#3D Printing Support Structures

Explore tagged Tumblr posts

Text

"An upcoming community center in Tanzania will be defined by its cutting-edge 3D-printed design. However, rather than being built from layered concrete as you'd usually expect with 3D-printed projects, its walls will be created using locally sourced soil.

The community center is being headed by Hassell, in collaboration with Australian-based charity foundation One Heart, for the Hope Village in Tanzania. It forms part of a wider plan to provide housing, a school, childcare and skills training to vulnerable young girls in Kibaha, eastern Tanzania.

"The Hope Village community hall design seeks to create a beautiful, functional, safe and uplifting environment that provides both hope and education for vulnerable girls," says Mark Loughnan, Principal and Head of Design at Hassell. "The hall is a welcoming space that creates an innovative central activity hub that also connects with its surrounding environment. The design and building process for the hall aims to engage the community and provide ongoing opportunities for local participation and education throughout construction."

Structurally, the community center is quite complex. Its walls (which are not load-bearing) will be built using soil sourced within 25 km (15.5 miles) of the site and a WASP 3D printer. WASP has been researching this stuff for years now and a previous project used a mixture of mud, straw, rice husk and lime. A similar process will be happening here, with a clay based earthen mixture being extruded out of a nozzle in layers to build up the walls. A representative at Hassell told us that the walls will also be reinforced with a thin wire mesh between layers.

Inside, the design brief calls for a large, open floorplan that suits the local climate, with a limited number of columns to ensure its flexibility. To achieve this, Hassell has conceived a central steel beam that serves as the structural spine of the hall. This will support a roof made from locally sourced timber sections. The roof will feature cladding made of readily available corrugated metal sheet panels, helping to keep costs down.

The project also involves the Institute for Advanced Architecture of Catalonia, IAAC, and ClarkeHopkinsClarke. We've no word yet on when it's expected to be completed, though prototype walls have already been produced.

Pictured: A prototype of the community center's 3D printed walls has already been created.

-via NewAtlas, August 13, 2024

#architecture#sustainable architecture#tanzania#africa#3d printing#sustainability#ecofriendly#good news#hope

227 notes

·

View notes

Text

Borrowed my father's 3D printer again so I could try out @solradguy's belt buckle model. The first attempt didn't go so well but after rotating it that went a lot smoother and I'm pretty happy with how it came out! It's not quite as streaky in-person, I assume either my camera did a weird job or the overhead light made the layers reflect oddly

Default (at least upon opening it with the program my father uses) is about 5 1/2 inches wide, which seems pretty realistic (it's a little small on me, but I'm a bigger guy and I'm just using this for decor anyway) so I think it would work well for a cosplay

Only issue I can think of aside from the initial fumble is that the support structures made the top come out a bit coarse and messy, but that's an issue I have with basically every print. I've sanded it down a little, and while it doesn't look perfectly flat it at least feels a lot smoother and doesn't snag on things. There were narrow supports on some of the letters, oddly enough, but those weren't too difficult a removal. I was genuinely very impressed at how nicely the letters came out given their thinness and uneven edges

48 notes

·

View notes

Text

New 3D printing technique replicates nature's delicate fibers with precision

Researchers have been trying to find new ways to produce and replicate the various useful features observed in nature. Fine hairs and fibers, which are ubiquitous in nature, are useful for various applications ranging from sensory hairs to the fibers that give hagfish slime its unique consistency. MechSE Professors Sameh Tawfick and Randy Ewoldt, doctoral candidate M. Tanver Hossain, and external collaborators have addressed this need with their cutting-edge embedded 3D-printing technique, recently published in Nature Communications. Their article, "Fast 3D printing of fine, continuous, and soft fibers via embedded solvent exchange," discusses the science behind their bioinspired approach to the rapid printing of fine fibers in gel. Unlike traditional 3D-printing methods, in which material is deposited layer by layer in ambient air, embedded 3D printing deposits material in a support medium such as hydrogel. When printing in air, models must be oriented such that each layer can support the subsequent layer or, for structures with complex architecture, removable support structures can be printed and later discarded.

Read more.

#Materials Science#Science#3D printing#Fibers#Materials processing#Biomimicry#Hydrogels#Soft materials#University of Illlinois

22 notes

·

View notes

Text

Learned about Rapid Liquid 3D printing and they talked about how the gel supports flexible structures and naturally my only thought was the Sayer Printers and the new bodies waking up in basically a gel mold

19 notes

·

View notes

Note

Do you think luka built that little stage structure in his room? Do you think it might be a hint he's an architect in the happy au?

.

I might be delusional

Building a model himself feels very in character for Luka due to the perfectionism he shows, but I think considering efficiency, it's more likely he requested a model and it was delivered with any other resources he would need to design his performance (like the official floor plans we see under the model).

Crafts are harsh on your hands and considering he's an idol I can't imagine Heperu allowing that, and while 3D printing is also an option, Heperu absolutely wouldn't permit him to waste time and energy learning an "irrelevant" skill like 3D-modeling.

Notably, in the American high school au Luka is an engineering nerd. This could relate to civil engineering but since he was holding a box of computer parts, it's more likely to be computer engineering.

Still this does indicate that he likes building stuff so keep indulging in your architect Luka delulus, I support!!

