EPACK PEB is a global leader of Pre-Engineered Buildings, Prefabricated Structures, Industrial Sheds & Sports Buildings. We keep enhancing our products in the terms of quality.

Don't wanna be here? Send us removal request.

Text

What You Need to Know About Industrial Building Construction

Buildings for industrial use are among the most important contributions of the commercial building industry. These buildings are a very important part of economic activity, where factories, warehouses, and production plants can freely produce and distribute goods. We at EPACK Prefab know how industrial building construction can be complex and that the best approach is needed to make your project a successful one.

Below, we discuss the major factors of industrial building construction and how EPACK Prefab delivers top-quality solutions for your industrial projects.

Types of Industrial Buildings

An industrial building is a kind of commercial property designed for production, manufacturing, storage, or distribution purposes. These structures form the backbone of industrial operations, housing the equipment, machinery, and storage required for large-scale production. Industrial buildings include warehouses, factories, research centers, and specialized facilities such as cold storage and telecom centers.

EPACK Prefab’s Expertise in Industrial Building Construction

Our expertise in industrial building construction enables EPACK Prefab to deliver structures that meet the needs of modern industries. Whether it’s for manufacturing, storage, or research, we can provide a facility tailored to your operations.

Common Types of Industrial Buildings

Various industrial buildings serve specific sectors. Below are some popular types: 1. Distribution Centers and Warehouses: These buildings are primarily used for the storage and distribution of goods. Featuring high ceilings and large spaces, they include tall racking systems and loading docks for transportation vehicles. EPACK Prefab specializes in constructing durable warehouses that optimize storage capacity. 2. Manufacturing Facilities: Heavy industrial buildings contain capital-intensive equipment necessary for production processes. These facilities require specialized power supplies, ventilation, and exhaust systems. EPACK Prefab ensures all safety and operational standards are met during construction. 3. Light Manufacturing Facilities: Light manufacturing buildings are less equipment-intensive and cater to industries such as electronics, textiles, and furniture manufacturing. EPACK Prefab offers flexible construction solutions that are cost-effective and energy-efficient for these operations. 4. Cold Storage Facilities: Cold storage buildings are critical for industries dealing with perishable goods. EPACK Prefab designs energy-efficient cold storage solutions that maintain the necessary temperature, ensuring your products remain in top condition. 5. Telecom and Data Centers: These facilities house data servers and equipment essential for telecommunications and IT companies. EPACK Prefab designs telecom spaces and data centers with high-security measures, proper ventilation, and energy-efficient systems.

Industrial Building Trends:

The industrial construction landscape is always evolving. Below are some key trends shaping the industry: Increased Demand for Warehouses: The rise of e-commerce has driven the need for larger warehouses. EPACK Prefab designs and builds warehouses that cater to the growing logistics industry, offering optimized storage solutions that improve operational efficiency. Growth in Cold Storage Solutions: With rising demand in the food and pharmaceutical sectors, there’s an increasing need for cold storage facilities. EPACK Prefab constructs state-of-the-art cold storage buildings to meet these growing requirements. Multistory Warehouses: In cities with limited land availability, multistory warehouses are becoming more popular. EPACK Prefab provides innovative multistory warehouse designs that maximize space while minimizing costs.

The Industrial Building Construction Process

The construction of an industrial building is a complex process involving multiple stages. Here’s an overview of the key stages: 1. Planning: Planning is the most crucial stage in industrial building construction. EPACK Prefab collaborates closely with clients to understand their requirements, assess the site, and create a project plan that outlines timelines, budgets, and material specifications. 2. Design: Industrial building design requires specialized expertise to accommodate heavy equipment, airflow requirements, and safety protocols. EPACK Prefab ensures every facility’s design adheres to regulatory standards and meets the client's operational needs. 3. Pre-Construction: Pre-construction involves securing permits, site preparation, and sourcing materials. EPACK Prefab manages the entire process, ensuring that everything is ready before construction begins. 4. Construction: During the construction phase, the building components are assembled, and all systems such as HVAC, plumbing, and electrical are installed correctly. EPACK Prefab focuses on safety and efficiency, completing projects on time and within budget. 5. Post-Construction: After construction is complete, the facility undergoes thorough inspections to ensure all systems function as intended. EPACK Prefab offers post-construction support to resolve any issues and ensure the building meets the client’s needs.

Why Choose EPACK Prefab for Industrial Building Construction?

EPACK Prefab has a proven track record of delivering high-quality industrial buildings that meet the needs of modern businesses. With a team of experienced engineers and architects, EPACK Prefab ensures each project is completed with precision and efficiency. Whether you need a manufacturing plant, warehouse, or cold storage facility, EPACK Prefab offers cost-effective, durable, and functional solutions. Backed by years of experience in industrial building construction, EPACK Prefab is committed to helping businesses succeed by providing reliable, energy-efficient, and customized building solutions. Contact us today to learn how we can assist with your industrial building project.

Read More: How Important is it to Assess the Long-term Benefits of Prefabricated Steel Buildings?

#IndustrialBuilding#IndustrialConstruction#WarehouseConstruction#ManufacturingFacilities#ColdStorageSolutions#PrefabConstruction#EPACKPrefab#IndustrialShed#CommercialConstruction#TelecomCenters#DataCenters#FactoryBuildings#IndustrialBuildingDesign#IndustrialBuildingSolutions#MultistoryWarehouses#PrefabBuildings#IndustrialWarehouse#ColdStorageFacility#ConstructionTrends#IndustrialArchitecture#BuildingSolutions

1 note

·

View note

Text

How to Take Care of Your Pre Engineered Steel Building Systems During the Monsoon Season?

With monsoon season comes relief from the head. However, it also comes up with its own set of problems for architecture and infrastructure. For businesses, this becomes even bigger headache.

For them, the best solution in modern times is pre engineered steel building systems, that can help them keep their operations up and running despite heavy rains. These are long-term solutions that have a lot of durability.

In this blog, we’ll discuss some ways how businesses, who have already invested in these modern structures can extend the lifespan of their buildings with basic care during winters.

Without waiting any more, let’s begin!

#1 Regular Inspections and Maintenance

One major step in protecting pre engineered building systems for long-term usage is conducting regular inspections during monsoon.

Check for signs like rust, corrosion, and damages that lead to water seepage. Even if there is a minor damage, don’t let it get unchecked, because it may convert into a bigger deal which will be difficult to handle later, or may invite a bigger cost.

Check for joints, seams, and bolts to find out if there is any wear and tear. Checking them can help prevent any accessive damage to pre engineered steel building systems later. With basic checks during rain, your investment will stay in top shape during the rainy season.

