Magicrete Building Solutions, India's leading manufacturer of AAC Bricks, AAC blocks. They offer Unmatched Benefits of Energy & Cost efficient Green building materials like lightweight concrete blocks at affordable rates. Visit the website to avail more details.

Don't wanna be here? Send us removal request.

Text

Importance of Wall Tile Adhesive: Tile Adhesive Companies in India

Do you want to get tiles fixed on your wall? There is no doubt that it is an excellent way of decorating your room. First, you need to go for a wall tile adhesive that attaches the tiles correctly on the wall. When you get in touch with the tile adhesive manufacturers in India, they will provide you with the right wall tile adhesive to fix the tiles on your wall.

After several studies, the experts now provide you with a wall tile adhesive that will keep the wall tile in a mint condition for years. These tiles will last longer and withstand all tests of time. The adhesives contain polymer modified grey/white cement and can fix both ceramic as well as vitrified tiles on the floor and wall. It is suitable for internal as well as external walls and comes with excellent waterproofing properties to prevent tile cracking. What’s more, the on-site preparation time is minimal. Thus, it saves time and money. Some of its features are as follows:

· High bond strength

It has high bond strength due to a proprietary technology and polymeric additives. Hence, it is very durable.

· High thermal insulation

Thin joints prevent heat transfer through walls.

· Zero wastage

Easy to apply. Avoids wastages.

· No shrinkage cracks

Water is retained in the mortar that prevents shrinkage and cracks.

· Economical and time saving

As it needs only minimal time to prepare, it reduces the cost of labor as well as overheads.

· Premixed

No need to blend the powder on the job site. You only need to add water to it.

Thus, this wall tile adhesive is handy for construction companies. It is ideal to buy these adhesives from the tile adhesive companies in India at competitive rates.

0 notes

Text

Know the Advantages of Using Tiles Fixing Chemical

Cement, polymers, and sand combine to form Perma NSA powder. It only requires that water be added to it whenever the adhesive is needed and mortar is obtained which is used for fixing tiles over a surface and also on top of existing mosaic tiles without having to remove it.

On comparing the advantages of using a tile fixing chemical over the traditional adhesive methods, we find that:

They are fast and efficient.

Easy to use, only mix with water.

Better bonding strength.

It can be grouted within 24 hours without waiting for the moisture to evaporate.

Applicable on existing tiles, many special substrates like polished cement, drywall system, etc.

A thinner layer is required.

Ordinary and traditional sand cement is made of Ordinary Portland Cement (OPC) and sand. OPC is used for crude work like masonry and rendering, the problem is that sand used is river sand which is dirty and the grain size too is not uniform.

It is very time-consuming --It has to be done with one tile at a time.

There is beauty and de-bonding problem.

Laying tiles traditional way by applying the sand-cement mixture in lump creates fissures and water can seep through. This creates a white stain problem. The tiles become susceptible to breaking as there is no support at the edges.

A thick layer of the sand-cement mixture is applied in the traditional system to make the floor even; this puts weight on the floor. This, in turn, puts more weight on the structure.

It cannot be applied on all tiles due to poor bonding strength of sand-cement mixture because of dirt in the sand and also because of the proportion of materials not being proper. The tiles on which this OPC mixture cannot be applied are Granito with 60 x 60 cm or greater size, low absorbent tiles, glass mosaics.

Other areas where OPC cannot be used are on smooth polished surfaces, substrates subject to movement, on existing tiles and areas which are subject to high-pressure impact.

Another important setback that OPC has is that a lot of material is wasted because it dry’s very fast and solidifies.

Thus we find that tile fixing chemicals score over the traditional methods of adhesives not only performance-wise but also economically.

