Don't wanna be here? Send us removal request.

Text

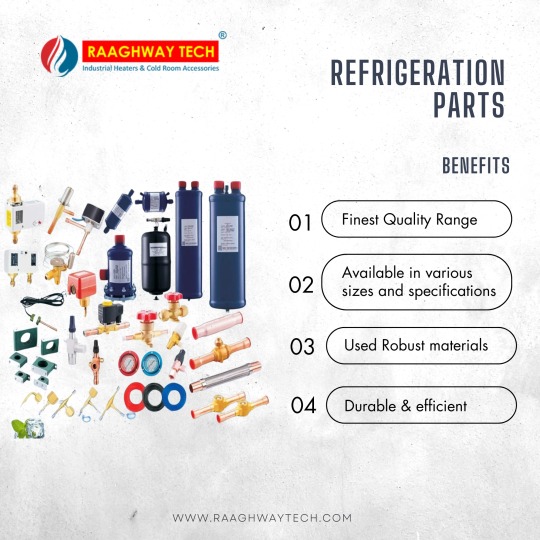

Refrigeration Parts: Essential Components for Efficient Cooling Systems

Refrigeration systems are the backbone of various industries, including food processing, pharmaceuticals, cold storage, and more. The efficiency and performance of these systems rely heavily on the quality and reliability of their components. Refrigeration parts are integral to maintaining optimal cooling, reducing energy consumption, and ensuring long-term operational efficiency.

In this blog, we’ll explore the key refrigeration parts, their functions, applications, and why Raghav Industries is a trusted supplier of premium refrigeration components.

What Are Refrigeration Parts?

Refrigeration parts encompass a range of components that work together to regulate temperature, circulate refrigerants, and maintain the functionality of cooling systems. From compressors and evaporators to valves and coils, each part plays a crucial role in ensuring the system operates efficiently and reliably.

Key Refrigeration Parts and Their Functions

1. Compressor

The compressor is the heart of the refrigeration system. It compresses the refrigerant, raising its pressure and temperature, and circulates it through the system. A high-quality compressor ensures consistent cooling and energy efficiency.

2. Condenser

The condenser is responsible for releasing heat absorbed by the refrigerant. It converts the high-pressure gas from the compressor into a liquid, preparing it for the next stage of the cooling cycle.

3. Evaporator

The evaporator absorbs heat from the surrounding environment or materials being cooled, turning the liquid refrigerant into gas. This is where the actual cooling takes place.

4. Expansion Valve

The expansion valve regulates the flow of refrigerant into the evaporator, ensuring optimal pressure and temperature for efficient heat absorption.

5. Refrigerant

The refrigerant is a fluid that absorbs and transfers heat within the system. Modern refrigerants are designed to be environmentally friendly while delivering high performance.

6. Fan Motors

Fans circulate air over the evaporator and condenser coils, improving heat exchange and maintaining consistent cooling.

7. Filters and Driers

Filters and driers remove moisture and contaminants from the refrigerant, protecting the system from damage and ensuring smooth operation.

8. Thermostats and Sensors

These components monitor and regulate the temperature within the system, ensuring it operates within the desired range.

Benefits of High-Quality Refrigeration Parts

1. Enhanced System Efficiency

Premium components ensure that the system operates efficiently, reducing energy consumption and operational costs.

2. Longevity and Reliability

Durable and high-quality parts extend the lifespan of refrigeration systems and minimize the risk of breakdowns.

3. Consistent Cooling

Reliable refrigeration parts maintain stable temperatures, ensuring the integrity of perishable goods and temperature-sensitive products.

4. Easy Maintenance

Well-designed components simplify maintenance, reducing downtime and service costs.

5. Environmental Compliance

Modern refrigeration parts are designed to be eco-friendly, using refrigerants and materials that comply with environmental regulations.

Applications of Refrigeration Parts

Refrigeration parts are used across a variety of industries and applications, including:

1. Cold Storage

Essential for preserving perishable goods like fruits, vegetables, dairy, and meat in cold storage facilities.

2. Food and Beverage

Used in commercial refrigeration systems for restaurants, supermarkets, and food processing plants.

3. Pharmaceuticals

Maintain precise temperature control for medicines, vaccines, and laboratory samples.

4. HVAC Systems

Key components in air conditioning and ventilation systems for residential, commercial, and industrial spaces.

5. Transportation

Integrated into refrigerated trucks and containers for transporting temperature-sensitive goods.

6. Industrial Cooling

Used in cooling towers, chillers, and process cooling systems for industrial applications.

Why Choose Raghav Industries for Refrigeration Parts?

Raghav Industries, based in Delhi, India, is a leading supplier of premium refrigeration parts tailored to meet the needs of diverse industries. Here’s why businesses trust our products:

1. Comprehensive Range

We offer a wide selection of refrigeration components, from compressors and condensers to thermostats and filters, catering to various system requirements.

2. High-Quality Materials

Our parts are crafted from durable and corrosion-resistant materials, ensuring reliable performance and longevity.

3. Customization

We provide components in various sizes, capacities, and configurations to suit specific applications and systems.

4. Energy Efficiency

Our parts are designed to enhance system efficiency, reducing energy consumption and operational costs.

5. Expert Support

From product selection to installation and after-sales service, we offer end-to-end support to ensure customer satisfaction.

How to Select the Right Refrigeration Parts

When choosing refrigeration parts, consider the following factors:

System Compatibility: Ensure the parts are compatible with your refrigeration system’s design and capacity.

Durability: Select components made from high-quality materials to withstand operational demands and environmental conditions.

Energy Efficiency: Opt for parts that contribute to reducing energy consumption without compromising performance.

Regulatory Compliance: Verify that the components meet environmental and safety standards.

Supplier Reputation: Choose a trusted supplier like Raghav Industries to ensure reliable and high-performance parts.

Why Refrigeration Parts Are Essential

High-quality refrigeration parts are the backbone of efficient and reliable cooling systems. They not only ensure consistent performance but also reduce operational costs, extend system lifespan, and maintain the integrity of temperature-sensitive goods.

Conclusion

Investing in high-quality refrigeration parts is crucial for maintaining the efficiency, reliability, and longevity of cooling systems. Whether you’re operating a cold storage facility, running a food business, or managing HVAC systems, the right components make all the difference.

At Raghav Industries, we take pride in offering premium refrigeration parts that cater to a variety of industries and applications. With our products, you can optimize your system’s performance and achieve reliable, long-term cooling solutions.

Learn more about our Refrigeration Parts here.

0 notes

Text

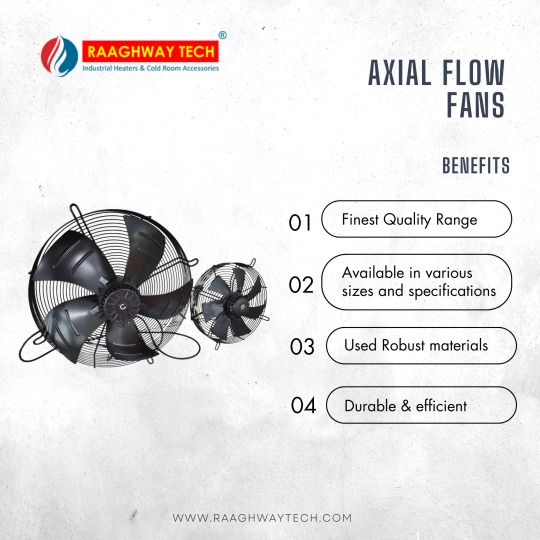

Enhance Airflow Efficiency with Axial Flow Fans

In industrial and commercial setups, efficient air movement is essential for maintaining proper ventilation, cooling, and temperature control. Axial flow fans are among the most effective solutions, designed to move large volumes of air efficiently while consuming minimal energy. With their robust construction and versatility, axial flow fans play a crucial role in industries like HVAC, manufacturing, and power generation.

This blog explores the functionality, benefits, applications, and features of axial flow fans while highlighting why Raghav Industries is a leading provider of high-quality axial flow fans.

What is an Axial Flow Fan?

An axial flow fan is a type of fan that moves air or gas parallel to the fan’s axis. Its design consists of blades mounted around a central hub, which is powered by an electric motor. The blades create a pressure differential that propels air in a straight, streamlined flow.

Axial flow fans are known for their high efficiency in moving large volumes of air with low power consumption, making them ideal for both industrial and commercial use.

How Do Axial Flow Fans Work?

Axial flow fans operate by converting rotational energy from the motor into kinetic energy in the air. As the fan blades rotate, they create a pressure difference that draws air into the fan and pushes it out in the same direction. This design ensures efficient airflow with minimal turbulence.

