Don't wanna be here? Send us removal request.

Text

Working Principle of Turbine Bypass Valves in Power Plants

Operational stability and equipment safety constitute the main aspects of treatment in power plants, particularly in plants with steam turbines. So, Turbine bypass valves provide utmost security. The plant can thus be subjected to different load conditions and emergency situations, as well as start-up/shutdown operations, while still avoiding mechanical stress or operational hindrances.

This gives turbine bypass valves the ability to divert selected steam flows into the condenser or the process steam lines, bypassing the turbine altogether. Let us take a look at the purpose, working, and integration of the turbine bypass valve in detail.

1. Purpose of the Bypass Valve System

The turbine bypass system is designed:

To protect the turbine from high-pressure steam during non-working conditions.

To support the functioning of combined cycle plants, where gas and steam turbine sections operate in tandem.

It allows for fast plant start-ups in terms of diverting steam until turbine conditions are suited.

To maintain the operation of the boiler or HRSG even when the turbine is not able to take the steam load.

Prevents overpressure in the steam lines during load rejection or abnormally fast turbine trip interventions.

Having this system installed provides an alternate way for the plant to continue producing steam in order to protect turbines.

2. Steam Flow Diversion

The main purpose of a Turbine bypass valve principle is to divert steam:

From boiler/HRSG outlets straight to the condenser in a thermal power plant.

From reheaters to condensers in reheat steam cycles.

Into process steam headers in cogeneration units.

When fully open, the bypass valve offers very low resistance compared to the turbine inlet and thus steam at high pressure can be diverted almost instantaneously. This diversion is so large a power plant, in thousands of kilograms per hour, needs the valve design to be powerful enough to handle such very high flow rates.

3. Automatic Operation via Control Signals

On a modern turbine bypass valve, actuation and operation are performed automatically by the plant's DCS or TCS. Control signals are sent to the valve based on:

Turbine load conditions

Boiler/HRSG pressure readings

Turbine trip detection

Steam temperature deviations

For example, if the turbine trips suddenly, the bypass valve is immediately commanded to open and divert steam so that dangerous pressurization will be avoided. Also, during start-up, the control system modulates the valve opening to regulate the steam flow until the inlet condition for the turbine is optimum.

4. Pressure Reduction Function

Almost always, the steam leaving the boiler or reheater is at a very high pressure, between 80 and 250 bar. This Turbine bypass valve operation lowers the pressure before the steam is sent to the condenser or process header.

That is done by:

Through multi-stage pressure reduction trim within the valve.

Passing the fluid through a flow path designed to convert the velocity kinetic energy of steam into heat, which essentially gets dissipated.

Making the valve out of erosion-resistant materials so it can withstand the erosive impacts of high-velocity steam.

The sudden release of high-pressure steam without this staged pressure drop could cause damage to downstream piping or even condenser equipment.

5. Temperature Control with Desuperheaters

High-temperature steam cannot be directly condensed in the condenser. Hence, any high bypass valve scheme usually provides for downstream desuperheaters (or attemperators).

Working principle:

Cold feedwater is sprayed into the steam through high-velocity nozzles.

The water absorbs heat, and the steam temperature is reduced almost to saturation.

Such arrangements protect the condenser tubes and piping from thermal stresses.

According to many design types, the desuperheater is combined with the bypass valve assembly so that pressure and temperature are controlled simultaneously.

6. Quick Response During Turbine Trip

A trip of the turbine is one of the most critical cases in which bypass valves do good. For example, a trip could occur because of overspeed, vibration, loss of lubrication, or a fault in the generator. In such cases:

The turbine stop valves close at once.

Steam from the turbine is cut off at once.

The bypass valves open in less than a second to cater to the sudden steam surplus.

Steam pressure is taken care of, thereby keeping the boiler from any further disturbance.

These fast movements prevent any unwarranted overpressure that might lead to a boiler trip or temporary lifting of the safety valve.

7. Role in Warm-Up and Cool-Down Cycles

At start-up:

Steam admission into the turbine should be slow enough to prevent thermal shock.

The turbine bypass valve allows most steam to bypass the turbine until the casing and rotor are warmed to the correct temperature.

As the turbine metal temperature equalizes, the bypass valve gradually closes and the main turbine inlet valves gradually open.

During shutdown:

Along with assisting in the decay of steam pressure is the bypass valve.

It diverts the steam away from the turbine as it cools to avoid uneven contraction damage.

The warm-up-and-cool-down operations help lengthen the life of the turbine and cut down on maintenance.

8. Fail-Safe Design and Redundancy

Due to the safety application of turbine bypass valves, they are to be designed with the following considerations:

Fail-open or fail-close configurations depending on plant safety philosophy (most often fail-open to relieve pressure).

Hydraulic or pneumatic actuators backed by accumulators.

Sensors and control circuits are provided redundantly so that in case one system fails, the other ensures operation.

Trims resistant to erosion and corrosion.

Therefore, if the control systems fail, the valve would then bridge protection to the plant.

9. Integration With Plant Protection Systems

The bypass valve system is not an isolated system. It has full integration into:

Boiler Master Control

Turbine Protection System

Condenser Protection Logic

Overpressure Protection Circuits

Such integration permits that any abnormal condition, be it from the turbine, boiler, or condenser, can initiate an operation of the bypass.

For instance:

A sudden load rejection coming from the generator protection system can force the opening of bypass valves even before the completion of the turbine trip sequence.

Should the condenser vacuum drop, the system modulates the bypass flow so as not to overload the condenser.

10. Support for Combined Cycle and Thermal Plants

Turbine bypass valves are needed for:

Thermal Plants (coal, oil, biomass)—where these valves act to safeguard the steam turbine on startup, shutdown, and in emergency cases.

In the Combined Cycle Power Plant – the steam must be taken care of from the HRSG during gas turbine trips or load changes with much attention.

Cogeneration Plant – a portion of the steam is used for industrial processes, and the other portion for power generation.

This versatility ensures steam is consistently managed, no matter what plant type is involved.

Conclusion

Turbine bypass valves are emergency equipment for power supply plants and are a key element to ensure safe, flexible, and efficient operation. These valves are thus indispensable for thermal and combined cycle power plants and for being capable of responding within milliseconds to rapid drops in pressure and temperature of steam at high pressure and temperature.

