n0wg0t0

29K posts

Don't wanna be here? Send us removal request.

Photo

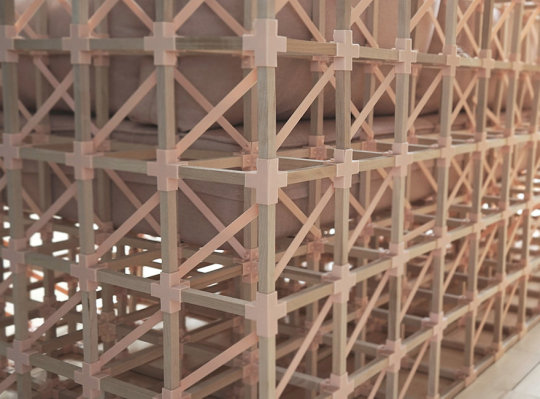

#HTE Reader Submitted: Disco Compacto 3d printed chair

The Disco Compacto Chair emerged from a desire to create something beautiful, unique, and sustainable that would challenge our relationship with furniture.

Dicco Compacto Chair

angle

assembly

back structure

View the full project here https://www.core77.com/projects/115765/Disco-Compacto-3d-printed-chair

4 notes

·

View notes

Photo

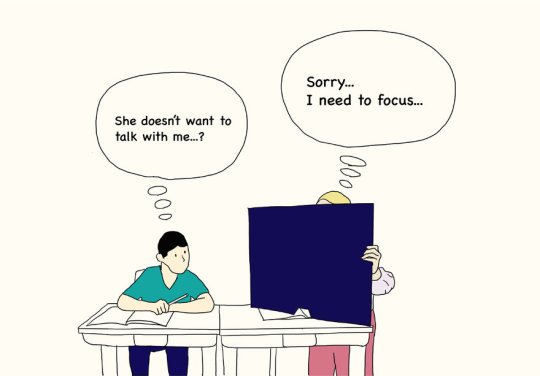

#HTE Reader Submitted: Forest - primary school desk partitions to help students with attention struggles

Have you ever caught yourself looking at the wall or a fly when you were supposed to focus on a lecture or work? I bet you have. Many people with ADHD experience this on daily basis with most of the activities. Japanese product designer and design researcher, Shion Ito jumped into a classroom of an elementary school in the Netherlands, where there were two students with ADHD who have difficulties focusing on their studies. With the goal of enabling all the students to feel connected with each other, he created a playful desk partition that encourages students to construct their physical bubble that helps them focus on their studies with other students.

The surrounding partitions help students to focus ontheir studies

students can create their original scenery

Students can chose how high and how densetheir Forest (partition) is

Slot profiles

Setting up of Forest

Separation between student who needs isolation to focus on their study and ones who doesn't need

Students construct their concentration bubble withother student.

Setting up of Forest

View the full project here https://www.core77.com/projects/115717/Forest-primary-school-desk-partitions-to-help-students-with-attention-struggles

1 note

·

View note

Photo

#HTE Reader Submitted: Newtons - a hand crafted sculpture using magnets to create tension

We always aim for "seemingly natural unnatural beauty." Although several products use magnets, their surfaces need to be flat for adsorption. However, what is innovative about Newtons is that the adsorption surface of the objects has been transformed into a perfect curve. Therefore, "fluctuation" occurs, and the surface does not remain stable while adsorbing with the exact appropriate strength. The fluctuating characteristic makes the objects, i.e., Newtons, seem like they are alive, creating a mild sense of discomfort with regard to space. Newtons may even become "a piece of everyday art." Coincidence and necessity create a free form.

newtons_1

newtons_2

newtons_3

newtons_4

newtons_5

newtons_6

newtons_7

newtons_8

View the full project here https://www.core77.com/projects/115768/Newtons-a-hand-crafted-sculpture-using-magnets-to-create-tension

5 notes

·

View notes

Photo

#HTE Traditional Japanese School Bag Colors Have Evolved

When I was living in Japan in the '90s, I saw a group of kindergarten-age kids all walking to school with the exact same comically-large leather backpack. A local explained to me that they were called randoseru, that they were based on a Dutch design, and that it was tradition in Japan for grandparents to purchase them (they're quite expensive*) for their grandchildrens' first day of school. All of the boys I saw carried black randoseru, and all of the girls had red ones; it didn't take a genius to figure out this was an informal rule.

That was over 20 years ago, and the rules have changed. The notion of gender-based color assignments now seems quaint even in tradition-obeying Japan, and randoseru manufacturer Tsuchiya Co. and others now offer them in a variety of shades, some of them riotous.

*Randoseru, by the way, run ¥56,000 to ¥140,000 (USD $439 to $1,098)! Talk about investing in a child's education.

https://www.core77.com/posts/115807/Traditional-Japanese-School-Bag-Colors-Have-Evolved

1 note

·

View note

Photo

#HTE Land Rover Announces New, Stretched Defender 130

Land Rover's new Defender, which was discontinued in 2016 and redesigned for its 2020 rollout, is an unusual proposition: A truly off-road-capable luxury vehicle with starkly modernist design principles.

