Don't wanna be here? Send us removal request.

Text

Arc Flash

What is an electric arc flash?

Mostly caused by inadvertent contact between an energized conductor with another conductor or an earthed surface, an arc flash short circuit can result in severe injury or even death. The risk is not just for those working on the equipment but also to those in close proximity. A full arc flash will melt the conductors, ionize the air and develop into a conducting plasma fireball. Temperatures within the arc may reach well over 20,000°C.

Arc flash injuries frequently include burns to the skin but also internal burns from inhaling hot gasses and vaporized metal. On top of this there may be damage to hearing and eyesight including blindness from the ultraviolet light. There are many of these devastating injuries recorded every year. More severe arc flash examples also involve an explosive force known as an arc blast. The blast pressure can launch shrapnel at speeds of up to 300 meteres per second and can lead to further injuries. Those who experience an arc flash event and are lucky enough to survive often have horrific injuries which require extensive treatment and rehabilitation. The physical, emotional and financial cost of these injuries can be extreme.

Read more at http://www.business2community.com/strategy/workplace-dangers-arc-flash-risk-management-0306995#VSsjfaT3F1YKTvWq.99

youtube

Shock and electrocution from contact with energized parts have long been recognized as a risk to electrical workers. According to the Electrical Safety Foundation International (ESFI):

Electrical hazards cause more than 300 work-related deaths and 4,000 injuries a year.

Electrical accidents rank sixth among all causes of work-related deaths in the United States.

There are important steps that companies should take to reduce risk and prevent electrical accidents. These steps are required as part of National Fire Protection Association (NFPA) standard 70E®-2012, which provides a detailed reference for facilities to meet electrical workplace safety requirements. A sixth step assists facility owners with fine-tuning the electrical system for safety and operability.

Step 1: Develop and audit an Electrical Safe Work Practices (ESWP) policy.

Step 2: Conduct an electrical system study to determine the present degree of arc flash hazards and label the equipment.

Step 3: Ensure adequate supplies of personal protective equipment (PPE) and proper tools.

Step 4: Conduct regular safety training and employee assessments.

Step 5: Maintain all electrical distribution system components.

Step 6: Follow strategies to reduce and control arc flash hazards.

Often overlooked, Steps 5 and 6 are crucial to optimizing safety and performance of the power system.

NFPA 70E dedicates an entire chapter to the subject of maintenance for electrical safety. All electrical distribution systems contain active components such as fuses, circuit breakers and relays that help protect the system in the event of an electrical fault. These components are also crucial when it comes to protecting workers from arc flash and arc blast hazards. Modern, properly adjusted overcurrent protective devices that have been well maintained are able to detect an arcing condition and clear the fault quickly.

The goal of arc flash mitigation is to reduce the arc flash energy, and thus the PPE, to a level that permits normal tasks to be performed on equipment. The methodologies to reduce arc flash energy or to mitigate its effects fall under two basic categories: A collection of engineering controls to reduce arcing time, and equipment and techniques to remove the worker from the danger zone.

Solutions that lower arc flash energy by reducing the arcing time include:

Over-Current Protective Device (OCPD) coordination studies

Specialized relaying such as light sensing technology

Virtual main relay

Solutions that remove the worker from a dangerous location or place a barrier between the worker and exposed energized parts include:

Wireless temperature monitoring system...More at More Reading

summary of the article

Images and video

0 notes

Text

Check Out Rusty Fixer!

https://www.youtube.com/watch?v=yd4uqA5hJQI

0 notes

Text

Check Out Our YouTube Channel!!

https://www.youtube.com/watch?v=XTVH47Fw73g

0 notes

Text

Single Point Lesson #251

http://www.fando.com/documents/File/SinglePointLesson/SPL251.pdf

Want more? subscribe and send an email! [email protected]

0 notes

Text

Single Point Lesson #250

http://www.fando.com/documents/File/SinglePointLesson/SPL250.pdf

Want more? subscribe and send an email!