According to their function to govern the steam flow, reduce pressure and temperature, and work with the safety system of the plant, these valves guarantee that turbines, boilers, and condensers remain protected under all operating conditions. Without the presence of these Turbine bypass valves, the modern power plant would be prone to considerable damage, considerable downtime, and costly maintenance.

0 notes

Text

Preventive Maintenance Strategies for PRDS in Industrial Steam Networks

Set at the very core of a large industrial steam site, yet small in dimension, a Pressure-Reducing and Desuperheating Station (PRDS) forms one of the finest components of the steam network. It accounts for the delivery of steam at the desired pressure and temperature for a number of processes. Like any other precision machine, PRDS systems need to be maintained periodically to operate with efficiency, safety, and longevity.

This blog looks at the role of PRDS maintenance strategies, some of the risks associated with this, and how maintenance can be done much in advance to avoid these concerns. To get the best quality PRDS with lesser maintenance costs, always choose reputable PRDS station manufacturers in India.

Facts to Know About PRDS Functionality

PRDS stands for Pressure Reducing and Desuperheating Station. In industries like power generation, chemical processing, refineries, and pulp & paper, a pressure-reducing and desuperheating station reduces high-pressure steam and adjusts its temperature before onward supply to downstream equipment such as turbines and heat exchangers.

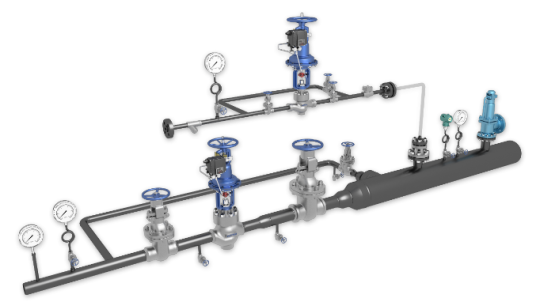

There are two devices in PRDS. The first is a Pressure Reducing Valve (PRV) that reduces the pressure of incoming steam, and the second is a desuperheater, which cools it down by the injection of water so that both of them will be at almost similar environmental conditions, making it safer and more effective for usage.

Pressure gauges, temperature sensors, and flow metres are crucial for monitoring system health and providing early diagnostics, preventing minor issues from escalating into major failures. Moreover, sufficient clearance around components like valves and sensors is essential to facilitate easy access for maintenance and inspection.

Utilising replaceable parts such as valve trims, spray nozzles, and actuators allows for straightforward system maintenance without requiring a complete shutdown for repairs.

Common Problems with PRDS Systems

While they are designed to withstand very tough operating conditions, PRDS systems tend to develop various problems as a result of incessant thermal and mechanical stresses. Some of the most common issues are as follows:

Valve Erosion or Sticking

High-velocity steam tends to carry impurities such as condensate and particulate matter, thereby eroding pressure-reducing valves over time. Eventually, this leads to wear in the valve seats and trims, causing erratic pressure delivery, if not the complete failure of regulation. Also, the valves can hang as a result of scale accumulation and misalignment, restricting system responsiveness.

Clogging or Wear of Nozzles

Mineral deposits or other impurities in the water block desuperheater nozzles, which limits the injection of water and, consequently, results in poor temperature control. In the worst-case scenario, the nozzles may perish due to water hammer or uneven cooling of the steam, both hazardous to the downstream equipment. It is the right way for preventing PRDS failure.

Setting Up a Preventive Maintenance Schedule

A successful maintenance strategy operates on consistency and foresight. Preventive maintenance scheduling should consider factors such as equipment running hours, manufacturer recommendations, and operational stresses. In general, quarterly or biannual checks are deemed advisable, while for very high-load systems, monthly checks could even be justified. Some key points of activity in a preventive maintenance programme include

Logging trends in valve performance.

Listening for unusual noise or vibrations.

Visually inspecting seals, flanges, and pressure gauges.

Pressure-Reducing Valve Inspection

Inspection begins with the preliminary visual and functional tests. Check for leaks around the valve body and flange connections. Operate the valve throughout its stroke to confirm smooth operation. Ensure proper actuation of the valve actuator—whether pneumatic or electric.

If required, dismantle the valve for inspection of internal parts such as the seat, disc, and cage. Replace any parts that are worn or otherwise damaged. Clean out foreign materials and re-lubricate the moving parts before reassembling.

Upkeep of Desuperheaters

Neglect is what usually happens until desuperheaters break down because proper maintenance allows more efficient temperature control while eliminating stresses on downstream piping.

Use clean water injection nozzles to remove scaling or deposits.

Check the water supply filter and strainer.

Spray control valves and actuators should be appropriately modulated.

Check cooling water for quality to avoid fouling.

An uneven spray pattern or dripping indicates the presence of erosion or blockage in the nozzles. Replace impaired nozzles as appropriate, and always check alignment with the steam flow direction.

Instrumentation and Control Monitoring

A well-engineered PRDS system solely depends on good sensors and controls. Hence, regularly check and calibrate:

Pressure transmitters (before and after the valve).

Temperature sensors in the proximity of the desuperheater.

Flow metres for both steam and water lines.

Control valves and positioners.

Test safety interlocks as well as verify alarm settings. Always check that your SCADA or DCS system is correctly logging data for trend monitoring over time.

Steam and Water Quality Management

As per experts at PRDS station manufacturers in India, poor quality of steam or cooling water literally induces early ageing of the components along with scaling, fouling, and corrosion. So, it should not be treated only as a boiler room concern, but it directly implies PRDS as well.

For steam:

Install excellent steam separators or steam traps upstream.

Monitor dryness fraction to keep wet steam from damaging valves.

For water:

Make use of demineralized or conditioned water for desuperheating.

Check for pH, hardness, and dissolved solids.

Regularly clean or replace inline filters.

Such straightforward checks boost the life of the system and significantly enhance thermal efficiency.

Leak Detection Plus Seal Integrity

Steam leakages lead to energy wastage and pose significant safety hazards. Sometimes, even minor flange leaks in PRDS piping can alert major issues inside.

