GM-TECH is a professional manufacturer of High quality moulds. https://www.gmmoldtech.com/

Don't wanna be here? Send us removal request.

Text

What Are the Main Methods of Forming Automotive Plastic Molds?

https://www.gmmoldtech.com/what-are-the-main-methods-of-forming-automotive-plastic-molds.html

There are many ways to classify automotive plastic moulds. According to the different methods of forming and processing plastic parts, they can be divided into the following categories:

1. Plastic injection molding for automotive plastic mould

The characteristic of plastic injection mold and molding is that the plastic raw material is placed in the heating barrel of the injection molding machine. The plastic is melted by heat, driven by the screw or plunger of the injection molding machine, enters the mold cavity through the nozzle and the pouring system of the mold, and the plastic is formed by heat preservation, pressure retention, and cooling in the mold cavity. Since the heating and pressing device can function in stages, injection molding can not only form plastic parts with complex shapes, but also has high production efficiency and good quality. Therefore, the injection mold occupies more than half of the proportion in the molding of plastic parts. Injection molding machines are mainly used for the molding of thermoplastics, and in recent years have gradually been used for the molding of thermoset plastics.

2. Compression molding for automotive plastic mould

The characteristic of the molding process of this automotive plastic mould is that the plastic raw material is directly added into the open mold cavity, and then the mold is closed. After the plastic is in a molten state under the action of high temperature and pressure, the cavity is filled with a certain pressure. At this time, the molecular structure of the plastic has a chemical cross-linking reaction, which gradually hardens and sets. Compression molds are mostly used for thermosetting plastics, and their molded plastic parts are mostly used for the shells of electrical switches and daily necessities, such as home appliance mold with GM-Tech home appliance plastic parts by injection molding services.

3. Transfer moulding for automotive plastic mould

The characteristic of the molding process of this automotive injection mold is that the plastic raw materials are added into the preheated feeding chamber, and then pressure is applied to the plastic raw materials in the feeding chamber by the pressure column. The plastic is melted under high temperature and high pressure and enters the cavity through the casting system of the mold. And then the chemical cross-linking reaction occurs and gradually solidified into shape. The transfer molding process is mostly used for thermosetting plastics, which can form plastic parts with more complex shapes.

4. Extrusion for automotive plastic mould

This automotive plastic mould can continuously produce plastics with the same cross-sectional shape, such as plastic pipes, rods, and sheets. The heating and pressurizing device of the extruder is the same as that of the injection molding machine. The plastic in the molten state will form a continuous molded plastic part through the machine head, and the production efficiency is particularly high.

In addition to the several types of plastic molds listed above, automotive plastic mould molding processes include vacuum molding molds, compressed air molds, blow molding molds and low-foaming plastic molds.

0 notes

Text

What Are the Common Products Made by Injection Molding in Our Life?

https://www.gmmoldtech.com/what-are-the-common-products-made-by-injection-molding-in-our-life.html

In fact, all products molded by injection molding machines are injection molded products. Including thermoplastic and now some thermosetting injection products. The most notable feature of thermoplastic products is that the raw materials can be re-injected, but some of the physical and chemical properties of the raw materials will be reduced. So usually high-end products made by injection molding will not use raw materials again.

1. Products made by injection molding in the medical industry

At present, the medical industry has a wide range of products made by injection molding, such as high-transparent PPT droppers, electronic thermometer shells, sprayer shell injection molded parts, laser writing instrument medical hands, physiotherapy hot compress spine neck protector plastic shells, medical sharp weapon boxes, and medical virus detector shells, shells of oral X-ray film machines.

2. Products of precision injection molding in the home appliance industry

The plastic injection molding products that are commonly used in our lives , such as home appliance plastic parts are small hand-held fans, humidifier shells, heater shells, hand warmers, mixers, rice cooker shells, air conditioner shells, TV shells, hairdryer shells, water heater shells, and so on. Bulk inquiry appliance plastic molding from GM-Tech

3. Products of precision injection molding in the cosmetic packaging industry

In the past, many cosmetic packaging materials were made of glass materials. The main disadvantages are that the materials are too heavy, easy to break, and the price is relatively expensive. Now, glass materials are gradually replaced with common injection molded plastic materials, which occupy 90% of the cosmetic packaging materials.

