Don't wanna be here? Send us removal request.

Text

Why Choose EcoPeb for Your Next Industrial Shed Project?

When planning an industrial shed project, the quality of the structure, construction speed, and cost-efficiency matter most.

That’s where EcoPeb, a trusted name in Pre-Engineered Buildings (PEBs), comes in. With years of expertise and a strong track record, EcoPeb is redefining how industrial sheds are built—faster, smarter, and more sustainably.

Engineered for Excellence

EcoPeb specializes in high-performance PEB structures that are tailored to meet the unique needs of industrial operations, be it manufacturing, warehousing, or logistics.

Every structure is factory-fabricated with precision, ensuring:

High load-bearing capacity

Long-lasting durability

Minimal on-site errors

Speedy Turnaround

Time is money in business. Our pre-engineered approach reduces construction timelines by up to 50% compared to conventional methods. From design to delivery, EcoPeb ensures your shed is ready in weeks—not months.

Cost-Effective Solutions

EcoPeb’s smart design and manufacturing process minimize material wastage and labour costs. Our clients typically save up to 30% on total project costs while getting superior quality.

Quality Assurance

EcoPeb follows ISO-certified processes, ensuring strict quality checks at every stage. From raw material selection to final installation, we maintain international standards in safety, durability, and structural integrity.

Sustainable Construction

Sustainability is not an afterthought—it’s a priority. EcoPeb uses recyclable steel, energy-efficient designs, and minimal site disruption techniques, making us the ideal partner for businesses that care about the environment.

Local Expertise, Pan-India Reach

Whether you’re in Gurgaon, Faridabad, Kolkata, or anywhere in India, EcoPeb has the network and logistics to serve you quickly and efficiently. Our regional teams understand local compliance and climate considerations.

Trusted by Industry Leaders

Over the years, we’ve delivered sheds for leading companies across sectors. Our client-first approach ensures on-time delivery, transparent pricing, and end-to-end support.

Ready to Build Smarter?

Choose EcoPeb for a future-ready industrial shed that combines strength, speed, and sustainability.

Contact us today for a free consultation or a site visit.

https://ecopeb.com/pre-engineered-buildings/

#pre engineered structure manufacturer#peb building#pre engineered buildings#branding#peb solution#pre engineered building#peb manufacturer#ecopeb

0 notes

Text

PEB Office Buildings Redefining Commercial Construction in India

EcoPeb brings more than a decade of expertise in delivering top-tier PEB solutions across India. Our PEB office building designs are tailored to meet modern functionality, aesthetic appeal, and energy performance standards, without compromising on speed or budget. From IT parks and corporate headquarters to startup hubs and co-working spaces, PEB office buildings are helping companies scale faster and smarter.

Source:

#peb manufacturer#pre engineered buildings#pre engineered building#pre engineered structure manufacturer#ecopeb#peb solution#branding#peb building

0 notes

Link

0 notes

Text

Pre Engineered Building Suppliers

ecopeb is the leading peb supplier in Delhi NCR. With years of experience in pre-engineered buildings, ecopeb builds customized cold storage and PEB structures across Delhi NCR with precision and durability.

#pre engineered structure manufacturer#peb solution#peb manufacturer#pre engineered buildings#branding#entrepreneur#pre engineered building#peb building#industrial building solutions#pebstrucutr#pebstructurmanufacter#pebmanufacturerinDelhi Ncr

0 notes

Text

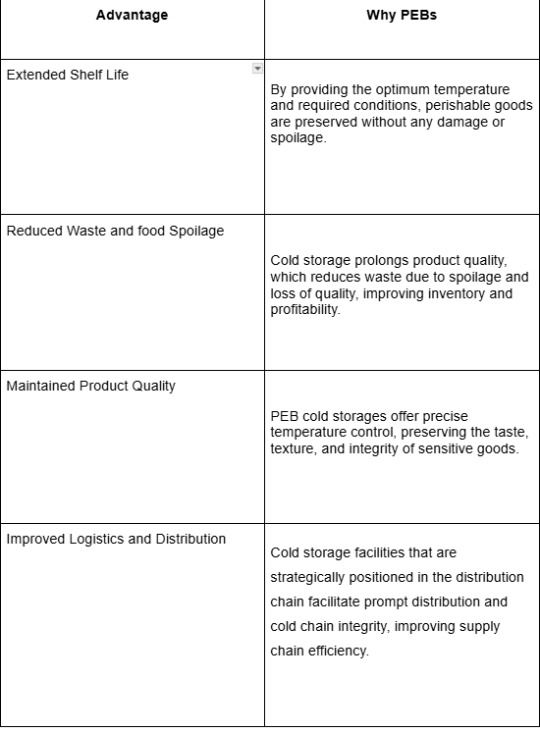

PEB Cold Storage Solutions: Engineered for Excellence in Quality and Preservation

