Don't wanna be here? Send us removal request.

Text

Supplying High-Performance Power Press Machines Across India, US & UAE – Mankoo Presses

Mankoo Presses has established itself as a pioneer in manufacturing and supplying high-performance power press machines, serving diverse industries across India, the United States, and the United Arab Emirates. Known for precision engineering, durability, and consistent performance, Mankoo Presses is empowering the global metal forming and fabrication industry with robust, reliable, and technologically advanced power presses.

A Legacy of Engineering Excellence

Founded on a strong foundation of industrial expertise and innovation, Mankoo Presses has decades of experience in the field of mechanical and hydraulic power press manufacturing. The brand is synonymous with quality and is trusted by manufacturers ranging from small-scale workshops to large industrial plants. Mankoo’s commitment to engineering excellence, innovation, and client satisfaction has helped the company build a loyal global clientele.

Comprehensive Range of Power Press Machines

Mankoo Presses offers a wide range of power press machines designed to meet the exact needs of sheet metal forming industries. Their product range includes:

C-Frame Power Press Machines

H-Frame Power Press Machines

Pneumatic and Mechanical Presses

Hydraulic Press Machines

High-Speed Press Machines

Special-purpose customized presses

These machines are used in automotive, aerospace, agriculture, home appliance manufacturing, electrical panel making, and general metalworking industries. Every press is engineered for strength, accuracy, and long-term performance.

Supplying to the Indian Market

India has always been the core market for Mankoo Presses. With a widespread network of dealers, service centers, and loyal industrial clients, the company supports the growth of Indian manufacturing with locally engineered solutions. From Punjab to Maharashtra, Tamil Nadu to Gujarat, Mankoo’s machines are powering small and large-scale industries that rely on accurate and uninterrupted metal forming operations.

Mankoo Presses provides extensive after-sales service and technical support throughout India. Their commitment to fast delivery, operator training, preventive maintenance, and spare part availability makes them a trusted name among Indian manufacturers.

Expanding Reach to the United States

The United States represents one of the most advanced manufacturing markets in the world. Mankoo Presses successfully caters to American industries with power presses that meet international standards for performance, safety, and automation. With CE-certified designs and robust structural engineering, Mankoo’s machines are used by fabrication shops, OEMs, and component manufacturers across the U.S.

Clients in the U.S. prefer Mankoo Presses for their precision, ease of maintenance, and competitive pricing. The company supports its American customers with detailed documentation, virtual setup assistance, and prompt shipping timelines. Mankoo’s ability to tailor machines for specific applications has made it a go-to choice for industrial buyers in the U.S. looking for reliable and cost-effective press solutions.

Strong Market Presence in the UAE and the Middle East

The UAE and broader Middle East markets have seen tremendous industrial growth in recent years, particularly in the areas of construction, steel fabrication, and electrical manufacturing. Mankoo Presses has been quick to meet this demand by supplying power presses that withstand high temperatures, heavy-duty operations, and demanding production schedules.

With a growing customer base in Dubai, Abu Dhabi, and other Gulf regions, Mankoo Presses is expanding its support infrastructure to better serve Middle Eastern clients. Their machines help regional businesses improve productivity, reduce production costs, and maintain high-quality output across all operations.

Customization and Quality Assurance

One of Mankoo Presses' biggest strengths is its ability to customize machines based on client requirements. Whether it’s modifying the stroke length, tonnage capacity, automation level, or integrating digital controls, Mankoo offers complete flexibility. Every machine undergoes rigorous testing and quality checks before delivery. Their use of premium materials, skilled craftsmanship, and high-tolerance machining ensures that each press is built to perform under pressure.

Each power press from Mankoo is designed using CAD/CAM software, manufactured with precision CNC tools, and assembled under strict quality protocols. Mankoo Presses complies with both Indian and international safety standards, making it suitable for global use.

Global Shipping and Export Management

Mankoo Presses has a dedicated export team that handles international logistics, compliance, and documentation. They provide:

Strong wooden crate packaging for international shipping

Detailed user manuals and service guides

CE certifications and quality test reports

Remote support for machine setup and operations

Clients in the US and UAE appreciate Mankoo’s transparent export process and reliable delivery schedules. The company ensures that all machines reach their destination in perfect condition and are ready for operation with minimal setup time.

Reliable Support and Service Network

Supplying power press machines is only part of Mankoo’s commitment. The company believes in building long-term relationships with clients by offering reliable support even after the sale. Services include:

Remote installation assistance

On-site operator training (available in select countries)

Preventive maintenance schedules

Emergency breakdown support

Readily available spares and consumables

With a strong network of service partners and remote support options, Mankoo ensures clients stay productive and minimize downtime.

Conclusion

Mankoo Presses is not just a machine supplier—it is a trusted global partner in industrial growth and manufacturing excellence. From powering Indian workshops to supporting American factories and serving fast-growing UAE industries, Mankoo continues to prove its engineering leadership and international capability.

Supplying high-performance power press machines across India, the US, and the UAE, Mankoo Presses stands for reliability, innovation, and long-term value. For businesses seeking a combination of quality, affordability, and after-sales assurance, Mankoo Presses remains the name to trust.

If your industry relies on precision metal forming, Mankoo Presses has the machine—and the experience—to elevate your production to the next level.

0 notes

Text

Supplying Quality Roll Forming Machines Across India, UK, USA & UAE – Jugmug Roll Forming

Jugmug Roll Forming has emerged as a reliable and innovative name in the roll forming industry, known for manufacturing and supplying high-performance roll forming machines across India and globally. With a commitment to engineering excellence and unmatched customer satisfaction, Jugmug Roll Forming has successfully expanded its footprint to international markets including the UK, USA, and UAE. The company’s dedication to delivering precise, durable, and custom-engineered roll forming machines has made it a preferred partner for metal forming businesses around the world.

What Sets Jugmug Roll Forming Apart

Jugmug Roll Forming stands out because of its focus on quality, customization, and customer support. The machines are designed with advanced technology to meet modern industrial demands, ensuring consistent performance and long life. Whether you need machines for door frames, roofing sheets, window sections, or other metal profiles, Jugmug Roll Forming provides fully automated and semi-automated solutions that boost productivity and reduce downtime.

The team at Jugmug Roll Forming understands that every client has specific requirements. That’s why they work closely with customers to design and deliver roll forming machines that align with their production goals, material types, and output expectations. From concept to commissioning, Jugmug Roll Forming ensures every detail is executed with precision.

Supplying Roll Forming Machines Across India

In India, Jugmug Roll Forming has built a strong reputation for supplying machines to small, medium, and large-scale industries. With a wide presence across key industrial hubs like Delhi, Mumbai, Pune, Chennai, Ahmedabad, and Hyderabad, the company supports manufacturers in construction, infrastructure, furniture, and automotive sectors. Indian industries trust Jugmug for machines that are not only robust but also easy to operate and maintain.

With growing demand for localized and custom solutions in India, Jugmug Roll Forming offers tailored machinery that suits regional requirements and project scales. The after-sales support, technical training, and spare part availability further ensure smooth operation and long-term value for Indian customers.

Expanding into the UK Market

The United Kingdom represents a mature and technically advanced market for metal forming technologies. Jugmug Roll Forming’s entry into the UK market was marked by its ability to deliver CE-compliant, precision-engineered roll forming machines that match European standards. UK manufacturers appreciate the reliability and affordability of Jugmug machines, especially for architectural metal products, structural steel profiles, and high-volume sheet forming.

Jugmug Roll Forming works with distributors and agents in the UK to provide pre-sales consultation, logistics assistance, and on-site commissioning. This local presence allows UK customers to receive quick support and ensure minimal disruption during installation and production.

Growing Demand from the USA

The United States, being one of the largest manufacturing economies in the world, presents significant opportunities for roll forming solutions. Jugmug Roll Forming supplies high-quality roll forming machines to American manufacturers who require accuracy, durability, and scalability. The company's machines cater to industries such as building and construction, HVAC, electrical, and energy.