Ultrasonic or acoustic leak detection surveys have to be carried out.

Examine gaskets, flanges, and threaded joints to determine leaking steam or water.

Apply appropriate torque to bolts and replace gaskets periodically.

Training Procedures and Safety Instructions

The human factor is often left out of the maintenance plan, yet it is vital for a fully trained team in the operating procedure for PRDS systems, LOTO protocols, emergency shutdown processes, and using safety gear in high-temperature inspections.

Retention of skills at refresher training sessions scheduled every six months would assist very well in ensuring that everyone knows the tricks and trades, especially during a breakdown or alarm.

Conclusion

It can be said that PRDS systems are essential for the health of an industrial steam network, and preventive maintenance is the best insurance policy that anyone can have.

Regular inspections of valves and nozzles, managing fluid quality, checking instrumentation, and investing in operator training will all ultimately prevent unplanned shutdowns, better energy efficiency, and greater life of your equipment. To know more about PRDS maintenance strategies, reach out to a reputed PRDS station manufacturer in India.

0 notes

Text

Design and Functionality of Pressure Reducing and Desuperheating Stations

Superheating stations play a crucial role in processes that include the use of superheated steam. These heat exchangers help regulate the temperature and the phase of the steam through the injection of a specific quantity of cooling water into the stream.

Superheated steam, having high temperature and pressure, can be potentially hazardous for the downstream equipment, designed for saturated or slightly superheated steam. They are used in power generation, chemical processing, and other industries where maintaining a consistent temperature of the system is crucial for the quality of the end product and efficiency of the process.

A PRDS working principle represents a highly technical balance between many aspects, from safety and regulatory ones to purely technical and economical ones. Indeed, a PRDS is very important in applications where the steam has to be conditioned for use—specifically, to reduce its pressure and temperature to satisfy process requirements. This blog explains the necessary critical considerations in designing such a system.

Flow Requirements

The design of the system must be based on maximum and minimum flow rates of steam to be handled. Peak flow rates need to be ascertained that can ensure stable conditions in the PRDS even when the conditions vary concerning loads.

The number of the flow range that a system can handle without losing its efficiency or control is known as the turndown ratio. Proper design with adequate turndowns ensures smooth operation over a wide range of flow conditions.

What is required here is accounting for the variability of process demand so that the system can be designed as responsive to changes in immediate downstream pressure and temperature requirements.

Pressure and Temperature Ratings

Functionality of Pressure Reducing station should be done in such a manner so as to handle the peak upstream pressure with downstream pressure at the desired level. The pressure ratings of the valves, pipes and fittings shall be chosen in such a way so as to meet the operating conditions of the system.

This desuperheating section shall be capable of cooling steam down to rated levels. Materials and parts that will be at the different levels of temperature are rated for those same temperatures so thermal stresses don't damage the system. Since safety is optimized by maintaining the design pressure a little higher than that required at normal operating pressure, plus 10 to 20%, this buffer space takes up any unforeseen surge.

Material Selection

Materials such as stainless steel are selected due to their resistance properties, mainly when steam has various contaminants or condensate that could corrode the system. Materials chosen offer resistance against extremely high temperatures and pressure conditions without deformation and degradation with time. Some of these examples include some alloys applied in the high-temperature usage of chromium-molybdenum steel.

Desuperheating stations' valves erode due to high-velocity steam. Hard-facing alloys or materials, such as tungsten carbide, can be applied for extending valve life and minimizing maintenance.

Control Systems Design

The system has to use modulating control valves to regulate steam pressure according to the variations in process demand. Such valves are pneumatically or electrically operated. The minimum requirement for desuperheating is the precise injection of certain quantities of water to cool down the steam. Thus, such control systems have to be fitted with temperature sensors and actuators to monitor and regulate the flow of spray water so that the appropriate amount is mixed with the steam.

Advanced control systems employ PID (Proportional-Integral-Derivative) controllers to fine-tune the process of steam conditioning in such a way that energy use is reduced but efficiency is gained.

Safety Features

Pressure relief valves are an essential part of avoiding overpressure conditions. They open and allow steam to vent when pressures become so high that they exceed the safe limits, thereby avoiding damage to downstream equipment.

Automatic Shutdown Systems allow for the isolation of the PRDS in the event of failure, such as from main leak or malfunctioning equipment, in a way to prevent further damage and ensure safety. Safety interlocks can be fitted to prevent water injection when the temperature falls below a critical value and thus effectively avoid water hammer and/or condensate formation that can harm piping and equipment.

Regulatory Compliance

Safety is important in Pressure reducing design consideration. Most of the places require designs of PRDS to abide by the ASME requirement of the American Society of Mechanical Engineers on the pressure vessels and piping systems.

Most steam and pressure system codes vary from one country to another. You are therefore advised to reach out to the concerned office and find out their requirements in terms of the system and whether it meets those requirements. There must be adherence to the emission standards, particularly condensate release and steam venting, to ascertain control over environmental effects or avert litigation.

Energy Efficiency

Today, the most important goal is energy saving and reduction of energy usage and its impact on the environment. Energy conservation measures, when adopted in industries, provide numerous advantages, such as cutting down costs, enhanced productivity, and environmental sustainability.

Energy efficiency measures range from improving industrial practices to using clean energy; they enhance sustainable practices, lower the emission of greenhouse gases and create a basis for a sustainable world. Energy efficiency is not just an economic opportunity but rather a moral obligation and a responsibility that lies in the hands of every individual towards our planet and future generations.

Integration with Steam Systems

Desuperheating stations are designed to blend with steam systems and offer control of the superheat temperature as well as improve efficiency. By controlling the temperature of superheated steam, such special systems provide safeguards for the critical parts from thermal stress to guarantee the operation reliability and safety.

There are specific points in the steam cycle where desuperheating stations can be located to effectively control the enthalpy of steam and increase the efficiency of the system. With the integration of desuperheating technology and steam systems, the efficiency of the energy used, the durability of the equipment, and the control of the process improve, making it a crucial part of modern industrial applications that require high-temperature steam.