As the demand for cold storage structures is increasing rapidly. Investing in efficient cold storage solutions is more crucial than ever due to increased rules on product safety and consumer demand for high-quality goods with preserved flavor, texture, and integrity.

This blog explores cold storage warehouses' significance, unique features, and how they support a wide range of businesses in ensuring product safety and quality.

Cold storage Warehouses are used for preserving perishable and sensitive Items. As India continues to experience a surge in imports and pharmaceutical production capacity, it becomes essential to have cost-effective and modern cold storage solutions.

PEB structures are manufactured in controlled factory environments, then transported and assembled on-site. These are made with precision and advanced technology, which makes them temperature-sensitive with quick installation, meeting the storage requirements.

Key Considerations When Planning a PEB Cold Storage Facility

Temperature Requirements & Zoning

Specify the temperature zones your product will need, which include frozen, chilled, and/or ambient, and design the PEB structure and ensure that it will allow for multi-zoning flexibility.

Location & Logistics Access

The site should be located in locations close to highways, ports, or production areas. to facilitate efficient logistics.

Compliance with Safety & Regulatory Standards

The facility must meet FSSAI, GMP, and specific regulatory requirements applicable to the sector, especially for pharma and food products.

Energy Efficiency & Operational Sustainability

Energy-efficient systems like solar panels, LED lighting, and transparent roofing panels need to be installed in the building to sustain sustainability.

Ventilation & Humidity Control

Ventilation and humidity should be controlled effectively to prevent spoilage and protect the integrity of sensitive goods.

Role of Cold Storage Buildings in India’s Growth

As India's capabilities in production and consumer base continue to grow, there is a greater need for reliable and scalable cold storage capabilities These facilities support various sectors, including agriculture, pharmaceuticals, and exports, contributing significantly to overall economic development.

Reducing Agricultural Waste

Cold storage reduces post-harvest losses, as India is one of the largest producers of fruits, vegetables, and dairy. When products are kept at the right temperature, they reduce waste through extended shelf life and ease of distribution in the country.

Strengthening the Pharmaceutical Industry

Cold storage maintains the effectiveness of vaccines, pharmaceuticals, and other medical products that must remain at specified temperatures for storage and shipping. It is particularly critical in a country that produces a substantial amount of pharmaceuticals in the world.

Promoting International Export and Trade

Cold storage buildings support India's role as a robust global supplier, fulfilling international quality standards and supply chain requirements in the rapidly developing export market, especially for perishables, e.g., fruit, seafood, and processed products.

Improving Supply Chain Effectiveness

cold storage solutions facilitate a steady supply of commodities by reducing transit delays, eliminating spoilage, and improving the overall resilience of supply chains, which is a key part of economic stability and development.

Partner with Us for Future-Ready Cold Storage Solutions

If you're looking for a smart, scalable, and cost-effective cold storage solution, our PEB-based warehouses offer the durability, speed, and flexibility your business needs.

Contact us today, the leading pre-engineered building manufacturer in India, to learn how we can help you build a high-performance cold storage facility tailored to your industry requirements.

#pre engineered structure manufacturer#peb building#peb manufacturer#pre engineered buildings#pre engineered building#peb solution#pre engineered building manufacturer in India#pre engineered building supplier in India#peb building manufacturer in Delhi NCR#PEB#industrial building#peb warehouse manufacturer#pre engineered warehouse construction#ecopeb

0 notes

Text

Faster, Smarter Airport Construction with PEB Systems

The constantly emerging demands of an industry are on all sectors, especially the construction industry, which has become very relevant to adopt innovative building solutions for better cost-effectiveness, efficiency, and speed. These would include airport infrastructure, a major civil construction sector on its own. Such complex projects can significantly benefit from prefabrication.

