Don't wanna be here? Send us removal request.

Text

A Geologist’s Nightmare: Slow Traditional Magnetometers? How JPMG’s 3‑Second Sampling Breaks the Deadlock

1. Introduction: The Speed Bottleneck That Haunts Geoscientists

In modern geological exploration, sampling speed often dictates project cost and feasibility. Traditional Proton Magnetometer and High‑Sensitivity Magnetometer units typically require 10–30 seconds per reading, severely hampering survey line efficiency. When faced with thick overburdens, subtle mineralization targets, and urban electromagnetic noise, geoscientists struggle to obtain reliable data in time, driving costs sky-high and creating safety risks.

2. Limitations of Conventional Magnetometers

Low Sampling Rate: Most legacy devices operate below 1 Hz, insufficient for real‑time profile mapping.

Poor Interference Rejection: Standard OCXO Magnetometer modules lack robust temperature drift compensation, leading to data distortion in varying climates.

Bulky Form Factor: Heavy Geomagnetic Survey Equipment demands extensive logistics support, limiting field agility.

Delayed Data Workflow: Wired data transfer hampers integration with Portable Magnetic Gradiometer and Underground Pipeline Detector systems, delaying analysis.

3. JPMG Series Proton Magnetometer: Cracking the 3‑Second Challenge

3.1 Core Sampling Technology

The JPMG Series combines an OCXO temperature‑controlled oscillator with an intelligent digital filtering algorithm, slashing single‑point sampling time to just 3 seconds while maintaining ±0.1 nT accuracy and enabling up to 0.33 Hz output.

3.2 Enhanced Sensitivity

Equipped with a High‑Sensitivity Magnetometer module, JPMG can resolve minute magnetic anomalies below 0.05 nT, delivering unmatched performance in subtle Magnetic Anomaly Detection.

3.3 Smart Data Integration

Seamless GPS/GIS, KML/CSV export, and real‑time telemetry make it trivial to synchronize with Portable Magnetic Gradiometer arrays or Underground Pipeline Detector networks, streamlining Mineral Exploration Tools and Archaeological Survey Equipment workflows.

4. Key Application Scenarios & Case Studies

Urban Pipeline Avoidance: Integrated with Underground Pipeline Detector systems, JPMG’s 3‑second cadence maps buried utilities in real time, safeguarding construction.

Hidden Mineral Target Delineation: In 30–50 m overburden settings, JPMG discriminates ore body boundaries that confounded traditional survey gear.

Archaeological Prospecting: As a part of Archaeological Survey Equipment, JPMG’s grid‑scan approach reliably hones in on subsurface ruins and foundation lines.

5. Competitive Comparison

Feature / MetricJPMG Series Proton MagnetometerCompeting Proton MagnetometerPortable Magnetic GradiometerAccuracy±0.1 nT±0.2 nT±0.5 nTSampling Time3 seconds10–15 seconds5 secondsInterference RejectionOCXO + digital filteringStandard oscillatorAnalog filteringData InterfacesGPS/GIS/KML/CSVCSV onlyProprietary formatPortabilityCompact handheldSplit‑bodyHandheld

6. Why Choose JPMG?

Efficiency: Reduces field survey time by over 30% with rapid 3‑second sampling.

Precision: ±0.1 nT accuracy and ultra‑high sensitivity catch even the faintest anomalies.

Portability: All‑in‑one handheld design thrives in rugged terrain where bulky gear falters.

Intelligence: Real‑time data upload complements any suite of Geological Prospecting Instruments, from Mineral Exploration Tools to Archaeological Survey Equipment.

7. Conclusion & Future Outlook

By fusing 3‑second sampling with high sensitivity and smart integration, the JPMG Series Proton Magnetometer redefines efficiency and accuracy across mineral exploration, urban survey, and archaeological applications. Looking ahead, as AI‑driven interpretation, UAV‑borne Magnetic Survey Equipment, and multi‑sensor fusion continue to evolve, JPMG is poised to anchor the next generation of portable Gradiometry and Geomagnetic Survey Equipment—ushering geological exploration into a new era of “real‑time data, intelligent insights.”

Tags

0 notes

Text

In-Depth Analysis of the JPMG Series Proton Magnetometer

I. Introduction

II. Definition and Concept

2.1 Overview of the Proton Magnetometer

The Proton Magnetometer operates based on the proton magnetic resonance principle, wherein the precession frequency of protons in a magnetic field is directly proportional to the magnetic field strength. By accurately measuring this precession, the instrument provides exceptionally precise magnetic data—making it a cornerstone for Proton Magnetometer applications in detecting magnetic anomalies and surveying geologic structures.

2.2 The Role of OCXO Technology

The incorporation of the Oven Controlled Crystal Oscillator (OCXO) in the JPMG series ensures ultra-stable frequency output under varying environmental conditions, minimizing temperature drift and providing high data accuracy. This technological innovation positions the JPMG as an industry-leading OCXO Magnetometer suitable for high-precision measurements.

2.3 Key Terminology Explained

To better understand the product’s market position, consider the following definitions:

Proton Magnetometer: An instrument that measures Earth’s magnetic field based on proton resonance.

High-Sensitivity Magnetometer: Capable of capturing minute variations in magnetic fields, vital for detecting subtle anomalies.

Geomagnetic Survey Equipment: Devices used for wide-ranging surveys of Earth’s magnetic field to infer subsurface structures.

Portable Magnetic Gradiometer: A compact device designed for field surveys with high mobility, crucial in challenging environments.

Mineral Exploration Tools: Equipment utilized to locate and evaluate potential mineral deposits.

Archaeological Survey Equipment: Instruments aiding in the non-invasive detection of subsurface cultural and historical artifacts.

Underground Pipeline Detector: Tools designed for accurately locating buried pipelines to avoid construction hazards.

Magnetic Anomaly Detection: The process of identifying local magnetic field variations that indicate hidden subsurface features.

Geological Prospecting Instruments: An umbrella term for devices used in detailed geological surveys and resource prospecting.

III. Comparative Analysis of Magnetic Survey Methods

3.1 Operational Principles

Different magnetometers, such as magnetic resistance sensors, Hall effect magnetometers, and optical-pumping magnetometers, operate on varying principles:

Proton Magnetometers (e.g., JPMG Series) use proton resonance, offering high accuracy and stability.

Magnetic Resistance Sensors are more cost-effective but sensitive to temperature variations and noise.

Optical Pumping Magnetometers offer high sensitivity but typically come with complex configurations and higher costs.

3.2 Performance Metrics

The JPMG Series excels in several performance areas:

Sensitivity and Accuracy: With an accuracy reaching 0.01 nT, it is among the most precise High-Sensitivity Magnetometers available.