#2 Clean the Roof and Gutters

The roof is the most exposed part of any building during the monsoon.

Keeping it clean and free from debris, such as leaves, dirt, and other materials, is essential to prevent blockages that can cause water to accumulate. Pre Engineered Building Systems often come with gutters and downspouts to facilitate water drainage. Ensure these are clear of any obstructions to allow the free flow of rainwater.

Blocked gutters can lead to waterlogging, which can affect the overall structural integrity of the building. If your PEB structure is yet to set up, contact your pre engineered metal building manufacturers to make room for easy inspection of gutters in the structure.

#3 Seal Any Gaps and Leaks

During the monsoon, even the smallest gaps or leaks can lead to water intrusion, which might damage the structure over time. Check for any signs of gaps around windows, doors, or other openings.

Applying a sealant to these areas can help keep water out and protect your Pre Engineered Steel Building Systems from potential damage. Also, ensure that any insulation materials are properly sealed and in good condition, as moisture buildup can reduce their effectiveness and lead to mold growth.

If you are looking for pre engineered metal building manufacturers that can help you with making structures that are easy to inspect EPACK Prefab can help you with that. They are a pre engineered metal building systems provider that ensure durability and longevity in their structures. For more information, check out their website.

Also Read: PEB Office Monsoon Checklist: How To Keep Your Workspace Rain Ready?

#PEBMaintenance#MonsoonCare#SteelBuildings#DurableConstruction#BuildingSafety#RainReady#EPACKPrefab#InfrastructureProtection#StructuralIntegrity#MetalBuildings

1 note

·

View note

Text

Looking for the best PUF panels in Uttar Pradesh? EPACK Prefab stands out as the top manufacturer and supplier, delivering quality and reliability in every project. Perfect for insulation and durability, our panels are trusted across industries.

#PrefabSolutions#BuildingInnovation#PUFPanelExperts#SustainableConstruction#UttarPradeshManufacturing#QualityEngineering#ConstructionExcellence#InsulationInnovation#IndustrialBuilding#EPACKPrefab

0 notes

Text

Top Advantages of Pre Engineered Buildings

Pre-engineered steel buildings (PEBs) are a modern construction solution designed to suit a variety of needs. They're made of metal beams connected together to form a customizable framework, perfectly tailored to your specific project.

This flexibility makes PEBs a popular choice across various industries, from factories to schools. Besides, it can also serve bigger complex projects, such as metro stations and airport terminals.

How Can PEBs Benefit You?

If you're curious about pre-engineered steel buildings, you might be wondering how they can specifically benefit your business or community.

Let's dive in and learn why they are getting popular as infrastructure choice.

Key Advantages of PEBs:

Time Efficiency: Traditional construction can take a long time, sometimes even over a year. PEBs, on the other hand, are built much faster. Their pre-fabricated parts are simply assembled on-site, significantly speeding up construction.

Cost-Effectiveness: Time is money in business. With PEBs, you can get your operations up and running much sooner, giving you a competitive advantage. Plus, their aesthetic appeal and easy assembly make them a great option for building multiple structures in a complex.

Low Maintenance: Thanks to modern technology, PEBs are incredibly durable and require very little maintenance over time. They're designed to resist rust and corrosion, and can even be repainted to keep up with changing styles.

Design Flexibility: PEBs offer a wide range of design possibilities, both in terms of function and appearance. You can easily customize them to fit your specific needs. And as your business grows or changes, PEBs can be extended or modified, making them a smart long-term investment.

These advantages highlight why pre-engineered steel buildings are a superior construction choice compared to traditional methods.

You can consult with EPACK Prefab who designs amazing Pre Engineered Steel Buildings, as they have experienced team of architects and designers that leverage the latest technology to deliver top-quality PEB projects.

#PreEngineeredBuildings#PEB#SteelBuildings#ModernConstruction#IndustrialArchitecture#SustainableConstruction#BuildingInnovation#PrefabConstruction#EfficientBuilding#SmartConstruction#EPACKPrefab#StructuralEngineering#GreenBuilding#ConstructionTech#DesignFlexibility#ArchitecturalDesign#SteelStructures#BuildingSolutions#CostEffectiveConstruction#LowMaintenance

0 notes

Text

Top PEB Manufacturer in Bihar for Tailored Industrial Solutions

Looking for a trusted PEB manufacturer in Bihar? EPACK Prefab is your go-to choice for top-quality pre-engineered buildings tailored to your specific needs. From industrial sheds to warehouses and more, we provide durable and efficient solutions that are perfect for the diverse requirements of Bihar's industrial landscape. Partner with us for your next project and benefit from our expertise and commitment to excellence.

#PEBBihar#EPACKPrefab#IndustrialSheds#PrefabBuildings#BiharConstruction#PEBConstruction#PreEngineeredBuildings

0 notes

Text

The Cost of Building an Industrial Shed with Prefabricated Solutions: A Detailed Overview

In the ever-evolving landscape of industrial construction, prefabricated solutions are gaining significant traction. The question on many business owners' minds is, "How much does it cost to build an industrial shed using these modern methods?

In this blog, we will explore the cost factors associated with prefabricated industrial sheds, while highlighting the advantages they offer over traditional construction methods. Our aim is to provide a comprehensive understanding for employees responsible for booking orders, business owners, business heads, and industry heads involved in commercial projects.

The Rise of Prefabricated Industrial Sheds

Prefabricated industrial sheds are constructed using components manufactured off-site and assembled on-site. This approach has revolutionized the construction industry by offering faster, more efficient, and cost-effective solutions compared to traditional methods. Prefabricated sheds are particularly popular in sectors such as warehouses, factory buildings, cold storage buildings, and more.

Cost Factors of Prefabricated Industrial Sheds

Several factors influence the cost of building an industrial shed using prefabricated solutions. Understanding these factors can help businesses make informed decisions.

Material Costs:

Steel: Steel is the primary material used in prefabricated sheds due to its strength and durability. The cost of steel can vary based on market conditions and the quality required.

Insulation and Panels: Depending on the intended use of the shed, insulation materials and panels such as PUF, EPS, or rock wool may be needed, impacting the overall cost.

Design and Customization:

Complexity: Simple designs are more cost-effective, while complex, customized structures can increase costs.

Size: Larger sheds require more materials and labor, thereby increasing the cost.

Labor and Installation:

Prefabrication Process: Prefabricated components reduce on-site labor costs as they are quicker to assemble.

Skilled Labor: Hiring skilled labor for the installation can impact the overall expense but ensures quality construction.

Transportation and Logistics:

Distance: Transporting prefabricated components to the construction site can add to the cost, especially for remote locations.

Handling: Proper handling and storage of materials during transit are essential to avoid damage and additional costs.