Common products include dozens of lipstick tubes, powder boxes, lip glaze tubes, eyebrow pencils, cream tubes, lip gloss tubes, sub-bottles.

0 notes

Text

What Are the Classification of Injection Mold Processing?

https://www.gmmoldtech.com/what-are-the-classification-of-injection-mold-processing.html

What Are the Classification of Injection Mold Processing?

Ⅰ. The plastic injection mold processing

Injection molding is a relatively common manufacturing method of industrial products in machining processing. This processing technology obtains the required shape by processing rubber and plastic. There are many types of injection mold processing. In the process of processing, the processing technology should be selected according to the requirements of the injection product.

��. The classification of plastic injection mold processing

1. Single parting surface injection mold

When the mold is opened, the movable mold and the fixed mold are separated, so that the plastic part is taken out, which is called a single parting surface mold. This processing method is the simplest of the plastic injection mold and molding. It can be divided into single-cavity injection molds or multi-cavity injection molds according to the design. It is widely used in today's production.

2. Double parting surface injection mold

Double parting surface injection molding has two parting surfaces. Compared with single parting surface injection molds, double parting surface injection molds have a movable intermediate plate in the fixed mold part, so this type of injection mold is called three-plate injection mold. It is most commonly used for single-cavity or multi-cavity molds with point gate feeding.

3. Injection mold with lateral parting and core pulling mechanism

When the plastic part has a side hole or a side depression, it needs to be formed with a core or slider that can move laterally. After injection molding, the movable mold will move down for a certain distance, and then the inclined surface of the bending pin fixed on the fixed template forces the slider to move outwards. At this time, the push rod of the ejection mechanism pushes the plastic part to take off from the core.

4. Injection mold with movable forming parts

Due to some special structures of plastic parts, injection molding will be required to be set into movable injection molded parts, such as movable punches, dies, movable inserts, movable threaded cores or shaped rings. During demolding, it can be moved out of the mold together with the plastic part and separated from the plastic part.

5. Automatic thread unloading injection mold

For plastic parts with threads, when automatic demolding is required, a freely rotatable thread core or ring can be set on the mold, and the mold opening action or the rotation mechanism of the injection molding machine can be used to drive the thread core or the threaded ring rotates and the plastic part comes out.

6. Runnerless injection mold

Runnerless injection mold refers to the method of adiabatic heating of the runner to keep the plastic between the nozzle and the cavity of the injection molding machine in a molten state, so that there is no condensate in the pouring system when the mold is opened and the plastic part is taken out.

7. The injection mold of the demoulding mechanism on the fixed mold

In the injection mold, the demolding device is installed on the side of the movable mold, which is of great help to the ejector device in the opening and closing system of the injection molding machine. In actual production, because of the shape limitation of some plastic parts, leaving the plastic parts on the side of the fixed mold is more helpful for forming.

0 notes

Text

Vacuum Moulding

https://www.gmmoldtech.com/products/vacuum-moulding.html

In order to meet the requirements of small batch production and material performance, we provide vacuum molding for customers.

Vacuum Moulding Plastic to the use of the original template to make a silica gel mold in the vacuum state, and pour it with PU material in the vacuum state, so as to clone the same replica as the original template.

This is similar to the processing method of custom plastic injection mould. Products can use any material, such as ABS, PC, PBT, PA66 and so on. But its disadvantage is that the product precision is low and the die life is short!

Features of Vacuum Moulding

GM-TECH, a professional plastic injection moulding products manufacturer, has designed and manufactured dozens of sets of automobile rear-view mirror molds for Kaiming hall in Murakami, Japan. The products are basically used in Toyota, Honda, and Nissan. In addition, we have also produced dozens of sets of lamp molds for Haila, including headlamp mask, headlight guide strip, headlight reflector, etc.

1. The production cost of vacuum moulding plastic is low. In the rapid prototype making industry, vacuum silica gel mold is often used for small batch reproduction production;

2. The service life of silica gel mold can reproduce and produce 10-20 same hand board products;

3. Fast speed, general working time: 1-4 hours / piece;

4. Standard copy accuracy of the replica hand plate: ± 0.10mm/100mm;

5. According to customer requirements, we can make vacuum moulding plastic products with exquisite appearance according to different colors;

6. It is suitable for trial production samples with complex product structure, uniform wall thickness and meeting certain functional requirements.