Data Acquisition Rate: Supporting flexible sampling rates, the instrument captures real-time magnetic variations ideally suited for dynamic field environments.

Portability: Its lightweight design ensures quick deployment in field surveys, classifying it as a premier Portable Magnetic Gradiometer.

Stability: OCXO technology significantly enhances measurement stability, a notable advantage over conventional systems.

3.3 Forward and Inverse Modelling Comparison

For geophysical data processing, forward modelling uses geological models to predict magnetic anomalies, while inverse modelling deduces subsurface structures from measured data. With its superior data quality, the JPMG series enables more reliable inverse modelling, reducing error margins by approximately 20% compared to older systems. This improvement is critical for accurate Magnetic Anomaly Detection and enhances the interpretative value for Geological Prospecting Instruments.

IV. Application Scenarios and Case Studies

4.1 Mineral Exploration

In mineral exploration, the ability to detect subtle magnetic anomalies is essential for delineating ore body boundaries. Case Study: In a northern mining district, the JPMG Series was deployed over a 50-meter thick cover layer. The high-sensitivity measurements revealed a clear magnetic anomaly corresponding to an iron-rich zone. Subsequent drill tests confirmed the anomaly, demonstrating the instrument’s effectiveness as a reliable Mineral Exploration Tool.

4.2 Archaeological Surveys

Archaeologists often rely on non-invasive methods to identify underground structures without damaging precious artifacts. Case Study: At a heritage site in the arid regions, the JPMG Series was employed to scan for subsurface cultural remnants. The instrument successfully isolated distinct linear magnetic anomalies indicative of ancient building foundations. This result not only streamlined the excavation process but also preserved site integrity, proving its value as advanced Archaeological Survey Equipment.

4.3 Underground Pipeline Detection

Accurate mapping of underground pipelines is critical for urban infrastructure planning and maintenance. Case Study: During a municipal upgrade project, the JPMG Series was used to detect buried pipelines amid a complex urban environment. Its portable design and high resolution enabled the rapid identification of multiple pipeline networks, reducing potential construction hazards and ensuring project safety. This application underscores its role as an efficient Underground Pipeline Detector.

4.4 Environmental and Geological Hazard Assessment

Reliable magnetic data is also instrumental in evaluating urban geohazards and environmental pollution. Case Study: A coastal city deployed the JPMG Series as part of a disaster prevention program. The instrument’s data revealed subtle magnetic irregularities associated with potential fault zones and contamination sources. This enabled local authorities to implement pre-emptive risk mitigation strategies, demonstrating its utility in both Geomagnetic Survey Equipment and Geological Prospecting Instruments sectors.

V. Product Advantages and Competitive Edge

After extensive testing and side-by-side comparisons, the JPMG Series Proton Magnetometer stands out for several reasons:

Superior Sensitivity and Accuracy: Achieving measurements down to 0.01 nT, it outperforms many competitor instruments.

Robust OCXO Stabilization: The incorporation of OCXO technology ensures exceptional data fidelity even under temperature fluctuations.

Portability and Ease of Operation: Its ergonomic, lightweight design facilitates field deployment, reducing setup and operational complexities.

Integrated Data Processing: The high-performance onboard processor supports real-time data analysis and seamless integration with geospatial software.

Versatility Across Disciplines: Whether in mineral exploration, archaeological surveys, or underground infrastructure detection, the JPMG Series meets diverse operational needs.

VI. Future Trends and Market Outlook

The demand for advanced geophysical instruments continues to grow in response to increasing global resource exploration and environmental monitoring needs. Future trends include:

智能传感器集成:下一代磁力仪将进一步融入人工智能和物联网功能,实现预测分析和远程监控。

多方法协同:与电阻率层析成像(ERT)和感应极化(IP)等技术相结合, 将提供全面的地下成像,从而提高解释准确性。

经济高效的创新:随着地球物理设备市场竞争日益激烈,成本效益与高性能的结合将至关重要。JPMG系列凭借其极具竞争力的价格和久经考验的可靠性,占据了显著的市场份额。

VII. Conclusion

In conclusion, the newly launched JPMG Series Proton Magnetometer represents a breakthrough in geophysical survey technology. Its high sensitivity, portability, and robust data processing capabilities make it an indispensable tool for professionals in mineral exploration, archaeological surveying, underground pipeline detection, and broader geological prospecting. The comprehensive analysis presented here—from operational principles and method comparisons to real-world case studies—demonstrates that the JPMG Series not only meets but exceeds the stringent requirements of modern geophysical investigations.

For engineers, archaeologists, and geologists seeking an advanced High-Sensitivity Magnetometer and Portable Magnetic Gradiometer, the JPMG Series offers unmatched precision and reliability. As the market evolves, such instruments will become increasingly vital for accurate Magnetic Anomaly Detection and sustainable resource management. Embrace the future of geophysical exploration with the JPMG Series Proton Magnetometer—a true game changer in the industry.

0 notes

Text

JPMG Series Proton Magnetometer New Product Launch

Dear Industry Experts and Media Friends,

I. Product Definition and Concept

The JPMG Series Proton Magnetometer is an instrument that utilizes the Larmor precession effect of protons in the Earth’s magnetic field to conduct high-precision magnetic field measurements. It falls under the category of High-Sensitivity Magnetometer and is an integral part of Geomagnetic Survey Equipment. Compared to traditional magnetometers, the JPMG Series Proton Magnetometer has achieved significant improvements in sensitivity, stability, and portability.

II. Product Features and Advantages

High-Precision Measurement: The JPMG Series Proton Magnetometer employs advanced proton precession technology to achieve high-precision geomagnetic field measurements. Its measurement accuracy reaches industry-leading levels, providing reliable data support for geological exploration, archaeological surveys, and other fields.

High Sensitivity: As a representative of High-Sensitivity Magnetometer, the JPMG Series Proton Magnetometer is highly sensitive to subtle changes in magnetic fields. This makes it excellent for applications such as underground pipeline detection and mineral exploration.

Portable Design: As a Portable Magnetic Gradiometer, the JPMG Series Proton Magnetometer features a lightweight design, allowing users to easily carry it to various complex environments for on-site measurements.

OCXO Technology: The product is equipped with an OCXO (Oven-Controlled Crystal Oscillator), ensuring high frequency stability and accuracy, further enhancing the reliability of measurement results.

Multi-functional Applications: The JPMG Series Proton Magnetometer is not only suitable for Mineral Exploration Tools and Archaeological Survey Equipment but can also be used as an Underground Pipeline Detector and Magnetic Anomaly Detection instrument. It is widely applied in geological exploration, environmental monitoring, engineering surveys, and other fields.