0 notes

Photo

AAC blocks have always been popular construction materials in Europe, and they are now quickly becoming recognized in other parts of the world. Read this blog to know why AAC Block Plant are Considered as Eco-Friendly in India. Visit- http://www.magicrete.in/

0 notes

Photo

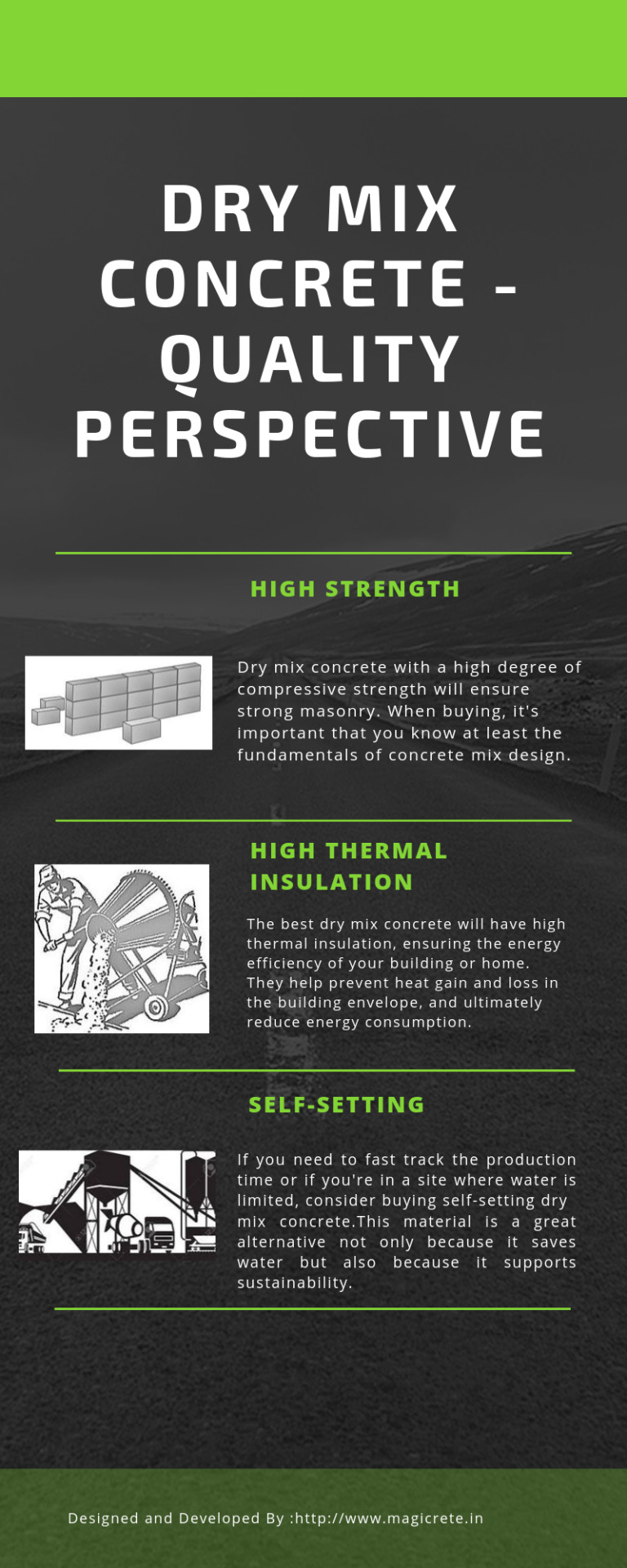

Dry Mix Concrete - Quality Perspective

Visit- https://www.magicrete.in/

0 notes

Text

Growing Trend of Ready-Mix Cement Plaster

Many construction companies and even DIY renovators now prefer ready-mix cement plaster to traditional mortar which has to be mixed with cement, sand, and water on the project site. After all, this ready-made plaster comes pre-mixed with raw materials in dry form. All you need to do is to add water and the plaster is ready for application.

The growing trend for the use of ready-mix cement plaster is one strong proof that this product is better than the conventional mortar in many ways. Here’s why:

Reduce construction time

You can finish your work faster using ready-mix cement plaster. As mentioned, preparing this type of mortar is fast and easy. Application is also a breeze, especially if you're using a brand that has water-retaining components. With this plaster, curing and drying time of the wall is faster, which reduces the curing or drying time of plaster. Consider using a spray plaster machine to complete your job quicker.

