Don't wanna be here? Send us removal request.

Text

Epoxy Floor Painting for Industrial and Commercial Floors

Industrial and commercial environments seek flooring systems capable of supporting heavy loads, enduring wear and tear with minimal maintenance, and epoxy floor painting satisfies all these requirements.

At Dr Cipy, we have seen firsthand how the introduction of an epoxy floor transformation can change operational spaces, from manufacturing plants to retail storefronts.

Let’s explore why epoxy floor painting stands out as the top flooring choice for industrial and commercial settings.

1. Unmatched Durability & Chemical Resistance

Industrial and commercial floors often withstand the movement of heavy machinery and forklifts, frequent foot traffic, and potential chemical spills. Here, standard paint does not provide an adequate floor finish. Industrial epoxy floor paint is composed of a resin and hardener mixed in a thermoset polymer that adheres to concrete and cures to create a seamless, durable surface.

The outcome? Epoxy resists wear and tear and provides outstanding durability against impacts and chemical attack. It is optimal for use in warehouses, auto garages, pharmaceutical plants, food-processing units, etc.

2. Seamless and Hygienic Surface

Unlike tiles or vinyl flooring, epoxy coatings create a continuous, grout-free surface. This eliminates crevices where dust, dirt, bacteria, or chemicals can hide, making the floor easy to clean and maintain.

This seamless finish supports high sanitation standards in sectors like healthcare, food and beverage, and retail, where hygiene is critical. For example, Dr. Cipy’s antimicrobial epoxy solutions are favored in hospitals and cleanrooms.

3. Safety & Visibility

Industrial and commercial floors need more than just durability; they must keep people safe. Epoxy coatings can be formulated with high-visibility pigments and embedded with non-slip additives to reduce slip risks, even when wet.

Cipy’s product range includes anti-slip textures and high-gloss finishes that reflect light, enhancing visibility in dimly lit areas like warehouses and loading bays. This not only improves safety but also promotes a cleaner, brighter work environment.

4. Cost-Effective Over the Long Haul

Although the initial cost of epoxy flooring may exceed that of traditional paints or tiles, the long-term benefits are significant. Epoxy floors are resistant to wear, stains, and damage, which greatly minimizes rework, repairs, and downtime.

In fact, lifecycle analyses show that epoxy can last a decade or more in commercial and industrial settings, outperforming most flooring alternatives when factoring in maintenance and replacement costs.

5. Customizable Aesthetics

Functionality doesn’t mean sacrificing style. Epoxy systems offer many design options. Choose from high-gloss finishes for showrooms, matte textures for industrial zones, or branded colors and metallic effects for corporate spaces.

Dr Cipy’s decorative epoxy terrazzo and water-based variants marry performance with visual appeal, creating floors that are as beautiful as they are tough.

6. Fast Installation & Minimal Downtime

Time is money. Installing new flooring in busy industrial or commercial environments usually means production stoppages or store closures. But modern epoxy systems cure quickly, sometimes in just 24 hours for light use, and 3–7 days for full load-bearing strength.

When paired with professional installation like what Dr Cipy provides, downtime is minimized and business stays on track.

7. Adaptable to Any Environment

Whether your facility deals with heavy-duty equipment, harsh chemicals, moisture-prone environments, or precise temperature control, epoxy floor painting can be tailored accordingly.

There’s an epoxy solution for every requirement, from solvent-free and moisture-tolerant primers to high-performance novolac and antimicrobial finishes.

Epoxy vs. Regular Floor Paint

Here’s a quick comparison to illustrate how epoxy stands tall:

Feature- Durability Regular Floor Paint- Prone to chipping, fading Epoxy Floor Painting-High impact & abrasion resistance Feature-Chemical Resistance Regular Floor Paint-Limited Epoxy Floor Painting-Excellent (oil, solvents, acids) Feature-Surface Integrity Regular Floor Paint-May crack or peel Epoxy Floor Painting-Seamless, non-porous, long-term bond

Feature-Maintenance Regular Floor Paint-Frequent re-coats needed Epoxy Floor Painting-Low upkeep, lasts for years

Feature-Safety Regular Floor Paint-Limited non-slip options Epoxy Floor Painting-Custom textures, anti-slip additives

Real-World Success with Dr Cipy

Manufacturing and WarehousingFor years, our floors have survived heavy vehicles, chemical spills, and high footfall, delivering reliable performance with minimal upkeep.

Healthcare & PharmaTrusted in clinics, labs, and hospitals for their non-porous finish and antimicrobial options, keeping environments cleaner and safer.

Commercial & Retail From showrooms to shopping centers, epoxy floors enhance aesthetics while handling daily challenges like trolleys, spills, and supermarket crowds.

To Conclude

Industrial and commercial floors require more than just a paint job; they need a durable, hygienic, safe, and long-lasting solution. Epoxy floor painting provides all that and more transforming concrete into a high-performance surface that endures daily wear without breaking the bank.

At Dr. Cipy, we combine proven epoxy technologies (Cipoxy, Aquoxy, Novolac) with comprehensive expertise to manage assessment, application, and post-installation care.

Our floors don’t just look good; they perform, last, and save your business on maintenance.

Ready to upgrade your space with the best epoxy floor painting solution? Contact us today for a tailor-made consultation and discover why industry leaders choose us for flawless, future-ready flooring.