While the original Defender's design seemed dictated by the limitations of 1980s sheet-metal-pressing capabilities, its off-road prowess earned it a cult following; would Defender lovers accept a radical redesign? Wasn't Defender's quirky utilitarian looks part of its charm?

Image: BoolaBoola2 at English Wikipedia

Auto designer Gerry McGovern, Jaguar Land Rover's Chief Creative Executive, and his design team have shown that they're willing to take risks. They worked on the new Defender's redesign for years, keeping all details secret. When pressed on what the new Defender would look like a few years ago, McGovern was mum, but confident:

"I haven't f*cked up yet," McGovern told Core77 in 2019, referring to his time as JLR's design chief since 2008, "and I'm damn sure not going to f*ck up with Defender."

The new Defender rolled out midyear in 2020 to rave reviews, and by 2021 was a confirmed sales hit, selling nearly as well as JLR's bestselling model, the Evoque. Anticipated sales of 5,000 units a month was closer to 7,000 per month (strong figures for a challenger brand), and probably would've been higher had the chip shortage not reduced supply.

This new Defender was introduced in two flavors, the stubby two-door Defender 90 (above) and the four-door Defender 110 (below).

Today the company announced they're rolling out a third, the stretched Defender 130, which adds the third row that consumers are demanding these days.

The Defender 130 has been lengthened by over a foot to deliver 2+3+3 seating, with each successive row raised for a stadium effect.

Despite lengthening the tail to provide more usable cargo space, the designers aren't jettisoning Defender's all-important off-road capabilities and have maintained a respectable departure angle; the 130 won't go where the 90 can, but drivers can still tackle a 28.5-degree slope.

Style-wise, the longer tail means "the surrounds for the rear LED lighting units have been re-engineered to maintain the three distinct lines that define Defender's side profile as they rise subtly towards the rear," the company writes.

As for the interior:

"Land Rover engineers have created an impressive interior space by effectively shrink-wrapping interior packaging components around the body-in-white, maximizing the amount of usable interior space, without the need for a large on-road footprint."

"The elegantly extended rear creates uncompromised accommodation in the third row, with enough width to provide comfortable seating for three adults, while the Defender's familiar outline ensures generous headroom in all three rows. Additional touches ensure a comfortable passenger experience in the third row, including heated seats, padded armrests, thoughtful storage and USB-C provision to charge devices on the move. "

Each row also gets their own vents; forget dual-zone climate control, the 130 has four-zone. For rear-seat passengers, side visibility is compromised by that crazy C-pillar, but a panoramic sunroof over the first and second rows, and an additional sunroof over the third row, is meant to provide an airier feeling.

The designers also added a techie feature to the tail: "From the tailgate, customers can simply lower the Defender's Electronic Air Suspension with buttons inside the load area to aid with loading items into the rear." That's a feature we want to see video of, but at press time the 130 announcement was fresh and no video assets were yet available. We'll update this entry when JLR starts rolling out clips.

https://www.core77.com/posts/115842/Land-Rover-Announces-New-Stretched-Defender-130

0 notes

Photo

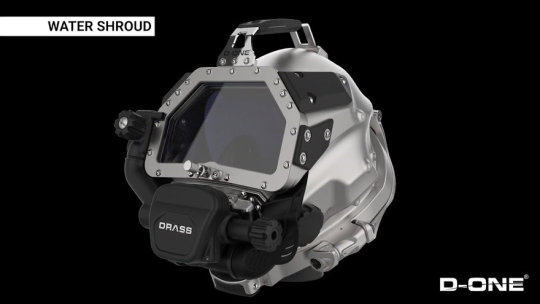

#HTE The Drass D-One Commercial Diving Helmet

"Attractive" might be the wrong word, but I do find beauty in a highly complicated form-follows-function object like this. This is the D-One Commercial Diving Helmet produced by Italian manufacturer Drass Galeazzi:

The design features a 30-degree angle in the back of the helmet, providing an improved range of motion and allowing the wearer to comfortably tilt their head back to look upwards.

The helmet can be kitted out with a camera, a light, a welding shield, a defogger and a water shroud (to protect the valves in debris-laden water).

To don or doff it, your head goes through this neoprene "neck dam" in the bottom.

This video gives you a look at how all of the features work:

https://www.core77.com/posts/115814/The-Drass-D-One-Commercial-Diving-Helmet

1 note

·

View note

Photo

#HTE Yea or Nay? A Weld-Free Bike Frame with "Mortise & Tenon" Joinery

Bike nerds, I need to hear from you: Are the welds on bike frames typically a problem?

An upstart manufacturer called Vanpowers Bike thinks so, and designed the frame of their City Vanture e-bike to be weld-free. "Many one piece frames are heated at high temperatures after welding," the company writes. "The frame tends to deform after being heated, and repeated manual correction and grinding will cause the frame to have a center deviation, resulting in an uneven and fragile frame structure that can be strenuous and unbalanced when riding." I'm not an avid cyclist, and had never heard that this was an issue.

"To resolve the problem," they continue, "City Vanture has an assembled frame with a symmetric deviation <1mm, the world's first electric bicycle to use this frame technology, making the riding smoother and better."