Airports are unique structures in that they work non-stop. This means that services continue without interruptions; delays in projects for infrastructure could easily cause serious disruptions. ecopeb’s prefab construction has proven to be a fast and streamlined solution, allowing expansion and even development without disturbing daily airport activities.

Safe Future for Airport Construction with ECOPEB PEB Structures

New airport construction or expansion work has become more about green and sustainable construction today. Refocusing things, one is now on modular buildings that answer green and responsible nudges in a better way, as by a PEB manufacturer in India offering innovative PEB solutions, better energy efficiency, and Thermal Insulation.

PEB structures are insulated right at their core, maintaining internal temperature optimally while lightening the load on HVAC. Furnished with leak-proof construction, energy-efficient electrical systems, and insulated composite panels, the airport facilities will have unmatched savings without sacrificing operation expenses through PEB solutions.

Economics that keep an infrastructure sound but do save money long-term. The capital-intensive segment of aviation has its focus on cost control and budget optimization as high priorities. prefab buildings by PEB companies in India are one big alternative to conventional construction methods, as they cost 50% less in most cases. Although these modular units are manufactured off-site and delivered as ready-to-install components, their on-site construction time and labor costs shrink by multiples.

The smoother workflow of all processes guarantees the completion of projects in a shorter time, allowing airport authorities to optimize the use of their assets and realize better returns on investments made in infrastructure-whether new build or expansion projects.

Seamless, scalable, and smart expansion of an airport. The aviation domain is fast, with infrastructural development matching that pace in totality without compromising the ongoing operations.

The ecopeb prefab makes seamless integration with existing airport facilities possible, offering maximum flexibility in their design and layout. Each component is carefully built in advanced production facilities and delivered to the site for fast assembly that minimizes downtime and maximizes convenience.

Thus, flexible designs allow these structures to be easily integrated with existing airport architecture to enable scalable and efficient expansion plans.

ecopeb: Crafting the Future of Airports.

Thus, modular PEB constructions will be rolling out the whole new dimension in the airport infrastructure sustainably, efficiently, and cost-effectively.

And one such company, which is something that has come out as one of the key players in the transformation leading manufacturer of pre-engineered buildings in India, is ecopeb—has just delivered a high-performance, durable, and energy-efficient prefabricated solution that sets the benchmarks in airport developmental endeavors.

It is going to pave the way for the next generation of airport infrastructure, not just improving operational continuity but also adding to better experiences for the traveling passengers and visitors, as well as service personnel.

Source: https://ekonty.com/blogs/207440/Accelerating-Airport-Infrastructure-Development-with-PEB-Construction-Solutions

#Pre Engineered Buildings#PreFabricated Buildings Manufacturer#PEB Solution#Prefab Buildings#Steel construction Company In India

0 notes

Text

PEB Designing Software: Streamlining PEB construction Process

The pre-engineered building industry has grown over the years by employing cutting-edge technology to increase efficiency and precision. One of the key advancements in this transformation is the use of advanced PEB software. These tools help in streamlining the project construction; from design to final stages, they ensure precision, accuracy, and full client satisfaction.

What role does this software play in Designing

In the pre-engineered building sector, PEB design software automates and optimizes structural design and, therefore, remains a critical part. These tools are used by engineers and architects to create precise 3D models, analyze structural capacity, and produce comprehensive fabrication drawings. In this way, the software assists in minimizing errors, reducing material wastage, and improving coordination among various stakeholders involved in the project.

Key Features of PEB Design Software

Structural engineering software is important because it is capable of ascertaining the load's strength and force capacities and finding the wind resistance, thus shaking issues of the building.

Fabricating drawings and reports contributes to getting off with concise information and clear details, therefore leaving no room for ambiguity in components that are to be built.

Integration with BIM allows an open-source platform for bringing others into the building design process beyond the local community.

Material Optimization: Reduces excess material usage, leading to cost savings and sustainable construction practices.

Fabrication Drawings & Reports: Generates precise manufacturing details for seamless assembly and construction.

Integration with BIM (Building Information Modeling): Enhances collaboration by allowing different stakeholders to work on a unified platform.

Advantages of PEB Design Software

1. Enhanced Accuracy and Efficiency

Conventional procedures for designing pre-engineered buildings are purely manual and take an extensive amount of time, leading to potential human errors. PEB design software automates these processes to guarantee correct calculations and substantially minimize rework.

