Joy Shing Glass : Provide integrated glass solutions, glass processing , online technical consulting services, etc.

Don't wanna be here? Send us removal request.

Text

Float Glass: The Unsung Hero of Our Transparent World

The windows, car windshields, phone screens, and even glass furniture you interact with daily mostly originate from one revolutionary process – float glass. It silently underpins our modern lives.

The Core Mystery: How Float Glass is Made

Before float glass, flat glass production was laborious and time-consuming. In 1959, UK's Pilkington Company successfully developed the float process, revolutionizing the industry.

Its secret lies in a bath of molten tin:

Melting Raw Materials: Sand, soda ash, and other materials melt into glass in a high-temperature furnace (around 1600°C).

Floating on Tin: The molten glass is poured onto the surface of the molten tin. Due to density differences, it naturally spreads out, forming an even thickness.

Perfect Formation: Under gravity and surface tension, the glass forms an incredibly smooth, mirror-like surface – no polishing needed! Thickness is controlled by temperature and drawing speed.

Annealing & Strengthening: The glass ribbon moves into a long annealing lehr for precisely controlled cooling. This removes internal stresses and significantly increases strength and stability.

Cutting to Size: The cooled, hardened glass ribbon is automatically cut into sheets of the required size.

The Outstanding Qualities of Float Glass

This unique process gives float glass unmatched advantages:

Exceptional Flatness & Optical Quality: The tin-formed surface is ultra-smooth with virtually zero optical distortion, providing clear vision.

Flexible Thickness Control: Ranges from ultra-thin (0.5mm) to ultra-thick (25mm), meeting diverse needs.

High Purity & Uniformity: Strict material and process control minimizes bubbles/stones, ensuring high, consistent light transmission.

Superior Cost-Effectiveness: Continuous, large-scale, automated production lowers costs, making quality glass widely accessible.

Excellent Processability: Easily undergoes deep processing like tempering, laminating, coating, or insulating to create safety glass, energy-efficient glass, decorative glass, and more.

Ubiquitous Transparency

Float glass is everywhere in modern life:

Architecture: Curtain walls, windows, doors, skylights – providing views and light.

Transportation: Car windshields/windows, train/aircraft windows – ensuring safety.

Technology: The foundation for displays in phones, tablets, TVs, etc.

Home & Industry: Glass furniture, mirrors, solar panel covers, instrument windows.

The Future: Transparency & Sustainability

The float process continues to evolve:

Greener: Optimizing fuels (e.g., natural gas, hydrogen), improving furnace efficiency, reducing emissions.

Smarter: Applying automation, big data, and AI to boost efficiency and quality.

Stronger: Developing ultra-thin, ultra-thick, ultra-clear, high-strength specialty glass.

Recycling: Increasing the use of recycled cullet (waste glass) to save resources and energy.

0 notes

Text

Thermal cracking mechanism and engineering response of single-piece fireproof glass

Introduction As a key material for building exterior protection, the thermal cracking behavior of glass in fire directly affects the escape of personnel and the spread of fire. This article focuses on the thermal cracking mechanism of single-piece fireproof glass (DFB) and analyzes its fire-resistant nature.

The core driving force of thermal cracking: temperature difference stress Research has confirmed (Xie, Keski-Rahkonen, etc.) that the fundamental cause of glass cracking is the critical thermal stress caused by **uneven heating: Ordinary soda-lime glass: critical temperature difference is only *80~90℃ 6mm tempered fireproof glass*: critical temperature difference *330~380℃ 10mm tempered fireproof glass*: critical temperature difference **470~590℃ When the temperature difference between the exposed area (fired) and the shielded area (frame) of the glass exceeds the threshold in a fire, the tensile stress generated exceeds the tensile strength of the glass (usually 30~50MPa), which triggers the crack.

