement.To fill the gap or stack cooling equipment and masonry masonry filler.

Refractory Ramming Mass Types:

The leveling layer with acidic, neutral and alkaline ramming material widely used in intermediate frequency coreless furnace core induction furnace, as if furnace ramming material used for melting aluminum and its alloys, melting of copper, brass, copper and bronze and copper alloy etc.

The carbon ramming mass as an example: according to the different type of blast furnace and the material design requirements of different carbon ramming material is mainly used for blast furnace carbon brick and bottom sealing gaps between plates and carbon bricks and the cooling wall, and filling the furnace bottom water cooling tube over the central line of the leveling and cooling wall, all parts are required by ramming carbon ramming after ramming mass has a certain strength and density, and filled every corner of a small gap, to achieve no leakage of hot metal and gas demand,Classification and construction: all ceramic ramming material consisting of material is divided into: clay, high alumina, carbon, magnesium and dolomite.

Refractory Ramming Mass Advantages:

High erosion resistance.

High bonding strength.

Short lead time.

Free engineering services to guarantee service life.

Ramming mass is used in various industrial places for manufacturing of many refractory materials. It is prepared with great precision using modern techniques and quality materials. Corrosion resistant with a high level of thermal stability, it offers maximum output and last longer. It can be used in lining of iron, lining the trough of blast furnaces, lining of induction furnaces, used as insulation for rapid drying. Also, available in a premixed form allows lesser wastage, consistent and longer lining and patching life. Ramming mass is prepared using quality components and other raw material as per the industrial set standards and norms with great precision. The even and regular granule of the powder are appreciated by the clientele.

Neutral Ramming Mass VS Silica Linings

Silica ramming mass can safely be used up to an operating temperature of 1600 deg C. Since it expands very little, it is superior to both alumina and magnesia refractories to resist thermal shocks. Though silica lining has good endurance against thermal shock, it has poor resistance against steelmaking slags. Temperature control is very necessary for a satisfactory lining life.

The addition of right quantity of boric acid is very important for optimum life of lining.

The quantity depends upon (i) temperature of liquid metal bath, (ii) chemical composition of quartzite mass, and (iii) thickness of crucible wall.

Silica linings are the conventional lining solution widely used in both ferrous and non-ferrous foundries. Mainly made of crystalline silica and commonly known as acidic ramming mass, the typical binding agents that aid in the sintering of silica linings are boron-based. This refractory lining exhibits mainly low thermal expansion and have excellent thermal shock resistance.

Neutral ramming mass are a unique, chemically neutral foundry solution that form joint-less linings. The in-situ spinels synthesise at high temperatures inside the refractory lining, creating a unique 3-layer structure. The outermost layer in contact with the molten metal is a hard, sintered surface, followed by an intermediate fritted layer. The innermost layer stays in a powdery form.

Neutral ramming mass

Lining wear and the causes of wear

The lining life of induction furnace lined with silica ramming mass depends upon the lining practice and operating practice of the furnace besides quality of the silica ramming mass. It is quite common to get inconsistent lining life of the furnace. There are cases when sudden failure of lining takes place.

The main factors which affects the lining life of the induction furnace are

(i) incorrect granulometry of the ramming mass,

(ii) non-uniform distribution of the binding agent,

(iii) superheating of the metal bath in the furnace,

(iv) penetration of metal,

(v) minimum slag free metal resulting in minimum erosion at slag line,

(vi) loss of refractory powder, and (vii) topping/lining interface cracking

For the proper failure analysis in case of pre-mature failure of the refractory lining, it is important that proper records about output, working temperature, and other parameters are maintained. These records not only help in finding the cause of failure but also help in the continuous performance of the lining life.

Article Source: The Development of Refractory Ramming Mass Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

How to Install refractory lining

Refractory lining play an important role in steelmaking. Learn how to use refractory lining and find out additional information about Refractory lining. This article describes in detail how to install Refractory lining and informs about other related knowledge about Refractory lining, read this article to have a detailed understanding of Refractory lining.

Installing the Refractory Lining. After consulting with the refractory technician, industrial refractory installation is conducted.

Curing the Refractory Lining.

Refractory Installation Temperature Control.

Water Removal of Refractory Installation.

Drying Out Process.

A refractory lining usually comprises a safety or backup layer behind the working lining in contact with the furnace contents. The whole body is encased in a metal shell. The temperature gradients in the system and the properties of all materials must be considered.

Process of Refractory Lining Installation

1. INSTALLING THE REFRACTORY LINING

After consulting with the refractory factory, industrial refractory installation is conducted.

This process is the mixing of a certain amount of water with a fixed amount of refractory castable.

If not, the incorrect amount of water can spoil the refractory lining. Among these are lower strength, longer time to set, and more water to remove during the dry out process.

Hence, the technician must use the right amount and type of water. Refer to the refractory material datasheet for the utmost accuracy.

2. CURING THE REFRACTORY LINING

The castable refractory curing procedure is the process where the water reacts with the refractory cement. It is completed when the refractory material has hardened to its final form.

However, it is an intricate process. This is because the temperature of surroundings and castable can impact curing success.

Thus, curing needs a precise temperature range for it to work. Lower temperatures can weaken the curing. This will lead to lower permeability and longer curing time.

Comparably, higher temperatures will set the refractory product too quickly. Hence, it will affect the densification, making the refractory lining unfit for application.

3. REFRACTORY INSTALLATION TEMPERATURE CONTROL

Temperature is a major part when installing refractory. So store all refractory materials and equipment under a controlled setting.

If they are cold, you will lose precious time waiting for them to reach the desired temperature. Thus, refractory contractors put heaters surrounding the curing process depending on the ambiance.

Additionally, uncontrolled storage and mixing temperatures will disrupt further steps to refractory installation methods. Hence, causing severe spalling to the refractory lining

4. WATER REMOVAL OF REFRACTORY INSTALLATION

After installing and setting the refractory monolithic, the next step is water removal. To do this, apply heat to remove both physical water and chemical water.

