Don't wanna be here? Send us removal request.

Photo

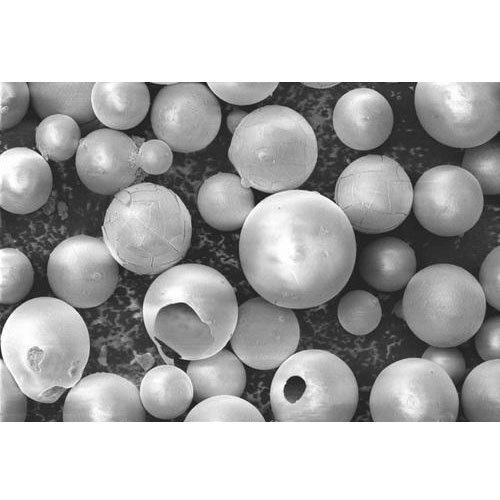

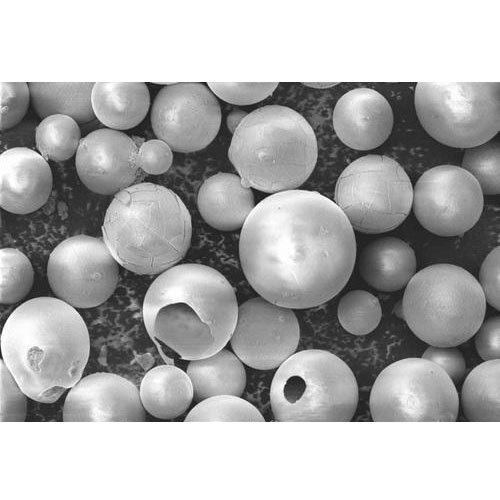

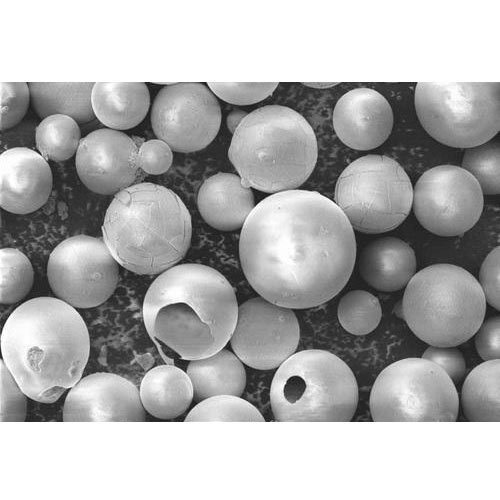

Cenosphere is growing globally on a steady pace

Expansion and the acquiring of resources appear to be the conclusion of the presented materials. China and India have developed within the market and have created high expectations within the Asian market as a whole. The Asia-Pacific region appears to be the most strategic as this region has undertaken a variety of initiatives. The increase in domestic participants and steady growth in local manufacturing are just a couple factors contributing to the expanding global cenosphere market.

Construction Information Initiative by Excellex Solutions

#cenosphereproduction#boostincenospheres#benefitsofcenosphere#cenosphereislitefil#cenospheresupplierinindia#bestcenosphereinindia#qualitycenosphereinindia

0 notes

Photo

Growth of Cenospheres across the world

Between 2015 and 2020, researchers expect the compound annual growth rate of cenospheres to grow by over 12% per year. At the end of this five-year term, the market for cenospheres is said to be worth $572 million, globally. The demand for cenospheres in places like the U.S and China are said to be the cause of this projection. Other countries whose demand for the product increases every day are France, Germany, Japan, and India. North America is the largest consumer of cenospheres, followed closely by Europe.

Construction Information Initiative by Excellex Solution

#boostincenospheres#cenosphereproduction#bestcenosphereinindia#qualitycenosphereinindia#benefitsofcenosphere#cenospheresupplierinindia#cenosphereislitefil

0 notes

Text

Production of Cenosphere is going to get a boost in the Upcoming Year

Excellex Solutions based in India delivers an inclusive quality of global cenosphere following the new and latest trends.

Between 2015 and 2020, researchers expect the compound annual growth rate of cenospheres to grow by over 12% per year. At the end of this five-year term, the market for cenospheres is said to be worth $572 million, globally. The demand for cenospheres in places like the U.S and China are said to be the cause of this projection. Other countries whose demand for the product increases every day are France, Germany, Japan, and India. North America is the largest consumer of cenospheres, followed closely by Europe.

Cenospheres are predominantly used by the oil and gas industries. Following this lead is the refractory industry, which is experiencing heightened demand for furnace and construction applications.