They designed the bike with what they refer to as "mortise & tenon"—and occasionally, "tenon & mortise" joinery, neither of which accurately describe their joint, at least from a woodworking perspective. "To make the frame more sturdy, City Vanture uses a tenon-and-mortise structure to ensure the stability of the electric bicycle. Woodworkers around the world have used tenon-and-mortise structures for thousands of years. They furnish a strong outcome and connect by either [sic] locking into place."

What they've in fact developed is kind of a scarf joint, at least axis-wise, whereby tubes are slid inside a connector at the joints. The connector is then bolted fast:

The bike arrives flatpacked, and the user assembles it. Here's the how-to video:

Bike people: Does this type of construction confer any actual advantage you can see, or is it a gimmick? Am sincerely curious.

https://www.core77.com/posts/115812/Yea-or-Nay-A-Weld-Free-Bike-Frame-with-Mortise-n-Tenon-Joinery

0 notes

Photo

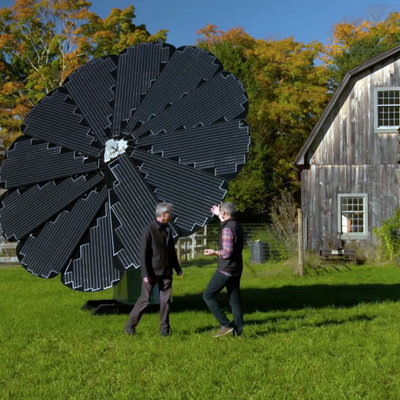

#HTE The Smartflower Ground-Based Solar System

My wife and I recently drove past the house of a neighbor who had solar panels installed during the pandemic. Because the house is in a shaded location, the panels were installed in a low-to-the-ground array in the yard. It's really unattractive. I didn't want to ask them for permission to photograph their yard, so I found this photo online that's close to what it looked like:

I applaud their decision to go solar, and would never volunteer my opinion of what it looks like, but I wondered if there isn't a more attractive solution to ground-mounted solar panels. What I found is the Smartflower, an invention from Austria that's been acquired by Boston-based Energy Management Inc.:

The Smartflower is inspired by sunflowers: It folds its "petals" up at night, with the sweeping action cleaning the panels. In the morning it unfurls them and, impressively, tilts to receive the sunlight at 90 degrees, and rotates to follow the sun's path throughout the day.

The renders made me suspicious it was nothing more than a concept. But this video from This Old House shows the system in action, and also shows the installation process:

I think the $30,000 price cited for the 5KW unit shown is competitive, particularly with that 30% incentive. I would like to see the design evolve a bit more—it has the air of being a 1.0—but I think it's a damn sight better-looking than the ground-based arrays I've seen online and down the road.

https://www.core77.com/posts/115806/The-Smartflower-Ground-Based-Solar-System

0 notes

Photo

#HTE Nike-Level Footwear Design Applied to Medical Protective Boot

Over the course of his career, industrial designer Michael DiTullo has designed everything from consumer electronics to soft goods, from toys to automotive work and, in his time at Nike and with the Jordan Brand, plenty of footwear for famous basketball players. But a year or two ago, he was at this stage on a multi-year project for a rather unusual piece of footwear without a well-known athlete's name attached:

That is—or ultimately would become—the Foot Defender. Technically speaking it's a revolutionary piece of medical kit, and one that could save tens of thousands of people from having their foot amputated each year.

If we're talking target markets, you might struggle to think of what professional basketball player has in common with a diabetic that's developed DFU (Diabetic Foot Ulcers). After all, elite ballers earn their living on two feet; people suffering from DFU have a 24% chance of having one of their lower extremities amputated within 6-18 months.

What they have in common is a need for precisely-designed footwear. Elite athletes with sponsorship deals get that attention, with footwear designers crafting shoes with support or flexibility in the areas preferred by the athlete. Those with DFU could use that same design attention, but until a certain Dr. Hanft came up with an idea, they have not received it.

To explain, when someone has diabetes, they can sustain nerve damage that prevents them from feeling foot pain. When someone without diabetes develops a blister, cut or scrape on their foot, they can feel it and take care of it, taking it easy on that foot. But a diabetic often can't feel that injury, and what started out as a treatable blister can turn into an ulcer. Then, the reduced blood flow that diabetics experience in the lower extremities slows the rate of healing, and that ulcer can become infected. If that infection spreads to the bone, it can lead to an amputation.

So how often does that actually happen? "Every 20 seconds someone loses a limb due to complications with diabetes, a condition that is 100% preventable," says DiTullo. "From 2009 to 2015, lower extremity amputations for diabetic patients increased by 50%.... This is unacceptable." The American Diabetes Association estimates these amputations to number from 80,000 to 100,000 each year.

DiTullo learned of the issue after being contacted by Dr. Jason Hanft, a Florida-based expert in lower extremity medicine and surgery, limb salvage, wound care and clinical research. Years ago he himself had suffered a grievous foot injury, and "As part of his treatment, Dr. Hanft was required to wear the same medical devices he prescribed to his patients, giving him first-hand experience with the pain points of each device," writes the company he founded, Defender. "From here, Dr. Hanft was driven to create a better healing experience with Defender's suite of foot care products."

You might wonder why an in-demand and practicing doctor--one who's today regarded in his industry as a foremost expert on foot injuries--would attempt to divide his time with starting a product company. The answer, paradoxically, is time; Dr. Hanft can only see one patient at a time, and the power of mass production is multiplication.

