Welcome to Modern Constructive—your go-to source for GFRP insights, trends, and solutions that build stronger, smarter, and sustainable futures!

Don't wanna be here? Send us removal request.

Text

5 Ways FRP Transforms Industry

FRP structural profiles offer a lightweight, durable, and corrosion-resistant alternative to traditional materials in demanding industrial settings.

0 notes

Text

GFRP Rockbolts for Mining and Tunneling Stability - ARC

Explore high-strength GFRP Rockbolts for reliable rock reinforcement in mining, tunneling, and civil engineering projects. Durable and chemically resistant.

0 notes

Text

FRP Structural Profiles - FRP Structural Shapes Manufacturer | ARC

Explore our cost-effective, high-performance FRP Structural Profiles and shapes, offering strength, corrosion resistance, and low maintenance. Custom designs to suit your needs.

0 notes

Text

FRP & GFRP Rebar Manufacturer and Supplier in India

ARC, India's top manufacturer of FRP rebar and GFRP (glass fiber reinforced polymer) rebar, offers corrosion-resistant, lightweight, and durable alternatives to TMT rebars.

0 notes

Text

Why FRP Structural Profiles Are Replacing Steel in Industrial Projects

In modern industrial construction, materials are chosen not only based on strength, but also based on how they behave with time under adverse conditions. While steel has traditionally been the preferred choice, industries have now started to shift towards Fibre-Reinforced Polymer or FRP structural profiles.

This transition has literally transformed the construction, transportation, chemical processing, and electrical infrastructural sectors.

What Are FRP Structural Profiles Made Of?

FRP structural profiles are modern composite materials that are manufactured using the pultrusion process. In this process, glass mat and rovings are drawn through a resin bath and are pulled into a heated die to form the required shape. These profiles resemble different forms of steel like I-beams, angles, and channels. But their utility typically excels in a number of critical aspects.

These FRP structural profiles are commonly used in industrial applications like:

Cooling Towers

Offshore Oil and Gas

Chemical Industries

Water treatment facilities

Power distribution sites

Why FRP Structural Profiles Are Replacing Steel in These Applications

Corrosion Resistance

FRP structural profiles are highly rust-proof and do not degrade when exposed to moisture, chemicals, and atmospheric pollutants.

Lightweight but Structurally Reliable

FRP profiles have superior strength-to-weight ratio, which make them lightweight but structurally strong. This property allows for easier handling, transportation, and fixing, along with minimizing the load on support structures.

Electrical and Thermal Insulation

FRP structural profiles have low thermal conductivity. They offer a major safety advantage in environments involving the usage of electrical equipment or in high temperatures, where steel’s conductivity can pose serious risks.

Low Maintenance and Extended Service Life

FRP structural systems require very little ongoing maintenance. This reduces operational costs and downtime throughout their lifecycle and makes them an economically attractive option for industrial projects.

Final Thoughts

The increasing adoption of FRP structural profiles over steel is not just a material switch, it represents a shift in engineering priorities. As project specifications evolve, so does the need for smarter materials—and FRP is leading that transformation.

0 notes

Text

ARC FRP Pipes: The Ultimate Solution for Strength & Corrosion Resistance!

Upgrade to ARC FRP Pipes for unmatched strength, longevity, and resistance to rust & chemicals. Ideal for industrial, marine, and infrastructure applications. Say goodbye to corrosion and maintenance hassles!

0 notes

Text

FRP Rebar: The Future of Durable & Corrosion-Free Construction!

Upgrade to FRP Rebar from ARC Insulations—engineered for superior strength, durability, and rust resistance. Perfect for bridges, marine structures, and concrete reinforcement. Say goodbye to corrosion and high maintenance costs! Build smarter with FRP Rebar.

0 notes

Text

Composite rebar represents a significant advancement in construction technology, offering benefits like corrosion resistance, high strength-to-weight ratio, and ease of installation compared to traditional steel rebars.

0 notes

Text

GRP (Glass Reinforced Plastic) pipes are the ultimate solution for corrosive environments, offering superior durability, chemical resistance, and long-term performance.