The Specification of Vacuum Moulding

Part name

sample, prototype,

Part material

plastic

Machining accuracy

+ / - 0.1

Tool life

20 shots

Exporting country

Israel

Delivery time

1 week

Delivery mode

DHL3 days

Mold quality customer satisfaction

100%

Project cooperation service customer satisfaction

100%

0 notes

Text

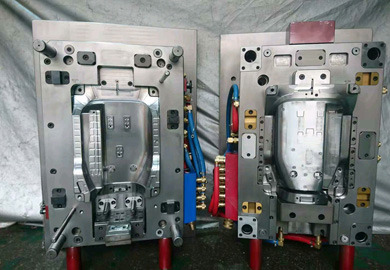

Two Shot Injection Moulding

https://www.gmmoldtech.com/products/two-shots-moulding-part.html

Two Shot Injection Moulding, also known as dual-shot, multi-shot, allows engineers to create multi-material or multi-colored parts without other steps.

It is a kind of plastic raw materials of injection molded parts after the parts out, fed into the second mold again with the same or another plastic material molding process.

Features of Two Shot Injection Moulding

The soft surface

The two-shot injection molded parts can make the surface of the product full of soft, which can increase the functionality.

High product value

The two-shot custom plastic injection molding by GM-TECH, a reliable injection mold components supplier, combines two or more materials with different characteristics to increase product value.

Versatile functions

The two-shot products made by the plastic injection mold and molding technique are known for being multifunctional. With this technology, two-shot moulding parts are widely used in noise reduction, shock absorption, waterproofing, and so on.

Specification of Two Shot Injection Moulding

Part material

ABS + TPU

Cavity

1

Mould steel

H 13

Mould steel

1.173

Runner

2 drops mold master

Mould life

100W

Mould standard

HASCO

Mould structure

5 lifters

Exporting country

Canada

Leadtime

5 weeks

Mould quality customer satisfaction

98%

FAI pass rate

99%

Project cooperation service customer satisfaction

98%

How Does the Two Shot Injection Moulding Work?

In order to meet the special needs of many plastic products, injection-molded plastic parts manufacturers use two or more two kinds of plastic raw materials many times. In the two-shot injection molded part process, the covering material is injected above, below, around, or inside the substrate, and the material is combined into a complete part. This process of two shots of precision injection molding can be completed through multiple injections or embedded injection.

0 notes

Text

Screw Thread Mould

https://www.gmmoldtech.com/products/screw-thread-mould.html

The screw thread plastic injection mold, a special part of the plastic injection molding process, is used for mass production of screw thread.

Nowadays, molded screw threads are everywhere -- on the cap of a Coca-Cola bottle, on the nut linking the drain pipe to the underside of the kitchen sink. So here comes a lot of screw thread plastic injection molding companies to perform the process of screw thread mould. GM-TECH, as a leading custom plastic injection molding company, will continuously spare efforts to produce high quality injection molds.

Features of Screw Thread Mould

Short cycle time

With plastic injection molding machine,the screw thread can be manufactured quickly.

Better maintenance

High precision injection molds of screw thread are tools requiring high maintenance. Everything must be timed, and that timing must be maintained to get the best productivity.

Low cost

Large plastic molds can be performed spontaneously to save the labor and material cost.

Fast ventilation

Usually the thread is formed in a blind pocket. Trapped gas will be vent out.

Mould design services

The Specification of Screw Thread Mould

Part material

PP

Cavity

1

runner

cold runner

Mold accuracy

+ / - 0.02

Mold steel

1.2343

Moldbase steel

1.173

Mold life

100W

Mold standard

HASCO

Mold structure

2 slides

Exporting country

Italy

Delivery time

4 weeks

Mold quality customer satisfaction

98%

FAI pass rate

98%

Project cooperation service customer satisfaction

95%

How does Screw Thread Mould Work?

There are four general steps to produce screw thread plastic injection mold.

Split tooling

Numerous screw-threaded parts are injection moulded by this step.

Thread jumping

This is the cheap plastic injection molding to produce screw thread molding product. It is very widely used for the manufacture of closure threads.

Collapsible coring

It is very convenient to manufacture common injection molded plastics.

Rotary unscrewing

Rotary unscrewing is used where split line witness cannot be tolerated or often when larger numbers of impressions are required.