12 notes

·

View notes

Text

CLASSIFIED: TOP SECRET FOR PRESIDENTIAL USE ONLY

REPOPULATION POD 5C724

Location: Thermopolis, Wyoming Date of Suspension: March 20th, 2039 Irradiation Risk: Tier 10 (Lowest Possible Concern) Pod Success Estimate: 95.8%

Pod 5C724 is a C-grade module containing the standard complement of three male hosts in suspended animation located 1.6 miles beneath Thermopolis, Wyoming. The bunker containing the three support tubes consists of a living area, approximately 1600 square meters in area, a supply storage area with enough rations to support six persons for a minimum of five years, a groundwater purification system designed to cleanse and treat irradiated water from local hot springs, abundant medical supplies, including a surgical center with autoclave, 3D printing facilities with extreme excesses of filament, freezer vault containing 750 vetted sperm samples from viable donors, and facilities adequate for the rearing and education of children.

Construction and final suspension of Pod 5C724's subjects finished only 87 days before The Meltdown, making it the fifth-to-last finished Pod ever constructed and currently the latest-constructed Pod still in service - Pods 1B952 and 9A680 ceased operation during The Meltdown, Pod 5A725 suffered catastrophic system failure in early 2041 during the Battle of the Last Silos, and Pod 7B277 successfully decanted its hosts in 2090, after which it was vacated in 2097. Pod 5C724, in contrast, was over 1000km from all blast sites during The Meltdown and suffered no damage as a result. All systems are nominal.

Pod 5C724 is notable for its extremely high Success Estimate, ranking among the highest given to any of the roughly 7,000 Repopulation Pods scattered across the United States prior to the outbreak of the Century War. Modern probabilists, taking into account environmental factors and skillsets, favorably compare 5C724's chances to the famed Pod 1C087, whose three hosts went on to found the city of New Denver - a booming metropolis of 13,000 people, 61% of whom can trace their ancestry back to at least one of the founders. Like 1C087, Pod 5C724's hosts are considered highly capable, with varied skills and abilities suitable for survival in a post-atomic world.

SUPPORT TUBE 1

Host Name: Giancarlo Orsini Former Occupation: Childhood Development Educator Seed Parent: Maine Senator Edwin Block (deceased 2039) Notable Fertility Attributes: Genetic propensity towards dizygotic twins due to hyperovulation inherited from both sides of his family; Both mother and father have dizygotic twin siblings. Chance of impregnation resulting in dizygotic multiples estimated at 13% per pregnancy.

SUPPORT TUBE 2

Host Name: Oliver Hull Former Occupation: Structural Engineer Seed Parent: Professor Baxter Holloway of Tulane University (deceased 2066) Notable Fertility Attributes: Possesses BRCA1 gene. Recommend preventative mastectomy after first fifteen births to reduce risk of breast cancer.

SUPPORT TUBE 3

Host Name: Dr. Blessing Oladele Former Occupation: Medical Doctor (Androcology Specialty) Seed Parent: Secretary of State Waldo Winchester (deceased 2050) Notable Fertility Attributes: Abnormally high sperm count (>150 million sperm per milliliter) and viability index of over 80%. Sperm was harvested and stored in 94 other Repopulation Pods prior to host's suspension, due to high quality. Oladele is estimated to have over 1000 direct descendants in various localities as a result.

In summary, Pod 5C724 is considered an exceptional candidate for decanting. All three hosts contain low-mutation DNA considered ideal for the creation of a genetically diverse breeding pool. All life support systems in the Pod remain stable, despite 153 years of continuous operation. Due to these factors, this Pod is President Yusupov's top choice for making good on his campaign promise to develop a "Second New Denver" in Wyoming, the territory that narrowly won him the 2188 election. President Yusupov believes that the 2192 election hangs solely on Wyoming voters once again and as such, requested the Department of Repopulation present this data on the most viable option for keeping his promise to voters, in their opinion.

Other Wyoming Repopulation Pods ruled out for various reasons include:

5B299 - Three of five support tubes suffered catastrophic failure, their hosts long dead. Remaining hosts are in excellent health, but the Pod is classed as under-resourced, due to power failures.

5A120 - Geiger counters within the Pod registered a 3 sievert dose during The Meltdown. Hosts are believed to have some level of radiation poisoning, though all ten are currently alive in suspended animation, according to computer systems (which may be unreliable).

5C617 - All hosts alive, but one is pregnant with triplets and another has a bipolar disorder diagnosis. None of the three is a medical doctor. Additionally, diagnostics indicate possible flooding within the Pod from seismic activity.

As such, by presidential decree, Pod 5C724 will begin decanting in one week's time.

16 notes

·

View notes

Text

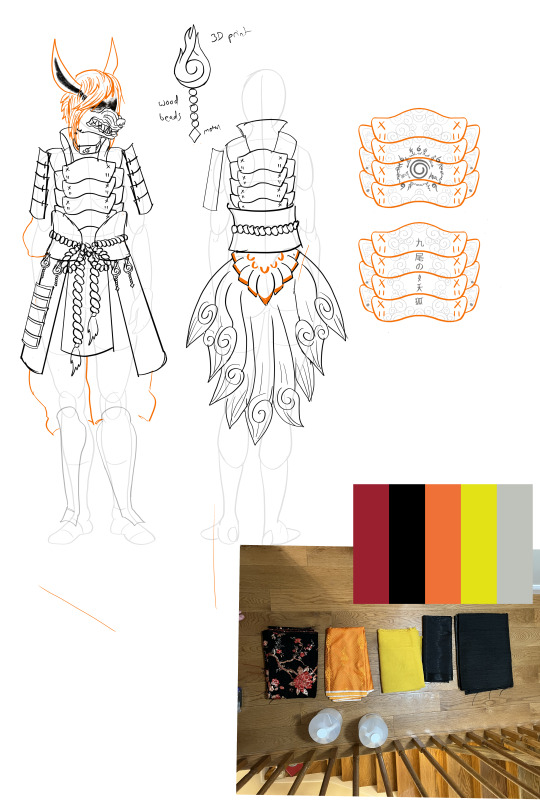

Kurama Samurai Armor Buildlog - The Armor Pt.1

Two years ago (!!!), I embarked on my first sewing cosplay build and first-ever samurai armor project. This was my interpretation of Kurama, the nine-tailed fox from Naruto, and it took about six months from start to finish for the initial version (the final version is pictured below). The design was heavily inspired by the Star Wars Samurai Art figures by Tamashii Nations and the incredible Naruto armor by bakkacosplay!