What makes Jugmug Roll Forming an attractive supplier in the US is its ability to match American technical expectations while offering competitive pricing. Every machine is manufactured with global-quality components and undergoes strict testing before shipment. Jugmug’s customer-centric approach and flexible production planning make it easier for American companies to integrate their machines into automated production lines.

Strong Presence in the UAE and Middle East

The UAE is a fast-growing market for construction and infrastructure projects, making it an ideal region for roll forming machine applications. Jugmug Roll Forming has successfully supplied roll forming machines to clients in Dubai, Abu Dhabi, Sharjah, and across the Gulf region. The company's machines are used in the production of steel framing, ceiling channels, roofing sheets, partition panels, and cable trays.

UAE industries value machines that are rugged, heat-resistant, and require minimal manual intervention. Jugmug Roll Forming delivers just that, along with rapid technical support and prompt delivery timelines. Its experience with international shipping and documentation ensures that Middle Eastern clients receive machines on time and with full compliance.

Customization and Technology-Driven Manufacturing

One of the core strengths of Jugmug Roll Forming is its ability to design and build custom roll forming machines as per client specifications. Whether it is about profile dimensions, sheet thickness, production speed, or automation level, Jugmug can configure the machine to meet exact operational needs. All machines are manufactured using premium-grade raw materials and incorporate features such as:

Hydraulic or servo feeding systems

PLC-based control panels

Pre-cut or post-cut operations

Multi-profile and adjustable tooling

Quick-change mechanisms

Jugmug Roll Forming keeps itself updated with the latest advancements in roll forming technology. By integrating automation and IoT-based monitoring, the company helps industries shift toward smart manufacturing.

Global Logistics and Export Capability

Supplying machines internationally requires excellent logistics planning and export capability. Jugmug Roll Forming has a dedicated export team that handles international documentation, packaging, sea/air freight coordination, customs clearance, and on-site setup. Machines are packed securely in heavy-duty wooden crates to prevent damage during transit.

The company ensures clear communication with international clients during each stage of production and shipping. Timely updates, video inspections, and factory testing reports are shared to maintain transparency and build trust.

After-Sales Service and Support

Jugmug Roll Forming is not just a machine supplier but a long-term partner for its clients. After-sales support is a crucial aspect of their global success. The company offers:

Installation and commissioning

Operator training

Maintenance guidance

Remote troubleshooting

On-demand spare parts

With remote support and online assistance, even international clients can resolve issues quickly and keep their machines running efficiently.

Conclusion

Jugmug Roll Forming is redefining the standards of roll forming machine supply, not just in India but across key global markets like the UK, USA, and UAE. By combining precision engineering, customization, competitive pricing, and reliable service, Jugmug has positioned itself as a trusted global partner in the metal forming industry.

Whether you’re a manufacturer in India looking to expand production, a UK-based company aiming for precision profiles, a US firm demanding rugged machinery, or a UAE business seeking fast production cycles—Jugmug Roll Forming has the expertise, technology, and global presence to meet your needs.

For businesses looking to invest in long-lasting, high-performance roll forming machines with full international support, Jugmug Roll Forming is the name to trust.

#roll forming machine suppliers#roll forming machine#roll forming machinery#roll forming uk#roll forming usa

0 notes

Text

How DaBRANDe Transforms Brands Through High-Impact Ad Films in India?

In today’s digital-first world, visuals speak louder than words. Brands that wish to stand out, connect with their audience, and leave a lasting impression need more than just a logo or tagline—they need a compelling story. And that’s exactly what DaBRANDe delivers through its powerful ad films. As a creative advertising and film-making agency in India, DaBRANDe specializes in turning brand messages into emotional, impactful, and memorable ad films that drive results.

The Role of Ad Films in Modern Branding

Ad films are no longer limited to television commercials. With platforms like YouTube, Instagram, Facebook, and OTT, video content is now everywhere. Consumers are drawn to visual stories, especially those that entertain, inspire, or evoke emotion. Ad films offer a unique way to do all three—building brand recognition, influencing buying decisions, and creating a deep connection with viewers.

DaBRANDe understands this shift and helps brands leverage it. Whether it’s a 30-second spot for Instagram or a 90-second brand film for YouTube, DaBRANDe crafts videos that not only look good but also perform well across platforms.

DaBRANDe’s Creative Process: Where Art Meets Strategy

At DaBRANDe, every ad film starts with strategy. The team dives deep into understanding the brand, its core message, target audience, and campaign goals. Whether it’s a product launch, brand awareness, or social cause, DaBRANDe builds the narrative accordingly.

The creative process includes:

Ideation and scripting: Crafting a storyline that reflects the brand’s essence while keeping it engaging and memorable.

Pre-production planning: Casting, location scouting, budgeting, and scheduling to ensure smooth execution.

Production: Filming with high-quality equipment, professional crews, and an eye for detail.

Post-production: Editing, sound design, visual effects, and color grading to make the final output visually stunning and emotionally effective.

Tailored Ad Films for Every Brand

DaBRANDe does not believe in one-size-fits-all. Every ad film is unique and tailored to match the brand’s voice and purpose. Whether the client is a startup looking for fresh attention or an established company aiming to revamp its image, DaBRANDe brings a flexible approach that adapts to the brand’s specific needs.

They have worked across industries such as fashion, FMCG, real estate, automobiles, health, technology, and more—proving their versatility in creating ad films that resonate with different audiences.

High Production Value, Even on a Budget

One of DaBRANDe’s biggest strengths is its ability to deliver cinematic-quality films without breaking the bank. Many Indian brands, especially startups and SMEs, shy away from ad films thinking they are too expensive. DaBRANDe breaks that myth by offering scalable production options that deliver high value for money. From small studio shoots to full-scale outdoor productions, they maintain quality and creativity at every level.

Focus on Emotion and Engagement

DaBRANDe’s ad films are not just visually appealing—they’re emotionally compelling. The team knows how to tap into human emotions and social values, which makes their content more shareable and impactful. Whether it’s a touching family moment, an inspiring transformation, or a witty punchline, DaBRANDe uses emotion as a tool to drive brand engagement.

Data-Driven StorytellingIn the digital age, data plays a huge role in content creation. DaBRANDe uses consumer insights, campaign analytics, and trend analysis to shape its storytelling. This ensures that every ad film is not only creative but also relevant to the audience's interests and behavior. From targeting Gen Z to connecting with rural markets, DaBRANDe customizes stories that reflect the viewer’s mindset.

Multilingual and Pan-India ReachIndia is a diverse country with many languages and cultures. DaBRANDe bridges this gap by offering ad film production in multiple Indian languages, enabling brands to connect with regional audiences. Whether the campaign is for a South Indian state, North India, or pan-India, DaBRANDe ensures cultural relevance and authenticity in every frame.

Case Studies: Real Results from Real FilmsSeveral brands have seen remarkable results after launching DaBRANDe-produced ad films. From a local skincare brand that went viral on Instagram to an educational startup that doubled its leads post-campaign, the agency has repeatedly proven that impactful ad films drive real ROI.

Client-Centric ApproachDaBRANDe believes in building lasting relationships with its clients. From the first briefing to the final delivery, the agency ensures clear communication, on-time execution, and complete transparency. Many clients praise DaBRANDe not only for its creative excellence but also for its professionalism and reliability.

ConclusionIn the crowded marketplace of brands shouting for attention, only those with a strong and clear voice stand out. DaBRANDe helps brands find that voice through powerful, high-impact ad films that connect, influence, and inspire. With a perfect balance of creativity, emotion, technology, and strategy, DaBRANDe is transforming how Indian brands tell their stories.

If your brand is ready to make a bold visual impact and leave a lasting impression, DaBRANDe is the creative partner you need. It’s not just about making an ad—it’s about making your audience remember who you are.

0 notes

Text

How DaBRANDe Helps Brands Stand Out with Ad Films in India?

