#Aluminium Scrap Importer Data

Explore tagged Tumblr posts

Text

Explore the latest insights on aluminium scrap import data for 2024. Discover key import data, top aluminium scrap importers, HSN codes, and market trends. Stay informed on the evolving aluminium recycling industry and how it impacts global trade.

#Aluminium Scrap Import Data#Aluminium Scrap Importer Data#aluminium scrap hsn code#top aluminium scrap importers#top 10 aluminium scrap importing countries#Aluminium scrap importers

0 notes

Text

The Global Dynamics of Aluminium Scrap Imports: Insights, Trends, and Key Players

Aluminium scrap plays a crucial role in the production and recycling industries, providing significant environmental benefits by reducing the need for new raw materials and lowering carbon emissions. This article delves into the global dynamics of aluminium scrap imports, highlighting key trends, major players, and the economic and environmental impacts of this vital resource.

Aluminium Scrap Import Trends in India

In 2024, India imported 135,816 metric tonnes of aluminium scrap in April, showing a slight increase from the previous month’s 128,861 metric tonnes but a decrease from the 141,894 metric tonnes imported in April 2023. This trend underscores India’s position as a major player in the global aluminium scrap market.

In 2023, India was the world’s top importer of aluminium scrap, with 506,864 shipments. Over 3,453 Indian importers sourced aluminium scrap from 14,928 suppliers worldwide, reflecting a robust and growing market.

Global Aluminium Scrap Market

Several countries dominate the global aluminium scrap market. China, India, and the United States are among the top importers, with India surpassing other major economies in recent years. China, the second-largest importer, brought in $2,030.01 billion worth of aluminium scrap in 2021.

Economic and Environmental Impact

Recycling aluminium scrap is environmentally beneficial, significantly reducing CO2 emissions and conserving energy. For instance, recycling aluminium scrap produces only 0.3 million metric tonnes of CO2 per tonne, compared to 14 tonnes of CO2 per tonne produced through traditional methods. Economically, the demand for aluminium scrap is driven by strong market dynamics and price trends, with the Asia Pacific region being the largest producer and consumer.

Challenges and Opportunities

The aluminium scrap market faces several challenges, including import duties and regional conflicts that disrupt supply chains. However, there are opportunities for growth, such as policy changes proposed by industry associations like MRAI, which advocate for the removal of import duties to support sustainability.

Aluminium Scrap HSN Codes

Understanding the correct HSN codes is essential for importers. For aluminium scrap, the primary HSN codes are:

7602: Aluminium waste and scrap

760200: Detailed categories of aluminium waste and scrap

Industry Insights and Future Outlook

The global aluminium market is projected to grow, with an expected value of USD 255.91 billion by 2029. Industry experts suggest that advancements in recycling technology and supportive policies will drive this growth, especially in regions like Asia Pacific, North America, and Europe.

Resources for Importers

Importers can access real-time aluminium scrap import data through platforms like Eximpedia, which provide comprehensive databases and market reports. New importers are encouraged to utilize these resources to stay informed and competitive.

Conclusion

Aluminium scrap imports are vital to the global aluminium industry, contributing to economic growth and environmental sustainability. By staying informed about market trends, policy changes, and technological advancements, traders can navigate the challenges and seize opportunities in this dynamic market. For further information, platforms like Eximpedia offer valuable insights and data to help importers succeed.

#globaltradedata#eximpedia#Aluminium scrap imports#Aluminium Scrap Importer Data#aluminium scrap hsn code#op aluminium scrap importers

0 notes

Text

Get rich insight into aluminum scrap import data with this informative article from Seair Exim Solutions. Explore comprehensive details, market trends, and key data to empower your understanding of the aluminum scrap import landscape. Stay ahead of the industry by exploring everything you need to know to make an informed decision.

#Aluminium Scrap Import Data#Aluminium Scrap Importer Data#aluminum scrap exporters data#aluminum scrap importers

0 notes

Text

https://www.thetradevision.com/global/aluminium-scrap-import-export-data

Aluminium scrap refers to discarded aluminium materials, such as cans, wires, and industrial waste, which are collected for recycling. Recycling aluminium scrap is environmentally friendly, as it reduces energy consumption and greenhouse gas emissions compared to primary aluminium production. It's a valuable resource in the global recycling industry. Download aluminium scrap export import data here.

#Aluminium Scrap Export Import Data#Aluminium Scrap Buyers Suppliers Details#Aluminium Scrap Importers Exporters Details#Aluminium Scrap Custom Data#Aluminium Scrap Shipment Data

0 notes

Text

Latest Trends in Ferro Titanium Alloys and Lumps as Seen by Global Ferro Alloy Suppliers!

The steel and metallurgical industries continue to evolve at a rapid pace, and the materials that support them must keep up. Among these critical inputs, Ferro Titanium Alloys have emerged as essential additives in the production of high-quality steel. With rising global standards, new environmental regulations, and advanced production technologies, these alloys are seeing increased demand — especially in specialized steelmaking segments.

This article explores the latest trends in the use and production of ferro titanium materials, based on industry strategies and global market developments.

Customized Alloy Compositions for Precision Applications

Today’s steelmakers demand more than just bulk materials — they require precision and consistency. Ferro titanium alloys are being customized to match specific industrial applications, especially in high-performance sectors like automotive, shipbuilding, defense, and aerospace.

Customization trends include:

Specific titanium content (ranging from 10% to 30%) depending on the desired steel characteristics.

Low residual impurities, especially aluminium, silicon, and phosphorus.

Tight control of particle size for uniform distribution during the steelmaking process.

This shift toward tailored compositions has pushed producers to invest in advanced refining and blending facilities, improving both product consistency and customer satisfaction.