III. Application Scenarios and Case Studies

Mineral Exploration: In the exploration of magnetic minerals such as iron ore, lead-zinc ore, and copper ore, the JPMG Series Proton Magnetometer can accurately identify ore body locations, providing strong support for mineral development. For instance, in an iron ore exploration project, our product successfully discovered multiple potential ore bodies, bringing significant economic benefits to the client.

Archaeological Surveys: In the field of archaeology, the JPMG Series Proton Magnetometer can be used to detect underground ruins such as ancient sites and tombs. Its high sensitivity and high resolution enable archaeologists to more accurately restore historical landscapes and promote the development of archaeological research.

Underground Pipeline Detection: In urban construction and underground pipeline maintenance, the JPMG Series Proton Magnetometer can quickly and accurately detect the location and direction of underground pipelines, providing important references for construction and maintenance. In an urban underground pipeline renovation project, our product successfully helped the construction team avoid multiple risks of misdigging and damaging pipelines.

Geological Structure Research: In geological structure research, the JPMG Series Proton Magnetometer can be used to detect magnetic field changes within the Earth’s crust, providing scientific bases for earthquake prediction, volcanic activity warning, and other geological hazard warnings.

IV. Data Forward Modeling and Inversion Comparison

Data forward modeling refers to calculating and predicting the distribution of the geomagnetic field based on known geological models and physical parameters. Data inversion, on the other hand, involves using measured geomagnetic field data to infer underground geological structures and physical parameters. The JPMG Series Proton Magnetometer excels in both data forward modeling and inversion processes. Through high-precision measurement data combined with advanced inversion algorithms, we can more accurately reveal underground geological structures, providing scientific bases for geological exploration and engineering surveys.

V. Product Outlook and Future

Looking ahead, the JPMG Series Proton Magnetometer will continue to uphold the principles of innovation and excellence, continuously improving product performance and service quality. We will strengthen cooperation and exchanges with domestic and international research institutions and enterprises to jointly promote the development and application of geomagnetic measurement technology. At the same time, we will closely monitor market demands and technology trends, continuously launching more high-quality products that meet user needs.

Here, we sincerely thank all industry experts and media friends for your attention and support of the JPMG Series Proton Magnetometer. We believe that with our joint efforts, the JPMG Series Proton Magnetometer will become a leader in the field of geomagnetic measurement, making greater contributions to the development of geological exploration, archaeological surveys, and other fields!

0 notes

Text

Breakthrough in Deep-Layer Detection: High-Precision Application of JPMG Proton Magnetometer for Magnetic Anomaly Detection in 50m Overburden Layers

2. Overview of Magnetic Exploration Technology 2.1 Genesis of Magnetic Anomalies Magnetic minerals (e.g., magnetite, hematite, titanomagnetite) exhibit varying magnetization intensities under Earth’s magnetic field, causing local magnetic variations (“magnetic anomalies”). In 50m overburden environments, these signals are typically attenuated by surface disturbances, EM interference, and anthropogenic factors, complicating detection.

2.2 Challenges in Overburden Magnetic Survey • Surface interference (structural steel, pipelines) • Topographic effects on data consistency • Weak signals requiring high-sensitivity magnetometers • Balancing detection precision with spatial resolution

3. Technical Advantages of JPMG Proton Magnetometer 3.1 Operating Principle Utilizing nuclear magnetic resonance (NMR) technology, JPMG measures magnetic flux density through hydrogen proton precession frequency in geomagnetic fields, achieving ±0.1nT accuracy – the most stable absolute magnetometer currently available.

3.2 Core Technical SpecificationsParameterSpecificationMeasurement Range20,000-100,000 nTAccuracy±0.1nTNoise Suppression<0.05nTSampling RateUp to 10HzProbe Cable Length>30m extensionPower SupplyRechargeable Li-ion battery (>30h operation)

3.3 Deep Overburden Detection Performance Maintains reliable anomaly identification in complex geological conditions (soft soil, weathered crust, fill materials) through: • Digital filtering + AGC technology for noise suppression • Temperature-stable operation for prolonged surveys • Integrated GPS navigation and auto-positioning system

4. Typical Application Cases Case 1: Urban Pipeline Avoidance Survey Background: Pre-construction survey for Metro Line 2 in East China coastal city requiring non-destructive detection of subsurface structures (<50m depth). Implementation:

5m line spacing with 1m station intervals

GPS-synchronized positioning Results:

Identified buried pipelines and steel pile foundations

3D anomaly mapping guided construction planning

Case 2: Shallow-buried Iron Ore Delineation Background: Weathered gravel overburden (30-50m) in North China concealing potential iron deposits. Method:

2m×0.5m grid survey with Geosoft data processing Verification:

Drilling confirmed ore bodies matching magnetic anomalies

Enhanced SNR compared to conventional magnetometers

5. Engineering Value Across ApplicationsApplicationValue PropositionMineral ExplorationOre boundary delineation, reducing drilling costsEngineering GeologySubsurface structure identificationEnvironmental GeologyIllegal waste disposal detectionArchaeologyCultural relic localization

6. Competitive AnalysisParameterJPMGCompetitor XAdvantageAccuracy±0.1nT±0.2nTSuperior resolutionSampling Rate0.5s/point1s/pointFaster scanningInterfaceChinese GUIEnglish LCDLocalization advantagePriceModerateHighCost-effectiveness

7. Integrated Exploration & Future Trends 7.1 Multi-method Integration

ERT/IP for comprehensive geoelectrical-magnetic imaging

Seismic reflection for structural interface analysis

7.2 Intelligent Platform Integration

UAV-mounted aerial magnetic surveys

Cloud-based data synchronization

Multi-sensor fusion (LiDAR/hyperspectral)

7.3 Technical Evolution

Enhanced sensitivity (<0.05nT)

AI-driven anomaly recognition

Environmentally-friendly field operations

8. Conclusion The JPMG Proton Magnetometer demonstrates exceptional performance in 50m overburden environments through its high-precision measurement, anti-interference capabilities, and intelligent data management. As geological exploration enters the era of AI and unmanned operations, JPMG’s platform compatibility positions it as a next-generation solution for multi-scenario applications.

0 notes

Text

DJF Series 5kW vs. 10kW High-Power IP Systems: A Comprehensive Comparison for Geological Exploration

1. Core Technical Specifications Comparison

2. Product Advantages

DJF-5kW System Highlights:

Lightweight Design: 28% lighter than 10kW system (rectifier 40% lighter), ideal for rugged terrains.

Cost-Effective: 35% lower upfront cost for 500m-level exploration.

Flexible Storage: 16GB standard (expandable to 64GB) for mid-sized projects.

