#API Ring Gasket

Explore tagged Tumblr posts

Text

API Ring Gasket is a high-performance sealing solution designed for extreme pressure and temperature conditions in critical industries like oil & gas, petrochemical, and power generation. Precision-engineered to meet API 6A and ASME B16.20 standards, these gaskets ensure leak-tight metal-to-metal sealing for flanges, valves, and pressure vessels. API Ring Gaskets are available in R, RX, and BX styles, making them ideal for high-integrity applications that demand maximum reliability and safety.

0 notes

Text

What is the Function of Flanges, and How Do They Work

Whether in oil and fuel, water treatment, power flora, or commercial piping, flanges are crucial for connecting pipes, valves, pumps, and other components. Not most effective do they create stable, leak-free connections, but they also permit easier meeting, upkeep, and inspection.

In this complete guide, we explore the features of flanges, how they operate, and why selecting the right flanges producer and flanges dealer in India is critical for challenge fulfillment.

What Are Flanges and Why Are They Essential?

A flange is a flat, ring-like issue that connects pipe segments or joins pipes with devices like valves, pumps, or stress vessels. The ordinary flange connection entails:

Mating flanges attached to two pipe ends or device portions

A gasket sandwiched between flanges to make sure a dependable seal

Bolts passing via aligned holes, tightened lightly to clamp the relationship

Flanges serve numerous pivotal features:

Pressure containment — Gaskets and bolts save you leakage even under high pressure

Ease of access — Providing short disassembly for inspection, servicing, or alternative

Flexibility — Flanges accommodate numerous pipe substances, sizes, and joining configurations

Maintenance performance — Sections of piping may be eliminated effortlessly with out severing welds

Common Types of Flanges and Their Uses

Different flange types are designed for particular applications:

Weld Neck Flanges

– Ideal for excessive-stress and high-temperature environments

– The lengthy tapered hub reinforces the flange and reduces pressure

– Ensures complete bore, minimal turbulence

Slip-On Flanges

– Cost-effective and clean to align

– Suited for low- to medium-strain systems

– Pipes are inserted and fillet-welded outside and inside

Blind Flanges

– Used to close off pipe ends or vessels

– Perfect for sealing and testing sections of pipelines

Socket Weld Flanges

– Great for smaller diameter, excessive-stress piping

– Pipes are inserted into a socket and fillet-welded

Lap Joint Flanges

– Frequently used with stub-quit adapters for easy alignment and coffee torque

– Common in systems requiring common dismantling

Threaded Flanges

– Easy to install with matching threaded pipes

– Do no longer require welding—perfect for low-strain structures

How Flanges Work: The Sealing Mechanism

A flange connection is predicated on four key factors:

1. Gasket:

Placed among flange faces, this compressible fabric (like graphite, PTFE, or metal) paperwork a primary seal stopping leaks. Flanges require an easy, flat surface to permit the gasket to work correctly.

2. Bolt Load:

Bolts draw the flanges together calmly, compressing the gasket. Correct torque is essential to balance sealing energy and flange integrity.

3. Flange Face Design:

The sealing surface may be flat-face, raised-face, tongue-and-groove, or ring-kind, depending on gasket and alertness necessities.

4. Pipe Support and Alignment:

Proper backing and alignment prevent flange misalignment or strain all through start-up, thermal shifts, or vibration, maintaining seal integrity.

Selecting the Right Flange: Key Considerations

To make certain most appropriate overall performance:

Pressure and temperature scores: ANSI/ASME instructions range from a hundred and fifty# to 2500#

Material compatibility: Choose stainless steel, carbon steel, alloy metallic, or duplex primarily based on media and surroundings

Gasket type: Select materials suitable for fluid type, temperature, and pressure

Face kind: Match flange face design to gasket and carrier utilit

Standards compliance: Ensure adherence to ASME, DIN, API, or IS codes

Why Quality Matters: The Role of a Trusted Flanges Supplier in India

Flanges supplier in India, Flanges are extra than pipe connectors—they’re stress obstacles. Partnering with a licensed flanges exporter, flanges stockist, and flanges producer like Bullion Pipe and Tubes gives

Material traceability: Mill test certificates, metallurgy reviews

Dimensional accuracy: CNC machining and precision forging

Strainer manufacturer

Thorough checking out: Ultrasonic, dye penetrant, and hydrostatic checking out

Consistency: Compliance with required requirements ensures dependable performance

Our worldwide footprint as a flanges provider in India ensures deliveries meet venture timelines with consistent nice and technical help. We stock flanges in all predominant materials and strainer supplier for brief dispatch.

Flange Maintenance and Safety Tips

To maximize overall performance and lifespan:

Torque in sequences — Use proper bolt styles and phased tightening method

Regular inspections — Check bolt anxiety, gasket situation, flange alignment

Proper alignment — Avoid bending or gasket over-compression

Correct gasket alternative — Swap gaskets as per provider periods

Use anti-capture lubricants on bolt threads for thermal cycling or corrosion conditions

Follow lifting and dealing with pointers to save you flange damage earlier than meeting

Flanges in Action: Application Scenarios

Oil and Gas: High-strain pipelines, wellheads, refinery structures

Power Plants: Steam lines, feed water, and condensate piping

Chemical Industry: Flow manage of corrosive and toxic substances

Water Treatment Plants: Distribution networks, pumping sections

Pharmaceutical / Food and Beverage: Hygienic connections with sanitary flange versions

Final Thoughts

Flanges may additionally appear regular, however they play an terrific position in piping systems—ensuring protection, performance, and serviceability. Understanding their function, mechanisms, and choice criteria elevates device reliability.

Bullion Pipe and Tubes is your relied on associate for all flange desires, from dependable flanges manufacturer to dependable flanges dealer in India, flanges exporter, and flanges stockist. With high-quality assessments, technical steerage, and spark off delivery, we steady your projects with precision-engineered solutions.