0 notes

Text

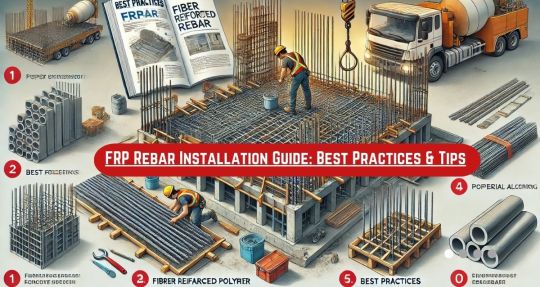

FRP Rebar Installation Guide: Best Practices & Tips

Conventional steel rebar usually does not work so well in harsh conditions due to its tendency to corrode. This is where FRP rebar (Fiber Reinforced Polymer) enters as a game-changing substitute. Having the attributes of being light and corrosion-resistant, FRP rebar aids in increasing the longevity and strength of the structures. If you plan to use FRP rebar for your upcoming project, knowing the best practices for its installation is a prerequisite for ensuring maximum performance. Here is a step-by-step procedure by which you can install and maintain FRP rebar like a pro.

Why Choose FRP Rebar?

Before embarking on the installation, let us talk about why FRP rebar is becoming increasingly popular:

Corrosion-Free: Unlike steel, FRP rebars would not rust nor degrade with time.

Lightweight: Easier to handle and has higher tensile strength.

Non-conductive: This is excellent for structures in proximity to power lines or susceptible electromagnetic fields.

Low Maintenance: Reduces repair costs and increases the overall lifespan of structures.

Step-by-Step Installation Guide

Installation of FRP bars is the most important in order to maximize the potential of improvement in its strength, durability, and customer satisfaction. Carry out following steps for easy and effective installation of FRP rebar:

Step 1: Preparing for Installation

Get ready for the installation. Collect all necessary materials—FRP rebar, plastic spacers, non-metal ties, and cutting tools. FRP rebar is lighter than steel but is more on the stiffer side; therefore, it would be prudent to go with pre-molded shapes that fit the design of your project.

Step 2: Cutting the FRP Rebar

Unlike steel rebar, which allows on-site bending, FRP rebar has to be cut so as to avoid damaging the fibers. It is chopped using fine-toothed saws or diamond or carbide-tipped cutters so that they offer clean and accurate cuts. Always remember safety first; wear a geared protection to avoid any debris or fiberglass particles that damages you.

Step 3: Correct Placement and Tying

In the placement of FRP rebars, observe the required spacing required for effective strength distribution. Use plastic or other non-metallic chairs for support of the rebar eliminating corrosion. Tie the bars every 3 to 4 feet with non-metal ties or zip ties to avoid any possible movement of the rebar during the concrete pour. Again, touching steel rebar would not be recommended as it could lead to issues related to conductivity.

Step 4: Pouring & Curing

Pour the concrete and cover the entire area surrounding the FRP rebar. Curing time is dependent on your project and whatever type of ambient environmental conditions exist. Be certain and adhere to the manufacturer's instructions for the best FRP-concrete-bonding.

Step 5: Ongoing Maintenance Tips

One of the biggest benefits of FRP rebar is that it has low maintenance. As it is resistant to corrosion, it will need less repair in the long run. If a piece of rebar is exposed or damaged, replace it at once to preserve the integrity of the structure.

You may also like: A Beginner’s Guide to GFRP Rebar: Everything You Need to Know

Bottom Line

FRP rebar is a good option, as far as durability and performance are concerned, especially in corrosive or harsh environments. Following these best practices and maintenance tips will aid in ensuring the longevity of your project.

0 notes

Text

Understanding the Benefits of Glass Fiber Reinforced Polymer (GFRP) Rebar for Modern Building Projects

Everywhere you go, the signs are there. Bridges with cracks so deep you can fit your fingers in them. Highways patched over so many times they look like a quilt. Parking garages leaking water through ceilings that were supposed to last a lifetime.

We act surprised every time a structure fails. A collapsed bridge as well as crumbling overpass adds to our woes. The response is always the same: repairs, repairs, and more repairs if the building crumbles.

The truth is, we know exactly what the problem is. The problem is a steel rebar.

Steel has been the backbone of concrete reinforcement for over a century. And in a perfect world, it might work just fine. But we don’t live in an ideal world. We live in a world with rain, salt, chemicals, extreme temperatures, and time. Note that steel can’t handle any of them.

It rusts, expands, and cracks the concrete from the inside out.

We’ve spent decades pretending this is normal—spending billions on repairs, rebuilding the same failing structures over and over again. But why?

We have a better option. It’s called Glass Fiber Reinforced Polymer (GFRP) rebar. And it doesn’t rust. It doesn’t crack. It doesn’t force us into this endless cycle of failure.

