#Advantages of 5PL

Explore tagged Tumblr posts

Text

The Future of Logistics: What Is 5PL and Why It Matters Today?

Fifth-party logistics, or 5PL, represents the next evolution in logistics management, providing complete oversight and optimization of multiple supply chains using cutting-edge technologies. 5PL providers offer strategic consultation, AI-powered planning, and total integration across global networks. What is 5PL and why it matters today lies in its ability to unify operations, reduce friction, and support scalable growth. This comprehensive guide to fifth-party logistics explains how businesses can gain competitive advantages through visibility, automation, and real-time analytics. As logistics becomes increasingly digital, understanding the value of 5PL can help enterprises future-proof operations and align with ever-evolving customer demands.

0 notes

Text

Fifth-Party Logistics Market - Forecast (2025 – 2030)

Global Fifth-Party Logistics (5PL) Market reached USD 9.78 billion, driven by a surge in e-commerce logistics complexity and a 45% spike in demand for integrated multimodal transport solutions. Companies adopting 5PL services have reported an average 18% reduction in logistics costs and 24% faster delivery times compared to traditional models.

By 2030, the market is projected to hit USD 15.56 billion, at a steady CAGR of 5.05%. Major growth catalysts include:

• Over 60% adoption of AI and real-time tracking by logistics players, enhancing supply chain visibility.

• Expansion of sustainable logistics practices, with 65% of 5PL users prioritizing green solutions.

• Asia-Pacific emerging as the fastest growth engine, driven by manufacturing shifts and rising e-commerce in India and Southeast Asia.

• Download Sample

This report delivers detailed segmentation across service types, transport modes, end-use industries, and customer categories. It also explores pricing shifts, regional dynamics, and deployment trends, offering actionable insights for companies aiming to optimize their supply chain strategies in 2025 and beyond.

Waiting could mean missed opportunities as digitalization, sustainability demands, and supply chain orchestration redefine global logistics.

The Fifth-Party Logistics (5PL) market represents the next evolution in the logistics and supply chain industry, where advanced integration, strategic planning, and technology-driven solutions take center stage. Unlike traditional logistics providers, 5PL companies do not just manage logistics operations — they design, build, and execute entire supply chains on behalf of clients, often leveraging big data, AI, blockchain, and cloud computing to optimize end-to-end processes. This model is especially attractive to e-commerce businesses and multinational enterprises aiming for fully customized, scalable, and cost-effective logistics strategies. As supply chains grow more complex and globalized, 5PL providers are playing a critical role in offering visibility, flexibility, and resilience, transforming logistics into a competitive advantage.

Key Market Insights:

The rise of e-commerce is significantly fueling the Fifth-Party Logistics (5PL) market, with global e-commerce sales expected to surpass $8 trillion by 2027. This surge is pushing businesses to seek advanced logistics partners capable of managing complex, multi-channel supply chains. Approximately 70% of major e-commerce brands are now outsourcing their logistics operations to specialized 5PL providers, ensuring faster deliveries and better customer experiences.

Technological advancements are deeply transforming the 5PL landscape. Nearly 60% of logistics companies are actively investing in AI, IoT, and blockchain to enhance supply chain transparency and automation. Cloud-based logistics solutions have seen a 45% adoption growth over the past two years, reflecting the industry's rapid shift toward digitalized and real-time supply chain management.

Sustainability is also emerging as a major focus area within the 5PL market. Studies show that over 65% of businesses consider eco-friendly logistics a top priority when selecting a supply chain partner. Green logistics initiatives, including route optimization and electric fleet management, are becoming standard practices among leading 5PL providers, helping clients meet regulatory demands and corporate sustainability goals.

Buy Now

Fifth-Party Logistics Market Drivers:

Growing Demand for Supply Chain Efficiency and Cost Reduction

The demand for enhanced supply chain efficiency and cost reduction is fueling the growth of the fifth-party logistics (5PL) market. Companies are increasingly looking for ways to streamline their operations and outsource their logistics needs to improve efficiency and cut costs. 5PL providers offer comprehensive services that include warehousing, transportation, and technology solutions, which help businesses reduce redundancies, optimize resources, and enhance their overall supply chain. This integrated approach is appealing to companies aiming to stay competitive while lowering their operational expenses.

Advancements in Technology and Automation for Enhanced Logistics Operations

Technological advancements, particularly in automation, AI, and IoT, are contributing significantly to the expansion of the 5PL market. By enabling smarter solutions such as real-time tracking, predictive analytics, and optimized routing, these technologies help logistics providers offer efficient and streamlined operations. Automation reduces human error and improves operational performance, while IoT and AI enhance real-time decision-making and visibility across the supply chain. This shift toward more technologically driven logistics solutions is a major factor driving the market’s growth.

Focus on Sustainability and Eco-friendly Supply Chain Practices

Sustainability has become a key consideration for businesses, contributing to the rising demand for 5PL services. Companies are under increasing pressure to adopt greener practices and reduce their environmental footprint. 5PL providers offer sustainable logistics solutions, including energy-efficient transportation, eco-friendly packaging, and optimized routing to reduce carbon emissions. With consumers and businesses alike becoming more conscious of their environmental impact, the need for logistics solutions that promote sustainability continues to drive demand for 5PL services.

Rising Complexity of Global Supply Chains and the Need for End-to-End Solutions

The complexity of global supply chains is rising, leading to an increased need for end-to-end solutions. With globalization and e-commerce expansion, businesses face increasingly intricate logistics challenges. Companies are seeking logistics partners who can handle the full scope of their supply chain needs, from warehousing to transportation to real-time tracking. As businesses aim to stay competitive in this complex environment, the demand for comprehensive, integrated solutions like 5PL services is rising, making it a driving force in the logistics market.