Rising Demand for Clean and High-Purity Inputs

In modern foundries and electric arc furnaces, the demand for Ferro Titanium Lumps with consistent quality and minimal contamination is growing steadily. These lumps are often preferred in processes like vacuum induction melting (VIM), where impurities must be minimized to maintain steel integrity.

High-purity lumps are now being characterized by:

Titanium content typically around 70–75%

Minimal carbon, sulphur, and oxygen

Carefully controlled size fractions (10–50 mm or as per client need)

Producers are adopting pre-screening, mechanical sizing, and vacuum packing techniques to ensure these quality standards are met. This level of refinement not only supports better metallurgical performance but also reduces waste and enhances energy efficiency.

Sustainability and Recycling of Raw Materials

Environmental responsibility has become a key driver across the metallurgical value chain. To meet rising sustainability expectations, many Ferro Alloy Suppliers are shifting toward greener production methods, including the use of recycled titanium scrap.

The use of secondary titanium sources provides:

Lower production costs

Reduced carbon emissions

Support for circular economy initiatives

Moreover, buyers are increasingly requesting documentation on carbon footprints, environmental certifications, and origin tracking — further pushing suppliers to build eco-friendly systems into their operations.

Digital Transformation Across the Supply Chain

As global competition increases, efficiency and transparency are more important than ever. Suppliers are turning to digital tools to streamline operations, enhance communication, and deliver better customer service.

Key digital trends include:

Live shipment tracking for better planning

Digital mill test certificates accessible through cloud portals

AI-based demand forecasting to manage inventory and raw material sourcing

Integrated ERP systems to coordinate production, sales, and logistics

This digital shift not only shortens lead times but also builds trust with buyers who value data-driven decision-making and real-time visibility.

Global Expansion and New Market Opportunities

In recent years, emerging economies in Asia, the Middle East, and Eastern Europe have become major consumers of titanium-based ferroalloys. Countries like India, Vietnam, and the UAE are ramping up steel production and infrastructure investments, leading to greater demand for high-performance alloys.

To serve these growing markets efficiently, suppliers are:

Establishing regional warehouses and processing hubs

Partnering with local distributors

Adapting products to region-specific requirements, such as packaging standards, delivery terms, and regulatory compliance

By providing localized service, this expansion approach not only expedites delivery times but also enhances the relationship between the provider and the client.

Standardization and Certifications

To support global competitiveness and client trust, standardization is becoming a must. Producers of ferro titanium materials are increasingly aligning their operations with international norms such as:

ISO 9001 (quality management)

REACH and RoHS (compliance for EU markets)

EN and ASTM specifications for alloy grading and composition

This focus on certified production helps ensure reliability, improves export capabilities, and opens doors to collaboration with multinational steelmakers.

Conclusion

The market for titanium-based additives in steel production is experiencing significant transformation, fueled by innovation, sustainability goals, and the need for precision. Suppliers today are stepping beyond traditional roles, becoming strategic partners that offer customized solutions to meet the evolving demands of modern steelmakers.

As the world moves toward cleaner, more efficient, and more reliable steel production, keeping pace with these trends is essential. Whether you're a manufacturer, foundry engineer, or procurement specialist, understanding the evolving ferro titanium landscape can give you a competitive edge in sourcing, performance, and cost-efficiency.

#FerroTitaniumAlloys, #FerroTitaniumLumps, #FerroAlloySuppliers,

0 notes

Text

Aluminium Alloy Ingot Prices Trend | Pricing | News | Database | Chart

Aluminium Alloy Ingot prices are a critical focus for industries relying on the metal's unique properties, including automotive, construction, and packaging. These prices are influenced by a complex set of factors that vary across global markets and impact the entire supply chain. The cost of aluminium alloy ingots often reflects changes in primary aluminium prices, which are heavily affected by fluctuations in raw material costs, energy prices, and global economic trends. Aluminium is energy-intensive to produce, and since energy costs can comprise a large portion of its production cost, any rise or fall in electricity prices has a direct impact on the overall ingot pricing. Additionally, fluctuations in the availability and price of bauxite and alumina, essential inputs in aluminium production, further shape the market.

The demand for aluminium alloy ingots is a significant driver of their prices. This demand varies by region and end-use sector. In recent years, increased demand from the automotive industry, driven by the transition to electric vehicles and the need for lightweighting solutions, has been a strong influence on prices. Aluminium alloy is preferred for its excellent strength-to-weight ratio, making it critical in developing fuel-efficient and electric vehicles. Similarly, the construction industry continues to be a substantial consumer due to its needs for durable, lightweight, and corrosion-resistant materials. When demand from these sectors increases, it puts upward pressure on prices, especially if production capacity does not match the growth in consumption.

Get Real Time Prices for Aluminium Alloy Ingot: https://www.chemanalyst.com/Pricing-data/aluminium-alloy-ingot-1358

Environmental regulations and sustainability initiatives are increasingly shaping the aluminium alloy ingot market. The drive to reduce carbon emissions and embrace greener production processes has pushed producers to invest in low-carbon and recycled aluminium options. These innovations come with added costs that can impact pricing, but they also create new value propositions for buyers prioritizing environmental sustainability. Governments around the world are implementing stricter environmental standards, prompting industries to find cleaner ways of producing and processing aluminium. This adds complexity to the market, as producers face a balancing act between meeting regulatory requirements, managing production costs, and offering competitive pricing.

