#Ampoule Labeling Machine

Explore tagged Tumblr posts

Text

Discover Different Sticker Labeling Machines for Industries

Labeling plays a crucial role in various industries, including pharmaceuticals, food and beverages, cosmetics, and chemicals. Proper labeling ensures compliance with regulations, enhances brand visibility, and improves efficiency in production lines. With the advancement of automation, sticker labeling machines have become an integral part of industrial packaging. These machines streamline the…

#Ampoule Labeling Machine#Automatic Labeling Machines#Double Side Labeling Machine#Food and Beverage Labeling#High-Speed Labeling Machines#Horizontal Sticker Labeling#Industrial Labeling Equipment#Labeling Machine Selection#Labeling Solutions for Industries#Packaging Automation#Pharmaceutical Labeling#Round Bottle Labeling#Semi-Automatic Labeling#Sticker labeling machines

0 notes

Text

Automatic Ampoule Labeler

youtube

Automatic Ampoule Labeler (ampoule labeling machine) including high speed ampoule labeler perform labeling operations on glass ampoules, vials and eye drop bottles. Printer can be installed onto machine for printing batch no., mfg. date & other details onto label. There is option of installing camera-based vision system print and barcode checking in pharmaceuticals. Different type of labels like paper labels, transparent labels, BOPP labels with self-adhesive sticker types can be uses.

We fabricate and supply extensive range of Vertical Ampoule Sticker Labeling Machine. These are manufactured using high quality components and available with optional accessories like printing devices. Further, these can be availed with the A.C. Drives for speed controls, no objects no label systems, objects sensors and label sensors.

AASL-120: Standard model machine labels up to 120 ampoules per minute.

AASL – 300: High Speed Ampoule Labeler labels up to 300 ampoules per minute.

AASL – 600: Super High Speed Ampoule Labeler labels up to 600 ampoules per minute.

#ampoule labeling machine#high speed ampoule labeler#Vertical Ampoule Sticker Labeling Machine#Youtube

0 notes

Text

Lodha Pharma's Sticker Labeling Machine is an innovative solution for accurate and effective labeling applications in a variety of industries, such as food and beverage, cosmetics, and pharmaceuticals. This high-performing machine incorporates modern technology in order to guarantee rapid, accurate, and consistent label placement on a variety of container sizes and shapes. Visit our website at https://www.lodhapharma.com/automatic-horizontal-sticker-labeling-machine.php for more information.

0 notes

Text

For pharmaceutical ampoule labeling, precision and speed are essential. Parth Engineers & Consultant’s Automatic Ampoule Sticker Labeling Machine offers high-speed output of up to 300 ampoules per minute, servo-driven label accuracy, and a compact design for cleanroom environments. With inline batch printing and ±0.5 mm precision, it’s the perfect solution for efficient and GMP-compliant labelling.

visit https://www.parthec.com/product/automatic-ampoule-sticker-labeling-machine

0 notes

Text

What Is Driving the Rapid Growth in the Pharmaceutical Packaging Equipment Market?

The Pharmaceutical Packaging Equipment Market is on an upward trajectory, with its valuation reaching USD 6.80 billion in 2023 and projected to exceed USD 10.91 billion by 2032, registering a CAGR of 5.42% over the forecast period 2024–2032. As pharmaceutical companies push for enhanced efficiency, compliance, and patient safety, the demand for advanced, automated, and sustainable packaging machinery continues to grow. For more details on market trends, growth opportunities, and regional analysis, view the full Pharmaceutical Packaging Equipment Market Size report.

https://www.snsinsider.com/assets/images/report/1731997958-709192537.png

The surge in chronic illnesses, rise in global drug consumption, and the increasing prevalence of biologics are pushing pharmaceutical manufacturers to adopt innovative packaging solutions. Additionally, regulatory frameworks laid down by the FDA, EMA, and WHO are enforcing the implementation of tamper-evident and traceable packaging practices.

With automation becoming a critical factor in reducing human error and improving production lines, companies are investing in cutting-edge technologies such as robotics, vision inspection systems, and AI-driven packaging analytics. This tech-forward approach not only enhances production efficiency but also aligns with sustainability goals by minimizing waste and supporting recyclable packaging formats.

Key Market Trends and Insights:

Automation and Robotics Integration: The incorporation of robotic arms and AI-enabled monitoring systems is transforming packaging lines with real-time analytics and predictive maintenance.