0 notes

Text

Single Point Lesson

http://www.fando.com/documents/File/SinglePointLesson/SPL249.pdf

0 notes

Text

Pharmaceutical-Equipment Reliability

Fuss & O’Neill Manufacturing Solutions began working with this Pharmaceutical company in November 2004. At the start of our engagement, their 5 Production lines averaged an OEE of 59%, due to many breakdowns and stoppages. This means that when they planned to run product, they produced good quality product 59% of the time. 8 months later their 5 lines were producing at a 20% higher rate. In 2009 they are consistently running these lines at an OEE of 83%. The increase in output has a high dollar value. It has also saved them Capital $$ that they did not have to spend to purchase additional equipment, when production requirements increased.

Unique Features:

• Implemented Total Productive Maintenance (TPM) by conducting 5 day Focused Improvement training sessions

• Cleaned, inspected, repaired and modified Lines 1, 2, 3, 4, & 5

• Modified equipment to allow more accessibility for operators and maintenance

• Improved the Preventive Maintenance guidelines to reflect new ideas learned

• Brought in Original Equipment Manufacturers, to train maintenance personnel on troubleshooting techniques on specific packaging equipment

• Collected and used maintenance breakdown data to focus the improvements

• Collected OEE data to achieve major productivity improvements

0 notes

Text

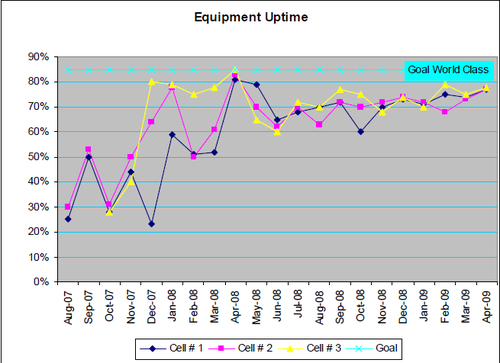

Metals Forming/Machining - Sustainable Increase in Factory Production

MANUFACTURING SOLUTIONS

Ongoing

Staff:

Robert Hydock, CMRP

Maintenance Management Consultant

Metals Forming/Machining - Sustainable Increase in Factory Production

Matamoros, Mexico.

Fuss & O’Neill Manufacturing Solutions began working with this Metals Forming client in 2007. The client could not meet production demands due to excessive equipment downtime and reliability issues. Production ‘bottlenecks’ were sequentially removed with application of hands-on Maintenance Excellence Techniques (TPM).

Unique Features:

• Performed site audit, including; equipment, safety, environmental and maintenance evaluation etc.

• Focused on equipment and infrastructure issues.

• Sequentially solved production bottlenecks, in order of criticality.

• Provided hands-on troubleshooting with technicians when equipment suffered breakdowns and drove root cause analysis by technicians. Training was on the job.

• Became the client’s Maintenance Manager and developed the Maintenance organization.

• Implemented daily review of downtime data.

• Modified existing PM’s, with more detail. Added key predictive maintenance technologies.

• Developed Daily Operator checklists for daily PM’s of equipment.

• Focused on reliability issues and reduced scrap as a result .

• Re-engineered unique one of a kind, equipment design flaws.

• Focused on and solved equipment quality issues that the Original Equipment Manufacturers could not solve.

Results:

• Increased Production output by 400% over 18 month time frame

• Reduced quality defects by 80%

• Developed Maintenance team to a high level of expertise for sustainment

0 notes

Text

Foundry Set-Up Reduction - SMED

MANUFACTURING

SOLUTIONS

Completion:

On-going

Staff:

David Stendahl

Project Manager

Foundry Set-Up Reduction - SMED

Jersey Shore, Pennsylvania

Fuss& O'Neill Manufacturing Solutions performed its fourth TPM Focused Improvement event at a SMED (Single Minute Exchange of Dies) during the week of July 25th, 2005.