0 notes

Text

China Rapid Injection Molding Prototyping

https://www.gmmoldtech.com/products/prototype-moulding.html

China rapid injection molding prototyping technology is a fast, convenient and practical mold manufacturing technology. The characteristics of prototype mold making are: short molding cycle, simple process, easy popularization, low molding cost, precision and service life, which can meet a specific functional needs, and good comprehensive economic benefits.Prototype mold making is especially suitable for new product development and trial production, process verification and function verification, as well as multi variety and small batch production.

Due to the increasingly fierce market competition and the accelerating speed of product renewal, multi variety and small batch will become an important production mode in the manufacturing industry. In this case, the manufacturing industry puts forward strong requirements for the rapid manufacturing of product prototype and mold. Therefore, China rapid injection molding prototyping technology presents a vigorous development trend.

Features of China Rapid Prototype Mold Making

GM-TECH, a professional manufacturer in prototype cnc machining, has designed and manufactured dozens of sets of automobile rear-view mirror molds for Kaiming hall in Murakami, Japan. The products are basically used in Toyota, Honda, and Nissan. In addition, we have also produced dozens of sets of lamp molds for Haila, including headlamp mask, headlight guide strip, headlight reflector, etc.

Prototype mold life is very low, cost is cheap. In order to meet the requirements of small batch production and material performance, we provide prototype injection molding.

Generally, we use poor steel, such as aluminum, S50C and so on. The structure and production principle of rapid die are the same as plastic injection moulding products.

The Specification of China Rapid Prototype Mold Making

Mold Name

Experimental mold

Part material

ABS

Machining accuracy

+ / - 0.02

Mold life

1W shots

Exporting country

Israel

Delivery time

4 weeks

Delivery mode

DHL 3 days

Mold quality customer satisfaction

100%

Project cooperation service customer satisfaction

100%

0 notes

Text

Vacuum Moulding

https://www.gmmoldtech.com/products/vacuum-moulding.html

In order to meet the requirements of small batch production and material performance, we provide vacuum molding for customers.

This is similar to the processing method of custom plastic injection mould. Products can use any material, such as ABS, PC, PBT, PA66 and so on. But its disadvantage is that the product precision is low and the die life is short!

Features of Vacuum Moulding

GM-TECH, a professional plastic injection moulding products manufacturer, has designed and manufactured dozens of sets of automobile rear-view mirror molds for Kaiming hall in Murakami, Japan. The products are basically used in Toyota, Honda, and Nissan. In addition, we have also produced dozens of sets of lamp molds for Haila, including headlamp mask, headlight guide strip, headlight reflector, etc.

The Specification of Vacuum Moulding

Part name

sample, prototype,

Part material

plastic

Machining accuracy

+ / - 0.1

Tool life

20 shots

Exporting country

Israel

Delivery time

1 week

Delivery mode

DHL3 days

Mold quality customer satisfaction

100%

Project cooperation service customer satisfaction

100%

0 notes

Text

Prototype Part

https://www.gmmoldtech.com/products/prototype-part/

Our company usually uses the following four methods to manufacture the first board: CNC Prototype, 3D Printing, Vacuum Moulding, Prototype Moulding.

If you design a product just to verify the structural feasibility of the product, we recommend that you give priority to the cost and cost of using 3D printing. Time is the lowest. If your product requires specified materials but does not require high accuracy, use Vacuum Moulding. If your product requires high material and product accuracy, it is recommended to use CNC prototype. If the product requires high and large quantities. We recommend using Prototype Moulding.

Prototype Part Features

l Our company usually uses the following four methods to manufacture the first board: CNC Prototype, 3D Printing, Vacuum Moulding, Prototype Moulding.

l If you design a product just to verify the structural feasibility of the product, we recommend that you give priority to the cost and cost of using 3D printing. Time is the lowest. If your product requires specified materials but does not require high accuracy, use Vacuum Moulding. If your product requires high material and product accuracy, it is recommended to use CNC Prototype. If the product requires high and large quantities. We recommend using Prototype Moulding.

Prototype Part FAQs

1.How many days does it take to send parts to Germany?How many days does it take to send parts to Germany?

The fastest DHL express delivery in Europe usually takes about 3 days to reach each country in Europe, while FedEx in the United States usually takes about 3 days to arrive

2.What is the tolerance of parts?What is the tolerance of parts?