This post focuses on the making of the armor, specifically the Dou (chestplate) and Sode (shoulder/upper arm pieces). Future posts will cover the clothing, wig, tails, and makeup.

Planning the Armor

I knew I wanted to use EVA foam for the armor to keep it lightweight and allow maximum flexibility for customization. Up until this project, I primarily designed and 3D-printed armor for commissions, but this one-off design was all about creative freedom.

To refine the silhouette and determine how everything would fit together and attach, I visited the Samurai section at the Metropolitan Museum of Art (NYC) to study the shapes and structures of historical armor. Incorporating Naruto’s iconic stomach seal and other subtle nods to the series was a priority, and these elements heavily influenced the final design. I mocked up the concept in Procreate, highlighting key design elements to ensure everything worked cohesively.

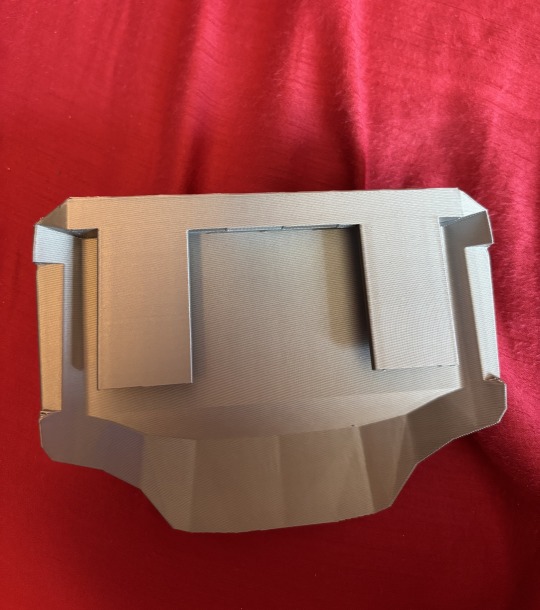

I started with a cardstock mockup to prototype the shapes and details. Cardstock is cheaper and more forgiving than EVA foam, making it perfect for trial runs.

The Dou (chestplate / cuirass)

With the base shape decided, I digitized the outline and added design details. I planned to use my laser cutter for the base design, carving by hand afterward to create a more weathered and textured look. For laser cutting, I created a vector file in Fusion360, though Illustrator would have worked too.

The original design felt a bit flat, so I incorporated the swirling cloud motif of the Akatsuki and added fiery edges for a dynamic, layered aesthetic. Digitizing this took forever but was totally worth it. (If I were to redo this now, I’d use Illustrator for speed!)

The laser cutting process required some trial and error to engrave rather than cut through the foam. Once dialed in, it was smooth sailing. Fresh off the laser cutter, the pieces looked flat, so I used a dremel and soldering iron to add depth and dimension. Each segment consisted of a base piece and a trim piece, which I glued together with contact cement after detailing. Rounding the edges with a dremel softened the look and tied everything together.

Initially, I wanted to carry the cloud pattern onto the backer pieces behind the main armor but found it too visually busy. Instead, I gave these pieces a hammered metal texture using a dremel with a round sanding tip, which allowed the detailed pieces to stand out more.

Sode (shoulder guards)

The process for the Sode (袖) followed a similar path: paper mockup, digitization, laser cutting, and detailing. I added a neckguard and upper chest plate to support the armor and hide attachment points. Here, I prioritized wearability and mobility over strict historical accuracy—an essential balance for costumes.

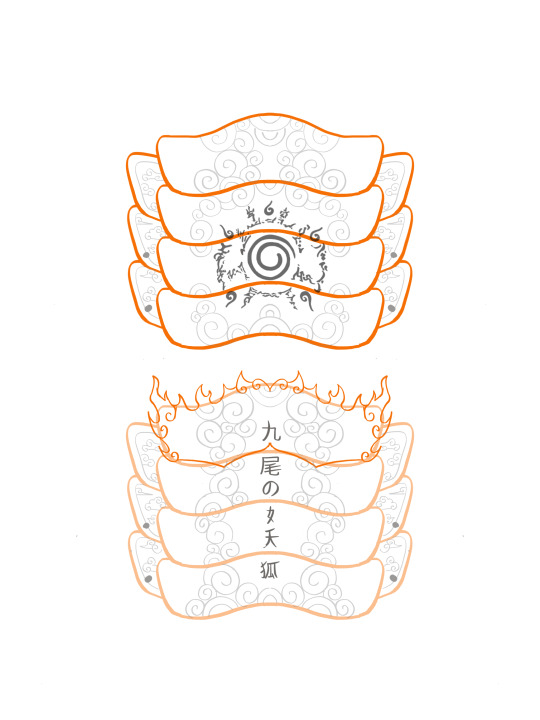

For the Sode pattern, I used a press rather than carving. I designed a stamp in Fusion360 with tiled motifs inspired by Naruto: the Village of the Leaf symbol, Naruto’s swirl, and the Nine-Tails. The stamp was 3D-printed in PETG for durability and used with an arbor press to emboss the foam. Heating the foam before pressing ensured clean transfers, but it meant waiting to shape the pieces until after sealing to preserve the designs.