Conclusion

In the constantly changing industrial processes, pressure reducing and desuperheating stations appear as essential tools to address heat and temperature issues. This in turn means that industries need to tap the best of the manufacturers and the state-of-the-art technologies to get the best out of these systems. Desuperheating stations are instrumental in protecting equipment, enhancing procedures, and minimizing harm to the environment, which creates a solid foundation for progress and profitability.

By understanding the importance of energy saving and environmental protection in industries, the addition of desuperheating stations is not only the need for innovation, competition, and development of industries but also a responsibility to provide a better future for future generations.

0 notes

Text

The Critical Role of Control Valve Performance in Process Stability

Control valves have played an important part in the continuous operation of different industrial processes, mainly energy and oil & gas. Control valves are necessary for regulating the flow of pipelines and equipment concerning pressure and temperature, as well as fluid levels.

Without control valves, such types of operations in industries would create huge problems with efficiency and safety, as well as compliance issues. This blog will shed light on the role of control valves as well as their importance in ensuring the smooth operation of the mentioned complex systems.

1. Operations

Control valves, at the core of efficiency, significantly contribute to the operational advantages that industries have created. It regulates the flow of fluids, gases, and steam through pipelines, equipment, processing units, and installations. The disequilibrium is always kept stable by control valves, which condition the whole system so it works at its best by changing the flow rates based on the operating conditions.

For instance, in energy generation, control valves work as regulators of steam flow within boilers, turbines, and heat exchangers for maximum plant efficiency. In addition to that, crude oil, natural gas, and different fluids in pipelines, separators, and storage tanks are also effectively managed using control valves in oil and gas production for regulating flow. The accuracy and speedy response of control valves reduce energy consumption and enhance throughput; hence, it is also the operational efficiency matrix.

2. Safety and Reliability in Critical Systems

These are the industries in which safety is considered an overarching priority. A minute error can trigger a chain reaction leading to catastrophe. Control valves are an integral component of the safety and reliability chain of critical systems, as they keep overpressure, over temperature, and other dangerous conditions from happening.

These valves are built to open according to pressure, flow, or temperature changes, thereby regulating the system within safe operational limits. Control valves are found in pressure relief systems. These control the safe operating pressures within pipelines and storage tanks. If a damage event or overload condition occurs within the system, it will open, enabling depressurization before equipment damage occurs and accidents become a reality.

Oil refineries will also have introduced the use of control valves that would assure safety while controlling the flow of incendiary materials. We assume that this control will ensure the process remains safe and steady. Control valves are perhaps among the most critical raw materials, as their contribution to safety and reliability is highly important. They keep systems from breaking down, prevent shutdown of equipment, and reduce even environmental hazards.

3. Adaptation for Particular Applications

Each industrial installation presents a unique case, and so do the requirements for the control valve for different applications. The energy and oil and gas industries, with their diverse and differentiated conditions, typically customize control valves to meet their operational needs. Sizes, materials, types, and designs can be customized according to several high-pressure, high-temperature, and corrosive application requirements.

An example can be given for control valves, which will be made to withstand extreme saltwater corrosion, fit within high-pressure environments, and tolerate temperatures below freezing for an offshore oil drilling operation where the operations are done.

Similarly, control valves in gas processing plants are used to modify gas flow, which uses more or fewer pressures to control the viscosity and composition of the gas. Customization options provide control valves that make sure every single system operates reliably, safely, and optimally under specific operating conditions. If you’re looking for a control valve manufacturer in India, reach out to IndiTech Valves.

4. Advancements in Technology and Innovation

Control valves still keep evolving with the highly competitive industries they serve. The oil and gas industries are not left behind in this wake; their fabricator has to continuously bring in advanced technologies to improve their customers' operations, reduce operational costs, and increase safety.

Today's innovations in control valve design comprise smart valves equipped with sensors and actuators that provide a real-time measurement state of monitoring and control.

5. Conservation & Sustainability in Energy

Energy conservation and sustainability become ever more important in today's industrial environment. In optimizing the energy use and reducing waste, control valves play an essential role in meeting the sustainability targets for the energy as well as oil and gas companies. These valves help minimize energy consumption by accurately controlling fluids and gas flow.

For instance, control valves minimize fuel consumption by maintaining optimal operating conditions in an electric generator, turbine, and boiler. Control valves in the oil & gas sector are used to sensibly control the distribution of natural gas, a relatively clean fossil alternative. One important thing that these control valves do is help make the transportation and distribution of natural energy sources more efficient. This cuts down on carbon emissions and speeds up the switch to more sustainable energy sources.

6. Facilitate Complex and Large Operations

Energy and oil and gas industries are both concerned with the complexity of operations on a large scale where dependability and accuracy are required. Control valves are crucial for smooth operation within such large systems with thousands of miles of pipelines, refineries, and plants.

For example, in crude oil refining, the control valves control the flow of crude oil from the distillation column into the reactor and the reactor into the separator. On the other hand, control valves manage the flow of various process streams so that the different steps of the refining process are carried out most efficiently.

7. Meeting Industry Standards and Regulation

The oil, gas, and energy sectors continued to comply with high standards and regulations on everything from environmental protection to safety regulations. Control valve manufacturers need to follow the regulatory requirements in ensuring operations with national and international compliance.

Control valves, for instance, include the American Society of Mechanical Engineers (ASME) and American Petroleum Institute (API) standards under pressure relief, safety, and performance as part of the industry. Additionally, these control valves must meet most of the environmental regulations, like the Environmental Protection Agency (EPA), to minimize emissions and environmental impacts.

Control valves, by adhering to these various standards, allow companies to avoid penalties, lower risks, and enhance reputation stature in the industry.

8. The Diminution of Maintenance and Downtime

One of the major advantages of modern control valves is that they require less maintenance time and less downtime for the system. Newer developments in valve technology generally contribute to these improvements, as most control valves now come with longer life expectancies and reduced wear.

Other new features such as self-cleaning, better seal materials, and improvements in flow control now allow modern control valves to have less frequent maintenance and replacement. The result is lower maintenance demands and therefore lower operating costs and reduced unplanned downtime, essential for industries like energy production and oil extraction that need continuous operation. Moreover, predictive maintenance technologies enable organizations to detect in advance failures to improve operational reliability.