So why aren’t we using it everywhere?

The GFRP Rebar Actually Lasts

Let’s say you’re building a bridge. You want it to last 50, maybe even 100 years. That should be reasonable, right? But if you reinforce it with steel rebar, you’ve already sealed its fate.

Within 10 to 15 years, the steel inside will start to corrode. Tiny cracks will form in the concrete. Water will invade, accelerating the rusting process. Soon, those cracks will widen, the structure will weaken, and before you know it—it's time for major repairs.

Now, let’s say you use GFRP rebar instead.

There will be no rust, no cracking from corrosion, and no expensive maintenance. A structure that actually lasts as long as it was designed to.

It sounds almost too simple. But that’s the reality of GFRP rebar. It’s made from high-strength glass fibers combined with a polymer resin. That means:

It never rusts. No corrosion, no unexpected failures.

It’s 75% lighter than steel. Easier to transport, easier to install.

It’s stronger than steel. Handles stress without breaking down over time.

It doesn’t conduct electricity. Perfect for hospitals, power plants, and tunnels.

It does everything steel rebar does—except falling apart.

Steel Rebar Was Never Meant to Last Forever

The reality is harsh but simple: Every structure built with steel rebar is on a countdown to failure. That’s not an exaggeration. That’s just how steel works.

What about Coastal structures? Steel rebar is eaten alive by saltwater. GFRP rebar stays intact.

What about Roads and bridges in cold climates? De-icing salts destroy steel reinforcement. GFRP rebar doesn’t care.

What about chemical plants and wastewater facilities? Corrosive substances weaken steel over time. GFRP rebar remains strong.

We’ve seen this happen a thousand times before. We know how the story ends. So why do we keep building with a material we KNOW will fail?

The “Steel is Cheaper” Myth Needs to Die

Every time GFRP rebar comes up in a construction project, someone will say, “But steel is cheaper.”

But is steel an affordable option?

Sure, if you look at just the cost of materials, steel rebar costs less upfront. But construction isn’t just about today’s costs. It’s about what you’ll pay over the next 50 years.

Steel Rebar = A Lifetime of Expensive Repairs

Steel is challenging to deal with due to the following reasons.

Bridges need constant maintenance.

Parking garages crack, leak, and need reinforcement.

Highways break down from salt and moisture exposure.

Entire structures have to be retrofitted to avoid catastrophic failure.

And who pays for it? We all do. Now, compare that to GFRP rebar:

There will be no rust.

You do not have to address costly maintenance.

There will be no emergency repairs.

That’s where the real cost savings come in.

A little more investment today saves millions in repairs down the road. And yet, we keep choosing the short-term option, even when we know it will cost more in the end. It’s insanity.

We Keep Repeating the Same Mistakes

Think about how many times you’ve seen a construction crew patching up the same stretch of highway, year after year. Or how often you hear about bridge repairs causing massive traffic delays. We build. It falls apart. We repair. It falls apart again.

We know steel rebar isn’t the best solution, but we keep using it because it’s what we’ve always used. Meanwhile, GFRP rebar is sitting right in front of us—a simple, proven solution that stops this cycle in its tracks. Why aren’t we using it everywhere?

The Future is GFRP Rebar—If We’re Smart Enough to Use It

This isn’t about some experimental material that’s still in testing. GFRP rebar is already being used worldwide.

Highways and bridges – Used in major roadways to prevent corrosion from de-icing salts.

Marine structures – Reinforcing piers, seawalls, and docks that are constantly exposed to saltwater.

Industrial plants – Protecting structures from chemical exposure that would destroy steel.

Underground projects – Keeping tunnels and foundations strong in moisture-heavy environments.

What about the results? Structures that last. No rust. No expensive surprises. No rebuilding the same thing over and over. It’s not a question of if GFRP rebar will replace steel. It’s a question of when.

The Bottom Line: Stop Fighting Rust. Start Building for the Future.

Every single project built with steel rebar is on borrowed time. We can keep fighting rust and pretending steel is good enough, or we can make a better choice. GFRP rebar is that choice. It’s stronger. It’s lighter. It lasts for generations instead of decades.

So, why are we still using a material that we know will fail? It’s time to stop throwing money into endless repairs and build structures that actually last. It’s time for GFRP rebar. The only question left is: Why haven’t we switched already?

0 notes

Text

GFRP Cable Trays vs. Metal Cable Trays: Which One Should You Choose?