#Flanges Manufacturer#Flanges supplier#Flanges stockist#Flanges dealers in India#Flanges exporter#Flanges producer

0 notes

Text

Enhance Sealing Efficiency with HTX Products R Type Oval Ring Joint Gaskets

HTX Products is offering high-performance gasket solutions for critical seal applications under high-pressure and high-temperature conditions. R Type Oval Ring Joint Gaskets are designed to API and ASME standards to ensure that flanged joints are leak-proof, specifically in industries such as oil, gas, and petrochemical. The oval shape creates a metal-to-metal seal that is secure enough to withstand harsh conditions. Trust HTX Products for durable and precise gasket solutions that deliver safety, efficiency, and longevity in your most demanding operations.

#HTX Products is offering high-performance gasket solutions for critical seal applications under high-pressure and high-temperature condition#specifically in industries such as oil#gas#and petrochemical. The oval shape creates a metal-to-metal seal that is secure enough to withstand harsh conditions. Trust HTX Products for#efficiency#and longevity in your most demanding operations.

0 notes

Text

Industrial Flange Selection Guide: One Step to the Right Place

Selecting the proper business flange is crucial for making sure a dependable, efficient, and secure piping system. With numerous flange kinds and makes use of, industries ought to apprehend the important element elements that impact flange selection. From stress rankings to cloth compatibility, each detail performs an important role. This flange selection guide will assist you navigate the complexities of choosing the right flange in your specific wishes. At Manilaxmi Industrial, we offer awesome industrial flanges tailored to meet numerous commercial necessities.

Understanding Industrial Flanges

Industrial flange selection serves as vital connectors in piping structures, making an allowance for smooth meeting, protection, and disassembly of pipes. The preference of a flange relies upon several elements, alongside software, strain, temperature, and material compatibility.

Common Flange Types and Uses

Different industries require unique flange types and uses and make use of to ensure optimal overall performance. Below are the maximum not unusual flange types:

Flange Type

Uses and Applications

Weld Neck Flange

High-pressure and high-temperature applications such as refineries and chemical plants.

Slip-On Flange

Low-pressure systems where welding is required to strengthen the joint.

Blind Flange

Sealing off piping systems or isolating sections for maintenance.

Socket Weld Flange

Ideal for small-diameter, high-pressure pipes in industrial processes.

Threaded Flange

Used in low-pressure systems where welding is not feasible.

Lap Joint Flange

Works well with stub ends and allows easy alignment adjustments.

Orifice Flange

Installed in flow measurement applications using an orifice plate.

Flange Material Selection

Selecting the appropriate flange raw material is essential for making sure durability and overall performance. The raw materials need to be like minded with the medium flowing through the pipes to prevent corrosion and put on. Below are the most common materials utilized in commercial flanges:

Material Type

Characteristics and Applications

Carbon Steel

Cost-effective, strong, and widely used in general piping systems.

Stainless Steel

Corrosion-resistant, ideal for chemical and food processing industries.

Alloy Steel

Enhanced strength and resistance to high temperatures and pressures.

Duplex Stainless Steel

Combines strength and corrosion resistance, used in marine and oil industries.

Copper-Nickel

Resistant to seawater corrosion, used in marine applications.

Aluminum

Lightweight and corrosion-resistant, ideal for specific aerospace and marine industries.

Factors in Flange Selection Guide

When choosing the proper flange, consider the subsequent key elements:

1. Pressure and Temperature Ratings

Different flange training, which embody Class A one hundred fifty, 300, 600, 900, 1500, and 2500, decide the stress coping with capacity. Selecting a flange with the perfect rating guarantees protection and normal overall performance.

2. Flange Standards and Applications

Flanges should observe enterprise standards to ensure compatibility and safety. Some key flange standards and applications consist of:

ASME/ANSI B16.5 – Standard for pipe flanges and fittings.

ASME B16.47 – Large-diameter flanges.

API 6A – Flanges used in oil and gasoline industries.

DIN and EN Standards – European standards for business applications.

JIS Standard – Japanese flange widespread.

3. Flange Face Types

The flange types and makes use of vary based totally on face kinds, which have an impact on sealing performance:

Flange Face Type

Characteristics and Uses

Flat Face (FF)

Used in low-pressure applications.

Raised Face (RF)

Common in high-pressure applications where a better seal is required.

Ring Type Joint (RTJ)

Used in extreme pressure and temperature conditions.

Tongue and Groove (T&G)

Prevents gasket blowout, used in high-pressure settings.

Male and Female (M&F)

Ensures better alignment and gasket containment.

Industrial Flanges Comparison

Understanding commercial flanges evaluation facilitates in determining the best option in your software:

Criteria

Weld Neck Flange

Slip-On Flange

Blind Flange

Threaded Flange

Strength

High

Moderate

High

Low

Installation

Requires welding

Requires welding

No flow passage

No welding needed

Cost

Higher

Lower

Moderate

Lower

Applications

High-pressure

Low-pressure

Maintenance

Low-pressure systems

Best Flange for Piping

The best flange for piping relies upon the system’s precise desires. Here’s how to decide the proper one:

For excessive-strain, high-temperature programs – Weld neck flanges

For easy installation and decrease price – Slip-on flanges

For separating piping sections – Blind flanges

For threaded connections without welding – Threaded flanges

For flexible alignments – Lap joint flanges

Selecting the proper flange requires a radical knowledge of flange choice guide factors, consisting of material, strain ratings, face types, and applications. The right preference complements gadget durability, efficiency, and safety. At Manilaxmi Industrial, we concentrate on offering top-best industrial flanges comparison to meet the best industry standards. Whether you need flange sorts and make use of, flange raw materials selection, or flange requirements and programs, we are right here to assist you.