Recycling is another important dimension influencing aluminium alloy ingot prices. Secondary aluminium production through recycling requires only a fraction of the energy compared to primary production, making it a more cost-effective and environmentally friendly option. This has helped stabilize ingot prices to some extent, as the supply of recycled material can offset some of the volatility associated with primary production. However, availability and quality of scrap materials can also impact costs and create variances in ingot prices. Markets with well-developed recycling systems tend to benefit from more stable pricing, while regions facing scrap shortages may experience cost increases.

Supply chain issues, logistical challenges, and regional production costs also play a crucial role in determining the price of aluminium alloy ingots. Transportation and distribution costs, particularly for countries with long supply chains, contribute to regional differences in pricing. In some regions, logistical bottlenecks or high transportation expenses can create disparities between domestic and international markets. Additionally, labour costs, taxation policies, and investment in production infrastructure vary widely and impact the cost structure of aluminium production and distribution.

The overall health of the global economy and consumer demand trends also have a notable impact on aluminium alloy ingot prices. In times of economic downturn, the demand for consumer goods, vehicles, and construction materials can drop, leading to a surplus of aluminium alloy ingots and putting downward pressure on prices. Conversely, economic recovery and growth spurts can cause a surge in demand, tightening supply and increasing costs. Tracking global economic indicators, including GDP growth rates, industrial production levels, and consumer confidence indices, provides valuable insights into price trends and market expectations for aluminium alloys.

Innovation in production techniques, technological advancements, and shifts in consumer preferences further influence the pricing landscape for aluminium alloy ingots. As new methods of reducing production costs or enhancing material properties emerge, producers who adopt these innovations may gain a competitive edge, potentially affecting market pricing. Advanced alloys tailored to specific applications can command premium prices, while market demand for standard grades may experience more stability. Finally, competition among producers both within and across borders plays a role in pricing, as manufacturers strive to meet evolving market demands efficiently and at competitive price points.

Overall, aluminium alloy ingot prices are shaped by a delicate interplay of supply, demand, economic policies, and global market dynamics. The industry’s response to regulatory changes, technological advances, and shifts in consumer expectations will continue to determine the trajectory of prices in the coming years. For stakeholders, understanding these factors and their interdependencies is key to navigating a market that is dynamic and increasingly influenced by environmental and geopolitical considerations.

Our Related News for Aluminium Alloy Ingot: https://www.chemanalyst.com/NewsAndDeals/NewsDetails/aluminium-alloy-ingot-prices-rise-in-asia-as-japan-and-indonesia-show-strong-demand-30965

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Alloy Ingot#Aluminium Alloy Ingot Price#Aluminium Alloy Ingot Price Monitor#Aluminium Alloy Ingot Pricing

0 notes

Text

Prognostic Solutions in Steel Plant and Tube Mill Industry

The global steel market reached a value of US$ 874.6 Billion in 2021. Looking forward, IMARC Group expects the market to reach a value of US$ 1,052.25 Billion by 2027, exhibiting a growth rate (CAGR) of 3.02% during 2022-2027. Significant growth in the automotive industry across the globe and Increasing oil & gas production owing to the transportation industry’s demand is creating a positive outlook for the market. But with growth comes a lot of challenges in the steel manufacturing process. Companies in the industry face major challenges with rapid digitalisation and unlocking potential in data, shifts in consumer demands, and the attraction of top talents.

To address these challenges and improve profitability, the largest integrated producer of engineering steels and specialized seamless tubes in the Asia Pacific region has the foresight to expand its market in the coming years. In recent years, the leadership team has placed a greater emphasis on better asset utilization and process optimization.

Steel Plant & Tube Mill Challenges:

Failure of AssetsComplex procedures and important resources are used to produce steel tubes. Production and product quality are both impacted by the unforeseen failure of assets. It is not practical to inspect equipment frequently due to the harsh steel mill environment and the risks that inspection of rotating equipment poses to operator safety.

Mills in poor condition A poorly maintained mill costs valuable time and scrap during setup and operation. The mill must be dependable so that the operator is not chasing mechanical problems during normal operation and setup. A good maintenance program, as well as rebuilds or upgrades when necessary, is essential.

Tube mill misalignment, poor mill condition, and inaccurate setup account for 95% of all problems in tube production. Most mills should be aligned at least once a year.

Low investment in technologyOne of the major problems which these industries face is the lack of incorporation of advanced technologies in Research and Development work in production. The same is the case for other sectors of the industry and has been the case for decades. One of the outcomes has been the relative unattractiveness of the sector vis-a-vis others among young engineers. With little research being done by the government or the private sector, Industries lack effective implementation of Industry 4.0 and technologies that can reduce risks and helps to cut overall production cost.

Process monitoringSteel mills’ inspection and monitoring process usually follow specific procedures, requiring that workers operate in a typical analog way. Since it is a critical environment, stopping production to execute corrective actions is unfeasible, and the current method for monitoring these problems is not able to predict failures in the same way as intelligent predictive models do, thus demonstrating an inevitable gap to errors.

Lack of Talent and TrainingEven though the operators are skilled and trained to operate in tube mills, there are still some challenges and issues that they need to face every day. Tube mill owners should arrange training sessions on how to troubleshoot the problem and figure out what was causing the problem. If these problems are not addressed properly, aluminium fabrication, steel fabrication, or stainless-steel fabrication processes won’t have precise tubes and pipes to work with.

MaintenanceBesides the difficulty in performing the inspection itself because of the hostile environment of steel industries, the maintenance of the encountered problems is also difficult.

The corrosion of equipment and structures is also a common problem in these industries and the maintenance of these components is very complicated because of the hostile environment, as mentioned before. Besides, the diversity of complex processes in this industry also makes it difficult to understand the extracted data in the operation, and the improper management of this information in diffuse systems compromises the maintenance of the structures.