Unfortunately, I didn’t document this part well, but I’ll create a dedicated post about embossing and sealing techniques in this series! Below is an image of the Sode after weathering and base-coating with metallic black, showing the embossed patterns clearly.

Neckguard and Chest Underlay

These pieces were made from 10mm foam for extra strength since they support much of the armor. Like the other parts, they were laser cut and detailed with a soldering iron. The underlay featured a hexagonal pattern with small circles, marking where I would later hand-sew accents.

For texture, I used a rock to create a natural, organic finish—simply heating the foam and "beating it up" with a textured surface. This technique was quick and gave a subtle, realistic look.

That wraps up Part 1 of the armor! Stay tuned for Part 2, where I’ll dive into the other armor pieces. Feel free to drop any questions below, and I’ll answer them as soon as I can!

9 notes

·

View notes

Text

Unveiling the Threads of Tomorrow: Top Ethnic Wear Trends in India – 2025

Unveiling the Threads of Tomorrow: Top Ethnic Wear Trends in India – 2025

Namaste, fashionistas! As we step into 2025, the world of Indian ethnic wear is more vibrant and exciting than ever. At The Pink Threads, we're constantly on the lookout for what's hot and what's next, and this year promises a beautiful blend of tradition, innovation, and conscious choices. So, get ready to refresh your wardrobes with these top ethnic wear trends!

1. The Rise of Sustainable & Handwoven Fabrics

Sustainability isn't just a buzzword; it's a movement deeply rooted in Indian heritage, and 2025 is seeing it take center stage. There's a growing demand for fabrics that tell a story, made with ethical sourcing and traditional craftsmanship.

What to expect: A surge in organic cotton, handwoven khadi, bamboo silk, and traditional weaves like Chanderi, Jamdani, and Maheshwari. Look for brands that highlight their artisan collaborations.

Why it's trending: Consumers are increasingly conscious of their environmental impact and want to support local artisans and eco-friendly practices. This trend is about timeless pieces that feel good and do good.

2. Indo-Western Fusion: Bolder & More Expressive

The fusion of Indian and Western silhouettes continues to evolve, becoming even more daring and individualistic in 2025. This trend is all about expressing personal style with a playful twist.

Key looks:

Sarees with a modern twist: Think pre-draped sarees for effortless elegance, corset blouses with traditional drapes, ruffle sarees for a playful touch, and even bold slit sarees. Organza and tissue silk sarees, known for their lightweight elegance and delicate sheen, remain popular.

Lehengas with a contemporary edge:Expect minimalist lehengas with statement blouses (think dramatic sleeves, crafted necklines, off-shoulder), fusion lehengas with crop tops, and even lehengas in metallic hues (gold foil, silver, chrome rose). Oversized motifs and 3D details on structured lehengas are also making waves.

Dhoti pants with crop tops, kurtas with structured jackets or shirts, and jumpsuits with ethnic embroidery.

Why it's trending: The younger generation is embracing this blend to express their individuality and create versatile outfits for various occasions, from festive gatherings to chic cocktail parties.

3. Anarkalis Reimagined: Elegance with a Modern Flair

The timeless Anarkali continues its reign, but with fresh, contemporary interpretations for 2025.

Popular styles:

Cape-style Anarkalis: Replacing dupattas with sheer, embellished capes for added drama.

Floor-length, full-sleeved designs: Perfect for a regal and sophisticated look.

Pastel Anarkalis with delicate Resham work: Ideal for daytime events.

Printed Anarkalis in airy fabrics: Offering lightweight elegance and comfort.

Anarkali gowns and tiered Anarkalis:Blending traditional flair with a modern gown silhouette.

Anarkalis with belts: To cinch the waist and add definition.

Fabric focus: Luxurious fabrics like silk, georgette, organza, and velvet, often with intricate zari work or heavy embroidery.

4. Kurta & Kurti Chronicles: Comfort Meets Chic

Kurtas and Kurtis remain a wardrobe staple, and 2025 introduces versatile and stylish options.

Trending silhouettes:

Straight-cut kurtas: Timeless and flattering for all body types, often featuring vibrant prints or embroidery.

A-line kurtas: Structured yet flowy, ideal for all seasons.

Asymmetrical and high-low hemlines:Adding a modern, edgy touch.

Overlay kurtas: Creating a graceful, layered effect.

Peplum kurtas: For a feminine and trendy silhouette.

Shirt-style kurtas: A fusion of Western and Indian fashion, perfect for office wear.

Floor-length kurtas: Exuding elegance and grandeur for festive occasions.

Popular pairings: Paired with straight pants, palazzos, shararas, or even jeans for a chic Indo-Western look.

5. Color Palette & Prints: A Riot of Expression

2025 is all about embracing a diverse and expressive color palette, from muted elegance to bold statements.

Dominant hues:

Soft pastels: Blush rose pink, mint green, lavender, and powder blue for a serene and sophisticated vibe.

Earthy tones: Moss green, rust, and various shades of brown for a grounded and elegant feel.

Vibrant jewel tones: Emerald green, royal indigo blue, ruby red, and fuchsia pink for festive occasions and evening wear. Golden champagne for understated glam.

Saffron orange and lime yellow: For a fiery, festive, and bright touch.

Prints & Patterns:

Maximalist prints: Oversized florals, digital prints inspired by Indian mythology and architecture, tribal motifs, and patchwork designs.