Key factors affecting cracking | Edge processing quality | Mechanical polishing edge strength (78MPa) > rough grinding edge (56MPa), micro crack expansion strength attenuation 15%+ | | Installation method | Point support stress concentration > frame installation; aluminum frame fire resistance > wooden frame | | External intervention | Spray cooling will accelerate cracking when the glass temperature is > 250℃ | | Glass type | Borosilicate glass (expansion coefficient 4×10⁻⁶/K) Thermal shock resistance Rolled soda-lime glass (9×10⁻⁶/K)

📌 Engineering warning: Fireproof glass design must reserve a safety factor K≥2.5 (refer to curtain wall specifications)

Technical breakthrough direction

Material upgrade Borosilicate glass: low expansion + high softening point (800℃), the mainstream fire protection solution in Europe, and has broken through the bottleneck of mass production in China Microcrystalline glass: zero expansion characteristics, temporarily limited to high-end special applications

Process control Stress strengthening: surface compressive stress > 90MPa (national standard bottom line) can improve bending strength (formula: σ≈0.83σ tempering + 38) Edge finishing: HF acid etching/mechanical polishing to reduce microcracks

Intelligent simulation application Thermal-mechanical coupling simulation based on tools such as ANSYS can predict: Stress distribution of different installation methods (see Figure 1) Critical rupture time (error <10%) Simulation confirms: The maximum tensile stress of framed glass is concentrated at the junction of the frame and shielding (31~32MPa)

IV. Engineering application suggestions

Carefully select glass type Borosilicate monolithic fireproof glass (EN 12600/ANSI Z97.1 certification) is the first choice for high-end projects Strictly control the discrete risk of soda-lime-silicon fireproof glass

Optimize installation design Preferentially use a four-point support structure to reduce stress concentration The shielding width needs to be verified by thermal simulation

Scenario protection Avoid enabling the sprinkler system at high temperature (>250℃)

Conclusion To understand the mechanism of thermal cracking, it is necessary to make breakthroughs in three dimensions: material nature (boron silicon > sodium calcium), process precision (edge stress control), and installation science (thermal stress dispersion). With the large-scale mass production of domestic borosilicate glass and the popularization of digital simulation technology, the safety of fireproof glass will achieve a qualitative leap.

#laminated glass#toughened glass#buildingglass#glass railing#building glass#insulated glass#ultra clear glass#tempered glass#glass doors#glass windows

0 notes

Text

Custom toughened glass shower doors

8mm: Most common, offers good stability.

6mm: Suitable for small doors or fixed panels.

10/12mm: Used for oversized or frameless doors, providing maximum solidity.

Optional features enhance function and aesthetics: laminated glass (extra safety), frosted/sandblasted glass (privacy), Low-E glass (heat retention).

Hole-drilling processes are vital:

Timing: All holes (for hinges, handles, etc.) MUST be drilled BEFORE tempering. Drilling after tempering causes instant shattering.

Precision: Holes require exact measurement and positioning based on design drawings, typically using specialized equipment (like CNC machines or waterjets) for accuracy.

Edge Treatment: Hole edges must be finely ground and polished to remove any chips or micro-cracks. This prevents stress concentration (which can cause spontaneous breakage) and ensures smooth, secure hardware installation.

In short: Choosing the correct, safe glass thickness and ensuring precise pre-tempering hole drilling and polishing are core to the safety and durability of custom shower doors.

Joy Shing Glass factory direct sales, wholesale purchase price is more favorable.

We can process glass as required, including size, shape, edge, corner, hole, groove, etc.

If you are looking for high-quality toughened glass, please contact us for quotation and sample.

0 notes

Text

Tempered Glass: The Safe & Strong Choice - Professional Manufacturing & Customization by Joy Shing Glass

In modern architecture, home design, and industrial applications where aesthetics meet safety demands, ordinary glass often falls short. Tempered glass, renowned for its exceptional strength and unique safety properties, stands as the trusted solution. As experts in glass manufacturing, Joy Shing Glass breaks down the core advantages and types of tempered glass, delivering reliable, professional manufacturing services.

Tempered glass (also known as toughened or safety glass) is created by subjecting high-quality float glass to a precisely controlled thermal process (heating to high temperatures followed by rapid, uniform cooling). This process builds powerful compressive stress layers within the glass, granting revolutionary properties:

Multiplied Strength:

Impact resistance 3-5 times higher than ordinary glass; bending strength 2-3 times higher.