Depending on the application, axial flow fans can be equipped with additional features such as variable speed drives or noise-reduction technologies for enhanced performance.

Key Features of Axial Flow Fans

1. High Airflow Efficiency

Axial flow fans are designed to move large volumes of air with minimal energy usage, making them highly efficient for ventilation and cooling.

2. Durable Construction

Built with high-quality materials like aluminum, steel, or composite plastics, these fans are resistant to wear, corrosion, and extreme temperatures.

3. Versatile Design

Available in a variety of sizes, blade configurations, and mounting options, axial flow fans can be customized for specific applications.

4. Low Noise Levels

Advanced aerodynamic blade designs reduce turbulence, ensuring quiet operation even at high speeds.

5. Easy Maintenance

The simple construction and robust design make axial flow fans easy to maintain, reducing downtime and operational costs.

Benefits of Axial Flow Fans

1. Improved Ventilation

Axial flow fans provide efficient air circulation, ensuring proper ventilation in enclosed or large spaces.

2. Cost-Effective Operation

With their energy-efficient design, these fans reduce power consumption and lower operational costs.

3. Versatility

Axial flow fans can handle a variety of applications, from cooling systems to industrial ventilation, making them highly adaptable.

4. Enhanced Durability

Their sturdy construction ensures long service life even in demanding industrial environments.

5. Reduced Environmental Impact

By optimizing airflow and reducing energy usage, axial flow fans contribute to sustainable operations.

Applications of Axial Flow Fans

Axial flow fans are widely used across industries for their ability to handle large-scale air movement effectively. Common applications include:

1. HVAC Systems

Axial flow fans are a core component of heating, ventilation, and air conditioning systems, providing efficient air circulation and cooling.

2. Industrial Ventilation

Used in factories and warehouses to expel heat, fumes, or pollutants, ensuring a safe and comfortable working environment.

3. Power Plants

Axial flow fans are critical for cooling turbines, condensers, and other equipment in power generation facilities.

4. Cooling Towers

These fans ensure efficient heat dissipation in water cooling systems for industrial processes.

5. Agriculture

Axial flow fans are used in greenhouses, barns, and storage facilities to maintain optimal air quality and temperature.

6. Mining and Tunneling

In underground operations, axial flow fans provide ventilation to maintain air quality and worker safety.

Why Choose Raghav Industries for Axial Flow Fans?

Raghav Industries, based in Delhi, India, is a trusted name in manufacturing and supplying high-performance axial flow fans. Here’s why businesses prefer our products:

1. Superior Quality

Our fans are made from premium materials, ensuring durability, reliability, and consistent performance in demanding environments.

2. Customization

We offer axial flow fans in various sizes, blade designs, and configurations to meet the unique requirements of your application.

3. Energy Efficiency

Designed with advanced aerodynamics, our fans deliver maximum airflow while minimizing energy consumption.

4. Noise Reduction

Our fans are engineered to operate quietly, even in high-speed settings, ensuring a comfortable environment.

5. Expert Support

From product selection to installation and after-sales service, we provide comprehensive support to ensure customer satisfaction.

How to Choose the Right Axial Flow Fan

When selecting an axial flow fan, consider the following factors:

Airflow Requirements: Determine the volume of air the fan needs to move and match it with the fan’s capacity.

Operating Environment: Consider factors like temperature, humidity, and exposure to corrosive substances when choosing the fan’s material and design.

Noise Levels: For applications where quiet operation is essential, select fans with noise-reducing features.

Energy Efficiency: Opt for fans with high efficiency to reduce power consumption and operational costs.

Mounting Options: Ensure the fan’s design is compatible with your setup, whether wall-mounted, ceiling-mounted, or freestanding.

Our experts at Raghav Industries can guide you in selecting the ideal axial flow fan for your needs.

Why Axial Flow Fans are Essential

In industrial and commercial operations, maintaining efficient airflow is critical for productivity, safety, and energy efficiency. Axial flow fans provide a reliable and cost-effective solution for large-scale air movement, making them a valuable asset in diverse applications.

Conclusion

Axial flow fans are a versatile and efficient solution for air circulation and cooling in industrial and commercial settings. Their ability to deliver high airflow with low energy consumption makes them a preferred choice for businesses seeking sustainable and reliable ventilation solutions.

At Raghav Industries, we take pride in offering premium axial flow fans tailored to meet your specific requirements. Whether you need fans for HVAC systems, cooling towers, or industrial ventilation, we have the expertise and products to enhance your operations.

Learn more about our Axial Flow Fans here.

0 notes

Text

Immersion Heaters: Reliable Solutions for Liquid Heating

Efficient liquid heating is essential in industries ranging from manufacturing to food processing, water treatment, and more. The immersion heater is a versatile and reliable tool designed to heat liquids directly and efficiently. With its robust construction and high-performance capabilities, it is a go-to solution for applications requiring consistent temperature control.

In this blog, we will explore what immersion heaters are, how they work, their advantages, applications, and why Raghav Industries is a trusted name in supplying high-quality immersion heaters.

What is an Immersion Heater?

An immersion heater is a heating device designed to be immersed directly into liquids such as water, oil, chemicals, or other fluids. It consists of a tubular heating element made from durable materials like stainless steel or Incoloy, ensuring efficient heat transfer and resistance to corrosion.

Immersion heaters are commonly used to heat tanks, reservoirs, or process fluids directly. Their ability to deliver rapid and uniform heating makes them indispensable in various industrial and commercial settings.

How Does an Immersion Heater Work?

The immersion heater operates by passing electrical current through a resistance wire embedded within the tubular heating element. As the wire heats up, it transfers the heat to the surrounding fluid through the outer sheath. This direct heating method ensures minimal energy loss and rapid temperature increases.

Many immersion heaters come with built-in thermostats or control systems, allowing users to set and maintain specific temperatures for precise heating.

Key Features of Immersion Heaters

1. Direct Heating

Immersion heaters heat liquids directly, ensuring fast and efficient heat transfer.

2. Durable Construction

Made from high-quality materials, these heaters are designed to withstand harsh environments, including exposure to corrosive chemicals and high pressures.

3. Versatile Design

Available in various shapes, sizes, and configurations, immersion heaters can be customized to fit different applications.

4. Temperature Control

Many immersion heaters feature built-in thermostats or controllers for precise temperature regulation.

5. Energy Efficiency

The direct heating process minimizes energy loss, making immersion heaters a cost-effective solution for liquid heating.

Benefits of Immersion Heaters

1. Rapid Heating

By immersing directly in the liquid, immersion heaters provide quick and uniform heating, reducing downtime and enhancing efficiency.

2. Adaptability

These heaters can be used for a wide range of liquids, including water, oil, chemicals, and viscous materials.

3. Long Service Life

Constructed with corrosion-resistant materials, immersion heaters are built to last, even in challenging environments.

4. Easy Installation and Maintenance

Their straightforward design makes them easy to install, use, and maintain, minimizing operational disruptions.

5. Cost-Effectiveness

Immersion heaters offer efficient heating with minimal energy wastage, making them a cost-effective choice for industrial and commercial applications.

Applications of Immersion Heaters

Immersion heaters are widely used in industries that require precise and efficient liquid heating. Common applications include:

1. Water Heating

Used in industries like food processing and water treatment, immersion heaters ensure rapid and consistent water heating.

2. Chemical Processing

Immersion heaters maintain the required temperatures for chemical reactions, ensuring process stability and efficiency.

3. Oil Heating

They are ideal for heating industrial oils and lubricants to maintain viscosity and improve performance.

4. Boiler Systems

Immersion heaters are integrated into boiler systems to provide efficient heating for large volumes of water or steam.

5. Food and Beverage Industry

Used for applications like heating syrups, sauces, and other liquid food products during processing.

6. Laboratories

Immersion heaters are employed in laboratories to maintain controlled temperatures for experiments and testing.

Why Choose Raghav Industries for Immersion Heaters?

Raghav Industries, based in Delhi, India, is a leading manufacturer and supplier of high-quality immersion heaters. Here’s why our products are trusted by industries worldwide:

1. Premium Materials

Our immersion heaters are constructed using stainless steel, Incoloy, or other high-grade materials, ensuring durability and resistance to corrosion.

2. Customization

We offer a variety of designs, sizes, and wattages to meet the unique needs of your application.

3. Advanced Features

Our heaters come with options like built-in thermostats, temperature sensors, and control systems for precise heating.

4. Energy Efficiency

Designed for optimal heat transfer, our heaters minimize energy consumption, helping you save on operational costs.

5. Comprehensive Support

From product selection to installation and after-sales service, we provide complete support to ensure customer satisfaction.