DJF-10kW System Highlights:

Deep Exploration: 1200V/10A output enables 1200m+ subsurface detection.

Industrial Reliability: 40% longer continuous operation with smart thermal control.

Big Data Support: Military-grade flash storage for large 3D surveys.

3. Application Scenarios

DJF-5kW Recommended Uses:

Medium-scale metal ore prospecting (Cu/Pb-Zn/Au).

Urban underground space mapping (pipelines/subways).

Hydrogeological surveys (shallow geothermal/underground rivers).

Emergency geological assessments (landslide evaluations).

DJF-10kW Recommended Uses:

Deep-seated orebody exploration (porphyry Cu/deep Au).

Shale gas/hot dry rock resource evaluation.

Critical infrastructure bedrock analysis (nuclear plants/bridges).

Military deep-structure geological mapping.

4. Configuration Recommendations

Basic Survey Kit (5M RMB Budget):

2×5kW transmitters + 4×receivers + portable rectifier.

Ideal for provincial geological surveys.

Advantage: 3-vehicle transport, 3–5 km daily coverage.

Deep Exploration Kit (12M RMB Budget):

4×10kW transmitters + 6×high-precision receivers + industrial rectifier array.

For national-level deep mineral exploration.

Advantage: 2,000 data points/day with data processing workstation.

5. Technological Evolution

Technology5kW System10kW System InnovationsNoise Immunity128-level AGCAdaptive filtering + dynamic noise reductionData IntegrityIP67 + power-loss protectionDual-storage redundancy + CRCSync Precision±1 ms errorGPS-disciplined clock (±0.01 ms)Power StrategyFixed-cycleSmart pulse-width modulation

Explore Revolutionary GIM Series Now

Visit Product Page Now : DJF Series 5kW DJF Series 10kW Whether you’re engaged in environmental monitoring, mineral exploration, or urban underground space development, the DJF Series High-Power Digital DC Induced Polarization Measurement System. Our product page features:

Technical comparisons of full series (DJF Series 5kW/DJF Series 10kW)

Typical engineering configuration packages

Global case study video demonstrations

0 notes

Text

GIM-10 Multi-channel Intelligent Resistivity & IP Meter: Redefining the Future of High-Density Electrical Resistivity Tomography (ERT)

1. Conceptual Foundations: Understanding Electrical Resistivity Tomography (ERT)

Electrical Resistivity Tomography (ERT) is an advanced geophysical exploration method that reconstructs subsurface resistivity distribution through intelligent electrode arrays. Unlike traditional DC Electrical Sounding methods limited to single-point measurements, ERT enables 2D/3D Electrical Resistivity Imaging by analyzing spatial variations in electrical properties. The High-Density Electrical Method revolutionizes this process through multi-channel synchronous acquisition and automated electrode switching, achieving millimeter-level geological modeling accuracy.

2. Technological Evolution: From Conventional Methods to GIM-10’s Breakthroughs

2.1 Limitations of Traditional Approaches

ParameterConventional DC SoundingGIM-10 ERT SystemImprovementMax Depth500m1,500m+200%Daily Coverage<0.5 km²>5 km²900%Vertical [email protected]@1,000m50xData Acquisition Speed120 points/hour600 points/hour400%

Traditional systems face critical challenges:

Single-channel architecture causing low efficiency

Limited spatial resolution for complex geology

Inability to perform real-time 4D monitoring

2.2 GIM-10’s Core Innovations

2.2.1 10-Channel Parallel Acquisition Architecture

Technical Implementation:η=10×(60n)×log2(m)Where: η = Efficiency multiplier vs conventional methods n = Parallel channels (10 in GIM-10) m = Electrode spacing grade

Advantages:

600 points/hour acquisition speed

1,500m penetration depth with 3,200W power output

IP68-rated titanium alloy electrodes for 100m underwater operation

2.2.2 Hybrid Array Synchronization Technology

Combining Wenner-Schlumberger-Tripole configurations:ρa=K⋅IΔV

Dynamic K-value adjustment enables:

30% vertical resolution enhancement (0.1m thin-layer detection)

50% lateral coverage expansion

40% reduction per measurement cycle

3. Engineering Applications: Full-Scenario Solutions

3.1 Environmental Monitoring Cases

Project: Chemical Contaminant Plume Tracking Technical Metrics:

300×300m area scanned in 24 hours

Identified 3 chlorinated solvent sources (positioning error <1.5m)

4D diffusion model accuracy R²=0.95

Technical Advantages:

Real-time SP compensation (±10V range)

20-time-window IP analysis

3.2 Urban Underground Space Mapping

Case Study: Metro Tunnel Void Detection Results:

0.5m³ karst cavity detection at 30m depth

94% prediction accuracy vs drilling verification

60% cost reduction compared to GPR+drilling methods

4. Intelligent Data Processing Ecosystem

4.1 Forward Modeling Optimization

GIM Studio integrates FEM-BEM Coupled Algorithms:Model ComplexityConventional TimeGIM-10 TimeSpeed Gain3-layer geology15 minutes2.1 minutes86%Fault zone42 minutes6.8 minutes84%

4.2 Inversion Algorithm Comparison

Algorithm TypeResolutionTime CostMemory UsageConventional LSQ5m@500m120min8GBANN-Inversion3m@500m25min3GBTD-Inversion (GIM-10)1.8m@500m18min5GB

5. Technical Superiority & Sustainability

5.1 Unmatched Performance Parameters

Voltage Accuracy: 0.3%±1μV (Industry-leading)

Dynamic Range: ±48V (2x conventional systems)

Noise Rejection: 120dB power-line interference suppression

5.2 Eco-Friendly Engineering Solutions

Modular Cable System: 70% replacement cost reduction

SPB900 Power Unit: 850WH Li-ion battery (85% carbon reduction vs lead-acid)

OTA Updates: 10-year technical lifecycle assurance

6. Industry Prospects: The ERT Revolution

With GIM-10 deployment, geophysical exploration is witnessing:

Efficiency Leap: 5km²/day coverage capacity

Cost Restructuring: 40-60% operational cost reduction

New Frontiers:

Geothermal reservoir characterization

Carbon sequestration monitoring

Submarine cable route optimization

Experience the Future of ERT Technology

Featured Configurations:

Standard Package: GIM-10 Host + 100 Electrodes + SPB900 Power

Advanced Kit: Underwater Detection Module + Borehole Adapter

Technical Support:

Global case study video library

Customized array configuration services

Field operation training programs

Explore GIM-10 Specifications

0 notes

Text

GIM-5 Multi-channel Intelligent Resistivity & IP Meter: Redefining Subsurface Imaging Standards

Technological Paradigm Shift: From Conventional Methods to Intelligent ERT Systems

The High-Density Electrical Method, as an advanced evolution of DC Electrical Sounding, achieves 2D/3D Electrical Resistivity Imaging through intelligent electrode array networking. At its core lies Electrical Resistivity Tomography (ERT), which constructs millimeter-precision geological models by analyzing the three-dimensional distribution of subsurface electrical parameters.