Unique Features:

As an element of Manufacturing Solutions’ Overall Equipment Effectiveness measurement, the teamfocused on Set-Up Reduction on three Finishing Department processes: Gage Blocks, Trays and Stops.Several times per day, the Operators would need to shut-down the entire “continuous flow” process lineto change to a different product length. These non value-added Set-Up steps are lost business revenue.

A summary of benefits:

Minimized variables = Process in Control = Higher Quality Yield

Reduced Set-Up time = Gained business revenue, more productivity

Greater flexibility for meeting Customer demands, using quick release fasteners

Quantum leap in Morale –less employee Frustrations,

Operators involved in every step of improvements made:

Ideas- Designs -Gathering Materials –Prototypes-Try outs

Annual Revenue Gained Using New Prototypes:

Gage Blocks = $1,147,608

Dead Length Trays = $467,775

Length Stops = $144,144

Total Annually = $1,759,527

0 notes

Text

Automotive Equipment Productivity

MANUFACTURING

SOLUTIONS

Completion:

Ongoing

Staff:

John Kravontka, CMRP

President/Project Director

Automotive -

Equipment Productivity

Las Vegas, Nevada

Fuss & O'Neill Manufacturing Solutions began working with this Automotive Supplier in November 2003. They were producing air bag tubes, at a high scrap rate. There were manybreakdowns, minor stoppages and longer than normal set up times. AB Tube, needed to producemore product for their customers, quickly and at a lower cost.

Unique Features:

In the first week, lowered their defect rate from 6,000 to 2,000 Parts per Million (PPM)

Improved equipment productivity by 25% and scrap rate to 200 PPM in a two month time frame

Began Total Productive Maintenance (TPM) on their Cut off/Chamfering lines, with training and implementation in Spanish, to help them with their diverse workforce

Modified the preventive maintenance guidelines to reflect new ideas, learned on their equipment

Cleaned, inspected, repaired, and set up daily operator preventive guidelines

Developed maintenance accessibility “countermeasures” to reduce the amount of time maintenance requires to make repairs

Worked with maintenance personnel to eliminate “shims” when replacing tooling, to reduce set up times and greatly improve quality

Performed 5’S (Sort, Straighten, Shine, Standardize & Sustain) techniques on their maintenance area

0 notes

Text

Foundry Equipment Productivity

MANUFACTURING SOLUTIONS

Completion:

Ongoing

Staff:

David Stendahl

Project Manager

Foundry Equipment Productivity

Jersey Shore, Pennsylvania Fuss & O'Neill Manufacturing Solutions implemented and led a Total Productive Maintenance Focused Improvement training session during the week of July 4th, 2005. The team was taskedwith correcting downtime issues and enhancing equipment productivity due to continuing bottleneckscaused by the shear machines.

Unique Features:

Improved equipment productivity by more than $2.5 million annually

Built a prototype guide plate to eliminate over 1,500,000product jams per year. These jams and minor stoppagesseemed insignificant, but added up to greater than 1 ½months of lost production, on an annual basis. Three daysof prototype testing was performed, proving that the newguide plate would work across all product lines. This teamobserved, discussed, designed, & experimented

288 tons of “good” products were discarded

Unnecessarily each year, due to product “Bars” flipping-over at Bundler Trays. New Bar Trays were standardized to 18” wide for each Dead Length Table, resulting in increased company revenue by $176,000 per year

Developed a Daily Operator Planned Maintenance “Walk-Around” diagram. This is an easy-to-understand visual, posted at each shear

Provided the maintenance department with 20 specific activities to periodically service their shears

Completed 12 electrical, mechanical and pneumatic machine repairs

0 notes

Text

PM Optimization Using OEE Observation

MANUFACTURING SOLUTIONS

Completion:

2004

Staff:

John Kravontka, CMRP

President/Project Director

Assembly Equipment – PM Optimization Using OEE Observation

Worcestor, England

Client was experiencing poor equipment performance of an assembly machine that assembled a latch mechanism. Operators did not want to operate this machine, because of too many stoppages, that were very frustrating. Maintenance PM’s were very generic and did not find potential problems. All of the equipment breakdowns and defects were “invisible”. They needed higher equipment output and much more focused PM’s.