How to Choose the Right Immersion Heater

When selecting an immersion heater, consider the following factors:

Liquid Type: Ensure the heater’s materials are compatible with the liquid being heated, especially if it’s corrosive or viscous.

Heating Requirements: Determine the desired temperature range and heating rate for your application.

Wattage: Choose a heater with the appropriate power output for your tank or vessel size.

Installation: Consider the mounting style (flange, screw plug, or over-the-side) based on your setup.

Temperature Control: Opt for a heater with built-in thermostats or external controllers for precise regulation.

At Raghav Industries, we help you select the perfect immersion heater tailored to your requirements.

Why Immersion Heaters are Essential

Immersion heaters offer an efficient and reliable way to heat liquids, ensuring consistent performance across a wide range of applications. Their versatility, durability, and energy efficiency make them a valuable asset in industries that rely on precise temperature control.

Conclusion

Immersion heaters are an indispensable tool for industries requiring efficient and precise liquid heating. With their robust construction, energy efficiency, and versatile design, they ensure reliable performance in even the most demanding environments.

At Raghav Industries, we are committed to providing top-quality immersion heaters that cater to the unique needs of our clients. Whether you’re in manufacturing, food processing, or chemical industries, our heaters deliver exceptional performance and long-term value.

Learn more about our Immersion Heaters here.

#immersion#immersionheaters#industrialheating#industrial#heaters#industrialheater#heatingsystem#heating

0 notes

Text

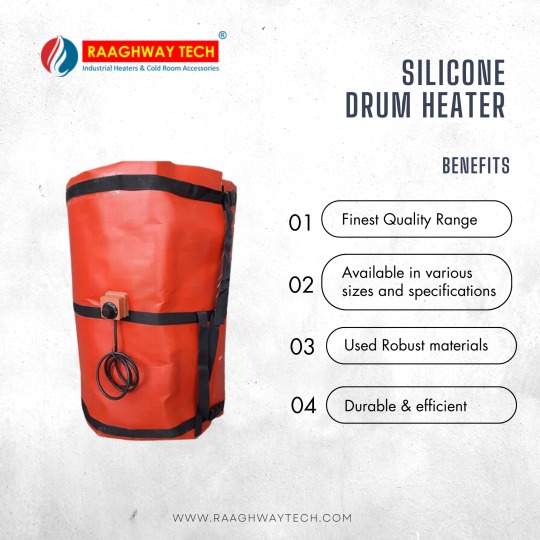

Silicone Drum Heaters: The Perfect Solution for Viscosity Control

In industrial operations, maintaining the right temperature of liquids stored in drums is essential for ensuring smooth processes and preventing material wastage. From viscous substances like oils and adhesives to sensitive liquids like chemicals and food products, controlling their temperature is critical. Silicone drum heaters offer a reliable, efficient, and cost-effective solution for maintaining optimal temperatures in a variety of industrial applications.

This blog will delve into the functionality, benefits, and applications of silicone drum heaters and explain why Raghav Industries is your trusted partner for high-quality heating solutions.

What is a Silicone Drum Heater?

A silicone drum heater is a flexible, wrap-around heating element designed to maintain or raise the temperature of liquids stored in standard-sized metal or plastic drums. Constructed with durable silicone rubber, these heaters are equipped with embedded heating wires or elements that deliver even heat distribution.

Silicone drum heaters are ideal for preventing freezing, reducing viscosity, and ensuring the smooth flow of liquids during dispensing or processing. Their lightweight and flexible design makes them easy to install and remove, providing both efficiency and convenience.

How Does a Silicone Drum Heater Work?

The heater wraps snugly around the exterior of a drum, providing uniform heat through embedded resistance wires or etched foil elements. The heat penetrates the drum’s surface and warms the liquid inside. Many silicone drum heaters come with adjustable thermostats, allowing users to set and maintain specific temperatures, ensuring precise control.

The combination of even heat distribution and accurate temperature regulation ensures that the liquid remains in its desired state without overheating or losing quality.

Key Features of Silicone Drum Heaters

1. Flexible Design

The silicone material allows the heater to conform to the shape of the drum, ensuring a secure fit and efficient heat transfer.

2. Uniform Heating

The heating elements are evenly distributed within the silicone, delivering consistent heat across the drum’s surface.

3. Adjustable Thermostat

Most silicone drum heaters feature built-in thermostats, enabling precise temperature control for various applications.

4. Durable Construction

Made from high-grade silicone rubber, these heaters are resistant to moisture, chemicals, and mechanical wear, ensuring a long lifespan.

5. Easy Installation

The lightweight and wrap-around design make these heaters easy to install, remove, and store when not in use.

Benefits of Silicone Drum Heaters

1. Viscosity Control

Silicone drum heaters are essential for reducing the viscosity of thick liquids like oils, syrups, or adhesives, making them easier to pour, pump, or process.

2. Prevents Freezing

For industries operating in cold climates, these heaters ensure that liquids remain in a usable state by preventing freezing or solidification.

3. Energy Efficiency

Designed to provide precise heating with minimal energy consumption, silicone drum heaters are both cost-effective and environmentally friendly.

4. Protects Liquid Integrity

By offering controlled and uniform heating, these heaters prevent overheating or localized burning, preserving the quality of the liquid.

5. Versatile Applications

Silicone drum heaters can be used with various drum sizes and are suitable for a wide range of industrial liquids.

Applications of Silicone Drum Heaters

Silicone drum heaters are versatile and can be used in numerous industries and applications, including:

1. Food and Beverage

Used to maintain the temperature of edible oils, syrups, and other food products for processing or packaging.

2. Chemicals and Pharmaceuticals

Ensure the stability and usability of sensitive chemicals, resins, or pharmaceutical ingredients during storage or transportation.

3. Adhesives and Sealants

Reduce the viscosity of adhesives, making them easier to dispense and apply.

4. Oil and Lubricants

Keep industrial oils and lubricants at optimal temperatures for smooth application and processing.

5. Manufacturing

Maintain the temperature of materials like waxes, soaps, or greases used in industrial production.

Why Choose Raghav Industries for Silicone Drum Heaters?

Raghav Industries, based in Delhi, India, is a leading manufacturer and supplier of high-performance silicone drum heaters. Here’s why businesses across industries trust us:

1. Superior Quality

Our silicone drum heaters are crafted with premium materials, ensuring durability, flexibility, and reliable performance.

2. Customization

We offer heaters in various sizes, wattages, and configurations to meet the unique requirements of your applications.

3. Energy Efficiency

Our heaters are designed to provide precise and uniform heating while minimizing energy consumption.

4. Easy-to-Use Design

The lightweight and flexible construction of our drum heaters makes them quick to install and remove, saving time and effort.

5. Comprehensive Support

From selecting the right heater to providing after-sales service, we ensure complete customer satisfaction at every step.

How to Choose the Right Silicone Drum Heater

When selecting a silicone drum heater, consider the following factors:

Drum Size: Ensure the heater fits snugly around the drum.

Temperature Range: Choose a heater that can achieve and maintain the desired temperature.

Wattage: Select a heater with the appropriate power rating for your application.

Liquid Type: Ensure the heater is compatible with the specific properties of the liquid being heated.

Environment: Consider the operating conditions, such as exposure to moisture or chemicals.

At Raghav Industries, we help you find the perfect solution tailored to your needs.

Why Silicone Drum Heaters are Essential

For industries that rely on temperature-sensitive liquids, silicone drum heaters provide an efficient and reliable solution. Their ability to maintain optimal temperatures, reduce viscosity, and prevent freezing makes them indispensable in various industrial operations.

Conclusion

Silicone drum heaters are a versatile and cost-effective solution for maintaining and controlling the temperature of liquids stored in industrial drums. With their flexible design, durable construction, and precise heating capabilities, they enhance operational efficiency and protect the integrity of stored materials.

At Raghav Industries, we are committed to providing top-quality silicone drum heaters that cater to the unique needs of our clients. Whether you’re in the food industry, chemical processing, or manufacturing, our heaters deliver reliable performance and long-term value.

Learn more about our Silicone Drum Heaters here.