If the customer does not have special requirements, the processing is generally within + / - 0.1mm.

3.How long is the delivery time for Prototype Part processing?How long is the delivery time for Prototype Part processing?

generally 3 days.

0 notes

Text

Prototype Moulding

https://www.gmmoldtech.com/products/prototype-moulding.html

Prototype mold life is very low, cost is cheap. In order to meet the requirements of small batch production and material performance, we provide prototype molding.

Generally, we use poor steel, such as aluminum, S50C and so on. The structure and production principle of rapid die are the same as plastic injection moulding products.

Features of Prototype Moulding

GM-TECH, a professional manufacturer in prototype cnc machining, has designed and manufactured dozens of sets of automobile rear-view mirror molds for Kaiming hall in Murakami, Japan. The products are basically used in Toyota, Honda, and Nissan. In addition, we have also produced dozens of sets of lamp molds for Haila, including headlamp mask, headlight guide strip, headlight reflector, etc.

The Specification of Prototype Moulding

Mold Name

Experimental mold

Part material

ABS

Machining accuracy

+ / - 0.02

Mold life

1W shots

Exporting country

Israel

Delivery time

4 weeks

Delivery mode

DHL 3 days

Mold quality customer satisfaction

100%

Project cooperation service customer satisfaction

100%

0 notes

Text

Product Development

https://www.gmmoldtech.com/products/product-development.html

Our company is not engaged in product development, but we are willing to assist customers to design product appearance and product structure in case of customer demand.

After the product design drawings are reviewed and confirmed by customers, we provide customers with Free custom 3d printing samples to check the feasibility of the product structure.

This is a drug release device designed by our company.

Custom Plastic Injection Molding Development

Plastic injection molded parts have a long history of 150 years. While modern technology development brings custom plastic injection molding with high precision and efficiency. GM-TECH, a professional plastic injection molding company in china, provides custom plastic injection moulding parts to meet your demanding requirements. Our custom plastic injection molding design can be your best choice. Here are the reasons why choosing us as your reliable injection moulding products manufacturer.

l Comprehensive service

Capable project management from design to the final part. One-stop service for all of our clients’ plastic molding needs.

l Industry experience

Decades of custom plastic injection molding engineering and processing experience.

l Premium quality products

Durable, high-quality components you expect are available in our injection molding factory.

l Variety of design and material options

Customized design and a full range of plastic material offerings including a wide variety of colorant and over-molding options.

0 notes

Text

Plastic Injection Mould

https://www.gmmoldtech.com/products/plastic-injection-mould/

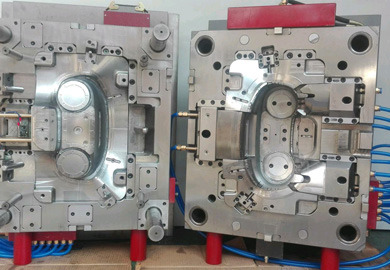

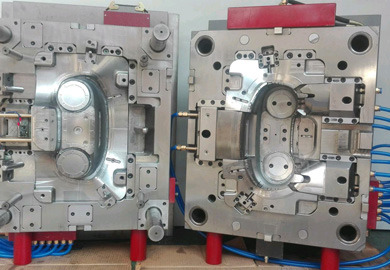

GM-TECH is mainly engaged in the production of high-precision injection mould production plants. And the production of precision injection moulds is very widely used, including products such as automotive plastic parts, medical plastic parts, electronic plastic products, toy plastic products, industrial products, etc.

In the early stage, we have won the trust and cooperation of customers with decades of professional plastic injection mold design experience. In the later stage, we will win the long-term trust and cooperation of customers with reliable and stable mould quality!

Plastic Injection Mould Features

l All the injection molds and molding parts that we made are exported to abroad such as,USA, Europe, Japan, Singapore, India and other countries. Molds vary from 50kg to 10 tons,including automotive plastic mould, electronic product molds, industrial product molds, home appliance molds, medical product molds and so on.

l The leadtime for mold manufacturing generally takes 4-8 weeks, depending on the ease of the mold.

l GM-TECH mainly produces and designs high-precision and high-quality moulds. We are good at the fields of automobile product mould, electronic product mould, home appliance mold, medical product mould, insert mould, two-color mould, multi hole mould, thread mould, gear mould, etc

Plastic Injection Mould FAQs

1.What are your common mold steel?What are your common mold steel?