2. Cost Reduction

By optimizing material usage and reducing errors, companies can save on raw materials and labor. Better cost estimation and budget planning lead to fewer unexpected costs.

3. Speedier Project Completion

Automation and smooth coordination improve speed on a PEB project. Engineers can make real-time changes in the shop drawing generation while expediting the approval process.

4. Better Collaboration

There are visualizations centered around cloud and BIM, enabling engineers, architects, project managers, and the like to work together. This eliminates communication gaps and fosters project transparency.

5. Sustainable Construction and Waste Minimization

PEB design software promotes the course of sustainable construction through the best optimization of material use with minimal waste through accurate planning with little-to-no environmental impact.

PEB Design Software Used Too Much in the Industry

Taking into account the above-linked PEB design software, it helps the manufacturers in every possible way to optimize their respective projects. Amongst those, the most commonly used are

STAAD.Pro—A very powerful analysis and design software.

Tekla Structures—For highly detailed 3D modeling and fabrication drawings.

AutoCAD—For drafting, modeling, and BIM integration

Conclusion:

The use of PEB design software has transformed the pre-engineered building industry in terms of accuracy, cost reduction, and timely project delivery. We continue to see ongoing advancements in these technology applications, which are expected to enhance the efficiency and sustainability of PEB construction. Companies that adopt advanced design software processes have a better capacity to deliver high-quality, cost-effective, and innovative building solutions.

ecopeb is adapted to the latest design software to provide its clients with world-class PEB solutions. Our commitment to technology-driven innovation guarantees high precision and timely execution of every project.

So, contact us today and realize how we could fast-track your next PEB project!

ALSO READ: https://ecopeb.com/2025/03/22/components-of-pre-engineered-warehouse/

#pre engineered structure manufacturer#pre engineered building#peb building#peb manufacturer#peb construction#peb structures

0 notes

Text

From Concept to Completion: A Case Study of ecopeb Successful Projects

How ecopeb excellent execution brought the client’s vision into reality

In today’s world, pre-engineered buildings are the first choice for industries because of their quick design setup, durability, and cost projection. and ecopeb is fulfilling these demands.

ecopeb is the leading manufacturer and supplier of peb buildings, with a mission to be swift, robust, and innovative. It has established a domain in this field with its excellent projects all over India.

ecopeb has undertaken the construction of many factory sheds, a warehouse of 10,4050 sq. ft. in Pune (Rajasthan), and a cold storage building in Srinagar (J&K) measuring 57000 sq. ft.

ecopeb has also worked on a government project by ALMICO for building a manufacturing unit of 203666 sq. ft. in Kanpur (UP).

In this project, ecopeb utilized a wide range of high-quality components and advanced software to timely deliver the pre-engineered building to the client.

The primary goals for the project were timely delivery, efficient execution, and structural integrity. However, the main challenge faced was to withstand the environmental conditions and mountain terrain.

It becomes more difficult when the erected structure collapses due to storms, which results in delays and increased workload on the workforce.

#pre engineered structure manufacturer#peb solution#peb warehouse#pre engineered building#peb building

1 note

·

View note

Text

Check out the new article now

ALSO READ: https://ecopeb.com/2025/02/04/pre-engineered-buildings-in-haryana/

0 notes

Text

2 notes

·

View notes

Text

Why more companies are choosing pre-engineered buildings for office space

The world is growing at a fast pace. In the meantime, we have to be parallel to it. The construction industry is also growing, with increasing competition from each other.

As demand for cost-effective, sustainable solutions is increasing, companies that want easy and fast office buildings are opting for PEB solutions because of the advantages they offer over conventional ones.

This article will explore some reasons why more and more companies are opting for pre-engineered office buildings.

Fast construction: PEB structures are manufactured off-site, which reduces the construction time. Once the construction is done, they are transferred on-site and quickly assembled, allowing businesses to move into their space much sooner.

Standardization with needs: Although pre-engineered buildings are standardized., they can be customized in terms of size, design, and layout according to the company's needs.

Translocation is easy: PEBs are expandable. As the company expands or moves to a new location, pre-engineered buildings can easily be dismantled and assembled again without any hassle. This is an important advantage for people looking for expansion in the near future.

Site is better utilized: Pre-engineered buildings are tailored and fit into exact dimensions, ensuring land is used efficiently and maximizing space utilization.