#siliconeheating#siliconedrumheater#heatingsystem#heaters#industrial#heater#heating#industrialheating#industrialheater#manufacturing

0 notes

Text

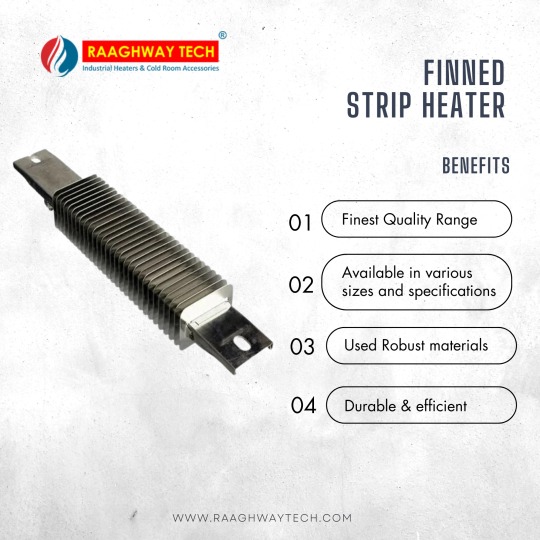

Efficient and Reliable Heating with Finned Strip Heaters

Industries requiring consistent and efficient heating solutions often turn to finned strip heaters for their reliability, versatility, and superior heat transfer capabilities. These heaters are designed to provide uniform heating across surfaces, making them ideal for applications such as drying, heating tanks, and maintaining controlled temperatures in industrial processes.

In this blog, we’ll explore the functionality, benefits, and applications of finned strip heaters and explain why Raghav Industries is your go-to supplier for high-quality heating solutions.

What is a Finned Strip Heater?

A finned strip heater is a flat, rectangular heating element with attached fins that significantly increase its surface area for efficient heat transfer. The fins are typically made of high-grade aluminum or stainless steel, while the core heating element is enclosed in a durable metal sheath, such as Incoloy or stainless steel.

Finned strip heaters are used in applications where rapid and even heat distribution is required. They are often mounted onto surfaces or integrated into systems that require direct heating.

How Does a Finned Strip Heater Work?

The finned strip heater operates by passing electrical current through a resistance wire inside the element. This generates heat, which is then transferred to the outer sheath and the attached fins. The fins dissipate the heat over a larger area, ensuring uniform temperature distribution and efficient heating.

Finned strip heaters are typically mounted using brackets or clamps, making installation straightforward. They can also be paired with fans or blowers to create forced air systems for enhanced heat distribution.

Key Features of Finned Strip Heaters

1. Increased Surface Area

The attached fins maximize the heater’s surface area, enabling faster and more efficient heat transfer.

2. Uniform Heat Distribution

Finned strip heaters provide consistent heat across their surface, ensuring even temperature control.

3. Durable Construction

Made with robust materials like stainless steel or Incoloy, these heaters are resistant to corrosion, oxidation, and mechanical wear.

4. Easy Installation

The compact design and mounting options make finned strip heaters easy to install on a variety of surfaces.

5. Energy Efficiency

By optimizing heat transfer, finned strip heaters minimize energy consumption while delivering high performance.

Benefits of Finned Strip Heaters

1. Superior Heating Efficiency

Finned strip heaters are designed to transfer heat effectively, reducing energy costs and improving process efficiency.

2. Longevity

The use of high-quality materials ensures that these heaters can withstand harsh industrial environments and frequent usage.

3. Versatility

With their compact design and customizable configurations, finned strip heaters can be adapted to suit a wide range of applications.

4. Low Maintenance

The durable construction and reliable performance of these heaters reduce the need for frequent maintenance and replacements.

5. Cost-Effectiveness

Their high efficiency and long lifespan make finned strip heaters a cost-effective solution for industrial heating.

Applications of Finned Strip Heaters

Finned strip heaters are widely used across industries for various applications, including:

1. Drying Systems

Ideal for drying textiles, paper, and other materials, these heaters provide consistent and efficient heat.

2. Air Heating

When integrated with fans or blowers, finned strip heaters are used to create forced air systems for space heating or process air heating.

3. Tank and Vessel Heating

These heaters are mounted on the outer surfaces of tanks or vessels to maintain the temperature of stored liquids or gases.

4. Industrial Ovens

Finned strip heaters ensure uniform heat distribution in industrial ovens used for baking, curing, or annealing processes.

5. Food Processing

In the food and beverage industry, these heaters maintain controlled temperatures for processing or packaging.

6. Dehumidification

Finned strip heaters are used in systems designed to remove moisture from air or materials, ensuring product quality and equipment longevity.

Why Choose Raghav Industries for Finned Strip Heaters?

Raghav Industries, based in Delhi, India, is a leading manufacturer and supplier of high-performance finned strip heaters. Here’s why our products are trusted by businesses across industries:

1. Premium Materials

Our finned strip heaters are crafted from high-grade stainless steel, Incoloy, and aluminum, ensuring durability and excellent heat transfer.

2. Customization

We offer heaters in various sizes, wattages, and configurations to meet the unique needs of your application.

3. Energy-Efficient Design

Our heaters are engineered to deliver maximum heat output with minimal energy consumption, helping you save on operational costs.

4. Expert Craftsmanship

With years of experience, our team ensures that every product meets the highest standards of quality and performance.

5. Comprehensive Support

From helping you select the right heater to providing after-sales service, we’re with you every step of the way.

How to Choose the Right Finned Strip Heater

Selecting the right finned strip heater involves evaluating several factors:

Application Requirements: Determine whether the heater will be used for drying, air heating, or another application.

Size and Wattage: Choose a heater that matches the heating capacity and power requirements of your system.

Material Compatibility: Ensure the heater materials are suitable for the operating environment, particularly if exposed to moisture or corrosive elements.

Mounting Options: Consider how the heater will be installed and ensure it’s compatible with your setup.

Our team at Raghav Industries can assist you in selecting the ideal solution for your needs.

Why Finned Strip Heaters are Essential

In industrial processes where efficient and uniform heating is crucial, finned strip heaters provide a reliable and cost-effective solution. Their ability to deliver consistent performance in a compact and durable design makes them a preferred choice for businesses looking to optimize their heating systems.

Conclusion

Finned strip heaters are a versatile and efficient heating solution for a wide range of industrial applications. With their advanced design, superior heat transfer capabilities, and durable construction, they offer exceptional performance and reliability.

At Raghav Industries, we take pride in offering high-quality finned strip heaters tailored to your specific requirements. Whether you need heaters for drying systems, tank heating, or industrial ovens, we have the expertise and products to meet your needs.

Learn more about our Finned Strip Heaters here.

#finnedstripheaters#stripheaters#heatingcable#heatingsystem#heating#industrial#industrialheating#industrialheater#manufacturing

0 notes

Text

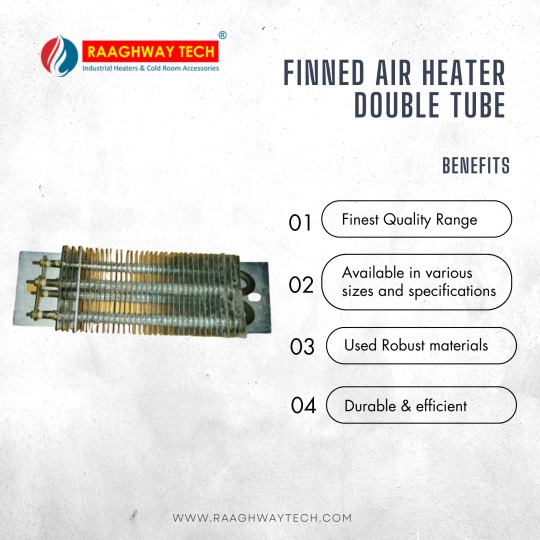

Double Tube Finned Air Heaters: Enhanced Heating for Industrial Applications

Industrial heating solutions require efficiency, durability, and the ability to handle high heat demands. The double tube finned air heater is a specialized heating element designed to deliver superior heat transfer and uniform temperature distribution in large-scale or demanding applications. By leveraging a double tube design and extended surface area, these heaters offer enhanced performance, making them a preferred choice for industries like HVAC, drying, and industrial ovens.

In this blog, we’ll delve into what makes double tube finned air heaters unique, their benefits, applications, and why Raghav Industries is a trusted supplier of these advanced heating solutions.

What is a Double Tube Finned Air Heater?

A double tube finned air heater is an advanced variation of the traditional finned air heater. It features a dual-tube design with heat transfer fins wrapped around both tubes, significantly increasing the surface area for heat exchange. This unique configuration enhances heat dissipation and ensures consistent temperature control, even in high-demand environments.

These heaters are built using durable materials like stainless steel or Incoloy, making them suitable for industrial applications where reliability and performance are critical.

How Does a Double Tube Finned Air Heater Work?

The double tube finned air heater operates by passing electrical current through resistance wires housed inside the tubes. As the wires heat up, the generated heat is transferred to the outer fins, which then distribute the heat evenly to the surrounding air. The dual-tube design ensures a larger heat exchange surface, enabling faster and more efficient heating.