Conclusion

Energy and oil industries are dependent upon the control valves that aid in making operations more efficient, safe, and sustainable. Control valves help regulate the flow, pressure, and temperature in a complex network and make large-scale operations happen under industry standards and regulations.

Control valves are increasingly vital in meeting the growing demands of a fast-changing world in the energy, oil, and gas industry, thanks to advancements in technology and a global supply chain.

0 notes

Text

Achieving Consistent Pressure Control: Mechanisms in Gas and Steam Pressure Reducing Stations

Effectively managing the consistency of pressure levels across gas and steam systems during operations in industrial settings ensures efficiency and the highest safety levels of equipment integrity over the long term.

Large systems often house pressure-reducing stations (PRS), which reduce high-pressure gases or steam to a level suitable for end users or other equipment. Complex control mechanisms must equip PRS to maintain the operating pressure level, regardless of flow, temperature, or external conditions.

A multitude of technologies, from pressure sensors to the smartest control algorithms, apply to the subject of holding pressure constant. This blog elaborates on the processes of gas and steam pressure-reducing and desuperheating stations, including different components and technologies that support precise control of pressure.

Pressure Reducing Stations: The Bottom Line

As the name implies, pressure-reducing stations play an important function as far as the critical infrastructure is involved. This type of station primarily drives gases or steam away from their high-pressure source to a more manageable one.

Pressure-reducing stations have a wide range of applications, from natural gas transmission networks to steam distribution in industrial plants, as their titles suggest. For instance, a natural gas system can transport gas from a gas gathering system at pressures exceeding 1000 psi (pounds per square inch).

However, it is too high for efficient and safe usage in homes and industries. Pressure-reducing stations lower the pressure to a much lower, discrete level of around 50–60 psi for distribution to buyers of residential and commercial property.

Types of Control of Pressure Mechanisms

Every PR station has a variety of control system types, each with its unique composition and functionality. Of all possible types of control mechanisms, the most commonly used ones are the specific types listed below:

Regulator Valves: Regulator valves, which operate by adjusting the valve opening in response to pressure changes at the flowing medium, are the simplest pressure control mechanism in pipeline systems for any kind of gas or steam detection rate adjustment.

Control Valves are an integral part of a sophisticated control system, responding to external control signals to regulate pressure. Conditions such as these features cause the valve's position to momentarily change and its flow capacity to alter, ensuring uniform pressure within a specific range.

Bypass Valves: In certain systems, bypass valves are positioned when necessary to redirect excess flow around the pressure reduction valve. The flow ensures that the pressure stays within the desired range due to its inherent properties, protecting against fluctuations in the upstream flow or pressure.

Use of pressure sensors and transducers.

Pressure sensors and transducers play a crucial role in accurately managing pressure across all operational process regions at the reducing station. These sensors continuously monitor the pressure, sending the obtained data to the control system for real-time evaluation and subsequent appropriate responses.

What Are Pressure Sensors? Pressure sensors convert physical pressures to electric signals to provide continuous feedback about pressure inside a system. This is essential for better regulation and control of the system.

What Are Pressure Transducers? Pressure transducers can convert pressure to an analog or digital signal, much like a sensor. We use these devices to measure pressure more precisely, which we can then practically apply within another control system for more sophisticated regulation.

PID Control Systems

Ideal process control Pressure regulation using a feedback process ranges from base control and feedforward to proportional, integral, and derivative control for many processes. PID control is the most advanced of these well-known base regulatory strategies.

It conjures up many possibilities beyond simply controlling static and steady-state process responses. The "PID" controller earned its name due to its ability to dynamically adjust each of the three variables that collectively produce the control signal in response to errors.

Proportional Control (P) is the act of controlling in proportion to the difference between the actual and the desired pressure.

Flow and pressure relationships

In pressure-reducing stations, it is essential to understand the relationship of flow with pressure and how the system works. When the system loses energy to make gas or steam flow, the pressure typically decreases. Conversely, as the flow decreases, the pressure will increase. The control system must manage this relationship, as a change in flow will result in significant pressure changes.

In order to manage the various changes, pressure control mechanisms must dynamically adjust themselves according to changing flow. For instance, when demand suddenly increases, a control valve may open more to accommodate larger flows, while simultaneously adjusting the flow to maintain the required pressure level.

Dynamic Response and Pressure Stability

If requirements necessitate a dynamic response in such transient events, pressure regulator systems will first construct a well-designed station to accommodate these transient scenarios, leading to a sudden change in performance. As an example, malfunctions in valves or any changes in loads introduce sudden changes in performance.

A competent PRS will manage these transients without disturbing the requirement that pressure is steady throughout its operation, but they should not blow any large swings of pressure into the system.

Pressure Reduction Stages in Multi-Stage Systems:

In large installations, especially those where initial high pressure exists, pressure may be brought down two or more stages in these systems as a multi-stage pressure reduction station is built to reduce pressure gradually instead of one large drop; pressure drop is thus smooth and avoids undue stress impacting equipment, plus sudden pressure shocks, which could cause blowouts or otherwise make the entire network demoralizing.

Control algorithms for loading and demand variations.

These load fluctuations are very common in gas distribution and steam systems and occur frequently due to static changes in delivery quantities or pump flow rate. Control algorithms have to be capable of changing their modes of operation according to these changing processes for the pressure control system to function effectively.

The more advanced control strategies, such as predictive algorithms, foresee the future set point load changes based on historical data, meaning that the system readjusts itself to adapt before a collision of problems occurs.

Influence of Temperature on Pressure Controlling

Temperature influence can directly influence the pressure control of both gas and steam systems. This is because as temperature increases, the gas equally expands and may raise the pressure in case it is out of range. Steam systems similarly increase their pressure as the temperature increases.

To control against disturbance due to changing temperatures, pressure-reducing stations are fitted with temperature sensors that operate in conjunction with pressure sensors; these sensors help the control system to adjust the pressure up or down to compensate for the temperature changes, enabling stable control despite environmental changes.

Emergency Measures for Pressure Control

Pressure reduction stations should have a high priority in terms of overall safety. Pressure excess could lead to system failures or even calamitous accidents. Therefore, these systems are equipped with a specific type of safety mechanism:

Safety Relief Valves: These valves automatically open when the pressure surpasses a specific threshold, allowing the excess pressure to escape and preventing system damage.