"As many professionals do, once you become competent at your profession you try to find ways to reach or help more people," Dr. Hanft told Core77. "My reach was limited to the hours I had to work. By actually solving problems and launching a business, you exponentially expand your reach. Addressing the issue of the utilization of protective devices seemed only natural after years of work in wound care."

Dr. Hanft had learned that the number of amputations among diabetics was rising each year; investigating why, he learned that patients with DFU typically didn't like wearing the supposedly corrective devices they were prescribed, which were just generic, bulky and ineffectual foot-covering objects designed for catch-all foot/ankle injuries. He then developed an idea for purposefully-designed medical footwear that people would want to wear, and that could help prevent amputations among those with DFU.

Dr. Hanft reached out to a local investment firm for help. They weren't interested in pursuing the project, but the firm's principal had seen DiTullo's work, suggested the two of them talk, and put them in touch. Given DiTullo's credentials--his designs had graced the likes of elite basketball players like Carmelo Anthony and Dwyane Wade--Dr. Hanft was initially skeptical that this was up DiTullo's alley, but luckily he was wrong. "From our first conversation," Dr. Hanft says, "it was clear Michael was like-minded in trying to help people and use his skills to improve others."

After Dr. Hanft explained the problem, DiTullo looked at the existing protective boots prescribed to those with DFU, and found this:

DiTullo signed on to the project, excited, as he saw "a massive opportunity to bring a product that someone would actually be proud to wear to a space that's highly stigmatized."

The goal: "Let's make a protective boot that performs better, is easier to put on properly, and aesthetically is something a person would actually want to wear."

DiTullo started out with gestural concept sketches that envisioned a piece of footwear with rigid side bracing:

Eventually the design evolved into the concept below, which featured an "injection-molded bucket," as DiTullo describes it, to cradle the foot:

But prototype after prototype, in testing, were not delivering satisfactory results. "We still were getting too much motion" from the test wearers, DiTullo recounts.

"And then like in so many projects, there's just a simple breakthrough that comes from frustration," DiTullo says. In a meeting with Dr. Hanft, DiTullo suggested "Why don't we stop trying to make this like a medical device, and start making it a lot more like a shoe? We're trying and failing so much with these molded components; let's do a simple, very durable rubber cup sole, a textile and leather upper, like a sneaker, and that will allow us to experiment below the skin [of the shoe] and tune everything exactly the way we want it."

With Dr. Hanft signing off on the new approach, DiTullo sketched this:

Gone were the rigid sides, replaced by more sneaker-like outer materials, with the intent of adding inner materials that would do the heavy lifting. DiTullo continued evolving the design, but spotted a new problem: Getting the shoe on and off. To counter this, he designed a removable spat for the front, with a carbon-fiber insert that maintained the curved shape and offered protection, while also providing an easy-grab surface than even someone with limited mobility or limited fingertip sensitivity could get ahold of and remove.

With the outer surface of the shoe established, extensive prototyping and testing began on the all-important unseen internal parts that would be doing the protective work inside the shoe. DiTullo drew on his footwear experience to create a cocktail of materials distributed in different locations: Some soft EVA here, medium-density foam there, high-compression foam here, some Absorbium (a visco-elastic polymer) there. Add a pneumatic system so users can dial in the fit to perfectly suit their foot. Shake. Serve. Test. Revise.

And DiTullo, of course, wasn't working in a vacuum: There was a lot of back-and-forth between Dr. Hanft, former Nike developer Drew Linth, podiatrists, surgeons, biomedical engineers, movement experts, material scientists, production specialists, not to mention the feedback from Dr. Hanft's thousands of patients.

Drew Linth and Michael DiTullo keep it rolling during the pandemic

Dr. Hanft, right, and a patient wearing the Foot Defender

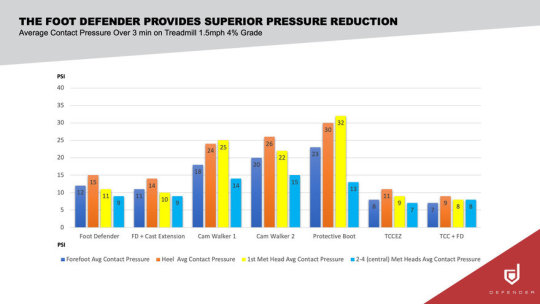

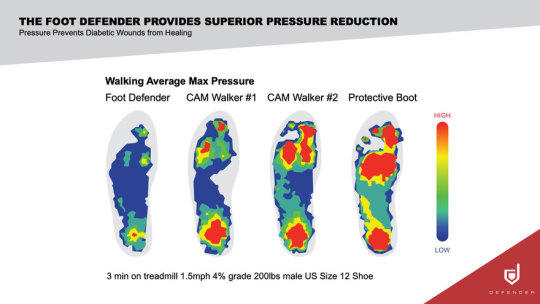

Finally--after 39 iterations--they achieved the testing results they were looking for, which demonstrated a clear advantage:

When stacked up against the competition, the Foot Defender, as the new product was christened, reduced pressure across the foot by up to 50%. "Whether standing or walking," Defender writes, "Foot Defender outperforms alternatives through innovative design resulting in a first-rate healing environment for the foot."