In a world overflowing with content, where every scroll brings a new visual or message, it has become increasingly difficult for brands to capture the attention of their audience. Especially in a market as diverse and competitive as India, a strong narrative and impactful visuals are essential. That’s where DaBRANDe steps in. As a full-service digital marketing and ad film agency in India, DaBRANDe specializes in helping brands cut through the noise with emotionally resonant, high-quality ad films that not only captivate but convert.

The Power of Ad Films in Modern Branding

Ad films are more than just commercials. They are visual stories that breathe life into a brand’s voice, values, and vision. Whether it's a 30-second spot for television, a digital ad for YouTube, or a short film for social media, ad films are among the most powerful tools to influence perception and build brand identity.

In India, where cultural diversity, language variations, and regional sensibilities play a huge role in marketing success, ad films become the bridge that connects brands with their audience on a human level. DaBRANDe understands this nuance better than most. The agency takes a deeply research-based and creative approach to ensure every frame resonates with the intended audience.

Storytelling that Sells

One of DaBRANDe’s strongest capabilities lies in storytelling. In today’s fast-paced digital environment, the audience doesn’t just want to be sold to—they want to be engaged, inspired, or entertained. DaBRANDe crafts brand films that don’t feel like advertisements but experiences. These stories are built around emotions, cultural relevance, and the human connection, which are far more likely to be remembered and shared.

DaBRANDe works closely with clients to understand the core essence of their brand. Whether it’s the journey of a local business, the innovation behind a new tech product, or the aspirations of a youth-oriented fashion brand, DaBRANDe weaves these insights into compelling scripts that reflect authenticity and originality.

A Team of Visionaries

DaBRANDe’s creative team includes scriptwriters, directors, cinematographers, editors, and motion graphic artists who bring a unique vision to each project. These are professionals who have worked on everything from national brand campaigns to regional ad films and digital shorts. Their collective experience and creative instincts ensure that every film produced is polished, professional, and strategically aligned with the brand’s objectives.

The agency also believes in collaboration. While the creative direction is led by DaBRANDe, clients are kept in the loop at every stage—from script to storyboard to the final cut. This results in a seamless process where brand values are never compromised, and the final product reflects the client’s vision along with DaBRANDe’s expertise.

High-Quality Production and Technology

In the world of ad films, visuals matter. The quality of production directly reflects on the brand’s credibility and appeal. DaBRANDe uses industry-standard equipment and post-production tools to ensure every film meets broadcast and digital quality benchmarks. Whether it’s a product showcase, a festive campaign, or a lifestyle montage, the attention to detail in lighting, sound, color grading, and editing makes all the difference.

The agency is also at the forefront of integrating new technologies such as drone videography, 3D product animation, augmented reality experiences, and interactive video formats to push the creative boundaries for clients.

Customized Ad Films for Every Platform

One size does not fit all when it comes to video marketing. A TV commercial needs a different structure and pacing than a Facebook video ad or an Instagram reel. DaBRANDe creates platform-specific commercial ad films optimized for engagement and conversion. Whether the goal is brand awareness, product launch, lead generation, or social cause promotion, each video is tailored to the platform and audience behavior.

For YouTube and OTT platforms, DaBRANDe creates cinematic, longer-format ad films that offer more narrative depth. For social media, they craft short, catchy, and highly visual content that grabs attention in the first few seconds. For websites and landing pages, explainer videos and brand story reels help increase retention and conversions.

Understanding the Indian Audience

India is not one single market—it is a mosaic of multiple subcultures, languages, traditions, and consumer behaviors. What works in Mumbai may not connect in Chennai or Lucknow. DaBRANDe’s strength lies in its deep understanding of Indian audiences and its ability to localize messaging while maintaining brand consistency.

From scripting in regional languages to casting local actors and adapting cultural nuances, DaBRANDe ensures that the brand message doesn’t just reach the audience, but speaks their language—literally and emotionally. This localization has helped many brands expand their reach into Tier 2 and Tier 3 cities with great success.

Success Stories That Speak for Themselves

Over the years, DaBRANDe has worked with startups, SMEs, and established corporations across industries such as fashion, food, technology, education, and health. The impact of their ad films is evident in increased social media engagement, higher conversion rates, brand recall, and even industry recognition.

One notable example is a festive campaign for a D2C ethnic wear brand, where DaBRANDe created a heartwarming story around family values and celebration. The campaign went viral, generated millions of views organically, and significantly boosted sales during Diwali. Another case involved a tech startup for whom DaBRANDe developed a crisp explainer film that led to a 40% increase in sign-ups within a month.

From Vision to Virality

What sets DaBRANDe apart is its ability to transform a brand’s vision into viral video content without losing depth or meaning. In a digital landscape where trends change daily and attention spans shrink, DaBRANDe blends speed, style, and storytelling to produce content that doesn’t just go viral—but builds lasting brand equity.

The agency doesn’t just stop at production. DaBRANDe also supports clients with video marketing strategy—right from deciding the ideal launch platform and time, to optimizing thumbnails, titles, and CTAs for maximum reach and impact.

Conclusion

Ad films are no longer optional—they’re essential. And in India, where every region has a different story to tell and every audience responds differently, having a partner like DaBRANDe can make all the difference. With a combination of creative brilliance, production expertise, and deep cultural insight, DaBRANDe helps brands not just stand out but stay remembered.

If your brand is ready to go beyond the ordinary and make a lasting impact through powerful visual storytelling, DaBRANDe is the digital marketing agency to call. Because when it comes to ad films in India, DaBRANDe doesn’t just deliver content—it creates conversations, builds communities, and drives conversions.

0 notes

Text

Precision Meets Performance: JUGMUG Roll Forming Machines for US Industries

In the ever-evolving landscape of industrial manufacturing, precision and performance are not optional—they are essential. US industries, from automotive to construction, rely on advanced machinery that can deliver accurate results, minimize material wastage, and optimize productivity. In this context, JUGMUG Roll Forming Machines are emerging as a preferred choice for American manufacturers seeking high-performance solutions in metal forming. With a reputation built on quality, innovation, and reliability, JUGMUG has positioned itself as a trusted global supplier now expanding its footprint in the United States.

Understanding the Demand in the USA

The US manufacturing sector is undergoing a significant transformation with a push toward automation, efficiency, and customized production. Roll forming technology fits right into this narrative. Roll forming machines offer continuous, high-speed production of metal components with consistent profiles and minimal waste. From producing steel framing systems and automotive reinforcements to solar panel structures and racking systems, the applications are wide-ranging.

American manufacturers are increasingly investing in roll forming solutions that can keep up with demand while ensuring cost-efficiency and quality. This is where JUGMUG Roll Forming Machines have captured attention. They bring world-class engineering, cost-effective performance, and adaptability to diverse industry needs.

Why JUGMUG Roll Forming Stands Out

JUGMUG is not just a machine supplier; it is a full-service roll forming solution provider. Each machine is engineered with precision, keeping in mind the specific requirements of different sectors. Their machines are built using high-grade steel, smart automation controls, and advanced hydraulic and electrical components.

One of the key advantages JUGMUG offers is customization. Every business has unique product requirements, and JUGMUG’s design team collaborates closely with customers to build machines tailored to their profile specifications, production volume, and budget. Whether it's a basic manual machine or a fully automatic production line, JUGMUG delivers machines that are ready to perform in the most demanding conditions.

Key Features of JUGMUG Roll Forming Machines

Robust Construction: JUGMUG machines are made from durable and high-quality materials, ensuring long life, minimal maintenance, and consistent performance.

High Precision Tooling: The machines use CNC-machined rollers designed for precise profile shaping. This results in accurate dimensions and better product quality.

Automation Ready: Many of JUGMUG’s machines come equipped with programmable logic controllers (PLCs), touch screen interfaces, and sensor-based automation to reduce manual labor and improve efficiency.

Versatility: JUGMUG supplies roll forming lines for roofing sheets, C/Z purlins, shelf panels, door frames, solar structures, cable trays, and more—making it a versatile choice for US industries.