Generally, we use steel materials required by customers, such as 1.1343, H-13, S136, NAK80, P20 and so on. And we will provide steel certification to customers.

2.How long is the delivery time for mold processing?How long is the delivery time for mold processing?

Specific to see the difficulty of mold, generally 2-8 weeks

3.Is your company familiar with export mould standard?Is your company familiar with export mould standard?

Yes, we are very familiar with DME, HASCO and Mishmi standards.

How do you guarantee the quality of the mould?How do you guarantee the quality of the mould?

Mold design: when the design is completed, our engineers will meet to review the mold. Mold processing: CMM inspection will be carried out for each machining step (electrode, CNC,) of parts.

0 notes

Text

Multi Cavity Mould

https://www.gmmoldtech.com/products/multi-cavity-mould.html

A multi-cavity mould is known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts.

Though multi-cavity injection molding process may be much more complex than others such as insert injection molding process, it is still popular as the improvements of production efficiency and cost-efficiency. As a leading multi-cavity mould manufacturer, GM-TECH provides you with high-grade multiple cavity mould to meet the needs of high-yield, high-precision products.

Features of Multi Cavity Mould

Multi cavity molds contain more than one cavity of the same part. It’s able to produce many parts per injection molding cycle with high-volume production. Here are some major features of a multi-cavity mould.

More parts can be manufactured by the same mold within the cavity.

l Generally speaking, a multi-cavity mould is at a lower custom plastic molding cost than a single cavity mould.

l The requested number of components will be finished faster due to the shorter lead time per batch.

l More efficient use of the cycle time

l The processes of multi-cavity mould are more stable

l It keeps flow balance of cavity injection molding

The Specification of Multi Cavity Mould

Part material

PP

Cavity

16

Runner:16 drops hot runner

Mold accuracy

+ / - 0.02

Mold steel

1.2343

Mold blank steel

1.1730

Mold life

100W

Mold standard

HASCO

Mold structure

12 lifters

Exporting country

Australia

Lead time

5 weeks

Mold quality customer satisfaction

100%

FAI pass rate

100%

Project cooperation service customer satisfaction

100%

How does Multi Cavity Mould Work?

l The basic manufacturing process of multi-cavity mould by GM-TECH, a professional company specializing in moulding products, are as follows:

l Plastic is melted in a plastic injection molding machine and then injected into a mold under high pressure. The material is cooled and solidified inside the mold, then the two halves are opened and the product is removed. The technology produces plastic products with predetermined fixed shapes.

l To simplify production, the parts of multi-cavity mould that function in the plastic injection molding process must be carefully designed. Products made using multi-cavity injection molding machines are first designed by industrial engineers or designers. The die manufacturer takes into account all the key conditions: the materials used in the final product, the function of the product; In addition, the material of the mold, and the characteristics of the multi-cavity injection molding machine.

0 notes

Text

Mould Slide

https://www.gmmoldtech.com/products/mould-slide.html

The slider is a mold component that can slide in a certain angle perpendicular to or with the opening and closing direction during the opening and closing action of the mold.

Features of Mould Slide

When the product structure makes it impossible for the mold to demould normally without the slider, the slider, the injection molding machine component, must be used. The material itself has appropriate hardness, wear resistance, enough to withstand the friction of the movement. The hardness of the cavity part or core part on the slider should be the same level as other parts of the cavity and core.

The Specification of Mould Slide

Part name

slider

Part material

1.2343

Mold accuracy

+ / - 0.015

Dimension detection method

CMM

Surface treatment

EDM

Exporting country

Germany

Delivery time

2 weeks

Mold quality customer satisfaction

100%

Project cooperation service customer satisfaction

100%

0 notes

Text

Mould Design

https://www.gmmoldtech.com/products/mould-design.html

GM-TECH have a much experienced design team, familiar with China domestic, European, American, Japanese and other mold design standards, be able to use all kinds of software skillfully for mold and product designing.

Features of Mould Design

There are more than 10 engineers who have much experience in plastic part design for injection molding:

l GM-TECH have got a set of mature design process, from parts analysis, mold flow, structural analysis to process analysis.

l Use full 3D design, With the design ability , can design more than 20 sets of complex molds monthly.