For professional guidance in deciding on the right flange, contact Manilaxmi Industrial today!

#industrial flange selection#flange selection guide#choosing the right flange#flange types and uses#best flange for piping#industrial flanges comparison#flange material selection#flange standards and applications

0 notes

Text

We are Ring Type Joint Gaskets manufacturer & supplier in India. A Ring Type Joint (RTJ) gasket is a forged ring that fits into the machined groove of an RTJ flange. The ring-type joint gaskets have octagonal or oval cross-sections. RTJ gaskets are often utilized for high-pressure, high-temperature applications. It is widely utilized in the refining, petrochemical, and oilfield drilling sectors. Ring type joints are made in accordance with ASME B16.20. They are dimensionally compatible with flanges manufactured to ASME B 16.5, ASME B16.47, and API 6A specifications.

#OrdinemEngitech#RingTypeJointGaskets#RTJGaskets#GasketManufacturer#SealingSolutions#IndustrialGaskets#CustomGaskets#GasketSupplier#HighPressureSealing#HighTemperatureGaskets

0 notes

Text

How to Choose the Perfect Gasket for Maximum Performance and Durability

Gasco Gasket Inc is a leading gasket manufacturer in India. Gaskets play a crucial role in ensuring leak-proof sealing, reducing friction, and enhancing the longevity of machinery. Selecting the right gasket is essential to prevent breakdowns, enhance efficiency, and minimize maintenance costs.

1. Understand the Application Requirements

Before selecting agasket, consider the application requirements, including:

Operating temperature: The gasket be exposed to extreme heat or cold

Pressure conditions: the application require a high-pressure or low-pressure seal

Chemical exposure: the gasket come into contact with chemicals, oils, or corrosive substances

Mechanical stress: subjected to vibrations, movements, or heavy loads

As a reliable gasket manufacturer, we provide different materials and types of gaskets, including spiral wound metallic gaskets, ring joint gaskets, and rubber gaskets suited for specific applications, so it's crucial to match the gasket with your operating conditions.

2. Choose the Right Gasket Material

Gaskets come in various materials, each suited for specific environments:

Rubber Gaskets (Nitrile, EPDM, Neoprene):

Best for water, oil, and fuel applications

Excellent flexibility and resistance to weathering

Metallic Gaskets (Spiral Wound, Ring Joint Gaskets)

Ideal for high-pressure and high-temperature environments

Commonly used in oil & gas, petrochemical, and power plants

Non-Metallic Gaskets (Compressed Fiber, PTFE, Graphite)

Suitable for chemical resistance and sealing low-pressure applications

Provides excellent conformability

Composite Gaskets (Combination of Metal and Soft Materials)

High-performance sealing for extreme conditions

Used in industries like automotive, aerospace, and manufacturing

As a leading gasket supplier in India, we provide a wide variety of gaskets to meet the specific needs of different industries. Whether it’s standard gaskets or custom-designed solutions, we ensure timely delivery and consistent quality to support industrial operations efficiently we provide material recommendations based on your requirements.

3. Consider the Gasket Thickness

The thickness of the gasket plays a crucial role in its sealing performance.

Thin gaskets are best for smooth, well-machined surfaces, providing a tight seal.

Thicker gaskets help compensate for uneven surfaces but may require higher bolt loads.

Choosing the right thickness prevents leaks and ensures a long-lasting seal.

4. Evaluate Pressure and Temperature Ratings

Every gasket has a pressure and temperature tolerance limit. Selecting a gasket that matches or exceeds your application's pressure-temperature (P-T) rating ensures:

Preventing gasket failure under extreme conditions

Reducing maintenance downtime

Increasing the overall lifespan of machinery

5. Ensure Proper Gasket Installation

Even the best gasket will fail if installed incorrectly. Follow these best practices:

Clean the sealing surface before installation.

Ensure even torque distribution while tightening bolts.

Avoid overtightening, as it can damage the gasket.

Choose compatible lubricants if necessary.

6. Look for Certifications and Quality Standards

A high-quality gasket should meet international and industry standards such as:

ISO 9001: Quality management certification

ASTM/ASME-Material and pressure rating standards

API 6A/6B—Standards for oil and gas gaskets

Conclusion

Selecting the perfect gasket involves evaluating material, thickness, pressure ratings, and installation practices. Whether you need industrial gaskets, automotive gaskets, or high-performance sealing solutions, partnering with a reputed gasket manufacturer in India or a gasket supplier in India ensures you receive durable and high-quality gaskets for your specific needs.

0 notes

Text

Choosing the Right Alloy for Ring Gaskets: A Material Selection Guide

Ring gaskets are critical components in maintaining the integrity of high-pressure and high-temperature systems. However, their effectiveness hinges on the correct material selection. Choosing the right alloy for your ring gasket is paramount to ensuring a reliable seal and preventing costly leaks or failures. This article delves into the key considerations for alloy selection, helping you make informed decisions for your specific application.

Understanding the Importance of Alloy Selection:

The alloy used in a ring gasket directly impacts its ability to withstand the operating conditions. Factors like pressure, temperature, and the media being handled all play a significant role in material selection. A mismatch between the alloy and the application can lead to:

Corrosion: Degradation of the gasket material due to chemical reactions with the media.

Creep: Gradual deformation of the gasket under sustained stress and temperature.

Stress Cracking: Failure of the gasket due to combined stress and corrosive environments.

Reduced Sealing Performance: Loss of sealing effectiveness due to material degradation or deformation.

Key Factors Influencing Alloy Selection:

Operating Temperature:

High-temperature applications require alloys with excellent high-temperature strength and creep resistance, such as stainless steel or nickel alloys.

Lower temperature applications may allow for the use of softer materials like low carbon steel or soft iron.