Quick Changeover Design: Many of their models feature quick change tooling or adjustable roll sets, allowing manufacturers to switch between profiles rapidly without extended downtime.

Technical Support: JUGMUG offers pre-sales consultation, installation support, operator training, and post-sales service to ensure clients in the USA get the most out of their investment.

Serving Diverse US Industries

JUGMUG’s roll forming technology is now being used across a wide array of sectors in the USA. In the construction industry, companies rely on their machines to produce wall studs, track channels, metal roofing, and framing elements. Automotive suppliers use JUGMUG machines for forming precision reinforcements and structural parts. Solar energy companies utilize their solutions to manufacture racking and support structures efficiently.

Additionally, warehouse and retail storage solution providers use JUGMUG roll forming lines to produce slotted angles, shelving panels, and upright frames. In the infrastructure segment, guard rails, crash barriers, and highway systems are being manufactured using JUGMUG’s high-speed machines.

Why US Manufacturers Trust JUGMUG

The US market values reliability, durability, and after-sales support. JUGMUG has demonstrated all three with its global client base and now brings that trust to American manufacturers. Unlike many international suppliers that provide only machines, JUGMUG delivers a complete package—from planning and design to commissioning and support.

JUGMUG’s engineering team ensures that the machines meet American safety and quality standards. They also understand the importance of lead times, ensuring that delivery and commissioning timelines are met without compromising quality.

Moreover, JUGMUG’s transparent pricing, accessible customer service, and commitment to performance make it a preferred choice for both new startups and established production houses in the USA.

Sustainability and Future Readiness

JUGMUG is committed to sustainable manufacturing. Their machines are designed to minimize material wastage and energy consumption. As US industries move toward greener operations, JUGMUG’s energy-efficient machines align perfectly with these goals. Furthermore, they are investing in smart manufacturing capabilities, integrating IoT-enabled sensors and remote diagnostics to support Industry 4.0 practices.

Client Success Stories

Several US-based companies have already adopted JUGMUG machines and reported significant improvements in production speed, accuracy, and downtime reduction. A mid-sized metal roofing manufacturer in Texas replaced their outdated roll former with a JUGMUG automatic roofing sheet line. Within weeks, they saw a 40% increase in output and a 25% drop in maintenance-related delays.

Conclusion

JUGMUG Roll Forming is not just entering the US market; it is elevating the standards of precision and performance across industries. With robust engineering, tailored solutions, and excellent customer support, JUGMUG is ready to become a long-term partner for American manufacturers looking to invest in future-ready metal forming technology.

As US industries continue to evolve, JUGMUG Roll Forming Machines offer the reliability, efficiency, and innovation needed to stay ahead in a competitive landscape. For those looking to upgrade their production capabilities, the choice is clear—Precision meets performance with JUGMUG.

0 notes

Text

Mankoo Power Presses: Trusted by Indian & European Manufacturers for Precision Engineering

In the competitive world of manufacturing, precision, power, and reliability are the three pillars of success. Whether it’s automotive, aerospace, appliance manufacturing, or general metalworking, industries across the globe rely heavily on high-performance machinery. At the heart of this infrastructure lies the power press machine — a vital asset for metal forming and fabrication. Among the many names in the global market, one that stands out with trust and technological excellence is Mankoo Presses. With a strong foundation in India and a growing reputation across Europe, Mankoo has emerged as a leader in precision engineering for power press solutions.

A Legacy of Manufacturing Excellence

Founded in Ludhiana, Punjab, Mankoo Presses began with a vision to offer world-class metal forming solutions at par with global standards. With decades of engineering experience, the company has built a legacy rooted in innovation, customer satisfaction, and uncompromising quality. Mankoo’s presses are not just machines — they are productivity tools that power industries in India and Europe alike. Over the years, Mankoo has grown from a regional manufacturer to a globally recognized brand serving customers in Germany, Italy, Spain, Poland, and beyond.

Diverse Range of Power Press Machines

Mankoo offers a broad spectrum of power press machines, engineered to meet the unique demands of various industries. The product lineup includes:

C-Frame Power Presses – Designed for light to medium-duty applications, these presses offer ease of access, flexibility, and high productivity. Perfect for small to mid-sized components with high repeatability.

H-Frame or Straight Side Power Presses – Suitable for heavy-duty operations and high tonnage requirements, these machines offer superior rigidity, minimum deflection, and perfect alignment during stamping.

High-Speed Presses – Ideal for mass production in sectors like electronics and automotive, these presses offer incredible accuracy at extremely high speeds.

Two-Point and Four-Point Crank Presses – For wide-bed applications and progressive die operations, Mankoo’s multi-point crank presses deliver even force distribution and stability throughout the stroke.

Mechanical and Pneumatic Presses – Depending on the client’s requirement, Mankoo provides both mechanical and pneumatic variants for versatility and application-specific performance.

Each press is designed with precision components, hardened gears, and durable frames to ensure consistent performance under the toughest conditions.

Why Indian and European Manufacturers Choose Mankoo

Mankoo’s success lies in its ability to understand the specific requirements of diverse manufacturing environments. Indian manufacturers trust Mankoo for its affordability, rugged design, and local support. European clients appreciate the CE-certified quality, advanced automation, and intelligent controls.

Customization and Engineering Support – Mankoo’s team works closely with each client to tailor machines for unique applications, tonnage, stroke length, and automation needs.

Robust After-Sales Service – With an expansive service network and dedicated technical team, Mankoo ensures quick response times, spare part availability, and long-term support for Indian and international clients.

Compliance with Global Standards – All machines are built to comply with ISO and CE standards, ensuring safety, performance, and energy efficiency.

Smart Automation Ready – Mankoo machines can be integrated with coil feeders, decoilers, stackers, and robotic arms, making them ideal for Industry 4.0-enabled environments.

Precision That Translates to Profit

Precision is the hallmark of Mankoo presses. High repeatability and accurate alignment reduce material wastage, enhance die life, and improve overall productivity. For European manufacturers operating under strict quality control regulations, this precision translates directly into profitability and competitiveness.

Mankoo’s straight side presses, in particular, are renowned for their ability to maintain tight tolerances even in long production cycles. This makes them a favorite among automotive OEMs and tier-1 suppliers in Germany, France, and Eastern Europe.

Sustainability and Innovation

As the manufacturing world moves towards greener practices, Mankoo is investing in energy-efficient drives, servo systems, and noise reduction technologies. Their R&D team continually explores innovations that reduce the environmental footprint without compromising performance.

In India, Mankoo has launched initiatives to train operators and engineers in sustainable operations and machine safety. In Europe, they are collaborating with automation partners to develop hybrid power presses that blend mechanical power with servo precision.

Customer-Centric Philosophy

One of the reasons Mankoo continues to grow is its customer-first approach. From machine design to installation, from operator training to after-sales service, every interaction is focused on delivering value. The company offers online support, remote diagnostics, and preventive maintenance packages, ensuring machines operate at peak performance around the clock.

Testimonials from satisfied clients in both India and Europe reflect Mankoo’s commitment to excellence. Whether it’s a small-scale manufacturer in Pune or a multinational stamping company in Milan, Mankoo presses have earned trust through performance and reliability.

Conclusion

Mankoo Power Presses have successfully bridged the gap between cost-effective Indian engineering and stringent European manufacturing standards. With a focus on precision, durability, and customization, Mankoo has carved a niche for itself in the global metal forming industry. As the demand for high-performance press machines continues to grow, Mankoo stands ready to serve Indian and European manufacturers with the same trust, innovation, and engineering excellence that has defined their journey for decades.

Whether you're in India looking to upgrade your workshop or in Europe seeking a reliable and affordable power press supplier, Mankoo is the name you can trust for precision engineering that performs.