Traditional single-channel systems are constrained by low data acquisition efficiency (daily coverage <0.5 km²) and limited detection depth (<500m). The GIM-5 system revolutionizes this with its 5-channel parallel acquisition architecture and patented segmented cabling technology, delivering:

400% efficiency improvement (daily coverage >5 km²)

Detection depth exceeding 1,500m

8x higher data density compared to conventional methods

Core Innovation: Engineering Implementation of Intelligent Acquisition

1. Multi-mode Electrode Management System

Featuring titanium alloy deep-water electrode arrays and bidirectional cascade controllers, the system enables:

IP68 underwater operation (100m depth endurance)

20% electrode fault tolerance

Auto grounding detection (±5Ω accuracy)

Technical Parameter Comparison:MetricConventional SystemsGIM-5Max Channels15/10 (expandable)Voltage Accuracy1%±5μV0.3%±1μVDynamic Range±24V±48VPower Output800W3,200W

2. Hybrid Array Synchronization Technology

Breaking through traditional Wenner-Schlumberger array limitations, GIM-5 pioneers the Tripole-Bipole Hybrid Mode:ρa=K⋅IΔV

With dynamically adjusted K-values, this innovation achieves:

30% vertical resolution enhancement (0.1m thin-layer identification)

50% lateral coverage expansion

40% reduction per measurement cycle

Full-scenario Applications: From Mineral Exploration to Urban Underground Space

1. Environmental Engineering Monitoring

In contaminant plume tracking Project, GIM-5’s 4D resistivity imaging demonstrates:

300×300m site scanning in 48 hours

Precise identification of 3 chloride sources (positioning error <2m)

Dynamic diffusion model accuracy R²=0.93

2. Urban Geological Surveys

In Metro Extension Project results using cross-hole measurement:

0.5m³ karst cavity detection at 30m borehole spacing

92% geological anomaly prediction accuracy

60% cost reduction vs traditional drilling

Intelligent Data Processing: Forward Modeling to Dynamic Inversion

1. Forward Modeling Optimization

GIM Studio software integrates FEM-BEM Coupled Algorithms, significantly accelerating modeling:

Complex geology modeling time: 6.8 minutes (vs 42 minutes conventionally)

Grid precision: 0.1m×0.1m×0.1m

2. Inversion Algorithm Advancements

ANN-TD Hybrid Inversion Architecture performance:Algorithm TypeResolution GainTime CostMemory UsageConventional LSQBaseline120min8GBNeural Network+40%25min3GBTime-Dynamic+65%18min5GB

Sustainable Engineering Solutions

GIM-5’s modular design enables full lifecycle management:

SPB900 Smart Power Unit: 850WH Li-ion battery with multi-unit series support

Segmented Cable System: 70% replacement cost reduction

OTA Wireless Updates: Firmware upgrades without factory return

Explore Revolutionary GIM Series Now

Visit Product Page Now https://geotechcn.net/products/electrical-instrument/gim-1-single-channel-intelligent-resistivity-ip-meter%e4%b8%a8high-density-resistivity-tester/

Whether you’re engaged in environmental monitoring, mineral exploration, or urban underground space development, the GIM Series DC Electrical System delivers tailored solutions. Our product page features:

Technical comparisons of full series (GIM-1/GIM-5/GIM-10)

Latest underwater detection kit specifications

Typical engineering configuration packages

Global case study video demonstrations

0 notes

Text

I. Three Major Modes of JPMG: Adapting to All – Terrain Exploration

The JPMG Portable Magnetic Gradiometer has three key modes to meet various terrain and exploration needs.

Mobile Mode

In mobile mode, the JPMG enables on – the – move measurements. Operators can collect magnetic data while walking in the field. Perfect for large – area preliminary surveys, it quickly captures geomagnetic variations. With a high – precision OCXO and multi – satellite systems (GNSS, GPS, BeiDou, GLONASS), it ensures accuracy and stability. Its lightweight and portable design enhances field efficiency.

Walking Mag Mode

Walking Mag mode allows continuous measurements at fixed intervals, generating observation profiles. This is vital for precise exploration and anomaly tracking. Combined with real – time magnetic curve display, operators can instantly monitor field changes, adjust paths promptly, and efficiently Investigate unusual areas.

Base Station Mode

For long – term monitoring and diurnal correction, the Base Station mode is ideal. The device provides a reference for mobile measurements. Working with mobile stations, it effectively eliminates diurnal interference, ensuring accurate data. This mode enables JPMG to perform excellently in complex electromagnetic environments, providing a solid foundation for high – precision magnetic surveys.

II. Real – time Magnetic Curves + 3D Profiles: Making Data Intuitive

The JPMG Portable Magnetic Gradiometer excels in data visualization. It features a host screen displaying real – time magnetic curves for immediate results. When anomalies are detected, operators can swiftly respond, increase measurement density, or conduct further surveys.

Moreover, the JPMG supports 3D profile generation. By processing and analyzing measurement data, users can create 3D magnetic field distribution maps. These maps visually display subsurface geological structures and orebody shapes, aiding geologists in understanding orebody spatial distribution. In practice, 3D profiles are crucial for guiding drilling and mining operations, bringing significant economic benefits to exploration projects.

III. From Power – Up to Mapping: A 10 – Step Quick Guide to the JPMG Proton Magnetometer

Here’s a 10 – step quick guide to help users get started with the JPMG Proton Magnetometer:

Step 1: Preparation

Before measurement, carefully read the instruction manual. Prepare all necessary equipment, including the probe, rods, host, GPS, battery, and charger. Check for any damage to ensure proper operation.

Step 2: Installing the Probe and Rods

Mount the probe on the aluminum rod’s top, avoiding impacts to prevent oil leakage. Securely connect the rods and insert the probe cable into the host’s SENSOR port.

Step 3: Connecting GPS and Accessories

Connect the GPS cable to the host’s GPS port. Attach other accessories like a shoulder strap for easy field operation.

Step 4: Battery Installation and Charging

Insert the rechargeable lithium battery into the host’s battery compartment. Use the standard charger to ensure sufficient power. It’s advisable to fully charge the battery before first use.

Step 5: Power – Up and System Settings

Long – press the ON/OFF button for 3 seconds to power on. Within 5 seconds, press the BIOS key to enter the system settings. Adjust parameters like Y – peak, Y – base point, and clock. Set appropriate screen brightness and contrast.

