#AC-DC Charging Module

Explore tagged Tumblr posts

Text

In which cases, you would prefer to use a DC-DC charging converter but not a AC-DC charging module?

DC-DC charging converters and AC-DC charging modules have their own advantages and applicability in different situations. Here are some situations where you may prefer to use a DC-DC charging converter instead of an AC-DC charging module:

DC power demand: When your electric device or system mainly requires DC power, a DC-DC charging converter is a more direct choice to avoid the energy loss of AC-DC conversion. Portable electric vehicle charger application: For portable chargers, especially those that require lightweight and portability, DC-DC charging converters may be more suitable because they are generally more compact and lightweight. Battery-based electric vehicle charging system: In battery-based electric vehicle charging systems, DC charging is more direct and efficient, so a DC-DC charging converter may be a better choice. In areas with unstable AC grid power: In areas with unstable power supply, using a DC-DC charging converter can better control and adapt to power fluctuations and improve system stability. Power transmission between batteries: When power needs to be transmitted between batteries, using a DC-DC charging converter can more efficiently achieve DC power conversion and transmission.

In general, when DC power, high efficiency, compact size, or direct battery charging are required, you may prefer to use a DC-DC charging converter instead of an AC-DC charging module.

1 note

·

View note

Text

AC/DC EV Charging Station, OEM/ODM Customization, Type 1 Sae J1772, Type 2, CCS1,CCS2 etc. Connectors/Socket #EVSECharger #EVcharging Station #Automotiveaccessories #EVChargingInfrastructure #EVChargingInstallation #ElectricVehicles #Emobility #plugandcharge #DCfastCharging

Goproenergy ODM/OEM AC/DC EV Charging Solutions Provider| Established in 1994| Listed in 2017| Stock Code: SZ300632

with six production bases in China and one in Malaysia, covering over 160,000 square meters,

With much export experience and strong capital support, products certified with ETL, FCC, Energy Star,CE and UKCA etc., trustable for the aftersales services.

For More info, please kindly check the followings, Thanks:

Mob/whatsapp/Skype :+86 13925006856

Email: [email protected]

Website: www.goproenergy.com

linkedin.com/in/goproenergy-evcharger-evse

youtube.com/@goproenergy_evcharger_evse

facebook.com/goproenergy.evcharger.evse

instagram.com/goproenergy_evcharger_evse

x.com/Gopro_EVCharger

tiktok.com/@goproenergy_evcharger

#electrocar#EVSE Charger#Electric Vehicles#Automotivesaccessories#Emobility#DC fast Charging#PlugandCharge#Electricvehicleinfrastructure#EVcharginginstallation#EVchargingstation#AC EV Charging pile#EV Charging Modules

1 note

·

View note

Text

Linkpowercharging: Leading the New Era of Electric Mobility

Founded in 2018, Linkpowercharging has been deeply engaged in the electric vehicle charging field for over 8 years. We specialize in providing comprehensive R&D solutions—including software, hardware, and design—for AC/DC charging stations, enabling our products to hit the ground running. With our expert team and relentless pursuit of innovation, Linkpowercharging has successfully delivered reliable products worth over $100 million to partners in more than 30 countries, including the United States, Canada, Germany, the United Kingdom, France, Singapore, Australia, and more.

Quality and Certification: With a team of over 60 skilled professionals, we have earned authoritative certifications such as ETL, FCC, CE, UKCA, CB, TR25, and RCM, ensuring that our products meet the strictest global safety and quality standards.

Technological Innovation: Our AC and DC fast chargers are powered by OCPP 1.6 software and have undergone rigorous testing with over 100 platform suppliers. We also support upgrades to the latest OCPP 2.0.1. In addition, by integrating IEC/ISO 15118 modules, we are actively advancing V2G (vehicle-to-grid) bidirectional charging technology.

Future Vision: Linkpowercharging is committed to driving the integration of clean energy and intelligent connectivity. In addition to offering high-performance EV charging solutions, we have also developed integrated systems that combine solar photovoltaic (PV) technology and lithium battery energy storage systems (BESS). Our mission is to build a greener, smarter future for global customers.

Whether you’re a forward-thinking business partner or an industry observer passionate about environmental innovation, Linkpowercharging is the trusted choice for your electric mobility transition. Let’s drive the future together and embark on this new era of electric mobility!

2 notes

·

View notes

Text

What Is The Difference Between UPS And Inverter?

Stable and reliable power supply has become the key to the normal operation of homes and businesses. Whether it is data centers, medical equipment, or home appliances and office equipment, power outages may cause losses or inconveniences. In order to ensure that key equipment can continue to operate during power outages, UPS (uninterruptible power supply) and inverters have become two common backup power solutions. In this article, we will analyze the difference between inverters and UPS.

What is uninterruptible power supply (UPS)?

UPS is a device that can immediately provide power to the load when the power is interrupted. Its core advantage is that the switching speed is extremely fast (milliseconds), which can ensure the stable operation of devices that are sensitive to power failures, such as servers, hospital instruments, industrial control systems, etc.

UPS usually includes batteries, battery chargers, transfer switches and inverter modules. When the mains power is normal, the UPS charges the battery through the charger; once the power is off, the system switches to battery power almost instantly without affecting the operation of the load.

UPS also has a power quality regulation function, which can effectively filter out voltage surges, spikes, low voltage and noise, providing a safer power environment for precision equipment.

UPS features:

Short switching time (<10 milliseconds), seamless protection of sensitive loads

With voltage regulation and surge suppression

Limited built in battery capacity, usually only supports 10-30 minutes of emergency power supply

Suitable for high demand scenarios such as IT equipment, bank terminals, industrial control, etc.

What is inverter?

The inverter is a device that converts DC power such as batteries or solar energy into AC power. Compared with UPS, the inverter has a slightly slower startup response time, usually between a few hundred milliseconds and a few seconds, but its scalable battery capacity makes it more advantageous in long term backup power supply, suitable for home and small and medium sized commercial use.

Inverters are mostly used in photovoltaic systems or areas with unstable city power, and can be used with batteries to power common loads such as lighting, fans, refrigerators, and TVs.

Inverter features:

Flexible energy storage capacity, can support power supply for hours or even longer

Slightly longer startup time, usually 0.5~2 seconds

Suitable for home, commercial and solar power generation scenarios

How should home or business choose?