Sustainability in Focus: Environmentally friendly packaging materials and energy-efficient equipment are gaining popularity across major markets.

Biopharmaceutical Boom: The rapid development of biologics and personalized medicine is creating demand for specialized packaging equipment, including cold chain solutions and sterile packaging lines.

Asia-Pacific as a Growth Engine: Countries such as China and India are emerging as major pharmaceutical hubs, prompting local and international investments in packaging infrastructure.

Top Segments Driving Market Growth:

By Product: Blister packaging, strip packaging, filling and sealing machines, labeling machines.

By Type: Primary packaging (vials, ampoules, syringes), secondary packaging (cartoning and case packing).

By Region: North America holds a significant share due to regulatory compliance, while APAC is set to grow at the fastest rate.

Competitive Landscape: The market is moderately consolidated, with key players including IMA Group, Körber AG, Uhlmann Group, Marchesini Group, and Syntegon Technology. Strategic collaborations, R&D investment, and new product launches are central to their competitive positioning.

Future Outlook: Over the next decade, the Pharmaceutical Packaging Equipment Market is expected to undergo major transformations with increased digitalization, green technology adoption, and the emergence of smart packaging systems that interact with mobile apps and IoT.

About Us: SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK) Email: [email protected]

#Pharmaceutical Packaging Equipment Market#Pharma Packaging Trends#Pharmaceutical Machinery Growth#Drug Packaging Technology#Global Pharma Equipment Market

0 notes

Text

Excellence in Machinery for Pharmaceuticals, Cosmetics, Chemicals, & Nutraceuticals

Welcome to Adinath International – your trusted partner in high-performance machinery for Pharmaceuticals, Cosmetics, Chemicals, and Nutraceuticals!

🔧 About Us Since 2005, Adinath has been designing, manufacturing, and supplying world-class filling, processing, packaging, and labeling equipment. We serve a wide industrial spectrum, including injectables, liquid orals, tablets, capsules, ointments, creams, and herbal & nutraceutical products.

🛠️ Product Range We offer a full suite of machinery: ampoule/vial/bottle washing, servo-driven filling (liquids, powders, capsules), tablet presses, granulators, mixers, cappers, labelers, blister packers, and turnkey production lines for pharmaceuticals, cosmetics, chemicals, beverages, dairy, and more.

💡 Tailored Solutions & Support Every machine is engineered for simple operation—even with semi-skilled staff—and custom-built to meet stringent regulatory demands. Our expert team backs you with installation, commissioning, validation, and AMC services.

🔬 R&D & Innovation Continuously investing in R&D, Adinath develops cutting-edge solutions that respond directly to customer feedback and evolving industry standards.

✅ What You’ll Discover in This Video:

• A walkthrough of our state-of-the-art machinery lines • Examples of turnkey production systems in action • Insights into our design philosophy, quality processes, and after-sales support

For more details, visit us at - https://www.adinath.co.in/

#AdinathInternational#PharmaMachinery#CosmeticMachinery#ChemicalProcessingEquipment#NutraceuticalMachinery#FillingMachines#PackagingMachinery#TabletPress#CapsuleFillingMachine#LiquidFillingMachine#GMPCompliant#TurnkeySolutions

0 notes

Text

Sticker Labelling Machine - High-Speed Sticker Labeller Best Price, Manufacturers & Explorer | Brothers Pharmamach

Whether you’re packaging pharmaceuticals, cosmetics, food products, or consumer goods, having the right sticker machine is essential to maintain production speed and ensure accurate branding. One such essential piece of equipment is the Sticker Labelling Machine — and Brothers Pharmamach stands as a trusted name among the top labelling machine manufacturers in India and across global markets.

What is a Sticker Labelling Machine?

A sticker labelling machine is a type of industrial labeling equipment that applies self-adhesive labels to a wide range of containers, bottles, jars, and packages. These labels can contain product names, barcodes, batch numbers, expiry dates, ingredients, and branding elements. The machine ensures consistent application, enhancing the aesthetic appeal and traceability of the product.

Sticker Labelling Machines are available in various configurations based on speed, container shape, label position, and automation level. From semi-automatic models to high-speed sticker machines, they cater to diverse industrial needs.

Why Choose a High-Speed Sticker Labeller?

When you're handling large-scale production, time is money. Investing in a high-speed sticker labeller can drastically reduce labeling time and boost your overall productivity. These machines are engineered to handle thousands of labels per hour with exceptional accuracy and minimal downtime.