Site Preparation:

Groundwork: Preparing the site, including leveling the ground and laying foundations, is a crucial step that affects the total cost.

Utilities: Installing necessary utilities like water, electricity, and sewage systems also adds to the expenses.

Advantages of Prefabricated Industrial Sheds

Cost-Effectiveness: Prefabricated sheds are generally more affordable than traditional construction methods due to reduced labor and faster assembly times.

Time Efficiency: The prefabrication process significantly cuts down the construction time, allowing businesses to start operations sooner.

Quality Control: Prefabricated components are manufactured in controlled environments, ensuring consistent quality and reducing the likelihood of defects.

Flexibility: These structures offer flexibility in design and can be easily expanded or modified as business needs evolve.

Sustainability: Prefabricated construction generates less waste and can incorporate sustainable materials, contributing to environmental conservation efforts.

India-Relevant Data Points and Statistics

Market Growth: The prefabricated buildings market in India is expected to grow at a CAGR of 8.65% from 2020 to 2027, driven by increasing industrialization and urbanization.

Cost Savings: Studies have shown that prefabricated construction can reduce overall project costs by up to 20% compared to traditional methods.

Time Reduction: Prefabricated construction can reduce project timelines by 30-50%, a significant advantage in a fast-paced industrial environment.

Conclusion

Prefabricated industrial sheds offer a modern, efficient, and cost-effective solution for various commercial applications. From warehouses and factory buildings to cold storage facilities and more, these structures meet the diverse needs of industrial sectors. As a leading prefabricated factory shed manufacturer, EPACK Prefab is committed to delivering high-quality, customized solutions that align with your business requirements.

At EPACK Prefab, we specialize in end-to-end solutions for prefabricated buildings and pre-engineered buildings. Our expertise extends across numerous sectors, including industrial sheds, factory buildings, cold storage buildings, and more. For more information on how we can assist with your industrial shed construction needs, please contact us:

EPACK Prefab

Website: www.epackpeb.com

Email: [email protected]

Phone: +91 9818660896

By choosing prefabricated solutions, you are not only opting for efficiency and cost savings but also contributing to a more sustainable future. Let EPACK Prefab be your partner in building the industrial infrastructure of tomorrow.

Read More: Why Indian Businesses Should Switch to PEB Industrial Sheds?

#PrefabricatedSolutions#IndustrialSheds#PrefabConstruction#FactoryShed#IndustrialBuilding#ConstructionCost#PrefabSheds#SteelSheds#EPACKPrefab#IndustrialConstruction#WarehouseConstruction#CommercialProjects#PrefabTechnology#CostEffectiveConstruction#SustainableBuilding#IndiaIndustrial#ConstructionIndustry#PrefabricatedBuildings#PEB#PEBManufacturer#IndustrialShedExperts

0 notes

Text

What Are the Benefits of Pre-Engineered Metal Buildings?

Pre-engineered metal buildings (PEMBs) have gained popularity in the construction industry due to their numerous advantages. These buildings are designed and fabricated in a factory-controlled environment and then assembled on-site, offering a range of benefits that make them a preferred choice for many commercial projects.

Here, we explore the key benefits of pre-engineered metal buildings.

1. Cost-Effectiveness

One of the most significant benefits of pre-engineered metal buildings is their cost-effectiveness. The streamlined design and fabrication process minimize material waste and reduce labor costs. Additionally, the shorter construction timeline compared to traditional building methods results in lower overall project costs.

2. Speed of Construction

Pre-engineered metal buildings are known for their quick assembly times. Since components are fabricated off-site and delivered ready for installation, the on-site construction process is significantly faster. This rapid construction reduces labor costs and allows businesses to start operations sooner, leading to quicker returns on investment.

3. Design Flexibility

PEMBs offer a high degree of design flexibility. They can be customized to meet specific requirements, including size, shape, and layout. This flexibility makes them suitable for a wide range of applications, from warehouses and industrial facilities to commercial buildings and recreational centers. The modular nature of these buildings also allows for easy future expansions.

4. Durability and Low Maintenance

Pre-engineered metal buildings are constructed using high-quality materials that offer excellent durability and resistance to environmental factors. The use of galvanized steel ensures that these buildings can withstand harsh weather conditions, reducing the need for frequent repairs and maintenance. This durability translates into long-term cost savings and a lower total cost of ownership.

5. Energy Efficiency

Many pre-engineered metal buildings are designed with energy efficiency in mind. Insulated panels, reflective roofing materials, and advanced ventilation systems help maintain optimal indoor temperatures, reducing the need for excessive heating and cooling. This energy efficiency leads to lower utility bills and a reduced environmental footprint.

6. Sustainability

PEMBs are an environmentally friendly construction option. The efficient use of materials and the reduction of on-site waste contribute to a lower environmental impact. Additionally, many metal building components are recyclable, further enhancing their sustainability credentials. By choosing pre-engineered metal buildings, businesses can support green building practices and reduce their carbon footprint.

7. Versatility

The versatility of pre-engineered metal buildings makes them suitable for various industries and applications. Whether you need a warehouse, an office building, a retail space, or a recreational facility, PEMBs can be designed to meet your specific needs. Their adaptability and scalability ensure that they can grow with your business, providing a long-term solution for your space requirements.

Conclusion

Pre-engineered metal buildings offer a myriad of benefits that make them an ideal choice for many commercial projects. From cost-effectiveness and speed of construction to design flexibility, durability, energy efficiency, sustainability, and versatility, PEMBs provide a reliable and efficient solution for modern construction needs.

At EPACK Prefab, we specialize in delivering high-quality pre-engineered metal building solutions tailored to meet your specific requirements. Our expertise and comprehensive services ensure that your project is completed efficiently and cost-effectively. For more information on how we can assist with your pre-engineered metal building needs, please visit our website or contact us directly.

By understanding the benefits of pre-engineered metal buildings, you can make informed decisions that will benefit your organization and contribute to the success of your projects.

Also Read: Pre-Engineered Steel Building Systems vs. Conventional Buildings

#PEMB#PreEngineeredBuildings#MetalBuildings#CostEffectiveConstruction#ConstructionEfficiency#SustainableBuilding#EnergyEfficientBuildings#CommercialConstruction#ModularBuildings#EPACKPrefab

0 notes

Text

How Pre-Engineered Buildings Impact Your Costs

In the ever-evolving world of construction, pre-engineered buildings (PEBs) have emerged as a game-changer. Their popularity is skyrocketing, particularly in commercial and industrial sectors, due to their cost-efficiency and versatility. But how exactly do pre-engineered buildings impact your costs? Let's dive into the details and explore the financial benefits that PEBs bring to the table.