FAQs

How long does an epoxy painted floor last? Properly installed epoxy floors typically last 10–15 years, and often longer under light to moderate conditions.

How long does an epoxy floor typically last in an industrial or commercial setting? In heavy-duty, high-traffic environments, an epoxy floor should last 7–10 years before recoating, depending on traffic, chemical exposure, and maintenance.

How is epoxy floor painting different from regular floor paint? Epoxy is a chemically crosslinked system that bonds into concrete to form a hard, seamless, and chemical-resistant coating, unlike surface-level paints that peel, chip, and wear quickly.

Where can epoxy floor painting be applied? You need durable, hygienic flooring anywhere: warehouses, factories, hospitals, labs, showrooms, commercial kitchens, garages, car parks, and cold storage.

#epoxy floor paint#epoxy floor painting#epoxy floor#Epoxy Floor Painting for Industrial#Epoxy Floor Pain for Commercial Floors

0 notes

Text

#Epoxy Floor Painting#Epoxy floor paint#Epoxy Floor Painting for Industrial#Epoxy Floor Pain for Commercial Floors

0 notes

Text

Decorative Epoxy Flooring for Commercial Spaces

Step into any number of new-age cafés, luxury showrooms, or upscale lobbies, and you’ll find that the floor beneath you does more than just greet you it tells a story about the brand and experience.

In the current business landscape, flooring goes beyond just functionality it plays a crucial role in branding and the customer experience. This is where decorative epoxy flooring becomes essential.

Whether in a busy retail store, posh restaurant, healthcare clinic, or corporate space, it is clear that decorative epoxy flooring enhances your property’s surface, durability, and value significantly. Here’s how.

Instant Boost to Aesthetic Appeal

First impressions matter in any business. Decorative epoxy flooring offers a change from the standard, grey concrete floor to a sleek surface effortlessly resembling marble, granite, terrazzo, or even high-end metallic finishes, all at a fraction of the cost of conventional flooring.

With numerous vibrant color flakes, stylish quartz blends, and endless options for textures and patterns, decorative epoxy flooring allows you to create the ideal atmosphere for your brand aesthetic. It can even help create a space that pleasantly surprises your customers, leaving a lasting impression.

Essentially, your floor is a work of art and reflects your business’s character, intentions, and values.

Durable for Heavy Traffic

Commercial properties experience consistently high traffic, spills, or other accidents. Epoxy flooring is ideal for these situations because it is not only attractive but also incredibly dense and durable.

Epoxy creates a seamless, non-porous surface that forms a highly resilient surface after application, resistant to scratches, chemicals, stains, and impact. Epoxy flooring is ideal for retail spaces, healthcare clinics, and showrooms because it continues to keep its shine and smooth surface under rigorous daily use.

Low Maintenance, High Efficiency

In the world of commercial spaces, much of the ongoing expense is tied up in maintenance. Decorative Epoxy will lower cleaning time and your maintenance costs, because it is much more efficient to clean.

Rather than worrying about grouted areas or other stains, you can sweep the surface and occasionally mop to keep it looking pristine. Epoxy also prevents dust, allergens, and bacteria from building up, making it an excellent hygienic option for restaurants, hospitals, and kitchens.

Built-in Safety Features

While aesthetics matter, safety in commercial flooring cannot be compromised. Decorative epoxy flooring can include slip resistant finishes and textures, providing superior traction in busy or moisture prone environments.

This built-in safety significantly minimizes slip and fall risks, a major advantage for businesses, healthcare facilities, educational institutions, and any public building that prioritizes visitor safety.

Long-Term Financial Benefits

At first glance, decorative epoxy flooring might seem more expensive compared to traditional flooring materials, but the long-term benefits far outweigh the initial investment:

Exceptional longevity compared to other flooring types.

Reduced maintenance and repair expenses.

Consistent appearance that remains fresh and vibrant over the years.

These advantages collectively lead to reduced long-term costs and minimal operational interruptions. Furthermore, a visually appealing and well-maintained epoxy floor can greatly increase your property’s resale or rental value, making it a wise investment for property owners and managers.

Quick Installation, Minimal Business Downtime

For businesses, lengthy renovation projects translate to lost revenue. Decorative epoxy flooring solutions provide relatively quick installations, often finished within just a few days, depending on the size of the space and the complexity of the design. This efficient installation minimizes disruption to your commercial operations, enabling your business to resume promptly, thus avoiding prolonged closures and revenue losses.

Versatile Applications of Decorative Epoxy Flooring

Decorative epoxy flooring is highly versatile and suitable across various sectors:

Retail stores and showrooms

Corporate offices and lobbies

Restaurants and cafés

Hospitals and clinics

Hotels and resorts

Educational institutions

Warehouses and industrial spaces (decorative or functional finishes)

The Dr Cipy Difference

At Dr Cipy, we bring decades of experience creating flooring solutions tailored to the demanding Indian commercial environment. Our decorative epoxy flooring is designed to endure heavy foot traffic and diverse climates while offering various aesthetic options.

From initial consultation to meticulous installation, each epoxy flooring solution we provide is precision-engineered to ensure your commercial space receives a stunning, safe, and durable surface designed to last.