Superior thermal shock resistance, withstanding temperature differentials up to 200-250°C, minimizing the risk of thermal breakage.

Safety First:

Core Advantage! Upon forceful impact, it shatters instantly into countless small, blunt, honeycomb-like granules, drastically reducing injury risks – making it true "safety glass".

Reliable & Durable:

High strength ensures better resistance to scratches, abrasion, and everyday impacts, extending its lifespan.

> Joy Shing Glass Key Note: Once tempered, glass cannot be cut, drilled, or reworked. All customization needs (size, shape, holes) must be finalized before the tempering process – a crucial step in our professional manufacturing flow.

2. Tempered Glass Types for Diverse Needs (All Customizable by Joy Shing Glass)

We offer a diverse range of tempered glass products to meet your specific project requirements:

1、By Strength & Safety:

Fully Tempered Glass: The Standard Choice! High strength, excellent safety (granular breakage). Widely used in doors, windows, curtain walls, shower enclosures, furniture tops, appliance panels – anywhere requiring personal safety protection. (Joy Shing Glass Core Product).

Heat-Strengthened Glass: Moderate strength (~2x ordinary glass). Breaks into larger, sharper shards – not classified as safety glass. Suitable for applications needing high flatness, moderate strength, and no strict safety requirements, like some interior partitions or curtain walls (designed to prevent total fallout). Always confirm safety needs!

2、By Shape:

Flat Tempered Glass: The most common type, available in various thicknesses.

Bent Tempered Glass: Specialized Craftsmanship! Glass is heated, bent to a specific curve, then tempered, combining strength with elegant form. Ideal for curved facades, architectural features, premium furniture, display cases. Joy Shing Glass utilizes advanced bending/tempering technology to accurately realize your design vision.

3、By Functional Combination (Often using Tempered Glass as Base):

Tempered Laminated Glass (PVB/SGP): Tempered glass + high-strength interlayer (e.g., PVB or SGP film). Even if shattered, fragments adhere to the interlayer, preventing penetration and fallout – top-tier safety! Essential for skylights, canopies, railings, banks, and high-risk curtain walls. Joy Shing Glass offers various interlayer options for different safety grades.

Tempered Insulated Glass Unit (IGU): Tempered glass + sealed dry air/gas cavity. Exceptional thermal insulation & soundproofing! The go-to for energy-efficient building windows and curtain walls. We provide Low-E coated tempered IGUs for enhanced energy savings.

Tempered Coated Glass (Solar Control / Low-E): Surface coating applied before tempering. Controls solar heat gain, reduces radiation, boosts energy efficiency. Key for high-performance building envelopes. Joy Shing Glass offers custom coating solutions.

3. Joy Shing Glass: Your Professional Tempered Glass Manufacturing Partner

Choosing tempered glass means choosing safety and quality. Choosing Joy Shing Glass means you get:

✅ Professional Manufacturing: Utilizing advanced tempering furnaces and strict process control to ensure every piece meets strength standards and safety reliability.

✅ Flexible Customization: Whether standard flat, complex bent shapes, large formats, or special thicknesses – we produce based on your detailed drawings and specifications (all cutting, edging, hole drilling, notching done before tempering).

✅ Quality Certification: Products comply with relevant national safety standards (e.g., GB 15763.2), with critical products carrying CCC certification.

✅ Complete Solution Provider: We supply not only premium tempered glass but also laminated tempered, insulated tempered, coated tempered, and other composite products.

✅ Reliable Supply: Stable production capacity ensures your project timelines are met.

Tempered glass is ubiquitous: from the sturdy curtain walls of skyscrapers to the safe shower screens in your home, from elegant furniture tops to protective panels on devices. It's the indispensable safety cornerstone of modern design.

Planning a project? Need a reliable tempered glass solution?

> > Contact the Joy Shing Glass Team Today! <<

We'll recommend the optimal tempered glass product or combination based on your specific application (architecture, home, furniture, appliances, specialty uses), safety level requirements, performance needs (strength, energy efficiency, soundproofing, aesthetics), and budget.