Fifth-Party Logistics Market Restraints and Challenges:

Limited Awareness and Adoption of 5PL Services

One of the key challenges hindering the growth of the fifth-party logistics (5PL) market is the limited awareness and adoption of these services. Many businesses, especially smaller enterprises, still rely on traditional logistics models like third-party logistics (3PL) and are hesitant to transition to more complex 5PL solutions due to a lack of understanding or perceived high costs. This lack of awareness about the potential benefits, such as enhanced efficiency, end-to-end integration, and scalability, limits the adoption of 5PL services across industries. Additionally, businesses may struggle with the initial investment in advanced technologies and the integration of diverse supply chain processes, making the shift to 5PL services challenging.

Enquire Before Buying

Fifth-Party Logistics Market Opportunities:

The fifth-party logistics (5PL) market offers remarkable opportunities for growth, particularly as businesses increasingly prioritize digital transformation and supply chain integration. As industries move toward more complex and globalized supply chains, 5PL services provide the ability to manage these intricate networks efficiently. The rise of e-commerce, the need for faster and more flexible supply chain solutions, and the growing demand for data-driven insights are key factors driving this growth. Additionally, advancements in technologies like IoT, AI, and big data analytics offer 5PL providers new ways to optimize logistics processes, offering businesses cost-effective and scalable solutions. As companies seek to enhance operational efficiency, 5PL’s role in providing comprehensive logistics strategies will continue to expand.

Fifth-Party Logistics Market Segmentation:

Market Segmentation: By Service Type:

• Supply Chain Orchestration • Transportation Management • Freight Forwarding • Warehousing & Distribution • Reverse Logistics • Customs Clearance & Compliance Management • Value-Added Logistics Services • Others (Order Fulfillment Support, Packaging, Labeling

0 notes

Text

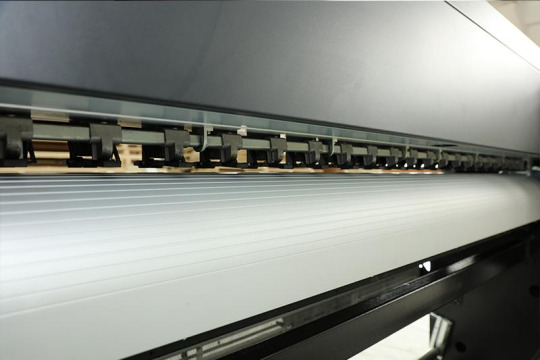

Fespa in Amsterdam – Look to the East

To some extent, this year’s main Fespa trade show was always going to be overshadowed by Drupa. That’s one reason why Fespa likes to get out of Germany and visit Amsterdam in Drupa years, plus Northern Europe tends to attract a more sign and display oriented crowd.

However, this year’s event was on a much bigger scale than previous Fespa outings to the Rai centre in Amsterdam, with three main halls – 1,2 and 5 – plus a further three – 10,11 and 12 – off to one side. Even better, the press office was handily located in the walkway between the two halves, complete with coffee, and there was a strong WiFi signal throughout the show.

My impression was that the show was busier than I would have expected, especially on the second day. However, a number of the established exhibitors were missing, including HP, Fujifilm and Canon. In part this was due to the upcoming Drupa but it’s also worth noting that this year’s show is a little earlier than usual, meaning that the vendors have to cover the costs of both last year’s and this year’s Fespa in the same financial year, with the added cost of Drupa just around the corner.

For journalists, this problem is amplified because Fespa took place right at the time that many vendors are starting to announce their Drupa plans in the hope of picking up coverage in the May issues of the trade magazines, which will mostly go to press early to mid-April.

http://indianprinterpublisher.com/wp-content/uploads/2024/04/Fespa_Entrance_L1049687_WQWeb650.jpg

And yet there was still plenty to see at Fespa, mostly in terms of how the large format market is evolving rather than any ground breaking new technologies. I was struck by how many vendors are now rounding out their portfolios, introducing mid-range products to fill perceived gaps in their offerings, but with very little that really raises the bar in terms of higher productivity or lower costs. This is a clear sign that the market has matured and that the vendors don’t see any further value in pouring money into R&D other than for incremental improvements. Nor do I have a sense that we are going to see a lot of new large format kit at Drupa; instead the vendors are moving into newer, more lucrative markets, mainly packaging and textiles, albeit building on the IP they have developed in large format.

In recent years Fespa has become a show of two halves, split between the sign and display markets and the textile printing, particularly for the garment sector. If anything, this contrast between the two halves was even more stark at this year’s show. Consequently, for this story I’m going to concentrate on the sign and display side but will follow up with a separate story on the garment solutions.

The other very noticeable trend was for more Chinese manufacturers which now make up a very large percentage of the overall vendors present. In some cases, the Chinese technology appears to be quite rudimentary, but many Chinese companies can now clearly rival their Western counterparts.

http://indianprinterpublisher.com/wp-content/uploads/2024/04/Ricoh_AngeloMandelli_L1049728_WQWeb450.jpg

Angelo Mandelli, Senior Product & Business Development manager for Ricoh Europe’s large format business, explains, “We recognised Flora as a good partner. They are already a Ricoh printhead customer. It’s a very stable device because this is the third generation of Flora hybrid solutions.” He adds, “We could change the brand on this product but anyone with experience in this market would recognize this machine.”

Flora were also happy to accommodate Ricoh with a number of changes, including switching from Gen5 to Gen6 printheads which allows Ricoh to work with a smaller native 5pL drop size. Mandelli adds, “We requested to use linear motors instead of stepper motors, which gives us less energy consumption and less maintenance and the carriage moves more smoothly and is quicker so there are a lot of advantages.”