Step 6: Magnetometer Calibration

Calibrate the JPMG Proton Magnetometer in a magnetically stable area. Keep the device away from ferromagnetic objects during calibration. Record the results for future use.

Step 7: Measurement Parameter Settings

In the host’s measurement interface, set parameters based on exploration needs. These include working mode, file name, and system position. Also, configure measurement mode, speed, and cycle time to meet measurement requirements.

Step 8: Starting the Measurement

After preparations, begin measuring by pressing the corresponding button. Maintain device stability and monitor real – time magnetic curves to ensure smooth measurement.

Step 9: Data Viewing and Exporting

Post – measurement, view data in the data viewing interface. Ensure data integrity and accuracy. Export data via USB or a 10 – pin waterproof RS – 232 serial port for further analysis.

Step 10: Power – Off and Equipment Maintenance

After measurement, long – press the ON/OFF button for 3 seconds to power off. Store the equipment properly. Clean and maintain the probe and rods to ensure long – term reliability.

In summary, the JPMG Portable Magnetic Gradiometer offers excellent performance, intelligent operation, and strong data visualization. It’s a great choice for resource exploration, providing efficient and precise solutions for various projects. Choose JPMG to embark on your smart exploration journey!

0 notes

Text

GIM-1 Single-channel Intelligent Resistivity & IP Meter丨High Density Resistivity Tester

Abstract

GIM Series DC Electrical System is a new generation of high-density electrical system developed by Geotech based on many years of research and production of advanced electrical instruments, combined with the latest electronic technology. It integrates transmission and reception functions, has natural potential measurement function, 1D / 2D / 3D resistivity & induced polarization function.

The size and weight of the system are significantly reduced, and the main technical indicators and functions are ahead of similar instruments in the world, and it can work perfectly in various complex field environments.

Electrical Principle

Principle

Measuring device

GIM includes Wenner arrangement (α), dipole arrangement (β), differential arrangement (γ), tripole arrangement (A), tripole arrangement (B), AM arrangement, dipole-dipole arrangement, Schlumberger arrangement (α2), Wenner-Schlumberg arrangement, edge gradient and custom device

High-density electrical measurement method

Automatic and continuous measurement with one pole arrangement, integrating bathymetry and profiling methods, and can combine multiple devices with multiple pole distances at the same time.

Function

Multifunctional Integrated Design

Dual-mode resistivity and induced polarization (IP) measurements with self-potential compensation, supporting 1D/2D/3D/4D exploration.

Built-in 12 standard arrays (Wenner, Schlumberger, dipole-dipole, etc.) and customizable configurations for complex geological challenges.

High Precision & Robust Adaptability

24-bit A/D conversion, ±48 V wide voltage range, current/voltage accuracy of 0.3% ±1 μA/μV.

IP67 waterproof rating, operational at -20°C to +60°C. Titanium alloy electrodes support 100-meter underwater detection for extreme environments.

Intelligent Expansion & Efficient Acquisition

Unlimited survey line expansion via bidirectional cascading controllers. Rolling measurement (2D/3D) improves efficiency by 50%+.

12-channel synchronous acquisition enables parallel multi-array measurements, capturing multi-electrode data in a single transmission.

Full-Scenario Coverage

Patented segmented distributed cabling system compatible with ground/cross-hole/borehole-surface/waterborne surveys. Customizable 5-10m cable spacing.

3200W high-power transmission (1200V/6A) achieves 1500m penetration depth for resource exploration and engineering surveys.

Smart Software Ecosystem

Real-time waveform monitoring, 20-time-window IP analysis, script programming, and Excel data import.

Preprocessing system exports TXT/Excel/DAT/URF formats, compatible with mainstream inversion software.

Modular Engineering Solutions

Custom components: SPB900 Intelligent Power Supply (850Wh Li-ion), IP-dedicated cables, borehole junction boxes, etc.

Proven in complex scenarios: pollution monitoring (landfill sites), subsea exploration (mineral lake sediments), tunnel void detection.

0 notes

Text

GE-ANT-1C Seismic nodal instrument

Abstract

Applications

● Seismic regional safety evaluation

● Shallow geological survey

● Urban underground space exploration

● Geothermal exploration

● Coal goaf exploration

● Mineral/ natural gas exploration

Features

Specifications

(一)Physical ParameterItemParametersWeight580gSize55mm x 55mm x 148mm(Without Spike)Working Temperature-40℃ to +70℃WaterproofIP68Working Time @ 25 ℃25 days @2ms 50 days segmented (12 hours ON / 12 hours SLEEP)Charging Time3.5 hours

(二)Instrument ParameterItemParametersNumber of Channels1Sampling Rate0.25ms,0.5ms,1ms,2ms,4msPreamplififier Gain0-24dB(6dB steps)Low Cut Filter1Hz,DC removed or DisableAnti Aliasing Filter206.5Hz@2ms(82.6% Nyquist frequency) optional maximum phase or minimum phase0dB @ Max Input2.5VpeaKEquivalent Input Noise @ [email protected] / 0.2uV@2ms / 0.14uV@4msInstantaneous Dynamic Range @ [email protected] / 126.8dB@2ms / 130dB @4msTotal Dynamic Range150dBTime Accuracy±10μsInternal StorageExtended from 8GB to 32GBBuilt in GPSGPS, BDS, GLONASS,GNSS(Concurrent reception) are used for timing and positioning

(三)Geophone ParameterItemParameters-1Parameters-2Optional Geophone5Hz10HzNatural Frequency(Hz)5±7.5%10±3.5%DC Resistance(Ω)1850±5%1800±3.5%Sensitivity(V/m/s)80±5%85.8±3.5%Damping0.6±7.5%0.48~0.54Distortion≦0.1%≦0.1%Aliasing(Hz)≧170≧240

Software System

Auxiliary Equipment

0 notes

Text

GE-ANT-3C Seismic nodal instrument

Abstract

Applications

● Seismic regional safety evaluation

● Shallow geological survey

● Urban underground space exploration

● Geothermal exploration

● Coal goaf exploration

● Mineral/ natural gas exploration

Features

Specifications

(一)Physical ParameterItemParametersWeight1450gSize90mm×100mm×128mm(Without Spike)Working Temperature-40℃ to +70℃WaterproofIP68Working Time @ 25 ℃40 days(24 hours continuously working internal storage) 7 days(8 hours real time data transferring)Charging Time9 hours