Receive expert material selection advice and technical support.

Benefit from fast responses to your quotes and customization requests.

Choose Joy Shing Glass for professionalism, safety, and guaranteed quality. Let's build stronger, safer spaces together!

#laminated glass#buildingglass#ultra clear glass#insulated glass#toughened glass#glass railing#building glass#tempered glass#glass doors#glass windows

0 notes

Text

Customized zigzag tempered glass stair handrails

Customized zigzag tempered glass stair handrails are made of ultra-clear tempered glass and have the following characteristics:

Ultra-clear transparency: Ultra-clear tempered glass has low iron content and no impurities, which makes it more clear and beautiful visually, and improves the brightness of the space.

High strength: Tempered glass has excellent strength and impact resistance, ensuring the stability and safety of the handrail.

Safety: Tempered glass will break into small particles when broken, reducing the splash of sharp fragments and improving safety.

Easy to clean: The smooth surface makes cleaning easier and keeps the handrail clean and hygienic. Joy Shing Glass can customize and process glass according to customer requirements to provide you with an integrated glass solution. Contact us for more details.

0 notes

Text

Customized Insulated Glass For Building

Insulated glass for building is a glass product consisting of two or more pieces of glass separated by a certain distance and enclosed in a frame. This hollow structure helps to improve the thermal insulation and sound insulation of the building, while providing design flexibility and can be customized according to customer needs.

Features of insulated glass:

1. Thermal insulation: The hollow structure effectively reduces heat conduction, improves the thermal insulation performance of the building, and reduces energy consumption.

2. Sound insulation: The hollow layer can effectively reduce the conduction of sound and improve the comfort inside the building.

3. Anti-condensation: Effectively prevent condensation caused by the temperature difference between indoor and outdoor, and keep the glass surface dry.

As a professional glass manufacturer, Joy Shing Glass supplies high-quality insulated glass for building, which can be customized in size, glass type, shape, pattern, etc. according to architectural design requirements to meet the requirements of different customers. Welcome to contact us for more details.

0 notes

Text

Process Clear Toughened Shower Glass As Required

Joy Shing Glass can process clear toughened shower glass according to requirements, including size, shape, edge, corner, hole, groove, film, silk screen, etc., to provide you with an integrated shower glass solution.

Clear toughened shower glass is a popular choice for its safety, durability and modern feel. By using this glass, you can bring a fresh and bright atmosphere to the shower space while ensuring safety and comfort.

Safety: Toughened glass has high strength and breaks into small particles when broken, reducing the risk of sharp fragments and improving safety.

Durability: Toughened glass has good wear and corrosion resistance and is suitable for long-term use in humid environments.

Easy to clean: The smooth surface makes cleaning easier, keeping the shower room clean and hygienic.

Transparency: Clear glass can provide a bright shower space and increase the overall sense of space.

If you need to get toughened shower glass quotation or sample, please feel free to contact us.

0 notes

Text

Customized Tempered Laminated Insulating Glass For Building

Customized tempered laminated insulating glass combines the advantages of tempered glass, laminated glass and insulating glass, and is suitable for glass curtain walls, windows, partition walls and other fields in the construction industry. It has the following characteristics:

Safety: Tempered glass has high impact resistance, while the interlayer of laminated insulating glass can stick the fragments together when broken, reducing the risk of sharp fragments splashing and improving safety.

Heat insulation: Insulating glass has good heat insulation performance, which can effectively reduce the temperature difference between indoor and outdoor, and save energy and protect the environment.

Sound insulation: The interlayer material of laminated insulating glass has sound absorption performance, which can effectively reduce the noise transmission between indoor and outdoor, and provide a quieter indoor environment.

Anti-ultraviolet: Laminated insulating glass can choose interlayer materials to filter ultraviolet rays and protect indoor items from ultraviolet rays. As a professional glass manufacturer, Joy Shing Glass can customize and process glass according to needs. If you are looking for a high-quality glass supplier, you can contact us at any time.