Mandelli notes, “Flora has a lot of mechanical competence with hardware. We can combine this with our skills in software and can create our ICC profiles to create our own Ricoh hybrid proposition and improve our portfolio. And it’s a quicker approach to the market for us. It takes a lot of time to produce stuff today and we already have a lot of good partners.”

He continues, “There are a lot of advantages to the Flora approach. It has a white cleaning system, an anti-crash sensor and an ioniser bar.” He adds, “And we decided to create ICC profiles dedicated to this product. And we have the Ricoh organisation with our services and sales and logistics team.”

He points out that Flora is very flexible and willing to use different printheads and RIPs to suit OEM partners. This flexibility seems to be a hallmark of Chinese manufacturers, with Pooja Rajpal of Zhongke India making exactly the same point to me earlier this year at the Pamex show in India.

The ink comes from a third party supplier based in EMEA but Mandelli won’t say who. There’s a choice of ink configurations, starting with just CMYK, then CMYK plus two white channels, or CMYK plus one white and one clear ink. Naturally Ricoh has created the waveform to drive the printheads. The RIP is Production Server 23 from ColorGate, which is a subsidiary of Ricoh, complete with dedicated device drivers for the X20. It will produce up to 116 square meters an hour in its Express mode but a more realistic production figure is 50 square meters an hour.

Interestingly, this arrangement is with Ricoh Europe rather than Ricoh as a whole, and so Ricoh is only planning on selling the X20UV in the Europe, Middle East and Africa region. Mandelli says that the company has other arrangements in different regions, such as the US where Ricoh cooperates with EFI. That’s not an option in Europe because the market is more fragmented, and more complicated as there are a lot of EFI dealers. He adds, “But Flora is not so present in Europe so we can offer our support to the product with no competition between us.”

He notes, “We have a lot of experience with the Flora system because the EFI machines are based on them.”

This limited sales strategy also means a limited R&D budget to develop a new solution, making a partnership the most practical option. Mandelli says that Ricoh Europe can put other Ricoh entities in touch with Flora if they want to do something similar for other regions. Mandelli also left open the possibility that Ricoh could use additional products to further expand its portfolio. But for now he says that he prefers to take a gradual approach and build confidence with the smaller hybrid before looking into bigger machines.

Mandelli explains that Ricoh wanted to close a gap in its portfolio between the L5100-series latex rollfed, which is an entry level printer costing around €25,000, and its two UV flatbeds, which sell for €130,000 to €150,000. He adds, “This is a price gap but it’s also a technology gap. We received a lot of requests for a compact hybrid device with the possibility to print to rigid and flexible materials.” Only the latex printer has been developed in-house, at Ricoh Asia, with the flatbed being a 50/50 co-development with another OEM. The X20 fits into this portfolio at around €100,000 to €110,000.

Mandelli says the feedback to the X20UV at Fespa was very positive. The machine that was at the show was shipped directly to Ricoh’s UK base in Telford so that Ricoh could complete its ICC profiles. It should be on sale in the next few weeks.

http://indianprinterpublisher.com/wp-content/uploads/2024/04/Flora_CorrugateRear_L1049596_WQ-wb450.jpg

Flora also showed off its version of the X20UV. Flora offers customers a choice of Konica Minolta or Ricoh printheads, along with a Flora edition of the PhotoPrint RIP and a one-year warranty, dependent on the local dealer.

Flora showed a number of other printers including its compact J330s inkjet label press, which prints CMYK plus white and can run at 30 mpm at 1200 x 600 dpi. There was also the C25h Pro corrugated printer, which has a maximum media width of 2.5 meters but was paired with a much smaller board feeder. It runs aqueous CMYK inks and can produce around 400 square meters an hour. However, it still appears to be under development.

There were plenty of other Chinese manufactures at the show – around 70 in total – though I didn’t have time to visit them all. But I think that the main takeaway is that the idea that the Chinese only make cheap and cheerful printers is way out of date. There’s very little in the way of technical superiority to distinguish machines made in the US, Europe or Japan, and indeed many of the printers sold by companies in the developed world are actually made in China.

Several people have told me that they believe the Chinese vendors still lack the necessary distribution and support infrastructure to sell into Western countries. Up to now the Chinese vendors have done very well out of OEM partnerships so they didn’t need a sales and support network. But since the pandemic, it appears to me that many of those Chinese vendors are now in the process of setting up distribution through established dealers in Eastern Europe and they already have a strong presence in other regions such as India. Besides, it’s only a matter of time before they start buying those established dealers and owning their own sales and support networks in Europe and the US.

So, for me the rapid expansion of Chinese vendors was one of the most noticeable trends from Fespa, and I would expect that we will see the same at Drupa. However, there were several other themes from Fespa that I will explore in the next part of this story.

First published in the Printing and Industry Journal on 8th April 2024. Reprinted with permission. www.nessancleary.co.uk

0 notes

Text

Transportation Management for Industrial Goods

Transportation Management for Industrial Goods" involves the strategic planning, execution, and optimization of transportation processes specifically tailored to the needs of the industrial goods sector. It encompasses the efficient movement of raw materials, components, and finished products between suppliers, manufacturers, distribution centers, and customers.

Key aspects of transportation management for industrial goods include:

Mode Selection: Determining the most suitable transportation modes such as road, rail, sea, or air based on factors like cost, transit time, distance, and product characteristics.

Carrier Management: Selecting reliable carriers and negotiating favorable contracts to ensure timely and cost-effective transportation services.

Route Optimization: Utilizing advanced routing software and algorithms to optimize delivery routes, minimize transportation costs, and reduce carbon emissions.

Freight Consolidation: Aggregating smaller shipments into larger, more economical loads to reduce transportation expenses and improve efficiency.

Tracking and Visibility: Implementing tracking technologies such as GPS, RFID, and EDI to provide real-time visibility into shipment status and location, enabling proactive management of transportation operations.