What Are Pre-Engineered Buildings?

Pre-engineered buildings are structures designed and manufactured in a factory, with all components fabricated to precise specifications. These components are then transported to the construction site for assembly. This method contrasts sharply with traditional construction, where most of the building process happens on-site. The pre-engineered approach offers numerous advantages, particularly when it comes to cost savings.

1. Reduced Material Costs

One of the primary ways PEBs impact your costs is through reduced material expenses. Since components are manufactured in a controlled factory environment, there is less waste compared to on-site construction. The precise engineering involved in PEBs ensures that only the necessary amount of material is used, which cuts down on excess and reduces overall costs.

2. Lower Labor Costs

Labor is one of the most significant expenses in any construction project. Traditional construction methods require a large workforce and extended timeframes, leading to high labor costs. PEBs, however, are designed for quick assembly, which significantly reduces the amount of labor required on-site. With fewer workers needed and shorter construction times, labor costs are drastically lowered.

3. Shorter Construction Time

Time is money, especially in construction. The longer a project takes, the higher the costs due to labor, equipment rental, and site management. Pre-engineered buildings are known for their rapid assembly times. Components are manufactured concurrently with site preparation, allowing for a seamless construction process. This efficiency means projects are completed faster, reducing the overall timeline and associated costs.

4. Minimal On-Site Disruption

Traditional construction can be highly disruptive, causing delays and increasing costs. PEBs minimize on-site disruption since the majority of the work is done off-site. This streamlined process not only accelerates the construction timeline but also reduces the chances of unforeseen delays and complications, which can be costly.

5. Energy Efficiency

Pre-engineered buildings are often designed with energy efficiency in mind. Advanced insulation, energy-efficient windows, and sustainable materials are commonly used in PEBs. These features reduce energy consumption, leading to lower utility bills over the building's lifespan. The initial investment in energy-efficient design pays off in the long run with substantial savings on heating, cooling, and electricity costs.

6. Lower Maintenance Costs

PEBs are known for their durability and low maintenance requirements. High-quality materials and precision engineering result in structures that withstand harsh weather conditions and wear and tear. This resilience translates to lower maintenance costs over time, as fewer repairs and replacements are needed compared to traditional buildings.

7. Scalability and Flexibility

The scalability and flexibility of pre-engineered buildings offer cost advantages as well. PEBs can be easily expanded or modified to meet changing needs without significant investment. This adaptability is particularly beneficial for growing businesses, allowing them to scale operations without the need for entirely new construction projects.

Conclusion:

Pre-engineered buildings offer a myriad of cost-saving benefits that make them an attractive option for modern construction projects. From reduced material and labor costs to shorter construction times and energy efficiency, PEBs provide a financially sound alternative to traditional building methods. Companies like EPACK Prefab are at the forefront of this innovative approach, delivering high-quality, cost-effective solutions that cater to various industrial and commercial needs.

By opting for pre-engineered buildings, you not only optimize your budget but also invest in a sustainable, efficient, and durable solution that supports your long-term growth and success. Embrace the future of construction with PEBs and experience the significant impact on your costs firsthand. Also Read: Understanding the Application of Pre Engineered Buildings (PEB) for Large-Scale Indian Projects

#PreEngineeredBuildings#CostSavings#ConstructionInnovation#EfficientConstruction#PEBImpact#BuildingCostEfficiency#ModernConstruction#SustainableBuilding#EPACKPrefab#IndustrialConstruction

0 notes

Text

When it comes to top manufacturers and suppliers of pre-engineered cold storage buildings, EPACK Prefab stands out. They provide high-quality, efficient solutions tailored to various needs. Their expertise ensures reliable temperature control and energy efficiency, making them a preferred choice in the industry. Whether for food storage, pharmaceuticals, or any other temperature-sensitive products, EPACK Prefab delivers superior performance and durability. If you’re looking for a trusted partner in cold storage construction, EPACK Prefab is the name you can rely on.

Website URL - https://www.epackpeb.com/pre-engineered-buildings/cold-storage-building-manufacturers/

#ColdStorage#PreEngineeredBuildings#EPACKPrefab#ColdRoomManufacturers#TemperatureControl#EnergyEfficiency#StorageSolutions#IndustrialBuildings#PrefabConstruction#ColdStorageSolutions

1 note

·

View note

Text

Unveiling the Future of Construction with Prefabricated and Pre-Engineered Commercial Buildings!

In the fast-paced world of construction, the demand for efficient, cost-effective, and sustainable solutions is shaping the way commercial buildings are designed and erected. Prefabricated and Pre-Engineered Commercial Buildings have emerged as groundbreaking alternatives, and at the forefront of this transformative movement stands EPACK Prefab – a distinguished manufacturer and supplier, setting new standards in the construction industry.

The Rise of Prefabricated Commercial Buildings:

Prefabricated commercial buildings are changing the game, offering a swift and streamlined construction process. These structures are manufactured off-site, with components assembled on-site, resulting in reduced construction timelines and minimized disruptions to business operations. EPACK Prefab, with its commitment to innovation, has been a key player in bringing these advantages to businesses around the globe.

Unlocking Efficiency with Pre-Engineered Commercial Buildings:

Pre-engineered commercial buildings take efficiency a step further. These structures are designed and engineered off-site, ensuring precision and quality control. EPACK Prefab has harnessed this approach, providing businesses with a faster, cost-effective, and reliable solution for their commercial space needs. From office complexes to retail outlets, pre-engineered buildings offer a versatile and scalable option.

EPACK Prefab's Leading Role:

As a top manufacturer and supplier, EPACK Prefab has earned a stellar reputation for its commitment to excellence and innovation in the realm of prefabricated and pre-engineered commercial buildings.

Customization Excellence: EPACK Prefab understands that each business has unique needs. Their prefabricated commercial buildings are not just convenient but also customizable to meet specific requirements, ensuring that the end result aligns perfectly with the client's vision.

Quality Assurance: EPACK Prefab prioritizes quality at every stage of the construction process. From the selection of materials to the manufacturing and on-site assembly, their commitment to delivering a high-quality product is unwavering.

Sustainable Solutions: In an era where sustainability is paramount, EPACK Prefab is dedicated to eco-friendly construction practices. Their commercial buildings incorporate green materials and energy-efficient designs, contributing to a more sustainable future.

The era of traditional construction is evolving, and EPACK Prefab is leading the charge in transforming commercial building projects. Prefabricated and pre-engineered solutions not only offer speed and efficiency but also provide a sustainable and customizable alternative for businesses. As we look towards the future, EPACK Prefab remains a beacon of innovation, reshaping the landscape of commercial construction one prefabricated and pre-engineered building at a time.