When combined with forced airflow systems, such as fans or blowers, these heaters provide uniform and rapid heating across large spaces or equipment.

Key Features of Double Tube Finned Air Heaters

1. Dual-Tube Design

The double tube configuration significantly increases the heating surface area, allowing for faster and more efficient heat transfer.

2. Enhanced Heat Dissipation

The extended fins ensure that heat is distributed evenly, preventing hotspots and improving overall system efficiency.

3. High Durability

Constructed with premium materials, these heaters are resistant to corrosion, oxidation, and wear, ensuring long-term reliability.

4. Energy Efficiency

The dual-tube design optimizes heat transfer, reducing energy consumption while delivering consistent performance.

5. Versatility

Available in various sizes, wattages, and configurations, these heaters can be tailored to meet specific industrial requirements.

Benefits of Double Tube Finned Air Heaters

1. Superior Heating Efficiency

The dual-tube design provides a larger surface area for heat transfer, resulting in faster and more efficient heating.

2. Uniform Temperature Control

These heaters eliminate temperature inconsistencies, ensuring uniform heat distribution across the application area.

3. Long Service Life

Built with durable materials and designed to withstand harsh operating conditions, double tube finned air heaters offer exceptional longevity.

4. Cost-Effective

The high efficiency and low maintenance requirements of these heaters translate into significant cost savings over time.

5. Adaptable to Various Applications

Their versatility makes them suitable for a wide range of industrial and commercial heating applications.

Applications of Double Tube Finned Air Heaters

Double tube finned air heaters are used in numerous industries and applications where efficient air heating is essential. Key applications include:

1. HVAC Systems

These heaters are used in heating, ventilation, and air conditioning systems to maintain consistent airflow and temperature.

2. Industrial Ovens

Double tube finned air heaters provide uniform heating for processes such as curing, baking, or drying in industrial ovens.

3. Textile and Paper Drying

These heaters ensure rapid and efficient drying in industries like textiles and paper manufacturing.

4. Air Handling Units

They are integrated into air handling systems to optimize temperature control and air distribution.

5. Dehumidification Systems

In environments requiring precise moisture control, these heaters assist in efficient dehumidification.

6. Aerospace and Automotive

They provide reliable heating for components and systems operating in extreme conditions.

Why Choose Raghav Industries for Double Tube Finned Air Heaters?

Raghav Industries, based in Delhi, India, is a leading manufacturer and supplier of high-quality double tube finned air heaters. Here’s why businesses choose our products:

1. Advanced Design

Our double tube finned air heaters are engineered to deliver superior performance and reliability, even in the most demanding environments.

2. Premium Materials

We use high-grade stainless steel, Incoloy, and other durable materials to ensure long-lasting performance.

3. Customization Options

We offer heaters in a variety of sizes, wattages, and configurations to meet the unique needs of our clients.

4. Energy Efficiency

Our heaters are designed to optimize heat transfer, reducing energy consumption and operational costs.

5. Comprehensive Support

From product selection to after-sales service, we provide end-to-end support to ensure customer satisfaction.

How to Choose the Right Double Tube Finned Air Heater

When selecting a double tube finned air heater, consider the following factors:

Application Type: Determine the specific requirements of your application, such as heating for HVAC systems or drying processes.

Size and Wattage: Choose a heater that matches the heating capacity and power requirements of your system.

Material Compatibility: Ensure the heater materials are suitable for the operating environment, especially if exposed to corrosive elements or high moisture.

Airflow Requirements: Evaluate the airflow rate to ensure optimal heat distribution and system efficiency.

Our team at Raghav Industries can guide you in selecting the perfect solution for your needs.

Why Double Tube Finned Air Heaters are Essential

For industrial applications requiring consistent and efficient air heating, double tube finned air heaters are a top choice. Their ability to deliver uniform temperature control, combined with their durability and energy efficiency, makes them indispensable in a variety of settings. Investing in high-quality heaters ensures smoother operations, reduced maintenance costs, and enhanced productivity.

Conclusion

Double tube finned air heaters represent a superior solution for air heating applications across industries. Their dual-tube design, coupled with extended surface fins, ensures maximum heat transfer efficiency and reliable performance.

At Raghav Industries, we are committed to delivering premium heating solutions tailored to your unique requirements. With our double tube finned air heaters, you can optimize your heating processes, reduce energy consumption, and achieve outstanding results.

Learn more about our Double Tube Finned Air Heaters here.

#finnedairheaters#airheaters#doubletubeheaters#heatingcable#heatingsystem#industrialheating#industrialheater#industrial

0 notes

Text

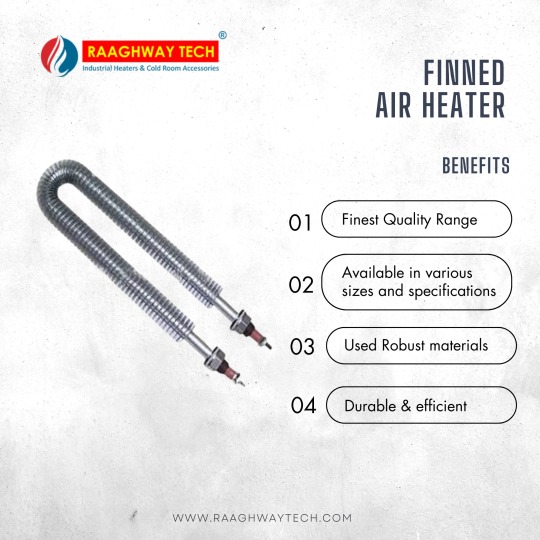

Maximize Heat Transfer Efficiency with Finned Air Heaters

Industrial heating systems require reliable and efficient solutions to maintain consistent performance, especially in applications demanding high heat transfer rates. Among the many options available, finned air heaters stand out as a versatile and effective choice for air heating applications. Designed to optimize heat transfer, these heaters play a crucial role in industries such as HVAC, drying processes, and industrial ovens.

In this blog, we’ll explore what finned air heaters are, how they work, their advantages, and their wide-ranging applications. We’ll also explain why Raghav Industries is your trusted partner for premium finned air heaters.

What is a Finned Air Heater?

A finned air heater is a heating element designed to maximize heat transfer by increasing the surface area exposed to air. The heater consists of a resistance wire embedded within a tubular element, surrounded by metal fins. These fins enhance the heat exchange process by efficiently transferring heat from the heating element to the surrounding air.

Finned air heaters are commonly used in forced air systems, where they provide consistent and efficient heating for a wide range of industrial and commercial applications.

How Does a Finned Air Heater Work?

The core heating element in a finned air heater generates heat when electrical current passes through the resistance wire. The fins attached to the element act as heat exchangers, rapidly transferring heat to the surrounding air. When air is forced over the fins using a fan or blower, the heated air is distributed evenly, ensuring consistent temperature control.

This design ensures efficient heat transfer, making finned air heaters ideal for applications where rapid and uniform air heating is required.

Key Features of Finned Air Heaters

1. Enhanced Heat Transfer

The addition of fins significantly increases the surface area of the heating element, allowing for faster and more efficient heat transfer.

2. Durable Construction

Finned air heaters are built with high-quality materials, such as stainless steel or Incoloy, ensuring resistance to corrosion, oxidation, and wear.

3. Uniform Heating

These heaters provide consistent and uniform heat distribution, eliminating hotspots and ensuring reliable performance.

4. Energy Efficiency

Designed to optimize heat transfer, finned air heaters deliver high performance while consuming minimal energy.

5. Versatility

Available in various sizes, configurations, and wattages, finned air heaters can be customized to suit specific applications.

Benefits of Finned Air Heaters

1. Improved System Efficiency

By maximizing heat transfer, finned air heaters enhance the overall efficiency of air heating systems, reducing energy consumption and operational costs.

2. Long Service Life

The robust construction and use of premium materials ensure that these heaters withstand demanding industrial conditions, offering a long operational lifespan.

3. Low Maintenance Requirements

Finned air heaters are designed for durability and reliability, requiring minimal maintenance and reducing downtime.

4. Adaptability

These heaters can be customized to fit a variety of industrial setups, making them suitable for a wide range of applications.

5. Cost-Effectiveness

Their energy-efficient design and low maintenance needs translate into long-term cost savings for businesses.

Applications of Finned Air Heaters

Finned air heaters are used across diverse industries and applications, including:

1. HVAC Systems

In heating, ventilation, and air conditioning systems, finned air heaters ensure efficient temperature control and air distribution.

2. Drying Processes

These heaters are ideal for drying materials in industries such as textiles, paper, and food processing.

3. Industrial Ovens

Finned air heaters are used to maintain consistent temperatures in ovens for baking, curing, or annealing processes.