Whether to choose UPS or inverter depends on the frequency of power outages, load type and backup time requirements:

Data centers, medical facilities or precision equipment that is extremely sensitive to voltage fluctuations: UPS is recommended to ensure uninterrupted and interference-free operation.

Home users or small and medium sized enterprises: If the power supply environment is unstable and electricity is required for a long time, it is recommended to use an inverter, which is more cost effective.

Mixed scenarios: Some users also use UPS and inverter at the same time, the former to protect precision equipment and the latter to support daily lighting and electricity.

If you already have an inverter, do you still need UPS?

For general home use, a reliable pure sine wave inverter is usually sufficient. But if you also need to protect critical equipment such as laptops and servers, you can install an additional UPS on these devices to ensure continued operation at the moment of power outage to avoid data loss.

It should be noted that the compatibility of UPS and inverter should also be considered. For example, if the inverter output is a non sinusoidal wave (such as a square wave or a modified sine wave), it may affect the normal operation of some UPS. Therefore, before purchasing a product, it is recommended to confirm the output waveform and load compatibility with the inverter manufacturer.

If you are looking for a suitable backup power system for your home, factory, shop or data center, please contact us at Xindun Power.

0 notes

Text

How Do Power, Motor & Robotics Development Tools Drive Innovation in Automation?

Introduction to Modern Development Ecosystems

As the era of intelligent machines, automation, and smart manufacturing continues to advance, Power, Motor & Robotics Development Tools have emerged as essential components in transforming ideas into functioning prototypes and commercial solutions. These tools serve as the backbone for developing precise and reliable control systems used in a wide variety of sectors—from industrial robotics to electric mobility.

With the increasing integration of microcontrollers, sensors, thermal management components, and electronic controllers, development tools offer a modular and practical approach to building sophisticated electronic and electromechanical systems.

What Are Power, Motor & Robotics Development Tools?

Power, Motor & Robotics Development Tools consist of hardware kits, interface boards, and control modules designed to help developers and engineers test, prototype, and deploy automated systems with precision and speed. These tools make it possible to manage current, voltage, mechanical motion, and real-time decision-making in a structured and scalable manner.

By combining essential components such as capacitors, fuses, grips, cables, connectors, and switches, these kits simplify complex engineering challenges, allowing smooth integration with controllers, microprocessors, and sensors.

Exploring the Primary Toolsets in the Field

Power Management Development Tools

Efficient energy management is crucial for ensuring stability and performance in any robotic or motor-driven system.

Development boards supporting AC/DC and DC/DC conversion

Voltage regulators and surge protection circuits for safe energy flow

Thermal sensors and oils to maintain system temperature

Battery management ICs to control charge-discharge cycles

High-efficiency transformers and current monitors

Motor Control Development Tools

Motor control kits are built to manage torque, direction, and speed across a range of motor types.

H-bridge motor drivers for bidirectional motor control

Stepper motor controllers with high-precision movement

Brushless DC motor driver modules with thermal protection

Feedback systems using encoders and optical sensors

PWM-based modules for real-time torque adjustment

Robotics Development Tools

Robotics kits merge both mechanical and electronic domains to simulate and deploy automation.

Preassembled robotic arm platforms with programmable joints

Sensor integration boards for object detection, motion sensing, and environmental monitoring

Wireless modules for IoT connectivity using BLE, Wi-Fi, or RF

Microcontroller development platforms for logic execution

Mounting hardware and cable grips for secure installations

Benefits of Using Professional Development Tools

Advanced development kits offer more than just experimentation—they serve as stepping stones to commercial production. These tools minimize development time and maximize productivity.

Enhance system performance with modular plug-and-play designs

Enable easy integration with laptops, diagnostic tools, and controllers

Reduce design errors through pre-tested circuitry and embedded protection

Facilitate rapid software and firmware updates with compatible microcontrollers

Support debugging with LED indicators, thermal pads, and status feedback

Key Applications Across Industries

The adaptability of Power, Motor & Robotics Development Tools makes them suitable for countless industries and applications where intelligent movement and power efficiency are essential.

Industrial robotics and pick-and-place systems for manufacturing automation

Smart agriculture solutions including automated irrigation and drone control

Automotive design for electric vehicle propulsion and battery systems

Aerospace applications for lightweight, compact control mechanisms

Educational platforms promoting STEM learning with hands-on robotics kits

Essential Components that Enhance Development Kits

While the kits come equipped with core tools, several other components are often required to expand capabilities or tailor the kits to specific use cases.

Sensors: From temperature and light to current and magnetic field detection

Connectors and plugs: For flexible integration of external modules

Switches and contactors: For manual or automatic control

Thermal pads and heatsinks: For preventing overheating during operation

Fuses and circuit protection devices: For safeguarding sensitive electronics

LED displays and character LCD modules: For real-time data visualization

How to Choose the Right Tool for Your Project

With a vast array of kits and tools on the market, selecting the right one depends on your application and environment.

Identify whether your project focuses more on power management, motor control, or full robotic systems

Consider compatibility with popular development environments such as Arduino, STM32, or Raspberry Pi

Check the current and voltage ratings to match your load and motor specifications

Evaluate add-on support for wireless communication and real-time data processing

Ensure the tool includes comprehensive documentation and driver libraries for smooth integration

Why Development Tools Are Crucial for Innovation

At the heart of every advanced automation solution is a well-structured foundation built with accurate control and reliable hardware. Development tools help bridge the gap between conceptualization and realization, giving engineers and makers the freedom to innovate and iterate.

Encourage experimentation with minimal risk

Shorten product development cycles significantly

Simplify complex circuit designs through preconfigured modules

Offer scalability for both low-power and high-power applications

Future Scope and Emerging Trends

The future of development tools is headed toward more AI-integrated, real-time adaptive systems capable of learning and adjusting to their environment. Tools that support machine vision, edge computing, and predictive analytics are gaining traction.

AI-powered motion control for robotics

Integration with cloud platforms for remote diagnostics

Advanced motor drivers with feedback-based optimization

Miniaturized power modules for wearable and mobile robotics

Conclusion: Is It Time to Upgrade Your Engineering Toolkit?

If you're aiming to build smarter, faster, and more energy-efficient systems, Power, Motor & Robotics Development Tools are not optional—they’re essential. These kits support you from idea to implementation, offering the flexibility and performance needed in modern-day innovation.

Whether you're developing a prototype for a high-speed robotic arm or integrating power regulation into a smart grid solution, the right development tools empower you to transform challenges into achievements. Take the leap into next-gen automation and electronics by investing in the tools that make engineering smarter, safer, and more efficient.