Improved Safety and Compliance: Prefab structures are made according to local rules, keeping guidelines in mind. This ensures structures meet safety requirements, reducing compliance issues in the future.

Reduced Overhead Cost: Pre-engineered buildings require an initial cost investment; in return, they have very little operational expenses compared to traditional ones.

The growing popularity of PEB is not just a trend, but it is a practical and forward-thinking choice for businesses balancing innovation, sustainability, and cost-effectiveness in mind.

ecopeb has been manufacturing pre-engineered office buildings for the last 10 years, providing customized innovative solutions to businesses.

If you have any requirements, feel free to contact us or quote us.

0 notes

Text

H Beams for better strength and durability.

0 notes

Text

Pre-Engineered Buildings | Reliable & Cost-Effective Solutions by ecopeb

E𝐱𝐩𝐞𝐫𝐢𝐞𝐧𝐜𝐞 𝐦𝐞𝐞𝐭𝐬 𝐩𝐞𝐫𝐟𝐞𝐜𝐭𝐢𝐨𝐧 𝐰𝐢𝐭𝐡 𝐞𝐜𝐨𝐩𝐞𝐛! 🌟 We proudly delivered Supply + Erection services for Carya Chemicals & Fertilizers Pvt. Ltd. in Baran, Kota (RJ), spanning 𝟏𝟏,𝟏𝟐𝟏 𝐒𝐪. 𝐅𝐭.. 🏗️ From design to execution, we've set the benchmark for excellence in 𝐏𝐫𝐞-𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐞𝐝 𝐁𝐮𝐢𝐥𝐝𝐢𝐧𝐠𝐬.

0 notes

Text

PEB Building Manufacturer in Kolkata: Revolutionizing the Construction Industry

Pre-engineered buildings (PEBs) have significantly changed the landscape of the construction industry, offering a cost-effective, versatile, and time-saving alternative to traditional construction methods. In Kolkata, a city known for its rich heritage and modern architectural marvels, the demand for PEB buildings has been steadily growing. This growth is largely attributed to the increasing need for commercial, industrial, and residential structures that are durable, cost-effective, and constructed within short timelines. In this context, PEB building manufacturers in Kolkata have emerged as key players in providing innovative solutions to meet these requirements. This blog will explore the role of PEB building manufacturers in Kolkata, their advantages, and why they are becoming the preferred choice for modern construction projects.

What Are Pre-Engineered Buildings (PEB)?

Pre-Engineered Buildings are a modern construction solution that uses a structural framework made from steel, designed and fabricated in a factory. The components are pre-designed based on the specific requirements of a project and then transported to the construction site for assembly. This method not only reduces construction time but also ensures precision, durability, and cost savings. PEBs can be customized for a variety of applications, such as warehouses, factories, office spaces, retail centers, and more.

Growing Demand for PEB Buildings in Kolkata

Kolkata, being an industrial hub and a major metropolitan city in India, has witnessed a growing need for flexible construction solutions. The rapid pace of industrialization, urban development, and infrastructural expansion has created a demand for construction methods that are both efficient and sustainable. This is where PEB building manufacturers come into play, offering solutions that cater to these evolving needs.

Businesses in sectors like logistics, manufacturing, and retail are increasingly opting for PEB structures due to their ability to provide large, column-free spaces ideal for warehouses, storage facilities, and industrial units. Additionally, commercial enterprises in Kolkata are also choosing PEBs for office spaces and showrooms due to their quick installation and aesthetic appeal.

Advantages of Choosing PEB Structures

PEB structures offer a host of advantages, making them an attractive option for various construction needs. Some of the key benefits include:

1. Cost-Effectiveness

PEB buildings are typically 20-30% more economical than conventional construction methods. This is due to the efficient use of materials, reduced wastage, and lower labor costs. The pre-fabrication process ensures that the required materials are optimally used, reducing the overall project cost.

2. Time-Saving

One of the most significant advantages of PEBs is their speed of construction. As the components are fabricated off-site and then assembled on-site, the construction time can be reduced by up to 50% compared to traditional methods. This is particularly beneficial for businesses that need to set up operations quickly.

3. Customization and Flexibility

PEBs offer a high degree of customization, allowing building designs to be tailored according to the specific needs of the client. From choosing the building dimensions to selecting insulation and cladding materials, every aspect can be customized. This flexibility makes PEBs suitable for a wide range of applications.