Compliance and Regulations: Ensuring compliance with transportation regulations, safety standards, and customs requirements to avoid delays, penalties, and legal issues.

Risk Management: Identifying potential transportation risks such as delays, disruptions, and security threats, and implementing mitigation strategies to minimize their impact on supply chain continuity.

Effective transportation management for industrial goods is essential for optimizing supply chain efficiency, reducing costs, and enhancing customer satisfaction. By leveraging technology, data analytics, and strategic partnerships, businesses can streamline transportation processes, improve visibility, and gain a competitive advantage in the dynamic industrial goods market.

0 notes

Photo

New Post has been published on https://fleetconcepts.com/3pl/3pl-logistics-company/

What is a 3PL Logistics Company?

3PL, or third party logistics, is a terminology to classify a company that provides complex outsourced logistics solutions and also supply chain management. A 3PL supplier participates in a range of services that receives product or material from the producer or supplier, manages it through the distribution or assembly network, and also ships it to the customer or seller.

3PL Logistics Management Companies

3PL companies have arisen in recent years to help corporations meet the global challenges of global commerce. The traditional functions of a company now extend to include risk management, supply chain management, and supply chain optimization. These days, much of what a company does involve data entry, data processing, and data entry management.

Companies provide these services because they can save money by doing so. The old companies that did manual management now no longer exist, but there are still large numbers of smaller businesses out there who would like to do manual work. However, with the advent of 3PL companies, there can do so much better.

In today’s growth in our society, everyone needs to be connected. This is especially true for businesses that must compete in a global market. The competition that we face is fierce. Each year, new products come on the market, and the benefits of these new products are apparent.

Logistics management was not originally meant to be a part of the business function. However, as the needs of consumers changes, so does the needs of the business to keep up with them. The combination of technology and convenience made it necessary for a company to be able to manage its global market.

Most people spend most of their time working in one area of their business. For example, most people will devote half of their day in one part of their business, such as production or sales. Meanwhile, most of the rest of the day is spent doing inventory or waste warehousing.

These two work together to keep production in balance. Waste management and inventory management are essential to the process as time passes; however, the need for these systems increases to keep everything running smoothly.

Businesses now can use 3PL companies to help them with the requirements of these systems. This capability allows companies to maximize their resources since it costs much less than employing human resources in this capacity. It is much more cost-effective using the same cost than having to hire a human resource to monitor all the processes.

Logistics management has been referred to as a complicated service. To get the full benefit of the services, a company has to understand what they can and cannot do, which means knowledge of the company and how it operates. However, these skills can be learned through online training from the original companies themselves.

Logistics management has become very complex, thanks to the changing way that companies operate. All companies can benefit from the services of an organization that can extend their knowledge. From company to company, the amount of experience, and the degree of expertise available vary.

Although it is important to have an organized logistical, it is also equally important to have someone who knows the subject. It is not enough to have a qualified logistician. They must also have a detailed understanding of the system that they are running.

Logisticians can only genuinely function at their best when they understand the subjects that they are addressing. Logistics management is a big undertaking. Therefore, these individuals must know every aspect of the subject matter.

Logisticians should possess the knowledge of the company; it’s history, the activities and scope of operations, and the kind of business it is. Their capacity to develop and provide customers with services should be tested. To do this, they should go through independent training from certified companies that offer this service. With this kind of training, they will be fully prepared to handle the demands of customers.

How the Title 3PL Logistics Developed

Initially, businesses under the 3PL classification were there to distinguish them from logistics companies that did not use the web to sustain their solutions. According to the Council of Supply Chain Management Professionals (CSCMP), the title was first useful to recognize what’s called Intermodal Advertising Companies (IMCs) associated with transportation agreements. Before the very early 1970s, when ‘3PL’ was initially made use of, these agreements just included shippers and carriers.

The term ‘3PL’ is used these days for a broad series of markets, as well as providers might supply a single service, like warehousing, or they may supply a group of services that handle the material through the supply chain. In short, 3PL may be used to define any kind of service agreement entailing the warehousing or distribution of products.

“When IMCs entered the scene as middlemen that approved shipments from the shippers and tendered them to the rail carriers, they came to be the third party to the agreement, the 3PL. The definition has widened to the point where these days, every company that provides some kind of logistics solution for hire calls itself a 3PL.” the CSCMP glossary states.

Listed below’s how the five present levels of party logistics are distinct:

1PL: A business or person that moves their items from point A to factor B. These companies are cargo proprietors that provide production or retail services.

2PL: A second-party carrier that owns, leases, or charters the approaches of transportation that they use to deliver a first-party’s products, such as an airline, truck business, or shipping line. Carriers are usually considered 2PL carriers of transportation solutions.

3PL: A logistics provider that makes use of 3rd party modern technology or logistics systems for some or every one of the functions of their supply chain circulation of goods. A 3PL partner is usually a logistics service provider.

4PL: Independent logistics suppliers that mix all obtainable capacities, resources, and modern technology (their very own, which of various other organizations) to create and take care of intricate supply chain options for their customers. Lead logistics companies, as well as experts, are identified as 4PL, supplying extensive supply chain management.

5PL: A logistics collector that combines the needs of their customers (occasionally consists of 3PL customers) into a bulk quantity to get lowered rates for shipping.

Patterns in 3PL Logistics Services

Like virtually any kind of sector, logistics has altered dramatically because of enhancements and also technologies with technology, impacting 3PL as well as 4PL carriers more than the lower degrees of logistics management. The market is creating higher efficiency, cost-effectiveness, and combination as a result of some critical fads:

Mobile applications provide enhanced adaptability. Luckily for the environment and organization, paper is almost a thing of the past for 3PL thanks to mobile apps. Tracking info is readily available in better information with RFID, and we can also handle intricate systems within the supply chain utilizing a mobile device.