#Power Motor & Robotics Development Tools#electronic components#technology#electricalparts#halltronics

0 notes

Text

How a Residential Solar Power System Works

Solar power systems convert sunlight into Direct Current (DC) electricity. The electricity is then converted into Alternating Current (AC) electricity by an inverter. The AC electricity is fed into your home's central electrical panel through copper wires.

In regions with net metering, the utility grid acts as a battery, banking excess solar energy for use at night. Adding a home solar battery provides further bill savings and energy independence.

Cost

A residential solar power system is a smart long-term investment in reducing your home energy costs and helping to create a more sustainable future. However, like any major purchase, the upfront cost can be a hurdle to overcome. Luckily, there are many financing options that allow you to reduce up-front expenses and start saving from day one.

The cost of your solar energy system depends on several factors. These include the type of solar panels and other equipment, such as inverters, racking systems, and monitoring technology, which can increase efficiency and longevity. Your energy consumption plays a big role as well. Review your recent electricity bills to estimate how many kilowatt-hours (kWh) you use annually.

Using the average kWh usage, you can determine what size solar system you need. Choosing an appropriately-sized system can help you maximize your financial savings.

Energy Savings

Homeowners can save money with solar power by reducing their electricity bills. Depending on how much energy they consume and their state's policies, they may also be able to sell excess electricity back to the grid.

The energy savings are maximized when a homeowner buys the system outright, avoiding the cost of financing. However, paying in cash isn't feasible for many homeowners.

PV cells convert sunlight into an electrical charge that runs through an inverter to create alternating current (AC) electricity. This energy can run your household appliances and, with the right monitoring tools like Tigo's module level performance monitors, help homeowners optimize, monitor and manage their solar systems for maximum efficiency.

In addition, the location of your property and its surrounding environment, including trees and tall buildings, will influence how efficiently your solar power system produces electricity. To make the most of your investment, ensure that your panels are not shaded by obstructions and regularly remove dirt and ice buildup.

Tax Credits

The federal Investment Tax Credit (ITC) helps make going solar a sound financial decision for homeowners by allowing them to deduct 26% of their system’s cost from their taxes. This incentive is available for homeowners who buy their system outright or who purchase electricity from a third party through a lease or power-purchase agreement.

The ITC is currently set to drop to 26% in 2033 and then 22% in 2034, but there’s still time to take advantage of this amazing opportunity before it expires. Additionally, New York City offers a property tax abatement that significantly reduces your upfront project costs.

To claim the tax credit, homeowners need to own their system and must complete IRS Form 5695. EnergySage has a handy guide to help homeowners navigate this process. It’s important to note that incentives paid out by a utility don’t count as qualifying expenses for the federal tax credit. However, NYSERDA rebates do. This can greatly reduce your upfront project costs and accelerate your payback period.

Installation

The residential solar installation process empowers homeowners to make informed choices that maximize efficiency and energy savings. It also helps them navigate costs and incentives, which can significantly impact the final cost of their system.

Once a homeowner has selected the type of solar power system that best matches their energy needs, they must determine their budget and work with a reputable installer to navigate local regulations to secure necessary permits. In doing so, they can ensure the system is installed properly and meets industry standards.

Once the permit process is complete, it’s important for the installer to schedule the installation date. This is based on weather conditions, as installers prefer clear days for installation. They will need access to your loft, consumer unit (also known as a fuse box), electricity meter, and the agreed locations for the battery and inverter. After the installation is complete, a city engineer will connect your system to the grid. Once connected, your solar energy system can supply energy for your home or provide any excess back to the grid.

0 notes

Text

AC-DC Rectifier: Bridging Two Worlds of Power

Imagine a world without electricity conversions — where your laptop won’t charge, your phone stays dead, and industrial motors fail to operate. Unthinkable, right? What stands between AC power from the grid and your DC-powered electronics is an essential, often invisible device: the AC-DC Rectifier.

Despite being critical to everything from daily gadgets to complex aerospace systems, the rectifier rarely gets credit for the massive transformation it enables. Let’s change that.

From Alternating to Direct – Why It Matters

Alternating Current (AC) is how electricity travels through our power grids. It’s efficient for long-distance transmission, easy to step up or down in voltage, and suitable for large-scale energy distribution. However, most electronics — your smartphone, LED lights, electric vehicles, and even high-end servers — run on Direct Current (DC).

So how do we bridge this gap?

Enter the AC-DC Rectifier, the vital converter that transforms grid-fed AC into usable DC. It’s not just about electricity; it’s about adaptation — evolving the flow of energy to meet the needs of technology. And in that transformation lies an intricate blend of science, design, and application.

A Story You Can Relate To

Meet Priya, an electrical engineer at a solar microgrid company in Rajasthan. Her challenge wasn’t lack of solar energy; it was inconsistent performance from stored power. The culprit? Cheap, inefficient rectifiers that distorted the signal and degraded batteries.

When Priya introduced industrial-grade AC-DC Rectifier modules with controlled ripple and thermal protection, battery life improved by 30%, and the system uptime went up dramatically. What seemed like a simple switch turned out to be a major performance boost — something her team hadn't fully anticipated until they saw it in action.

The rectifier wasn’t just a component anymore — it was an enabler.

The Tech Under the Hood

So how exactly does an AC-DC Rectifier work?

At its core, rectification involves converting a sinusoidal AC wave into a linear DC line. This is achieved through the use of diodes, thyristors, or MOSFETs, depending on complexity and application.

1. Half-Wave Rectification

Only the positive half of the AC signal is allowed to pass through. It’s simple, but inefficient and used only in low-demand circuits.

2. Full-Wave Rectification

Both halves of the AC waveform are utilized. With the help of bridge rectifiers, the output is more consistent, ideal for higher-power applications.

3. Controlled Rectifiers

These use semiconductor devices like SCRs or IGBTs, allowing engineers to control output voltage levels — essential for motor speed controllers and battery chargers.

4. Filtered Rectifiers

To reduce “ripple” — the leftover wave-like behavior in DC — capacitors and inductors are added to smooth out the flow.

Each rectifier type serves different needs, from tiny phone chargers to complex power supplies in industrial automation.

Why It Matters More Than Ever

The rise of DC-based technologies makes AC-DC Rectifier systems even more critical today than they were a decade ago.