When it comes to choosing the right cable trays for industrial use, one often has to sacrifice on durability, functionality, and the environment where it is going to be used. The two options that would suffice the fulfilment are metal cable trays and GFRP cable trays.

What are GFRP Cable Trays?

GFRP (Glass Fiber Reinforced Polymer) cable trays are engineered using fiberglass and resin composites into a specialised cable management system. These lightweight cables exhibit notable resistance to chemicals, corrosion and all weather conditions. For harsh conditions, non conductive GFRP cable trays are superior because of their strength, electrical insulation and zero maintenance.

Features of GFRP Cable Trays

GFRP cable trays offer unique advantages, being economically favourable.

Resistance to Corrosive Agents: GFRP cable trays have high resistance to corrosion because of the protective layer that is formed over the surface protecting against moisture and rust.

Hassle-Free Installation: Installation is simple and inexpensive because GFRP cable trays are light weight.

Electrical Insulation: Since GFRP cable trays are poor electric conductors, they are not susceptible to unexpected short circuits.

Properties of Metal Cable Trays

Usually metal cable trays are made of galvanised steel, stainless steel, or aluminium. They provide a cost effective solution for a range of commercial and industrial uses. Being robust and sturdy, they provide commendable support for large cable loads. For projects where corrosion is not a problem, metal cable trays can be the best affordable substitute to GFRP alternatives.

Why not Metal Cable Trays:

Corrosion Vulnerability: Even with a coating, metal trays are susceptible to corrosion due to chemicals used, moisture exposure and adverse weather conditions, leading to additional maintenance and replacement costs in the long run.

Weight: Since metal trays are heavier, they require more support structures resulting in increased time and cost of installation.

Electrical Conductivity: Metal trays are highly conductive and are proven to be very dangerous in high-voltage environments, which makes the need for careful grounding with added cost.

Bottom Line

GFRP cable trays have several advantages over metal trays and include: corrosion resistance, easier installation, and lower operational costs over time. Even though metal trays may be cheaper initially, but their high maintenance cost make them highly expensive than GFRP cable trays, making the latter the best alternative.

0 notes

Text

Discover innovative rebar designs by ARC, blending strength and precision for durable construction. Elevate your projects with cutting-edge rebar solutions.

0 notes

Text

https://www.arcinsulations.com/gfrp-rockbolt-ultimate-solution-for-mining/

Discover how innovative GFRP rockbolts enhance safety and efficiency in tunneling and mining with lightweight, durable, and corrosion-resistant solutions.

0 notes

Text

https://www.arcinsulations.com/gfrp-rebars-cost-effective-solution/

Discover the benefits of GFRP rebars—lightweight, corrosion-resistant, and eco-friendly materials revolutionizing durability in modern construction.

0 notes

Text

A Beginner’s Guide to GFRP Rebar: Everything You Need to Know

Picture this. You are driving over a bridge. It is a structure that seems to stretch forever over the sea. The waves crash below relentlessly, salty. What you cannot see is the steel rebar inside the concrete accumulating rust. The corrosion creeps deeper with the formation of cracks. Repairs are needed. Then more repairs. Eventually, a full replacement.

But what if it didn’t have to be that way? What if the material reinforcing that bridge didn’t rust? What if it could stand up to salt, water, chemicals—even time itself?

That’s where Glass Fiber Reinforced Polymer (GFRP) rebar comes in. This guide is here to give you everything you need to know about this incredible material that’s changing how we think about construction.

What Is GFRP Rebar?

Think of GFRP rebar as the upgrade steel has been waiting for. It’s made from glass fibers and polymer resin—two materials that don’t care about rust, saltwater, or chemicals. Together, they create a lightweight, tough material that reinforces concrete without the constant maintenance headaches steel brings.

Here’s how it works: manufacturers align glass fibers to maximize strength, then coat them in resin to hold it all together. What is the result? A rebar that is strong as well as immune to the elements.

It is not just for fancy projects. GFRP rebar is already being used in bridges, tunnels, seawalls, parking garages.

Why GFRP Rebar Is Changing the Game?

1. Rust Is a Thing of the Past

Steel rebar rusts. Everyone knows it, and yet we’ve relied on it for decades, patching up the damage as we go. GFRP doesn’t rust. Ever. Not when it’s soaked in saltwater. Not when it’s doused with chemicals.

Imagine the impact of rebars battered by ocean spray. No rust means no cracks as well as no endless cycles of repair.