Then, the water will evaporate at certain temperatures. However, the steam will cause volume expansion which can increase the internal pressure.

By applying the correct methods, the refractory lining is stronger with no risk of spalls.

5. DRYING OUT PROCESS

Lastly, conduct the drying out process for the refractory castable lining.

The dry-out process requires expertise from the right refractory engineering factory. If done improperly, the refractory lining will crack and weaken quickly. Also, the steam explosion might happen, risking the workers and the refractory project.

Therefore, discuss with your refractory technician for a dry-out plan of your plant.

Changxing Refractory Material

Types of Refractory Lining Materials

Refractories can be classified based on various different parameters in multiple ways as listed below:

Based on Chemical composition:

Acidic refractories (Silica refractories, Zirconia refractories, Aluminosilicate refractories);

Basic refractories (Magnesite refractories, Dolomite refractories, Magnesia-chrome refractories);

Neutral refractories (Carbon graphite refractories, Alumina refractories, Chromite refractories)

Method of manufacture: Dry press process, Hand molded, Fused cast, Formed, Unformed.

Fusion temperature: Normal refractories, High refractories, Super refractories.

Refractoriness: Super duty, High duty, Intermediate duty, Low duty.

Thermal conductivity:

Heat-resistant (temperatures≤ 1100 °C),

Refractory (temperatures≤ 1400 °C),

High refractory (temperatures≤ 1700 °C),

Ultra-high refractory (temperatures ≤ 2000 °C).

Purpose of Refractory Lining

Refractory lining is widely used in very high-temperature services.

Serve as a thermal barrier between the pipe/equipment wall and hot medium.

Withstand physical stresses.

Protect against corrosion and erosion.

Provide thermal insulation

Refractory Lining Materials

The common materials that are used as refractory lining materials are:

Alumina or Aluminum oxide (High Alumina bricks)

Silicon oxide

Magnesium oxide

Calcium oxide

Fire clays (Clay bricks)

Zirconia

Silicon carbide

Tungsten carbide

Boron nitride

Hafnium carbide

Molybdenum disilicide

Tantalum hafnium carbide

Corundum bricks

Plastic refractory

Refractory lining material consists of refractory aggregate, admixture, powder, binder, water, or other liquid, made of amorphous refractory products or fixed refractory products.

Induction Furnace Refractory Products

The refractory tamping process for induction furnaces is a critical step that must be performed carefully to ensure the longevity and efficiency of the furnace. Here is a step-by-step guide for tamping induction furnace refractory wall material:

Filling the floor with refractory: First step is to fill refractory carefully on the furnace floor and then leveling it. Pay attention to grounding cables.

Using bottom (floor) ramming machine: Place bottom rammer into the furnace and then start vibration with the desired duration depending on furnace size. Check leveling then remove machine after bottom refractory is tight enough.

Placing the former for wall ramming: Place the steel former into the middle of furnace. Use some tools to fix it into the position and make sure it won't move while the vibration.

Filling the refractory material into the wall: Fill refractory material space between former and furnace wall. De-air with fork tool into the layers while filling completely.

Ramming the wall refractory material: Wall rammer are placed into the former, and a level close to the bottom floor. Vibration starts and wall ramming machine starts rotating while making hits into the steel former. These hits create vibration and impact in granular refractory lining material. Wall ramming machine raised up step by step until to the surface while working and hitting.

Curing: Once the refractory material has been rammed, it must be allowed to cure. The curing time can vary depending on the specific refractory material used and furnace size.

By following these steps carefully, it is possible to create a durable and long-lasting refractory lining for an induction furnace. It is important to use high-quality refractory materials and equipment to ensure optimal results.

Article Source: How to Install refractory lining Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

How to choose right refractory castable for your needs

1.Refractory castable based on Application

Generally, the refractory material is engineered to perfection. But, it might not suit your refractory lining. Focus on the type of application of your refractory insulation. Choose suitable refractory products.

2. Choose Common Refractory Materials

Basically, everyone wants fast and cheap options, no matter the industry.

However, choosing cheap refractories ceramics will cost more in the future. So, consider buying the tried and tested refractory material regardless of price.Because refractory contractors know they are best for boiler refractory and furnaces.

3. Research Refractory Lining Trends

Although there is new refractory insulation technology, discuss with your refractory contractor first.This is because trends may seem too good to be true. Avoid asking for new types of furnace bricks for your refractory contractor to use.The engineering contractor will suggest a material that suits your refractory insulation.

4. Choose the Right Refractory Contractor

Basically, everyone thinks they are the best. But, in the end, the most experienced engineer will make the correct decision. Therefore, choose a refractoryfactory that fits your criteria. Then, they will provide refractory products and services that suit your refractory lining.

Different Refractory Castable

Things To Remember When Using Castable

Castables must always be stored in a cool and dry area.

One must ensure that the mixers and tools are free from old castable or any other material that can contaminate the product. Such contamination could affect the strength of the castable mix.

Only drinking suitable water should be used to mix castable. The temperature of the mix should be optimal as well.

Be careful while mixing castable, like castable refractory cement. Too much mixing generates heat and speeds up the setting time.

The forms should be covered with oil or grease to prevent moisture loss.

After placing the mix, the castable needs to be cured for 18 to 24 hours straight. Cover it with polyethylene sheets and spray it with cold water periodically. It will maintain the moisture of the mix and promote uniform curing at the applied area.

Silica Ramming Mass

Advantages Of Castable Refractories

Saves Time

Ease in usage

Significantly Better Structure Performance

Choosing refractory castable for the insulation process is one of the most thoughtful decisions. Their advantages and wide application seal the deal. But what is even more important is finding a reliable refractory material supplier. Welcome to contact us anytime.