1. Electric Vehicles (EVs)

Charging stations rely heavily on rectifiers to ensure batteries receive pure, stable DC. A poor rectifier can shorten battery life and reduce driving range.

2. Renewable Energy

Solar panels generate DC, but many systems need AC to interface with the grid — and vice versa. Modern energy systems use rectifiers to maintain voltage stability.

3. Data Centers

Servers operate on DC. Rectifiers convert incoming AC to keep massive infrastructure running smoothly — a split-second glitch can cause thousands in downtime.

4. Medical Devices

Precision instruments like MRI machines or ventilators require pure, distortion-free DC. This level of quality is only possible through specialized rectifiers.

Humanizing the Current

Let’s not reduce this technology to circuits and silicon. The AC-DC Rectifier is a guardian of stability. When you’re working late on a presentation, your laptop humming reliably — thank the rectifier. When hospitals maintain life-support systems during a blackout with the help of inverters and UPS systems — thank the rectifier. When satellites silently collect data while orbiting Earth — again, thank the rectifier.

It doesn’t just convert voltage; it converts possibilities into realities.

The New Era of Smart Rectifiers

Thanks to advancements in power electronics, today’s rectifiers are smarter, more efficient, and application-specific.

Wide Bandgap Semiconductors (SiC, GaN): They allow for faster switching, higher temperatures, and smaller components. Great for high-frequency and aerospace applications.

Digital Control Systems: Feedback-based systems help monitor current, correct fluctuations, and adjust to real-time demand.

Energy Recovery: Some modern rectifiers are designed to push unused energy back into the grid or battery systems.

Modular Rectifier Systems: Ideal for scaling power supplies. Need more output? Just plug in another rectifier module.

Tips When Choosing an AC-DC Rectifier

Whether you're an engineer, project manager, or someone setting up a high-powered system, here’s what to consider:

Power Rating: Match it to your load requirements.

Input Voltage Range: Ensure flexibility for different global standards.

Efficiency (>90%): Better efficiency means less heat and lower power bills.

Thermal Management: Good rectifiers come with built-in cooling or heat sink options.

Certifications: UL, CE, or ISO depending on the region and industry.

EMI Filtering: Reduces interference in sensitive systems.

Redundancy Features: In mission-critical applications like healthcare or aviation, dual rectifiers with automatic failover are a must.

Final Thoughts: More Than a Converter

The next time you plug in a charger, boot up a server, or admire an EV silently gliding past, remember — an AC-DC Rectifier is working behind the scenes. It's the bridge between chaotic currents and calm, directed energy. It's not just about volts and amps; it's about reliability, precision, and trust.

If you're building or maintaining systems where power matters — give the rectifier its due importance. Because in a world that runs on conversions, AC-DC Rectifier technology is the unsung foundation of modern energy infrastructure.

0 notes

Text

Liquid Cooling Plates: Versatile Thermal Management Across Industries

Liquid cooling plates have become essential across numerous industries, thanks to their superior heat dissipation capabilities. They address the increasingly demanding thermal management requirements of modern technologies, ensuring both performance and reliability.

Electronics Industry: Enabling High-Performance Computing

In the electronics sector, liquid cooling plates are transforming thermal management—especially in high-performance computing. Data centers, filled with thousands of servers running CPUs, GPUs, and other critical components, generate vast amounts of heat. By being mounted directly on these heat-intensive components, liquid cooling plates efficiently draw heat away, preventing overheating-related slowdowns or system failures. This allows servers to maintain peak performance, essential for applications like cloud computing, big data analytics, and online gaming.

Enthusiasts and professionals using high-performance personal computers also rely on liquid cooling plates—especially when overclocking processors or utilizing high-end graphics cards. During tasks like 3D rendering or immersive gaming, these components can produce intense heat. Integrated with liquid cooling loops, the plates help maintain safe operating temperatures, enhancing both system performance and component longevity.

Automotive Industry: Supporting the EV Revolution

In the automotive world—particularly the rapidly growing electric vehicle (EV) market—liquid cooling plates play a critical role. EV battery packs generate significant heat during both charging and discharging. To ensure optimal performance, safety, and extended battery life, liquid cooling plates are embedded within the battery design, often wrapping around cells or modules. This is particularly crucial during fast-charging, where high current leads to rapid heat buildup. Liquid cooling plates mitigate this by maintaining a stable temperature, thereby improving charging efficiency and preventing thermal runaway—an uncontrolled and potentially dangerous overheating scenario.

Beyond batteries, EV drivetrain components like electric motors and power electronics also benefit from liquid cooling. These systems operate under high loads, and effective cooling helps sustain efficiency, reliability, and overall vehicle range.

Renewable Energy Systems: Enhancing System Efficiency

Liquid cooling plates are also integral to renewable energy technologies. In solar power systems, power conversion units like inverters convert direct current (DC) from solar panels into alternating current (AC) for grid use. These inverters generate substantial heat, and liquid cooling plates help manage it effectively, ensuring continuous and efficient operation. Stable inverter performance translates into more reliable energy output and improved system efficiency.

In wind turbines, control units and power electronics are exposed to harsh environmental conditions while generating heat during operation. Liquid cooling plates protect these sensitive components by maintaining safe operating temperatures, thus ensuring reliable turbine performance even in extreme climates.

Industrial Applications: Boosting Equipment Reliability

Industrial environments host a wide array of high-power equipment where precise thermal control is vital. High-power lasers used in applications such as cutting, welding, and engraving produce significant heat. Liquid cooling plates are used to cool laser diodes and essential optics, maintaining precision and consistent output—critical for quality-driven manufacturing.

Similarly, industrial power inverters, responsible for converting DC to AC in large-scale power systems, depend on liquid cooling to manage heat from high-power handling. Furthermore, in high-speed machining or heavy-duty manufacturing operations, liquid cooling plates are used in motors, spindles, and bearings to reduce friction, wear, and heat-induced degradation—ultimately improving productivity and equipment lifespan.

Conclusion: A Growing Role in Advanced Thermal Management

From electronics and automotive to renewable energy and industrial machinery, liquid cooling plates have established themselves as a foundational solution for advanced thermal management. As technologies become more powerful and compact, and the demand for efficient heat dissipation rises, the role of liquid cooling plates will continue to expand—driving innovation, performance, and safety across diverse sectors.