0 notes

Text

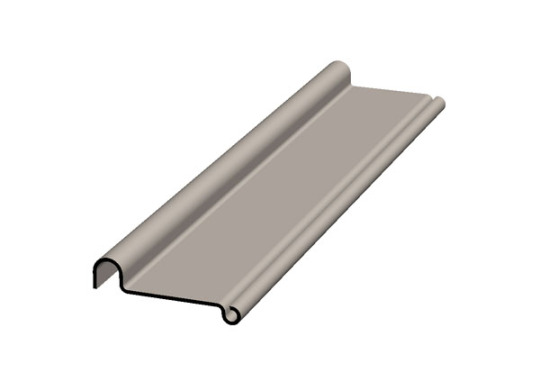

Transforming Sheet Metal with JUGMUG’s Super L Bottom Roll Forming Technology

In today’s fast-paced and quality-focused manufacturing world, the demand for highly precise, efficient, and reliable forming machines is at an all-time high. One such technological marvel that stands out in the domain of roll forming is the Super L Bottom Roll Forming Machine, especially when crafted by industry pioneers like JUGMUG Roll Forming. Known for their dedication to quality, durability, and engineering precision, JUGMUG has revolutionized the way sheet metal is transformed into structurally vital components using their advanced Super L Bottom Roll Forming Machines.

What is Super L Bottom Roll Forming?

The Super L Bottom Roll Forming process is a continuous metal forming technique where a long strip of metal—typically steel or aluminum—is passed through a series of precisely aligned rollers to create an “L” shaped profile with enhanced bottom support. These profiles are widely used in shelving systems, support brackets, metal racking, cable trays, wall partitions, and more.

What sets the Super L Bottom design apart is its structural strength and ease of integration into modular systems. It ensures better weight distribution, superior rigidity, and enhanced support—all critical elements in industrial and commercial applications.

JUGMUG Roll Forming: Pioneering Perfection

With decades of expertise in designing and manufacturing roll forming machinery, JUGMUG Roll Forming has carved a strong niche in the Indian and global sheet metal forming industry. Their machines are not just tools—they are engineering solutions that offer long-term reliability, low maintenance, and high output, making them the first choice of manufacturers across multiple industries.

Key Features of JUGMUG’s Super L Bottom Roll Forming Machine

Precision Engineering Every JUGMUG machine is built with premium-grade components, CNC machined parts, and hardened rollers to ensure unmatched forming accuracy and durability. The Super L Bottom profiles produced are consistent in dimensions, angles, and thickness, reducing material wastage and rework.

Customizable Profile DesignJUGMUG understands that one size doesn’t fit all. Their Super L Bottom Roll Forming Machines are fully customizable to cater to specific profile shapes, sizes, thickness ranges, and punch hole patterns based on your unique production requirements.

High-Speed ProductionTime is money in manufacturing. JUGMUG machines operate at high linear speeds without compromising on quality. Whether you need a few hundred meters or large-scale continuous production, these machines deliver exceptional throughput.

Robust StructureBuilt with heavy-duty frames and industrial-grade material handling systems, JUGMUG’s machines are designed for long-term stability, minimal vibration, and zero deviation under heavy loads.

Servo-Based Precision FeedingFor operations that require punching or notching, JUGMUG integrates servo feeders that ensure exact distance control between holes or cutouts. This is especially useful for profiles that need to be pre-punched before forming.

PLC-Controlled AutomationJUGMUG machines come with intelligent PLC control systems and touch-screen HMIs for user-friendly operation, real-time production monitoring, and error detection.

Energy Efficient With smart motor controls and energy-saving designs, these machines consume less power per meter of production, offering long-term savings and sustainability.

Applications of Super L Bottom Profiles

The profiles produced by JUGMUG’s Super L Bottom Roll Forming Machines are vital components across numerous sectors:

Electrical & Cable Trays: For supporting wiring and cable networks in commercial buildings and factories.

Racking & Storage Systems: Used in warehouses, retail shelves, and logistic racks due to their high load-bearing capacity.

Partition Wall Frames: In prefabricated structures, these profiles are perfect for wall and ceiling partitions.

Construction & Infrastructure: Used in temporary fencing, formwork systems, and scaffold supports.

Solar Mounting Systems: The L Bottom profile provides strength and compatibility for solar panel frameworks.

Why Choose JUGMUG for Your Roll Forming Needs?

Unmatched Industry Experience With years of innovation and successful client partnerships, JUGMUG brings unparalleled expertise and reliability to every machine they build.

End-to-End Support From consultation and design to installation, training, and after-sales service, JUGMUG offers complete technical support and maintenance assistance.

Strong R&D Capabilities The team at JUGMUG constantly invests in research and development to adapt to new industry trends, materials, and automation technologies.

Proven Track Record With a vast list of satisfied customers across India and abroad, JUGMUG Roll Forming has consistently proven their capability to deliver world-class solutions that stand the test of time.

In-House Manufacturing All JUGMUG machines are manufactured in-house using advanced machining, welding, and quality control systems. This ensures timely delivery, consistent build quality, and complete control over every component.

Conclusion

As industries continue to demand better strength, higher precision, and faster production in sheet metal forming, JUGMUG Roll Forming stays ahead of the curve with its Super L Bottom Roll Forming Technology. These machines are more than just equipment—they’re enablers of innovation, productivity, and long-term growth for manufacturers.

Whether you're upgrading from older systems or entering the roll forming business for the first time, JUGMUG’s solutions guarantee performance that transforms not just metal—but your entire business process.

For more details, demos, or quotations, contact JUGMUG Roll Forming today and step into the future of sheet metal forming.

0 notes

Text

What Makes a Great Brand Film? DaBRANDe Explains

Introduction – More Than Just a Video

In today’s digital-first world, a brand is more than just a logo or a catchy tagline. It is an emotional experience. And nothing conveys emotion quite like a well-crafted brand film. At DaBRANDe, we believe that a powerful brand film doesn’t just tell a story — it builds a connection, evokes trust, and leaves a lasting impression on your audience.

Whether you're a startup trying to make your first impression or an established name seeking deeper engagement, a great brand film can become the most valuable asset in your marketing toolkit. But what exactly makes a great branding ads film? Here’s our perspective, drawn from real experience, creative insight, and our deep connection to brands across Punjab and beyond.

1. A Clear Purpose Behind the Film

Every great brand film starts with clarity of purpose. Are you trying to build awareness? Showcase your company culture? Launch a new product? Inspire an emotion? Educate your audience?

At DaBRANDe, we begin by asking the right questions. We collaborate with the brand team to understand goals, audience personas, and market context. Without clarity, even the most visually stunning film can fall flat. With clarity, even a simple concept can strike gold.

2. A Story That Resonates

The heartbeat of every brand film is storytelling. People don't remember data; they remember stories.

A great brand film doesn’t just list features — it narrates a compelling story that humanizes your brand. Whether it's the journey of a local entrepreneur, the transformation of a customer, or the behind-the-scenes dedication of your team — the story must feel authentic, relevant, and emotional.

DaBRANDe's creative team often draws inspiration from real-life situations in Punjab — local dialects, cultural moments, and emotional triggers that truly connect with the people. This is especially powerful for brands wanting to build regional loyalty.

3. Powerful Visual Aesthetics

Visuals aren’t just decoration. In a brand film, they amplify emotion. Cinematography, color grading, camera angles, lighting — every element matters.

At DaBRANDe, we use cinematic techniques to turn a simple shot into a story by itself. Whether it's the slow motion of a wheat field swaying in Punjab’s heartland or a bustling cityscape in Ludhiana, every frame is thoughtfully constructed to reflect your brand identity.

A great brand film doesn’t compromise on production quality. It doesn’t mean expensive — it means thoughtful. You can shoot a great film even with a lean budget if the visuals are purposeful.

4. Authentic Voice and Tone

Your film should sound like your brand. The tone can be playful, emotional, inspiring, authoritative — but it must feel authentic.

For example, a luxury real estate brand in Chandigarh needs a polished, aspirational tone. But a homegrown organic food brand in Amritsar may connect better with warmth, simplicity, and mother-tongue narration.