Because of this lack of precise management tools, failure prediction in the operation is not usually achievable, leading to unplanned shutdowns and the extensive use of corrective maintenance methods.

Our Solution:

With the advent of Industry 4.0, predictive maintenance has gained huge popularity in maintaining machine health. Predictive maintenance is aimed at reducing costly and unplanned downtimes and offers organizations to plan maintenance schedules in advance for increased efficiency. According to McKinsey, predictive maintenance typically reduces machine downtime by 30% to 50% and increases machine life by 20% to 40%.

CIMCON Digital’s VIBit is an intelligent, powerful, and compact sensor that monitors the conditions of machines or equipment and predicts their failures in advance using the latest AI/ML Technologies to avoid unplanned downtime saving time and money for the owners.

We set up VIBit, a platform for detecting and diagnosing machine anomalies so that we could track the real-time performance of crucial machinery and processes throughout the year. VIBit Tri-axial vibration, Temp, and audio sensors installed on rotary equipment transmit machine health data over Plant’s Wi-Fi. AI/ML algorithms on the edge platform provide early machine anomaly detection along with diagnostics and recommendations for corrective and preventive action.

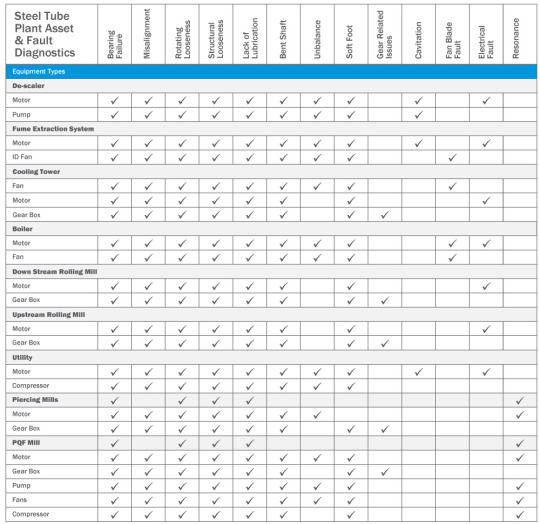

It can be used in Steel Tube Plant Asset and Fault Diagnostics to identify faults like bearing failure, misalignment, and electrical faults in types of equipment like De-scalar: motor/pump, Fume extraction system: motor/pump, etc.

Benefits of setting up a VIBit:

Real-time monitoring of critical equipment’s health on a single dashboard.

Prioritize and plan maintenance action before catastrophic failure.

Reduce the risk of operator safety with remote monitoring.

Reduce planned downtime and eliminate unplanned downtime.

Reduce process and quality-related issues.

Increase equipment efficiency and reduce carbon emissions.

In conclusion, the steel and metal industries are undergoing significant changes and it is important for manufacturers to adopt technologies that can assist in reducing manual labour, leveraging data, and improving asset health. By embracing the latest technological advances, steel and metal manufacturers can use predictive analytics to anticipate failures and proactively take action to reduce unplanned downtime and improve plant efficiency.

0 notes

Link

ALUMINIUM SCRAP EXPORT DATA is present on the best prices at the web portal of SEAIR Exim Solutions. It can help to view shipping details of ALUMINIUM SCRAP including HS code, description, net weight, price, destination port, importer & exporter details etc. This data report assists to plan better and smart business strategies. For more details, click on the given below web page

1 note

·

View note

Text

Metal Waste and Recycling Market Growing Popularity and Emerging Trends in the Industry

Latest business intelligence report released on Global Metal Waste and Recycling Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Metal Waste and Recycling market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are :

ArcelorMittal (Luxembourg)

Nucor Corporation (United States

Commercial Metals Company (United States)

Sims Metal Management Limited (United States)

Aurubis AG (Germany)

Remondis SE & Co. KG (France)

American Iron & Metal (Canada)

Gerdau (Brazil)

Tata Steel (India)

Dowa Holdings Co. Ltd (Japan)

European Metal Recycling Limited (United States)

OmniSource Corporation (United States)Metal Waste and Recycling Metal waste and recycling specializes in the recycling of ferrous and non-ferrous metals without altering its properties. The surge in prices of raw materials is one of the most crucial factors driving the scrap metal recycling growth. The most common recyclable metals are aluminium and steel, and the other metals are silver, copper, brass and gold are so valuable that they are rarely thrown away to be collected for recycling. Metal recycling is gaining significant importance attributed to the rising problem pertaining to disposal of metal wastes across the globe. Key Market Trends: Changing Regulatory Landscape with Regards to Metal Scrap Recycling Opportunities: Increasing Scarcity of Rare Earth Metals

Rising Demand for Recovering Metal from Slag Residue Market Growth Drivers: Rising Demand for Metal Recycling in Numerous End Use Industries Including Electronic, Building and Construction and Shipbuilding

The Rapid Growth of Industrialization and Urbanization in Developing Nations and Increasing Consumer Awareness Challenges: High Initial Investment

Lack of Proper Infrastructure Especially in Developing Economies The Global Metal Waste and Recycling Market segments and Market Data Break Down by Type (Ferrous metal (Iron), Non-ferrous metal (Copper, Silver, Brass, Aluminium, Gold)), Application (Building & Construction, Automotive, Equipment Manufacturing, Shipbuilding, Consumer Appliances, Battery, Packaging, Others), Equipment Type (Shredders, Shears, Granulating machines, Briquetting machines)