4. Dehumidification Systems

By providing controlled heating, these heaters aid in moisture removal for improved air quality and equipment longevity.

5. Space Heating

In large industrial or commercial spaces, finned air heaters deliver efficient and uniform air heating.

6. Air Handling Units

These heaters are integral components in air handling systems, ensuring optimal performance and energy efficiency.

Why Choose Raghav Industries for Finned Air Heaters?

Raghav Industries, based in Delhi, India, is a trusted manufacturer and supplier of high-quality finned air heaters. Here’s why our products are the preferred choice for businesses:

1. Superior Quality Materials

Our finned air heaters are constructed using premium materials like stainless steel and advanced insulation, ensuring durability and reliable performance.

2. Customization Options

We offer finned air heaters in various sizes, wattages, and configurations to meet the unique needs of your application.

3. Energy-Efficient Design

Our heaters are engineered to maximize heat transfer while minimizing energy consumption, helping businesses save on operational costs.

4. Expert Craftsmanship

With years of experience, we ensure that every heater we produce meets the highest standards of quality and performance.

5. Comprehensive Support

From product selection to installation and after-sales service, we provide complete support to ensure customer satisfaction.

How to Choose the Right Finned Air Heater

Selecting the right finned air heater depends on several factors, including:

Application Type: Determine whether the heater will be used for HVAC, drying, or another application.

Size and Wattage: Choose a heater that matches the heating requirements of your system.

Material Compatibility: Ensure the heater’s materials are suitable for the operating environment, especially if exposed to moisture or corrosive elements.

Airflow Requirements: Consider the airflow rate to optimize heat transfer and ensure uniform heating.

Our team at Raghav Industries can help you find the perfect solution for your specific needs.

The Importance of Reliable Heating Solutions

Efficient and reliable heating is critical for maintaining productivity and reducing operational costs in industrial environments. Finned air heaters offer a unique combination of high efficiency, durability, and versatility, making them a valuable asset for a wide range of applications.

Conclusion

Finned air heaters are a powerful and efficient solution for air heating applications across various industries. Their ability to deliver uniform heat transfer, combined with their durability and energy efficiency, makes them an indispensable tool for businesses looking to optimize their heating systems.

At Raghav Industries, we are committed to providing premium finned air heaters tailored to your specific needs. With our products, you can enhance operational efficiency, reduce energy consumption, and achieve reliable heating performance.

Learn more about our Finned Air Heaters here.

#finnedairheaters#airheaters#industrialheaters#heating#heatingsystem#industrialheater#industrialheating#industrial#manufacturing

0 notes

Text

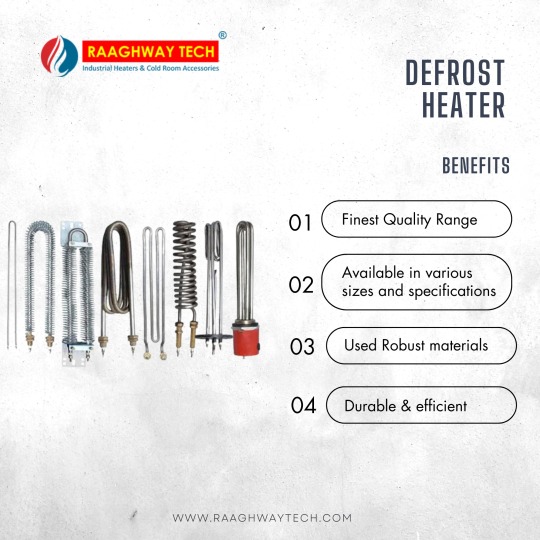

Keep Your Refrigeration Systems Running Smoothly with Defrost Heaters

In refrigeration systems, frost and ice buildup can significantly impact performance and efficiency. This is where defrost heaters play a vital role. These innovative devices are specifically designed to prevent ice accumulation on critical components like evaporator coils, ensuring smooth and consistent operation.

In this blog, we’ll explore what defrost heaters are, their benefits, common applications, and why Raghav Industries is a trusted provider of reliable defrost heating solutions.

What is a Defrost Heater?

A defrost heater is a heating element installed within refrigeration and freezer units to eliminate frost and ice buildup on evaporator coils and other components. By melting the accumulated ice, these heaters maintain efficient airflow and cooling, ensuring the system operates at optimal performance.

Defrost heaters typically activate during scheduled defrost cycles, melting any frost or ice that has formed, and then automatically switch off once the cycle is complete. This process helps maintain the system's efficiency and reduces the likelihood of breakdowns caused by ice accumulation.

How Does a Defrost Heater Work?

Defrost heaters work by generating controlled heat to melt ice and frost without affecting the overall cooling environment. These heaters are strategically placed near evaporator coils or other areas prone to ice buildup.

When the refrigeration system detects excessive frost accumulation, the defrost cycle activates. The heater warms the affected areas, melting the ice and allowing it to drain away. Once the ice is cleared, the heater turns off, and the refrigeration system resumes normal cooling operations.

Key Features of Defrost Heaters

1. Efficient Ice Removal

Defrost heaters are designed to eliminate ice buildup quickly and effectively, ensuring minimal disruption to the cooling process.

2. Durable Construction

Made from high-quality materials like stainless steel and durable insulation, these heaters are built to withstand harsh conditions and frequent usage.

3. Energy Efficiency

Modern defrost heaters are engineered to use minimal energy while providing maximum performance, reducing operational costs.

4. Automatic Operation

Defrost heaters are integrated into automated systems, activating only during defrost cycles and shutting off when the task is complete.

5. Versatility

Available in various sizes and configurations, defrost heaters can be tailored to suit different refrigeration systems and applications.

Benefits of Defrost Heaters

1. Enhanced System Efficiency

By preventing ice buildup on evaporator coils, defrost heaters ensure that the refrigeration system operates at peak efficiency, maintaining consistent cooling performance.

2. Reduced Maintenance Costs

Ice buildup can lead to system inefficiencies, increased energy consumption, and frequent repairs. Defrost heaters minimize these issues, reducing maintenance costs.

3. Prolonged Equipment Lifespan

Preventing ice-related damage helps extend the lifespan of refrigeration components, saving businesses from costly replacements.

4. Improved Safety

Ice accumulation can cause hazards like water leaks and electrical malfunctions. Defrost heaters mitigate these risks, ensuring a safer working environment.

5. Consistent Cooling Performance

Defrost heaters maintain proper airflow and temperature control, ensuring reliable operation and product integrity.

Applications of Defrost Heaters

Defrost heaters are essential in a wide range of refrigeration and cooling applications, including:

1. Commercial Freezers and Refrigerators

Supermarkets, restaurants, and food storage facilities rely on defrost heaters to maintain efficient cooling and prevent ice buildup.

2. Industrial Refrigeration Systems

In large-scale refrigeration systems used in manufacturing and cold storage, defrost heaters ensure smooth and consistent operation.

3. Walk-In Freezers

Defrost heaters are crucial for walk-in freezers, where ice accumulation can hinder door seals and cooling performance.

4. Refrigerated Trucks and Containers

Mobile refrigeration units require defrost heaters to maintain efficiency during transportation.

5. HVAC Systems

Defrost heaters are also used in HVAC systems to prevent frost from obstructing airflow and heat exchange.

Why Choose Raghav Industries for Defrost Heaters?

Raghav Industries, based in Delhi, India, is a trusted manufacturer and supplier of high-quality defrost heaters. Here’s why our products are the preferred choice for businesses:

1. Superior Build Quality

Our defrost heaters are crafted from premium materials, ensuring durability and reliable performance in demanding environments.

2. Energy Efficiency

We design our heaters to deliver optimal heating with minimal energy consumption, helping businesses save on operational costs.

3. Customization Options

Our defrost heaters are available in various sizes and configurations, tailored to meet the specific needs of your refrigeration systems.

4. Easy Installation

Our heaters are designed for quick and hassle-free installation, reducing downtime and ensuring seamless integration.

5. Comprehensive Support

From product selection to after-sales service, Raghav Industries provides end-to-end support to ensure customer satisfaction.

How to Select the Right Defrost Heater

When choosing a defrost heater, consider the following factors:

System Size: Ensure the heater matches the size and capacity of your refrigeration system.

Ice Accumulation Rate: Choose a heater capable of melting ice within the required time frame.

Energy Efficiency: Opt for a heater that minimizes energy consumption without compromising performance.

Durability: Select a heater made from high-quality materials that can withstand frequent defrost cycles.

Compatibility: Ensure the heater integrates seamlessly with your existing system.

With the expertise of Raghav Industries, you can find the perfect defrost heater for your specific requirements.