Key benefits of high-speed sticker machines:

Increased Throughput: Suitable for large-volume production lines.

Precision & Consistency: Labels are applied without wrinkles or misalignment.

Reduced Labor Costs: Automation minimizes manual intervention.

Integration-Friendly: Can be easily integrated with other packaging line equipment.

Smart Controls: Advanced machines come with touchscreen HMIs and PLCs for easy operation and monitoring.

Applications Across Industries

Brothers Pharmamach's sticker labelling machines are used extensively across multiple sectors, including:

Pharmaceutical Industry: For labeling vials, ampoules, bottles, and cartons with essential information.

Cosmetics and Personal Care: For tubes, bottles, and jars of varying shapes and sizes.

Food & Beverages: For applying labels on jars, cans, bottles, and pouches.

Chemical Industry: For labeling bottles with safety warnings, batch numbers, and product details.

Agro & Fertilizers: For accurately labeling containers with regulatory and branding information.

Features to Look for in a Sticker Labelling Machine

Choosing the right sticker machine depends on your specific operational needs. Here are some features to consider while selecting:

Label Application Type: Depending on whether the label is to be placed on the top, side, wrap-around, or front and back, different machine configurations are available. Brothers Pharmamach offers custom solutions to match your labeling requirement.

Automation Level: While Semi-Automatic Machines are suitable for smaller operations, high-speed fully automatic machines are ideal for mass production lines. They come with automated container feeding, label dispensing, and label placement.

Container Compatibility: From flat containers to round bottles, square jars, and irregularly shaped packages, the machine should be compatible with your product's container shape.

Speed and Output Capacity: Speed varies from model to model. A high-speed sticker labeller can label up to 300 containers per minute, making it a preferred choice for fast-moving production lines.

Label Accuracy and Sensing: Equipped with advanced sensors, these machines ensure perfect label placement. They can detect the presence of a label, container, or missing labels to reduce waste and prevent mislabeling.

Automatic Sticker Labelling Machine: Many high-end models include an Automatic Sticker Labelling Machine that tracks the number of labels applied, helping with inventory control and quality assurance.

Build Quality and Compliance: Machines should be made from high-grade stainless steel and should comply with industry standards such as GMP and CE. This ensures long-lasting performance and regulatory compliance.

Why Choose Brothers Pharmamach?

Brothers Pharmamach is one of the leading labelling machine manufacturers known for its innovative, durable, and high-precision sticker labelling machines. With decades of expertise and a global presence, Brothers Pharmamach has established itself as a pioneer among manufacturing companies in India and beyond.

Salient Features of Brothers Pharmamach Machines:

User-friendly design with touch screen interfaces

Microprocessor-based or PLC-based control systems

High-speed label dispensing for unmatched productivity

Servo motor-driven systems for accurate label positioning

Flexible design for compatibility with various container types

Custom-built solutions tailored to client requirements

Quick changeover and minimal maintenance

Whether you are a startup in the cosmetics industry or a well-established pharma company, Brothers Pharmamach provides cost-effective and robust solutions with best price sticker machine options without compromising on quality.

Our Range of Sticker Labelling Machines

Here’s a quick look at some of the most popular models offered by Brothers Pharmamach:

Automatic Round Bottle Labelling Machine: Ideal for applying wrap-around labels on round containers. Can be integrated with bottle turntables and shrink tunnel systems.

Front and Back Labelling Machine: Used to label the front and back surfaces of flat and oval bottles simultaneously.

High-Speed Ampoule and Vial Labelling Machine: Perfect for the pharmaceutical industry. Offers precision labeling at speeds exceeding 200 containers per minute.

Top-Side Sticker Labelling Machine: For labeling cartons, pouches, and caps from the top. Commonly used in FMCG and food industries.

Automatic Label Counting Machine Integration: Equipped with inbuilt counting functionality to keep track of the number of labels applied.

Industrial Labeling Equipment Built to Last

The industrial nature of the equipment means it must withstand 24/7 operation under harsh factory conditions. At Brothers Pharmamach, machines are engineered with quality components, rugged structures, and modular parts to ensure longevity, safety, and superior performance.

Every component – from rollers to motors to control systems – is carefully selected and tested. These machines are built with high-precision technology to minimize waste, reduce changeover time, and enhance operational efficiency.