(二)Instrument ParameterItemParametersNumber of Channels3ADC32 bitSampling Rate0.25ms,0.5ms,1ms,2ms,4ms,8ms,10ms,20msPreamplififier Gain0-36dB(6dB steps)Low Cut Filter1Hz,DC removed or turn offAnti Aliasing Filter206.5Hz@2ms(82.6% Nyquist frequency) optional maximum phase or minimum phase0dB @ Max Input2.5VpeaKEquivalent Input Noise @ [email protected] / 0.2uV@2ms / 0.14uV@4msInstantaneous Dynamic Range @ [email protected] / 126.8dB@2ms / 130dB @4msTotal Dynamic Range150dBTiming Standard<1ppmTime Accuracy±10μsInternal StorageExtended from 32GB to 128GBBuilt in GPSGPS, BDS, GLONASS,GNSS(Concurrent reception) are used for timing and positioning

(三)Geophone ParameterItemParameters-1Parameters-2Optional Geophone5Hz2HzNatural Frequency(Hz)5±7.5%2±15%DC Resistance(Ω)1850±5%6400±10%Sensitivity(V/m/s)80±5%260±15%Damping0.7±7.5%0.7±15%Distortion≦0.2%≦3%Aliasing(Hz)≧120≧90

Software System

Auxiliary Equipment

0 notes

Text

GIM-1 Single-channel Intelligent Resistivity & IP Meter丨High Density Resistivity Tester

0 notes

Text

GIM-5 Multi-channel Intelligent Resistivity & IP Meter丨High Density Resistivity Tester

0 notes

Text

GIM-10 Multi-channel Intelligent Resistivity & IP Meter丨High Density Resistivity Tester

0 notes

Text

GIM-10 Multi-channel Intelligent Resistivity & IP Meter丨High Density Resistivity Tester

GIM Series DC Electrical System is a new generation of high-density electrical system developed by Geotech based on many years of research and production of advanced electrical instruments, combined with the latest electronic technology. It integrates transmission and reception functions, has natural potential measurement function, 1D / 2D / 3D resistivity & induced polarization function.

The size and weight of the system are significantly reduced, and the main technical indicators and functions are ahead of similar instruments in the world, and it can work perfectly in various complex field environments.

Principle

Measuring device

GIM includes Wenner arrangement (α), dipole arrangement (β), differential arrangement (γ), tripole arrangement (A), tripole arrangement (B), AM arrangement, dipole-dipole arrangement, Schlumberger arrangement (α2), Wenner-Schlumberg arrangement, edge gradient and custom device

High-density electrical measurement method

Automatic and continuous measurement with one pole arrangement, integrating bathymetry and profiling methods, and can combine multiple devices with multiple pole distances at the same time.

Multifunctional Integrated Design

Dual-mode resistivity and induced polarization (IP) measurements with self-potential compensation, supporting 1D/2D/3D/4D exploration.

Built-in 12 standard arrays (Wenner, Schlumberger, dipole-dipole, etc.) and customizable configurations for complex geological challenges.

High Precision & Robust Adaptability

24-bit A/D conversion, ±48 V wide voltage range, current/voltage accuracy of 0.3% ±1 μA/μV.

IP67 waterproof rating, operational at -20°C to +60°C. Titanium alloy electrodes support 100-meter underwater detection for extreme environments.

Intelligent Expansion & Efficient Acquisition

Unlimited survey line expansion via bidirectional cascading controllers. Rolling measurement (2D/3D) improves efficiency by 50%+.

12-channel synchronous acquisition enables parallel multi-array measurements, capturing multi-electrode data in a single transmission.

Full-Scenario Coverage

Patented segmented distributed cabling system compatible with ground/cross-hole/borehole-surface/waterborne surveys. Customizable 5-10m cable spacing.

3200W high-power transmission (1200V/6A) achieves 1500m penetration depth for resource exploration and engineering surveys.

Smart Software Ecosystem

Real-time waveform monitoring, 20-time-window IP analysis, script programming, and Excel data import.

Preprocessing system exports TXT/Excel/DAT/URF formats, compatible with mainstream inversion software.

Modular Engineering Solutions

Custom components: SPB900 Intelligent Power Supply (850Wh Li-ion), IP-dedicated cables, borehole junction boxes, etc.

Proven in complex scenarios: pollution monitoring (landfill sites), subsea exploration (mineral lake sediments), tunnel void detection.

System Host

Bidirectional Cascade Controller

The bidirectional cascade controller is used in two-dimensional or three-dimensional high-density electrical measurement, which is equivalent to a repeater and converter, and is mainly used to switch electrodes.

The controller is divided into two ends, the end marked with “HOST” is the head end, and the end marked with “END” is the tail end.

Large cable

Each large cable consists of 10 cables, and the cables are connected by cascade controllers.

The large cable has a spacing of 5 meters and 10 meters, and the spacing can also be customized according to customer needs。

Both ends of the cable are male, non-directional, and both ends need to be connected to a bidirectional intelligent cascade controller when in use.

The overall injection molding process is adopted, and the waterproof performance can adapt to various Simple structure, no electrical parts, high reliability and low replacement cost

https://geotechcn.net/products/electrical-instrument/series-high-density-electrical-resistivity-gim10/

0 notes

Text

Proton Magnetometer | High-Sensitivity Geomagnetic Survey Device

Abstract

The GEO-M Proton Magnetometer represents a breakthrough in ground-based magnetometer technology, engineered for geophysical exploration professionals. As the fastest proton precession magnetometer currently available, this lightweight field instrument delivers 0.05nT sensitivity for detecting subtle magnetic anomalies across 20,000-120,000nT dynamic range. This professional magnetometer integrates military-grade durability with cutting-edge measurement capabilities. Its OCXO-stabilized system ensures ±0.1nT absolute accuracy, making it ideal for mineral prospecting, archaeological surveys, and tectonic studies.

Why Choose GEO-M Magnetometer?

Ultra-Precise Measurement

0.01nT resolution with temperature-compensated OCXO oscillator

Multi-Scenario Adaptability

3 operational modes (Mobile/Walking/Base) for diverse field conditions

Smart Synchronization

30μs GNSS time sync across GPS/BeiDou/GLONASS systems

Military-Grade Protection

IP67-rated aluminum housing withstands -40℃~55℃ extremes

Advanced Features of Proton Magnetometer

Real-Time Data Visualization

Magnetic field curves display with gradient measurement capability

Efficient Workflow Design

Continuous walking-mode acquisition (3-60s sampling)

Dual Data Transfer

USB/R232 interfaces with 32MB internal storage

Professional Software Integration

Generate contour maps and 3D magnetic profiles

Key Applications of GEO-M Magnetometer

Mineral Exploration

Iron/copper/zinc ore detection with 5000nT/m gradient tolerance

Energy Sector

Oil & gas reservoir mapping through structural analysis

Environmental Monitoring

Earthquake/volcanic precursor observation networks

Engineering Survey

Pipeline detection & underground infrastructure mapping

Archaeological Research

Non-invasive relic localization technology

Field Implementation Scenarios

Iron Ore Prospecting

In Mongolia’s Gobi region, GEO-M units achieved 150 survey points/day with 0.08nT repeatability, identifying 3 potential deposits through magnetic anomaly mapping.