0 notes

Text

12mm Clear Toughened Glass for Railings

12mm clear toughened glass for railings ensures a combination of strength, safety, and clarity, making it a suitable choice for various railing applications where safety and aesthetics are paramount.

Features:

High strength: 12mm clear toughened glass provides solidity and strength, with impact resistance and strength 3-5 times that of ordinary glass, suitable for railings.

Safety: When tempered glass breaks, it will break into small and blunt fragments, reducing the risk of injury.

Clarity: Clear glass maintains transparency and is more modern.

Thermal stability: 12mm clear toughened glass can withstand a temperature difference of 300℃

Joy Shing Glass supplies high-quality toughened glass and can customize and process glass as required. For more details, please contact us.

0 notes

Text

15mm ultra clear tempered glass for railings

We customize 15mm ultra clear tempered glass for railings according to customer requirements, with polished edges. Ultra clear tempered glass has high transparency, low iron content, no impurities, and is visually clearer and more beautiful. It is used for stair railings and has a more modern feel. At the same time, ultra clear tempered glass has strong strength and impact resistance and high safety. As a professional glass manufacturer, Joy Shing Glass supplies high-quality toughened glass, which can be customized and processed as required to provide an integrated glass solution for your project. Welcome to contact us for more details.

0 notes

Text

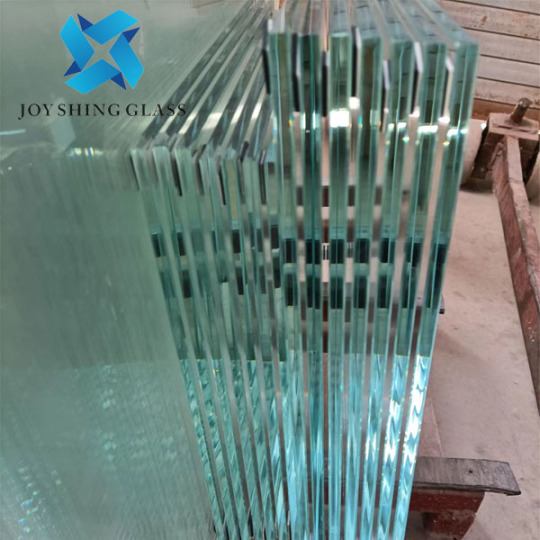

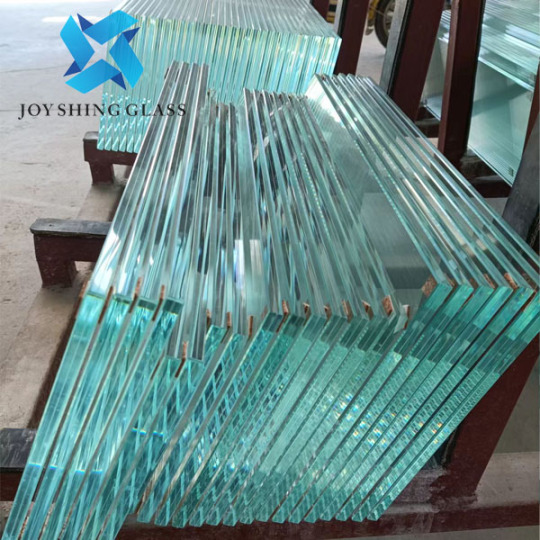

High Quality Toughened Glass Factory

Toughened glass has the characteristics of high strength, strong bending resistance, good thermal stability and safety. It is widely used in building curtain walls, glass railings, doors and windows, glass balcony guardrails, shower doors, glass doors and windows, etc.

As a professional glass manufacturer, we supply high-quality toughened glass with thicknesses including: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 19mm, 22mm, etc. At the same time, we can customize and process glass as required, including glass size, shape, edges, corners, holes, grooves, etc. Provide an integrated glass solution for your project.