Smarter, devoted modern technology enhances performance. Specialized software, smarter IT, and also other technologically increased systems are much better than ever when it comes to ROI. 3PLs are buying these technologies increasingly more to drive down expenses, increase the efficiency of procedures, conserve time, and boost accuracy. For instance, the speech acknowledgment software program has created the capability for employees to communicate straight with the storage facility’s management system, quickening their ability to access and direct products in the supply chain.

Big Data is driving systems modifications for greater success. A lot of the 3PLs of today are embracing Big Information as well as incorporating cloud-based innovation right into their systems and procedures. Clients can utilize these systems to access and also track their product as it moves via the supply chain, improving their experience as well as complete satisfaction. The real-time, globally easily accessible data assists track products far better and refine them a lot more efficiently.

Shippers and 3PL companies are teaming up more than ever. Innovation has drastically changed the way information is shared between logistics as well as shipping, permitting these events to connect, team up, and also involve on a higher level. The convenience of access to real-time data simplifies efficiency enhances adaptability with procedures as well as eliminates the risk of trading incorrect or obsolete info for greater precision.

Globalization of the supply chain, together with the global economic situation. The global economic climate is ending up being a growing number of integrated and also 3PL supply chains along with it. Down the road, these logistics businesses will collaborate with a lot more international expectations and on a larger scale. With this globalization, the supply chain is probably going to come to be much more intricate, sustained by reliable and efficient operations thanks to technology improvements.

Advantages of a 3PL Partnership

Third-party logistics allows your business to take care of all facets of storehouse operations without straining your economic and employee resources, rather than counting on integrated software application applications to decrease administrative as well as resource financial investment.

Reduced Cost: 3PL business is far more experienced at supply chain management, and also bring valuable know-how that reduces errors and also maximizes performance to simplify prices and conserve your company money.

Shared Duty: By managing supply chains across the United States, your company can rely on real-time info and tracking, dependable inventory levels, and order accuracy to get rid of a few of your duty as well as guarantee customer satisfaction.

Competitive Edge: A 3PL partner has access to an international distribution network, which enables your organization to fulfill the needs of a global market. This competitive edge could be a considerable benefit to help with the development and the success of your service.

Call us to review your demands for a 3PL partner!

0 notes

Text

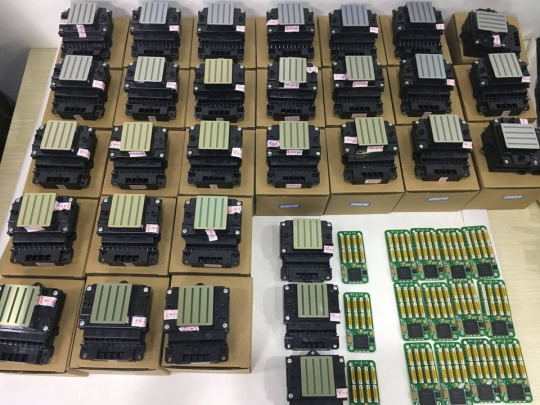

Why Epson 5113 Print Head Sells So Well in the Market?

Do you know why Epson 5113 print head are so popular? Today, I will tell you the answer.

Epson 5113 print head are popular nowadays because of it’s high speed and high resolution. Compared with DX5 and DX7 print head, we will find there are many advantages of 5113 print head.

1. The number of nozzles DX5 and DX7 print heads: 8 lines*180 nozzles=1440

nozzles,the smallest nozzle is 3.5PL/5PL.

5113 print heads: 4 lines*800 nozzles=32 00 nozzles, the smallest nozzles is 1.5PL.

2. The size of the print head The size of 5113 print head is 1.3 inch, 30% width than the DX5 and DX7 print heads.

3. High speed Because the amount of nozzles are much more than the DX5 and DX7 print head, so the 5113 print head can print with 3 pass and the speed can up to 30 m2/h.

4. The price The price of 5113 printhead is much cheaper than DX5 and DX7 print heads.

We FeiYue Digital Technology Co., Ltd mainly manages sublimation paper, inkjet printer, digital printing inks, calendering machines and accessories, operating sublimation printing industry has been more than 10 years experience. After continuous improvement of the product, to ensure product quality can also be profit at the same time to the minimum, to ensure that customers enjoy the best price and the best quality products.

0 notes

Text

What are the biggest trends in logistics technology

With so many growing industries today, it’s hard to keep up with the constant innovations and trends that occur. However, there are two very helpful tips when it comes to such activities. The first – you always have companies that do all the work and put it into a very simple and readable article for you. So, whether you are looking at trends in the moving industry or current housing opportunities, you can find it all out with a simple Google search. Second, you don’t have to go too far to find the information you need – you should simply rely on companies in your or a similar line of business for “the scoop”. This is why Movers Development is here today to present you with the biggest trends in logistics technology today.

9 biggest trends in logistics technology you should explore

1. Blockchain technology

If you’ve been having difficulties with monitoring your logistics processes, you can wave them goodbye with the use of blockchain tech. The introduction of blockchain technology is definitely one of the biggest trends in logistics technology presently. How does it work?

Simple – it is a specifically designed system that can help companies record transactions, track assets, and manage all the paperwork involved. This way, everyone involved in the logistics process, from manufacturers and suppliers to customers and auditors, will be able to monitor all aspects of the business in question. What does this bring to the table? Maximum transparency, which leads to improved efficiency in every department.

2. Digitalization

Digitalization is reshaping all industries, one by one. So, it was only a matter of time when the logistics industry was going to go through the transformation. And that time is now, given how the increasing digital literacy and consumer awareness through the use of different online platforms is customizing the buying process for clients.

Digitalization of online shopping has brought about many ideas and demands to consider.