Operating Pressure:

High-pressure applications demand alloys with high yield strength and tensile strength to prevent deformation.

Consider the pressure rating of the flange and ensure the gasket alloy can withstand the maximum operating pressure.

Media Compatibility:

The media being handled is a crucial factor in alloy selection.

Corrosive media, such as sour gas, acids, or seawater, require alloys with excellent corrosion resistance, such as stainless steel or nickel alloys.

Ensure the alloy is compatible with the specific chemicals or fluids in the system.

Mechanical Properties:

Consider the mechanical properties of the alloy, such as yield strength, tensile strength, hardness, and ductility.

These properties will determine the gasket's ability to withstand mechanical stresses and deformations.

Cost and Availability:

The cost and availability of the alloy are also important considerations.

While high-performance alloys may offer superior properties, they may also be more expensive.

Balance performance requirements with cost considerations.

Common Ring Gasket Alloys:

Soft Iron:

Suitable for general-purpose applications with low to moderate pressures and temperatures.

Cost-effective option.

Low Carbon Steel:

Offers improved corrosion resistance compared to soft iron.

Suitable for moderate pressures and temperatures.

Stainless Steel (e.g., 304, 316):

Excellent corrosion resistance and high-temperature capabilities.

Versatile option for a wide range of applications.

Nickel Alloys (e.g., Inconel, Monel):

Superior corrosion resistance and high-temperature strength.

Ideal for extreme environments and highly corrosive media.

Making the Right Choice:

Consult material selection charts and corrosion resistance guides.

Refer to industry standards and specifications, such as ASME B16.20 and API 6A/6B.

Consider the specific requirements of your application and the operating conditions.

When in doubt, consult with a gasket specialist or materials engineer.

By carefully considering these factors, you can select the right alloy for your ring gaskets, ensuring a reliable and long-lasting seal.

0 notes

Text

All About Ring Joint Gasket Flanges

A ring joint gasket flanges is a specialized sealing component used in high-pressure and high-temperature applications, primarily in the oil and gas, petrochemical, and power industries. These gaskets are designed to form a reliable seal between RTJ flanges and provide a secure connection in critical piping systems.

Available in various ring joint types, such as RTJ gaskets and ring gaskets, they ensure leak-proof seals that are essential for maintaining system integrity. Standards like API 6A govern the specifications and manufacturing of these gaskets, ensuring safety and performance in demanding conditions.

Relevance of the ring joint gasket

Ring type joint flange face surfaces are an increasingly popular option regarding flange connections. RTJ Flanges are a good alternative to raised face in certain applications. Typically, higher pressure and temperature projects use Ring Type Joints.

They provide a more effective sealing solution to media critical pipeline and pressure vessel infrastructure. Although only an option in ANSI/ASME class flanges, they are the required standard surface sealing in API specification flanges.

This is due to the fact that API flanges typically operate at a higher pressure in comparison to their ANSI/ASME flange counterparts.

The seal of an RTJ gasket occurs under the force of closing the bolt and hardware after mating one flange to another. Typically, the gaskets are made of softer material than the metal of the flanges they are sealing.

The most common of these materials is a soft iron. Slow and steady pressure on the hardware of the flange “crushes” the gasket within the ring joint surface. This helps to prevent any type of leakage during operation of the flange assembly.

Ring Type Joint gaskets are designated by an “R” number. R gaskets are available in oval type and octagonal configuration. Given the smooth sealing surface of ring joint faces, both configurations are virtually interchangeable.

When in doubt, higher pressure and temperature applications typically call for ring joint facings. When optimal surface sealing is necessary, ring gasket type joint flanges are the ideal choice.

Choosing the right ring joint gasket flanges is crucial for ensuring a reliable, leak-free seal in high-pressure environments. Whether you're working with RTJ flanges or other critical piping components, using the correct RTJ gasket can prevent costly failures and downtime.

Always ensure compliance with industry standards like API 6A when selecting ring gaskets for your applications to guarantee optimal performance and safety.

0 notes

Text

SORF Manufacturers and Sellers

About SORF

One kind of flange that is designed to fit over the end of a pipe and be welded in place is called a slip on raised flange. Raised slip-on flanges are round, flat discs with a hole in the center. The objective is to connect two pipes using screws. These consist of four parts. This is a base ring that attaches to the pipe. An integrated raised surface provides stability and strength when connected; a hub holds all the components together; and finally, gaskets provide additional sealing.

Slip-on flanges are easy to install and remove and are less expensive than other flange types. Slip-on flanges are ideal for applications where cost is an important consideration and the flange is not exposed to high pressure or vibration

Grades in SORF

Stainless Steel Slip-On Raised Face Flanges

Carbon Steel Slip-On Raised Face Flanges

Low Temperature Carbon Slip-On Raised Face Flanges

Alloy Steel Slip-On Raised Face Flanges

Duplex Steel Slip-On Raised Face Flanges

Nickel Alloy Slip-On Raised Face Flanges

Standard Basic flange dimensions for ASME B16.5. include ANSI B16.47, ANSI B16.36, ANSI B16.48 BS 4504, EN 1092 DIN, or API 6A.

Slip-on flanges are easy to install and remove and are less expensive than other flange types. Slip-on flanges are ideal for applications where cost is an important consideration and the flange is not exposed to high pressure or vibration

Use Of The Product

Slip-on flanges manufacturers are primarily suitable for fluids operating at low pressures. Additionally, these flanges perform well and have very little leakage. These flanges are now very commonly found in cooling water lines, fire water lines, low pressure compressed air lines, and process lines for substances such as steam, oil, gas, and condensate. These flanges are suitable for low pressure and high temperature systems.