Also Read: The Rise of Prefab Commercial Buildings: A Sustainable Business Solution

#PrefabDesign#CommercialConstruction#PrefabRevolution#GreenBuilding#SustainableSpaces#InnovationInConstruction#ModernOffice#EcoFriendlyBuildings#EfficientConstruction#PrefabCommercial#PreEngineeredBuildings#FutureOfBuilding#PrefabTrends#QuickConstruction#CustomCommercialBuildings#SmartConstruction#EPACKPrefab

0 notes

Text

The Future of Agricultural Buildings: Trends and Innovations

Agriculture has always been the backbone of the Indian economy, and the evolution of agricultural buildings plays a critical role in enhancing productivity and sustainability. As the world leans towards innovative construction solutions, prefabricated (prefab) structures are becoming increasingly popular in agricultural settings.

This blog delves into the latest trends and innovations in agricultural buildings, highlighting the advantages of prefab technologies over traditional structures.

Trends in Agricultural Buildings

Insulation and Temperature Control

Effective insulation is crucial in agricultural buildings to maintain optimal temperatures, especially during extreme weather conditions. Puf Insulated Sandwich Panels are increasingly being used for their excellent thermal insulation properties, keeping indoor environments stable and energy-efficient. These panels are lightweight, easy to install, and offer superior insulation compared to traditional materials.

2. Moisture Control

The monsoon season in India can wreak havoc on agricultural structures if proper moisture control measures are not in place. Sandwich Puf Panels and Puf Roofing Panels provide excellent moisture resistance, preventing water seepage and protecting stored produce from dampness and mold. These panels help maintain the structural integrity of buildings, ensuring longevity and reliability.

3. Natural Lighting

Maximizing natural light not only reduces energy costs but also creates a healthier environment for both livestock and workers. Incorporating large windows, skylights, and translucent roofing materials can significantly enhance the amount of natural light entering the building. Prefabricated Structures Manufacturers offer various design options to optimize natural lighting, improving the overall functionality of agricultural spaces.

4. Ventilation Systems

Proper ventilation is essential to maintain air quality and regulate temperature within agricultural buildings. Modern prefab structures are designed with advanced ventilation systems that promote airflow and reduce the buildup of harmful gases. This is particularly important in livestock buildings to ensure the health and well-being of the animals.

5. Sustainable Materials

The use of sustainable materials in construction is a growing trend, driven by the need to reduce environmental impact. EPS Panel Construction is gaining popularity due to its eco-friendly nature and excellent insulation properties. These panels are recyclable and offer a sustainable alternative to conventional building materials.

Innovations in Agricultural Building Design

Modular and Expandable Designs

Prefab agricultural buildings offer modular and expandable design options, allowing farmers to easily scale their operations. Whether it's adding new storage units or expanding livestock facilities, prefab structures provide flexibility and cost-efficiency. Prefab Structure Manufacturer solutions are designed to meet the specific needs of agricultural businesses, making expansion seamless and hassle-free.

2. Quick Assembly and Cost-Effectiveness

One of the most significant advantages of prefab buildings is the speed of construction. Prefab structures can be assembled quickly, reducing downtime and labor costs. This is particularly beneficial for farmers who need to set up facilities swiftly to meet seasonal demands. The cost-effectiveness of Prefabricated Sandwich Panels and other prefab components also makes them an attractive option for agricultural projects.

3. Durability and Weather Resistance

Agricultural buildings must withstand harsh weather conditions, including heavy rains, high winds, and extreme temperatures. Puf Panel Supplier products are known for their durability and weather resistance, ensuring that buildings remain sturdy and functional for years. These panels offer superior protection against environmental elements, reducing maintenance costs and enhancing the lifespan of the structures.

4. Enhanced Aesthetic and Functional Design

Modern agricultural buildings are not just functional but also aesthetically pleasing. Prefab structures come in various designs and finishes, allowing farmers to create visually appealing spaces that reflect their brand and values. Additionally, innovative design elements such as ergonomic layouts and multi-functional spaces contribute to the overall efficiency and productivity of the facilities.

Conclusion

The future of agricultural buildings lies in embracing innovative construction technologies that offer efficiency, sustainability, and durability. Prefab structures, with their myriad benefits, are set to revolutionize the agricultural sector in India. By opting for Prefabricated Structures Manufacturers and utilizing advanced materials like Sandwich Puf Panels, farmers can build resilient and efficient agricultural facilities.

At EPACK Prefab, we pride ourselves on being pioneers in prefab technology in India. Our solutions are tailored to meet the unique needs of the agricultural sector, offering unmatched quality and reliability. To learn more about our cutting-edge prefab structures and how they can benefit your agricultural operations, visit our website or contact us today. Together, let's build the future of agriculture.

Also Read: WHY PEB STRUCTURES ARE A SMART CHOICE FOR AGRICULTURE IN INDIAN MONSOONS?

#PrefabSolutions#SustainableAgriculture#ModernAgriculture#AgriTech#InnovativeFarming#FarmInnovation#EcoFriendlyFarming#AgricultureTrends#PrefabBuildings#GreenBuildings#FarmBuildings#AgricultureTechnology

2 notes

·

View notes

Text

HOW CAN SOLUTIONS FROM PEB MANUFACTURERS MITIGATE MONSOON-RELATED DISASTERS?

It’s not a surprise that India has diverse climatic conditions. Because of these weather extremities, our nation is also not a stranger to the intense and destructive monsoon season conditions.

Undoubtedly, the rainy season is vital for agriculture. However, it also brings severe issues like flooding, landslides, and cyclones, which ultimately cause rampant damage and loss of life.

While climate change is an essential reason for the recent weather pattern, one must recognize how our obsolete construction techniques further exaggerate the problem. Due to this, the demand for pre-engineered buildings (PEBs) has been rising lately.

PEB manufacturers register multiple orders every day because these structures have shown their advantage across different necessities, including monsoon readiness. These are robust, versatile, and long-term cost-saving structures that enhance community resilience and the durability of infrastructure against such disasters.

Pre-Engineered Building Structures Can Enhance Early Warning Systems

One of the critical aspects of disaster management is establishing early warning systems. PEBs can play a vital role in this regard. Pre-engineered structures can be rapidly deployed to house weather monitoring and communication equipment, ensuring that remote and vulnerable areas receive timely alerts. These installations can withstand harsh weather conditions, ensuring the continuity of operations even during severe storms. PEB Manufacturers in India can customize these structures, considering the intensity at which a specific region faces floods.