Traditional revivals: Leheriya and Bandhani prints are making a grand comeback, often mixed with modern tailoring.

Intricate embroidery: Hand-embroidered motifs, from delicate florals to intricate geometric patterns, are shining brighter than ever.

6. Artisan Craftsmanship: Honoring Heritage

There's a renewed appreciation for the rich heritage of Indian textile crafts. In 2025, these artisanal techniques are being celebrated and integrated into contemporary designs.

Crafts to watch: Cheriyal, Madhubani, Sikki craft, Block Prints, and Sujani embroidery.

Why it's trending: Consumers are seeking unique, handcrafted pieces that tell a story and support local communities, aligning with the broader sustainable fashion movement.

Final Word from The Pink Threads

2025 is set to be a landmark year for Indian ethnic fashion, where comfort, conscious choices, and personal expression reign supreme. Whether you're a minimalist who loves subtle elegance or a maximalist who embraces bold prints and vibrant colors, there's a trend for everyone. So, go ahead, experiment with textures, embrace handmade crafts, and celebrate your unique style with pride!

Ready to Weave Your Own Style Story?

Inspired by the trends of 2025? It's time to transform your wardrobe! Explore our latest collection at The Pink Threads and discover stunning ethnic wear that embodies these trends—from sustainable weaves to bold Indo-Western fusions.

Shop Now and Elevate Your Ethnic Style!

What are your favorite ethnic wear trends for 2025? Share your thoughts in the comments below!

#The Pink Threads#Ethnic Wear Trends India 2025#Indian fashion#fashion forecast#ethnic fashion blog#sustainable ethnic wear#handwoven fabrics#Indo-Western fusion#Anarkalis#cape-style Anarkalis#floor-length Anarkalis#pastel Anarkalis#printed Anarkalis#Anarkali gowns#tiered Anarkalis#Anarkalis with belts#Kurtas#straight-cut kurtas#A-line kurtas#asymmetrical kurtas#high-low hemlines#overlay kurtas#peplum kurtas#shirt-style kurtas#floor-length kurtas#Kurtis#Sarees#pre-draped sarees#corset blouse saree#ruffle saree

2 notes

·

View notes

Text

National Institute of Fashion Technology - [NIFT], Patna

National Institute of Fashion Technology (NIFT), Patna – An In-Depth Overview (800 Words)

Established in 2008, the National Institute of Fashion Technology (NIFT), Patna is one of the key centers of excellence under the Ministry of Textiles, Government of India. Since its inception, NIFT Patna has been committed to nurturing creativity, innovation, and professionalism in the field of fashion and design. Strategically located in Bihar’s capital, this institute blends traditional cultural richness with cutting-edge design education.

Academic Programs

NIFT Patna offers various undergraduate and postgraduate programs designed to equip students with both creative and technical skills essential for the fashion and lifestyle industry.

Undergraduate Programs:

Bachelor of Design (B.Des) in:

Fashion Design

Fashion Communication

Textile Design

Bachelor of Fashion Technology (B.FTech):

Specialization in Apparel Production

Postgraduate Programs:

Master of Design (M.Des) – Focused on advanced design methodology and design thinking.

Master of Fashion Management (MFM) – Concentrated on business strategies, retail, and fashion marketing.

The curriculum is structured to provide theoretical knowledge, hands-on training, and industry exposure. A blend of classroom learning, workshops, internships, and live projects ensures that students develop a deep understanding of design concepts and business dynamics.

Campus Infrastructure and Facilities

NIFT Patna’s campus offers a modern environment conducive to learning, innovation, and collaboration:

Design Studios and Labs are equipped with high-end machinery and tools that allow students to practice weaving, dyeing, garment construction, printing, pattern making, and digital design.

Computer Labs: Advanced software for CAD, 3D modeling, graphic design, and garment manufacturing systems are accessible to students for academic and project work.

Library: A vast collection of books, journals, and digital resources covering subjects like fashion, textiles, marketing, and management.

Workshops and Resource Centers: For practical training in accessory design, leather craft, and traditional Indian textiles.

Exhibition Spaces: Areas for displaying student projects and hosting fashion events and displays.

Hostel Facilities: Comfortable and safe accommodation options for both male and female students with necessary amenities like Wi-Fi, common rooms, mess, and laundry services.

Cafeteria and Recreation: Clean dining facilities with a variety of food options, along with indoor and outdoor sports infrastructure.

Placement and Industry Interface

NIFT Patna maintains strong ties with leading fashion houses, retail giants, and manufacturing units, facilitating career opportunities and internships for students.

Placement Cell Activities:

Organizes annual campus placements

Conducts workshops on resume writing and interview preparation

Hosts mock interviews and career counseling sessions

Arranges industry visits and interaction programs

Top Recruiters Include:

Adidas

Arvind Mills

H&M

Levi’s

FabIndia

Pantaloons

Raymond

Van Heusen

Future Group

Tommy Hilfiger

Placement Statistics:

Average Salary: ₹5 to ₹8 LPA

Highest Package: Up to ₹12 LPA

Sectors Covered: Fashion design, apparel manufacturing, brand management, fashion merchandising, retail strategy, and textile development

Scholarships and Financial Assistance

NIFT Patna offers financial aid through scholarships to ensure that deserving and meritorious students are not denied education due to economic constraints.

Sarthak Scheme: Provides fee waivers ranging from 50% to 100% based on the student’s family income and academic performance.

UDAAN Program: Supports students pursuing higher studies abroad under exchange or twinning programs.