Expansion and the acquiring of resources appear to be the conclusion of the presented materials. China and India have developed within the market and have created high expectations within the Asian market as a whole. The Asia-Pacific region appears to be the most strategic as this region has undertaken a variety of initiatives. The increase in domestic participants and steady growth in local manufacturing are just a couple factors contributing to the expanding global cenosphere market.

Construction Information Initiative by Excellex Solution

#cenosphereproduction#boostincenospheres#qualitycenosphereinindia#cenosphereislitefil#benefitsofcenosphere#cenospheresupplierinindia#bestcenosphereinindia

0 notes

Photo

In summary, fly ash has a wide range of attributes. It saves time and money, provides strength and durability, yields improved concrete flow and workability, and helps produce high-quality finished products. It is an excellent building and structural material.

In addition, the appearance of concrete can be affected by excess lime. As mentioned earlier, Portland cement reacts with water to generate lime. As the lime leaches onto the surface of the concrete and evaporates, it leaves behind a milk-colored, powdery residue. On vertical and sloped concrete structures, streaks may occur.

Construction Information Initiative by Excellex Solution

#qualitiesofflyashinindia#benefitsofflyash#bestflyashinindia#qualityflyashinindia#flyashsupplierinindia

0 notes

Text

How Micro silica helps in improving the strength of Concrete?

Micro silica is a mineral admixture composed of very fine solid glassy spheres of silicon dioxide. Most micro silica particles are less than 1 micron (0.00004 inches) in diameter, generally 50 to 100 times finer than average cement or fly ash particles. Frequently called condensed silica fume, micro silica is a by-product of the industrial manufacture of ferrosilicon and metallic silicon in high-temperature electric arc furnaces.

How Micro silica works in Concrete?

Micro silica in concrete contributes to strength and durability in two ways: as a pozzolan, micro silica provides more uniform distribution and a greater volume of hydration products; as a filler, micro silica decreases the average size of pores in the cement paste. Used as an admixture, micro silica can improve the properties of both fresh and hardened concrete. Used as a partial replacement for cement, micro silica can substitute for energy-consuming cement without the sacrifice of quality.

The addition of micro silica to a concrete mix alters the cement paste structure. The resulting paste contains more of the strong calcium-silicate hydrates and less of the weak and easily soluble calcium hydroxides than do ordinary cement pastes. Because the micro silica particles are so small they disperse among and separate the cement particles. The resulting fine, uniform matrix can give markedly higher compressive, flexural, and bond strength.

Micro silica reduces the rate of carbonation, decreases permeability to chloride ions, imparts high electrical resistivity, and has little effect on oxygen transport. Therefore, micro silica concrete can be expected to be strongly protective of reinforcement and embedment.

Mixing and placing considerations

Because of its extreme fineness, micro silica presents handling problems. Some producers mix micro silica with water on a pound-for-pound basis to form a slurry that is transportable in tank trailers designed to handle liquids. The water of the slurry replaces part of that ordinarily added to the mix. When no water reducing agent is used, the addition of micro silica to a concrete mix calls for more water to maintain a given slump. The gel that forms during the first minutes of mixing micro silica concrete takes up water and stiffens the mixture, necessitating adjustment of the timing of charging and placing.

Construction Information Initiative by Excellex Solutions

#qualitiesofmicrosilicainindia#qualitymicrosilicainindia#benefitsofmicrosilica#bestmicrosilicainindia#microsilicasupplierinindia

0 notes

Photo

Protective Qualities of Fly Ash blended with Concrete

FA-concrete is also less susceptible to many of the common environmental stressors that take a toll on traditional concrete. Decreased permeability is the primary reason. FA-concrete can fend off surface assaults and sustain considerably less damage because it has fewer voids and consequently blocks deleterious substances from freely penetrating the concrete. A major concrete corrosive is salt, and particularly the chloride it contains. Salt can also have negative effects on the steel bars and latticework often embedded in concrete as reinforcement. Both seawater vapor in coastal areas and deicing salt in colder regions can quickly ravage concrete.

The smooth, spherical, fly ash particles can maneuver around aggregate and fill voids without as much help from water. In addition, when FA-concrete is used in the proper mix proportions, microscopic voids remain. These tiny air pockets serve as safe storage vessels for freezing water in which it expand safely without compromising the concrete's integrity.

Construction Information Initiative by Excellex Solution

#qualitiesofflyashinindia#benefitsofflyash#bestflyashinindia#qualityflyashinindia#flyashsupplierinindia

0 notes

Text

Is Fly Ash necessary in concrete?