4. Durability and Low Maintenance

PEB structures are known for their strength and durability, as they are made using high-quality steel. This makes them resistant to environmental factors like moisture, pests, and corrosion. Additionally, they require minimal maintenance, leading to long-term cost savings.

5. Sustainability

PEBs are environmentally friendly as they use recyclable materials like steel and produce minimal construction waste. Moreover, they can be designed to incorporate energy-efficient features such as insulation, natural lighting, and ventilation systems, which can help reduce the overall energy consumption of the building.

Leading PEB Building Manufacturers in Kolkata

Several PEB building manufacturers in Kolkata have established a strong reputation for delivering high-quality structures tailored to meet the diverse needs of the market. These manufacturers offer end-to-end solutions, from design and engineering to fabrication and installation, ensuring a seamless construction experience. Here are some of the key aspects that set the leading PEB manufacturers apart:

1. In-House Design Capabilities

Top PEB manufacturers have in-house design teams that use advanced software to create detailed building plans. This ensures that the structures are designed with precision, adhering to industry standards and client requirements.

2. State-of-the-Art Manufacturing Facilities

These manufacturers operate state-of-the-art facilities equipped with modern machinery for fabricating PEB components. The use of advanced technology allows for faster production cycles and ensures the highest standards of quality control.

3. Experienced Installation Teams

The assembly of PEB structures requires skilled labor, and leading manufacturers in Kolkata have experienced installation teams that ensure the structure is erected quickly and safely. Their expertise helps in minimizing on-site errors and ensuring that the project is completed within the stipulated time frame.

4. After-Sales Support

Reliable PEB manufacturers offer comprehensive after-sales support, including maintenance and repair services. This ensures that clients receive ongoing support for any issues that may arise, adding to the long-term value of their investment.

Why Choose PEB Buildings in Kolkata?

Opting for PEB buildings in Kolkata makes sense for a range of construction projects due to the city’s unique climatic conditions and space constraints. The lightweight nature of PEB structures makes them ideal for regions with high seismic activity, while their durability ensures they can withstand Kolkata’s heavy monsoon rains. Moreover, with urban land becoming increasingly expensive, the ability of PEBs to maximize usable space through large, open interiors is an added advantage for businesses and industrial units looking to optimize their investments.

Conclusion

PEB building manufacturers in Kolkata are at the forefront of the city's construction industry, offering a modern solution that aligns with the demands of speed, efficiency, and sustainability. Whether it's for industrial warehouses, commercial spaces, or even residential buildings, the versatility and advantages of PEB structures make them an ideal choice for many. As the city continues to grow and modernize, the role of PEB manufacturers will only become more significant, helping to shape Kolkata’s skyline with structures that are built to last. Choosing a reliable PEB manufacturer can make all the difference in ensuring that your construction project is completed on time, within budget, and to the highest standards of quality.

0 notes

Text

PEB Manufacturer Limited Companies in Pune: A Comprehensive Overview

Pune, often referred to as the "Oxford of the East," is known for its rich cultural heritage, educational institutions, and flourishing industrial base. The city has become a significant hub for various industries, including automotive, IT, and manufacturing. Among these, the Pre-Engineered Buildings (PEB) sector has seen remarkable growth, with Pune being home to some of the leading PEB manufacturer limited companies in India. This article explores the factors contributing to Pune’s prominence in the PEB industry, the role of PEB in modern construction, and a few notable PEB manufacturers based in Pune.

Understanding the PEB Industry

Pre-engineered buildings (PEB) involve constructing buildings by designing components at a factory and assembling them on-site. This construction approach has gained popularity due to its speed, cost-effectiveness, and durability. PEB structures are used in warehouses, factories, offices, and various industrial and commercial buildings. Unlike conventional construction methods, PEB offers a faster timeline, reduced wastage, and better structural integrity.

With the growing demand for infrastructure and industrialization, the need for quick and efficient construction solutions has driven the demand for PEB structures. Pune, with its strategic location, proximity to ports, skilled workforce, and supportive industrial policies, has emerged as a preferred location for PEB manufacturers to set up their operations.

Why Pune is a Hub for PEB Manufacturers

Several factors make Pune a strategic location for PEB manufacturer limited companies:

1. Proximity to Industrial Areas: Pune is located close to major industrial zones like Pimpri-Chinchwad, Chakan, Talegaon, and Ranjangaon. These areas host numerous automotive, engineering, and manufacturing companies that often require PEB structures for warehouses, workshops, and production facilities.