Competitive Pricing with High ROI

Finding the best price sticker machine doesn’t mean compromising on features. Brothers Pharmamach ensures its range of sticker machines delivers the best value for your investment. With competitive pricing, minimal maintenance, and unmatched reliability, your return on investment is assured.

Additionally, the machines are designed to grow with your business. As your production line expands, your industrial labeling equipment can be easily upgraded or integrated into a complete automated line.

Custom Solutions for Every Need

Every industry has its own unique labeling requirements. Whether you need tamper-proof labelling, transparent labels, promotional stickers, or multilingual labeling, Brothers Pharmamach provides tailored solutions based on your exact needs.

From machine layout to label type, automation level, and integration with upstream/downstream equipment, we ensure everything fits your production line perfectly.

After-Sales Support and Service

What sets Brothers Pharmamach apart from other labelling machine manufacturers is their commitment to customer satisfaction. Comprehensive support includes:

Installation and commissioning assistance

Operator training

Spare parts availability

Preventive maintenance and service contracts

Remote troubleshooting and technical guidance

This commitment makes us a trusted partner for numerous companies across pharmaceutical, food, chemical, and cosmetic sectors.

Ready to Upgrade Your Labeling Line?

Discover the full potential of automation with Brothers Pharmamach’s industry-leading sticker labelling machines and high-speed sticker labellers. Whether you're starting a new line or upgrading an existing setup, our expert team will guide you to the best solution tailored for your business — at the best price.

Contact Brothers Pharmamach today to explore our complete range of labeling machines and industrial labeling equipment. Get in touch now for a free consultation or quote!

For more info: https://www.brothers.in/

Email ID: [email protected]

Phone: 9825300706

Location: Plot No. 2, phase II, GIDC, Vatva, Ahmedabad 382445. Gujarat india

#sticker machine#sticker Labelling machine#High-Speed Sticker Machine#High-Speed Sticker Labeller#manufacturing companies#automatic label counting machine#Industrial Labeling Equipment#Best Price Sticker Machine#Labelling Machine Manufacturer

0 notes

Text

0 notes

Text

Revolutionizing Production: The Power of High-Speed Labelling Machines

In today's fast-paced manufacturing landscape, efficiency and accuracy are paramount. From pharmaceuticals to food and beverage, cosmetics to chemicals, every industry relies on impeccable product presentation and crucial information dissemination. This is where the high-speed labelling machine emerges as an indispensable asset, a technological marvel that has revolutionized production lines worldwide.

Gone are the days of tedious, error-prone manual labeling. High-speed labelling machines automate the process, applying labels with precision and consistency at rates far beyond human capability. These machines are designed to handle high volumes, often labeling hundreds to thousands of products per minute, ensuring continuous production and minimizing bottlenecks. This accelerated pace directly translates to enhanced productivity and increased throughput, allowing businesses to meet escalating market demands.

Beyond sheer speed, accuracy is a cornerstone of these advanced systems. Equipped with sophisticated sensors and control systems, high-speed labelers ensure millimeter-level precision in label placement, regardless of container shape or size. This is particularly vital in industries like pharmaceuticals, where even slight misalignments can compromise readability of critical information and lead to regulatory non-compliance. Reduced human error, a significant benefit, minimizes waste from mislabeled products and ensures consistent branding across entire product lines.

The versatility of high-speed labelling machines is another key advantage. They can accommodate a wide array of label types – from wrap-around and front-and-back labels to shrink sleeves and tamper-evident seals. Furthermore, they are adaptable to various product sizes, shapes, and materials, making them suitable for diverse industrial applications. This flexibility, combined with quick changeover capabilities between different labeling formats, significantly reduces downtime and maximizes operational efficiency.

The integration of these machines into existing production lines is seamless, often synchronized with other packaging equipment to create a fully automated workflow. This not only optimizes the entire packaging process but also contributes to significant cost savings by reducing reliance on manual labor. While the initial investment might seem substantial, the long-term return on investment (ROI) is evident through increased production efficiency, reduced errors, and minimized material waste.

The Indian market, for instance, has witnessed a growing demand for high-speed labelling machines, with numerous manufacturers offering a range of solutions. Companies like Maharshi Udyog and Worldpack Automation Systems are prominent players, providing advanced systems tailored to various industry needs, from high-speed ampoule and vial labelers for pharmaceuticals to versatile machines for food and beverage packaging.