Conclusion

Your commercial flooring should be more than just functional; it should reflect your brand. Decorative epoxy flooring delivers beauty, durability, low maintenance, and exceptional returns on your investment.

Ready to elevate your commercial flooring? Contact Dr Cipy today and transform your space with confidence!

FAQs

1. How does decorative epoxy flooring enhance the appearance of commercial spaces? It transforms dull concrete into a glossy, customized surface with endless design options, instantly boosting visual appeal.

2. Is decorative epoxy flooring easy to maintain? Yes. It’s seamless and non-porous, so regular sweeping and mopping keep it looking fresh without intensive cleaning.

3. How long does decorative epoxy flooring last? With proper installation and care, decorative epoxy flooring can last 10-20 years or more, even in busy commercial settings.

4. Can decorative epoxy flooring increase property value?Absolutely. Its aesthetic appeal, durability, and low upkeep costs can enhance your property’s market and rental value.

0 notes

Text

0 notes

Text

Novolac Epoxy vs Polyurethane Coatings

Choosing the right coating in industrial flooring and protective surface sections is very important in achieving the desired results in durability, chemical resistance, and longevity hence, each project’s requirements must be considered. Among the endless options lies Novolac Epoxy Coatings and Polyurethane Coatings, which are some of the more notable options. Knowing the characteristics of each coating and its application areas help make the right decision.

What is Novolac Epoxy Coating?

Novolac Epoxy Coatings are the uppermost protective coats obtained from epoxy phenol novolac resins. These coatings are best known for their chemical and thermal resistance and are perfect for tough industrial applications.

The main features of Novolac Epoxy Coatings are: These coatings have exceptional resistance to concentrated acids, alkalis, and a broad spectrum of chemicals, making them ideal for highly corrosive zones of chemicals, fertilizers, petrochemicals industries.

Superior Chemical Resistance – They offer exceptional resistance to concentrated acids, alkalis, and various chemicals, making them suitable for aggressive corrosive zones in industries such as chemicals, fertilizers, and petrochemicals.

Higher Glass Transition Temperature – This property ensures stability and performance under elevated temperatures, enhancing the coating’s durability.

Improved Mechanical Properties – Novolac epoxies exhibit enhanced mechanical strength, contributing to their robustness in industrial applications.

What is Polyurethane Coating?

Polyurethane Coatings are the most flexible and resilient protective layers. They are used widely because of their biomechanical properties in various industries. These coats have the following:

UV Absorption – Polyurethane coatings do not lose color and gloss due to sunlight. Therefore, they are good outdoors.

Impact and Abrasion Resistance – Their inherent flexibility allows them to absorb impacts and resist scratches, contributing to a longer lifespan.

Gloss Retention and Surface Appearance – These coatings maintain a glossy finish over time, increasing the appeal of surfaces.

Novolac Epoxy vs. Polyurethane Coatings

When comparing Epoxy Coatings vs. Polyurethane Coatings, several factors come into play.

1. Chemical Resistance: Novolac Epoxy Coatings take the cake for this one. Dr Cipy observes their, “extreme resistance against concentrated acids, alkalines and even solvents.” These chemicals are abundant in processing plants, and nova lobes are ideally suited for such zones. Concerning mild chemicals, Polyurethane Coatings hold up decently, but they cannot compete with novolacs’ extreme conditions.

2. Durability & Flexibility: Polyurethane Coatings take the lead with their elasticity—great for floors with slight movement or heavy foot traffic, like showrooms. Novolac Epoxy, while super durable, is more rigid and can crack under stress if not applied right, per Dr Cipy’s industrial focus.

3. Heat Resistance: Polyurethane coatings do well with heat but cannot take the same extremes. Novolac Epoxy Coatings perform significantly better than standard epoxies in high-heat zones, for example factory ovens.

4. UV Protection: Polyurethane Coatings shine here. They resist yellowing under sunlight and are perfect for outdoor patios or sunny warehouses. Novolac Epoxy tends to fade or chalk if exposed to UV long-term, so it’s better indoors.

5. Finish & Looks: Polyurethane Coatings are for you if you’re after a glossy, showroom coated appeal. Novolac Epoxy coatings focus on function over flash.

Why Choose Dr Cipy?

Consider Dr Cipy, a leading manufacturer specializing in a wide range of flooring and coating products for high-quality coating solutions. Our offerings include Novolac Epoxy Coatings, which is known for its extreme resistance to concentrated acids and chemicals, making them ideal for aggressive corrosive zones in industries such as chemicals, fertilizers, and petrochemicals.

Conclusion

The choice between Novolac Epoxy Coatings and Polyurethane Coatings hinges on the application’s specific requirements. For environments demanding high chemical and thermal resistance, Novolac Epoxy Coatings are the superior choice. Conversely, Polyurethane Coatings are more suitable for applications where flexibility, UV stability, and abrasion resistance are paramount.

Dr Cipy specializes in many flooring and coating products, such as epoxy, polyurethane, EPU and PU concrete, to name a few. We cater to various industries, from food and beverages to healthcare, pharmaceuticals and manufacturing. Dr. Cipy is a market leader and manufacturer of coating solutions, so for the best quality epoxy flooring solutions, look no further than here. Our commitment to innovation and quality ensures durable and high performing product delivery.

Ready to coat your floors right? Contact us now.