2. Skilled Workforce: The presence of renowned engineering and technical institutes in Pune ensures a steady supply of skilled professionals in the fields of civil engineering, architecture, and project management. This workforce is crucial for PEB companies that require expertise in structural design and fabrication.

3. Connectivity and Infrastructure: Pune's well-connected road, rail, and air transport systems facilitate the easy movement of raw materials and finished PEB components. The city's proximity to Mumbai, India's financial capital, also enhances trade opportunities, making it an attractive destination for manufacturing companies.

4. Supportive Government Policies: Maharashtra's government has implemented industry-friendly policies, such as the "Make in Maharashtra" initiative, which encourages manufacturing activities. These policies have attracted investments in various sectors, including the PEB industry.

Key Players in the PEB Industry in Pune

Pune hosts several well-established PEB manufacturers that have made a mark in the industry. Below are some of the notable PEB manufacturer limited companies in the region:

1. Kirby Building Systems India Ltd.

- Overview: A subsidiary of Kirby Building Systems, one of the pioneers of PEB in India. Kirby Building Systems India Ltd. has been operating in Pune for several years, offering turnkey solutions for PEB structures.

- Key Offerings: Kirby specializes in designing, manufacturing, and erecting pre-engineered buildings for industrial, commercial, and institutional applications. They provide a complete range of PEB products, including warehouses, factory sheds, and multi-story buildings.

- USP: Known for its global standards in quality and innovation, Kirby has established a strong reputation in Pune's market.

2. Zamil Steel Buildings India Pvt. Ltd.

- Overview: A prominent player in the PEB industry, Zamil Steel is an international brand with a significant presence in India, including Pune. They are known for their extensive experience in designing and manufacturing steel structures.

- Key Offerings: Zamil Steel provides customized PEB solutions, including industrial structures, commercial complexes, and cold storage units. Their solutions are known for durability and compliance with international standards.

- USP: Zamil Steel's focus on customer-specific requirements and their capability to deliver complex projects has made them a preferred choice among clients in Pune.

3. Interarch Building Products Pvt. Ltd.

- Overview: Interarch is a leading Indian PEB manufacturer with a strong foothold in Pune. The company has been involved in several prestigious projects across India, contributing to its growth in the PEB segment.

- Key Offerings: Interarch provides complete turnkey solutions, from design and fabrication to installation. Their product range includes heavy industrial buildings, large-span structures, and airport terminals.

- USP: Interarch’s expertise in delivering large-scale projects with precision and their commitment to innovation have earned them a reputable position in Pune's PEB market.

4. Tata BlueScope Steel Ltd.

- Overview: Tata BlueScope Steel, a joint venture between Tata Steel and BlueScope Steel, is a major player in the PEB industry in Pune. The company is known for its high-quality steel products and sustainable building solutions.

- Key Offerings: They provide a wide range of PEB solutions, including roofing, cladding, and structural systems, catering to industrial, commercial, and institutional needs.

- USP: Tata BlueScope Steel emphasizes sustainable practices and energy-efficient solutions, aligning with the growing demand for eco-friendly construction methods.

The Future of PEB Industry in Pune

The PEB industry in Pune is poised for significant growth, driven by the expansion of the manufacturing sector and the increasing demand for faster construction solutions. With advancements in design software and manufacturing techniques, PEB manufacturers are now able to deliver highly customized and complex structures, meeting the diverse needs of clients.

The demand for industrial and logistics spaces is also on the rise due to the growth of e-commerce and the implementation of the GST regime, which has led to the consolidation of warehousing. PEB structures are ideally suited for large-scale warehouses and distribution centers, making them a preferred choice for logistics companies.

Conclusion

Pune's strategic advantages, such as its industrial ecosystem, skilled workforce, and infrastructure, have made it a thriving hub for PEB manufacturer limited companies. With leading players like Kirby Building Systems, Zamil Steel, Interarch, and Tata BlueScope Steel operating in the city, Pune has established itself as a key player in the PEB sector in India. As industries continue to evolve and demand efficient construction solutions, the role of PEB manufacturers in Pune is likely to grow, contributing to the city’s economic progress and shaping the future of construction in India.

0 notes