Don't wanna be here? Send us removal request.

Text

Three Types Of Plastic Molds

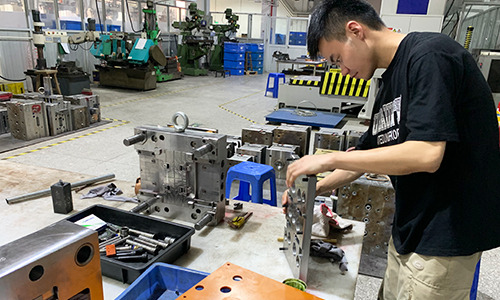

Plastic molds are tools used with plastic molding machines in the plastic processing industry, and can provide complete structural configurations and precise dimensions for plastic products. According to different molding methods, plastic molds can be divided into the following three types.

1. Injection molding tooling

Injection molding tooling is often used to produce thermoplastic parts, and its corresponding processing equipment is an injection molding machine. The manufacturing process is as follows: first put the plastic into the injection molding machine, heat and melt it through the heating barrel at the bottom, and then push through the injection molding machine's nozzle and the injection system of the mold under the push of the injection molding machine screw or column, and finally cool the plastic. It hardens to form, and then the product is demolded.

The structure of custom plastic injection molds is usually composed of molding parts, pouring system, guide parts, push-out mechanism, temperature regulation system, exhaust system, support parts and other parts. Its overall structure is made of plastic mold steel. The injection molding process is usually suitable for the production of thermoplastic products, and the plastic products produced by the injection molding process are widely used. Daily necessities, complex electrical appliances, auto parts, etc. are all made by injection molding tooling, so people often say that injection molds are plastic products. The most widely used processing method.

2. Blow mold

Blow molds are molds used to form hollow plastic containers, such as beverage bottles, daily chemicals and other packaging containers. According to the process principle, blow molding mainly includes extrusion blow molding, hollow molding, injection blow molding, hollow molding, multi-layer blow molding, and sheet blow molding. The corresponding equipment for blow molding of hollow products is usually called a plastic blow molding machine. In addition, blow molding is only suitable for the production of thermoplastic products, and its structure is relatively simple, and the materials used are mostly made of carbon.

3. Compression mold

Compression molds include two mold structure types, namely compression molding and injection molding, which are mainly used for thermosetting plastic molding. The corresponding supporting equipment is a pressure molding machine. Among them, the compression molding is mainly composed of a cavity, a feeding cavity, a guide mechanism, an ejection part, a heating system, and so on. According to the characteristics of the plastic, the compression molding method heats the mold to the molding temperature, usually 103°-108°, puts the compression molding powder into the cavity and the feeding cavity, and then closes the mold to allow the plastic to soften under high temperature and high pressure, and After a certain period of time, it will be solidified and formed into the desired product shape. The difference between injection molding and compression molding is that there is no separate feeding chamber for injection molding. Injection molds are widely used and are often used for packaging electrical components.

0 notes

Text

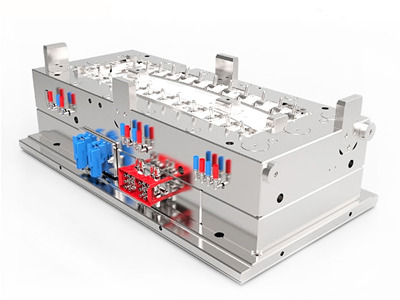

4 Characteristics Of Injection Molding Tooling

The plastic products we see in our lives are formed by custom plastic injection molding suppliers injecting plastic raw materials into the injection molding tooling. The process of injection molds is to inject the molten material into the cavity through high pressure, and then cool and solidify to obtain the molded product . Injection molding tooling is widely used in many industries. According to the molding characteristics, it can be divided into thermosetting plastic molds and thermoplastic plastic molds. So, what are the characteristics of plastic injection mold company?

Wide range of applications

The injection molding tool has a wide range of applications, and can simultaneously form plastic parts with complex structure, accurate size, and good internal quality. Therefore, it is widely used in the production of plastic products.

High precision requirements

Whether the design and manufacture of injection molding tooling, the geometric shape and the structural size are reasonable, directly affect the rheological properties and filling effect of the polymer melt in the mold channel, and ultimately affect the molding quality of the plastic part.

Professional operation

There are many uncertainties in the early design and development of injection molding tool. First, the preliminary design requires experienced practitioners, and most of them need to rely on the knowledge and experience of mold designers. Features such as jet flow, warpage deformation, welding seam and pouring are closely related to the design of the pouring system.