Lockout mechanism: These systems feature a lockout mechanism that disables the pressure-reducing valves in the event of a malfunction or unsafe conditions, thereby prohibiting the system from operating under dangerous conditions.

The significance behind system calibration and maintenance

Regulatory recalibration and routine maintenance are crucial for achieving highly secure pressure control measures. Over time, various components, including sensors, valves, and the control systems, may wear and corrode, leading to failure in pressure control.

Monitoring and routine calibration activities are a prerequisite in maintaining system performance and warding off possible issues such as pressure swings, equipment failure, or safety hazards.

Conclusion

Operation is critical in these systems, as gas and steam pressure stations are essential elements of industrial systems that control consistent pressure and achieve high operation smoothness.

These pressure-reducing and desuperheating stations use various controls, innovative sensors, and precise control algorithms to ensure that the gas pressure remains pure and does not exceed the administrators' setpoints. They also ensure that control is not affected when flow, temperature, or demand varies.

Without complexity in the relationships between pressure, flow, temperature, and control systems, successful optimization of system performance can reduce risk and costs, while also extending the life span of equipment.

0 notes

Text

A Deep Dive Into Control Valve Actuators: Choosing The Best Actuation Technology

The control valve actuator has become one of the major building blocks of modern industrial automation systems, linking control systems with mechanical valves. They convert control signals into physical motion to control the flow of fluids, gases, or steam in a process with accuracy, safety, and efficiency.

Actuators play a crucial role in industries such as oil and gas, water treatment, power generation, and manufacturing where maintaining process control is a priority. With the arrival of this technology, actuators today can come in different types; therefore, choosing the right actuator is important.

This blog explores these technologies and offers advice on choosing the best actuator for your needs.

Types of Actuation Technologies

There are three main types of actuation technologies: pneumatic actuators, hydraulic actuators, and electric actuators. However, each type operates in a different way, has its own advantages and shortcomings, and therefore is appropriate for particular applications and industries.

Let’s take a closer look at each of these technologies:

Electric Actuators

Powered by electricity, this actuator type incorporates electric motors that drive the valve stem to position it with extreme accuracy. Various industries commonly use these actuators for controlled and automated processes.

Advantages:

High Precision and Control: Applications that require fine adjustments allow the use of electric actuators with excellent positioning accuracy.

Low Energy Consumption: Due to their power efficiency, they only use energy when they are actively operating.

Easy Integration: Because electric actuators can easily interface with digital control systems, they allow automated capability and the opportunity to monitor data.

Quiet Operation: Electric actuators do not have much noise—unlike pneumatic or hydraulic actuators.

Limitations:

Higher Initial Cost: In general, the electric actuators carry a higher initial cost compared to pneumatic systems.

Limited Force Output: For applications that require very high torque or force, they may not be suitable.

The need for backup systems arises from the vulnerability to power failures.

Pneumatic Actuators

Pneumatic actuators use compressed air to move the valve stem. Industries widely use them due to their reliability, simplicity, and cost-effectiveness.

Advantages:

Fast and Reliable Operation: Because of their quick response times, pneumatic actuators are best suited for on/off applications.

Cost-Effective: With a lower initial cost compared to electric actuators and the ability to operate in hazardous environments, they are more efficient.

High Force Output: The pneumatic systems have the ability to deliver high forces using relatively small amounts of energy.

Safety in Hazardous Environments: Pneumatic actuators are safe for explosive or flammable environments because they do not produce sparks.

Limitations:

Energy Losses: Compressed air systems experience energy losses that lead to a reduction in efficiency.

Noise Levels: An air movement can be a cause of noise in pneumatic actuators.

Maintenance Requirements: Regular filter and compressor maintenance can ensure the air supply is clean and dry.

Hydraulic Actuators

Hydraulic actuators, which rely on pressurized hydraulic fluid for their operation, are suitable for heavy-duty applications that require significant power. Hydraulic actuators are good for heavy-duty applications needing high power because they use pressurized hydraulic fluid to produce force.

Advantages:

High Force Output: Hydraulic actuators have such extreme torque and force capacity that they are well suited to large valves and heavy industrial applications.

Precise Control: Their accurate positioning makes them a fantastic choice for demanding tasks and smooth operation for difficult tasks.

Durability: Hydraulic actuators are robust and reliable, being able to take harsh environments and heavy loads.

Limitations:

Complex Systems: They require additional components such as pumps, reservoirs, and piping, which further complicate the system.

Leakage Concerns: Hydraulic fluid leaks cause environmental contamination and accident hazards.

Maintenance Costs: Leaks also require regular maintenance in order to prevent and ensure system efficiency.

Cost considerations and budget impacts

Cost is often a deciding factor for choosing control valve actuators. Typically, pneumatic actuators have the lowest upfront cost, followed by electric actuators with higher upfront investment but lower long-term operating costs due to energy efficiency. Hydraulic actuators fall in the middle, but there may be higher long-term expenses because of the maintenance and replacement power of the fluid.

However, organizations must first determine the costs associated with purchase, installation, and maintenance to determine the most optimal and cost-effective solution for their specific application.

Maintenance and durability factors

The type of actuator technology determines the maintenance requirements.

Electric Actuators: They have fewer parts moving around and thus require minimal maintenance but might occasionally need a calibration.

Pneumatic Actuators: Regular maintenance is necessary for air compressors, seals, and filters to operate at their best.

Hydraulic Actuators: They are subject to frequent inspections to avoid leaks, contamination, and damage to hydraulic components.

The application environment also determines application durability. Hydraulic actuators are best in high torque, harsh duty cycles, while electric actuators excel in clean, controlled environments.

Control and integration capabilities

Seamless integration with automated control systems becomes a must in modern industrial processes. Therefore, electric actuators excel in this regard due to their compatibility with digital communication protocols like Modbus, Profibus, and Ethernet.

While reliable, of course, pneumatic and hydraulic actuators typically need additional components like positioners and solenoid valves to achieve the same level of control. Industries that prioritize advanced automation and real-time monitoring are increasingly utilizing electric actuators.