With the coming of digitalization, logistics companies should brace for procurement and supply chain cost reductions. Another keynote here is the growth of company revenue. Put all this together and you get one of the biggest trends in logistics technology. That and the increased safety and efficiency of it all.

3. The emergence of 3PL and 5PL

Third-party logistics (3PL) and fifth-party logistics (5PL) are on the rise and accelerating the global logistics market. Given the contribution of 3PL in the past couple of years, logistics companies were able to cover a wide range of end-to-end transport and logistics, including:

Transporting goods;

Maintaining inventory logs and travel insurance;

Offering a shield against property loss.

4. Last mile deliveries as one of the biggest trends in logistics technology

Here, we have another logistics trends expected to offer promising logistics market’s growth in the upcoming years. With the surge of online ordering, e-commerce businesses are more focused than ever to offer customers the ultimate buyer experience. And that solution lies in the implementation of the Last Mile Delivery process. After the introduction of same-day deliveries, this is simply the next logical step to staying ahead of your competition.

5. Integration of drones and smart glasses

Drones are definitely one of the more current and popular trends in logistics technology.

The introduction of drones and smart glasses is directly related to the previously mentioned aspect of last mile delivery. This is yet another example of how trends in logistics technology are connected and work towards a common goal. VR and AI innovations are giving logistics companies the chance to improve both flexibility and speed of delivery. Additionally, smart glasses are laying the foundation for error-free deliveries, with the application of:

hand-free route searches

face recognition software solutions.

6. Big data logistics and data analytics

As a general rule of any business, the more information you have, the better equipped you are to make the right decision. And with detailed data analytics and big data in logistics, stakeholders are able to do just that. Make an informed business decision based on a plethora of information about a certain product or service. Additionally, companies are able to use this advanced data to further their own business development goals.

7. Logistics Automation and IoT

The introduction of logistics 4.0 has brought about many ideas to the table.

This is where logistics 4.0 comes into the discussion, as one of the key logistics trends that is transforming the global supply market. Combine that with the adoption of the Internet of Things (IoT) and you receive the ideal tool to battle setbacks such as:

transportation delays;

operator errors;

poor monitoring of cargo;

outdated IT failures;

thefts etc.

Digitalization is bringing many advantages, but also a number of concerns when it comes to cyber security and data protection. This is why many logistics companies, following the hacking scandals with Amazon, Walmart etc. are choosing a very cautious and safe approach to all this.

8. Elastic Logistics

This has become somewhat of a buzzword in the world of logistics. Logistics companies and the supply chain industry have been looking for a way to align their capabilities with given timeframes for years now. And the notion of elastic logistics offers just that. This strategy offers companies the chance to enhance customer experience, provide agility and add real-time visibility. Basically, it connects all business processes within different ranges and timeframes, which is why it is among the biggest trends in logistics technology.

9. Chatbots and Collaborative Robots (Cobots)

According to the Logistics Bureau, Chatbots that will help online buyers during the shopping, ordering and checkout processes are sure to become a major trend in upcoming years. Similarly, e-commerce giants such as Walmart and Amazon are researching the introduction of CoBots to their warehousing efforts. AI promises the ability of robotics to replace manual labor when it comes to packaging, storing and picking in warehouses and other distribution centers.

Final thought on the subject

As a company oriented towards development and digital progress of businesses, Movers Development understands the importance of new and exciting trends. You always have to keep the ball rolling, if you hope to stay competitive and interesting to customers. Focus some of your efforts on some of these trends in logistics technology if you haven’t already. It can only benefit your business long-term.

The post What are the biggest trends in logistics technology appeared first on Movers Development.

from What are the biggest trends in logistics technology

0 notes

Photo

New Post has been published on https://fleetconcepts.com/3pl/3pl-logistics-services-companies-defined/

3PL Logistics Services & Companies Defined

[vc_row][vc_column][vc_single_image image=”6544″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Third-party logistics or 3pl’s in logistics and supply chain management is a company’s use of third-party companies to contract out elements of its distribution, warehousing, and fulfillment services.

Third-party logistics companies will typically concentrate on integrated operations of warehousing and transport services that can be scaled and personalized to clients’ requirements, based on market conditions, to satisfy the demands and shipment service requirements for their products. Services frequently extend beyond logistics to include value-added services connected to the production or procurement of products, such as services that integrate parts of the supply chain. A service provider of such integrated services is referenced as a third-party supply chain management company (3PSCM), or as a supply chain management provider (SCMSP). 3PL targets particular functions within supply management, such as warehousing, transport, or raw material arrangement.

The international 3PL market reached $75 billion in 2014, and grew to $157 billion in the United States; need growth for 3PL services in the US (7.4% YoY) surpassed the development of the United States economy in 2014. Since 2014, 80 percent of all Fortune 500 companies and 96 percent of Fortune 100 used some kind of 3PL services.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”6545″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

3rd Party Logistics Service Types

Third-party logistics companies include freight forwarders, carrier companies, and other businesses integrating & offering farmed out logistics and transportation services. Hertz and Alfredsson explain four categories of 3PL providers:

Standard 3PL Service Provider: this is one of the most basic types of 3PL supplier. They would carry out activities such as choice and pack warehousing, and distribution (business) the most standard functions of logistics. For many of these firms, the 3PL function is not their main activity.

Service Designer: this kind of 3PL provider will generally provide its customers with advanced value-added services such as tracking and tracing, cross-docking, specific product packaging, or offering a special security system. A strong IT structure and a concentrate on economies of scale and scope will allow this kind of 3PL service provider to carry out these kinds of tasks.

The Consumer Adapter: this kind of 3PL provider is available at the demand of the consumer and essentially takes over complete control of the business’s logistics activities. The 3PL service provider enhances logistics significantly however does not develop a new service. The customer base for this particular type of 3PL service provider is typically quite little.