Article Source: How to choose right refractory castable for your needs Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

How to improve service life of ladle purge plug

Ladle purge plug or porous plug is a critical component in ladle bottom purging system. Apart from the purge plug life its reliability, gas flow rate quality of steel produced etc are evolving as the most important parameters to judge the purge plug quality.

Methods to improve service life of ladle purge plug

The wear of the purging plugs mainly consist of erosion due to intensive liquid steel stirring, corrosion by aggressive iron-oxide rich slag at high temperature and, as well as the spalling of layers from the hot face, which is owing to horizontal cracking.In order to prolong the service life of purging plugs, many efforts have been made by adjusting the chemical components so as to improve the material properties.

1.The results showed that higher refractoriness and better iron-oxide-rich slag corrosion resistance could be achieved in the non-cement systems.

2. Systematically investigated the effect of cement contents on the mechanical properties and found that the phase compositions and microstructure can be optimized through adjusting the cement content in corundum castables.

3. Furthermore, Prepared three kinds of castables, of which physical properties were characterized along with their microstructures at both room temperature and high temperature to increase cold and hot mechanical strengths. It was concluded that the calcium hexaluminate phase in the matrix of the corundum-based low-cement castable enhances the cold and hot mechanical strengths.

As a part of ladle lining, the geometries of the purging plug may also influence their temperature distribution, stress responses, and service life. It was found that two optimal lining concepts were proposed to decrease heat loss through the steel shell and thermomechanical load at the hot face of the working lining.

Ladle refining furnaces are widely employed in the modern steel-making process for decarburization, desulfurization, inclusion removal and homogeneous temperature and composition. As the crucial part of the ladle, purging plugs experience an intermittent thermal shock when the liquid steel is poured into and out of the ladle in cycles during the refining process. Moreover, an intense extra heat exchange occurs within the purging plug when the argon is continuously blown into the liquid steel through the slits assembled in the purging plug. Due to these severe service conditions, the working time of the purging plug, is less than that of the refractory lining of the ladle. Consequently, downtime is needed to repair or replace the purging plug, which leads to more energy consumption and lower production efficiency. Therefore, the service life of the purging plug has long been recognized as an important issue in improving steel-making production efficiency.

What are the causes of damage to a ladle purging plug?

Due to vigorous lancing (oxygen )

Due to Back Pressure when plug chowking

If Purging Plug well Block not patching regular

Due to boundary side oxygen lancing with high pressure.

The main reason of damage to refractory materials, including chemical erosion, mechanical abrasion and thermal stress. Thermal stress which is caused by damage to the refractory cracking the direct cause of damage.

The purging plug is an indispensable refining component; Its slit structure and distribution are important factors that influence refining efficiency.

To achieve homogenous temperature and composition of steel by fostering of slag metal refining reaction Argon gas is purged through bottom purging blocks into the steel bath. Purging is the most important activitiy in secondary steel refining process. For smooth running of the process with less downtime, plug performance need to align with operation without failure. Ladle Purging brick are widely used in the secondary refining process, and its service life determines the downtime and usage efficiency of the whole ladle.

Ladle Purge Plug

More details about ladle purge plug

What is purging in ladle?

To achieve homogenous temperature and composition of steel by fostering of slag metal refining reaction Argon gas is purged through bottom purging blocks into the steel bath. Purging is the most important activitiy in secondary steel refining process.

What is purging in steel plant?

Purging is an inerting method commonly used in safety-critical process chambers such as reactors to eliminate oxygen and moisture when operations are started up or shut down.

What does purging mean in steel ladle?

Dual gas purging is often done in a ladle to accelerate the refining operations in steel industries. The purged gas, mainly argon imparts momentum to the molten metal and establishes a turbulent recirculating flow in the melt, which generates shear stresses on the ladle walls.

What is ladle purging?

The purpose of ladle purging plug used by steelmaking factories is to remove harmful gases and impurities, adjust the composition, so as to complete the basic tasks of oxygen supply, slagging, stirring, heating and other steelmaking.

Article Source: How to improve service life of ladle purge plug Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

How to prevent the tundish nozzle from clogging

Tundish nozzle plays a very important role in ladle steel making.It is very important to learn the measures to prevent the clogging of the nozzle of the tundish. There are some measures to stop clamping at tundish nozzle.

Measures to stop clamping at tundish nozzles

(1) Ensure that there is no deformation in the sliding mechanism of the continuous casting sizing nozzle, there is no foreign matter on the sliding stroke of the sizing nozzle, and the gap between the sizing nozzles is less than or equal to 0.3mm.

(2) The size of the zirconium sizing nozzle is reasonably designed, there is no damage and cracks before use, and the board surface is flat without unevenness.

(3) The production rhythm is stable, the quality of molten steel is qualified, and there is no phenomenon of high and low temperature and molten steel interception.

(4) The personnel for replacing the sizing nozzle are skilled, and there should be no accidental burning or diameter expansion caused by human factors.

The disorder of casting process because of nozzle clogging is a long-standing issue ever since the continuous casting process has been introduced. Nozzle clogging is the build-up of solid or semi-solid material on a refractory surface which can become problematic during steel pouring, as it can affect the stream dynamics, reduce the pouring rate, and cause large agglomerated particles to be intermittently released into the liquid steel stream in severe cases. Because of the nozzle clogging, the casting speed is frequently decreased, and even an entire cast is to be abandoned. Further, nozzle clogging can give rise to both quality and productivity problems.

During the continuous casting of liquid steel, steel flows from the tundish to the mould through a submerged entry nozzle, (SEN) as shown. This protects the liquid steel from reoxidizing in contact with the atmosphere. The flow rate is controlled with a gate or stopper rod to maintain optimum casting conditions. If the nozzle clogs and the flow control cannot make up for the reduced flux, the nozzle has to be replaced which means the production is interrupted. The clog build-up can also result in decreased steel quality as oxide particles can loosen from it, giving rise to rather large inclusions.