Flange fittings with compression designation classes 150 and 300 in sizes NPS 1/2 to NPS24 Requirements are specified in both metric and US units, and slip-on raised flange thread diameters and tapped holes are specified in inches. unit

Flanged fittings such as the ANSI B16.5 Class 150 Slip-On Flanges with designated pressure rating classes such as 400, 600, 900, and 1500, sizes NPS 1/2 to NPS 24, and slip-on flange JIS 10k fittings with Class 2500 pressure rating designations in sizes NPS 1/2 to NPS 12 have been recognized in the non-mandatory Appendix E section,

We are one of the leading and most reputed manufacturers of Slip forged flanges. In addition to manufacturing ANSI B16.5 slip-on flanges, we are also known for supplying, selling, and exporting ASME B16.47 SORF flanges. ANSI/ASME B16.5 slip-on flange manufacturer in India. Our inventory list includes a large selection of ASTM A182 SS Class D slip-on flanges. Our factory also manufactures customized stainless steel slip-on flanges with flat faces.

Applications

ASME B16.5 slip-on flanges are known for their superior performance and are commonly designed for the following applications. To meet demand we offer a wide range of slip-on flat flanges through our global warehouse branch.

These slip flanges are used in various industries like Stainless Steel Slip on Flanges are used in Oil and Gas Pipeline Slip on Raised Face Flanges used in the chemical industry Alloy Steel SORF Flanges are used in Plumbing Flat Faced Slip-On are used in Heating

Slip on Pipe Flanges used in Water Supply Systems ANSI B16.5 Slip on Forged Flanges Used in Power Plant Steel slips on flanges are used in the fabrication industry. Slip on Flanges are used in Structural Pipe

SPECIFICATIONS

Flanges are specified by, for example, “weld neck RTJ” or “socket weld RF”. Dimensions of the ASME B16 ring connection surface and his RTJ seal. 5. Nominal Pipe Size (NPS). This is a dimensionless designation used to define the nominal pipe size (NPS) of a connecting pipe, fitting, or nozzle. Examples of this are NPS 4 and NPS 6.

Flange pressure class. This refers to the pressure and temperature rating of the flange and is required for all flanges. Examples include Classes 150, 300, 600, 900, 1500, and 2500.

SORF Manufacturing Standards

The ASME B16.5 slip-on flange specification for pipe-to-flange connections covers a variety of parameters such as materials, dimensions, pressure ratings, temperature ratings, marking, testing, and methods of designating openings for pipe Hastelloy flanges and flanged fittings.

Included are the following points:

Copper-nickel SORF flanges designated in ratings 150, 300, 400, 600, 900, and 1500. These ratings for Alloy 20 slip-on flanges are typically available in sizes NPS 1/2 to NPS 24 and in duplex. Steel SORF flanges with the classification designation 2500 are available in sizes NPS 1/2 to NPS 12. These alloy steel sliding flange requirements are given in both metric and US customary units, and stainless steel sliding flange bolt and threaded hole diameters are given in inches

Slip on face flanges Material Grade

Discover a comprehensive range of Slip On Raised Face Flanges meticulously crafted to meet diverse industrial needs. Our Grades collection features top-quality materials, including ASTM A182, A240 F grades for stainless steel, ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3, CL1/CL2 for carbon steel, ASTM A182 F1, F5, F9, F11, F22, F91 for alloy steel, and more. Embracing precision engineering, our nickel alloy Slip raised face flanges encompass ASTM SB564, SB160, and SB472 series, while our copper alloy selection boasts ASTM SB 61, SB62, SB151, and SB152 standards. Elevate your projects with our Duplex Steel Slip On Raised Face Flanges, featuring ASTM A182, and A240F grades. Explore the epitome of durability and performance with our extensive Grades range, meticulously tailored to exceed industry standards.

Slip on Raised Flanges, Alloy Steel slip on raised face flanges Manufacturer & Exporter. ASME B 16.5, ASME B 16.47, ASTM A182, 105, 350, SB564, 160, 472 Slip On Flanges, Nickel Alloy SORF Flanges Suppliers.

Platinex Piping Solutions LLP is one of the leading Manufacturers, Supplier and Exporters of High quality Slip On Raised Face Flanges. These SORF Flanges are made using premium quality materials. These Flanges is available in various size, grades, Specification & thickness as per the clients requirements. These flanges are attached to the pipe by fillet welding at the hub and at the end of the pipe inside the flange. Slip-on flanges are available with raised, flat or RTJ faces, and are also available in orifice configurations. These are easily fitted and welded into different pipes. We Provide these flanges at market leading rates.

0 notes

Text

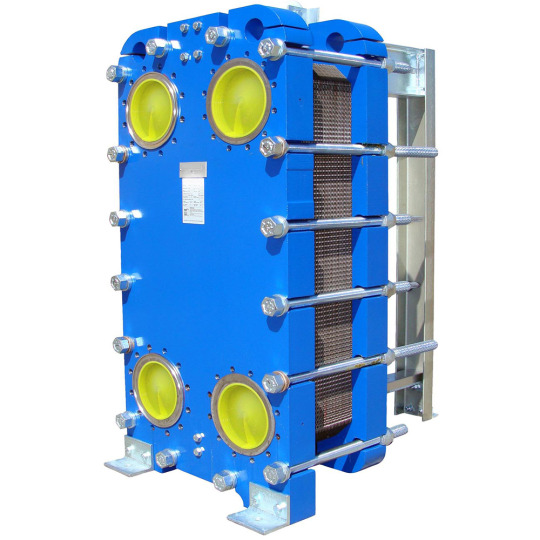

Semi-Welded Plate and Frame Heat Exchanger

API Energy Semi-Welded Plate Heat Exchangers are used for safety and corrosive media (i.e including ammonia refrigeration, CFCs, HCFCs, and aggressive process fluids. Resistant to stress and leakage), where two individual plates are laser welded together to create gas-tight modules for the “plate pack”. Only two ring gaskets fitted between two welded modules are in contact with the aggressive media. The modules are mounted between a fixed and movable pressure plate compressed by tightening bolts. This heat exchanger is ideal to be used for special process conditions, in particular aggressive media.