The Client Developer: this is the highest level that a 3PL provider can achieve with respect to its procedures and activities. This happens when the 3PL company integrates itself with the client and takes over their entire logistics function. These companies will have a couple of clients but will carry out comprehensive and comprehensive tasks for them.

Outsourcing might involve a subset of an operation’s logistics, leaving some items or operating actions untouched due to the fact that the internal logistics has the ability to do the work much better or less expensive than an external provider. Another crucial point is the customer orientation of the 3PL provider. The service provider needs to fit the structures and requirements of the company. This fit is more important than the pure expense savings, as a study of 3PL providers shows clearly: The client orientation in form of adaptability to changing client requirements, dependability and the versatility of third-party logistics companies were pointed out as far more crucial than pure cost savings.

Lead Logistics Providers

3PL suppliers without their own assets are called lead logistics service providers. Lead logistics providers have the distinct advantage that they have specialized market expertise integrated with low overhead expenses, but lower negotiating power and fewer resources than a third-party supplier has actually based on normally big business size, a good client base and established network systems. 3PL providers might sacrifice performance by preferring their own assets in order to optimize their own efficiency. Lead logistics suppliers might also be less governmental with much shorter decision-making cycles due to the smaller size of the business.

Party Logistics Layers

First party logistics companies (1PL) are single companies in a specific geographical location that concentrate on specific items or shipping methods. Examples are bring companies, port operators, depot business. The logistics department of a producing firm can likewise be a first-party logistics provider if they have their own transportation possessions and storage facilities.

Second-party logistics providers (2PL) are a company that provides their specialized logistics services in a bigger (national) geographical area than the 1PL do. Typically there are frame agreements between the 2PL and the customer, which regulate the conditions for the transport duties that are primarily put short-term. 2PLs provide own and external logistics resources like trucks, forklifts, storage facilities, etc. for transport, handling of freight or warehouse management activities. Second-party logistics came about in the course of the globalization and the uprising pattern of lean management when the companies started to outsource their logistics activities to concentrate on their own core business. Examples are courier, reveal and parcel services; ocean providers, freight forwarders, and transshipment providers.

The most significant distinction between a 2nd party logistics service provider and a third-party logistics supplier is the truth that a 3PL provider is always integrated into the customer’s system. The 2PL is not integrated; in contrast to the 3PL, it is only an outsourced logistics company with no system combination. A 2PL works typically on call (e.g. reveal parcel services) whereas a 3PL is almost every time notified about the work of the near future. As technology advances, the methodology for notifying a 3PL of incoming workload normally falls on API integrations that link, for instance, an E-commerce store with a fulfillment center. Another point that varies 2 and 3PL is the requirements and customizing of services. A 2PL usually only provides standardized services, whereas 3PLs typically provide services that are tailored and specialized to the needs of their consumers. This is made possible due to long term contracts that are usual in the third-party logistics market. The cost-effectiveness of a third-party logistics service provider is just given over long periods of time with stable agreements and profits. In contrast to that 2nd party logistics services can’t be tailored, concerning to the varying market with difficult competition and a rate fight on a low level. And there we have another distinguishing point between 2PL and 3PL: Toughness of contracts. 3PL contracts are long term contracts, whereas 2PL agreements are of low toughness so that the consumer is versatile in responding to market and price changes.

With companies running globally, the requirement to increase supply chain exposure and lower-danger, enhance speed and reduce costs all at the same time requires a typical technological solution. Non-asset based service providers carry out functions such as assessment on packaging and transport, freight pricing estimate, financial settlement, auditing, tracking, client service, and concern resolution. However, they do not employ any truck drivers or storage facility workers, and they don’t own any physical freight distribution possessions of their own no trucks, no storage trailers, no pallets, and no warehousing. A non-assets based provider consists of a team of domain professionals with built-up freight market knowledge and infotech assets. They fill a function similar to freight representatives or brokers however keep a considerably higher degree of “hands-on” participation in the transport of products. These suppliers are 4PL and 5PL services.

A fourth party logistics supplier has no owned transport possessions or storage facility capability. They have an allocative and integration function within a supply chain with the goal of increasing the performance of it. The idea of a fourth-party logistics service provider was born in the seventies by seeking advice from company Accenture. Firms are outsourcing their selection of third-party logistics service providers and the optimization procedure of the integration of these to a PL as an intermediary. That minimizes costs and the 4PL has to have an overview of the entire logistics market to choose the ideal 3PL for all operative logistic activities. For being able to supply such an ideal solution fourth-party logistics providers need an excellent understanding of the logistics branch and great IT facilities. A 4th party logistics service provider chooses the 3PL companies from the market which are most suitable for the logistical issues of their client. Unlike the allocative function of a 4PL in the supply chain, the core proficiency of a 3PL service provider is the operative logistics.

5th party logistics service providers (5PL) provide supply chain management and deal system-oriented consulting and supply chain management services to their customers. With key developments in technology and the associated boosts in supply chain presence and inter-company interactions have actually triggered a relatively brand-new design for third-party logistics operations the “non-asset based logistics provider.”[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”6543″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

3PL On-Demand Transport

On-demand transportation is a relatively brand-new term coined by 3PL suppliers to explain their brokerage, ad-hoc, and “leaflet” service offerings. On-demand transport has ended up being a compulsory capability for today’s successful 3PL companies in providing client-specific options to supply chain needs.

These shipments do not normally move under the “least expensive rate wins” circumstance and can be really rewarding to the 3PL that wins the business. The cost priced quote to consumers for on-demand services are based on particular circumstances and schedule and can differ greatly from typical “published” rates.

On-demand transportation is a niche that continues to grow and progress within the 3PL market.