Presented By

AMA Research & Media LLP

0 notes

Link

Drinking Water System Manufacturers, Hotel Reservations For Chandigarh, Aluminium Door Lock Wholesalers, Strategy Consultants, Hearing Aid Battery Dealers-Resound, Overseas Placement Services For Maid (Candidate), Automobile Lubricant Dealers, Chilled Shower Manufacturers, T Shirt Retailers-Levis, Condom Dealers-Moods, Agricultural Land Consultants, Computer Training Institutes For Educational Software, Non Ferrous Casting Manufacturers, Computer Training Institutes For Gniit, Lighting Fixture Dealers-Philips, Frozen Seafood Retailers, Electronic Calculator Dealers, Laptop Repair & Services-Zenith

0 notes

Text

Metal Recycling Market Analysis, Size, Share, Growth, Trends And Forecast, Leading Players are PSC Metals, AMG Resources Corporation, OmniSource Corporation

Metal Recycling Market overview, production, producers, dimensions, income, price, consumption, growth rate, sales revenue, import, supply, export, future plans and technological advancements in the global Aerogel market. This information of the market assists in providing an appropriate understanding of the development of market growth. Moreover, the report incorporates information such as company profiles, product picture, and specification, capacity, production, price, cost, revenue, and contact information.

Metal recycling market is expected to grow at a rate of 7.5% for the forecast period of 2020 to 2027. Metal recycling market report analyses the growth, due to rapid industrialization in the developing economies leading to increased demand for metal products.

Sample Report Available in PDF Version along Graphs and Figures@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-Metal Recycling-market

Metal recycling market is segmented on the basis of type, scrap type, equipment and end-user. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

On the basis of type, the metal recycling market is segmented into ferrous metal and non-ferrous metal.

On the basis of f scrap type, the metal recycling market is segmented into old scrap and new scrap.

On the basis of equipment, the metal recycling market is segmented into shredders, shears, granulating machines, briquetting machines.

On the basis of end-user, the metal recycling market is segmented into construction, automotive, equipment manufacturing, shipbuilding, others.

Relevant features of the study that is being offered with major highlights from the report:

1) Which companies are profiled in current version of the report? Can list of players be customizing based on regional geographies we are targeting.

The major players covered in the metal recycling market report are European Metal Recycling, DOWA HOLDINGS Co., Ltd, Tata Steel, Baosteel Co.,Ltd., REMONDIS SE & Co. KG, Novelis Aluminum, Norton Aluminium Ltd, Kuusakoski, REAL ALLOY, Tom Martin & Co Ltd., TMS International, Ferrous Processing & Trading., PSC Metals, AMG Resources Corporation, Alter Trading Inc, Mervis Industries, OmniSource Corporation, Schnitzer Steel Industries, Inc, AMERICAN IRON & METAL, SUNRISE METAL RECYCLING LTD., Upstate Metal Recycling, Inc., WM. MILLER SCRAP IRON & METAL CO., GFG Alliance, BL Duke, Cozzi Recycling, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately

2) What all regional break-up covered? Is it possible to add specific country or region of interest?

Currently, research report gives special attention and focus on following regions: Asia-Pacific, South America, North America, Europe and & Middle East & Africa

3) Can Market be broken down by different set of application and types?

Additional Metal Recycling Market segmentation / Market breakdown is possible subject to data availability, feasibility and depending upon timeline and toughness of survey. However a detailed requirement needs to be prepared before making any final confirmation.

MAJOR TOC OF THE REPORT

Chapter One: Metal Recycling Market Overview

Chapter Two: Manufacturers Profiles

Chapter Three: Global Metal Recycling Market Competition, by Players

Chapter Four: Global Metal Recycling Market Size by Regions

Chapter Five: North America Metal Recycling Revenue by Countries

Chapter Six: Europe Metal Recycling Revenue by Countries

Chapter Seven: Asia-Pacific Metal Recycling Revenue by Countries

Chapter Eight: South America Metal Recycling Revenue by Countries

Chapter Nine: Middle East and Africa Revenue Metal Recycling by Countries

Chapter Ten: Global Metal Recycling Market Segment by Type

Chapter Eleven: Global Metal Recycling Market Segment by Application

Get Detailed Toc @ https://www.databridgemarketresearch.com/toc/?dbmr=global-Metal Recycling-market

Key Stakeholders Audience Covered:

In order to better analyze value chain/ supply chain of the Industry, a lot of attention given to forward and backward Integration of Metal Recycling Market

- Metal Recycling Manufacturers

- Metal Recycling Distributors/Traders/Wholesalers

- Metal Recycling Sub-component Manufacturers

- Industry Association

- Downstream Vendors

Data Bridge Market also provides customized specific regional and country-level reports, see below break-ups.

North America: United States, and Mexico.

South & Central America: Argentina, LATAM, and Brazil.

Middle East & Africa: Saudi Arabia, UAE, Turkey, Egypt and South Africa.

Europe: UK, France, Italy, Germany, Spain and Russia.

Asia-Pacific: India, China, Japan, South Korea, Indonesia, Thailand, Singapore, and Australia.

Reasons for Buying this Metal Recycling Report

1. Metal Recycling market report aids in understanding the crucial product segments and their perspective.

2. Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Metal Recycling industry.

3. Even the Metal Recycling economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

4. This report provides a more rapid standpoint on various driving facets or controlling Metal Recycling promote advantage.

5. This worldwide Metal Recycling report provides a pinpoint test for shifting dynamics that are competitive.

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-Metal Recycling-market

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like West Europe, North America, MENA Countries, LATAM, Southeast Asia or Asia Pacific.

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Browse Related Reports@

Butyl Acrylate Market

Ceramic Fiber Market

Coated Fabric Market

0 notes

Text

https://www.seair.co.in/blog/aluminium-scrap-import-data.aspx

Unlock success in the aluminium scrap import business with Seair Exim Solutions. Explore comprehensive Aluminium Scrap Import Data, gain valuable insights, and stay ahead in the market. Your guide to informed decisions and prosperous ventures starts here!