Strengthen your walls

Aside from creating smooth and even surface, another purpose of plastering is to protect the wall. Leading brands of ready-mixed plasters can create a stronger based surface with better compressive and tensile strength than traditional plasters. In fact, they are very versatile that they can bind to most types of wall surfaces such as cement and bricks.

Environment-friendly

The construction industry of today is moving towards green building solutions, looking for better ways to help the environment. Ready-made plaster is seen as an eco-friendly material because it requires less water. Thus, it leaves behind less waste.

Cost-effective

It often takes a few coatings for traditional plasters to create smooth walls, but all you need is a single bag of ready-mixed plaster to cover a larger surface area on a single coating for internal wall and double coating for external wall. This makes the plaster a more cost-effective option that facilitates faster application time.

0 notes

Text

AAC Blocks Manufacturers – Improve Your Industry Knowledge

AAC (Autoclaved Aerated Concrete) blocks are light-weight, insulating, load-bearing, and highly durable building products used in a variety of construction applications. AAC blocks manufacturers produce these blocks in a range of sizes as well as variable strengths and load-bearing capacities. They are extremely lightweight (up to 3 times lighter than red bricks), which makes them a popular alternative for modern building applications.

AAC blocks come as pre-cast, foam concrete blocks that are made up of a combination of quartz sand, lime, calcined gypsum, aluminum powder, cement, and water. They are suitable for use as concrete masonry units and are considered superior to other materials because they simultaneously provide insulation, structure, and critical properties like mold and fire resistance. AAC blocks manufacturers use an autoclave to cure AAC products under the appropriate levels of heat and pressure. Forms range from basic blocks to floor, wall, and roof panels, lintels, and cladding or façade panels. AAC products are widely used in exterior and interior construction. They are quick to install and easy to work with, as the material can be sanded, routed, and cut to size right on site, with the help of standard power tools and carbon steel cutters. AAC blocks and panels can be painted over or coated with plaster compound or stucco for added protection against the elements. They can likewise be covered with standard siding materials like vinyl and veneer bricks.

AAC blocks manufacturers use grained particulates no larger than sand. This is one of the main things that set AAC materials apart from other concrete applications. Quartz sand, lime, calcined gypsum and/or water and cement serve as binding agents during production. when mixed and cast, AAC blocks go through different chemical reactions, which give the material its lightweight and thermal properties. The resulting bricks are typically just 20% of the total weight of standard concrete. This is because Aluminum powder would react with water and calcium hydroxide to form hydrogen gas, which foams up and doubles the volume of the mix. When forms are taken out of the mold, they are solid but soft enough to be cut into panels or blocks, after which they can be fired and pressurized in an autoclave chamber to facilitate the hardening and curing process.

0 notes

Text

AAC Blocks India: Why It’s A Sustainable Building Material

Green building continues to be a trend as more builders and property owners are looking to shift to environmentally friendly processes that may be safer for them and our planet. Autoclaved aerated concrete (AAC) blocks are among the preferred sustainable building materials when it comes to crafting green structures because they are made of recyclable material, like fly-ash, which comes from steel manufacturing. As long as you get high-quality AAC blocks in India, you should be able to add a sustainable factor to your project.

Before AAC blocks, there were clay bricks, which are cultivated from soil from forests. High-quality AAC blocks in India are made of recycled fly-ash, the waste that accumulates in furnaces for steel manufacturing. They are considered beneficial for our planet right from their production to their transportation and when they are actually used and maintained down the line. Producing AAC blocks uses at least 30 percent less energy compared to the energy needed to manufacture clay bricks, and that says a lot when it comes to carbon emissions.

AAC blocks in India are lighter than conventional clay bricks, even when prepared in the same volume. So, transportation costs are usually less, which means more savings on logistics costs. Lightweight bricks also mean energy efficiency when they need to be transported to elevated areas. When preparing and assembling the AAC blocks, you will only need to use minimal water and the curing time is faster compared to when you use conventional concrete blocks and clay bricks. Just be sure to get the appropriate eco-friendly products to keep them in place.

Structures that have been built with autoclaved aerated concrete have a high thermal insulation index. This means that their ambient temperatures will not change as fast as external temperatures would. So, they tend to be cooler in the summer and warmer in the winter, and this means minimal heating and cooling requirements down the line. For this reason, AAC blocks in India are greatly popular with builders who make hospitals, schools, office complexes, shopping malls, homes, and high-rise buildings.