These initiatives promote inclusivity and accessibility in fashion education, encouraging students from diverse backgrounds to pursue their passion.

Student Life and Activities

Student life at NIFT Patna is vibrant, collaborative, and filled with opportunities to express creativity beyond the classroom.

Cultural and Technical Fests: Events like Spectrum and Converge provide platforms for students to showcase their talent in fashion, performing arts, and innovation.

Clubs and Societies: Various student-led clubs cater to interests like photography, styling, film-making, design thinking, entrepreneurship, and sustainability.

Guest Lectures and Workshops: Regular sessions by industry professionals and alumni offer practical insights into the global fashion ecosystem.

Internships: All students undergo compulsory internships with fashion brands, designers, or production houses to apply theoretical knowledge in real-world settings. Many of these internships convert into pre-placement offers.

Conclusion

NIFT Patna is a center of excellence that offers a holistic fashion education combining design, technology, and management. With its modern infrastructure, committed faculty, industry-oriented curriculum, and strong placement support, it creates well-rounded professionals ready to meet the demands of the global fashion and lifestyle market. The campus environment encourages experimentation, innovation, and cultural exchange—making it an ideal place for aspiring fashion designers, technologists, and managers to grow and thrive.

#NIFTPatna#NationalInstituteOfFashionTechnology#FashionEducation#DesignYourFuture#TextileDesign#FashionDesign#ApparelProduction#FashionManagement#NIFTIndia#CreativeCareers

2 notes

·

View notes

Text

1. Structural Foundations of the SMART Visa Program

1.1 Legislative Architecture

The SMART Visa operates under:

Royal Decree on SMART Visa B.E. 2561 (2018)

Thailand 4.0 Economic Policy Framework

BOI Investment Promotion Act (No. 4) B.E. 2560

1.2 Interagency Governance

Primary Authority: Board of Investment (BOI)

Implementation Partners:

Immigration Bureau (visa issuance)

Ministry of Digital Economy and Society (tech qualifications)

Ministry of Higher Education (academic validation)

2. Category-Specific Qualification Matrix

2.1 SMART-T (Specialists)

Technical Thresholds:

Salary Floor: THB 200,000/month (USD 5,800)

Experience Validation:

5+ years in qualifying field

Patent holders given priority

PhD waivers for certain disciplines

Industry Prioritization:

Biotechnology (Gene Therapy, Precision Medicine)

Advanced Manufacturing (Robotics, 3D Printing)

Digital Infrastructure (AI, Quantum Computing)

2.2 SMART-I (Investors)

Due Diligence Process:

Phase 1: BOI business plan review (45 days)

Phase 2: Anti-money laundering clearance

Phase 3: Investment tracing audit

2.3 SMART-E (Entrepreneurs)

Startup Validation Framework:

Tier 1 Incubators: DEPA, Thai Venture Capital Association

Minimum Traction Metrics:

THB 10M ARR or

50,000 MAU or

Series A funding

Capital Requirements:

Bootstrapped: THB 600,000 liquid

Funded: Minimum THB 5M valuation

3. Advanced Application Mechanics

3.1 Document Authentication Protocol

Educational Credentials:

WES or IQAS evaluation for non-Thai degrees

Notarized Thai translations

Employment History:

Social security cross-verification

Reference checks with former employers

3.2 Technical Review Process

Stage 1: Automated system screening

Stage 2: BOO specialist committee review

Stage 3: Final approval by Deputy Secretary-General

4. Privilege Structure and Limitations

4.1 Work Authorization Scope

Permitted Activities:

Primary employment with sponsor

Consulting (max 20% time allocation)

Academic collaboration

Prohibited Activities:

Local employment outside specialty

Unapproved commercial research

Political activities

4.2 Dependent Provisions

Spousal Work Rights:

General employment permitted

No industry restrictions

Child Education:

International school subsidies

University admission preferences

4.3 Mobility Advantages

Fast-Track Immigration:

Dedicated SMART lanes at 6 major airports

15-minute clearance guarantee

Re-entry Flexibility:

Unlimited exits without visa voidance

Automatic 48-hour grace period

5. Compliance and Renewal Dynamics

5.1 Continuous Eligibility Monitoring

Quarterly Reporting:

Employment verification

Investment maintenance

Research output (for academics)

Annual Review:

Salary benchmark adjustment

Contribution assessment

5.2 Renewal Process

Documentation Refresh: Updated financials, health insurance

Performance Evaluation: Economic impact assessment

Fee Structure: THB 10,000 renewal fee + THB 1,900 visa stamp

5.3 Grounds for Revocation

Material Changes: Employment termination, investment withdrawal

Compliance Failures: Missed reporting, legal violations

National Security Concerns: Classified determinations

6. Comparative Analysis with Global Competitors

6.1 Strategic Advantages

Tax Optimization: 17% flat rate option

Research Incentives: BOO matching grants

Commercialization Support: THBI co-investment

7. Emerging Policy Developments

7.1 2024 Program Enhancements

Blockchain Specialist Category (Q3 rollout)

Climate Tech Fast-Track (Carbon credit linkage)