FAQs

1. What is the main difference between Novolac epoxy and polyurethane coatings? Novolac Epoxy offers superior chemical and heat resistance, while Polyurethane Coatings provide better flexibility and UV resistance.

2. Which coating is more durable: Novolac epoxy or polyurethane?Novolac Epoxy is more durable in harsh chemical and high-temperature environments, whereas Polyurethane is better for impact and abrasion resistance.

3. Which coating is better for industrial flooring? Novolac Epoxy Coatings are ideal for industries exposed to chemicals, while Polyurethane Coatings work better in high-traffic areas due to their flexibility.

4. Can polyurethane and Novolac epoxy be used together? Yes, Novolac Epoxy can be used as a base coat for chemical resistance, with Polyurethane as a topcoat for UV protection and durability.

0 notes

Text

Mistakes To avoid When Applying Epoxy Flooring

India’s industrial hubs, business centers, and modern commercial towers such as the high-rises of Mumbai and factories in rural Maharashtra make epoxy floor painting the most used option for a shiny, easy-to-maintain finish. Epoxy Floor Paint has the best durability and glossy finish that can wow people, whether it’s a car showroom in Delhi, the busiest mall in Bangalore, or a company warehouse in Pune. However, there is one problem; achieving that flawless finish requires more effort than just pouring some paint and saying “job done”.

Let’s face it: using epoxy floor paint is like making your best-loved biryani. Everything from ingredients to preparation to flawless timing should be on point to achieve the desired goals. Otherwise, you would be left with sticky peeling disappointment instead of the delicious masterpiece.

Avoid These 7 Common Mistakes When Applying Epoxy Flooring

1. Inadequate Surface Preparation

The foundation of a successful epoxy floor paint application lies in thorough surface preparation. Applying epoxy over a contaminated floor with grease, oil, paint, wax, or chemicals can lead to adhesion failures.

2. Insufficient Mixing of Epoxy Components

Mixing the resin and hardener properly is crucial in achieving an epoxy that cures correctly. A failure to mix correctly may lead to uneven color, loss of gloss, slow curing, tacky surfaces, or even coating failure.

3. Ignoring Moisture Content in Concrete

Epoxy cannot be applied on concrete that has not dried fully because it traps moisture and results in bubbles and delamination. It is necessary that the slab to be poured is already free of moisture before applying the epoxy surface to make sure these problems don’t arise.

4. Applying Epoxy Over Contaminated Floors

Applying epoxy over dirtied floors already contaminated with grease, oil, paint, wax or chemicals will lead to adhesion failures. These contaminants are “bond-breakers” that stop the epoxy from adequately bonding with the concrete substrate.

5. Rushing the Application Process

Patience is key when applying epoxy floor paint. Rushing the process can lead to uneven application, air bubbles, and other imperfections. Following the manufacturer’s recommended application techniques and curing times is crucial to achieve a professional finish.

6. Not Considering Environmental Conditions

Environmental factors such as temperature and humidity play a significant role in the curing process of epoxy. Applying epoxy in unsuitable conditions can affect its adhesion and durability. Always ensure that the application environment meets the recommended conditions specified by the manufacturer.

7. Overlooking Safety Precautions

Epoxy products contain chemicals that can be hazardous if not handled properly. It’s essential to wear appropriate personal protective equipment (PPE), ensure adequate ventilation, and follow all safety guidelines during the preparation and application process.

Conclusion

Avoiding these common mistakes is crucial for a successful epoxy floor painting project. Ensuring proper surface preparation, mixing, application techniques and environmental factors will guarantee the longevity and beauty of an epoxy floor.

Dr Cipy specializes in many flooring and coating products, such as epoxy, polyurethane, EPU and PU concrete, to name a few. We cater to various industries, from food and beverages to healthcare, pharmaceuticals and manufacturing. Dr. Cipy is a market leader and manufacturer of coating solutions, so for the best quality epoxy flooring solutions, look no further than here. Our commitment to innovation and quality ensures durable and high performing product delivery.

By partnering with experts like Dr. Cipy, you can ensure that your epoxy flooring project is executed perfectly, resulting in a floor that stands the test of time.

FAQs

1. What are the most common mistakes when applying epoxy floor paint? Skipping surface preparation, improper mixing, applying on a moist surface, and ignoring curing time can lead to epoxy failure.

2. Why is surface preparation important for epoxy floor coatings?Proper surface preparation for epoxy ensures strong adhesion, prevents peeling, and increases the durability of the coating.

3. How long should I wait before using the floor after applying epoxy? Typically, 24-72 hours for light use and 7 days for full curing, depending on the product and environment.

4. How do I properly prepare my floor before applying epoxy paint?Clean thoroughly, remove grease or contaminants, repair cracks, and etch or grind the surface for better adhesion.