About the Author

Magicrete Building Solutions Pvt.Ltd is one of India’s leading manufacturer of AAC Blocks which are light weight concrete blocks and other green building materials. They offer high quality and precisely designed blocks manufactured with Autoclaved Aerated Concrete (AAC) - a path-breaking technology in the construction Industry. They offer durable and Eco-friendly construction materials.

0 notes

Link

Remember the days of disposable cameras and dialling “69 to see who called you”? Thanks to the technological enhancement, those days are long gone.

0 notes

Link

Agreeing to that, when it comes to building a construction site from the ground up, construction manager is by act and by work, one very important person. Further his involvement in proper execution of the project plan is huge and cannot be underestimated.

0 notes

Link

AAC blocks or Autoclaved Aerated Concrete are a lightweight and environment-friendly alternative to clay bricks, and has bring significant change in the construction industry in India.

0 notes

Link

AAC blocks are a revolutionary building material that can transform the way construction projects are carried out in India. And Magicrete is proud to be a leading manufacturer and supplier of these blocks to various sectors in India today.

0 notes

Link

Having a healthy and clean environment is the need of the hour. After decades of activism, legislating and international conventions, humanity is finally waking up to the sad state of affairs in environmental conservation, and this has resulted in a range of efforts to mitigate the loss caused by rampant and unchecked pollution.

0 notes

Link

Worker’s safety is closely related to overall instances of how a society treats its less fortunate sections. For a first world nation, taking a serious approach towards worker’s safety is a good indicator that it respects the human rights of its blue-collar working class.

0 notes

Text

Comparing Ready-Mixed Plaster with The Traditional Plaster

Ready-mixed plaster and traditional plaster are both important building materials that are used across many construction applications. What are their differences from each other? Which one is better for your project? Here are all the basics you need to know to make an informed decision.

Application

Traditional sand cement plaster is versatile. It can be used for almost any kind of application. Ready-mixed plaster can be applied to external and internal walls and even ceilings. Moreover, you can also use it for horizontal and vertical planes and patterned or textured surfaces. However, it is not recommended for wet areas like bathrooms and kitchens.

Speed

Mixing traditional plaster on-site is labour intensive. Construction workers must be mindful of the right amount of raw materials they add to the mix and maintain consistency of mixing. On the other hand, preparing and applying ready-mixed plaster is quick and easy. Most brands only require you to add a sufficient amount of water, mix it a little, and then you can start covering the walls. The best brands of ready-mixed plasters also have excellent water-retaining components, which speeds up the curing or drying time of plaster. Some are even available in spray plaster machines, allowing you to complete the application faster. This is why many construction companies and DIY home builders prefer ready-mixed plasters to conventional ones.

Strength

In terms of strength, ready-mixed plasters are superior to sand cement plasters. Ready-mixed plasters can create a stronger base that has a higher tensile and flexural strength. On the other hand, sand cement plasters build a surface base that has a weak tension and flexural strength as their walls are more prone to cracking.

Environment-friendliness

Ready-mixed plasters are the top choices of green builders because they are eco-friendly. Aside from the fact that they don't need too much water, they also leave significantly less waste.

Value for money

Top quality ready-mixed plasters not only save you time but also money. They can create smooth and strong walls with a single coating. A bag of ready-mixed plaster can cover more internal and external walls and ceilings than a bag of traditional plaster.

One thing you must understand about ready-mixed plaster is that they are not created the same. To be safe, source your supply only with a trusted supplier or manufacturer of top-quality and award-winning building materials in India.

About the Author

Magicrete Building Solutions Pvt.Ltd is one of India’s leading manufacturer of AAC Blocks which are light weight concrete blocks and other green building materials. They offer high quality and precisely designed blocks manufactured with Autoclaved Aerated Concrete (AAC) - a path-breaking technology in the construction Industry. They offer durable and Eco-friendly construction materials.