DaBRANDe spends time defining voice and tone based on your audience. We explore voiceovers, dialogues, background music, and language to make sure every second feels real and on-brand.

5. Emotional Connect – Heart Over Hype

Brands that win hearts win the market.

We always tell clients: people don’t just buy what you make; they buy why you make it. And a great brand film puts that "why" at the center.

At DaBRANDe, we believe in the power of emotion — pride, nostalgia, love, hope, courage. These emotions become the foundation of brand loyalty. Whether it’s the pride of using local craftsmanship or the joy of a mother receiving a gift from her son, emotional connection is key.

6. Strong Opening and Memorable Closing

In the age of short attention spans, the first 10 seconds of your brand film are everything.

A great film grabs attention instantly — a bold statement, a surprising visual, or a powerful question. Similarly, it must end with a clear takeaway or a memorable line that echoes in the viewer’s mind.

DaBRANDe carefully crafts every film's opening and closing to ensure maximum impact. We often use hooks like direct eye contact, breaking the fourth wall, or regional music beats to instantly pull viewers in.

7. Sharp and Smart Editing

Editing isn’t just technical — it’s storytelling with rhythm. A great brand film has a pace that feels natural yet keeps you engaged. Transitions, cuts, zooms, and overlays all work together to create flow.

Our post-production team at DaBRANDe understands the science of visual rhythm. We know when to hold a moment for emotion and when to speed up for energy. The edit brings everything together — and it’s where average films are either elevated or destroyed.

8. Brand Integration Without Being Pushy

Nobody likes a hard sell.

A smart brand film weaves your brand naturally into the storyline. It shouldn’t feel like an ad — it should feel like an experience. A well-placed logo, product usage in context, or subtle color themes do more than shouting a sales pitch.

DaBRANDe ensures that your brand presence is organic. Your values, visuals, and voice subtly stay in focus — even if your logo appears only once.

9. Music That Enhances Mood

The right music can make you cry, smile, or feel goosebumps. That’s why music selection in a brand film is never an afterthought.

We at DaBRANDe believe in emotion-first music. Whether it's a soul-stirring flute, upbeat dhol beats, or cinematic orchestral background — the music must support the mood of the film.

Sound design, ambient audio, and silence (yes, even silence) are all part of the experience. We spend hours mixing soundtracks that elevate your brand message.

10. Call to Action – What’s Next?

A great brand film always guides the viewer toward a next step — visit our store, join our mission, share the video, subscribe, or simply remember us.

Without a CTA, even a powerful film can lose momentum. We help our clients define clear, concise, and relevant CTAs that feel natural and not forced.

Conclusion – Why DaBRANDe?

At DaBRANDe, we don’t just make brand films — we build brand experiences. We bring together Punjab’s passion, creative vision, and strategic storytelling to help your brand stand out in the clutter.

Every frame, every sound, and every second of our films are crafted with purpose. Whether it’s for a TV commercial, digital campaign, or corporate video, we ensure it doesn’t just look great — it feels right and performs well.

So if you're looking for a brand film that doesn’t just look good but makes people feel, connect, and act — DaBRANDe is here to bring your story to life.

0 notes

Text

Boost Production with Plunger Guided Link Motion Press Technology

In today’s highly competitive industrial environment, the demand for precision, efficiency, and durability in metal forming processes is greater than ever. Among the advanced machinery powering this transformation is the Plunger Guided Link Motion Press Machine, a robust solution designed for high-performance operations. Mankoo Presses, a trusted name in industrial manufacturing, proudly brings to the market its line of precision-engineered plunger guided link motion presses that are transforming production capabilities for metalworking industries.

What is a Plunger Guided Link Motion Press?

A Plunger Guided Link Motion Press is a type of mechanical press that uses a sophisticated link mechanism to control the motion of the ram. Unlike traditional crank presses, link motion presses slow down at the bottom of the stroke, offering better control during die contact and significantly reducing shock loads. The added plunger guide system enhances slide motion stability, precision alignment, and longevity of the press components. This combination is ideal for complex forming operations that require consistency and dimensional accuracy.

Why Choose Mankoo Plunger Guided Link Motion Press Machines

Mankoo Presses has been a pioneer in delivering high-performance mechanical press machines that meet global industrial standards. With decades of engineering excellence, Mankoo has consistently provided solutions that address real-world manufacturing challenges. Their Plunger Guided Link Motion Press Machines are no exception.

Precision Engineering

Every Mankoo press is designed with precision in mind. The plunger guide ensures minimal lateral movement, reducing wear and maintaining alignment throughout continuous operations. This precision plays a critical role in industries where micron-level accuracy is essential, such as automotive, electrical components, and appliance manufacturing.

Improved Tool Life and Reduced Maintenance

One of the standout features of Mankoo’s link motion technology is its ability to reduce impact forces during the working stroke. This not only preserves die life but also decreases maintenance costs and machine downtime. The reduced shock loads protect both the press and the tooling, ensuring longer operational life and consistent performance.

Enhanced Production Speed

Despite its slow-down mechanism near the bottom of the stroke, the link motion design allows for higher overall production rates due to its controlled return stroke. Mankoo’s design optimizes this motion for maximum output without sacrificing accuracy or product quality. Manufacturers benefit from shorter cycle times and higher throughput, which directly impacts profitability.

Energy Efficient Operation

Energy efficiency is a core priority for Mankoo Presses. The optimized movement of the ram in the link motion system consumes less energy compared to conventional crank presses. The result is lower electricity bills, reduced carbon footprint, and a greener manufacturing process without compromising on strength or reliability.

Applications of Mankoo Plunger Guided Link Motion Press Machines

Automotive Components Manufacturing

Mankoo presses are widely used in the automotive sector for producing parts like clutch plates, brake components, body panels, and chassis elements. The need for dimensional stability and repeatability in these parts makes plunger guided link motion presses the ideal choice.

Electrical and Electronic Components

Precision stamping for connectors, terminals, switchgear components, and transformer parts requires machines that offer micro-level accuracy. Mankoo’s machines deliver the necessary control and precision, making them perfect for electrical component manufacturers.

White Goods and Appliances

From refrigerator panels to washing machine parts, consumer appliance manufacturing involves large sheet metal components that must be produced in large volumes with consistent quality. The high-speed performance and durability of Mankoo’s link motion presses make them perfect for this sector.

General Engineering and Fabrication

Apart from industry-specific applications, Mankoo presses are also used in general fabrication shops where flexibility, reliability, and robust construction are needed. Whether it’s punching, blanking, or deep drawing, Mankoo’s machines handle the job efficiently.

Key Features of Mankoo’s Plunger Guided Link Motion Presses

Heavy-Duty Construction

Mankoo presses are built with high-grade materials and undergo rigorous quality testing. The robust frame minimizes deflection and ensures stability even under full load, resulting in extended machine life.

Advanced Control System

With the integration of programmable logic controllers (PLCs), touch screen interfaces, and real-time diagnostics, operators have better control over press operations. Mankoo’s systems also support integration with automation systems like feeders, stackers, and robots.

Customizable Configurations

Mankoo understands that every production line is different. That’s why their link motion presses come in customizable configurations with various tonnage capacities, stroke lengths, and table sizes to match specific production requirements.

Safety Features

Operator safety is a top priority. Mankoo machines are equipped with advanced safety mechanisms including two-hand controls, emergency stops, interlocked doors, and overload protection systems to ensure safe operation.

After-Sales Support and Service

A machine is only as reliable as the support behind it. Mankoo Presses takes pride in offering exceptional after-sales support, including machine commissioning, training, preventive maintenance services, and readily available spare parts.

Client Success Stories with Mankoo Presses

Numerous companies across India and abroad have benefited from Mankoo’s Plunger Guided Link Motion Press Machines. From Tier-1 automotive suppliers to multinational appliance manufacturers, clients consistently praise the performance, reliability, and cost-efficiency of Mankoo equipment.