Temperature control

To control the injection molding tooling temperature is to heat the mold to the working temperature. The key is to keep the mold temperature constant at the working temperature.

0 notes

Text

How To Make Plastic Injection Molding Parts With High Processing Precision?

Plastic has great fluidity, which makes it difficult to produce plastic injection molding parts in strict accordance with the requirements of the drawings, especially for some plastic injection molding parts that require relatively high dimensional accuracy. The dimensional accuracy of custom injection molding parts refers to the obtained The degree of conformity between the size of the plastic part and the size in the product drawing is to obtain the accuracy of the size of the plastic part. Goodtech is a professional china custom plastic injection manufacturer, how can we make injection molded parts with high precision products?

Firstly, there are many factors that affect the dimensional accuracy of plastic injection molding parts. The first is the injection molding tooling manufacturing accuracy and the degree of mold wear, and the second is the fluctuation of plastic shrinkage rate and the change of process conditions during molding.

The aging change of the plastic part after molding and the structure and shape of the injection molding tooling, etc. Therefore, in order to reduce the processing difficulty of injection molding tooling and the manufacturing cost of the mold, under the premise of meeting the requirements of the use of injection molded parts, the dimensional accuracy of the plastic parts should be as good as possible The design is lower.

The dimensional tolerances of plastic injection molding parts can be designed and processed according to SJ1372-78, which is the tolerance value standard of plastic parts. According to this standard, the injection precision of plastic parts is divided into 8 precision grades, of which grades 1 and 2 belong to the technical grade of injection molding processing. , It is only used under special requirements. The standard only specifies the standard tolerance value, and the basic size upper and lower deviations can be allocated according to the matching properties of the plastic parts.

For the dimensions that are greatly affected by the active part of the injection molding tooling, such as the height dimension of the compression part, due to the influence of the thickness of the horizontal profile overflow, the tolerance value is the sum of the tolerance value and the additional value in the table, and the accuracy is level 2 The additional value is 0.05mm, the additional value of 3~5 precision is 0.10mm, and the additional value of 6~8 precision is 0.20mm.

In addition, for uninjected tolerance dimensions, it is recommended to adopt the 8-level accuracy in the standard. Only by strictly following the tolerance value standard of plastic injection parts can the dimensional accuracy and quality of plastic parts be guaranteed.

In order to meet the human pursuit of plastic injection molding processing, the performance of products in various industries is constantly improving. Products are composed of accessories. This requires higher and higher product accessories, which greatly allows product accessories to reach the beginning of design The size of the injection molding industry is the same, and injection molding processing has become a field in which major injection molding companies compete.

Nowadays, many products can't reach the life of their original design. There are many reasons for this. One of the reasons is that the product accessories cannot reach the size of the original design. A complete product consists of several or even more. Composed of tens of thousands of accessories, the size fails to meet the design requirements, causing problems during use, and even if it takes a long time, the accessories are replaced.

For example, every accessory on a spacecraft is manufactured through thousands of selections. Perhaps a small size problem can cause a major accident. Therefore, in recent years, various industries have increased their investment in manufacturing. Whoever can master good manufacturing technology will be able to occupy a dominant position in the future competition.

Goodtech is a group of companies specializing in injection molding tooling and plastic injection molding parts production for many years. The company focuses on providing customers with a complete set of solutions from product design, mold manufacturing, medical molds, injection molding and assembly, and after-sales service. Products are widely used It is used in the fields of housing accessories for household appliances, and injection molding accessories for medical and medical equipment.

0 notes

Text

What Are The Components Of Injection Molding Tooling?