0 notes

Text

Novolac Epoxy vs Polyurethane Coatings

0 notes

Text

Common Mistakes When Applying Epoxy Flooring

0 notes

Text

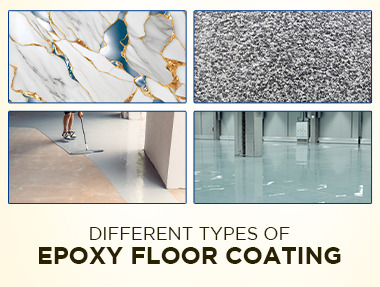

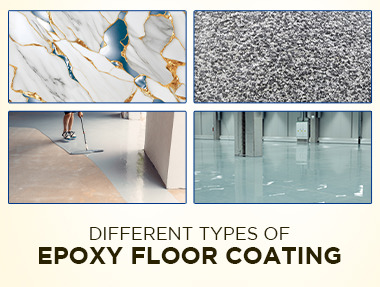

Understanding Epoxy Floor Coating and Its Various Types

Flooring has become a key focus for commercial establishments and industrial establishments. Among the many options available, epoxy floor coating stands out as one of the most durable and long-lasting choices. Epoxy floor coating, made from a resin base and hardener, is applied over concrete floors to provide a strong, protective layer. Epoxy floor coating is a versatile material, capable of protecting surfaces from wear and chemical damage, and is ideal for high-traffic areas such as garages, industrial sites, and commercial spaces. When considering epoxy for your floors, it’s important to understand its benefits, types, and various applications.

Why Use Epoxy Floor Coating?

Epoxy floor coatings are favoured due to their low cost, easy maintenance, and attractive appearance. When used in commercial establishments, they offer a smooth, glossy finish that can withstand heavy foot traffic and exposure to chemicals. The epoxy floor coating provides excellent bonding abilities making it resistant to stains, cracks, and abrasions. Additionally, epoxy is available in a range of designs, making it suitable for both functional and decorative purposes.

Types of Epoxy Coatings for Floors

There are several types of epoxy coatings, each suited to different needs:

Self-Levelling Epoxy Coating – Ideal for rough or damaged concrete floors, this type of epoxy levels itself out, creating a smooth, even surface. It’s commonly used in warehouses and commercial spaces that require a durable, self-surfacing solution.

Epoxy Mortar Coating – Made by blending epoxy resin with mortar, this type offers a high-strength, abuse-resistant coating. It’s perfect for areas that experience heavy wear and tear, like manufacturing facilities.

Gravel Epoxy Floor Coating – For a more textured surface, gravel is embedded in the epoxy layer, providing a non-slip finish. This is commonly used in garages for enhanced safety and strength.

Anti-Static Epoxy Floor Coating – Used in industries like electronics, anti static epoxy flooring prevents the build-up of static electricity, protecting sensitive equipment from damage.

Decorative Epoxy Floor Coating – For those seeking a more visually appealing floor, decorative epoxy floor coating is available in a variety of colours and finishes, including metallic pigments and flakes, offering custom aesthetic options.

Epoxy Floor Coating Advantages

Epoxy floor coatings offer a variety of benefits, making them suitable for commercial spaces. Some of the key epoxy floor coating advantages include:

Easy Maintenance: Epoxy floors are easy to clean. Typically, a mop and detergent are enough to maintain their appearance.

Polished Appearance: The glossy finish of epoxy floors helps make spaces look cleaner and brighter.

Safety: Epoxy floor coatings, especially those with anti-slip properties, reduce the risk of slips and falls in commercial or industrial environments.

Cost-Effectiveness: Epoxy is an affordable flooring option that requires minimal upkeep and offers long-lasting durability.

Epoxy Floor Coating Durability

Once applied, epoxy floor coating bonds strongly to concrete, offering long-term durability with minimal signs of wear. This makes them a popular choice for areas with heavy foot traffic, including commercial and industrial spaces.

Commercial Epoxy Floor Solutions

Dr Cipy offers a range of epoxy floor coatings suited to various industries. Whether you need a heavy-duty coating for a manufacturing plant or a decorative finish for a shopping mall, Dr Cipy provides high-quality products that combine functionality with aesthetics.

Epoxy Floor Coating for Garages

Epoxy floor coating for garages not only provides a clean, glossy finish but also protects the concrete floor from spills, stains, and general wear. Additionally, the anti-slip properties of epoxy floor coatings ensure that your garage remains safe to use, even when wet.

Conclusion

Epoxy floor coatings offer a variety of benefits, making them suitable for both commercial spaces and industrial applications. Whether you need a durable solution for high-traffic areas or a decorative finish for your business, epoxy floor coating is an affordable and effective option. Dr Cipy’s expertise in epoxy floor coatings ensures you receive high-quality, durable solutions for all your flooring needs.

Ready to upgrade your floors? Contact us today to find the ideal epoxy floor coating solution for your space.

FAQs

0 notes

Text

Top Benefits of Installing ESD Flooring in Data Centers

Data centers form the backbone of communication and business operations in the tech-driven world we all dwell in. However, an often-overlooked challenge in maintaining their efficiency is static electricity, which can cause significant damage to sensitive equipment. Electrostatic Discharge (ESD) poses risks such as system failures, equipment breakdowns, and operational downtimes. ESD flooring has become a critical addition to modern data centers to combat these risks.

What is electrostatic discharge prevention flooring or ESD Flooring?

ESD Flooring, or electrostatic discharge prevention flooring, is a specially designed flooring solution that helps control and dissipate static electricity. These floors use conductive materials to direct static charges safely into the ground, preventing harmful discharges. Dr. Cipy understands the importance of static control in data centers and offers durable and seamless ESD flooring systems that not only protect sensitive equipment but also enhance the aesthetics of data centers and server rooms. Thus providing the best data center flooring solutions for static protection.