#AluminiumScrapImportData#aluminiumscrapexportersdata#aluminiumscrapimporters#top10aluminiumscrapimportingcountries

0 notes

Text

Aluminium Ingot Prices Trend | Pricing | News | Database | Chart

Aluminium Ingot prices are influenced by a range of factors that make the market dynamic and complex. These factors include global economic conditions, supply-demand fluctuations, raw material costs, energy prices, trade policies, and production capacities. In recent years, the price trends of aluminium ingots have been highly sensitive to both macroeconomic shifts and industry-specific events. For example, economic slowdowns in major consuming countries can result in reduced demand for aluminium products, which in turn causes a decline in ingot prices. On the other hand, periods of economic recovery often drive demand for aluminium across various industries, leading to a rise in prices.

The supply of aluminium ingots is heavily dependent on the mining and refining of bauxite ore, as well as the smelting process that converts alumina into pure aluminium metal. Fluctuations in the cost of raw materials, such as bauxite, can impact production costs and, subsequently, the market prices of aluminium ingots. Energy is another key factor because the smelting process is energy-intensive. In regions where electricity prices are high or energy supplies are disrupted, the cost of producing aluminium increases, and this can reflect in higher ingot prices. In addition, changes in environmental regulations have a significant impact on aluminium production costs, as producers must comply with standards that often require investments in cleaner technologies and emissions controls.

Get Real Time Prices for Aluminium Ingot: https://www.chemanalyst.com/Pricing-data/aluminium-ingot-1351

Global trade policies and geopolitical factors also play a crucial role in shaping aluminium ingot prices. For instance, tariffs and trade restrictions imposed by major economies can alter market dynamics by either creating supply shortages or diverting trade flows to different regions. Recent trade tensions have demonstrated how such measures can lead to price volatility. If major producers or consumers of aluminium impose tariffs on imports or exports, it can create uncertainty in the market and influence the prices of aluminium ingots on a global scale.

The demand for aluminium ingots is largely driven by industries such as construction, transportation, automotive, aerospace, packaging, and electrical equipment. Any increase in demand from these sectors tends to push prices upward, while a slowdown can exert downward pressure. For example, the automotive industry has been increasingly using aluminium for lightweighting purposes to enhance fuel efficiency. This trend has created a steady demand for aluminium ingots. Similarly, the construction sector's health can have a direct impact on demand, as aluminium is widely used in building materials, window frames, and structural components.

In recent times, sustainability and recycling have become prominent topics in the aluminium industry. The use of recycled aluminium or secondary aluminium has seen a significant uptick due to environmental considerations and cost advantages. Recycling aluminium requires only a fraction of the energy needed for primary production, making it a cost-effective alternative. As a result, increased recycling rates can mitigate supply constraints and reduce the pressure on ingot prices. However, the quality and availability of scrap metal, as well as changes in consumer behavior, can affect the supply chain for secondary aluminium and, consequently, the market prices.

Price trends for aluminium ingots are often linked to global events that can disrupt supply chains or alter production patterns. For instance, natural disasters, strikes at mining facilities, or logistical disruptions can lead to supply shortages and price hikes. Conversely, new production capacity coming online, especially from major producing regions, can increase supply and lead to lower prices. The aluminium industry has also faced challenges related to excess capacity, particularly in certain regions that produce a large volume of the metal. When supply exceeds demand, prices tend to decline, but industry consolidation efforts and production cuts can sometimes stabilize the market.

The price of aluminium ingots is also affected by market speculation and financial instruments such as futures contracts. Commodity markets allow producers, consumers, and investors to hedge against price risks, but they can also introduce speculative activities that cause short-term price swings. The role of major commodity exchanges, such as the London Metal Exchange (LME), in determining benchmark prices for aluminium further adds a layer of complexity to the market. Movements in LME prices can reflect global supply-demand conditions, investor sentiment, and macroeconomic indicators, influencing the spot prices of aluminium ingots around the world.

Energy transition and decarbonization efforts have added another dimension to the dynamics of aluminium ingot prices. As the global push towards cleaner energy intensifies, producers are increasingly investing in renewable energy sources and low-carbon production technologies. While these efforts are essential for reducing the industry's carbon footprint, they can also lead to higher production costs in the short term, which may be passed on to consumers in the form of higher ingot prices. Moreover, consumer preference for low-carbon aluminium is driving a market premium for ingots produced using sustainable practices, creating a differentiation within the broader market.

In conclusion, the pricing landscape for aluminium ingots is shaped by a multitude of interconnected factors ranging from raw material costs, energy prices, and supply-demand dynamics to broader macroeconomic and geopolitical considerations. The evolution of the market reflects both short-term fluctuations driven by external shocks and long-term structural changes influenced by technological advancements, trade policies, and sustainability goals. Understanding these trends and their implications is essential for stakeholders in the aluminium value chain, from producers and traders to consumers and policymakers.

Our Related News for Aluminium Ingot: https://www.chemanalyst.com/NewsAndDeals/NewsDetails/aluminium-ingot-prices-surge-amid-supply-disruptions-and-rising-production-costs-31116

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Ingot#Aluminium Ingot Prices#Aluminium Ingot Market#Aluminium Ingot Demand#Aluminium Ingot Supply#Aluminium Ingot News

0 notes

Text

Prognostic Solutions in Steel Plant and Tube Mill Industry

The global steel market reached a value of US$ 874.6 Billion in 2021. Looking forward, IMARC Group expects the market to reach a value of US$ 1,052.25 Billion by 2027, exhibiting a growth rate (CAGR) of 3.02% during 2022-2027. Significant growth in the automotive industry across the globe and Increasing oil & gas production owing to the transportation industry’s demand is creating a positive outlook for the market. But with growth comes a lot of challenges in the steel manufacturing process. Companies in the industry face major challenges with rapid digitalisation and unlocking potential in data, shifts in consumer demands, and the attraction of top talents.