"The Foot Defender is specifically designed to reduce pressure on the bottom of the foot through a combination of locking the ankle at a specific angle, negative heel drop raising the balls of the feet, and a proprietary viscoelastic material under the foot called Absorbium. In addition to being functionally superior, the Foot Defender is easy to put on properly and take off due to its unique removable spat design."

"The Foot Defender looks more like an athletic shoe and less like a medical device to reduce the visual stigma of needing to wear the product. Unused products fail 100% of the time so we designed the Foot Defender to be acceptable to be worn daily until the patient is healed."

All told the entire process took over five years. DiTullo even went the extra mile after seeing the user manuals for competing products, which looked like "something typed up on Microsoft Word and shoved into a polybag." Instead DiTullo used visuals to create a more easily comprehensible guide:

He also designed eye-catching packaging to communicate the design difference of the product. (From an efficiency standpoint, note that the shapes can be nested for palletization and shipping.)

Foot Defender finally hit the market late last year, and is already in use in diabetes clinics across the country.

DiTullo is used to seeing sketches on paper turned into real-life production models, but Dr. Hanft was not. Upon seeing the finished product, "My thoughts were amazement," he says, "that our team and a large group of caring consultants had actually taken our ideas and turned it into a reality."

"The Foot Defender has the potential to help millions of diabetics every year."

DiTullo, too, is stoked: "I feel like I got to use my decades of footwear design experience for something really good and helpful."

https://www.core77.com/posts/115818/Nike-Level-Footwear-Design-Applied-to-Medical-Protective-Boot

1 note

·

View note

Photo

#HTE The 3D-Printed Mythos Elix Bike Stem

UK-based Metron Additive Engineering uses innovative design and digital fabrication to create high-end medical, aerospace, automotive and bicycle components. The company was founded by Dimitris Katsanis, a cycling enthusiast and engineer, whose bio states that Metron has created bike components used to win over 100 gold medals in Olympics and World Championship events.

While those components were specifically crafted for individual cyclists and teams, Katsanis has now formed Mythos, a retail spin-off, to sell Metron's bike components to the public. This week they announced their first product, the Elix bike stem.

Designed using FEA (Finite Element Analysis) to calculate load paths, the unusual-looking and lightweight (~150g) part is DMLS (Direct Metal Laser Sintering) 3D printed in Scalmalloy, an alloy of scandium, aluminum and magnesium. The unique shape is said to maximize stiffness during sprints while better soaking up vibration on rough surfaces.

"Having been designed specifically around the most extreme load-paths experienced by a stem, the Elix stem is 15% stiffer in torsion than an equivalent alloy stem while maintaining the same bending stiffness, so you can put more power down when you need to and still stay comfy on the rough stuff."

There is one type of shock the Elix can't help absorb, that of sticker. They run £500 (USD $627).

https://www.core77.com/posts/115805/The-3D-Printed-Mythos-Elix-Bike-Stem

1 note

·

View note

Photo

#HTE NASA Exploring Solar Sailing Technology, Turning Sun's Rays Into Thrust

Long-distance ocean travel began with watercraft using zero-emission propulsion systems. Gigantic sails harnessed the power of the wind.

As technology developed, oceangoing craft switched to fossil-fuel-based propulsion.

Fascinatingly, spacecraft may be taking the opposite trajectory: Our first rockets traveled through space by burning fuel, but now NASA is looking into enormous solar sails that would turn the sun's energy into thrust. This week they announced the NASA Innovative Advanced Concepts Program is working on a system they call Diffractive Solar Sailing. "Solar sail propulsion uses sunlight to propel vehicles through space, much the way wind pushes sailboats across water," NASA writes.

Yeah, but how?

"The technology uses solar photons—sunlight—which are reflected off giant, mirror-like sails made of lightweight, reflective material 40 to 100 times thinner than a piece of writing paper. The continuous photonic pressure provides enough thrust to perform maneuvers, such as hovering at a fixed point in space and rotating the space vehicle's plane of orbit, which would require too much propellant for conventional rocket systems. Because the Sun supplies the necessary propulsive energy, solar sails also require no onboard propellant, thus reducing payload mass."

Image: MacKenzi Martin, via NASA

The "diffractive" in Diffractive Solar Sailing refers to the trick of using "small gratings" to diffract light that passes through it, spreading that light across the surface of the sail. "This would allow the spacecraft to make more efficient use of sunlight without sacrificing maneuverability," NASA says.

If the sails actually will be rainbow-colored, as in the rendering, I'd imagine a number of organizations—Skittles, Pride, the state of Hawai'i—might be interested in sponsorship deals.

Solar sails were been depicted in the sci-fi movie Alien: Covenant (albeit for charging purposes rather than propulsion), and while they weren't rainbow-colored, they looked pretty cool. In the first clip below, the sails are deployed; in the second, crew members work to repair damaged sails.

https://www.core77.com/posts/115804/NASA-Exploring-Solar-Sailing-Technology-Turning-Suns-Rays-Into-Thrust

0 notes

Photo

#HTE Wearable Sensors That Turn Your Body's Movements Into Music

The SOMI-1 is a fascinating object created by Instruments of Things, a Germany-based music technology company. It's a wearable sensor that turns movement into sound, which essentially enables you to use your body as a musical instrument. I know that sounds weird, but watch the demo and you'll get it right away:

IoT says the sensors are highly precise, and contain eight motion parameters: Velocity, slew, acceleration in three axes, and tilt in three axes.