One notable success story involves a leading automotive parts manufacturer who upgraded their production line with Mankoo’s 250-ton plunger guided link motion press. Within months, they reported a 30% increase in productivity and a 25% reduction in tool maintenance costs.

Conclusion

The demand for high-performance metal forming solutions continues to grow across industries, and the Plunger Guided Link Motion Press Machine stands out as a proven solution for precision, speed, and reliability. Mankoo Presses, with its rich heritage and engineering excellence, delivers machines that not only meet but exceed industry expectations.

Whether you are looking to expand your manufacturing capacity, improve product quality, or reduce downtime, Mankoo’s Link Motion Presses are your ideal choice. Invest in the future of your production line with Mankoo Presses – Where Performance Meets Precision.

0 notes

Text

Mankoo Drop Forge Hammer Press – Precision Forging Power

Mankoo Presses is a name that resonates with engineering excellence, unmatched durability, and high-performance machinery in the field of metalworking. Among their diverse product range, the Drop Forge Hammer Press Machine stands out as a powerful solution for heavy-duty forging applications.

With decades of experience and a reputation for delivering top-of-the-line power presses, Mankoo Engineering Works has established itself as a leading manufacturer in India and across global markets. This blog explores the features, benefits, and industrial applications of the Mankoo Drop Forge Hammer Press, emphasizing why it remains a preferred choice among modern manufacturers and forging units.

The Legacy of Mankoo Presses

Established with a mission to provide robust, reliable, and technologically advanced power press solutions, Mankoo Presses has grown to become a trusted brand in the machine tools industry. From mechanical and hydraulic power presses to high-speed precision machines, Mankoo has engineered a complete portfolio of equipment that caters to small workshops as well as large-scale industries. With a strong presence in sectors such as automotive, aerospace, defense, agriculture, and railway, Mankoo has earned recognition not only for its machine quality but also for its excellent after-sales support.

What is a Drop Forge Hammer Press Machine

A Drop Forge Hammer Press Machine is a heavy-duty forging machine used to shape metal through repeated, high-impact hammering. The machine operates by lifting a massive hammer and dropping it on the workpiece to deform and mold it into the desired shape. This process is essential in producing high-strength metal components such as crankshafts, axles, gears, connecting rods, and various structural parts that require superior durability and precision. The drop forging method enhances grain structure, reduces porosity, and improves mechanical properties, making it ideal for critical load-bearing parts.

Features of Mankoo Drop Forge Hammer Press

1. High-Impact Forging Power Mankoo’s drop forge hammer is designed to deliver consistent, high-impact blows that ensure deep penetration and accurate shaping of the material. The forging force is calibrated to handle both ferrous and non-ferrous metals, making it versatile for a wide range of applications.

2. Rigid and Durable Frame Construction Built with a heavy-duty steel frame, the Mankoo Drop Forge Hammer Press offers excellent stability during operations. The robust design eliminates vibrations and ensures long-term durability even under continuous usage in demanding environments.

3. Precision Engineering Each Mankoo hammer press is precisely engineered using CNC and automated technologies. This allows for accurate alignment, superior balance, and repeatable performance, which are critical factors in high-quality forging operations.

4. Efficient Ram Movement The vertical ram or hammer head is designed to move smoothly with minimum resistance, ensuring maximum energy transfer on every strike. The result is a powerful impact with reduced energy loss, contributing to the machine’s overall efficiency.

5. Customization and Automation Options Mankoo provides the option of customizing the drop forge hammer based on customer requirements. Features like programmable automation, die cooling systems, safety guards, and digital stroke counters can be integrated to enhance productivity and user safety.

6. Easy Maintenance and Accessibility With a focus on user-friendly design, Mankoo ensures that all parts of the machine are easily accessible for routine maintenance. The use of high-grade components also means that wear and tear is minimized, reducing downtime and increasing machine life.

Industrial Applications of Mankoo Drop Forge Hammer Press

Automotive Industry Used to forge critical parts like crankshafts, axles, steering knuckles, and suspension arms, the Mankoo drop hammer ensures high mechanical strength and fatigue resistance, which is vital for automotive applications.

Railway and Aerospace Forging components for railway coaches and aircraft structures demands the highest levels of precision and strength. Mankoo machines are capable of producing such components with exact dimensional accuracy and metallurgical integrity.

Agricultural Equipment From plowshares to couplings and gear parts, the Mankoo Drop Forge Hammer Press helps create durable, weather-resistant parts used in heavy agricultural machinery and tools.

Defense Manufacturing The machine is ideal for manufacturing armor plates, weapon components, and other critical defense parts that must withstand extreme conditions and operational stress.

Tool and Die Making Precision dies and hammers can be forged using the Mankoo press, ensuring durability and resistance to repetitive strain, which is essential for tool manufacturing industries.

Advantages of Choosing Mankoo Drop Forge Hammer Press

Made in India, Trusted Worldwide Mankoo machines are manufactured in India under strict quality standards but are designed to compete with global counterparts. They are exported to countries across Asia, Africa, and the Middle East, proving their reliability on international platforms.

Cost-Efficient Solution Compared to imported machinery, Mankoo offers a highly cost-effective alternative without compromising on quality or performance. The return on investment is high due to the machine’s productivity and low maintenance.

Strong Service Network Mankoo’s wide service network ensures that customers receive prompt assistance, installation support, and genuine spare parts. Their engineering team is always ready to guide and resolve technical issues.

Environment-Friendly Forging Solution The machine is built with energy efficiency in mind. With improved energy transfer, minimal vibration, and optional oil-lubrication systems, Mankoo helps industries meet their environmental compliance goals.

Customer Success Stories

Over the years, numerous clients have trusted Mankoo Drop Forge Hammer Press for their forging needs. From leading auto part manufacturers to government railway units, Mankoo machines have played a vital role in helping businesses scale their production while maintaining quality. Several clients have also reported significant reductions in cycle time and material wastage after switching to Mankoo presses.

Conclusion

When it comes to forging precision, power, and durability into one machine, Mankoo Drop Forge Hammer Press stands tall as a leader. Built with cutting-edge technology, engineered for perfection, and backed by decades of trust, it is an indispensable asset for any industry involved in heavy metal forging. Whether you're a manufacturer looking to expand capacity or a startup exploring reliable forging solutions, Mankoo has the machine and the support you need to succeed.

Mankoo Presses continues to set new standards in metal forming technology, and the Drop Forge Hammer Press is a perfect reflection of their commitment to quality and performance.

0 notes

Text

Unmatched Forming Accuracy – Plunger Link Press Machine by Mankoo Presses

In the world of industrial metal forming, precision, durability, and efficiency are the benchmarks of a superior power press machine. Mankoo Presses, one of India’s leading names in mechanical press manufacturing, proudly presents the Plunger Guided Link Motion Power Press Machine — a solution engineered to deliver unmatched forming accuracy for the most demanding production environments.

About Mankoo Presses – A Legacy of Engineering Excellence

For decades, Mankoo Presses has been a trusted name in the field of mechanical power presses. With a deep commitment to quality, performance, and innovation, the company has established itself as a pioneer in manufacturing a wide range of forging and metal forming machines. From C-frame and H-frame presses to knuckle joint and friction screw presses, Mankoo continues to evolve its product line to serve the growing needs of heavy industries across India and abroad.

Their latest offering, the Plunger Guided Link Motion Press, is a reflection of their technological advancement and focus on high-precision manufacturing.

What is a Plunger Guided Link Motion Power Press?

The Plunger Guided Link Motion Power Press Machine is a specialized type of mechanical press that uses link motion technology combined with plunger-guided slide systems. This unique mechanism ensures a slower and controlled slide movement near the bottom dead center, which is essential for high-precision and high-quality metal stamping operations.

Unlike conventional crank presses, the link motion system reduces impact, vibration, and die wear, while the plunger guide ensures perfect vertical alignment, preventing side thrust and improving die life.