Tundish nozzle clogging problems take several different forms, and can occur anywhere inside the nozzle, including the upper well, bore, and ports. They are classified into four different types according to their formation mechanism namely

(i) the transport of oxides which are present in the steel to the nozzle wall,

(ii) air aspiration into the nozzle,

(iii) chemical reaction between the nozzle refractory, and the steel, and (iv) steel solidified in the nozzle. In practice, a given nozzle clog is frequently a combination of two or more of these types, and its exact cause(s) can be difficult to identify.

Problems caused by clogged tundish nozzles:

Clogging of the tundish nozzle is a major castability problem in continuous casting of steel for several reasons. Firstly, clogging increases the frequency of operation disruptions to change nozzles or tundishes or even to stop casting. These extra transitions increase operating cost, decrease productivity, and lower quality. Secondly, clogging can lead directly to a variety of quality problems. Clogs change the nozzle flow pattern and jet characteristics exiting the ports, which can disrupt flow in the mold, leading to surface defects in the steel product and even breakouts. Dislodged clogs also disturb the flow and either become trapped in the steel or change the flux composition, leading to defects in either case. Quality problems also arise from the mold level transients which occur as the flow control device compensates for the clogging.

FAQ:

What is a tundish nozzle?

Tundish Nozzles are an integral part of Continuous Steel Casting process. These products are instrumental in controlling the flow of Molten Steel from Tundish to Continuous Casting.

What is the HS code for tundish nozzle?

69032090

What is the function of a nozzle?

The primary function of a nozzle is to control flow rate and convert the spray liquid into droplets (via atomisation) that are of a suitable size for depositing on the intended target.

What are the uses of tundish?

What does a tundish do? A tundish is installed to prevent cross-contamination between an overflow pipe and a drain pipe. Unsanitary water from the drain pipe could theoretically enter the system if a tundish is not installed to block this.

The number of melting sequences is important in choosing a Tundish nozzle. Different nozzles for single use Melting or multiple melts are produced and used. It seems necessary to use more resistant material to achieve higher sequences. Welcome contact us to choose the right nozzle at the lowest cost.

0 notes

Text

How to make magnesia brick

Magnesia Brick Manufacturing Process:

The manufacturing process of magnesia brick includes the following steps:

1. Break and smash:

Crushing is the process of processing large pieces of material into ideal particle size materials.

2. Ingredients (weighing):

The raw materials are prepared in a predetermined proportion and mixed in a strong sand mixer. The order of feeding is magnesia aggregate – carbon fiber – binder – carbon raw material.

3. Mixing:

Mix thoroughly to get perfect coating. Add mixture made in step (B) and remix the batch intensively. Now add powder Resin (item 9), then Hexamine (item 10) and mix once again.

4. Molding:

Use a molding machine to make the mixture into bricks.

5. Drying:

Use a drying oven to dry the bricks for several hours.

6. Firing:

Fire the bricks in a kiln at temperatures of 1550 to 1600 degrees Celsius.

7.Finishing:

The final step is to grind and polish the bricks to get the desired shape and size.

Types of magnesia brick:

Magnesia bricks can be divided into two categories: sintered magnesia bricks (also known as fired magnesia bricks) and chemically combined magnesia bricks (also known as unburned magnesia bricks). Magnesia bricks with high purity and firing temperature are called direct-bonded magnesia bricks due to the direct contact of periclase grains; Bricks made of fused magnesia as raw materials are called fused re-bonded magnesia bricks.

Uses of Magnesia Bricks:

Magnesia bricks are used in steelmaking furnaces, electric furnace bottom and wall, and high temperature tunnel kiln. Magnesia bricks are also used as heat storage room lattice bricks in glass kilns.

Magnesia brick is used for permanent layers in steel making converters, AOD furnaces, and more. Magnesia brick is also used to line steel ladles and Basic Oxygen Furnaces (BOFs). Magnesia bricks can be used in a variety of applications, depending on the type of brick being used. Common uses include furnaces, ladles, secondary refining vessels, and cement and glass making kilns.

Magnesia Brick for sale

The most important steps need to be considered to avoid or reduce the possibility of magnesia bricks hydration are:

1). Magnesia bricks must be transported in a container to protect the material against moisture.

2). Magnesia bricks should be stored inside storage rooms where it is dry, free of frost, ventilated, and with a temperature between 10°C and 30°C. Note that magnesia bricks storage underneath a tarpaulin cover outside is not sufficient.

3). Bricks may not be stored for more than four weeks prior to installation and preheating.

4). Lining should be protected against moisture during installation and preheating.

Article Source:How to make magnesia brick Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

How to reduce ladle nozzle clogging during continuous casting

The article explains how to prevent ladle nozzle blockage, what causes ladle spout blockage. Learn how to prevent ladle nozzle blockage and the factors that lead to ladle nozzle blockage.

How to reduce ladle nozzle clogging, as the following:

Preventing ladle nozzle clogging is not successfully completed by one simple action but rather many actions working together: inclusion count reduction, inclusion modification by the use of calcium, protecting from re-oxidation of the steel, proper tundish geometry, and proper tundish and nozzle refractories. While the concept of making only liquid inclusions appears simple in application, it can be rather difficult to maintain these liquid inclusions throughout the entire casting process.

Nozzle clogging during steel pouring in the continuous casting process is a long-standing problem for Al-killed steels. During casting the flow rate of liquid steel through the nozzle is reduced due to the nozzle clogging, which leads to serious operational problems. Even though the ladle slide gate is fully open, the molten steel flow rate can hardly meet the demand of the tundish, causing the level in the tundish to drop. To continue the casting sequence the casting speed must be reduced. In some cases casting is terminated if clogging takes place at early stage of ladle opening and the ladle returns with the remaining steel poured in the EAF/ other ladles for reprocessing or lost as ladle loss. Ladle nozzle clogging reduces productivity, decreases process yield and impacts the steel quality.