While the application seems geared towards performance art, I wonder if the system would be of use in a physical therapy/rehabilitation environment; for example, if it produced different chimes or tones when you moved in the "right" or "wrong" way. At this point the sensors are only meant to be worn on the wrists or ankles, but if they covered a greater range of joints, I could see that being useful in any field attempting to formalize gestures and motion; say, martial arts instruction or sports training. I also think they might be fun for kids to use in a physical education setting.

The SOMI-1's are not cheap: A kit with the receiver and two sensors were selling for $427 during their concluded and successful crowdfunding campaign, and the price was advertised as being 40% off; that puts the expected retail for the kit at $712. While that might place them out of reach for less-than-well-funded organizations, prices are bound to come down over time.

https://www.core77.com/posts/115793/Wearable-Sensors-That-Turn-Your-Bodys-Movements-Into-Music

0 notes

Photo

#HTE Mizugomo: Unusual Ninja Footwear

In Mie Prefecture, Japan, is the Iga-Ryu Ninja Museum. My scout learned of this on the Instagram of Hiroshi Seki (Muji's former Director of Industrial Design and founder of Seki Design Lab). Seki posted this shot from the museum's exhibition of ninja tools:

I was eager to see more, but the museum's website doesn't have many photos. However, I found the blog of Japanese resident Manisha Kundu-Nagata, who visited the museum nearly a decade ago and wrote a comprehensive entry on the experience. She posted this photo of specialty ninja footwear called mizugomo, which translates to "water spider:"

Image: Manisha Kundu-Nagata

To explain, some Japanese castles were surrounded by marshy moats or flooded rice paddies. These were impossible for invaders to swim through and difficult to traverse on foot. The mizugomo were developed as the solution. They're essentially snowshoes for marshy conditions.

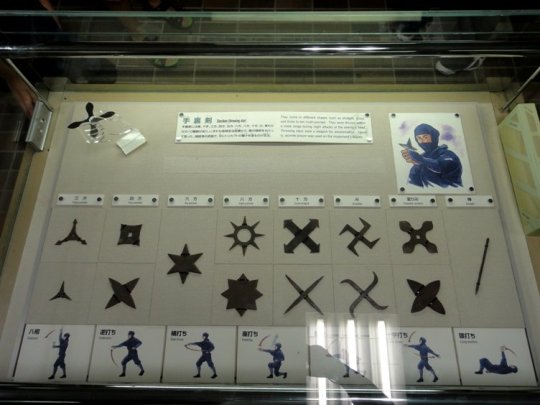

Kundu-Nagata also posted photos of a variety of weapons and tools with detailed descriptions:

"Second display case exhibiting 1) Makibashi (caltrops), 2) Manrikigusari (chain & weight), 3) Sojingama (double-edged sickle), 4) Shuriken (throwing stars), 5) Kusarigama (sickle & chain), 6) Fundo tsubute (throwing weights), and 7) Fukiyazutsu (blowgun)" - Image: Manisha Kundu-Nagata

"Third display case exhibiting Shuriken stars of different shapes" - Image: Manisha Kundu-Nagata

I don't want to rip off her entire blog, so if you'd like to see more, do click over to her entry. There's enough interesting stuff that if I were in that area of Japan, I'd definitely drop by the museum.

https://www.core77.com/posts/115792/Mizugomo-Unusual-Ninja-Footwear

0 notes

Photo

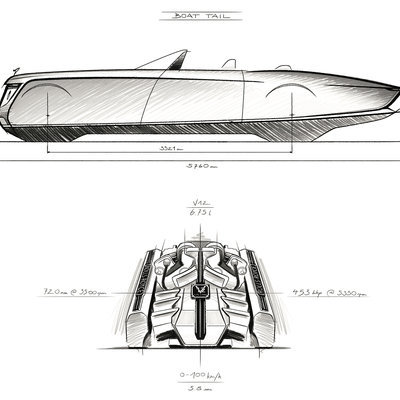

#HTE Design Sketchs and Build Shots of Rolls-Royce's Latest Boat Tail

Rolls-Royce has unveiled another bespoke Boat Tail, a hand-built car built for a specific client that apparently enjoys having car-based picnics. While the car itself is beautiful, cost $30 million to make, blah blah blah…

…what I found interesting is that they also released design sketches and renders…

…as well as actual build shots. What does $30 million get you, in terms of design? The price tag does warrant a full-scale clay model:

It looks like they then transfer those dimensions to a forming buck…

…on which they shape the aluminum panels:

Unfortunately we don't get to see any of the finishing or interior work, the image dump just jumps from there to the finished product.