Regional Expansion: Eastern Economic Corridor focus

7.2 Pending Legislative Changes

Dual Intent Provision: PR application without visa surrender

Skills Transfer Mandate: Local training requirements

Global Talent Pool: Reciprocal agreements in negotiation

8. Practical Application Strategies

8.1 Pre-Application Optimization

Salary Structuring: Base vs variable compensation

Patent Portfolio Development: Thai IP registration

Local Network Building: Thai professional associations

8.2 Post-Approval Planning

Tax Residence Strategy: 180-day calculations

Asset Protection: Thai holding company formation

Succession Planning: Will registration requirements

9. Critical Risk Factors

9.1 Common Rejection Reasons

Document Discrepancies: Date inconsistencies

Qualification Gaps: Unrecognized certifications

Financial Irregularities: Unverified income streams

9.2 Operational Challenges

Banking Restrictions: Foreign account limitations

Healthcare Access: Specialty treatment approvals

Cultural Integration: Workplace adaptation

10. Conclusion: Strategic Implementation Framework

For optimal SMART Visa utilization:

Pre-qualification Audit: 90-day preparation period

BOI Engagement: Pre-submission consultation

Compliance Infrastructure: Digital reporting systems

Contingency Planning: Alternative category eligibility

#thailand#immigration#immigrationinthailand#thailandvisa#thaivisa#visa#thai#thailandsmartvisa#smartvisa#smartvisainthailand#thaismartvisa

2 notes

·

View notes

Text

Welding materials on the moon

Before humans can colonize the moon or Mars, scientists and engineers must first develop techniques for building permanent structures and pressurized habitats in harsh, thin-atmosphere and low-gravity environments.

Dr. Wei Li, an assistant professor of mechanical engineering in the Erik Jonsson School of Engineering and Computer Science at The University of Texas at Dallas, is developing a virtual lunar welding platform to troubleshoot assembling large structures in such conditions.

“As we try to return to the moon and reach Mars, keeping astronauts safe while achieving the missions is very important,” said Dr. Edward White, professor and department head of mechanical engineering and holder of a Jonsson School Chair. “Being in Earth’s orbit is a lot easier knowing that when things go wrong, we can make repairs and return safely. I’m really excited that Dr. Li’s research will help play an important role in making space travel safer and will enable us to successfully complete space missions.”

Li recently received an Early Stage Innovations three-year grant from NASA for up to $750,000 to support his study of welding on the surface of the moon. He was one of six researchers nationwide selected to receive the 2024 annual award, which is designed to accelerate the development of groundbreaking, high-risk/high-payoff space technologies.

“There are three main challenges for the astronauts working on the moon’s surface,” Li said. “The moon has a very thin atmosphere, so there are steep temperature changes, from around minus 387 degrees Fahrenheit to 260 degrees Fahrenheit. There is also an extreme vacuum environment due to the thin atmosphere. Finally, the gravity on the moon’s surface is only about one-sixth that of the Earth. The extreme environment can complicate the reliable implementation of building or manufacturing large structures on the moon’s surface and can lead to manufacturing defects.”

Welding metal in such an environment can cause defects that impact the material’s load-bearing capability, leading to fractures and ductile cracks; nevertheless, in-space assembly is vital to NASA’s long-term exploration goals, Li said.

“It would be very hard to establish regular machine shops on the moon’s surface to manufacture metal structures as we do on Earth,” Li said. “However, it could be possible to use spacecraft to ship metal components from the Earth to the moon, then deploy welding technology there to assemble the components into large structures that could enable the establishment of a human community.”

Li’s project will simulate lunar conditions to test the processes of electrical arc, laser and electron-beam welding in that type of environment. His virtual lunar welding platform simulates the welding process and welding-joint mechanical properties with a multiple-physics modeling approach. Among the equipment he is using is a custom-built, directed energy deposition machine, a technology typically used for additive manufacturing of metals. Li said the research also could be applied to fused deposition modeling, a type of 3D-printing process that can print nonmetallic parts in space.

Li, who directs the Comprehensive Advanced Manufacturing Lab in the Jonsson School, will work with his team to create the simulated environment at UT Dallas while working directly with NASA researchers, including Dr. Fredrick Michael from NASA’s Marshall Space Flight Center.

Li said his team will validate the simulation framework and modeling results with both space-based and on-the-ground experiments, as well as with historical experimental flight data from Skylab, the first U.S. space station. He said the model could be developed further for other space environments, including Mars and the International Space Station.

Dr. Wei Li received a grant from NASA to develop a platform that could overcome some of the challenges in building permanent structures in harsh, thin-atmosphere and low-gravity environments. Credit The University of Texas

2 notes

·

View notes

Text

Anyone with a Masters degree in materials engineering (or potentially related field) background looking for a PhD scholarship in New Zealand? I'm about to post this on my work LinkedIn...

PhD scholarship – Large format 3D printing with biocomposites

Background: We have a fully-funded PhD scholarship as part of the MBIE Endeavour project “Āmiomio Aotearoa: A Circular Economy for the Wellbeing of New Zealand”. The project is a collaboration between universities, research institutes, industry, community groups and government ministries hosted by the School of Engineering at Waikato University. It aims to pave the way through materials science, engineering, energy, economics, kaupapa Māori, business, law and regulation, social science and public policy for a more sustainable New Zealand.

As a PhD student at the University of Waikato, you would be focused on advancing sustainable manufacturing practices through the development and application of biocomposites.

The successful candidate will explore the use of biopolymers, recycled thermoplastics, and natural fibres to formulate high-performance biocomposites suitable for large format 3D printing (furniture, small structures, interior design). The research will delve into multiple aspects of these materials, including their performance, printability, design optimisation, and life cycle assessment.

This interdisciplinary project provides a unique opportunity to contribute to cutting-edge research at the intersection of materials science, environmental sustainability, and advanced manufacturing technologies. We invite passionate and driven individuals to join our team and contribute to this transformative research endeavour.