Ladle Nozzle Clogging can be divided into three classes and is grouped according to their sources:

Class 1: Oxide formation :

Category -1.1 by air aspiration, 1.2 by reaction between nozzle refractory and steel.

Class 2: Transportation of oxides to the nozzle wall :

Category – 2.1 deoxidation products, 2.2 reoxidation products, 2.3 exogenous inclusions, 2.4 products of inclusion modification.

Class 3: low temperature chilling of steel

A way to solve ladle nozzle clogging.The concluded that:

The bigger diameter of a nozzle or less nozzle clogging could effectively generate an enough flow rate for a CC process and maintain the target casting speed. We can predict if nozzle clogging is happening by comparing the actual value and the theoretical one of the percentage of a slide gate opened

The main inclusions which caused the nozzle clogging during a CC process of the silicon steel were Al2O3 and its composite inclusions.

Ca-treatment can be a method that transform inclusions into C12A7 by adding Si-Ca wires and prevent nozzle clogging of the silicon steel theoretically. And the amount of Si-Ca wires for Ca-treatment of the silicon steel, with different dissolved Al and total O can be calculated. Ca-treatment can prevent the nozzles from clogging during a CC process of the silicon steel.

Ladle Nozzle Manufacturer

Ladle nozzle clogging during a continuous casting process

To figure out the reason causing ladle nozzle clogging during a continuous casting process for the silicon steel and get away to solve it, the theoretical calculation of flow rates during casting, inclusions around the ladle slide gate where ladle nozzle clogging happened, and Ca-treatment on refining units for producing the silicon steel.

The bigger diameter of a nozzle or less nozzle clogging can guarantee an enough flow rate for reaching the target casting speed. Ladle nozzle clogging can be predicted by analyzing the percentage of a slide gate being opened. Al2O3 and its composite inclusions were the main ones which cause the nozzle clogging during the CC process of the silicon steel. Ca-treatment could transform those high melting point inclusions into C12A7 by adding Si-Ca wires and prevent the ladle nozzle clogging of the silicon steel.

Due to nozzle clogging, a casting speed often decreased, and even an entire cast would be canceled in severe cases. The transformation of inclusions, electroslag remelting process (ESR for short), and ceramic filters were effective methods to reduce the clogging. And calcium-treatment for transforming inclusions was thought as a lower cost and a simpler process than the others, and thus there were many studies on it for solving the clogging of submerged entry nozzles.

Some steel with high silicon, such as welding steel, calcium should be not be added into the steel, because it can increase the welding cracks of the steel. That meant that not all steel can use calcium-treatment for solving the clogging, and there has no been a research on ladle nozzle clogging of silicon steel. But there has been being ladle nozzle clogging during CC of silicon steel, which is deoxygenated by using Al. Moreover, silicon steel has unique properties and its processes are more complicated compared to other steel. Therefore, it is necessary to study what causes ladle nozzle clogging for casting silicon steel, figure out a effective method to solve the problem, and confirm that the method would not obviously affect the properties of silicon steel. The theoretical calculation for flow rates that could affect nozzle clogging, analyzed the inclusions causing the ladle nozzle clogging, validated the effects of Ca-treatment on solving ladle nozzle clogging of the silicon steel both theoretically and practically, without a decrease of the magnetic properties.

0 notes

Text

How to make magnesia carbon brick

The article describes in detail the process of how to make magnesium carbon bricks. What’s more, the article also expresses some other issues related to magnesia carbon bricks. Weclcome to visit our factory to see magnesium carbon brick product process.

Magnesia carbon brick Production process

The steps in the production process of MgO-C bricks are described here. First, the refractory raw materials are graded into coarse, medium, and fine sizes and are classified as necessary. Next, they are mixed and kneaded with a binder in pre-determined blend proportions by particle size. The kneaded mixture is press formed into bricks.

By a magnesia-carbon brick there is understood a brick based mainly on the components burned magnesite, carbon in the amount of typically 5-30% carbon by weight and a suitable binder. Magnesia-carbon bricks are used in the wear lining of a converter for steel production, and are substantially more resistant to wear than magnesite bricks in which the percentage of carbon used is not so high. The wear lining of a converter can, depending on the price of the bricks, be wholly or partly constructed from magnesia-carbon bricks, especially at the location of the trunnions of the converter, where the wear is greatest.

Magnesia Carbon Brick for sale

Production process for MgO-C bricks

Uniaxial forming with an oil press or a friction press is normally used as the pressing equipment. The magnesia aggregate and graphite in MgO-C bricks show orientability depending on the forming direction of the press. The strength and thermal conductivity of MgO-C bricks show anisotropy . It is hence important to consider the forming direction of bricks when laying the bricks. A cold isostatic press (CIP) with small anisotropy is also used for the production of large refractory products such as bottom blowing tuyere bricks and taphole bricks.

Formed bricks are dried to remove moisture and other volatile components, processed, and coated as needed, visually inspected for cracks, chips, and other defects, and dispatched after removing defective bricks.

MgO-C (magnesia-carbon) refractories are widely used in several steelmaking linings. These refractories are exposed to extreme stress due to high temperatures (T > 1600 °C) required to cause the metallurgical reactions. These working conditions produced refractory wear through various related processes. The different types of degradation that the material suffers can be from thermochemical or thermomechanical origin.

Method for the manufacture of a magnesia-carbon brick, comprising the steps of:

a. preparing a mixture comprising:

1. burned magnesite

2. carbon

3. a binder solution comprising:

3.1 pre-condensed novolak resin

3.2 a solvent for this novolak resin.

4. a hardener for the resin.

b. pressing a brick from the mixture.

The method also provides bricks produced by the method and a converter having a wear lining consisting at least partly of such bricks.

FAQ:

How are magnesia carbon bricks made?

The traditional magnesia carbon brick manufactured by the synthetic tar binder in the cold mixing process is hardened during the process of tar damage and the necessary strength is obtained, thus forming isotropic glassy carbon.