0 notes

Text

ARMxy Industrial Computer BL410 in Electric Vehicle Charging Stations

Introduction

As the electric vehicle (EV) market continues to grow, the demand for efficient, reliable, and intelligent charging infrastructure is surging. With its flexible I/O configuration, high-performance processing capabilities, and industrial-grade reliability, the BL410 is well suited to meet the complex demands of EV charging systems. This case study explores the application of the BL410 in EV charging stations and highlights its key features and benefits.

Application Scenario

EV charging stations require real-time data acquisition, communication with cloud platforms, and precise control of charging processes. These stations must operate reliably in diverse environmental conditions, support multiple communication protocols, and enable remote monitoring and maintenance. The ARMxy BL410 series addresses these needs through its advanced hardware and software capabilities, making it an excellent choice for both AC and DC charging stations.

Solution Implementation

The BL410 industrial computer is deployed as the central controller in EV charging stations, managing critical functions such as data acquisition, protocol conversion, and cloud integration. Below is an overview of how the BL410 is utilized in this application:

1. Hardware Configuration

The BL410 is customized to meet the specific needs of EV charging stations:

Processor and Memory: Equipped with a Rockchip RK3568J/RK3568B2 quad-core ARM Cortex-A55 processor (up to 2.0 GHz) and 4GB LPDDR4X RAM, the BL410 ensures efficient processing of real-time data and multitasking for charging operations.

Storage: A 32GB eMMC storage configuration provides ample space for firmware, logs, and application data.

I/O Interfaces:

X Series I/O Board (e.g., X23): Configured with 4 RS485 ports for communication with charging modules and meters, and 4 digital inputs/outputs (DI/DO) for controlling relays and monitoring status signals.

Y Series I/O Board (e.g., Y31): Includes 4 analog inputs (0/4-20mA) for monitoring current and voltage during charging.

Communication:

Ethernet Ports: 3x 10/100M Ethernet ports enable robust connectivity to local networks and cloud platforms.

4G Module: A Mini PCIe slot with a 4G module (e.g., BL410L) ensures reliable cellular connectivity for remote access and data transmission.

WiFi Module: Optional WiFi support for local wireless communication.

Power and Protection: Supports a wide voltage range (9-36V DC) with reverse polarity and overcurrent protection, ensuring stable operation in fluctuating power conditions.

Mounting: DIN35 rail mounting facilitates easy installation within charging station enclosures.

2. Software Integration

The BL410’s software ecosystem enhances its suitability for EV charging applications:

Operating System: Runs Ubuntu 20.04, providing a stable and developer-friendly environment for application development.

Protocol Conversion: The pre-installed BLIoTLink software supports protocols such as Modbus, MQTT, and OPC UA, enabling seamless communication with charging modules, energy meters, and IoT cloud platforms like AWS IoT Core and Alibaba IoT.

Remote Access: BLRAT (Beilai Remote Access Tool) allows operators to monitor and maintain charging stations remotely, reducing downtime and service costs.

Node-RED: Facilitates rapid development of IoT applications, such as real-time monitoring dashboards and automated fault detection workflows.

Docker Support: Enables containerized deployment of applications, ensuring scalability and ease of updates.

3. Key Functions

The BL410 performs the following critical functions in EV charging stations:

Data Acquisition: Collects real-time data from energy meters (voltage, current, power) and environmental sensors (temperature, humidity) via analog and digital inputs.

Charging Control: Manages charging sessions by controlling relays and communicating with charging modules to regulate power delivery.

Cloud Integration: Transmits operational data (e.g., charging status, energy consumption) to IoT cloud platforms for analytics and billing.

Fault Detection: Monitors system health and triggers alerts for anomalies, such as overcurrent or communication failures, using Node-RED workflows.

User Interface: Supports optional HDMI output for local display of charging status or integration with touchscreen HMIs using Qt-5.15.2.

4. Environmental Reliability

The BL410 is designed to withstand the harsh conditions often encountered in outdoor charging stations:

Temperature Range: Operates reliably from -40°C to +85°C (with RK3568J SOM), suitable for extreme climates.

IP30 Protection: Prevents dust ingress, ensuring durability in dusty environments.

EMC Compliance: Passes rigorous electromagnetic compatibility tests (e.g., ESD Level III, EFT Level III), minimizing interference and ensuring stable operation.

Vibration and Shock Resistance: Complies with sinusoidal vibration and free-fall tests, making it robust for transportation and installation.

Benefits

The deployment of the ARMxy BL410 in EV charging stations offers several advantages:

Flexibility: Customizable I/O boards and SOM configurations allow tailored solutions for different charging station designs.

Reliability: Industrial-grade design with extensive environmental and EMC testing ensures long-term stability.

Scalability: Support for Docker and cloud integration enables easy expansion as the charging network grows.

Cost-Effectiveness: Remote access and maintenance via BLRAT reduce on-site service costs.

Rapid Development: Node-RED and Qt tools accelerate application development, shortening time-to-market.

Conclusion

The ARMxy BL410 series industrial computer is a powerful and versatile solution for managing EV charging stations. Its high-performance hardware, flexible I/O options, and robust software ecosystem enable efficient data acquisition, reliable communication, and seamless cloud integration. With its proven reliability in harsh industrial environments, the BL410 is helping to power the future of electric vehicle infrastructure, ensuring efficient and scalable charging solutions for a growing market.

0 notes

Text

Top 5 Reasons to Choose Polycab Inverters for Your Solar System

When investing in a solar system, one component that often gets overlooked—but plays a crucial role—is the inverter. It’s the heart of your solar setup, converting solar energy into usable electricity. And when it comes to performance, reliability, and innovation, Polycab inverters are leading the charge.

Here are the top 5 reasons why choosing a Polycab inverter can be a smart decision for your solar energy journey:

1. Superior Efficiency

Polycab inverters are engineered for high conversion efficiency, ensuring minimal energy loss during the DC to AC conversion process. This means more of the power your panels generate gets used — maximizing your system’s output and reducing your electricity bills.

Why it matters: Higher efficiency = better ROI on your solar investment.

2. Robust Build & Durability

Made with premium materials and cutting-edge engineering, Polycab inverters are built to withstand harsh Indian weather conditions — be it heat, humidity, or dust. Their long operational life ensures peace of mind for years to come.

Why it matters: A durable inverter means fewer replacements and reduced maintenance costs.

3. Smart Monitoring & Control

Polycab inverters come with advanced monitoring capabilities. Through their digital interfaces or mobile apps, you can track your system’s performance in real time — giving you full control and insight into your energy usage.