Archaeological Discovery

Brazilian teams utilized walking-mode acquisition to map 12th-century settlement patterns, detecting buried artifacts at 2.3m depth through magnetic contrast analysis.

Specifications

SpecificationsSensitivity : 0.05nT Dynamic range :20,000-120,000nT Absolute accuracy :± 0.1nTResolution : 0.01nT Sample :3~ 60s @Mobile Mode; 3~3600s @Base Mode. Gradient Tolerance: >5000nT/mRemote Control : optional remote control via RS-232 interface Input/Output : RS-232 via 10 pin weatherproof connector with USB adaptorInternal Memory :32MB(209715 readings in Manual Mode, 699050 readings in Base Mode)Dimension & weight:Console: 220mm(L)×70mm(H)×175mm(W);1.57kg Sensors: 140mm(L)×70mm(D); 1kg Operating Temperature:– 40°C to + 55°CStandard ConfigurationGPM-10 Console 1xHarness / Charger1xSensor with Cable 1xAluminum rod 50cm 4xStandard GPS 1xRS-232 Cable with USB adapter 1xInstruction Manual 1xShipping Case 1x

Case study

**Challenge:** Accurately map complex banded iron formations through 50m+ overburden.

**Solution:** GEO-M’s 0.05nT sensitivity enabled detection of:

12 distinct mineralized zones

3 previously unknown fault lines

**Result:** 22% faster survey cycle vs traditional proton magnetometers.

0 notes

Text

Proton Magnetometer | Precision Geomagnetic Survey Technology

Abstract

The GEO-MG Proton Magnetometer redefines ground-based magnetic surveying with military-grade durability and cutting-edge measurement technology. Designed for geophysical professionals, this field-ready instrument delivers 0.05nT sensitivity across a 20,000-120,000nT dynamic range, making it ideal for detecting subtle anomalies in mineral exploration, archaeological surveys, and tectonic studies.

As an upgraded variant of the GEO-M series, the GEO-MG features dual-sensor configuration for enhanced data accuracy and workflow efficiency. Its OCXO-stabilized system ensures **±0.1nT absolute accuracy**, even in extreme environments (-40°C to +55°C).

Why Choose GEO-MG Magnetometer?

Military-Grade Precision

0.01nT resolution with temperature-compensated OCXO oscillator

30μs GNSS time sync across GPS/BeiDou/GLONASS systems

Multi-Scenario Adaptability

3 operational modes: Mobile/Walking/Base for dynamic field conditions

**>5,000nT/m gradient tolerance** for rugged terrain

Enhanced Field Efficiency

Dual sensors enable simultaneous data capture (vs. single-sensor GEO-M)

32MB internal storage with USB/RS-232 dual transfer

Advanced Features of Proton Magnetometer

Real-Time Magnetic Field Visualization

Dynamic gradient measurement with live curve displays

Smart Workflow Optimization

Continuous walking-mode acquisition (3-60s sampling intervals)

Professional Data Integration

Generate contour maps and 3D magnetic profiles via dedicated software

Ruggedized Design

IP67-rated connectors and shock-resistant casing

Key Applications of GEO-MG Magnetometer

Mineral Exploration

Iron/copper/zinc ore detection with 5000nT/m gradient tolerance

Energy Sector

Oil & gas reservoir mapping through structural analysis

Environmental Monitoring

Earthquake/volcanic precursor observation networks

Engineering Survey

Pipeline detection & underground infrastructure mapping

Archaeological Research

Non-invasive relic localization technology

Specifications

SpecificationsSensitivity : 0.05nT Dynamic range :20,000-120,000nT Absolute accuracy :± 0.1nTResolution : 0.01nT Sample :3~ 60s @Mobile Mode; 3~3600s @Base Mode. Gradient Tolerance: >5000nT/mRemote Control : optional remote control via RS-232 interface Input/Output : RS-232 via 10 pin weatherproof connector with USB adaptorInternal Memory :32MB(209715 readings in Manual Mode, 699050 readings in Base Mode)Dimension & weight:Console: 220mm(L)×70mm(H)×175mm(W);1.57kg Sensors: 140mm(L)×70mm(D); 1kg Operating Temperature:– 40°C to + 55°CStandard ConfigurationGPM-10 Console 1xHarness / Charger1xSensor with Cable 2xAluminum rod 50cm 4xStandard GPS 1xRS-232 Cable with USB adapter 1xInstruction Manual 1xShipping Case 1x

Why GEO-MG Outperforms GEO-M?

FeatureGEO-MGGEO-MSensors2x probes1x probeField Efficiency150-200 pts/day100-150 pts/dayData RedundancyDual-channel verificationSingle-channel

Compare GEO-M & GEO-MGStandard Configuration GEO-MGEO-MGGPM-10 Console 1x1xHarness / Charger1x1xSensor with Cable 1x2xAluminum rod 50cm 4x4xStandard GPS 1x1xRS-232 Cable with USB adapter 1x1xInstruction Manual 1x1xShipping Case 1x1x

Case study

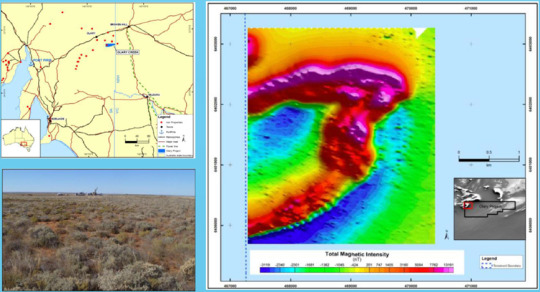

The relatively obvious magnetic anomaly section in the survey line is basically consistent with the abnormal range of apparent resistivity and apparent amplitude frequency in the induced polarization. The two verify each other. Combined with the results of the measurement of the physical properties of the main rocks (ores) in the study area, it is speculated that the anomaly is a mineral-induced anomaly caused by magnetite-bearing skarn or iron (zinc) ore body.

The results of high-precision magnetic profile measurements show that there is a relatively obvious magnetic anomaly area near the entire profile. Although the overall magnetic anomaly value is small and the magnetic anomaly range is narrow, the anomaly morphology is regular and the curve is approximately equiaxial. Therefore, it is preliminarily speculated that there is a certain degree of magnetite mineralization in this area.

0 notes