Manufacturing Solutions facilitated the client’s team of maintenance personnel, through a PM Optimization shop floor session, using Overall Equipment Effectiveness (OEE) observation techniques. A maintenance technician observed (and recorded data) the equipment running production, for 60 minutes. Using the data the technician worked on the obvious problem areas, for 3 hours. Next day he observed for another 60 minutes and worked for another 3 hours. The procedure was repeated for the third day. Many problems were now seen, by talking to the operator and observing the equipment run.

Results:

250% increase in equipment output

10% reduction in scrap

Improved Operator morale

New maintenance PM’s developed byobservations and repairs

Discovered raw material quality issues

12 air leaks located and repaired,resulting in $2,200 annual savings

Started development of a manualassembly method to further improve productivity

0 notes

Text

Maintenance Excellence- Path to Success

The path to maintenance excellence is a long road that includes a variety of checkpoints along the way. Each organization takes its own route, and some are further along than others. Everyone wants to improve plant maintenance and reliability, but many often don’t know where to start, let alone where they want to end.

Start with a Gap Analysis,

Assess your program. Stabilize and then improve your maintenance program.

Benchmarking

It is vital to perform a gap assessment with key operations and maintenance personnel. Our Bronze, Silver, and Gold benchmarking looks at over 70 aspects of how your maintenance organization is performing. The assessment is designed to be used as a road map to improve and begin building an effective maintenance Strategy. We will use this later during our Maintenance Manager 101 training when we assist you with a short and long term strategy.

Maintenance as a Profit Center

Short Term Strategiesort

Long Term Strategies

Maintenance Software

Maintenance Culture

Developing a Maintenance Matrix

Maintenance Manager Training

What is your Maintenance Vision?

Develop a Maintenance Vision

What are your critical pieces of equipment?

Ratings A, B or C

Within 30 days determine your critical equipment

What is the condition of those critical pieces of equipment?

Evaluate critical equipment; assign a “code” for use with an annual capital plan.

What are the maintenance skills required, to maintain that critical equipment in your facility?

Perform a maintenance “skills matrix” evaluation, to provide training in the correct areas, or to hire people with the correct skills.

Maintenance Mapping – locate waste in your current maintenance process.

Work on case studies of various maintenance situations

Develop a future state Maintenance map of your maintenance organization

What does it take to approach Zero Equipment Stoppages?

How does equipment fail?

Stabilizing equipment failure rates

Overall Equipment Effectiveness (OEE)

How do you rate in the 4 phases of approaching Zero Stoppages?

How to develop Lubrication Excellence

Evaluate your Lubrication strategy

Receiving of oils/greases

Storage of oils/greases

Delivery of oils/greases to equipment

Disposal of oils/greases

Troubleshooting of lubrication systems

Do you perform good solid Preventive Maintenance?

PM Optimization

Developing Condition Based Preventive Maintenance

Predictive Maintenance

Planning & Scheduling

Identify and understand the six support systems maintenance relies on:

Planning

Scheduling

Barriers to World Class Maintenance

Discuss problems

Maintenance Measures

Evaluate your current state utilizing TPM/Maintenance Criteria.

Re-cap and develop a going forward plan.

#gap analysis#benchmarking#maintenance success#Maintenance Culture#Lubrication Excellence#Preventive Maintenance#•Planning & Scheduling

0 notes

Text

Dental Supply Equipment Productivity

MANUFACTURING SOLUTIONS

Completion: 2008

Staff:

John Kravontka, CMRP-President

David Stendahl-Project Director

Dental Supply Equipment Productivity

Milford, Delaware

Fuss & O’Neill Manufacturing Solutions began working with this Dental Supply Company in July of 2007, through the Delaware Manufacturing Extension Partnership (DEMEP). At thestart of the engagement, their production machines were very unreliable. They had to deal with manybreakdowns and stoppages. The first critical machine that was focused on was a machine thatpackages materials for composite fillings, and assembles into an easy to use kit. There were twomachines but the focus was on just one. This one had an OEE of approximately 30%. At the end ofthe week, the OEE was 60+%. By October 2007, the second machine was taken out of production,because of the increased production level of the first and an additional product line was brought in,because of the freed up floor space.