Application Suitability

Each actuator type is suitable for specific applications:

Electric actuators are used in applications that require precise control, such as those in the HVAC, water treatment, and pharmaceutical industries.

Pneumatic actuators have proven to be effective in fast-acting on/off applications within the oil and gas, chemical, and manufacturing sectors.

Hydraulic Actuators are used in heavy-duty operations in the marine, construction, and power generation industries.

The choice of actuator depends on the application's operational requirements, control precision, and environmental conditions.

Environmental and safety considerations

Actuator selection can be crucially dependent on environmental factors. Pneumatic actuators, with their non-sparky operation, find use in explosive and flammable environments. Hazardous areas may require clean, quiet electric actuators to be explosion-proof.

The use of hydraulic actuators exposes the environment to the potential for leaking fluid. Industries that must comply with safety and environmental regulations must implement these systems.

Emerging Trends in Actuation Technology

Automation, energy efficiency, and sustainability advancements are driving the future of control valve actuator technology.

Smart Actuators : integrate IoT and smart sensors to provide real-time monitoring, predictive maintenance, and enhanced performance.

Energy-Efficient Designs: The electric actuators feature improved motors that consume less power.

Hybrid Actuators: The integration of the advantages of the electric, pneumatic, and hydraulic systems is in trend.

Sustainability Initiatives: However, there is a demand for eco-friendly actuators with little environmental impact and low emissions.

Conclusion

For industries of all sizes, the selection of an appropriate control valve actuator is important to ensure operational efficiency, reduce costs, and support reliable performance while meeting current technological demands and sustainability goals.

If you’re looking for a control valve manufacturer in India, reach out to IndiTech Valves.

0 notes

Text

A Comprehensive Guide to Selecting Materials for Desuperheating stations

Several industries, including the power plant industry and chemicals, use desuperheating in a wide range of processes. It involves cooling the superheated steam to its saturation temperature.

To ensure efficiency and safety, desuperheating systems require careful design, and the selection of component materials is crucial. You will learn how to select the materials for the desuperheating station.

Understand the Operational Environment

First of all, it is important to define the operational environment with regards to the choice of materials. This consists of the temperature and pressure that the steam will have to meet, the type of steam, and the user system's requirements.

In this scenario, understanding these factors is beneficial when choosing materials that can endure operational stresses and provide satisfactory performance.

Evaluate Material Properties

After that, assess the property of the material. These are, of course, heat conductivities, corrosion performances, mechanical features, and coefficients of thermal expansion. Thermal conductivity is important for efficient heat transfer, and so materials with high thermal conductivity are preferred, whereas the corrosion resistance of materials for application in a corrosive environment makes the material more durable.

Thermal conductivity plays a major role in the process because it determines to what extent heat transfer will be possible from the steam to the cooling agent. We recommended using conductive materials like copper and aluminum in this type of application due to their high thermal conductivity. However, other factors, such as their resistance to rusting, may make them less desirable.

Also important is corrosion resistance because pipes and other equipment are used in harsh environments. Desuperheating stations are usually employed in areas where they are exposed to moisture, chemicals, and other corrosive substances.

Metals such as stainless steel and some of the high-alloy steels are well known for their resistance to corrosion; hence, they are well suited for use in these applications.

Another factor is mechanical strength and thermal expansion. The materials must possess the ability to withstand the mechanical loads and temperature fluctuations that the assembly will encounter during its service. Such materials have to retain a certain level of strength and dimensional stability during these processes.

Material options for different components

It can be observed that various aspects of a desuperheating system can be made using different kinds of materials. Here are some common options:

Nozzles: These are used because they have high corrosion resistance and strength, such as stainless steel or high alloy steels. It also revealed that these materials are capable of withstanding high-velocity steam in addition to the normal wear and tear.

Pipes: Carbon steel is often applied due to its rather low price and relatively high performance in numerous applications. In situations where higher temperatures are involved, perhaps the best alloy steels will be used. The materials used are good because of their restraint cost and acceptable performance levels.

Valves: Stainless steel or special alloys are some of the most effective materials used because they resist wear and tear easily. Valves are components that need to work under various conditions; hence, it is very important to select materials appropriately.

Consider environmental and chemical factors

When considering materials chemically and environmentally, many factors are traditionally taken into account. If the environment in which the desuperheating system is exposed includes corrosive chemical or extreme conditions, then materials with high corrosion resistance, for instance, stainless steel or nickel alloys, should be used.

Assess maintenance and longevity

Durability plays a very important role in defining the material to be used for construction. Long-lasting and low-maintenance materials enable a company to have minimal downtime and frequent maintenance, resulting in low operational costs. Think about metals, which are usually defined by their high endurance and low need for cleaning and polish.

Review cost and budget constraints

While it may be necessary to consider quality materials, one cannot disregard cost and the budget. Balance the performance and duration requirements with the available funds.

Sometimes, one material for desuperheaters may initially cost a few dollars more than the other, but it can last much longer and ultimately prove to be cheaper in the long run due to fewer replacements.

For instance, although at one point carbon steel requires a lower upfront cost compared to a material such as stainless steel, other expenses relating to maintenance and replacement may be higher in the long run.

Examine industry standards and regulations

However, always make sure that the materials selected are according to the standards and legal requirements set by the industry. This eliminates risks or putting the lives of the people involved in danger, guarantees that the completion will be as per the requirements, and keeps the construction of the building in line with the law.

ASME, ASTM, and ISO are examples of standards for material selection and use that you should become acquainted with.

Another way to ensure system safety and avoid legal and regulatory issues is to follow these standards. Individuals need to stay informed about the standards and regulations, as they undergo periodic changes.

Assess fabrication and availability

Functionality considerations include the workability and availability of materials. Choose materials that are easy to source and machine into the desired or needed parts. This has the advantage of helping in the reduction of lead times and, therefore, timely delivery of the projects.

For instance, some of the most common materials, such as carbon steel as well as stainless steel, cannot be regarded as specialized materials in any way and can be easily worked using conventional procedures. This makes them an easily implementable material in many applications.