The advantage of this construction is that, one side of the cassette is a sealed welded channel, whilst the other is a traditional gasketted plate channel (i.e isolate refrigerant or process fluids from the gasketing). Making assembly and cleaning of this site easier.

Advantages

Laser welded plates

Safe operation without leaking

High working pressure

Can be used for evaporators and condensers

Suitable for NH3

Minor gasket area

Small liquid volume

Semi-Welded Plate and Frame Heat Exchanger

0 notes

Text

Our Products

Standard Orifice Plates

Our standard orifice plates are available in a variety of sizes and configurations to suit common flow measurement applications. These plates are designed for easy installation and maintenance.

Custom Orifice Plates

Need something specific? We offer fully customizable orifice plates to match your exact requirements. Our engineering team will collaborate with you to design and manufacture plates that fit perfectly into your system.

Orifice Plate Assemblies

We provide complete orifice plate assemblies, including carrier rings, gaskets, and mounting hardware. Our assemblies are designed for seamless integration and optimal performance.

Specialty Orifice Plates

For unique or challenging applications, our specialty orifice plates offer tailored solutions. Whether it's for high-temperature environments, corrosive fluids, or unusual flow conditions, we have the expertise to deliver.

Industries We Serve

Oil and Gas

Chemical Processing

Water and Wastewater Management

Power Generation

Pharmaceuticals

Food and Beverage

Pulp and Paper

Quality Assurance

At Precision Orifice Plate Manufacturers, quality is our top priority. We adhere to stringent quality control procedures throughout the manufacturing process, ensuring that every product we deliver meets the highest standards of excellence. Our orifice plates are compliant with industry standards such as ISO 5167, ASME MFC, and API.

Contact Us

Ready to learn more about how our orifice plates can improve your flow measurement systems? Contact us today for a consultation or to request a quote. Our knowledgeable team is here to assist you with all your flow measurement needs.

0 notes

Text

API Ring Joint Gaskets are high-performance sealing solutions designed for high-pressure and high-temperature applications. Commonly used in the oil, gas, and petrochemical industries, these metal-to-metal gaskets fit precisely into grooved flanges, ensuring a tight, leak-proof seal. They are available in styles like R, RX, and BX, and are built to meet API 6A and ASME B16.20 standards.

0 notes

Text

WMASS Flanges Distributor

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Exclusive Distributor & Stockist Of WMASS Flanges (Germany) & fundamental supplier, stockist, and exporter of various things like Pipe Fittings, Flanges, fasteners, etc in different ferrous and non-ferrous materials like Flanges, Buttweld Fittings, Forged Fittings, Pipes & Tubes, Sheets & Plates, Round Bar, Fasteners, Wires, Tube Fittings, Dairy Fittings, Gasket etc.

We have top tier advances to make and offer high-regard exceptional steel things to our clients. Our things are for the most part used in various endeavors and applications, including building projects, infrastructural workplaces, cars, electrical applications, and machines. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is remarkable for its business and sensibility practices.

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. WMASS Flanges are of the ring joint sort and are not typical for versus make-up. The affiliation makes up catapulting power answers on the metallic ring gasket. Programming Association Point Companion flanges are of through affected or studded structure. Programming points of alliance Weld Neck Flanges are of a through shot or studded outline. Eye to eye affiliation isn't pulverizing for the best working of the Programming Point of Interaction Line Flanges. Appraisals for Programming Connection Point Flanges Material. We are modifying connection point 6a Flanges Producers in UAE.

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. Api 6A is a trusted stockist of Programming connection point 5l Level B Flanges to Bahrain, Russia, UK, Kuwait, Egypt, Canada, Iran, Qatar, USA, France, Indonesia, UAE, Oman, Turkey, Singapore, Malaysia, Italy, Thailand, Sweden, Israel, Germany, Australia, Sri Lanka and Saudi Arabia. Nutech Abroad are serious solid areas for the vast majority of Programming Point of interaction flanges material kept up by Saudi Aramco. You can email us to get Programming point of interaction Flanges evaluations, Programming connection point Flanges weight outline or Programming point of interaction Flanges pressure rating plan.

If you are looking for best expense of Programming point of interaction Connector Flanges or Programming point of interaction Plate flanges, Programming connection point 10000 Psi flanges near you with most short period of time progress or free occasion of Programming connection point Hung flanges.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#WMASS Flanges Manufacturers in UAE#WMASS Flanges Suppliers in UAE#WMASS Flanges Stockists in UAE#WMASS Flanges Exporters in UAE

0 notes

Text

Types of Flanges Demystified: Matching the Right Flange to Your Project Needs - Arcellor Controls India

Flanges are a crucial but often overlooked component of fluid or gas transportation. These indispensable pieces serve a critical role in seamlessly connecting pipes, valves, and various other equipment across a wide array of industrial applications. The selection of the right flange type, among the many available options, can indeed be a daunting task. At Arcellor Controls India, a reputable and leading flange manufacturer and exporter, we are dedicated to demystifying the intricate world of flanges, making it easier for you to identify the perfect flange coupling for your project needs. Explore the extensive variety of flange types we offer, and find the ideal solution to meet your specific requirements.

Understanding the Types of Flanges

Flanges play a critical role in connecting pipes, valves, and other equipment in various industries, ensuring a leak-free and secure connection. However, not all flanges are created equal, and it's essential to understand the different types available to match your project needs effectively.

Weld Neck Flanges: These flanges are designed for high-pressure applications. Their long neck, or hub, is ideal for situations where thermal expansion and contraction occur.

Coupling Flanges: Also known as slip-on flanges, they are easy to install and are commonly used in less critical, low-pressure applications.