What is the use of magnesia carbon bricks?

MgO-C (magnesia-carbon) refractory bricks are widely used in steel industry, the primary consumer of refractory linings, such as basic oxygen furnaces, electric arc furnaces, and ladle furnaces.

What is the raw material for magnesia carbon bricks?

Sea water magnesia is mainly used in SAIL as the main raw material for manufacturing of magnesia carbon bricks.

What is magnesia carbon brick?

Magnesia-Carbon brick is resin-bonded brick made from dead-burned or fused magnesia and graphite. Anti-oxidant is added if required. Our control over bonding agents mean that these products are classed as eco friendly in terms of steel production.

In conclusion, Welcome to learn how to make magnesia carbon bricks and learn other information about magnesia carbon bricks. If you are interested in other refractory products and production processes, please feel free to browse our website or visit our factory.

Article Source:How to make magnesia carbon brick Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

Magnesia Carbon Bricks

0 notes

Text

How to avoid clogging in tundish nozzles

Various methods employed to avoid clogging in Tundish nozzles are:

1.Erosion of Alumina build-up

2.Steel reinforcement of Alumina matrix

3.Flow model studies

4.Argon purging facility in the bore of nozzles

5.Anti-clogging mix employment at bore

Tundish nozzles are manufactured by alumina carbon refractory material. The porosity ranges between 12%-15%. In order to have a purging facility however, the bore porosity must be >18% without compromising strength.

Tundish Nozzle

The results of tundish nozzles Clogging

Clogging in continuous casting tundish nozzles is build-up of material in flow passage between the tundish and mold, and results in:

Decrease in productivity

If clogging becomes sufficiently severe, the flow control device will no longer be able to compensate, resulting in either a decrease in casting speed or making it necessary to replace the nozzle. These events reduce net casting throughput and thereby reduce productivity.

Increase in cost

Depending on the casting shop, some portions of clogged nozzles (e.g. submerged entry nozzle) can be independently replaced during casting. This is done by use of a sub entry shroud or a tube changing SEN. However other clogged refractory (e.g. tundish nozzle) can only be replaced by changing tundishes. Therefore nozzle clogging results in additional costs in terms of tundish refurbishment or nozzle replacement.

Depletion of quality

Clogged particles can get dislodged from the build-up and result in unacceptable cleanliness-related defects in the product. The restriction of flow passage may also cause biased flow patterns in the mold which thereby cause quality problems such as mold flux ingestion, shell thinning etc.

The process of Continuous Casting has achieved new heights in recent years, as tundishes are no longer treated as simply a transfer vessel but as a metallurgical reactor. Progress in technology has led many producers to move to casting high quality steel of all grades with very long casting duration i.e. >20 hrs. We all know nozzle clogging has been a serious productivity and quality problem in continuous casting of Aluminium killed steel, which limits the slab casters to last a defined (short) time. This led to development of TCD (Tube Changing Device) casters where the SEN can be changed during an ongoing casting process.

In addition, products of steel-refractory interactions such as CA6, commonly found in tundish nozzles, were observed in the lab tests. Alumina-graphite nozzle materials were shown to clog at a faster rate since industrial alumina-graphite has strong thermochemical interactions with steel. No significant steel-refractory interactions were observed in the pure oxide or zirconia-graphite nozzles however.

Tundish Nozzle for sale

FAQ:

What is a tundish nozzle?

Tundish Nozzles are an integral part of Continuous Steel Casting process. These products are instrumental in controlling the flow of Molten Steel from Tundish to Continuous Casting.

What is the function of a nozzle?

The primary function of a nozzle is to control flow rate and convert the spray liquid into droplets (via atomisation) that are of a suitable size for depositing on the intended target.

What is the result of tundish nozzle clogging?

Irregular flow through a tundish nozzle increases the probability of generating a number of quality defects such as re-oxidation of the steel and slag entrapment. Nozzle clogging also affects productivity in that less steel is able to be cast because of the blockage in the nozzle.

What is the HS code for tundish nozzle?

69032090

Why is my tundish nozzle clogging?

The cause of the clogging is related to a combination of operating criteria including ladle slag practice, tundish refractory, deoxidation methodology and temperature.

What causes nozzle clogging?

The reason behind this problem is that some of the old material remains in the extruder due to the lower temperature needs of the new material. As a result, the old filament will not melt completely, and the residue left behind may cause the nozzle to clog in the long run.

0 notes

Text

The process of firing refractory bricks includes three process

The process of firing refractory bricks includes three processes

1. Kiln installation

The so-called kiln loading refers to the operation process of reasonably arranging and stacking bricks that meet the technical conditions of semi-finished products in the kiln according to the structural characteristics of the kiln and the requirements of the thermal system when the products are fired. For the tunnel kiln, it is also called loading (kiln) car.

1) Determine the kiln installation height and kiln installation method according to different brick types. Usually, the kiln height of magnesia bricks and first-class high-alumina bricks is 1-1.1m; that of silica bricks is 1-1.7m; and that of clay bricks is between the two. Most of the bricks are installed flat, the silica bricks are installed vertically and the clay bricks are installed sideways.

2) According to different brick types, determine the kiln loading ratio of ordinary bricks and special-shaped bricks. Generally, the ratio of special-shaped bricks and ordinary bricks on the same kiln car is about 4:6. At the same time, it is necessary to determine the kiln installation positions of different varieties according to different brick types. Generally, the standard and ordinary bricks are installed in the lower part, and the special-shaped bricks are installed in the upper part, and some special-shaped bricks or adobes that are easy to crack when fired are packaged (bricks wrapped in bricks).

3) On the premise of ensuring the quality of firing, increase the density of bricks (that is, the amount of bricks per unit kiln car) to increase production and reduce fuel consumption.