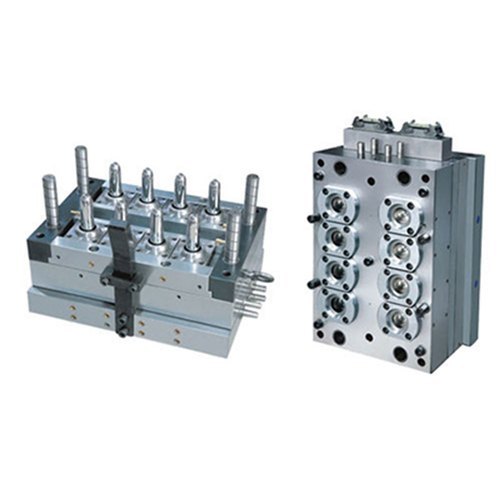

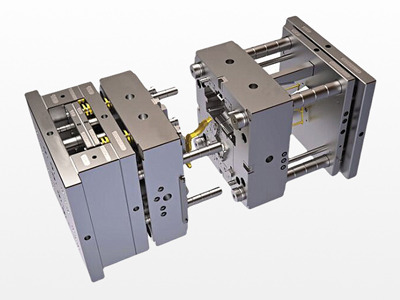

Injection molding tooling consists of two parts: a movable mold and a fixed mold. The movable mold is installed on the movable template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form a pouring system and a cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic products. In order to reduce the heavy workload of mold design and manufacturing, most of the injection molds use standard mold bases

Purchasing injection molding tooling and choosing a good company can reduce a lot of shopping time, and the product you choose will be very good in the end. There are many companies that can be selected in the shopping mall, but many customers directly choose Goodtech. A very excellent plastic injection mold company, Goodtech provides one-stop service from the initial planning to the final product, which can bring a lot of convenience to customers.

0 notes

Text

The Effect Of Thermal Processing Quality Of Injection Molding Tooling On Performance

The thermal processing quality of injection molding tooling has a great influence on the performance and service life of the mold. In real life and work, our mold workshop requires excellence in the design and production of various molds, and there will be problems in the specific operation. We will discuss and exchange the problems in the use of molds with the plastic injection mold company.

The quenching deformation and cracking of custom plastic injection molds, and the early fracture in the use process are all related to the thermal processing technology of the mold.

(1) Forging process, which is an important link in the manufacturing process of mold working parts. For high-alloy tool steel molds, technical requirements are usually put forward for the metallographic structure of the material carbide distribution. In addition, the forging temperature range should be strictly controlled, the correct heating specification should be formulated, the correct forging force method should be adopted, and the slow cooling or timely annealing after forging should be used.

(2) Preliminary heat treatment. Depending on the material and requirements of the injection molding tooling, preliminary heat treatment processes such as annealing, normalizing or quenching and tempering are used to improve the structure, eliminate the structural defects of the forging blank, and improve the processing technology. High-carbon alloy die steel can eliminate network secondary cementite or chain carbide through proper preliminary heat treatment, spheroidize and refine the carbide, and promote the uniformity of carbide distribution. This will help ensure the quality of quenching and tempering and increase the life of the mold.

(3) Quenching and tempering. This is the key link in mold heat treatment. If overheating occurs during quenching and heating, it will not only cause greater brittleness of the workpiece, but also easily cause deformation and cracking during cooling, which will seriously affect the life of the mold. Special attention should be paid to prevent oxidation and decarburization during the quenching and heating of the die, and the heat treatment process specifications should be strictly controlled. When conditions permit, vacuum heat treatment can be used. After quenching, it should be tempered in time, and different tempering processes should be adopted according to the technical requirements.

(4) Stress relief annealing. The working parts of injection molding tooling should be subjected to stress relief annealing treatment after rough machining. The purpose is to eliminate the internal stress caused by rough machining, so as to avoid excessive deformation and cracks caused by quenching. For molds with high precision requirements, they need to undergo stress relief and tempering treatment after grinding or electrical machining, which is conducive to stabilizing the precision of the mold and improving the service life.

0 notes

Text

Why Does Injection Molding Tooling Need To Try?

Most of the defects of plastic injection molding products are caused in the injection molding tooling and injection molding stages, but sometimes they are also related to unreasonable design. The influencing factors include: the type of injection port, the number of mold cavities, position and size, and cold/ The design of the hot runner system and the structure of the product itself. Therefore, in order to avoid product defects caused by mold design, plastic injection mold manufacturers need to analyze injection molding tooling during production.

After getting the test results of custom plastic injection molds, the operator usually needs to evaluate the specific conditions of the mold to avoid unnecessary cost and time during the modification process. In most cases, in order to make up for the shortcomings in the mold design, the operator may make incorrect settings without knowing it, because the parameter setting range required to produce qualified products is very small. Once there is any deviation in the parameter setting, it may Will cause the quality of the final product to far exceed the allowable error range

The purpose of injection molding tooling is to find out the optimized process parameters and mold design. Not just to get a good sample. this point is very important. Even if the materials, machine settings or environmental factors change, a stable and uninterrupted mass production environment can still be ensured.

1 note

·

View note