Specification of Mould Design

l Emphasizesthe importance of early involvement in projects, designingand developing the product together with the customer.

l Preparation of prototype part tools or SLA samples for pre-testing production conditionsof products.

l Optimizethe mold structure designingand cooling system

l DFM, Mould-flowanalysis

l UG, Pro-E, AutoCAD, CAE, CAM

l Designers: Average Working Experience: 12 years

Custom Plastic Injection Mold

Custom plastic injection mold has provided solutions to mass production of various parts and components such as household mould, medical mould, electronics mold, home appliance mould, etc. This personalized injection moulding design gives you a high level of production while minimizing the cost per unit. GM-TECH, an certified injection mold design company, has earned a high reputation for a professional design for manufacturing injection molding. We offer you high-quality, low-cost products and mold design services as follow:

In-house plastic injection mold design and engineering with professional guidance through every step of the process.

Our mold makers have rich experience with custom plastic mold design and tooling.

Quality-controlled experts are in a wide variety of capabilities, materials, and sizes in terms of plastic injection molding mold design.

0 notes

Text

Mould Component

https://www.gmmoldtech.com/products/mould-component/

Mould Components are also a part of the mould. GM-TECH not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing accuracy can be controlled within + /-0.015mm. Delivery time is 2-3 weeks, DHL or FedEx will take about 3 days for shipping.

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing of different types of injection moulding, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

Mould Component Features

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts.

Mould Components are also a part of the mould. GM-TECH, a reliable injection molded plastic parts manufacturer, not only produces precision moulds but also provides customers with high-precision, low-cost mould parts. For example: mould cores, inserts, sliders, lifter, wear plates, ejector pins, etc. Usually, processing accuracy can be controlled within + /-0.015mm. Delivery time is 2-3 weeks, DHL or FedEx will take about 3 days for shipping.

All the steel and tolerances of the parts are processed according to the drawings of the customers. In order to ensure the quality of parts processing, we will provide customers with dimensional measurement report, hardness measurement report, material proof.

We also use new technology to do DLC surface treatment to guarantee the life of the parts such as medical device molding parts.

Mould Component FAQs

1.What is the tolerance of parts?What is the tolerance of parts?

If the customer does not have special requirements, the processing is generally within + / - 0.02mm.

2.How long is the delivery time for mold part processing?How long is the delivery time for mold part processing?

Specific to see the difficulty of part, generally1-2 weeks.

3.How many days does it take to send parts to Germany?How many days does it take to send parts to Germany?

The fastest DHL express delivery in Europe usually takes about 3 days to reach each country in Europe, while FedEx in the United States usually takes about 3 days to arrive.

0 notes

Text

Injection Moulding Products

GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in automotive, electrical and home appliance industries but also manufacture moulds for other industries requiring plastic injection moulds. We are able to offer you complete services in this area, from design of the moulds, over their high-quality manufacturing in own tool shop, up to production (incl. parts with metal inserts) and deliveries of plastic products right on schedule. All manufacturing processes are subject to quality management system and environment.With 100-450t Haitian injection molding machine for trial mold and mass production. Due to the continuous development of the company, we will continue to purchase larger injection molding machines. At the same time we have a good relationship with the mold testing company, machine 100 - 3600t

Injection Moulding Products Features

The production uses of precision injection molded parts are very wide, including automotive plastic parts, medical plastic parts, electronic plastic products, toy plastic products, industrial products and other products.

We are familiar with the use of a wide variety of injection molding materials such as ABS, PP, PVC, PC, POM,etc.

And also have extensive experience dealing with various defects in injection molding products such as Flow lines, Burn marks, Warping, air pockets, Sink marks, Weld lines, Short shot, etc.

With 100-450t Haitian injection molding machine for trial mold and mass production. Due to the continuous development of the company, we will continue to purchase larger injection molding machines. At the same time we have a good relationship with the mold testing company, machine 100 - 3600t

Injection Moulding Products FAQs

What kind of injection molding materials do you usually use?What kind of injection molding materials do you usually use?

For example: PP, ABS, PC, PA66, PBT, PVC, PE, HDPE, etc. Special materials are generally provided by customers.

How do you control product quality?How do you control product quality?

QC will check the dimensional of products every hour.

Can your company design products?Can your company design products?

Our company has design engineers to provide customers with optimized products and design product services.

https://www.gmmoldtech.com/products/injection-moulding-products/

0 notes