Looking ahead, advancements in high-speed labeling technology are set to further enhance their capabilities. The integration of IoT, AI-powered systems, QR codes, and RFID technologies is transforming labels into dynamic tools for traceability, consumer engagement, and real-time data monitoring. Digital printing allows for on-demand, variable data printing, enabling personalization and reducing waste. These innovations underscore the evolving role of high-speed labelling machines – no longer just applicators, but integral components of a smart, connected, and efficient manufacturing ecosystem.

In conclusion, high-speed labelling machines are more than just equipment; they are strategic investments that empower businesses to optimize production, ensure quality, achieve regulatory compliance, and ultimately, gain a competitive edge in today's demanding market

0 notes

Text

Ampoule Sticker Labeling Machine

Ampoule Sticker Labeling Machine is a super-advanced servo based labeling machine known for brilliant accuracy and productivity. Equipped with high end system machine is capable of sticker labelling up to 600 ampoules per minute. Ampoule Labeler incorporate latest technology microprocessor based label dispensing system with servo drive for accurate positioning. Being ampoule labeling machine manufacturer we understand need of pharmaceutical industry as per changing regulatory framework and we design equipment according to latest compliance. Label length detection system can optionally incorporate to make equipment world class. With this feature there is no need to feed label length data in memory and remember every time to select it. Such exceptional features save time and achieve higher output.

Ampoule Sticker Labeling Machine with more than 200 installations in India and across the globe. Machine is having option of feeding through feeding hopper for indigenous operation and through wire mesh conveyor for automatic online operation. When working with wire mesh conveyor equipment can be attached to inspection machine to receive ampoules automatically onto labeling machine. Such feeding mechanism reduce inconvenience to operator and ampoule breakage, hence achieve very higher production accuracy. Optionally infeed turn table offer for online transfer of ampoules and vials from capping/inspection to labeling machine conveyor. With this arrangement there is no need to stop machine for ampoule loading. Machine can work continuously throughout the batch without hassle.

Ampoule Labeling Machine is an ultra-modern machine that consists of a simple linear design mechanism. Also, capable of applying transparent or no look labels at astonishing high speeds, the machine features an advanced microprocessor control label dispensing system and sensing system making this machine pretty much self-sufficient. Our ampoule self-adhesive sticker labeling machine boasts of SS 304 construction and it is pretty easy to clean and maintain.

These exclusive features of automatic ampoule labeling machine such as cGMP compliance, sturdy design and less maintenance makes this preferred choice in pharmaceutical industry.

0 notes

Text

Sticker Labeling Machine Manufacturers: Custom Solutions for Every Industry

In the rapidly moving environment of product packaging, one can never provide enough stress on the need for speed, accuracy, and reliability in labeling. With so many industries involved, including pharmaceutical, food and beverage, cosmetics, and chemicals, sticker labeling machine manufacturers fulfill their end of the demands. With businesses gearing toward automation and compliance, selecting the right sticker labeling machine manufacturer becomes an added strategic decision affecting productivity, quality, and brand reputation.

What is the Role of Sticker Labeling Machine Manufacturer?

Sticker labeling machine manufacturers are engaged in the design and production of machines that ensure the automatic application of self-adhesive labels onto all sorts of containers. The machines are built in such a manner that they can apply labels onto products ranging from tiny vials and ampoules to huge bottles and jars. The main objective remains to accurately apply each label quickly and consistently, with little to no human error, thereby increasing throughput.

Types of Sticker Labeling Machines

The manufacturing companies present an array of sticker labeling machines to meet every packaging requirement:

Automatic Sticker Labeling Machine: These sticker labeling machines are made for high-speed, high-volume operations in which hundreds of containers can be labeled per minute. Such machines find their best use in instances where the demand for efficiency and accuracy are very high.

Bottle Labeling Machine: Being specifically designed for round, flat, oval, and square bottles, these machines can label any bottle smoothly, regardless of its shape or material.

Front and Back Labeling Machines: These systems label both the fronts and backs of containers in just a single pass, allowing for greater productivity of items that require dual labeling.

Wrap-Around Labeling Machine: These machines provide cylindrical bottles with a wrap-around label and are mostly used for beverages and pharmaceuticals.

Custom Labeling Solutions: Custom solutions are offered by the top manufacturers to address any unusual container designs, label sizes, and production requirements.

Learn more, How Sticker Labeling Machines Improve Efficiency in Packaging

Key Features Offered by Leading Manufacturers

The leading sticker labeling machine manufacturers put all advanced technologies in and the user interface depending on the operations:

Label dispenser with microprocessor control: Ensures labels are positioned with precision, hence reducing wastage.