To address these challenges and improve profitability, the largest integrated producer of engineering steels and specialized seamless tubes in the Asia Pacific region has the foresight to expand its market in the coming years. In recent years, the leadership team has placed a greater emphasis on better asset utilization and process optimization.

Steel Plant & Tube Mill Challenges:

Failure of Assets Complex procedures and important resources are used to produce steel tubes. Production and product quality are both impacted by the unforeseen failure of assets. It is not practical to inspect equipment frequently due to the harsh steel mill environment and the risks that inspection of rotating equipment poses to operator safety.

Mills in poor condition A poorly maintained mill costs valuable time and scrap during setup and operation. The mill must be dependable so that the operator is not chasing mechanical problems during normal operation and setup. A good maintenance program, as well as rebuilds or upgrades when necessary, is essential.

Tube mill misalignment, poor mill condition, and inaccurate setup account for 95% of all problems in tube production. Most mills should be aligned at least once a year.

Low investment in technology One of the major problems which these industries face is the lack of incorporation of advanced technologies in Research and Development work in production. The same is the case for other sectors of the industry and has been the case for decades. One of the outcomes has been the relative unattractiveness of the sector vis-a-vis others among young engineers. With little research being done by the government or the private sector, Industries lack effective implementation of Industry 4.0 and technologies that can reduce risks and helps to cut overall production cost.

Process monitoring Steel mills’ inspection and monitoring process usually follow specific procedures, requiring that workers operate in a typical analog way. Since it is a critical environment, stopping production to execute corrective actions is unfeasible, and the current method for monitoring these problems is not able to predict failures in the same way as intelligent predictive models do, thus demonstrating an inevitable gap to errors.

Lack of Talent and Training Even though the operators are skilled and trained to operate in tube mills, there are still some challenges and issues that they need to face every day. Tube mill owners should arrange training sessions on how to troubleshoot the problem and figure out what was causing the problem. If these problems are not addressed properly, aluminium fabrication, steel fabrication, or stainless-steel fabrication processes won’t have precise tubes and pipes to work with.

Maintenance Besides the difficulty in performing the inspection itself because of the hostile environment of steel industries, the maintenance of the encountered problems is also difficult.

The corrosion of equipment and structures is also a common problem in these industries and the maintenance of these components is very complicated because of the hostile environment, as mentioned before. Besides, the diversity of complex processes in this industry also makes it difficult to understand the extracted data in the operation, and the improper management of this information in diffuse systems compromises the maintenance of the structures.

Because of this lack of precise management tools, failure prediction in the operation is not usually achievable, leading to unplanned shutdowns and the extensive use of corrective maintenance methods.

Our Solution:

With the advent of Industry 4.0, predictive maintenance has gained huge popularity in maintaining machine health. Predictive maintenance is aimed at reducing costly and unplanned downtimes and offers organizations to plan maintenance schedules in advance for increased efficiency. According to McKinsey, predictive maintenance typically reduces machine downtime by 30% to 50% and increases machine life by 20% to 40%.

CIMCON Digital’s VIBit is an intelligent, powerful, and compact sensor that monitors the conditions of machines or equipment and predicts their failures in advance using the latest AI/ML Technologies to avoid unplanned downtime saving time and money for the owners.

We set up VIBit, a platform for detecting and diagnosing machine anomalies so that we could track the real-time performance of crucial machinery and processes throughout the year. VIBit Tri-axial vibration, Temp, and audio sensors installed on rotary equipment transmit machine health data over Plant’s Wi-Fi. AI/ML algorithms on the edge platform provide early machine anomaly detection along with diagnostics and recommendations for corrective and preventive action.

It can be used in Steel Tube Plant Asset and Fault Diagnostics to identify faults like bearing failure, misalignment, and electrical faults in types of equipment like De-scalar: motor/pump, Fume extraction system: motor/pump, etc.

Benefits of setting up a VIBit:

Real-time monitoring of critical equipment’s health on a single dashboard.

Prioritize and plan maintenance action before catastrophic failure.

Reduce the risk of operator safety with remote monitoring.

Reduce planned downtime and eliminate unplanned downtime.

Reduce process and quality-related issues.

Increase equipment efficiency and reduce carbon emissions.

In conclusion, the steel and metal industries are undergoing significant changes and it is important for manufacturers to adopt technologies that can assist in reducing manual labour, leveraging data, and improving asset health. By embracing the latest technological advances, steel and metal manufacturers can use predictive analytics to anticipate failures and proactively take action to reduce unplanned downtime and improve plant efficiency.

1 note

·

View note

Text

Weld Defects And Practical Advice For Stainless Steel Welding.