0 notes

Text

Growing Popularity of AAC Blocks in India

The emergence of AAC blocks in India and different parts of the world is proving that it is the new construction standard. This new alternative to traditional bricks offers so many advantages—it’s easy to see why so many construction companies are switching to it. In fact, for many years, the sales of AAC blocks in India have been continuously increasing— and for very good reasons.

Lightweight

AAC blocks weigh 1/3 of the weight of conventional blocks. Because they are light, they are easier to work with. More importantly, they reduce the dead load on the foundation of a structure and are safer in case of an earthquake. Construction companies enjoy significant savings on the transportation of these blocks, too. Since they are lightweight, the supplier can send them to the site in larger batches.

Versatile

AAC blocks are so versatile that they can be used in most types of construction projects because they can be cut, chiselled, nailed, drilled, and be shaped into different forms. This is another reason why AAC blocks are easier to work with.

Lower environmental impact

The production of AAC blocks in India leaves 30% less solid waste as compared to traditional concrete blocks. Aside from this, AAC blocks manufacturers also emit 50% less greenhouse gases, so in terms of environmental impact, AAC blocks are better.

Safe and strong structures

AAC blocks are fire-resistant with a melting point of over 1600 degrees Celsius. They offer better thermal conductivity, sound insulation, energy efficiency, and ventilation.

The increase in demand for AAC blocks in India has led to an increase in production by almost 500%. A lot of manufacturers from India and other countries are meeting the demand. Yet, of course, not all of them promise the same quality and value for money. Therefore, when partnering or buying from a supplier, make sure to do some research on the brand of their AAC blocks. Choose a brand from award-winning and well-recognised manufacturer in the construction industry.

0 notes

Text

Lightweight Concrete Blocks vs Insulating Concrete Form Construction Technology

Lightweight concrete blocks are some of the best green building materials that industrial and residential construction companies use. They are made of expanded aggregates that make them less dense or lighter than standard concrete blocks. They come in three types: autoclaved aerated concrete, no-fines concrete, and lightweight aggregated concrete. Lightweight concrete blocks are stacked together like bricks and bound by mortar or a specialised joining adhesive.

Pros of Using Lightweight Concrete Blocks

Durability - Lightweight concrete block specifically AAC blocks are proven to be resistant to frost and heat. They are fireproof, too. This means they are ideal for almost anywhere in the world, from tropical areas to countries that experience all four seasons.

High Thermal Insulation - AAC blocks have amazing thermal insulation properties. That's why they are used by LEED certified constructions. Because of this, residential and commercial building owners can experience energy savings.

Strength - AAC blocks may be lightweight, but they have a relatively higher compressive strength of 3.5-4N/m2 compared to clay bricks with 2.5-3N/m2. These materials are used for constructing hospitals, schools, and high-rise buildings.

Another popular material or system used in construction is the insulating concrete form (ICF). Just lie lightweight concrete blocks, ICF hollow foam blocks are also stacked together. But since they are hollow, they are reinforced by steel and filled with concrete afterwards, creating a wall.

ICF is fairly durable. It has proven on many occasions to be resistant against tornado and hurricane. Properly engineered, ICF homes may also withstand earthquakes. This technology is also energy-efficient. Like AAC blocks, residential owners can have significant energy savings with their ICF homes. Compared to homes made of wood, ICF homes offer as much as 50% savings on heating and cooling. That's because of their great insulation properties.

Which Is the Better Choice?

Both building materials are energy efficient and easy to work with. But according to many construction experts, lightweight concrete blocks are a better option. Consistency in construction is harder to achieve using ICF since they need cement to create a wall. When concrete is poured too rapidly, it can lead to costly cleanup.

Meanwhile, lightweight concrete blocks are bound by ready-mix mortar, making construction fast, easy, and safe. Consistency and accuracy are easier to achieve.

About the Author

Magicrete Building Solutions Pvt.Ltd is one of India’s leading manufacturer of AAC Blocks which are light weight concrete blocks and other green building materials. They offer high quality and precisely designed blocks manufactured with Autoclaved Aerated Concrete (AAC) - a path-breaking technology in the construction Industry. They offer durable and Eco-friendly construction materials.

0 notes