Why it matters: Informed users can make smarter energy decisions and detect issues early.

4. Seamless Compatibility

Whether you have Adani solar panels or any other leading brand, Polycab inverters offer wide compatibility with different module types. This makes them a flexible and future-ready choice for your solar setup.

Why it matters: You won’t be locked into specific brands or components.

5. Backed by a Trusted Brand

Polycab is a trusted name in electrical solutions across India. Known for quality and innovation, their solar inverters are backed by solid warranties and customer support. You’re not just buying a product — you’re partnering with a brand you can trust.

Why it matters: Reliable after-sales support can save time, money, and frustration.

Final Thoughts

Inverters are the unsung heroes of any solar installation, and with Polycab, you get the perfect blend of performance, reliability, and smart technology. Whether you’re installing a solar system for your home, business, or high-rise building, Polycab inverters can help you get the most out of your investment.

Looking to upgrade or install a solar system with Polycab inverters? Contact Solar 4 All today or call us at +91 74474 01171-76-77.

0 notes

Text

How Solar Inverters Help Reduce Electricity Bills Efficiently

As the world shifts towards sustainable living, solar energy has become one of the most efficient and eco-friendly sources of power. At the heart of any solar energy system lies the solar inverter, an essential device that plays a critical role in converting sunlight into usable electricity. Not only does it enable the efficient functioning of solar panels, but it also significantly contributes to reducing electricity bills. This article explores how solar inverters work, their benefits, and how they can help you save on your energy expenses.

What is a Solar Inverter?

A solar inverter is an electronic device that converts the direct current (DC) electricity generated by solar panels into alternating current (AC) electricity, which is the standard form of electricity used in homes and businesses. Without a solar inverter, the energy produced by your solar panels would be unusable for most household appliances.

There are three main types of solar inverters:

String Inverters: Common in residential setups, these connect multiple solar panels in series.

Microinverters: Installed on each individual panel, allowing panel-level performance monitoring.

Hybrid Inverters: Work with solar panels and battery storage, ideal for off-grid and backup power.

How Solar Inverters Reduce Electricity Bills

1. Harnessing Free Solar Energy

Once installed, solar panels start producing energy from sunlight, which is free. The solar inverter ensures that this energy can be used by household appliances, drastically reducing the need for grid electricity.

2. Net Metering Support

Many solar inverters support net metering—a billing mechanism that credits solar energy system owners for the electricity they add to the grid. When your system produces more power than you use, the excess is sent to the grid, and you earn credits that reduce your monthly utility bills.

3. Efficiency Optimization

Modern solar inverters, especially MPPT (Maximum Power Point Tracking) inverters, constantly adjust the electrical operating point of the modules to ensure they produce the maximum power possible. This means you get the most energy out of your solar panels, which translates to more savings.

4. Smart Monitoring and Energy Management

Many solar inverters come with built-in smart monitoring systems that allow homeowners to track energy production and consumption in real-time. This helps users identify high energy usage times and manage their consumption accordingly, further helping to reduce electricity bills.

5. Reduced Dependence on the Grid

With a solar inverter, you can significantly reduce your dependence on the utility grid. During daylight hours, your home can be powered by solar energy alone. With a hybrid inverter and battery storage, you can even use solar energy during the night, reducing your reliance on grid power to nearly zero.

6. Battery Backup Systems

Hybrid solar inverters work seamlessly with battery storage. During the day, excess energy is stored in batteries and can be used during peak hours or at night. This not only ensures uninterrupted power supply but also helps in further minimizing energy bills by reducing peak demand charges.

Long-Term Financial Benefits

Although the initial cost of installing a solar energy system with an inverter may be high, the long-term savings on electricity bills can be substantial. On average, homeowners can save up to 50%–70% on their electricity bills depending on system size and energy usage. Over time, these savings can completely offset the initial investment, making solar inverters a cost-effective solution.

Environmental and Government Incentives

Governments around the world are promoting solar energy through various incentives like tax rebates, subsidies, and grants. Installing a solar system with an inverter not only reduces your bills but also qualifies you for these benefits, further increasing your return on investment.

Maintenance and Reliability

Modern solar inverters are highly reliable and require minimal maintenance. Most come with warranties ranging from 5 to 12 years, with many lasting even longer. Routine checks and occasional software updates ensure that the inverter runs efficiently throughout its lifespan.

Choosing the Right Solar Inverter

To maximize your energy savings, it’s essential to choose the right type of solar inverter. Factors to consider include:

Size and capacity of your solar panel system

Availability of battery backup

Budget constraints

Type of appliances in use

Consulting a certified solar energy professional can help you select the best inverter for your specific needs.

Conclusion

A solar pcu inverter is more than just a component in your solar power system—it’s a smart investment that can lead to substantial energy savings and a greener lifestyle. By efficiently converting solar energy into usable electricity, supporting net metering, enabling energy storage, and offering smart monitoring, solar inverters play a pivotal role in reducing your electricity bills. As energy costs continue to rise, now is the perfect time to switch to solar power and make the most of what nature has to offer.

With the help of advanced technology and support from government incentives, adopting solar inverters for your home not only makes financial sense but also supports a sustainable future. Make the switch today and watch your electricity bills go down while your savings rise!