Making a reasonable kiln installation plan is the premise to ensure the quality of the kiln installation, but if the kiln installation operation is improper, the qualified rate of the appearance of the fired product will be reduced. Therefore, in the production of refractory materials, the basic requirements for the quality of the kiln are to ensure that the brick stack is flat, stable and straight, to avoid bonding between the bricks due to high temperature firing, and to reduce the distortion of the fired products. In order to meet the above requirements, a layer of sand filling with a particle size of 0.5-3mm is usually evenly sprinkled between each layer of bricks when the kiln is installed. Products with different properties have different requirements for kiln filling sand. Usually, clay bricks and high alumina bricks use silica sand, bauxite chips, rice husk or rice husk ash; silica bricks use waste silica brick sand or silica sand; Magnesia bricks use magnesia or chrome ore.

2. Firing

The adobe undergoes a series of physical-chemical reactions during the firing process, making the adobe compact, increasing its strength, stabilizing its volume, and ensuring accurate dimensions. The whole firing process can be divided into three stages:

(1) The heating stage, that is, from the time when the product enters the kiln or is ignited to the time when the product reaches the highest temperature for firing. As the temperature increases, the liquid phase formation temperature and the phase synthesis temperature are reached. Due to the diffusion, flow, dissolution, precipitation, and mass transfer process of the liquid phase, the particles are further approached by the surface tension of the liquid phase to promote the densification of the green body. The strength is increased, the volume is reduced, the porosity is reduced, and the green body is sintered.

(2) The heat preservation stage at the highest firing temperature. Various reactions in the green body tend to be complete and sufficient, the amount of liquid phase increases, the crystalline phase grows further, and the brick body reaches densification. In the firing process of the product, not only the surface must reach the firing temperature, but also the interior of the product must also reach the firing temperature. This temperature homogenization process is achieved by heat transfer, which requires a certain amount of time. It can be seen that the larger the product and the higher the kiln density, the longer this time will be. In addition, due to the uneven temperature of various parts in the kiln, a certain holding time is also required.

(3) The cooling stage refers to the period from the highest firing temperature to the kiln exit temperature. During this stage, the structural and chemical changes that the article undergoes at high temperatures are essentially fixed. At the beginning of this stage, some physical-chemical changes are still going on in the product, such as the crystallization of the physical phase, the crystal transformation of some crystals, the solidification of the glass phase, and the generation of microcracks. The cooling system will affect the physical properties of the product such as strength and thermal shock resistance.

In order to reasonably fire various refractory products, the firing system of each product should be determined in advance, including: the maximum temperature of firing; the heating rate at each stage; the holding time at the highest temperature; product cooling The lower cooling rate; the nature of the atmosphere in the kiln in the above stages. The firing process of refractory products can be completed by two heating methods, that is, the products are fired at a lower temperature for a longer time, or at a higher temperature for a shorter time. But in fact, due to the slow heat transfer in the kiln and the uneven heating of the products in the kiln, there is a limit to the use of fast firing refractory products.

The firing system of refractory products is not only related to the variety, shape and size of refractory products, but also closely related to the type of firing equipment. For example, a large downdraft kiln requires a slower heating rate and a longer holding time to ensure the uniformity of the brick temperature. An unsuitable firing system will increase the reject rate and reduce the quality of the product. The proper firing system is based on theoretical guidance and practical experience.

3. Out of the kiln

Kiln exit is the operation process of taking out the burnt products from the kiln after cooling, or unloading them from the kiln car. The quality of the kiln operation has a direct impact on the appearance quality of the finished product. In the production of refractory materials, the following points should be paid attention to in the kiln operation:

(1) When taking and placing bricks, handle them with care to avoid appearance defects of the product due to careless operation out of the kiln.

(2) Products of different brick numbers should be stacked strictly separately, that is to say, products of different brick numbers cannot be placed on the same brick board when they leave the kiln, otherwise, it is easy to cause confusion when checking and selecting finished products. Because the appearance of some products with different brick numbers can be exactly the same, but there is little difference in a certain size (several mm or more than a dozen mm), if they are mixed on a brick board, it is easy to distinguish them when checking. The product of one of the brick numbers is mistaken as a waste product, which will not only cause waste, but also affect the use.

(3) Tool bricks (frame bricks, drawn bricks, etc.) should be arranged and stacked for continued use during kiln installation.

(4) Pay attention to safe operation and labor protection when leaving the kiln and transporting bricks.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality refractory products are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source:The process of firing refractory bricks includes three process Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-product-solution Email:[email protected] Website:https://www.cxrefractories.com

High Alumina Bricks & Magnesia Bricks

0 notes

Text

What are the measures to improve the purity of continuous casting steel

Purity refers to the quantity, shape and distribution of non-metallic inclusions in steel. The inclusion in steel shall be reduced to the required level according to the steel grade and product quality,

We should start from the following five aspects:

① Reduce [O] content in steel as much as possible.

② Prevent the molten steel from interacting with air.

③ Reduce the interaction between molten steel and refractory materials.

④ Reduce slag entrainment in molten steel.

⑤ The improved flow promotes the floating of inclusions in molten steel.

In terms of process operation, the following measures shall be taken:

(1) Slag free tapping: slag retaining balls are adopted for the converter and eccentric bottom tapping is adopted for the electric furnace to prevent a large amount of slag from falling into the ladle.

(2) Ladle refining: select the appropriate refining method according to the steel grade, to uniform the temperature, fine tune the composition, reduce the oxygen content, remove gas inclusions, etc.

(3) Non oxidation casting: after the molten steel is treated by ladle, the total oxygen content in the steel can be reduced from 130ppm to below 20ppm. If the injection flow from ladle to tundish is not protected or poorly protected, the total oxygen content in tundish steel will rise to the range of 60-100ppm, which will return to the level before external refining, and the effect of external refining will be wasted.

(4) Tundish metallurgy: the tundish adopts large capacity, and the addition of retaining walls and dams is an effective measure to promote the floating of inclusions. For example, for 6T tundish, the scrap rate of slab inclusion is 12%, and the inclusion is 0.82 pieces / m2; 12t tundish + retaining wall, 0 scrap inclusion in slab, 0.04 inclusions / m2.