"The result," says Alex Innes, RR's Head of Coachbuild Design, "far exceeds a means of conveyance to become, quite literally, a moving work of art."

https://www.core77.com/posts/115791/Design-Sketchs-and-Build-Shots-of-Rolls-Royces-Latest-Boat-Tail

1 note

·

View note

Photo

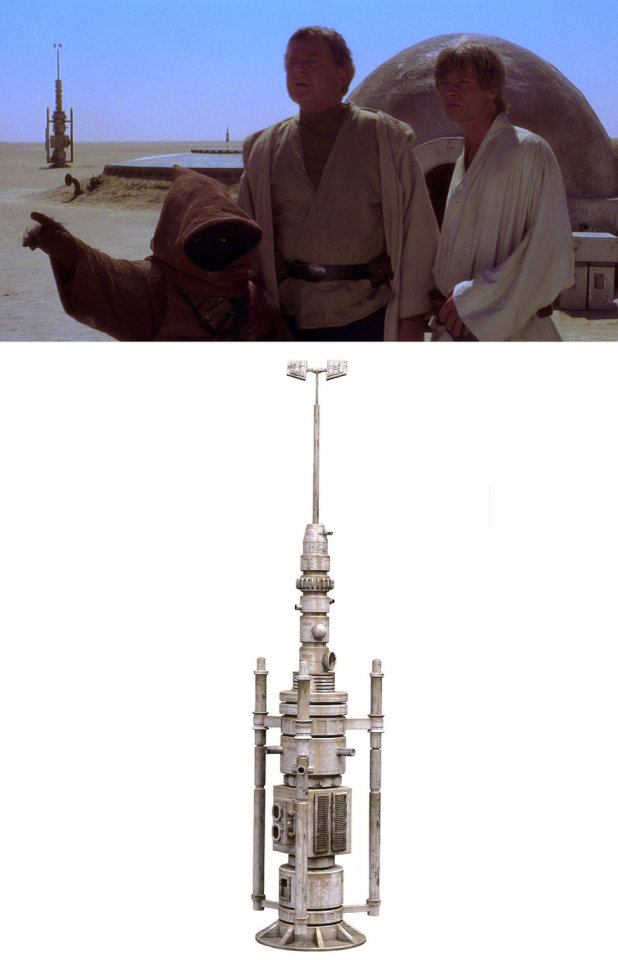

#HTE Researchers Create Gel That Can Harvest Water Out of Dry Air

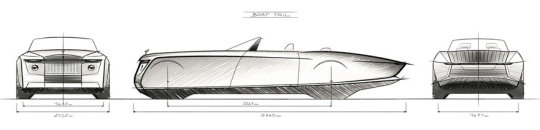

In Star Wars, the Skywalker family are introduced as "moisture farmers." On their desert planet, they somehow pull water out of the sky using towering metal structures, which sounds more sci-fi than placing buckets under in-window air conditioners.

Researchers at UT Austin have developed a material that can actually produce water out of thin air, and it doesn't involve any metal towers or drippy A/C units. Instead they've concocted a simple, low-cost gel—apparently something even you or I could make in our kitchen—with astonishing properties. When placed in an area with 30% relative humidity, 1kg of the stuff can produce 13 liters (3.4 gallons) of water a day. (For reference's sake, Arizona and Nevada have average relative humidities around 38%.) Even when placed in a bone-dry climate of just 15% humidity, the gel can still generate 6 liters (1.6 gallons) daily.

"This new work is about practical solutions that people can use to get water in the hottest, driest places on Earth," said Guihua Yu, professor of materials science and mechanical engineering in the Cockrell School of Engineering's Walker Department of Mechanical Engineering. "This could allow millions of people without consistent access to drinking water to have simple, water generating devices at home that they can easily operate."

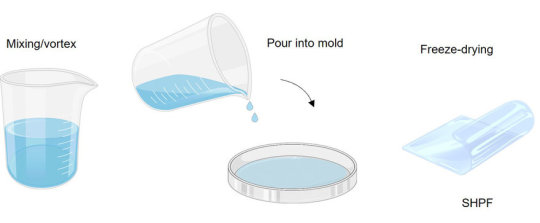

So how does it work? The gel, called SHPF (super hygroscopic polymer film) is made from just two ingredients: Konjac gum, a common food additive made from the root of the konjac plant, and cellulose, i.e. plant fiber. The konjac gum is what absorbs the water from the air. The cellulose has been somehow engineered to be thermo-responsive (details aren't provided) and is hydrophobic, so they shed the water when heated.

Making the gel is apparently cheap--$2 yields enough material to produce 1kg—and straightforward: The two ingredients are mixed and poured into a mold, where they reportedly set in two minutes. The mold is then freeze-dried, after which it's ready to use.

"This is not something you need an advanced degree to use," said Youhong "Nancy" Guo, the lead author on the paper and a former doctoral student in Yu's lab, now a postdoctoral researcher at the Massachusetts Institute of Technology. "It's straightforward enough that anyone can make it at home if they have the materials."

The research was funded by the U.S. Department of Defense's Defense Advanced Research Projects Agency (DARPA), and drinking water for soldiers in arid climates is a big part of the project. However, the researchers also envision this as something that people could someday buy at a hardware store and use in their homes because of the simplicity.