Sensor-equipped systems: These sense the position of bottle and labels for exact application.

Servo and stepper motor drives create smooth and synchronized movement to label consistently even at high speeds.

PLC and touchscreen controls for operators to change settings, observe workings, and diagnose problems.

Adjustment without tools allows fast changeovers from one product to another or from one label size to another, reducing downtime.

Durability: Machines are typically constructed from stainless steel, ensuring durability, and conforming to hygiene standards laid down for food and pharma sectors.

Industries Benefiting from Sticker Labeling Machines

Pharmaceuticals: Exactly labeled to comply with regulatory requirements for traceability of vials, ampoules, and bottles.

Food & Beverage: High-speed bottle labeling machines are used to aid mass production and branding.

Cosmetics & Personal Care: Labeling solutions are customizable to accommodate various packaging designs and materials.

Chemicals & Agrochemicals: The machines are very sturdy to endure harsh conditions and are capable of labeling different containers.

Why Choose a Reputable Sticker Labeling Machine Manufacturer?

Choosing a trusted sticker labeling machine manufacturer guarantees:

Constant Quality: Machines are manufactured to international standards, giving them reliable performance and requiring little maintenance.

Customization: Machines can be customized by manufacturers according to requirements of a particular production, specific container shapes, and specific materials of labels.

After-Sales Support: Comprehensive service, training, and provision of spare parts ensure long-term operational goals.

Cost-Efficiency: By use of advanced automation, further saving on labor cost and increasing output, provides rapid rate of return.

Bottle Labeling Machine: A Fine Look

An indispensable part of the packaging lines of beverage, pharmaceutical, and cosmetic industries, labeling machines treat bottles of all shapes-rounded, flat-sides with different capacities and speeds. PLC control systems and servo-based label dispensers combined with sensor/alignment systems make sure the sticker labels are perfectly placed on bottles even at speeds of 100 bottles/minute.

Manufacturing Trends in Sticker Labeling Machines

Integration with Smart Manufacturing: Modern machines integrate IoT connectivity for real-time monitoring and data analytics.

Sustainability: The focus for manufacturers is towards energy-efficient designs and compatibility with eco-friendly label materials.

Versatility: More and more machines are becoming modular in order to be modified rapidly for new products or new packaging formats.

Conclusion: Aim Technologies-Your Trustworthy Sticker Labeling Machine Maker

Choosing a trustworthy sticker labeling machine manufacturer puts Aim Technologies in a category by itself. They offer a full range of automatic sticker labeling machines and bottle-labeling machines serving pharmaceuticals, food and beverage, and chemical lines. An abiding commitment to innovation, quality, and customer satisfaction ensures that clients receive the latest state of art labeling solution designed to fit their very own requirements. When it comes to sticker labeling machine manufacturers, Aim Technologies is the name a business would want to associate for precision, efficiency, and long-term value.

0 notes

Text

Label up to 300 ampoules or vials per minute with the SBRSL-300 Ampoule & Vial Sticker Labeler – a sturdy, user-friendly, and maintenance-free sticker labeling machine for round containers. Equipped with a microprocessor-controlled label dispensing system and advanced sensors for precise application – even on transparent or “no-look” labels.

For more details, visit - https://www.bhagwatilabeling.com/products/ampoules-and-vials-sticker-labeler/

#bhagwatilabeling#AmpouleLabelingMachine#VialLabelingMachine#StickerLabelingMachine#PharmaLabeling#HighSpeedLabeler#RoundContainerLabeling#TransparentLabeling

0 notes

Text

What You Need to Know Before Buying a Liquid Filler

The Essential Role of Liquid Filling Machines in the Pharmaceutical Industry

In the pharmaceutical industry, precision, hygiene, and efficiency are not just desired—they are mandatory. Every stage of pharmaceutical production is held to the highest standards to ensure product quality, patient safety, and regulatory compliance. Among these stages, the filling process—particularly for liquid medications—is one of the most critical. This is where Liquid filling machines come into play.

What Are Liquid Filling Machines?

Liquid filling machines are specialized equipment designed to accurately dispense and fill various types of liquid products into containers such as vials, bottles, ampoules, and syringes. These machines are engineered to handle a wide range of viscosities, volumes, and formulations, making them ideal for pharmaceutical applications.