(5) Submerged nozzle + casting mold powder: the mold powder shall be able to fully absorb inclusions. The submerged entry nozzle material, nozzle shape and insertion depth shall be favorable for the floating and separation of inclusions.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality casting powder are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source: improve the purity of continuous casting steel Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-product-solution Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

What are the prominent problems in the tundish

At present, there are many problems in the tundish used in China, especially in the tundish used for billet caster.

The specific performance is as follows:

(1) The shape of tundish cavity is unreasonable. Due to the unreasonable shape of the inner cavity, the flow of molten steel in the tundish is unreasonable and the residence time is short, which can not purify the molten steel. The distance from the drop point of the large ladle injection into the tundish to the tundish nozzle is short, or the distance from each nozzle is too different; The volume at the drop point of the ladle is too small, resulting in serious steel slag mixing and lining scouring, affecting the service life of the tundish and polluting the molten steel.

(2) The capacity of tundish is small and the depth of molten pool is shallow, so it is not suitable for high-speed caster. The molten steel stays in the tundish for a short time, which makes it difficult to purify the molten steel and remove inclusions; It is difficult to maintain constant casting speed when changing the package; During pouring, the steel slag in the tundish is agitated seriously, which makes it difficult to float the inclusions and easy to enter the mold, especially when changing the tundish.

(3) The position of tundish nozzle clogging is not properly designed, especially the nozzle on both sides is too close to the two sides, which is easy to cause unsmooth pouring of the two side nozzles.

(4) The tundish nozzle control device is too thin and unreliable, which makes it difficult to accurately control the flow of molten steel, making it difficult to stabilize the liquid level of the mold and often causing out of control accidents.

(5) The large deformation of tundish and the problems of design and manufacturing accuracy result in insufficient centering accuracy of multiple water outlets.

(6) The lifting device of tundish is ineffective, and most of them can not be lifted, which brings difficulties to the continuous casting process and causes many defects of the slab.

(7) The distance from the bottom of tundish to the upper mouth of crystallizer is improperly selected. Most of the distance is too high, which makes it difficult to align the nozzle, and also makes the nozzle too long, which increases the refractory consumption per ton of steel nozzle.

(8) Insufficient attention has been paid to the quick change technology of submerged entry nozzle.

The above tundish can only be used at low casting speed, which is not suitable for the requirements of high casting speed. Modern tundish should not only adapt to the conditions of constant speed casting at high drawing speed, high steel throughput and strength, and intense agitation in the tundish, but also play the role of purifying molten steel and removing inclusions.

The specific measures adopted include:

(1) Optimize the shape of the inner cavity of the tundish, make the liquid steel flow reasonably in the tundish, expand the volume of the large ladle at the drop point of the tundish and optimize the distance from the drop point of the large ladle to each water inlet under the condition of adapting to the high pulling speed;

(2) Tundish with large capacity deep melting bath;

(3) Prevent deformation of tundish shell;

(4) Adopt firm and reliable tundish nozzle control device;

(5) Adopt reliable tundish lifting device under load;

(6) Optimize the distance from the tundish to the upper mouth of the crystallizer.

Article Source: What are the prominent problems in the tundish Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-product-solution Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

Measures to increase the life of tundish

1. The working layer of tundish adopts dry material

Under the condition that the technological conditions and the material and masonry form of tundish refractory are fixed, the life of tundish mainly depends on the chemical erosion, high temperature melting loss and mechanical erosion of the molten steel in the working layer of tundish. The tundish dry material has strong erosion resistance and erosion resistance, which can meet the requirements of long continuous pouring time.

2. The lining is made of magnesia refractory

Magnesium refractory adsorb the inclusion in steel is very strong, and good erosion resistance, erosion resistance, can meet the requirements of high number of continuous casting furnace, but also improve the quality of molten steel. After use, it is observed that the lining slag line of the middle bag is the thinnest, and other parts are 30 ~ 40mm. After a pouring time is completed, it is easy to disassemble the middle bag.

3. Use a current stabilizer

Because the steel flow directly impacts the tundish from the large tundish, the erosion of tundish is very serious, which is likely to cause the penetration of tundish. For this reason, it is decided to use the current stabilizer. The material of the current stabilizer is magnesium carbon, and the structure of the current stabilizer is a container structure with hollow cavity. The bottom of the inner cavity of the current stabilizer is large, and the mouth is small. The continuous casting tundish current stabilizer with this structure can prevent liquid steel from slagging obviously and stably, the tundish steel water quality is high, and the tundish refractory material consumption is low.

4. Raise the water level of the intermediate steel envelope

The original minimum liquid level requirement for tundish pouring was 600mm, but now it must be greater than 700mm. After the liquid level of molten steel is raised, the stagnation time of molten steel in tundish is prolonged. In a deep molten pool, the resistance between molten steel from ladle to flow stabilizer is large, and the flow velocity of the contact surface of flow stabilizer is small, thus the impact on the flow stabilizer is small, and the continuous pouring time of flow stabilizer is improved. The tundish life is also improved.

5. Improve slag overflow operation

The original slag overflow mouth close to the pouring point, slag overflow is difficult. With the increase of the number of continuous casting furnace, slag quantity is large and can not be discharged in time, slag line erosion on the lining is serious, and affect the quality of molten steel. For this reason, the position and shape of the slag overflow mouth is changed, and the assessment system is formulated. The slag thickness should not exceed 30mm, and the slag thickness should be controlled below 30mm in time when the rhythm is appropriate, so as to prevent serious erosion of the slag line of the wall and the occurrence of the wall through the steel. At the same time, the large contractor should strengthen the operation, and avoid a large amount of slag into the tunbale, which will cause serious erosion of the slag line of the bale wall.

6. Improve the service life of tundish water outlet