1 note

·

View note

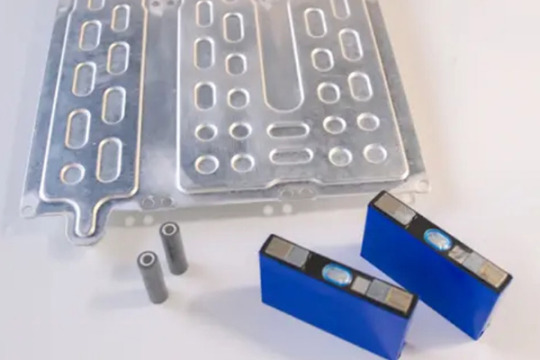

Photo

RCT Axpert ESS 8Kva-KW Energy Storage System This energy storage system is an all-in-one solution, which integrates an inverter and a battery into one unit. It has combined an 8KW off-grid and a 5KWh expandable lithium-iron battery module. This ESS offers an economical and self-sufficient solution allowing homeowners to seamlessly store excess clean energy during the daytime to power their home both day and night. The product features include an easily scalable lithium-Iron battery modules for energy expansion which is lighter than lead-acid batteries and has a compact and elegant design. Main Features Integrated 8Kw off-grid inverter and lithium-iron battery module Built-in Wi-Fi for mobile monitoring (Android/ iOS App is available) Supports USB on-the-go function Reserved communication port for BMS (RS485. CAN-bus or RS232) Configurable AC/PV Output usage timer and prioritisation Selectable high power charging current Selectable input voltage range for home appliances and personal computers Lithium Iron Phosphate (LFP) cell Scalable Li-Iron battery expansion IP20 Inverter Mode Specifications Utility Inverter Mode Rated Output Power: 8000W Output Voltage Waveform: Pure Sine Wave Output Voltage Regulation: 230Vac+5% Output Frequency: 60Hz or 50Hz Peak Efficiency: 93% Overload Protection: 100ms@205% load; 5s@150% load; 10s@110%~150% load Surge Capacity: 2* rated power for 5 seconds Low DC Warning capacity: Setting of Program 29 + 10% Low DC Cut-off level: Setting of Program 29 High DC Recovery Voltage: 52.5Vdc (ESS LIO-I-4810) 56Vdc (ESS LIO-II-4810) High DC Cut-off Voltage 54Vdc (ESS LIO-I-4810) 57.5Vdc (ESS LIO-II-4810) DC Voltage Accuracy: +/-0.3V@ no load THDV:

0 notes

Text

Battery Aging and Testing System for Modern Energy Storage Solutions

In the rapidly evolving field of battery technology, efficient and accurate battery aging and performance testing systems are essential for quality control and R&D. The 60V 20A 40-Channel Battery Charge-Discharge System (BCDS) represents a next-generation solution for comprehensive battery module testing and is ideal for testing pouch cell, li on pouch cell, and lithium pouch cell batteries.

Broad Application Across Battery Chemistries

This system is designed to support a wide array of battery types including lithium-ion (NMC, LFP), lead-acid, nickel-metal hydride, and nickel-cadmium. It accommodates both co-port and split-port battery configurations, making it highly versatile for manufacturers and developers of battery-powered devices, including vacuum cleaners, electric tools, and electric scooters. It is also compatible with lithium battery systems and pouch cell battery pack configurations.

Key Functional Capabilities

The testing system offers an impressive range of functionalities: • Cycle Life Testing to evaluate long-term durability • Capacity Testing for understanding usable energy • Charge/Discharge Characteristic Testing for performance profiling • Thermal Characteristic Testing to monitor battery response under varying temperatures It also works effectively as a lithium-ion battery capacity tester for prismatic cell testing scenarios.

Sophisticated Design and Composition

The system integrates a power module, AC/DC bi-directional inverter, control unit, heat dissipation system, data acquisition hardware, and a software-driven upper computer system for data processing. It supports centralized control via networked management and offers remote monitoring.

Engineered for high-precision tasks, it is especially useful when paired with high voltage prismatic cell tester setups for advanced R&D.

Precision, Protection, and Performance

Engineered for precision, the system achieves ±0.05% accuracy and features independent control across its 40 channels. It includes robust software and hardware protections such as: • Reverse connection protection • Overvoltage and overcurrent cutoffs • Power-off continuation to resume tests after outages • Real-time abnormality captures and alarm features

All operations—from constant current charging to constant voltage transitions—are seamless, eliminating current surges and protecting battery integrity during testing. This precision makes it highly suitable for lithium-ion pouch cell applications.

Intelligent Software Control

Operators benefit from a fully programmable software interface that supports: • Step-by-step test sequence customization • Nested loop test execution • Real-time log tracking and fault detection • Excel-based data exports and multi-parameter graphing • Barcode and QR code integration for traceability

Each channel functions autonomously, allowing fully independent charge-discharge testing with programmable voltage (0V–60V) and current (100mA–10A) ranges.

Technical Specifications

• Channel Count: 40, each operating independently • Voltage Range: 0–60V with 1mV resolution • Current Range: ±10A with 1mA resolution • Response Time: <10ms for rapid current transition • Output Power: 1.2kW per channel with 0.1% FS stability • Data Interval: Configurable, as frequent as every second

Enhanced Safety and Maintenance

Safety is paramount, with built-in hardware for emergency cut-offs and software-based over-temperature and reverse polarity protections. The modular construction supports fast servicing with spare parts availability and regular software updates. Additionally, when integrated with laser welding machine, laser welding equipment, or laser fiber welding machine, the system supports a seamless battery pack production and testing flow.

For manufacturers in India, this system also pairs well with laser welding machine in India options and portable laser welding machine setups for lab or factory environments. It's also a perfect companion to a lithium-ion battery spot welding machine for complete cell assembly and verification.

Conclusion

This battery testing system is tailored for manufacturers aiming to maintain high standards in energy storage products while ensuring safety, traceability, and operational efficiency. Whether for production line QA or R&D labs, it sets a benchmark for comprehensive battery testing—especially for pouch cell battery, prismatic cells, and advanced lithium-ion pouch cell applications.

#high voltage prismatic cell tester#laser fiber welding machine#laser welding equipment#laser welding machine#laser welding machine in India#li on pouch cell#lithium battery systems#lithium pouch cell#lithium-ion battery capacity tester for prismatic cell#lithium-ion battery spot welding machine#lithium-ion pouch cell#portable laser welding machine#pouch cell#pouch cell battery#pouch cell battery pack

0 notes

Text

Why Do Solar Battery Systems Need Inverters?

In solar power systems, inverters are an indispensable core component. Its main function is to convert the direct current (DC) generated by solar panels into alternating current (AC) used in our daily lives. Because most household appliances and industrial equipment rely on AC to operate, if solar systems want to achieve stable power supply to these devices, they must complete the power conversion through inverters.

Solar panels themselves can only output direct current, and their voltage levels are usually 12V, 24V or 48V. Although some devices support DC input, most power needs, such as commercial and industrial loads, require standard 220V or 380V AC. Therefore, configuring efficient and stable inverters in solar systems is not only the basis for achieving energy conversion, but also a key link to ensure power safety and equipment compatibility.

In certain specific situations, such as using DC equipment or charging batteries, some systems can temporarily operate without inverters. However, this method is only applicable to a very limited load range. For users who need to fully replace the mains power supply, inverters are still indispensable equipment. Especially in high power systems, if there is no inverter, the output voltage of the system cannot be stably regulated, which can easily cause equipment damage or system failure.