For more details, please refer to the catalog: Safety toughened glass

0 notes

Text

Supply high quality insulated glass for doors and windows

Insulated glass is used in doors and windows, which can provide good thermal insulation effect, reduce energy consumption and improve living comfort. Features:

Thermal insulation: The air or rare gas filling layer in the middle of the hollow glass has good thermal insulation effect, effectively prevents heat conduction and improves the thermal insulation performance of doors and windows.

Reduce noise: The multi-layer structure can effectively block external noise, provide a quieter and more comfortable indoor environment, and is suitable for places that require sound insulation.

Reduce condensation: The design of thermal insulation glass helps to reduce the occurrence of condensation, keep the indoor glass surface clear, and improve indoor comfort. Joy Shing Glass supplies high-quality insulated glass, which can be customized and processed as required to provide you with an integrated glass door and window solution. Contact us for more details, samples, prices, etc.

0 notes

Text

Supply ultra clear tempered glass railings, customizable

We supply high-quality ultra clear tempered glass railings, which can be customized and processed according to requirements or drawings, including size, shape, edges, corners, drilling, grooving, lamination, etc.

Features of ultra-clear tempered glass railings:

High transparency, beautiful

High strength and impact resistance, 3-5 times that of ordinary glass

High safety, ultra-clear tempered glass, low iron content, low self-explosion rate, not easy to break. Even if the glass is broken by impact, it will not produce sharp fragments to cause major injuries. If you want to further improve safety, it can be processed into tempered laminated glass.

As a professional glass manufacturer, Joy Shing Glass provides you with an integrated glass solution. For more details, please contact us.

0 notes

Text

Crystal Toughened Laminated Glass For Stair Steps

Crystal toughened laminated glass for stair steps improves the safety and aesthetics of the staircase. Crystal tempered laminated glass combines the strength of tempered glass with the safety features of laminated glass, providing a durable and safe surface for stairs.

Features:

Tempered strength: The glass is tempered to improve its strength and impact resistance

Safety of laminated structure: The glass can be glued together even if it breaks, maintaining the complete glass structure and reducing the risk of fragments falling off.

Crystal clear appearance: The glass has a crystal clear appearance, which enhances the visual appeal of the stairs and makes the space brighter.

Joy Shing Glass supplies high-quality glass, can customize and process glass as required, and provide you with an all-in-one stair glass solution.

0 notes

Text

Customized Ultra Clear Non-slip Tempered Laminated Glass For Floor

Customized ultra-clear non-slip tempered laminated glass floor, both beautiful and safe, very suitable for areas that need to be non-slip.

Non-slip surface: glass customized non-slip texture to reduce the risk of slipping. Texture can be customized

Tempered strength: tempered glass is processed, the strength is higher than ordinary glass, and it is more resistant to impact and thermal stress.

Ultra-white: ultra-white glass is used, which is more beautiful

Laminated structure: high safety and impact resistance, even if the glass is broken, the glass structure can be maintained intact, no flying fragments will be generated, and it is safer

Joy Shing Glass can customize and process glass as required, including size, thickness, shape, edge/corner processing, drilling, etc. If you need it, please feel free to contact us.

0 notes

Text

Customized ultra clear tempered glass railings

Supply ultra clear tempered glass railings, we process edges, corners, sizes, shapes, etc. as required.

Ultra clear tempered glass has low iron content and high transparency, and is beautiful and safe when used for glass railings. Joy Shing Glass supplies high-quality tempered glass, can customize and process glass as required, and provide integrated glass solutions.

0 notes

Text

Customized Ultra Clear Tempered Glass For Building Facade

Beautiful and clear appearance: Ultra clear tempered glass has excellent clarity and transparency, and is visually clearer and more beautiful. It allows maximum natural light to enter the building, creating a bright and open interior space. Strength and safety: Ultra clear tempered glass has low iron content, no impurities, and is not prone to self-explosion. And tempered glass has stronger impact resistance and bending resistance, which is 3-5 times that of ordinary glass. Even if it breaks, it will break into small blunt-angle particles, reducing the risk of injury.

Joy Shing Glass supplies high-quality tempered glass. We can customize and deep-process glass as required to provide you with an integrated glass solution. If you are interested in our products, please feel free to contact us for a quote.

0 notes