PEB Buildings Are Reliable Community Shelters in Times of Crisis

Monsoons often necessitate the evacuation of communities from flood-prone or landslide-affected areas. Here, PEBs come into their own as efficient and reliable community shelters. These structures can be quickly erected to provide safe and secure housing for displaced populations. Unlike traditional buildings, industrial shed manufacturers and suppliers take a fraction of the time to design these structures. At the same time, these buildings can endure extreme weather, offering protection against heavy rains and high winds.

All Types of PEB Structures Are Resilient

Critical infrastructure resilience is paramount during monsoon seasons. Traditional construction methods often lack the durability and speed required to rebuild or reinforce infrastructure in disaster-prone regions. PEBs, however, offer an ideal solution. Well-known PEB companies like EPACK Prefab make modular designs, which allow for quick assembly. Also, their steel framework provides superior strength and durability. This makes PEBs suitable for constructing resilient bridges, roadways, and utility buildings that can better withstand monsoon impacts.

PEBs Can Protect Lives and Resources in Coastal and Flood Zones

In coastal regions prone to cyclones, PEB structures can be used to build emergency response centers that remain operational during and after storms. PEB building manufacturers can construct elevated storage facilities in flood-affected areas, protecting vital supplies from water damage.

PEBs Vs Traditional Structures: Who Wins?

Traditional structures pale in comparison to pre-engineered building systems when it comes to the range of benefits the latter offers. Here’s a review:

Construction Speed: PEBs have a rapid construction timeline. In disaster scenarios, where time is of the essence, the ability to quickly erect shelters and infrastructure can save lives and resources. The swift assembly is possible because components of a PEB structure are manufactured off-site, then transported to the location, where they are quickly assembled.

Cost-Effectiveness: These structures are generally more cost-effective than traditional building methods over time, as the prefabrication process reduces labor costs and material waste, making PEBs an economical choice for disaster management.

Durability and Maintenance: PEBs require minimal maintenance compared to conventional structures. Their steel components resist corrosion, pests, and mold, ensuring long-term durability even in harsh monsoon climates.

Flexibility and Scalability: Such buildings can be easily modified or expanded to meet changing needs. This flexibility is crucial in disaster-prone areas where the demand for shelters and infrastructure can vary significantly.

PEBs emerge as a clear winner, offering a versatile and efficient solution to disaster management’s unique challenges. Their unmatched combination of speed, affordability, durability, and adaptability makes them a game-changer in disaster preparedness and recovery efforts.

Get in Touch with Pre-Engineered Building Manufacturers Today!

Flash floods and other monsoon-related disasters are rising in intensity every year. Shifting to pre-engineered buildings is a promising solution that can help create infrastructure that lasts longer and make our community more resilient.

From early warning systems to community shelters and resilient infrastructure, PEBs provide versatile, cost-effective, and robust options that traditional building methods often cannot match.

As one of the best PEB manufacturers in India, we at EPACK Prefab are committed to leveraging the potential of prefabricated solutions to safeguard communities and infrastructures against the adverse effects of monsoon seasons.

Curious to know more about how PEB works? Check out our blog section, which explains how PEB is changing the face of infrastructure. To find out how we have established PEB-based resilient structures, kindly check out EPACK Prefab projects, where we’ve displayed our innovative solutions.

Also Read: ESSENTIAL PRE-MONSOON CHECKLIST FOR PRE-ENGINEERED BUILDINGS (PEB)

#Tags: PreEngineeredBuildings#PEB#MonsoonPreparedness#DisasterManagement#ClimateResilience#FloodProtection#CycloneSafety#PrefabStructures#EPACKPrefab#SustainableConstruction#RapidConstruction#CommunityShelters#InfrastructureSafety#ConstructionInnovation#WeatherResistantBuildings

0 notes

Text

Looking for the best in PEB sheds? Look no further! EPACK Prefab is the leading manufacturer and supplier, offering unmatched quality, innovation, and reliability.

Elevate your projects with our top-notch PEB sheds today!

Website URL - https://www.epackpeb.com

#PEBSheds#TopManufacturer#Supplier#Construction#Prefab#Structures#BuildingMaterials#Industrial#Innovation#QualityAssured

0 notes

Text

Exploring Warehouse Construction: Building Your Storage Space

Warehouse construction is a crucial aspect of logistics and supply chain management. It involves the design, planning, and building of structures specifically tailored to store and manage goods and materials. Whether it's for short-term storage or long-term warehousing needs, constructing a warehouse requires careful consideration of various factors to ensure efficiency, safety, and cost-effectiveness.

Understanding Warehouse Construction

A warehouse serves as a hub for businesses to store their inventory before distribution to customers. The construction of a warehouse is a complex process that begins with meticulous planning. It involves determining the size, layout, and features required to meet the specific needs of the business.

Components of Warehouse Construction

A typical warehouse consists of various components designed to facilitate the storage and retrieval of goods:

Structural Framework: The structural framework forms the skeleton of the warehouse and provides support for the entire structure. It includes columns, beams, and other load-bearing elements that ensure the stability and strength of the building.

Roofing System: The roofing system plays a crucial role in protecting the warehouse and its contents from weather elements. Different roofing materials, such as metal, concrete, or composite panels, can be used based on factors like climate, budget, and durability requirements.

Walls and Enclosures: Walls and enclosures define the perimeter of the warehouse and provide security and insulation. They can be constructed using various materials, including concrete, steel, or prefabricated panels, depending on factors like structural requirements and aesthetic preferences.

Flooring: Warehouse flooring should be durable enough to withstand heavy loads and constant traffic from forklifts and other equipment. Concrete is a common choice for warehouse flooring due to its strength, durability, and ease of maintenance.

Storage Systems: The storage system is a critical component of warehouse construction, as it directly impacts the efficiency of inventory management. It includes shelving, racks, mezzanines, and other storage solutions designed to optimize space utilization and facilitate easy access to goods.

Different Types of Warehouse Construction

Warehouse construction can vary based on the specific needs and requirements of the business. Some common types of warehouse construction include:

Distribution Centers: Distribution centers are large-scale warehouses designed to receive, store, and distribute goods to various locations. They often feature high ceilings, wide aisles, and advanced material handling systems to accommodate the movement of large volumes of goods.

Cold Storage Warehouses: Cold storage warehouses are designed to store perishable goods, such as food and pharmaceuticals, at controlled temperatures. These warehouses feature specialized insulation, refrigeration, and temperature monitoring systems to maintain the required cold chain conditions.

Industrial Warehouses: Industrial warehouses are tailored to the specific needs of manufacturing and industrial businesses. They are designed to accommodate heavy machinery, raw materials, and finished products, with features such as high ceilings, wide doors, and reinforced flooring.