Unique Features:

Modified grease fittings to allow them to be greased while equipment is running

Solved gripper problems

Improved operator ergonomics

Replaced cracked water lines and kinked pneumatic lines, eliminating potential breakdownsReduced Set-Up time, by labeling water connections and color coding pneumatic tubing

Optimized the generic PM’s to make them easier, quicker and better

Developed a Daily Operator PM for daily inspection of equipment

Relocated one operator panel for easier operator access

Eliminated unused stations and re-programmed PLC

Results 2007:

·Doubled the OEE, allowing one machine to be eliminated and another product line brought into the facility, in its place

·Located and repaired air leaks, resulting in a $1,500 per year savings

#Dental supply#problemsolving#Productivity#Preventive Maintenance#production#OEE#increasedrevenue#increased savings

0 notes

Text

Corrugated Equipment – Production/Reliability Improvement

MANUFACTURING SOLUTIONS

Completion:

2007

Staff:

John Kravontka, CMRP

President/Project Director

Corrugated Equipment Production/Reliability Improvement North Haven, Connecticut

Client was experiencing a high frequency of equipment breakdowns, stoppages and qualityissues.

Downtime over 20%

Slow run speeds

Numerous maintenance issues

Unpredictable PM’s

No communications between operators and maintenance

Quality issues affecting converting equipment (down line)

F&O facilitated the client’s team (maintenance & operators) through the following:

Training on equipment evaluation

Basic measurements

Cleaning, inspections, repairs, modifications

Establishing basic system conditions

Setting up meaningful Daily Operator checks

Setting up Maintenance PM’s

Use of Predictive maintenance tools to locate bearing failures and electrical loose connections

These improvements were part of a TPM 5 Day Focused Improvement session.

Results:

9% increase in Corrugator output

31% drop in Maintenance downtime

16% drop in Maintenance occurrences

Shorter duration of mechanical downtime

34% decrease in Cart changeover time

7% increase in converting equipment productivity (down line)

ROI of 3 weeks

Improved morale/pride in work area

0 notes

Text

Nuclear Industry Productivity

MANUFACTURING SOLUTIONS

Completion: 2003

Staff:

John Kravontka, CMRP

President / Project Director

Nuclear Industry – Equipment Productivity Total Productive Maintenance

Windsor, Connecticut

Fuss & O’Neill Manufacturing Solutions was retained to provide guidance and training byapplying Total Productive Maintenance (TPM) techniques at this manufacturing facility.

From March to September 2002, Overall Equipment Effectiveness (OEE) averaged 45% on this critical laser welder. This means that 55% of the time this equipment did not produce, or produced substandard products. A TPM 5 Day Focused Improvement week was used to strategically improve the productivity of the laser welder as follows:

Improved laser welder OEE from 45% to 72%, in one week

Increased laser capacity by 60%

Reduced rework and overtime costs by $65,000 per year

Saved over 23,000 kilowatt hours in energy

Eliminated contamination in the weld area by increasing the suction that removes

Improved accuracy and reliability of the laser welding head

Teams received shop floor guidance to discover the reasons behind the poor equipment performance and identify countermeasures to improve performance. During the week we:

Identified and eliminated the two major causes of 80% of the equipment failures

Located and minimized six major equipment related losses

Established quick, simple and effective methods to clean and inspect the equipment

Developed low cost methods to clean the air in the facility

Taught the 5'S (Sort, Straighten, Shine, Standardize & Sustain) workplace organization principle

#nuclear industry#TPM#equipment productivity#savings#increasedrevenue#increased savings#improved accuracy

0 notes