2. Lightweight and Labor-Friendly

Steel is a heavy metal. It is expensive to transport, hard to handle, and a pain to install. GFRP, on the other hand, is about a quarter the weight.

Construction crews notice the difference right away. It’s easier to carry, quicker to position, and doesn’t leave workers drained by the end of the day. Lighter materials also mean fewer transportation costs. It is not just the workers who benefit—your budget does too.

3. Strong Enough to Handle the Pressure

The answer is yes if you are wondering whether GFRP can hold its own. It might be lightweight. However, it is built to take serious loads. Its tensile strength is impressive. The strength matches or even exceeds steel.

This kind of reliability is a must for extensive projects. GFRP rebar does not just hold the line—it redefines it.

4. Non-Conductive as well as Non-Magnetic

Specific projects need materials that would not interfere with electrical or magnetic systems. Think power plants, MRI labs, or tunnels carrying sensitive wiring. Steel’s conductivity can cause big problems in these situations. GFRP, being non-conductive and non-magnetic, fits the bill perfectly.

It’s the kind of solution you don’t think about until you need it. But when you do, there’s nothing else like it.

Where You’ll Find GFRP Rebar Making a Difference?

Coastal and Marine Construction

The ocean is beautiful, but it’s brutal on steel. Saltwater, constant moisture, and the wear-and-tear of waves break steel down faster than you’d think. GFRP rebar solves this.

It’s a natural choice for seawalls, docks, piers, and offshore platforms. Builders trust it to hold up in places where steel simply can’t compete. And the result? Structures that stay strong, year after year, without the endless upkeep.

Roads and Bridges

Roads as well as bridges face a barrage of de-icing salts in winter months. These salts may keep us safe from icy conditions. However, they are a death sentence for steel. The rusting begins. The maintenance bills start piling up.

GFRP rebar eliminates this problem. It doesn’t just survive in these conditions—it thrives. That means fewer cracks as well as safer infrastructure for everyone.

Underground Projects

Building underground is a challenge. You’re dealing with moisture, chemicals, and sometimes the need to avoid electrical interference. Steel struggles here, but GFRP excels.

From subway tunnels to utility corridors, GFRP rebar provides the strength and resilience these projects need without the complications steel can bring.

Industrial Facilities

Factories and chemical plants push materials to their limits. Steel, when exposed to aggressive chemicals, doesn’t stand a chance. GFRP rebar, on the other hand, is built for these environments.

It holds up against chemical exposure, ensuring that industrial facilities remain safe and operational. For engineers designing in extreme conditions, GFRP is a trusted partner.

How GFRP Stacks Up Against Steel?

Rust and Corrosion: Steel rusts in wet or salty environments; GFRP doesn’t. It’s as simple as that.

Weight: GFRP is significantly lighter, making it easier to handle and transport.

Lifespan Costs: While GFRP costs more upfront, it saves money over time by reducing maintenance and repair needs.

Specialized Applications: GFRP’s non-conductive and corrosion-resistant properties make it perfect for unique projects that steel just can’t handle.

If your priority is long-term durability and minimal maintenance, GFRP wins every time.

Tips for Installing GFRP Rebar

Switching to GFRP isn’t complicated, but there are a few things to keep in mind:

Cutting Tools: Use diamond-blade saws for smooth, clean cuts. Regular tools for steel won’t work.

Tying: Stick with plastic or coated tie wires. Metal ties can damage GFRP or introduce issues over time.

Handle with Care: While GFRP is strong, it can be scratched if mishandled. Treat it gently during transport and installation.

Training: Make sure your crew understands how GFRP works. A little knowledge upfront can prevent big mistakes later.

With these tips, GFRP installation is straightforward and efficient.

Building for a Better Future

Every construction project leaves a legacy. GFRP rebar helps ensure that legacy lasts. By resisting rust, lowering maintenance needs, and standing strong in harsh conditions, it’s helping to create infrastructure that serves communities for generations.

It’s not just about saving money or building faster—it’s about peace of mind. When you choose GFRP, you’re choosing materials that work as hard as the people who build with them.

Conclusion

GFRP rebar isn’t just a replacement for steel—it’s an upgrade. Whether you’re building bridges, protecting coastlines, or reinforcing tunnels, it offers strength, durability, and a future free from rust and constant repairs.

In a world where infrastructure faces more challenges than ever, GFRP rebar stands out as a material built to last. If you want structures that endure, it’s time to make the switch. Because the only thing better than building strong is building smarter.

0 notes