Fly ash is a group of materials that can vary significantly in composition. It is residue left from burning coal, which is collected on an electrostatic precipitator or in a baghouse. It mixes with flue gases that result when powdered coal is used to produce electric power. Since the oil crisis of the 1970s, the use of coal has increased. In 1992, 460 million metric tons of coal ash were produced worldwide. About 10 percent of this was produced as fly ash in the United States. In 1996, more than 7 million metric tons were used in concrete in the U.S. Economically, it makes sense to use as much of this low-cost ash as possible, especially if it can be used in concrete as a substitute for cement.

Construction Information Initiative by Excellex Solution

#qualitiesofflyashinindia#benefitsofflyash#bestflyashinindia#qualityflyashinindia#flyashsupplierinindia

0 notes

Text

What are the Important Factors of Fly Ash in Concrete?

Fly ash is a group of materials that can vary significantly in composition. It is residue left from burning coal, which is collected on an electrostatic precipitator or in a baghouse. It mixes with flue gases that result when powdered coal is used to produce electric power. Since the oil crisis of the 1970s, the use of coal has increased. In 1992, 460 million metric tons of coal ash were produced worldwide. About 10 percent of this was produced as fly ash in the United States. In 1996, more than 7 million metric tons were used in concrete in the U.S. Economically, it makes sense to use as much of this low-cost ash as possible, especially if it can be used in concrete as a substitute for cement.

Here are a few benefits of Fly Ash:

1. Pocket and Planet Friendly

Because fly ash is initially a waste byproduct of coal-burning operations, FA-concrete is a cost-effective alternative to concrete made with only Portland cement as the binder. That alone is enough to pique the interest of concrete producers and contractors. Its versatility as a construction material makes it even more attractive. Because it has greater flowability, contractors find it reduces time at the job site. In addition, FA-concrete has shown improved strength and durability, which means that buildings, bridges, roads, and sewers have the potential for longer life.

Fly ash's "green" qualities provide yet another enticement. Cement production requires heat, which uses energy and releases copious amounts of carbon dioxide, a greenhouse gas, into the atmosphere. In contrast, fly ash is a plentiful waste product. The amount of fly ash generated annually is enormous, with the United States alone producing more than 60 million metric tons every year. By using fly ash as a construction material, contractors are recycling a waste product that would otherwise find its way into a landfill, and reducing the demand for cement.

2. Provides increased Strength for a longer time

The advantages of concrete made with fly ash (FA-concrete) grow from its physical and chemical characteristics. Fly ash particles are small, smooth, and round in shape, attributes that allow them to move readily around the aggregate to create an FA-concrete mixture with fewer voids. On the chemical side, fly ash makes a critical contribution by reacting with the lime (calcium hydroxide) that results when cement mixes with water. The fly ash reacts with the lime to make the same binder, called calcium silicate hydrate, that is created when cement and water mix. In other words, hydrated cement yields the concrete binder along with lime, and fly ash uses that lime to make more binder. Fly ash, therefore, can be used to replace at least some of the cement in a concrete mixture.

3. Protective Qualities

FA-concrete is also less susceptible to many of the common environmental stressors that take a toll on traditional concrete. Decreased permeability is the primary reason. FA-concrete can fend off surface assaults and sustain considerably less damage because it has fewer voids and consequently blocks deleterious substances from freely penetrating the concrete. A major concrete corrosive is salt, and particularly the chloride it contains. Salt can also have negative effects on the steel bars and latticework often imbedded in concrete as reinforcement. Both seawater vapor in coastal areas and deicing salt in colder regions can quickly ravage concrete.

The smooth, spherical, fly ash particles can maneuver around aggregate and fill voids without as much help from water. In addition, when FA-concrete is used in the proper mix proportions, microscopic voids remain. These tiny air pockets serve as safe storage vessels for freezing water in which it expand safely without compromising the concrete's integrity.

4. Quality Finished Product

Strength and durability are vital to a quality finished product, and so is appearance. In this aspect, FA-concrete again improves upon traditional concrete.

The augmented flowability of FA-concrete helps ensure that the concrete will more completely fill the formwork used to contain it in its plastic state until it sets or hardens. It will spread from top to bottom and to all edges of the formwork with less work, with an even consistency, and with fewer voids.

In addition, the appearance of concrete can be affected by excess lime. As mentioned earlier, Portland cement reacts with water to generate lime. As the lime leaches onto the surface of the concrete and evaporates, it leaves behind a milk-colored, powdery residue. On vertical and sloped concrete structures, streaks may occur.

In summary, fly ash has a wide range of attributes. It saves time and money, provides strength and durability, yields improved concrete flow and workability, and helps produce high-quality finished products. It is an excellent building and structural material.

Construction Information Initiative by Excellex Solution

#qualitiesofflyashinindia#benefitsofflyash#bestflyashinindia#qualityflyashinindia#flyashsupplierinindia

0 notes

Photo

What are the Uses of Cenosphere?