Evaluate its impact on system efficiency

Last of all, assess the effect on system productivity. Choosing the correct material would further facilitate heat transfer at the desuperheating point and reduce energy losses. This should also include materials that improve the overall system's performance and productivity within the facility.

Conclusion

By evaluating the above factors, you will be in a better position for desuperheating station material selection, which in turn will enhance performance and safety as well as reduce cost.

It is also important to emphasize that the materials chosen for the construction of such systems not only affect the system's efficiency but also its longevity, which fosters the organic conditions necessary for effective operation.

0 notes

Text

Advantages of Using Blowdown Valves in Industrial Processes

Blowdown valves may not be at the forefront of industrial processes where pressures and temperatures are out of the question. Still, they surely deserve their place as the silent guardians of safety and productivity. These critical components play an important role in facilitating the fine line that separates high performance from failure.

Oil refineries, power plants, and many other industries use blowdown valves. When a buildup occurs, these valves open and release pressure to protect both people and equipment. However, the need to include them in any plan goes beyond safety concerns alone.

What are blowdown valves?

Blowdown valves are specific mechanical tools designed to discharge water, sand, and other contaminants from industrial piping. These valves work on the principle of opening and discharging a small fraction of the system’s content, thereby ‘blowing down’ the unwanted contents.

Blowdown valves are common in boilers, pressure vessels and pipelines, and they are of the following types: manual blowdown valves, automatic blowdown valves, and continuous blowdown valves.

The primary purpose of a blowdown valve is to protect the integrity of the system by preventing the accumulation of contaminants that can cause corrosion, scaling or reduced efficiency. In steam power systems, they are useful in regulating water chemistry by eliminating specific ions. Some of the most typical examples of its use are power generation plants, petrochemical facilities, food processing facilities, and HVAC systems.

Benefits of a Blowdown Valve

Safety Advantages

Therefore, blowdown valves' greatest strength lies in their ability to enhance industry safety. These critical components are used as safety devices that prevent pressure buildup that may cause major catastrophes in systems.

Pressure Relief and System Protection

In order to prevent hazardous overpressure, blowdown valves safely relieve pressure in vessels and pipelines. This function is useful for preventing equipment ruptures or explosions that can cause serious accidents, injuries, or even death.

Prevention of Equipment Damage

Since they offer a chance to release pressure and eliminate contaminants at the right time, blowdown valves lower the chances of equipment failure. It is preventive to reduce the chances of total system failure, leakage, or structural problems that may affect the overall performance.

Reduction of Workplace Hazards

The use of blowdown valves helps reduce hand usage in high-pressure conditions. This reduces the likelihood of individuals encountering potentially dangerous situations, thereby enhancing workplace safety, these valves maintain optimal system conditions to prevent the production of hazardous products or the release of harmful compounds into the work area.

Improved system performance

Apart from their safety benefits, blowdown valves are also very efficient devices that can revolutionize many industrial processes.

Blowing down valves ensures that operating conditions are ideal in industrial systems by removing sediment, scale, and other impurities. This action ensures the absence of contaminants in heat transfer areas, unobstructed fluid passages, and the achievement of chemical equilibrium.

Energy Savings

Optimizing blowdown practices results in significant energy savings and industrial efficiency.

Maintaining clean heat exchange surfaces reduces the fuel required to produce the required amount of heat. Likewise, in compressed air systems, blowdown to eliminate moisture buildup is energy efficient compared to the energy required to build up the pressure in the system.

Extended Equipment Lifespan

The frequent use of blowdown valves increases the service life of industrial equipment by a tremendous deal. These valves prevent the buildup of corrosive materials and abrasive wear from contaminants, protecting pipes, vessels, and other components. This preventive maintenance strategy results in fewer replacements, less time off, and overall lower long-term operating costs.

Cleaning and flushing the system is easier

Blowdown valves significantly simplify and enhance maintenance procedures in industrial settings, offering several key advantages:

Regular cleaning benefits from these valves as they provide a single point for the removal of debris and contaminants. This feature allows for more frequent cleaning of the equipment, eliminating the need for lengthy shutdowns or complex disassembly.

Contaminant buildup is reduced

We frequently use blowdown valves to prevent the long-term accumulation of substances like scale and sludge. It also reduces the formation of tenacious deposits, which, if they were to form, would require a strong force to remove or even replace the components.

Simplified troubleshooting and repairs

The use of blowdown valves results in cleaner system internals, making it easier to identify problems when they arise. Maintenance personnel can easily carry out component inspection and repairs without struggling with layers of built-up dirt. This clarity makes it easier to diagnose problems and perform maintenance, thus minimizing time spent and increasing the effectiveness of the interventions.

Economic Advantages

The use of blowdown valves provides significant economic benefits for industrial operations.

These valves help maintain the system conditions to the best state they can be in terms of energy consumption and optimized processes; thus, the company will be saving much money in the long run.

The company experiences low maintenance costs because it spends less time on repair and maintenance.

This is one of the most effective ways to avoid harm to large pieces of equipment; as a result, it greatly reduces cases of equipment failure and costly repairs. This method of working out does not allow for idle time and increases the time between large maintenance tasks.

Investing in the best blowdown valves may be costly, but the long-term benefits are substantial. Long equipment life, reliability, and low maintenance costs offer a good return on investment.

Environmental Advantages

Blowdown valves contribute to environmental sustainability in industrial processes.

Reduced Emissions: By enhancing system efficiency, blowdown valves assist in lowering the overall energy utilization and, hence, the minimal carbon emissions from power production and fuel burning.

Improved Resource Management: These valves control the discharge of material to a level that aids in the conservation of water and other resources in industries.

Conclusion

Blowdown valves become critical elements of contemporary industrial applications, which have numerous benefits that go far beyond their original purpose. They help boost safety and industry efficiency by making maintenance and management easier and cutting costs across multiple industries. As a result, the use of blowdown valves will continue to expand in the future due to the growing emphasis on safety, performance, and sustainability.

Future development of new technologies will guarantee even better blowdown systems and their compatibility with intelligent industrial processes. Implementing and integrating blowdown valves into industrial’ operations can make the difference between safe and efficient operations, as well as the ability to adapt to the changing environment in the future.

1 note

·

View note