Goldschmidt's discovery confirmed specifically helpful for welding with each other the tracks for a tram in the town of Essen in 1899. Steel detecting aids the environment due to the fact that every one of the nails, screws, and also screws you locate before you struck the prize will enter the garbage as opposed to being in the ground. Because of the unawareness of the harm aluminium causes to wellness, this increasing use of aluminium cooking equipment spread. If you think you have actually grasped the plug welding process then go ahead and also rather than adding a lamp and also cord to either end. Both are made from limited, energy-intensive sources, namely, aluminium as well as petroleum, specifically. The table could have pipe or angle iron legs with a sturdy top bonded over the top them. I do not know a lot concerning welding, however I believe my sibling had to invest added time and also take additional safety measures since the sheet metal is rather slim. Of all the manufacturing activities, it is welding that is filled with great deal of dangers and also certain preventive actions are important for safe welding. Aluminium reduces remarkably easy with a respectable table saw, specifically when you utilize a blade created for cutting non-ferrous steels. Lastly, ideally, try out for a union work, as you will certainly always have actually much better negotiated agreements with union works compared to private works. If you crane your neck forwards, or draw your head back, you'll put excessive stress and anxiety and also strain on the neck and also upper back. The cut or bent metal components or equipment made components need to be set up and also this is normally done by welding. Still, I won't refute that Survive isn't taking the Metal Equipment name and dragging it with the mud, I'm just stating that it's not like it would certainly be outside the realm of opportunity for some kind of zombies to be component of an MGS game. In addition to undersea hyperbaric welding and underwater arc welding, a typical way of welding joints on surface areas underwater is to bring the surface area into dry land, develop a pressurized chamber around the joint, and make use of a hyperbaric dry welding process. Steel Gear Strong 4, specifically, handle the innovation of battle as a business, in a globe where nationwide armies have actually paved the way to Exclusive Army Corporations, as well as where soldiers' bodies are infused with nanotechnology to manage their tools or even their activities. Seeking the company that could give you economical as well as quality resilient aluminium doors and bifolds !! It posses tool crushing and flexing toughness and its texture is reasonably coarse, on which usually ribbon figures are discovered. By having the feet level on the ground, flexing the knees as well as sinking into a squat like position, one is deeply rooted to the ground and also firm in their position. On top of that, you will need dimensions from the extremely start of the actual bend and also most large benders have a suitable outside the flexing shoe to hold the pipe but offers no actual bend. When welding the very alloyed austenitic stainless-steels, nickel-base fillers are used. Workloads such as big data systems, backup as well as healing services, and also applications that often go to and from storage are the most effective prospects for bare steel clouds. There are numerous industries that heavily rely on steel construction welding and prototype machining at different stages in the product style as well as development process. The manufacture of steels includes a few of the usual methods consisting of bending of metal, metal developing, laser cutting, welding, ending up and also lots of various other approaches like these. An additional concern the black steel frameworks experienced were bending stretcher rails or bars.http://universelledelabeaute.info ='text-align:center'>

If the metals vary, the filler metal will certainly have to be picked inning accordance with which is least likely to break as well as which is most compatible with the base metal. While excellent treatment as well as time is taken on the hand crafting elements of your custom designs, there are additionally some areas where welding could significantly speed up the procedure, and assist develop a better general product when completed. The welding tests provided could range from a 3/8 inch grove weld as much as some 1 inch thick grove weld test. Absolutely nothing matches the power of bending the observer's very own coin right before them, so this is the method you will discover-- flexing an actual coin right before your viewers, up close. The steel sheet embossing procedure is commonly achieved with a combination of warmth and stress on the sheet steel depending on what type of embossing is required. See to it that the pressure on the rolls is not as well extreme as that could make the aluminium cable to collision. Although the majority of codes approve the credentials of a Certified Welding Examiner (CWI) for aesthetic evaluation of welds, they DO N'T REQUIRE that the Assessor be a CWI. The streamlined appearance and also smooth working technicians of glass as well as aluminium doors gives your home an appealing look from inside and out, without being lightweight or unconfident. Little arms fire is almost unnecessary as it will jump off the metal of the pedestrian. Wrench: You'll need a wrench for several reasons as you service your tasks. Also there are some sectors which utilize the scrap metal to ensure that we could do away with harmed as well as undesirable product quickly. The first procedure of sheet steel manufacture is frequently to either shear, laser cut, or punch shapes into it. The equipment utilized to perform these actions is a steel shear, a laser, and a turret punch. Essentially, you need two equipments required for welding the electrode and also steel for welding.

That claimed, various welding works may require various techniques, while TIG is normally more powerful and higher in high quality, you must utilize MIG or another method if the task requires it. Many steel roofing suppliers have made Class-4 hail-resistive rankings which is the highest possible hailstorm score a roof product could receive. With MIG welding a minor little bit of dirt or corrosion is OKAY yet anything more is asking for trouble. Welding light weight aluminum is a dangerous job, lots of treatment as well as interest needs to be taken, throughout the warmth treatment. They were amongst the leading lights of the 'New Wave of British Heavy Metal (NWOBHM) after their debut cd 'The Nightcomers' in 1981. Those competent in 6G needs to be able to do welding under the various other placements, such as 1G, 5g as well as 2g. 6G welders in pipe welding tasks, earn the greatest income by far, and one of the most respect from their peers. There are an overwhelming variety of steel subgenres, and also these will certainly vary relying on who you speak to. Understanding the kinds of metal will help you explore your preferences and also expand your perspectives. I assume the the aluminium craze in the kitchen area is over, but the products will certainly reside on for several years. The most effective method is to have a stainless-steel wire brush devoted to just light weight aluminum work to stay clear of contamination from various other metals.

0 notes

Link

By consulting any authentic data sharing firm, one can be able of obtaining ALUMINIUM SCRAP IMPORT DATA . It makes you aware of every shipping detail of surgical products like in which quality these products export, from which country & port, at what price and so on. This updated, latest, and advanced trade intelligence data report is present at SEAIR Exim Solutions. Since 2009, it has been serving the best data solutions to the clients overseas. For additional information, visit Seair.co.in now ALUMINIUM SCRAP IMPORT DATA .

0 notes