ESD Flooring Advantages in Data Centers

Protection for Electronics: Safeguard sensitive equipment by maintaining a balance in static charges.

Seamless Design: Joint-free construction prevents cracks and ensures long-lasting durability.

High Strength: Can withstand heavy traffic and extreme operating conditions.

Standard Compliance: Meets stringent standards like EOS/ESD 7.1, ensuring optimal electrostatic control.

Why Static Control is Crucial for Data Centers?

Data centers house critical components such as servers, switches, and storage devices. These delicate electronics are highly susceptible to static discharges, which can lead to:

Equipment failures.

Data loss or corruption.

Increased repair and replacement costs.

Top Benefits of Anti-static Floors for Server Rooms

Electrostatic Discharge Prevention – Static discharges can wreak havoc on expensive equipment. Flooring systems like Dr. Cipy’s Statguard ESD efficiently dissipate static, ensuring maximum protection.

Enhanced Durability – Solutions like Duracrete ESD 2000 are designed to withstand heavy use, offering robust protection against wear, abrasion, and chemical reactions. Thus, providing the best electrostatic discharge prevention flooring.

Low Maintenance – Seamless ESD flooring options, such as Aquoxy ESD, are easy to clean and maintain, reducing downtime and keeping operational costs low.

Cost-Effectiveness – Investing in ESD flooring prevents costly equipment repairs and replacements, making it a budget-friendly, long-term solution.

Improved Operational Efficiency – By preventing sudden equipment failures caused by static, ESD flooring or electrostatic discharge prevention flooring ensures smooth operations and extends the lifespan of electronic systems.

Why Choose Dr. Cipy for ESD Flooring?

Dr. Cipy is a trusted name in resinous flooring solutions, offering specialized ESD flooring systems tailored for data centers. Our product range includes:

Duracrete ESD 2000: Ideal for heavy-duty static dissipative applications.

Statguard ESD 104: Designed for highly conductive environments.

Cipoxy 18 & 17: Durable primers for seamless and efficient flooring installation.

Dr. Cipy’s solutions prioritize quality, compliance, and durability, ensuring that data centers are protected against the invisible threat of static electricity.

Conclusion

In a world where data centers drive business success, ensuring their protection is paramount. ESD flooring not only prevents electrostatic discharge but also enhances the overall safety and efficiency of operations. With solutions like those provided by Dr Cipy, businesses can invest in reliable, durable, and cost-effective static control systems.

Ready to protect your data center from static risks? Choose Dr Cipy’s innovative ESD flooring solutions today!

FAQs

1. What is ESD flooring, and why is it important in data centers?

ESD flooring prevents static electricity buildup, protecting sensitive equipment in data centers from damage and downtime.

2. How does ESD flooring benefit data center operations?

It ensures equipment safety, reduces maintenance costs, prevents system failures, and enhances operational efficiency.

3. Can ESD flooring improve the durability of flooring in data centers?

Yes, ESD flooring like Dr. Cipy’s Duracrete ESD 2000 resists heavy traffic, heat, and wear, ensuring long-lasting performance.

4. What types of ESD flooring options are available for data centers?

Solutions include Duracrete ESD 2000 for heavy-duty use, Statguard ESD 104 for conductive environments, and seamless options like Aquoxy ESD.

#ESD flooring#Benefits of Installing ESD Flooring#Benefits of ESD Flooring#ESD Flooring in Data Centers

0 notes

Text

5 best options for Heavy Traffic Car Parking Flooring Areas

0 notes

Text

ESD Flooring, or electrostatic discharge prevention flooring, is a specially designed flooring solution that helps control and dissipate static electricity. These floors use conductive materials to direct static charges safely into the ground, preventing harmful discharges.

#ESD Flooring#ESD Flooring in Data Centers#Benefits of Anti static#Installing ESD Flooring#data center with ESD flooring

0 notes

Text

Types of Epoxy Coatings for Floors

#Epoxy Coatings#Types of Epoxy Coatings#Epoxy Coatings for Floors#anti static epoxy flooring#Epoxy Floor Coating Advantages

0 notes

Text

Choosing the Right Epoxy Flooring for Your Healthcare Facility

Each and every single thing in healthcare facilities counts – right from the equipment used to the flooring underfoot. The choice of flooring is particularly significant because it affects hygiene, safety, and patient care in general. Epoxy flooring for healthcare facilities is one of the most reliable and long-lasting solutions compared to others. However, what kind of epoxy floor should you choose for your facility?

Why Use Epoxy Flooring for Healthcare?

Healthcare facilities including hospitals, clinics, and laboratories need flooring that meets strict standards regarding cleanliness, safety, and durability. They must be able to withstand constant foot traffic as well as regular cleaning using harsh chemicals and exposure to possible contaminants. This is where epoxy flooring for healthcare stands vital.

Epoxy is a kind of floor finish that is seamless, durable and can be tailored in many ways to meet particular requirements within healthcare settings. While it is aesthetically pleasing, it also offers great hygienic properties making it ideal for areas where sanitation matters most. By installing epoxy on the floors throughout your facility – from surgical suites to patient rooms – you will make each space a safe and clean environment.