Socket Weld Flanges: These flanges are used for smaller-sized pipes and offer good flow and structural integrity. They are ideal for high-pressure systems.

Threaded Flanges: Threaded flanges are suitable for low-pressure applications and pipes with external threads. They provide easy installation and are commonly used in plumbing systems.

Lap Joint Flanges: These are used with stub ends in systems requiring frequent dismantling. They allow easy alignment of bolt holes during assembly.

Blind Flanges: Blind flanges are used to close the end of a pipe, valve, or vessel. They are essential for maintenance, inspection, or future expansion.

Selecting the Right Face Type

In addition to the types of flanges, it's important to consider the face type, which determines the sealing and pressure capabilities of the connection.

Flat Face (FF) Flanges: These have a flat, smooth surface and are suitable for low-pressure applications. They provide excellent gasket seating.

Raised Face (RF) Flanges: The raised surface ensures better alignment, improved sealing, and enhanced pressure capabilities, making them suitable for higher-pressure systems.

Ring Type Joint (RTJ) Flanges: RTJ flanges use a metal ring gasket, making them ideal for extreme temperatures and high-pressure environments, such as in the oil and gas industry.

Flanges Specifications and Standards

Standard

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Dimensions

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

Materials

Stainless Steel Flanges, Duplex and Super Duplex Steel Flanges, Carbon Steel Flanges, Low-Temperature Carbon Steel Flanges, Alloy Steel Flanges, Copper Alloy Steel Flanges, and Nickel Alloy Flanges (Monel, Inconel, Hastelloy)

Size

1/2″ (15 NB) to 48″ (1200NB)

Type

Weld Neck Flanges, Slip On Flanges, Socket weld Flanges, Spectacle blind flanges, Coupling Flanges, Threaded Flanges, Lap Joint Flanges, Blind Flanges Face Type Flanges - Flat Face (FF) Flanges, Raised Face (RF) Flanges & Ring Type Joint (RTJ) Flanges

Flange Face Type

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Applications of Flanges

Flanges are an integral component in various industries and applications, primarily in piping systems. They serve several important functions, including connecting, terminating, and supporting pipes or other equipment. Here are some common applications of flanges:

Piping Systems

Oil and Gas Industry

Chemical Industry

Power Generation

Water and Wastewater Treatment

Aerospace

Marine Industry

Food and Beverage Industry

Construction

Automotive Industry

Heating, Ventilation, and Air Conditioning (HVAC)

Hydraulic Systems

Instrumentation

Nuclear Industry

Renewable Energy

Other Applications

Final Words!

Selecting the right flange for your project is a critical decision that impacts the performance and safety of your industrial systems. At Arcellor Controls India, we offer a wide range of flanges, including weld neck, coupling, socket weld, threaded, lap joint, and blind flanges, as well as various face type options, to cater to diverse project requirements. Moreover, we export our flanges to numerous countries, including Oman, Qatar, the USA, Germany, the UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia, at highly competitive prices, making us the go-to choice for businesses worldwide.

When choosing your flanges, always consider factors such as pressure, temperature, and maintenance requirements. Our team is here to assist you in making the right choice for your specific project. Contact us today at [email protected] or [email protected] your trusted partner for high-quality flanges, and let us provide the perfect solution for your industrial needs.

0 notes

Text

Everything You Need to Know About Ring Gaskets

When it comes to high-pressure and high-temperature sealing, ring gaskets are the ultimate solution! Used extensively in oil & gas, petrochemical, and power generation industries, these gaskets ensure a leak-proof and secure seal, even in the most extreme conditions.

🔥 Why Choose Ring Gaskets?

✔ Exceptional Strength – Made from stainless steel, Inconel, and other high-grade materials ✔ High-Pressure Resistance – Ideal for extreme environments ✔ Leak-Proof Performance – Ensures tight and durable sealing ✔ Industry Compliant – Meets ASME, API, and other global standards

⚙️ Where Are Ring Gaskets Used?

🔹 Oil & Gas Pipelines 🔹 Refineries & Petrochemical Plants 🔹 Steam & High-Temperature Systems 🔹 Pressure Vessels & Heat Exchangers

For industries that demand precision and reliability, ASP Ring Gaskets provide top-notch sealing solutions that keep operations running smoothly.

0 notes

Text

Ananka

Q1) Fasteners in the Oil and Gas Industry: Meeting Rigorous Demands

Ans) Fasteners are crucial components in the oil and gas industry, where they face some of the most demanding and rigorous conditions. This sector encompasses exploration, drilling, production, refining, and transportation of petroleum products, requiring fasteners that can withstand extreme environments, high pressures, corrosive substances, and temperature fluctuations. To meet the stringent demands of the oil and gas sector, specialized fasteners are necessary to ensure safety, reliability, and performance. Here are key aspects of fasteners in the oil and gas industry:

1. Corrosion Resistance: Fasteners in this industry must withstand corrosive environments, such as offshore drilling platforms or sour gas fields. Superior corrosion resistance is achieved using materials like stainless steel and high-grade alloys.

2. High Strength and Load-Bearing Capacity: With heavy loads and pressures common in oil and gas equipment, fasteners must possess high tensile and yield strength to endure without failure. High-strength materials like alloy steels and exotic alloys are chosen to meet these demands.

3. Temperature Extremes: Fasteners should maintain integrity and performance under extreme temperatures, especially in deep drilling or refining processes.

4. Sealing and Leak Prevention: Effective sealing is critical to prevent leaks of hazardous substances. Fasteners often incorporate gaskets and O-rings to ensure secure and leak-free connections.

5. Compliance with Industry Standards: Adherence to industry-specific regulations and standards, such as API specifications, ensures safe and reliable performance.