Why Defrost Heaters are Essential

Ice buildup in refrigeration systems can lead to inefficiencies, increased energy consumption, and equipment damage. Defrost heaters address these issues by maintaining clear and functional evaporator coils, ensuring smooth operation and prolonged system life. Investing in a high-quality defrost heater is a proactive step towards enhancing performance and reducing costs.

Conclusion

Defrost heaters are an essential component of refrigeration systems, ensuring optimal performance and preventing costly disruptions caused by ice buildup. Their efficiency, durability, and ease of use make them a valuable investment for businesses across industries.

At Raghav Industries, we are committed to providing reliable and energy-efficient defrost heaters tailored to meet the unique needs of our clients. With our products, you can safeguard your refrigeration systems and achieve consistent cooling performance.

Learn more about our Defrost Heaters here.

#defrostheater#refrigeration#heaters#manufacturer#industrial#industrialheating#industrialheater#heatingcable#heating#heater#heatingsystem#manufacturing

0 notes

Text

Precision Heating for Industrial Applications: Cartridge Heaters

In the realm of industrial heating, precision and reliability are paramount. Among the various heating solutions available, cartridge heaters stand out for their efficiency and adaptability. Designed for confined spaces requiring controlled and concentrated heat, these heaters are widely used across industries for their versatility and durability.

In this blog, we will explore what cartridge heaters are, their advantages, applications, and why Raghav Industries is the go-to supplier for high-quality cartridge heaters.

What is a Cartridge Heater?

A cartridge heater is a cylindrical heating element designed to provide localized and precise heating. It consists of a resistance coil wound around a ceramic core, encased in a sheath made of materials like stainless steel or Incoloy. This design ensures excellent heat transfer and durability, even under extreme conditions.

Cartridge heaters are typically inserted into drilled holes or placed in tight spaces to deliver concentrated heat, making them ideal for applications where space is limited.

How Does a Cartridge Heater Work?

Cartridge heaters operate by converting electrical energy into heat through the resistance wire inside the heating element. The heat is then transferred to the sheath and distributed evenly to the surrounding environment. Advanced designs feature high-density wattage, ensuring rapid heating and consistent temperature control.

Some cartridge heaters come with built-in thermocouples or sensors, enabling precise temperature monitoring and control.

Key Features of Cartridge Heaters

1. High-Density Wattage

Cartridge heaters are designed to deliver high watt density, ensuring rapid heating and efficient energy usage.

2. Compact and Versatile Design

The cylindrical shape and compact size allow cartridge heaters to fit into tight spaces, making them ideal for intricate applications.

3. Superior Heat Transfer

The construction ensures uniform heat distribution, minimizing energy loss and enhancing efficiency.

4. Durability

Made with high-quality materials, cartridge heaters are resistant to oxidation, corrosion, and wear, ensuring long operational life.

5. Temperature Control

Many cartridge heaters feature integrated sensors, allowing for precise temperature regulation.

Benefits of Cartridge Heaters

1. Precise Heating

Cartridge heaters provide targeted heating, making them ideal for applications requiring accurate temperature control.

2. Energy Efficiency

The high-density wattage and efficient heat transfer reduce energy consumption, lowering operational costs.

3. Versatility

These heaters can be used in a wide range of applications, from industrial machinery to laboratory equipment.

4. Longevity

Built to withstand harsh conditions, cartridge heaters offer reliable performance and require minimal maintenance.

5. Easy Installation

Cartridge heaters are designed for easy insertion and removal, simplifying installation and replacement processes.

Applications of Cartridge Heaters

Cartridge heaters are used in a variety of industries and applications, including:

1. Plastic Injection Molding

They provide precise heating for molds, ensuring consistent product quality.

2. Packaging Equipment

Cartridge heaters are used to maintain the correct temperature for sealing and cutting operations.

3. Medical Devices

They are used in medical equipment requiring precise and localized heating.

4. Food Processing

Cartridge heaters help maintain the correct temperature in machinery used for food production.

5. Aerospace

They are used in applications requiring reliable and efficient heating in extreme conditions.

6. Semiconductor Manufacturing

Cartridge heaters provide precise heating for processes like soldering and bonding.

Why Choose Raghav Industries for Cartridge Heaters?

Raghav Industries, based in Delhi, India, is a trusted name in the manufacturing and supply of cartridge heaters. Here’s why our products are the preferred choice:

1. Premium Quality

We use top-grade materials, such as stainless steel sheaths and nickel-chrome resistance wires, to ensure durability and high performance.

2. Customization Options

Our cartridge heaters are available in various sizes, wattages, and configurations to meet your specific requirements.

3. Energy Efficiency

Designed for efficient heat transfer, our heaters minimize energy consumption, helping businesses save on operational costs.

4. Advanced Features

We offer heaters with integrated sensors and thermocouples for precise temperature control.

5. Comprehensive Support

From product selection to after-sales service, we provide end-to-end support to ensure a seamless experience.

How to Choose the Right Cartridge Heater

When selecting a cartridge heater, consider the following factors:

Application Requirements: Determine the size, wattage, and temperature range needed for your application.

Material Compatibility: Ensure the sheath material is compatible with the environment and the substance being heated.

Temperature Control: Choose heaters with built-in sensors if precise temperature regulation is required.

Environmental Conditions: Consider factors like exposure to moisture, chemicals, or high pressure.

Raghav Industries offers expert guidance to help you find the ideal cartridge heater for your application.

The Importance of Reliable Heating Solutions

Cartridge heaters are a vital component in industries where precision heating is essential. Their compact design, high efficiency, and durability make them an indispensable tool for a variety of applications. Investing in high-quality cartridge heaters not only enhances operational efficiency but also reduces maintenance costs and downtime.

Conclusion

Cartridge heaters are a versatile and efficient solution for precise and localized heating in industrial applications. Their ability to deliver consistent performance in tight spaces makes them a preferred choice for industries ranging from manufacturing to medical devices.

At Raghav Industries, we are committed to providing top-quality cartridge heaters tailored to meet your unique needs. With our innovative products, you can optimize your heating processes, reduce energy consumption, and achieve reliable results every time.

Learn more about our Cartridge Heaters here.

#cartridgeheater#cartridge#heater#heatingcable#heatingsystem#industrial#industrialheater#industrialheating#manufacturing#entrepreneur

0 notes

Text

Unlock the Potential of Uniform Heating with Silicone Pad Heaters

Industrial heating often requires precision, flexibility, and durability to cater to a wide range of applications. One such versatile solution is the silicone pad heater, a flexible and efficient heating element designed for uniform heat distribution across various surfaces. Its innovative design and exceptional performance make it an indispensable tool for industries requiring reliable and consistent heating.

In this blog, we’ll dive deep into the functionality, benefits, and applications of silicone pad heaters and explore why Raghav Industries is a leading supplier of these essential heating solutions.

What is a Silicone Pad Heater?

A silicone pad heater is a flat, flexible heating element made of durable silicone rubber, embedded with heating wires or circuits. Its lightweight and adaptable design allows it to fit onto irregular or curved surfaces, delivering even heat across its surface area. Silicone pad heaters are widely used for applications requiring controlled heating, such as tanks, pipes, equipment, and even medical devices.

These heaters are available in various sizes, wattages, and configurations to suit specific industrial needs.

How Does a Silicone Pad Heater Work?

Silicone pad heaters work by converting electrical energy into heat through resistance wires or etched foil elements embedded within the silicone. The heating element is evenly distributed throughout the pad, ensuring uniform heat transfer across the entire surface. The silicone rubber provides insulation and protection, making the heater durable and resistant to environmental factors.

The heater can be easily secured to surfaces using adhesives, straps, or clamps, ensuring efficient heat transfer without the need for extensive modifications to the equipment.

Key Features of Silicone Pad Heaters

1. Flexibility and Adaptability

Silicone pad heaters are designed to conform to various surfaces, including curved or irregular shapes. This flexibility makes them suitable for a wide range of industrial applications.

2. Uniform Heat Distribution

The embedded heating element ensures consistent heat across the entire pad, eliminating cold spots and improving efficiency.

3. High Durability

Made from high-quality silicone rubber, these heaters are resistant to moisture, chemicals, and mechanical stress, ensuring a long operational life.

4. Temperature Control

Many silicone pad heaters are equipped with thermostats or temperature sensors, allowing precise control over the heating process.

5. Lightweight and Easy to Install

The lightweight design and flexibility of silicone pad heaters make them easy to install, reducing setup time and costs.

Benefits of Silicone Pad Heaters

1. Enhanced Operational Efficiency

By providing uniform heating, silicone pad heaters optimize energy usage and improve the efficiency of industrial processes.