Key Benefits of Mankoo's Plunger Link Motion Press

1. Unparalleled Accuracy

The plunger-guided slide ensures the slide travels vertically without angular deviation. This is crucial in operations like blanking, embossing, deep drawing, and fine blanking, where high precision is non-negotiable.

2. Longer Tool Life

The link motion reduces the speed near the bottom of the stroke, which minimizes shock loads and increases the life of both the tool and the die.

3. Reduced Noise and Vibration

Compared to traditional presses, this machine operates with significantly lower noise and vibration, ensuring a better working environment and smoother operation.

4. Superior Load Distribution

The plunger guide system ensures uniform distribution of forming force, resulting in better surface finish and component consistency.

5. High Tonnage Capabilities

Mankoo's engineering allows for high-tonnage operations, making this machine suitable for automotive, defense, white goods, and electrical component manufacturing.

Technical Highlights of Mankoo’s Plunger Guided Link Press

Frame Type: Robust welded steel frame for minimum deflection

Slide Movement: Smooth, controlled link motion with adjustable stroke

Guiding System: 6-point plunger guide system for perfect alignment

Drive Mechanism: Flywheel driven with high-torque clutch and brake

Lubrication: Centralized and automated lubrication system

Safety: Integrated overload protection and electronic safety features

Every machine from Mankoo is tailor-made to meet specific client requirements, including optional features like die cushions, automatic feeders, and digital control panels.

Applications Across Industries

Mankoo’s Plunger Guided Link Motion Power Press finds wide applications in various industries such as:

Automotive: Pressing of structural body parts, brackets, and deep-drawn components

Electricals: Manufacturing of switchgear components, enclosures, and terminals

Home Appliances: Forming of panels, doors, and internal structural parts

Defense: Precision pressing of metal casings and armor plates

Hardware Tools: Punching, coining, and fine blanking of hardware components

Why Choose Mankoo Presses?

Custom Engineering

Mankoo offers customized press solutions to suit your exact operational requirements, ensuring perfect integration into your production lines.

Rugged Build Quality

All machines are built with heavy-duty, stress-relieved frames and components tested under real-world load conditions.

Pan-India Support

With an extensive service network, Mankoo provides installation, training, AMC, and rapid after-sales support across India.

Trusted by Industry Leaders

From OEMs to MSMEs, Mankoo machines power the production lines of India’s top manufacturers in metal forming and stamping.

Enhance Your Production with Intelligent Features

Mankoo’s latest models come equipped with smart automation features including:

Touchscreen HMI with diagnostics

Sensor-based die protection systems

Programmable logic controllers (PLC) for seamless operations

Integration with coil feeding and de-coiling lines

ROI-Driven Investment for Your Workshop

Choosing a Plunger Guided Link Motion Press by Mankoo isn’t just about machinery—it’s an investment in quality, reliability, and long-term profitability. With minimal downtime, low maintenance needs, and long tool life, the machine pays back faster and adds precision to your production capabilities.

Conclusion

The Plunger Guided Link Motion Power Press by Mankoo Presses is a testimony to India’s growing mechanical engineering strength. With its superior accuracy, controlled slide movement, and rugged design, this machine is the perfect solution for manufacturers aiming for higher output and zero defects. Mankoo continues to set new standards in metal forming with innovation, integrity, and industry-driven performance.

0 notes

Text

DaBRANDe – Professional Brand Identity & Marketing Services in India

In the competitive world of branding, businesses need more than just a logo—they need a voice, a story, and a visual presence that leaves a lasting impression. That’s where DaBRANDe, one of India’s top branding and marketing agencies, comes in. Specializing in brand identity, digital marketing, creative design, and ad film production, DaBRANDe helps businesses turn bold ideas into bold brands

Whether you're a new startup or an established business seeking a fresh outlook, DaBRANDe provides full-spectrum solutions that define your identity and elevate your presence in the market.

What Makes DaBRANDe Different?

DaBRANDe believes branding isn’t just decoration—it’s strategic communication. By blending data, creativity, and storytelling, DaBRANDe builds brands that connect, captivate, and convert.

Core Services Offered by DaBRANDe:

1. Brand Identity Development

Logo & Visual Identity Design

Typography, Color Systems & Brand Guidelines

Naming, Slogans, and Messaging Frameworks

2. Marketing & Digital Growth

SEO & Content Marketing

Google Ads (PPC), Meta Ads

Social Media Strategy & Management

Email Campaigns and Funnel Automation

3. Creative & Graphic Design

Brochures, Catalogues, Product Packaging

Visual Campaigns & Brand Collateral

Web Design (UI/UX) and Mobile Interfaces

4. Ad Film Production

TV Commercials (TVCs)

Social Media Video Ads

Corporate Films & Brand Story Videos

Product Launch Films & Explainers

DaBRANDe’s in-house film production team creates cinematic-quality visuals that bring your brand narrative to life—from concept and scripting to shooting and editing. These ad films aren’t just visually stunning—they’re designed to influence emotions, drive engagement, and boost brand recognition.

5. Brand Strategy & Consultation

Brand Positioning & Market Entry

Audience Persona Development

Competitive Analysis

Rebranding & Evolution Plans

DaBRANDe’s Branding Philosophy

At DaBRANDe, every project starts with one question: “What story does your brand need to tell?” Their branding process is rooted in understanding your purpose, audience, and market landscape. With that clarity, DaBRANDe crafts a brand identity that’s not only beautiful but impactful and scalable.

Key branding principles include:

Consistency across touchpoints

Authentic, value-driven messaging

Visual design that reflects purpose

Marketing aligned with audience psychology

Industries DaBRANDe Works With

DaBRANDe serves a wide range of sectors, including:

Tech & SaaS Startups

Education & eLearning

Fashion & Lifestyle Brands

Healthcare & Wellness

Real Estate & Infrastructure

Food & Beverage

Manufacturing & B2B

Each project is customized with industry-specific insight, ensuring the brand feels native to its niche while standing out creatively.

Why Choose DaBRANDe?

One Agency for All Your Branding NeedsFrom brand name to ad campaigns, DaBRANDe handles the full branding lifecycle.

In-House Ad Film StudioNo outsourcing. Every video is directed, shot, and edited by professionals who understand your brand goals and creative voice.

ROI-Focused MarketingMarketing at DaBRANDe isn’t guesswork. It’s data-driven and results-oriented.

Award-Worthy Designs

Each design—from your logo to your product’s packaging—is crafted to impress, engage, and influence.

Pan-India & Global ReachDaBRANDe works with brands across India and internationally, combining local insights with global trends.

Success Stories with DaBRANDe

A fashion label saw 200% growth in sales within three months of launching a visual branding and ad film campaign.

A health tech startup went from local player to national brand using DaBRANDe’s branding + performance marketing + video strategy.

An FMCG company revamped its entire product line packaging and brand story through DaBRANDe’s visual identity and product explainer films, increasing shelf pull and online sales.

Advertising Films That Speak Louder Than Words

In a world dominated by visual content, ad films have become a vital tool for storytelling and conversions. DaBRANDe’s video production services bring cinematic storytelling to your business, helping you:

Launch a product with impact

Humanize your brand with authentic stories

Communicate complex ideas quickly

Enhance digital ad performance with scroll-stopping creatives

Their ad film production includes:

Conceptualization & Scriptwriting

Casting, Directing & Shooting

Post-production, VFX & Voiceovers

Platform-optimized delivery (Instagram, YouTube, OTT, TV)

Whether you need a 30-second reel, a corporate brand film, or a TV commercial, DaBRANDe ensures it captures your voice—and grabs your audience’s attention.

The Power of a Unified Brand Experience

Your customer journey spans many touchpoints—website, social media, packaging, and ads. DaBRANDe ensures all of them speak the same language, creating a cohesive experience that:

Builds trust

Enhances recognition

Increases retention

Drives customer loyalty

By aligning identity, voice, and marketing, DaBRANDe creates brands that live in minds and hearts.

Partner with DaBRANDe – Build the Brand You Dream Of