Retail Warehouses: Retail warehouses are typically located near urban centers and are designed to store goods for retail distribution. They often feature a combination of storage space and showroom areas to showcase products to customers.

Choosing the Right Warehouse Construction Company

When it comes to warehouse construction, selecting the right construction company is paramount. Warehouse Construction Company EPACK Prefab emerges as a top manufacturer and supplier in the field of warehouse construction. Their expertise and experience in designing and constructing prefabricated warehouses make them a reliable choice for businesses looking to build efficient and cost-effective storage facilities.

Conclusion

Warehouse construction is a multifaceted process that requires careful planning and execution to meet the diverse needs of businesses. Whether it's for storing raw materials, finished products, or perishable goods, a well-designed warehouse plays a critical role in optimizing supply chain operations and ensuring customer satisfaction. With the right construction company, such as EPACK Prefab, businesses can streamline their warehouse construction process and create a storage space that meets their specific requirements. Also Read: WHY PEB WAREHOUSE IS BETTER THAN CIVIL WAREHOUSE

#WarehouseConstruction#PrefabConstruction#Logistics#SupplyChain#ColdStorage#RetailWarehousing#ConstructionIndustry#BuildingMaterials#WarehouseDesign#GreenBuilding#SustainableConstruction#InnovationInConstruction#EcoFriendlyDesign#EPACKPrefab#SteelBuildings

0 notes

Text

Factors to Consider When Planning Commercial Warehouse Construction

Hey there! So, you’re thinking about building a commercial warehouse? That’s awesome! But before you start dreaming of towering shelves and speedy forklifts, let’s talk about what you need to consider to make this project a smashing success.

Here’s a handy guide to help you navigate the exciting (and sometimes tricky) world of warehouse construction.

1. Pick the Perfect Spot

First things first, where’s your warehouse going to be? Location is key. You want a spot that’s easy for trucks to get in and out of, close to highways, ports, or railways. Don’t forget to check local zoning laws and make sure you have all the utilities you need like water, electricity, and internet.

2. Smart Design and Layout

How you design your warehouse can make a huge difference in how efficiently it operates. Think about the flow of goods from arrival to storage to shipping. A well-planned layout reduces time and effort, making your operations smoother and quicker. Plus, leave some room for future expansion—you never know when you might need more space!

3. Right Size, Right Space

Getting the size right is crucial. Too small, and you’ll be cramped. Too big, and you’re wasting money on space you don’t need. Consider the type of products you’re storing, how much inventory you’ll have, and any special storage needs like climate control for perishable items.

4. Choose Quality Materials

The materials you use can affect everything from durability to maintenance costs. Pre-engineered buildings (PEBs) are a great option—they’re fast to build, cost-effective, and flexible in design. EPACK Prefab, for example, offers high-quality PEBs that can stand up to tough conditions and last for years.

5. Follow the Rules

Construction comes with a lot of rules and regulations. Make sure you’re up to date on local building codes, zoning laws, fire safety regulations, and environmental standards. Working with knowledgeable contractors and consultants can help you avoid legal headaches and costly fines.

6. Embrace Technology

Incorporating the latest technology can make your warehouse operations a breeze. Think about using warehouse management software (WMS), automated storage and retrieval systems (ASRS), and conveyor systems. These tools can save time, reduce errors, and boost productivity.

7. Energy Efficiency

Energy costs can add up quickly, so plan for efficiency from the start. Good insulation, energy-efficient lighting, and HVAC systems can make a big difference. If possible, consider renewable energy options like solar panels. EPACK Prefab offers solutions that can help you save energy and money.

8. Safety and Security First

Keeping your warehouse safe and secure should be a top priority. Install security cameras, alarms, and access control systems to protect your assets. Ensure you have fire suppression systems, adequate lighting, clear signage, and train your employees on safety protocols.

9. Budget Wisely

Budgeting is a critical part of any construction project. Make sure you have a detailed budget that covers everything from land purchase to finishing touches. It’s also smart to have a contingency fund for unexpected expenses. Working with reputable suppliers like EPACK Prefab can help you stick to your budget without sacrificing quality.

10. Project Management is Key

Managing a construction project can be overwhelming. Hiring an experienced project manager can keep everything on track. They’ll coordinate all aspects of the project, from design and permits to construction and inspections, helping to avoid delays and handle any issues that come up.

Conclusion

Building a commercial warehouse is a big deal, but with careful planning, it can be a fantastic investment for your business. By considering location, design, size, materials, regulations, technology, energy efficiency, safety, budgeting, and project management, you’re setting yourself up for success.

And remember, you don’t have to go it alone. Partnering with industry experts like EPACK Prefab can provide the support and quality you need to bring your warehouse vision to life. So get excited, plan smart, and watch your business thrive in your new, efficient, and well-built warehouse. Happy building!

Also Read: PREFAB COMMERCIAL BUILDINGS: THE FUTURE OF COMMERCIAL BUILDING CONSTRUCTION

#PreEngineeredBuildings#PEB#PrefabConstruction#ModularBuildings#FastConstruction#ConstructionTips#CommercialWarehouse#Logistics#ConstructionIndustry#Warehousing

1 note

·

View note

Text

Pre-engineered Buildings: PEB Structure & Features

The construction industry has been witnessing a paradigm shift with the advent of Pre-engineered Buildings (PEBs). These innovative structures are redefining the way buildings are designed, constructed, and utilized. Offering numerous advantages over traditional construction methods, Pre Engineered Building Systems are becoming the preferred choice for various applications. EPACK Prefab, a leader in this domain, stands out as the top manufacturer and supplier of these cutting-edge building solutions.

What Are Pre-engineered Buildings?

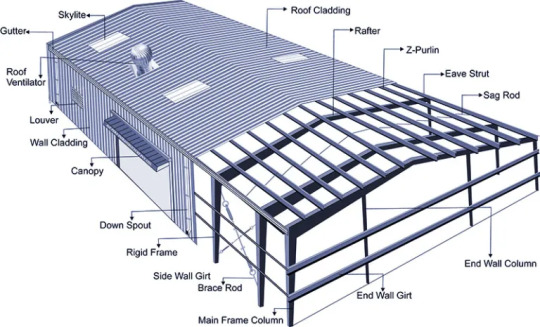

Pre-engineered Buildings are factory-fabricated structures designed to meet specific project requirements. The components of these buildings, including beams, columns, roof panels, and wall panels, are pre-designed and manufactured in a controlled environment. These components are then transported to the construction site for assembly, ensuring a swift and efficient construction process.

Key Features of Pre-engineered Building Systems

Versatility in Design: Pre Engineered Building Systems offer immense flexibility in design. They can be customized to fit a wide range of applications, from industrial warehouses to commercial complexes and residential buildings. This versatility makes PEBs suitable for various sectors, including agriculture, manufacturing, and retail.