6. Subsea Applications: In offshore drilling, fasteners used in subsea equipment and infrastructure must withstand high hydrostatic pressures, aggressive sea environments, and potential underwater fatigue.

7. Inspection and Testing: Due to the critical nature of the oil and gas industry, fasteners undergo extensive testing and inspection processes to verify performance, integrity, and compliance with standards.

8. Environmental Considerations: Fasteners used in environmentally sensitive areas must meet specific requirements to prevent potential hazards like oil spills or gas leaks.

In conclusion, fasteners in the oil and gas industry are designed and engineered to meet rigorous demands. They exhibit exceptional corrosion resistance, high strength, and reliability under extreme conditions. Compliance with industry standards, thorough testing, and inspection processes ensure the safety and efficiency of oil and gas operations. Specialized fasteners play a crucial role in meeting the unique challenges posed by this critical industry.

Fasteners Manufacturers Mumbai

Q2) The Science of Torque: Properly Tightening Fasteners

Ans) Fasteners are crucial components in the oil and gas industry, where they face some of the most demanding and rigorous conditions. This sector encompasses exploration, drilling, production, refining, and transportation of petroleum products, requiring fasteners that can withstand extreme environments, high pressures, corrosive substances, and temperature fluctuations. To meet the stringent demands of the oil and gas sector, specialized fasteners are necessary to ensure safety, reliability, and performance. Here are key aspects of fasteners in the oil and gas industry:

1. Corrosion Resistance: Fasteners in this industry must withstand corrosive environments, such as offshore drilling platforms or sour gas fields. Superior corrosion resistance is achieved using materials like stainless steel and high-grade alloys.

2. High Strength and Load-Bearing Capacity: With heavy loads and pressures common in oil and gas equipment, fasteners must possess high tensile and yield strength to endure without failure. High-strength materials like alloy steels and exotic alloys are chosen to meet these demands.

3. Temperature Extremes: Fasteners should maintain integrity and performance under extreme temperatures, especially in deep drilling or refining processes.

4. Sealing and Leak Prevention: Effective sealing is critical to prevent leaks of hazardous substances. Fasteners often incorporate gaskets and O-rings to ensure secure and leak-free connections.

5. Compliance with Industry Standards: Adherence to industry-specific regulations and standards, such as API specifications, ensures safe and reliable performance.

6. Subsea Applications: In offshore drilling, fasteners used in subsea equipment and infrastructure must withstand high hydrostatic pressures, aggressive sea environments, and potential underwater fatigue.

7. Inspection and Testing: Due to the critical nature of the oil and gas industry, fasteners undergo extensive testing and inspection processes to verify performance, integrity, and compliance with standards.

8. Environmental Considerations: Fasteners used in environmentally sensitive areas must meet specific requirements to prevent potential hazards like oil spills or gas leaks.

In conclusion, fasteners in the oil and gas industry are designed and engineered to meet rigorous demands. They exhibit exceptional corrosion resistance, high strength, and reliability under extreme conditions. Compliance with industry standards, thorough testing, and inspection processes ensure the safety and efficiency of oil and gas operations. Specialized fasteners play a crucial role in meeting the unique challenges posed by this critical industry.

Eye Bolt Manufacturer in Mumbai

Q3) Fastening Solutions for Renewable Energy Projects

Ans) Fastening solutions play a pivotal role in ensuring the success and longevity of renewable energy projects, where components must withstand diverse environmental conditions and operational demands. These projects encompass the installation of solar panels, wind turbines, and other renewable energy systems. Here are common fastening solutions employed in renewable energy projects:

1. Solar Panel Mounting Systems:

Rail-Based Mounting: Solar panels are affixed to rails attached to rooftops or ground-based support structures, utilizing bolts, nuts, and washers for secure fastening.

Ballasted Mounting: Weighted ballasts stabilize solar panels without roof penetration, utilizing ballast fasteners to ensure stability, even during high winds.

2. Wind Turbine Foundations:

Anchor Bolts: Large, heavy-duty bolts secure wind turbine towers to foundations, with proper torquing ensuring stability and preventing structural issues.

Grouting Solutions: In some cases, fasteners are combined with grouting materials to secure anchor bolts and reinforce the foundation.

3. Racking Systems for Solar Tracking:

Solar tracking systems move panels to follow the sun's path, optimizing energy generation. Various fasteners secure the tracking mechanism to the foundation and solar panels.

4. Floating Solar Farms:

Floating solar farms on water bodies require special fasteners designed to resist corrosion and with stand water exposure.

5. Cables and Connectors:

Cable Clips and Ties: Fasteners secure cables and wires to prevent damage from environmental exposure and mechanical stress.

Connectors and Junction Boxes: Fasteners play a critical role in securing connectors and junction boxes for electrical connections in solar panel installations.

6. Lightning Protection Systems:

Fasteners secure lightning protection systems to renewable energy structures, guarding against lightning strikes.

7. Hybrid Solutions:

Some renewable energy projects combine different fastener types, such as welding and mechanical fasteners, for optimal performance and structural integrity.

Considerations for Fastening Solutions in Renewable Energy Projects:

Corrosion Resistance: Fasteners must resist outdoor elements, necessitating the use of corrosion-resistant materials for long-term performance.

Structural Integrity: Sufficient clamping force and structural integrity are essential for fasteners to endure wind loads, vibrations, and location-specific forces.

Environmental Impact: Sustainable and recyclable fasteners align with renewable energy projects' eco-friendly principles.

Expert Consultation: Consulting fastener experts and adhering to industry standards ensures the selection of appropriate fastening solutions for each renewable energy project.

In conclusion, fastening solutions are vital components in renewable energy projects, providing stability and security to withstand diverse environmental conditions. Properly selected and installed fasteners contribute to the efficiency, reliability, and long-term success of these sustainable energy systems.

Hex Nut Suppliers

0 notes