2. Reduced Maintenance Costs

The durability and reliability of silicone pad heaters minimize the need for frequent replacements or repairs, saving businesses time and money.

3. Versatile Applications

From industrial tanks to medical devices, silicone pad heaters are suitable for a wide range of uses, making them a versatile solution.

4. Space-Saving Design

Their thin, lightweight construction allows them to be installed in tight spaces without adding significant bulk.

5. Safety

Silicone pad heaters are designed with insulating materials and safety features to prevent overheating and ensure safe operation.

Applications of Silicone Pad Heaters

Silicone pad heaters are used across a variety of industries and applications, including:

1. Tank Heating

Used to maintain the temperature of liquids in storage tanks, such as chemicals, oils, or water.

2. Pipe Heating

Prevents freezing or maintains the viscosity of fluids flowing through pipelines.

3. Medical Equipment

Provides controlled heating for medical devices and laboratory instruments.

4. Food and Beverage Industry

Used for applications like warming food containers or maintaining temperatures during processing.

5. Aerospace and Automotive

Provides de-icing and preheating solutions for components in extreme conditions.

6. Electronics

Maintains optimal operating temperatures for sensitive electronic devices.

Why Choose Raghav Industries for Silicone Pad Heaters?

Raghav Industries, based in Delhi, India, is a trusted name in the manufacturing and supply of high-quality silicone pad heaters. Here’s why our products are preferred by businesses across industries:

1. Premium Quality Materials

Our silicone pad heaters are made from top-grade silicone and advanced heating elements, ensuring reliability and long-lasting performance.

2. Customization Options

We offer a variety of sizes, shapes, and wattages to meet the unique needs of each application.

3. Energy Efficiency

Designed for maximum heat transfer with minimal energy consumption, our heaters help reduce operational costs.

4. Easy Installation

Our heaters are lightweight and flexible, making them quick and easy to install on-site.

5. Comprehensive Support

From product selection to after-sales service, we provide complete support to ensure customer satisfaction.

How to Choose the Right Silicone Pad Heater

When selecting a silicone pad heater, consider the following factors:

Application Type: Determine whether the heater will be used for tank heating, pipe heating, or another purpose.

Size and Shape: Choose a heater that matches the surface area and shape of the equipment.

Temperature Requirements: Ensure the heater can deliver the desired temperature range.

Wattage: Select a heater with sufficient wattage for your specific application.

Environmental Factors: Consider exposure to moisture, chemicals, or extreme temperatures.

Partnering with Raghav Industries ensures that you receive the perfect solution tailored to your requirements.

The Importance of Reliable Heating Solutions

In industrial operations, consistent and efficient heating is often a critical requirement. Silicone pad heaters address these needs with their unique combination of flexibility, durability, and performance. Whether it’s maintaining the temperature of liquids or ensuring the smooth operation of sensitive equipment, these heaters deliver unmatched reliability and efficiency.

Conclusion

Silicone pad heaters are a versatile and indispensable tool for industries requiring precise and consistent heating. Their ability to adapt to various surfaces, combined with their durability and energy efficiency, makes them a valuable investment for any business.

At Raghav Industries, we are dedicated to providing innovative heating solutions that cater to the diverse needs of our clients. With our silicone pad heaters, you can enhance your operational efficiency, reduce maintenance costs, and achieve reliable results every time.

Learn more about our Silicone Pad Heaters here.

#siliconepadheater#padheater#heater#industrialheater#industrialheating#industrial#heatingcable#heatingsystem#heating#manufacturing

0 notes

Text

Crankcase Heaters: A Must-Have for Refrigeration Systems

Efficient refrigeration and HVAC systems are the backbone of industries like food storage, pharmaceuticals, and manufacturing. A critical yet often overlooked component in these systems is the crankcase heater. This compact yet powerful device ensures smooth compressor operations by preventing refrigerant migration, which can lead to costly damages and inefficiencies.

In this blog, we’ll dive into what a crankcase heater is, how it works, its benefits, and why Raghav Industries is your trusted source for reliable crankcase heaters.

What is a Crankcase Heater?

A crankcase heater is a heating element installed in or around the crankcase of a refrigeration or HVAC compressor. Its primary purpose is to maintain a consistent temperature inside the crankcase to prevent refrigerant migration. Refrigerant migration occurs when refrigerant condenses and mixes with crankcase oil during system shutdown, causing poor lubrication and potential damage when the compressor restarts.

By warming the crankcase, the heater keeps the refrigerant in a gaseous state, ensuring proper lubrication and smooth compressor operations.

How Does a Crankcase Heater Work?

When a refrigeration or HVAC system shuts down, the refrigerant in the evaporator or condenser can flow back into the compressor crankcase, where it mixes with the lubricating oil. Upon startup, this mixture can lead to compressor wear, overheating, or even system failure.

A crankcase heater solves this issue by maintaining the temperature of the oil in the crankcase. This prevents the refrigerant from condensing into the crankcase and ensures the oil remains pure and effective for lubrication. The heater operates only when the system is off, making it an energy-efficient solution.

Benefits of Crankcase Heaters

1. Prevents Refrigerant Migration

The primary benefit of a crankcase heater is its ability to prevent refrigerant migration. By keeping the refrigerant in a gaseous state, it ensures that the crankcase oil remains uncontaminated and effective for lubrication.

2. Extends Compressor Life

Refrigerant-contaminated oil can cause significant wear and tear on the compressor. By maintaining oil purity, crankcase heaters reduce stress on the compressor, extending its lifespan and reducing the need for repairs or replacements.

3. Enhances System Efficiency

A well-lubricated compressor operates more efficiently, consuming less energy and delivering optimal performance. Crankcase heaters play a key role in maintaining this efficiency.

4. Reduces Maintenance Costs

By preventing refrigerant-related damage, crankcase heaters minimize the frequency of maintenance and repairs, saving businesses time and money in the long run.

5. Ensures Reliable Startup

Crankcase heaters prevent issues like slugging or compressor lockup during system startup, ensuring smooth and reliable operation every time.

Applications of Crankcase Heaters

Crankcase heaters are essential in a variety of refrigeration and HVAC applications, including:

Commercial Refrigeration: Used in supermarkets, restaurants, and food processing plants to maintain compressor efficiency.

Cold Storage Facilities: Prevent refrigerant migration in large refrigeration units.

Air Conditioning Systems: Essential for HVAC systems in commercial and residential buildings.

Industrial Refrigeration: Protects compressors in manufacturing and industrial cooling systems.

Refrigerated Trucks and Containers: Ensures smooth operation during transport, especially in fluctuating temperature conditions.

Why Choose Raghav Industries for Crankcase Heaters?

When it comes to reliable and high-performance crankcase heaters, Raghav Industries is a trusted name in the industry. Based in Delhi, India, we specialize in manufacturing durable and energy-efficient heating solutions. Here’s why businesses prefer our crankcase heaters:

1. Superior Build Quality

Our crankcase heaters are made from high-quality materials, ensuring durability and consistent performance in demanding environments.

2. Energy Efficiency

Designed to operate only during system shutdown, our heaters deliver optimal performance with minimal energy consumption, making them cost-effective and eco-friendly.

3. Wide Range of Options

We offer crankcase heaters in various sizes and wattages, catering to diverse refrigeration and HVAC systems.

4. Easy Installation

Our heaters are designed for quick and hassle-free installation, minimizing downtime during setup.

5. Excellent Customer Support

At Raghav Industries, we provide comprehensive support, from helping you choose the right heater to offering after-sales service.

How to Select the Right Crankcase Heater

Choosing the right crankcase heater for your system involves considering several factors:

Compressor Size: Ensure the heater is compatible with the size and type of your compressor.

Wattage: Select a heater with adequate wattage to maintain the desired crankcase temperature.

Environmental Conditions: Consider factors such as ambient temperature and system location.

Energy Efficiency: Opt for a heater that minimizes energy consumption without compromising performance.

With the guidance of experts at Raghav Industries, you can easily find the perfect solution for your needs.

The Importance of Crankcase Heaters

In the fast-paced world of refrigeration and HVAC systems, downtime or equipment failure can lead to significant losses. Crankcase heaters play a vital role in preventing such issues by ensuring smooth and efficient compressor operations. Their ability to prevent refrigerant migration, reduce maintenance costs, and enhance system reliability makes them a valuable investment for businesses of all sizes.

Conclusion

Crankcase heaters may be a small component in refrigeration and HVAC systems, but their impact on performance and longevity is immense. By maintaining proper lubrication and preventing refrigerant migration, they ensure efficient and reliable compressor operations.