Benefits of Choosing the Right Epoxy Flooring in Healthcare

1) Hygienic Flooring Solutions

The main reason for choosing epoxy flooring for healthcare industry is its ability to provide a seamless nonporous substrate which traditional floor coverings like tiles do not have as they contain grout lines where dirt can accumulate. Aside from being glossy, this makes them a good choice when hygiene comes first. This makes sanitary flooring for healthcare an excellent hygienic flooring solution, reducing the risk of contamination and contributing to infection control efforts.

2) Durability and Longevity

Healthcare facilities experience heavy foot traffic and frequent use of medical equipment, which can cause significant wear and tear on floors. Hospital epoxy flooring by Dr Cipy is known for its durability and ability to withstand impact, abrasions, and chemicals. This sanitary flooring for healthcare is built to last, reducing the need for frequent repairs or replacements, which can be both disruptive and costly.

3) Safety/Slip Resistance

Safety is a major concern in healthcare environments where the risk of slipping or falling is high. Epoxy flooring for healthcare facilities can be textured to make it slip-resistant, ensuring patient safety as well as that of staff and visitors. Additionally, hospital epoxy flooring can have colour-coded zones for clear designation of different areas such as sterile zones or pathways thus improving overall safety within the establishment.

4) Aesthetic Flexibility

Beyond its functional benefits, epoxy flooring offers a wide range of aesthetic options. Healthcare facilities can choose from various colours, patterns, and finishes to create a soothing and professional atmosphere that aligns with the facility’s branding. The ability to customize the appearance of the flooring without compromising on performance makes epoxy a versatile choice for any healthcare setting.

Choosing the Right Epoxy Flooring for Your Healthcare Facility:

Selecting the right epoxy flooring involves considering several factors, including the specific needs of your facility, the types of spaces that need flooring, and budget constraints. Here are some key considerations:

Type of Epoxy: There are different types of epoxy flooring such as self-leveling epoxy, epoxy terrazzo, and antimicrobial epoxy. For healthcare facilities, the best choice is antimicrobial epoxy floors which go further in reducing bacterial growth.

Application Area: Consider the application of the floor. For example, operating rooms may require more stringent flooring solutions than corridors or administrative areas. The right epoxy flooring should meet the specific requirements of each division in your institution.

Maintenance Requirements: While epoxy flooring is generally low-maintenance, different finishes may have varying upkeep needs. Choosing a finish that aligns with your facility’s cleaning protocols will ensure longevity and maintain hygiene standards.

Conclusion:

Choosing suitable epoxy flooring for your healthcare organization is essential since it affects both the safety of patients as well as operating effectiveness. A clean functional pleasant environment can be ensured if you opt for a floor that emphasizes hygiene, sustainability, and secureness. Whether setting up new premises or refurbishing old ones, investing in epoxy coating brings long-term rewards.

At Dr. Cipy, we understand the unique challenges of healthcare environments and are dedicated to providing tailored flooring solutions that meet your facility’s specific needs. Contact us today to learn more about how our epoxy flooring solutions can enhance the safety and efficiency of your healthcare facility.

#Hospital epoxy flooring#benefits of anti static flooring#epoxy flooring#Epoxy Flooring in Healthcare

0 notes

Text

Why to Choose Epoxy Flooring?

While choosing a floor covering, the most versatile and durable option available for industrial, commercial or even residential purposes is epoxy flooring. Epoxy floorings made from epoxide resins are high-performing solutions and provide a smooth and durable surface which can last for many years, sustaining heavy abuses.

This article will examine various epoxy flooring benefits, why it is widely used in different applications as well as real-life examples indicating its advantages.

So, Why Choose Epoxy Flooring?

Epoxy flooring refers to a floor surface composed of several layers of epoxy, a thermosetting resin poured to at least 2 mm depth over the concrete floors. It has an incredibly robust, long-lasting nature that makes it the perfect option for areas with heavy footfall. By combining hardener and resin, epoxy flooring is created, resulting in a chemically resistant and strong surface.

Damage Resistance

Extraordinary strength and durability are some prominent reasons why most people prefer using epoxy flooring. Epoxy floors are resistant to wear and tear, which makes them ideal for areas with high foot traffic and heavy vehicle movement. Unlike traditional flooring options, epoxy does not easily crack or chip, ensuring the surface remains intact for years.

Cost-Effective Flooring

While the initial installation cost of epoxy flooring might be higher than some traditional flooring options, its long-term benefits make it a cost-effective choice. Epoxy flooring requires minimal maintenance and has a long life span, reducing the need for frequent repairs or replacements. This makes it an economically sound investment in the long run.

Easy-to-clean flooring

Epoxy floors are highly resistant to stains and spills, making them very easy to clean and maintain. They do not absorb liquids since they are non-porous, hence many spills can be easily wiped out of the floor without leaving any stains behind. Such types of floor finishes are commonly used in places like hospitals, hotels, F&B or pharma where hygiene comes first.

Slip-resistant flooring

Safety should always be considered while selecting flooring, which makes epoxy floors so popular. Slip-resistant epoxy floorings are available which make walking safer even in wet conditions. This is very important in factories where slips and falls are common.

Heavy duty flooring

The main reason why most people prefer epoxy flooring is because of its ability to withstand heavy-duty loads and vehicular traffic. This type of floor is often used in warehouses, automotive workshops and factories where forklifts and pallet trucks move quite often.