In construction, it is used in acoustic enhancement, acrylic, adhesives, coatings, backer board, wall panels, types of cement, cultured marble, epoxy, explosives, Exterior Insulation Finishing Systems(EIFS), fiberglass, laminates, lightweight aggregate, synthetic wood, spackle, carpet backing, geothermal types of cement, concrete fiberboard, joint a compound, wood fillers.

In coatings, it is used in highways, driveways, underground pipes etc.

In ceramics, it is used in Tiles, firebricks, coatings, refractory, insulating materials, high-temperature cement.

Construction Information Initiative by Excellex Solution

#qualitycenosphereinindia#cenospheresupplierinindia#bestcenosphereinindia#benefitsofcenosphere#cenosphereislitefil

0 notes

Photo

The cenosphere market can be described as expanding, with the number of applications available to these small balls of alumosilicate microspheres growing. New markets have been established among battery manufacturers, plastics producers, in paints and industrial coatings, as well as in the construction industry. While developers of modern composites are finding new uses all the time, including in the automobile industry as a lightweight alternative to aluminum.

Construction Information Initiative by Excellex Solution

#benefitsofcenosphere#qualitycenosphereinindia#cenosphereislitefil#bestcenosphereinindia#cenospheresupplierinindia

0 notes

Photo

Manufacturing advantages of hollow ceramic microsphere is that it improves flowability and provides distribution of filler material. Because of its natural property’s microsphere can be used in wet slurry or dry form. Hollow ceramic microsphere provides low surface area-to-volume ratio with easy application. It has great inert properties they are not much affected by water, alkalis, solvents or acids.

They are 30% lighter than all resins and 70% lighter among other minerals that are currently used as fillers.

Construction Information Initiative by Excellex Solution

#qualitycenosphereinindia#benefitsofcenosphere#bestcenosphereinindia#cenosphereislitefil#cenospheresupplierinindia

0 notes

Photo

The cenosphere market can be described as expanding, with the number of applications available to these small balls of alumosilicate microspheres growing. New markets have been established among battery manufacturers, plastics producers, in paints and industrial coatings, as well as in the construction industry. While developers of modern composites are finding new uses all the time, including in the automobile industry as a lightweight alternative to aluminum.

Construction Information Initiative by Excellex Solution

#cenospheresupplierinindia#bestcenosphereinindia#qualitycenosphereinindia#benefitsofcenosphere#cenosphereislitefil

0 notes

Text

How Cenosphere is useful in the modern World?

Firstly, Cenosphere is also known as Litefil. A hollow microscopic ball made up of some minor ceramic elements with the smooth silica-aluminum is Cenosphere. Its derivation has been done from the extreme fire of coal-fired power plants and now it is being used to improvise the qualities of manufactured products in India.

In India, Cenospheres are made of iron, alumina & silica by Petra Buildcare Products. In thermal power plants, burning coal produces fly ash which has ceramic particles largely made of alumina and silica.

Manufacturing advantages of hollow ceramic microsphere is that it improves flowability and provides distribution of filler material. Because of its natural properties microsphere can be used in wet slurry or dry form. Hollow ceramic microsphere provides low surface area-to-volume ratio with easy application. It has great inert properties they are not much affected by water, alkalis, solvents or acids.

They are 30% lighter than all resins and 70% lighter among other minerals that are currently used as fillers.

What are the Uses of Cenosphere?

In construction, it is used in acoustic enhancement, acrylic, adhesives, coatings, backer board, wall panels, cement, cultured marble, epoxy, explosives, Exterior Insulation Finishing Systems(EIFS), fiberglass, laminates, lightweight aggregate, synthetic wood, spackle, carpet backing, geothermal cement, concrete fiberboard, joint the compound, wood fillers.

In coatings, it is used in highways, driveways, underground pipes etc.

In ceramics, it is used in Tiles, firebricks, coatings, refractory, insulating materials, high-temperature cement.

What are the major benefits of Cenosphere?

Reduces Weight

Sphericity

Sound Attenuation

Thermal Reflectivity

Refractory

Strength

Overall, the cenosphere market can be described as expanding, with the number of applications available to these small balls of alumosilicate microspheres growing. New markets have been established among battery manufacturers, plastics producers, in paints and industrial coatings, as well as in the construction industry. While developers of modern composites are finding new uses all the time, including in the automobile industry as a lightweight alternative to aluminum.

Construction Information Initiative by Excellex Solution

#, #, #, #, #

#qualitycenosphereinindia#benefitsofcenosphere#bestcenosphereinindia#cenosphereislitefil#cenospheresupplierinindia

1 note

·

View note