Specific modes of transportation that may be subject to the on-demand model consist of (however are not restricted to) the following:

FTL, or Full Truck Load

LTL, or Less-than Truckload

Hotshot (direct, exclusive courier)

Next Flight Out, often also referred to as Best Flight Out (airline shipping)

Expedited services: (direct, special carrier) Immediate delivery or “just-in-time” (JIT)

International Expedited

New brokers tend to utilize what has become referred to as “smile and dial” brokering that essentially work as telemarketing call centers. Brokers have no responsibility to effectively ship all loads (rather than contract logistics providers) and almost all sales representatives are heavily (and 100%) commissioned, and much of the employees’ day is spent cold-calling sales leads. Smile-and-dial brokerages usually require a 15% gross profit margin (the difference in between what the carrier pays the brokerage and what the brokerage pays the carrier), and the commission payment scheme means that the turnover of workers in the call focuses methods 100% per year.

For the periodic carrier, smile-and-dial brokerages can supply a practical way to have actually products delivered. However the absence of deep know-how due to constant turnover, integrated with the 15% pricing margins, indicate that a fairly capable traffic specialist can get transportation services much more financially and dependably, while a carrier requiring shipment as soon as possible, from air freight, air charter, ground sped up, flatbed services, refrigerated, LTL or complete truckload, liftgate, van or lorry. With JIT delivery the rate will be secondary to on-demand as soon as possible delivery.

3PL Horizontal Alliances

Raue & Wieland have explained the example of horizontal alliances between logistics companies, i.e., the cooperation between two or more logistics companies that are potentially competing. Logistics companies can easily benefit twofold from such an alliance. In one way, they can gain access to tangible resources that are directly exploitable. This includes extending common transportation networks, their storage facility infrastructure and the capability to supply more complicated service packages by integrating resources. In another way, LSPs can access intangible resources, which are not directly exploitable. This includes know-how and info and, in turn, innovation.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”6542″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

3PL Logistics Advantages

Expense and Time Cost Savings

Logistics is the core competence of third-party logistics service providers. Companies may have a greater understanding and better knowledge than the producing or selling business, and might likewise have more international networks enabling greater time and expense effectiveness.

The devices and the IT systems of 3PL companies are constantly updated and adjusted to match the requirements of their customers and their consumer’s suppliers. Making or offering companies often do not have the time, resources, or proficiency to adjust their devices and systems as rapidly.

Low Capital Dedication

If a lot of or all personnel functions are outsourced to a 3PL company, there is usually no need for the client to own its own warehouse or transport centers, decreasing the amount of capital required for the client’s service. This is particularly helpful if a company’s warehouse has high variations in capability usage, leading to over-purchasing of warehouse capacity and minimizing profitability.

3PL Focus

Logistics outsourcing allows companies with restricted logistics proficiency to concentrate on their core business. Increasing complexity in business suggests that businesses gain from not committing resources to areas in which they are not experienced.

3PL Versatility

Third-party logistics providers can supply greater versatility for geographical circulation and might use a bigger variety of services than clients might attend to themselves. Postal services and private carriers generally consider the range when they determine the expense of shipping; numerous 3PL service providers market the benefit of what is referred to as zone skipping to possible clients, due to the fact that it shortens the distance between products to be shipped and customers, resulting in lower shipping expenses. This also permits businesses to more predictably manage their resources including labor force size, and turn fixed costs into variable expenses.

3PL Logistics Drawbacks

Loss of Control

One drawback is the loss of control a client has by utilizing third-party logistics. With outgoing logistics, the 3PL provider usually assumes interaction and interactions with a company’s customer or provider. To reduce this, some 3PL’s attempt to brand themselves as their customers, such as using customers’ logos on their assets and dressing their workers like their clients’ workers.

IT

The IT systems of the service provider and the client need to be interoperable. Technology assists increase presence for the customer by way of constant status updates by means of Dispatch Management Software and Electronic Data Interchange (EDI) which does involve an expense, but it can help prevent charges for delays and subsequent monetary losses such as from not dumping freight in time.

Reverse Logistics

Various studies have actually shown that selling products online, rather than in a brick and retail environment, adds extra costs when it pertains to dealing with returns (i.e. reverse logistics). The reliance upon third-party logistics suppliers to manage aspects of the E-commerce supply chain such as warehousing and pick-and-pack also indicates these businesses need to be counted on to manage reverse logistics. Artificially induced need events such as Black Friday in the United States or Songs’ Day in China included an influx of returned products, which can slow down warehouse operations and in turn delay the releasing of refunds or other methods for alleviating dissatisfied customers. The extra layer of a 3rd party to deal with delicate customer-facing concerns such as returns is hence a heavily-debated subject within the realm of E-commerce.[/vc_column_text][/vc_column][/vc_row]

0 notes

Text

WHY THE 5113 PRINT HEAD SELLS SO WELL ON THE MARKET?

Do you know why Epson 5113 print head are so popular? Today, I will tell you the answer.

Epson 5113 print head are popular nowadays because of it’s high speed and high resolution. Compared with DX5 and DX7 print head, we will find there are many advantages of 5113 print head.

1. The number of nozzles

DX5 and DX7 print heads: 8 lines*180 nozzles=1440

nozzles,the smallest nozzle is 3.5PL/5PL.

5113 print heads: 4 lines*800 nozzles=32 00 nozzles, the smallest nozzles is 1.5PL.

2. The size of the print head

The size of 5113 print head is 1.3 inch, 30% width than the DX5 and DX7 print heads.

3. High speed

Because the amount of nozzles are much more than the DX5 and DX7 print head, so the 5113 print head can print with 3 pass and the speed can up to 30 m2/h.

4. The price

The price of 5113 printhead is much cheaper than DX5 and DX7 print heads.

0 notes