Versatile & Attractive

Epoxy flooring from Dr Cipy can be customized with a variety of colours and finishes for an appealing look. You can go for a shiny surface if you want your showroom to look elegant or matt finish on the factory floor, as epoxy floors are customizable. Its seamless appearance also adds to its aesthetic appeal, providing a modern and clean look.

Use Case Examples

Industrial Warehouses

Epoxy flooring can sustain daily abuses like forklift movements, constant vehicle traffic, movement of heavy machineries etc. Despite the harsh environment, the floor will always remain intact owing to its high wear resistance and resistance towards chemicals and oil spills.

Commercial Kitchens

The foremost things in commercial kitchens are tidiness and safety. For instance, the epoxy flooring which can be cleaned easily without slipping has been the best choice. It is easy to wash away spills, thus reducing accidents as well as maintaining a clean environment.

Hospitals

In healthcare surroundings, keeping the environment clean is very significant. Epoxy flooring protects the entire facility from waterborne bacteria and microbes, since it is nonporous and seamless thereby making it an ideal option for hospitals and clinics.

Conclusion

Choosing epoxy flooring guarantees you durability, and affordability in terms of maintenance, ease as well as safety. Epoxy floors are versatile with attractive finishes, hence applicable in many areas ranging from warehouses to hospitals and kitchens. With epoxy floorings, you get a durable solution that fits all your needs.

Consider Dr Cipy for high quality epoxy floorings. Over the years Dr.Cipy has been providing epoxy flooring solutions that are both functional and elegant.

For more information visit Dr Cipy, and find out why you need an epoxy floor today.

0 notes

Text

Why to Choose Epoxy Flooring?

Explore the benefits of epoxy flooring for durability, safety, and easy maintenance. Ideal for any space. Visit Dr Cipy now to discover top-quality epoxy flooring solutions!

0 notes

Text

The Benefits of Anti-Static Flooring

Today, electronic equipment is increasingly important in many industries. In such surroundings, it is critical to protect sensitive electronic components from electrostatic discharge (ESD) in manufacturing plants, data centres and hospitals. Anti static flooring is a fundamental solution that ensures a safe ESD-safe environment, preventing potential damage to electronic devices and protecting both equipment and people within the facility. This flooring solution is designed to control and dissipate static electricity, offering numerous benefits that go beyond basic functionality.

What is Anti-Static Flooring?

Anti-static flooring minimizes static electrical energy buildup on its surface through its specially engineered design as a flooring system. Static electricity may seem insignificant but it could cause more harm in environments where there are delicate electronic components. A simple release of static charge can cause malfunction, data loss or even permanent damage to electronic devices. This makes static control flooring a crucial aspect of safety and operational efficiency in high-tech industries.

Usually, materials used in making Anti-Static Flooring have some conductive elements allowing for safe dissipation of static electricity. This means that any movement-induced or friction-generated electric charge will be immediately discharged so as not to reach harmful levels. In industries such as electronics manufacturing, telecommunication and healthcare even the slightest electrostatic discharge can lead to severe consequences.

Benefits of Anti-Static Flooring

Protection of Sensitive Equipment: One of the most noteworthy benefits of anti-static flooring is the protection it offers to sensitive electronic equipment. In environments such as data centres or semiconductor manufacturing facilities, static electricity can cause data corruption, equipment failure, and costly downtime. By installing anti-static flooring from Dr Cipy, these risks are significantly reduced, providing continuous and reliable operation of critical systems.

Enhanced Safety for Personnel: Static electricity doesn’t just pose a risk to equipment; it can also be hazardous to people. In environments where flammable materials are present, a static discharge could ignite a fire or explosion. Anti-static flooring helps to prevent such incidents, creating a safer work environment for employees.

Compliance with Industry Standards: Many industries are subject to stringent regulations regarding ESD-safe environments (electrostatic discharge). Anti-static flooring helps businesses comply with these standards, ensuring that their facilities meet all necessary safety and operational guidelines.

Durability and Low Maintenance: Anti-static flooring material is designed to be durable and easy to maintain. It withstands heavy foot traffic and resists wear and tear, making it a cost-effective solution for facilities that require long-lasting performance. Regular maintenance is minimal, further reducing the overall cost of ownership.

Versatility in Application: Anti-static flooring by Dr Cipy is versatile and can be installed in a variety of settings. Whether it’s a cleanroom, a laboratory, a manufacturing plant, or an office environment, this flooring solution can be customized to meet the specific needs of the space. The versatility of anti-static flooring installation ensures that it can be seamlessly integrated into any facility design.

Conclusion

At a time when technology plays a pivotal role in virtually every industry, shielding electronic equipment and ensuring a safe work environment is paramount. Anti-static flooring is an indispensable solution that offers a range of benefits, from protecting sensitive equipment to enhancing workplace safety and ensuring compliance with industry standards. Its versatility and durability make it an ideal choice for a wide range of applications, from high-tech manufacturing to healthcare.

For businesses looking to implement an effective static control solution, Dr. Cipy’s anti-static flooring offers the expertise and quality required to create a safe and efficient environment. With a proven track record in providing top-notch static control solutions, Dr. Cipy stands out as a trusted partner in achieving operational excellence. Contact us now.

0 notes