Your ideal background:

MSc/ME in a related Science/Engineering discipline

experience with natural materials

familiar with CAD design and 3D printing is a plus

experience in life cycle assessment is a plus

a willingness to learn, up-skill and work in multidisciplinary group

a professional attitude, good writing and time management skills

resilience to take on the challenge of the research experience

Value: a stipend of NZ$30,000 per year, domestic tuition fees and insurance, and support for research materials.

Application documents required

CV including contact details for 2-3 referees (including at least one academic reference)

Academic transcript from previous study undertaken (and thesis if available/applicable)

A personal statement (max 1 page) describing your motivation, interests and background related to the research project

English language Certificate where English is not the first language (IELTS/TOEFL)

LINKEDIN for contact details of the guy and you can see he's got the scholarship listed as well.

7 notes

·

View notes

Text

Empa researchers are working on artificial muscles that can keep up with the real thing. They have now developed a method of producing the soft and elastic, yet powerful structures using 3D printing. One day, these could be used in medicine or robotics -- and anywhere else where things need to move at the touch of a button. Artificial muscles don't just get robots moving: One day, they could support people at work or when walking, or replace injured muscle tissue. However, developing artificial muscles that can compare to the real thing is a major technical challenge. In order to keep up with their biological counterparts, artificial muscles must not only be powerful, but also elastic and soft. At their core, artificial muscles are so-called actuators: Components that convert electrical impulses into movement. Actuators are used wherever something moves at the push of a button, whether at home, in a car engine or in highly developed industrial plants. However, these hard mechanical components do not have much in common with muscles just yet.

Read more.

7 notes

·

View notes

Text

Veterinary Orthotics-Prosthetics Market Drivers Shaping the Future of Animal Healthcare and Rehabilitation

The veterinary orthotics-prosthetics market has seen significant growth in recent years due to an increasing demand for advanced solutions to enhance the mobility and quality of life for animals. Veterinary orthotics and prosthetics (O&P) refer to devices designed to assist animals suffering from mobility issues caused by injury, disease, or congenital conditions. These devices are typically custom-made to suit the unique anatomical structure of each animal, offering both functional and therapeutic benefits. With the rising awareness about animal healthcare and a greater emphasis on improving animal welfare, several key drivers have emerged, fueling the expansion of this market.

Growing Awareness of Animal Healthcare

One of the most significant drivers of the veterinary orthotics-prosthetics market is the increasing awareness surrounding animal healthcare. As more pet owners recognize the importance of medical treatments and rehabilitation for their animals, the demand for customized orthotic and prosthetic devices has risen. Pets, especially dogs and cats, often experience joint disorders, fractures, or amputations, necessitating rehabilitation through these devices. As people become more conscious of their pets' well-being, they are seeking solutions to manage pain, improve mobility, and ultimately enhance their quality of life.

Advancements in Veterinary Medicine and Technology

Technological advancements in veterinary medicine play a vital role in driving the veterinary orthotics-prosthetics market. The continuous development of 3D printing, CAD (computer-aided design) software, and materials science has led to more precise, effective, and affordable orthotic and prosthetic devices. These innovations have allowed for better customization of devices, ensuring a perfect fit for animals while improving comfort and mobility. In addition, the use of high-tech materials that mimic the natural movement of joints and bones has contributed to more durable and efficient solutions for pets.

Increase in Pet Ownership and Humanization of Pets

The humanization of pets has played a crucial role in the growth of the veterinary orthotics-prosthetics market. As pets are increasingly seen as members of the family, pet owners are willing to invest in treatments that enhance their pets' health and overall well-being. The rising number of pet adoptions, particularly in urban areas, has created a growing market for specialized healthcare solutions. With an increasing focus on providing pets with the same quality of care as humans, the demand for advanced orthopedic treatments and mobility devices has surged.

Rising Incidence of Pet Injuries and Disabilities

The rising incidence of injuries, diseases, and disabilities in pets has further contributed to the growth of the veterinary orthotics-prosthetics market. Accidents, joint issues, and congenital abnormalities have become more prevalent in both domestic and wild animals, necessitating the use of specialized orthotics and prosthetics. Dogs, for example, are particularly prone to hip dysplasia, fractures, and ligament tears, leading to the increasing demand for joint braces, prosthetic limbs, and other mobility aids. The aging population of pets also requires more frequent interventions to manage conditions like arthritis, driving the need for orthopedic solutions.

Support from Veterinary Professionals and Research

Veterinary professionals and research institutions play a crucial role in the development and adoption of orthotic and prosthetic devices. As more veterinary professionals embrace these technologies, they are not only improving treatment outcomes but also educating pet owners about the benefits of orthotic and prosthetic solutions. Additionally, ongoing research and clinical trials continue to optimize the design and functionality of these devices. With a growing body of evidence supporting the effectiveness of O&P treatments in animals, the market is expected to continue expanding.

Expanding Veterinary Care Networks and Facilities

The expansion of veterinary care networks and specialized animal hospitals has also contributed to the growth of the veterinary orthotics-prosthetics market. Veterinary clinics that offer specialized services, including orthotics and prosthetics, are becoming more common. This expansion has made these treatments more accessible to pet owners, leading to an increase in demand for customized solutions. As these services become more mainstream, pet owners are more likely to explore O&P devices as viable options for their animals' care.

In conclusion, the veterinary orthotics-prosthetics market is driven by a combination of factors, including increasing awareness of animal healthcare, technological advancements, the humanization of pets, rising pet injuries, and support from veterinary professionals. These drivers are shaping the future of veterinary care and rehabilitation, ultimately improving the lives of countless animals around the world.

3 notes

·

View notes