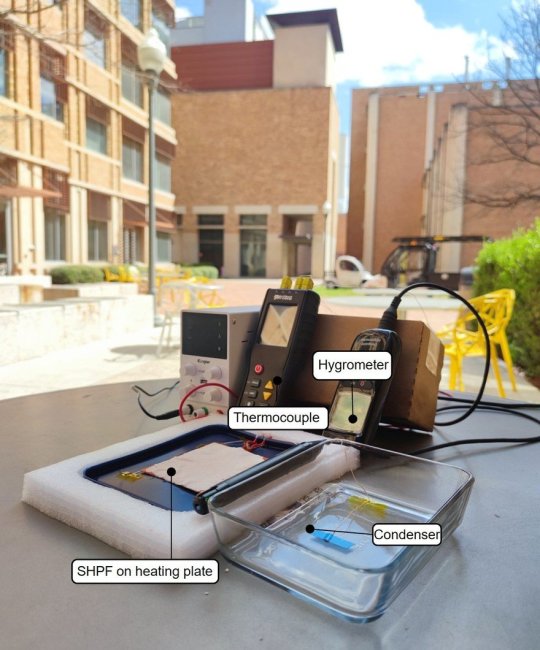

The gel can easily be cut into different shapes to suit whatever vessel or contraption it's meant to inhabit. Which brings us to the next thing needed to realize this technology: Design. The lab-built equipment used to prove the technology looks like what you'd expect from a lab:

I think a good next step would be to pair with an Industrial Design program and have the students work on forms and UI/UX.

https://www.core77.com/posts/115790/Researchers-Create-Gel-That-Can-Harvest-Water-Out-of-Dry-Air

0 notes

Photo

#HTE Riding a Bicycle with an Omnidirectional Front Wheel

We looked at a wide variety of applications for omnidirectional wheels, or Mecanum wheels, here. And we saw at least one guy claim to have installed them on his Toyota. But one applications we'd never thought of was to put one on a bicycle.

After all, what would the point of that be? For engineer and former toy designer James Bruton, curiosity is enough of an end in itself. Thus he hacked together this bike with a transverse-mounted omni-wheel up front, to see how it would ride. (If you want to skip the fabrication part, the riding starts around 11 minutes in.)

https://www.core77.com/posts/115785/Riding-a-Bicycle-with-an-Omnidirectional-Front-Wheel

0 notes

Photo

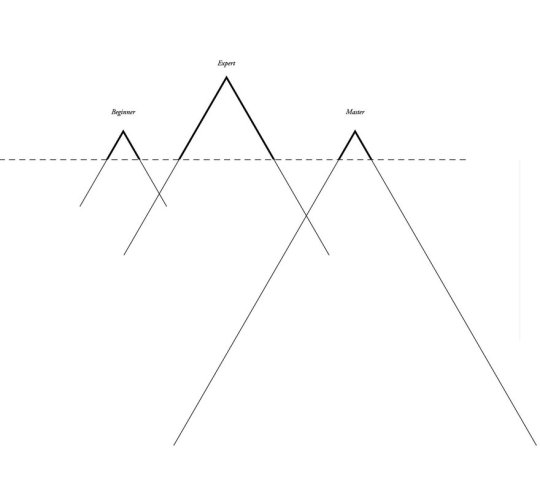

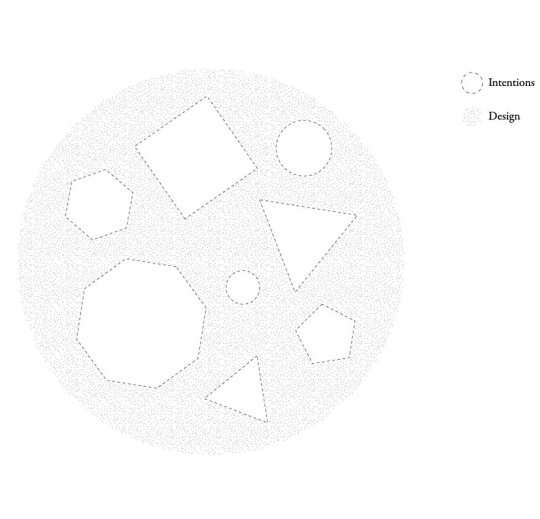

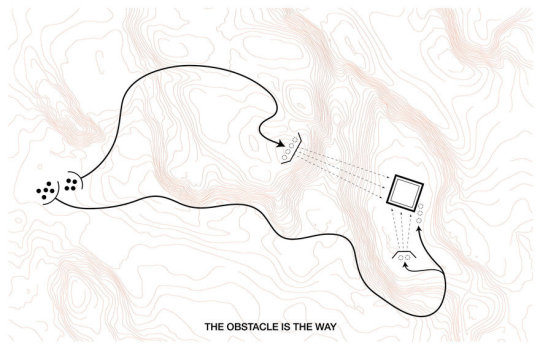

#HTE Joey Roth's Letterpress Posters Now Available as Digital Files

Joey Roth is now selling the original files for his letterpress posters, which perfectly express certain situations, feelings and personality types we've all encountered as designers.

For $8.95 a pop, you can "Print them at any size. Use them digitally. Build tool paths for engraving or laser cutting," Roth writes. "Your purchase entitles you to an unlimited personal use license. For commercial use, please get in touch."

Check 'em out here.

https://www.core77.com/posts/115784/Joey-Roths-Letterpress-Posters-Now-Available-as-Digital-Files

0 notes