Why Liquid Filling Machines Are Crucial in Pharmaceutical Manufacturing

1. Precision and Accuracy

In pharmaceuticals, even a slight variation in dosage can lead to serious consequences. Liquid filling machines ensure highly accurate and repeatable fills, reducing the risk of underfilling or overfilling. Modern machines use technologies such as servo-driven pistons, peristaltic pumps, and volumetric or gravimetric controls to deliver precise results every time.

2. Enhanced Efficiency

Manual filling is time-consuming and prone to error. Liquid filling machines significantly increase production speed and throughput, making them essential for large-scale pharmaceutical manufacturing. liquid filling machines manufacturer High-speed models can fill hundreds or even thousands of containers per hour, boosting productivity without compromising on quality.

3. Hygiene and Contamination Control

Maintaining sterility is paramount in pharmaceutical production. Liquid filling machines are often built to comply with GMP (Good Manufacturing Practices) and are designed for cleanroom environments. They feature clean-in-place (CIP) and sterilize-in-place (SIP) systems, ensuring that the product remains uncontaminated throughout the process.

4. Versatility and Customization

Pharmaceutical companies manufacture a wide variety of liquid products, from oral syrups to injectables. Liquid filling machines can be customized to handle different container types, fill volumes, and product viscosities. Some advanced systems also integrate capping, labeling, and inspection, providing a complete packaging solution.

5. Regulatory Compliance

Liquid filling systems are designed to meet stringent regulatory standards set by agencies like the FDA, EMA, and WHO. Accurate documentation, batch tracking, and integration with quality management systems ensure that the production process remains transparent and auditable.

Types of Liquid Filling Machines Used in Pharmaceuticals

Volumetric Fillers – Dispense a fixed volume of liquid using pistons or rotary pumps.

Peristaltic Pump Fillers – Ideal for sterile or sensitive liquids; easy to clean and maintain.

Vacuum Fillers – Suited for low-viscosity liquids; often used in bottling.

Time-Pressure Fillers – Use consistent pressure and time intervals to fill containers.

Aseptic Fillers – Specialized machines designed for sterile filling of injectables and biologics.

Key Features to Look for in a Pharmaceutical Liquid Filling Machine

High filling accuracy

Cleanroom compatibility

Ease of cleaning and sterilization

Scalability and modular design

User-friendly interface and automation

Validation and compliance documentation

Future Trends in Liquid Filling Technology

With the growing demand for personalized medicine, biologics, and sterile drug delivery systems, the need for advanced liquid filling solutions is increasing. Future machines will likely feature AI-driven quality checks, IoT integration for real-time monitoring, and greater automation, allowing for smart manufacturing with minimal human intervention.

Conclusion

In pharmaceutical manufacturing, the importance of a reliable and accurate liquid filling machine cannot be overstated. It is the cornerstone of safe, efficient, and compliant production processes for liquid medications. Investing in the right liquid filling system not only enhances operational efficiency but also ensures patient safety and regulatory approval.

As the industry continues to evolve, liquid filling technology will remain a critical component in delivering high-quality pharmaceutical products to the global market.

0 notes

Text

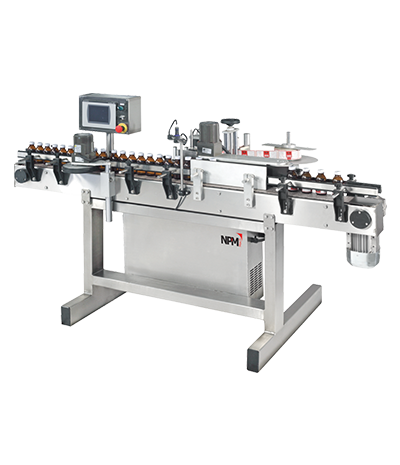

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

Streamline your pharmaceutical packaging with our Automatic Ampoule Sticker Labeling Machine — perfect for 1ml to 20ml sealed glass ampoules. Compact, high-speed, and cGMP compliant, labeling up to 300 ampoules per minute.

For more details, visit- https://www.parthec.com/product/automatic-ampoule-sticker-labeling-machine

#parthengineersandconsultant#AmpouleLabelingMachine#StickerLabelingMachine#AutomaticLabelingMachine#AmpoulePackaging#PharmaLabeling#PharmaceuticalMachinery#RotaryLabelingMachine#HighSpeedLabeler#cGMPCompliant

0 notes