High-Quality Construction: The components of PEBs are manufactured in a controlled environment, ensuring high quality and precision. The use of advanced technology and stringent quality control measures results in durable and reliable structures. EPACK Prefab, for instance, employs state-of-the-art manufacturing techniques to deliver top-notch pre engineered building systems.

Cost-Effective: One of the most significant advantages of PEBs is their cost-effectiveness. The prefabrication process reduces material wastage and on-site labor costs. Additionally, the quick assembly time translates to faster project completion, saving both time and money.

Energy Efficiency: Pre-engineered buildings are designed to be energy-efficient. The use of insulated panels and energy-efficient materials helps in reducing the overall energy consumption of the building. This not only lowers operational costs but also contributes to environmental sustainability.

Scalability: PEBs can be easily expanded or modified to meet changing needs. This scalability is particularly beneficial for businesses that anticipate growth or need to adapt their space to different uses over time.

EPACK Prefab: Leading the Way in Pre Engineered Building Systems

When it comes to pre engineered building systems, EPACK Prefab is a name synonymous with quality and innovation. As a top manufacturer and supplier, EPACK Prefab has carved a niche for itself in the construction industry. Here’s what sets them apart:

Innovative Solutions: EPACK Prefab is committed to delivering innovative building solutions that meet the evolving needs of their clients. Their team of skilled engineers and designers leverage the latest technology to create efficient and sustainable PEBs.

Superior Quality: Quality is a hallmark of EPACK Prefab's offerings. From sourcing the best raw materials to employing rigorous quality control measures, every aspect of their manufacturing process is geared towards delivering superior products.

Customer-Centric Approach: EPACK Prefab places a strong emphasis on customer satisfaction. They work closely with clients to understand their requirements and provide tailored solutions that align with their needs and budget.

Sustainable Practices: Sustainability is at the core of EPACK Prefab's operations. They incorporate eco-friendly practices in their manufacturing processes and design energy-efficient buildings that minimize environmental impact.

Applications of Pre-engineered Building Systems

Pre-engineered buildings are incredibly versatile and can be used for various applications, including:

Industrial Warehouses: Ideal for storage and distribution centers due to their large, open spaces and robust construction.

Commercial Complexes: Retail stores, office buildings, and shopping centers benefit from the flexibility and aesthetic appeal of PEBs.

Residential Buildings: Multi-family homes and apartment complexes can be efficiently constructed using PEB systems.

Agricultural Facilities: Storage sheds, barns, and other agricultural structures are perfectly suited for PEB solutions.

Conclusion

Pre-engineered buildings represent a significant advancement in the construction industry, offering a blend of efficiency, cost-effectiveness, and sustainability. EPACK Prefab, as a top manufacturer and supplier of pre engineered building systems, is at the forefront of this revolution. Their commitment to quality, innovation, and customer satisfaction makes them the preferred choice for PEB solutions. Whether for industrial, commercial, or residential use, Pre Engineered Building Systems by EPACK Prefab provide a reliable and future-proof solution for modern construction needs.

If you're considering Pre Engineered Building Systems for your next project, EPACK Prefab is here to help. Our team of experts is ready to provide you with innovative, high-quality, and cost-effective solutions tailored to your needs. Contact us today to learn more about how our pre-engineered buildings can transform your construction projects.

Also Read: THE COMMON MYTHS SURROUNDING PRE ENGINEERED BUILDINGS THAT NEED TO BE ADDRESSED

#PreEngineeredBuildings#PEBStructures#SteelBuildings#EPACKPrefab#ModernConstruction#BuildingInnovation#SustainableConstruction#PrefabBuildings#ConstructionSolutions#IndustrialConstruction#CommercialBuildings#SmartConstruction#EcoFriendlyBuilding

1 note

·

View note

Text

The Power of Industrial Sheds: A Wise Investment for Business Owners

In the realm of modular construction, few assets offer the versatility and practicality of prefabricated industrial shelters. Often referred to as pre-engineered steel sheds, these structures have become increasingly sought-after in recent years, and for good reason. With applications ranging from factory sheds to warehouses and agricultural structures, their adaptability knows no bounds. But what sets them apart from traditional construction methods?

The advantages are manifold, and in this post, we'll delve into why industrial sheds are a valuable business asset, with EPACK Prefab leading the charge as the top manufacturer and supplier in the industry.

Low-Maintenance Structures:

PEB industrial sheds are designed with simplicity and efficiency in mind. Unlike traditional buildings that require periodic maintenance such as painting, prefabricated shelters feature pre-painted galvanized sheets that require minimal upkeep. This offsite prefabrication not only saves time and labor but also ensures long-lasting durability, making industrial sheds a cost-effective and low-maintenance solution for businesses of all sizes.

Enduring Durability:

Steel, the primary material used in prefabricated industrial sheds, is renowned for its strength and resilience. These structures are built to withstand harsh weather conditions, ensuring uninterrupted operations even in the face of adverse environmental factors. With EPACK Prefab's expertise in engineering durable and reliable steel structures, business owners can trust in the longevity and durability of their industrial sheds, providing peace of mind for years to come.

Environmentally Friendly and Sustainable:

In an era where environmental consciousness is paramount, prefabricated industrial sheds offer a sustainable solution to businesses. Steel-framed buildings generate less waste compared to traditional construction methods, and much of the steel used can be recycled and repurposed, minimizing environmental impact. By choosing prefabricated steel sheds, businesses can contribute to green building initiatives while enjoying the benefits of a durable and eco-friendly infrastructure.

Cost-Effective and Efficient:

Industrial sheds are not only durable and environmentally friendly but also cost-effective and efficient. With offsite prefabrication and rapid installation processes, businesses can save both time and money compared to traditional construction methods. EPACK Prefab's commitment to quality and efficiency ensures that projects are completed on time and within budget, allowing businesses to maximize their return on investment and focus on their core operations.

In conclusion, industrial sheds represent a cornerstone of efficiency, durability, and sustainability for businesses across various industries. With EPACK Prefab leading the industry as the top manufacturer and supplier of prefabricated industrial shelters, businesses can rest assured knowing they have a trusted partner for their infrastructure needs.

Whether you require a custom solution tailored to your specific requirements or a standard industrial shed for your operations, we are here to help. Contact us today to discuss your project requirements and discover how our expertise and innovation can benefit your business.

#PrefabConstruction#IndustrialSheds#SteelStructures#ModularBuildings#EPACKPrefab#SustainableConstruction#GreenBuilding#PrefabRevolution#IndustrialShedManufacturer

0 notes