The role and importance of solar inverters

In addition to the basic power conversion function, modern solar inverters also undertake multiple system management and protection responsibilities. Xindun's inverter can automatically monitor current and voltage changes to avoid system damage caused by electrical faults such as overload and short circuit; it can also monitor system operation data in real time to achieve remote management and intelligent alarm. In the grid connected system, the inverter can also synchronize with the public power grid and intelligently switch the power supply mode according to load changes to improve the overall system efficiency and safety.

Can solar panels be directly connected to the inverter?

Solar panels can be directly connected to the inverter, but this depends on whether the output voltage of the panel matches the input range of the inverter. If the panel voltage is too high or too low, it will damage the inverter or make it unable to start. In order to ensure voltage stability and system safety, it is usually recommended to add a charge controller, battery pack or buck/boost module between the solar panel and the inverter, especially in off grid systems or hybrid systems.

Different types of solar inverters

Based on the application scenarios and configuration methods of solar systems, there are currently three main types of inverters on the market:

1. Off Grid Inverter

Off Grid inverters are mainly used for independent power systems that are not connected to the public power grid. They are widely used in remote mountainous areas, rural households, small industrial and commercial or communication base stations. This type of inverter is usually used with batteries to store the power generated by solar energy in the battery, and then converted into AC power for load use through the inverter. Off grid inverters have high requirements for battery management capabilities, and usually integrate multiple functions such as charge and discharge control and battery protection to ensure that the system continues to operate stably in an environment without mains power.

2. On Grid Inverter

On grid inverters are used in solar systems connected to the mains, and are commonly found in urban household rooftop solar, industrial and commercial factories or large solar power stations. This type of inverter can convert solar power into AC power synchronized with the power grid in real time, and directly transmit it to power consuming equipment or back to the national power grid. The on grid inverter must have precise on grid control capabilities to ensure that the frequency and voltage are fully synchronized with the grid, and automatically disconnect the system when the mains power is cut off to ensure safety.

3. Hybrid Inverter

The hybrid inverter combines the functions of off grid and on grid inverters. It can be connected to the battery pack for energy storage and can also be connected to the grid for power supply. It has flexible and diverse power supply methods. It can intelligently allocate power according to conditions such as power load, light intensity, and electricity price strategy, and realize multiple functions such as self generation and self use, energy storage and backup power, and peak valley electricity price arbitrage. Hybrid inverters are suitable for commercial customers or medium and large factories that have high requirements for power supply continuity and cost control.

What is solar inverter charger?

Solar inverter charger is a composite device that integrates the functions of an inverter and a charging controller, and is often used in off grid systems. It can not only complete the basic function of DC to AC conversion, but also replenish energy for the battery pack through the mains or generator to ensure that there is still electricity available when there is insufficient light or at night. For those who live in areas with insufficient sunlight or need backup power supply, inverter charger is a cost effective solution.

Xindun hopes to discuss the future development of solar with industry professionals through the sharing of relevant inverter knowledge above.

0 notes

Text

What is the difference between a generator and an inverter?

Generators and inverters are widely used in modern society, such as solar inverter systems, fuel generators, renewable energy generators, etc. However, many people are not clear about their differences and their respective usage scenarios. Now I will analyze the working principles, differences and application scenarios of generators and inverters, so that everyone can better know which option is more suitable for their application.

Generator

A generator is a device that converts mechanical energy into electrical energy and is widely used in various industrial and civil occasions. The working principle of the generator is based on the principle of electromagnetic induction, that is, the rotating conductor cuts the magnetic lines of force in the magnetic field to generate current. There are many types of generators, mainly including:

DC generator: outputs direct current, suitable for occasions requiring stable current, such as motor drive, charging, etc.

AC generator: outputs alternating current, widely used in power systems, factories, shopping malls and other places.

The main advantages of the generator include high efficiency and stability, and its disadvantages are mainly large size and heavy weight, which are suitable for use in fixed places.

Inverter

An inverter is a device that converts direct current into alternating current. It is commonly used in solar power generation systems, energy storage equipment, electric vehicles and other fields. It relies on existing DC power supplies (such as gel batteries or lithium batteries, solar panels, and vehicle power supplies) and cannot generate electricity independently. The working principle of the inverter is to modulate DC pulses into AC waveforms through a switching circuit. The types of inverters are mainly divided into:

Sine wave inverter: outputs high-quality sinusoidal AC, which is exactly the same as the mains power. It is suitable for equipment with high power requirements, such as home energy storage, farms, medical equipment, and schools.

Square wave inverter: outputs simple square wave AC, which is suitable for equipment with low power requirements, such as power tools and lamps. Only pure resistive loads (such as incandescent lamps) are supported, which are basically eliminated and only seen in extremely low-cost scenarios.

Modified sine wave inverter: The waveform is a step-like approximation to a sine wave, with low cost, suitable for ordinary resistive loads (such as light bulbs, electric heaters), suitable for low-budget off-grid systems, vehicle power supplies, simple tool power supplies, etc. Disadvantages: May damage inductive loads, cause noise, heat, etc.

The advantages of inverters are that they are small and light, suitable for mobile or temporary use. However, their prices are higher than generators, and their power output is usually lower than similar generators.

Generators are "autonomous power generation equipment" suitable for long-term, high-power power supply, but they rely on fuel.

Inverters are "power conversion equipment" that rely on batteries (gel batteries or lithium batteries) or solar energy and are suitable for clean, quiet and portable power.

The main differences between generators and inverters

GeneratorInverterWorking principleMechanical energy generates electrical energyand direct current is converted into alternating currentApplication scenariosFactories, construction sites, etc.,Solar energy systems, wind power systemsOutput typeProviding DC or ACSpecializing in converting DC into ACSize and portability BulkySuitable for use in fixed locations Smaller and lighterSuitable for portable useEfficiencyHigh efficiencyHigh efficiency

When choosing a generator or inverter, users should consider the following points:

1. Power requirements: First, you need to know how much power you need to provide and choose the right device. 2. Power type: Confirm whether the device requires DC or AC power, and then choose the right device. 3. Usage scenario: Consider the portability, size and weight of the device, and choose the device that is suitable for the specific use occasion. 4. Budget: According to your own financial situation, choose a generator or inverter reasonably to ensure the long-term use value of the equipment. 5. Efficiency and maintenance: Understand the efficiency of the equipment, choose equipment that is easy to maintain and use, and ensure the normal operation of the equipment.

0 notes