#Applications of Industrial Cable Connectors

Explore tagged Tumblr posts

Text

What are Industrial Cable Connectors?

Introduction:

Industrial cable connectors play a vital role in establishing reliable and secure connections in various industrial applications. From power transmission to data communication, these connectors ensure seamless connectivity and efficient performance. In this comprehensive guide, we will explore the ins and outs of industrial cable connectors, their types, applications, and key considerations. So, let's dive in and understand the importance of industrial cable connectors in modern industries.

Understanding Industrial Cable Connectors:

Industrial cable connectors are specialized devices designed to facilitate secure and reliable connections between cables, wires, and other electrical components in industrial environments. These connectors are engineered to withstand harsh conditions, provide efficient transmission of power or data signals, and ensure safe and durable connections.

Types of Industrial Cable Connectors:

a. Circular Connectors:

These connectors feature a cylindrical shape and are commonly used in applications where robustness and durability are crucial, such as heavy machinery, automation systems, and outdoor installations.

b. Rectangular Connectors:

Rectangular connectors are versatile and widely used in industrial settings. They offer a wide range of configurations and can accommodate multiple contacts for power, signal, and data transmission.

c. Fiber Optic Connectors:

Fiber optic connectors are specifically designed for high-speed data transmission over long distances. They use optical fibers to transmit light signals, providing excellent bandwidth and immunity to electromagnetic interference.

d. Coaxial Connectors:

Coaxial connectors are primarily used for RF (radio frequency) applications. They feature a central conductor surrounded by insulation, a metallic shield, and an outer insulating layer, ensuring proper impedance matching and minimal signal loss.

Key Features and Specifications:

Industrial cable connectors come with various features and specifications that are crucial for their optimal performance. These include:

Connector housing material: Robust and durable materials such as metal or high-grade engineering plastics are commonly used to withstand harsh environmental conditions.

IP rating: The IP (Ingress Protection) rating indicates the connector's resistance to dust and water intrusion. Higher IP ratings signify better protection against environmental elements.

Contact configuration: Connectors can have different contact arrangements, such as pin-and-socket or plug-and-jack, depending on the application requirements.

Voltage and current rating: Industrial cable connectors are designed to handle specific voltage and current levels, ensuring safe and reliable power transmission.

Locking mechanisms: Many connectors incorporate locking mechanisms to ensure secure connections and prevent accidental disconnection due to vibrations or movements.

Applications of Industrial Cable Connectors:

a. Automation and Robotics:

Industrial cable connectors are extensively used in automation and robotics applications to connect various sensors, actuators, and control systems, enabling seamless communication and power transfer.

b. Automotive Industry:

Cable connectors play a crucial role in the automotive industry, facilitating connections between electrical systems, sensors, and components in vehicles.

c. Energy Sector:

In the energy sector, industrial cable connectors are utilized in power generation, transmission, and distribution systems, ensuring reliable and efficient electricity transfer.

d. Telecommunications:

Industrial connectors are integral to telecommunication networks, providing reliable connections for data transmission, telephony, and networking equipment.

e. Aerospace and Defense:

In aerospace and defense applications, industrial connectors are essential for reliable communication, power distribution, and signal transmission in challenging environments.

Factors to Consider when Choosing Industrial Cable Connectors:

a. Environment and Operating Conditions:

Consider the temperature range, moisture levels, dust exposure, and other environmental factors to select connectors that can withstand these conditions.

b. Electrical and Mechanical Specifications:

Evaluate the voltage and current ratings, contact resistance, insulation resistance, and mechanical durability to ensure compatibility with your application requirements.

c. Signal and Power Requirements:

Determine the type and bandwidth of signals or power being transmitted to choose connectors that offer the necessary performance and compatibility.

d. Industry Standards and Certifications:

Look for connectors that comply with industry standards and certifications to ensure quality, reliability, and compatibility with other equipment.

Installation and Maintenance Tips:

a. Proper Cable Termination:

Follow manufacturer guidelines for cable termination to ensure a secure and reliable connection. Use appropriate tools and techniques to achieve proper insulation and strain relief.

b. Secure Connection Techniques:

Employ locking mechanisms, such as threaded couplings or bayonet-style locks, to prevent accidental disconnection and ensure stable connections.

c. Regular Inspection and Maintenance:

Regularly inspect connectors for signs of wear, damage, or contamination. Clean connectors using recommended methods and replace any faulty or damaged components promptly.

Future Trends in Industrial Cable Connectors:

The industrial cable connector industry is continually evolving to meet the demands of advancing technology and changing industrial requirements. Some emerging trends include miniaturization, increased data transmission speeds, and improved resistance to extreme temperatures and vibrations.

Conclusion:

Industrial cable connectors are indispensable components in modern industrial applications, enabling secure and reliable connections for power transmission and data communication. Understanding the types, features, applications, and key considerations when choosing these connectors is crucial to ensure optimal performance and long-term reliability. By selecting the right industrial cable connectors and following proper installation and maintenance practices, industries can enhance efficiency, safety, and overall productivity.

#Industrial Cable Connectors#cable connectors#Types of Industrial Cable Connectors#Coaxial Connectors#Fiber Optic Connectors#Applications of Industrial Cable Connectors

0 notes

Text

DB9 connector is a widely used electrical connector. Recognizable by its distinctive D-shaped metal shell and 9-pin configuration, the DB9 connector has been a staple in electronics for decades, especially for serial communication.

What Is a DB9 Connector?

The DB9 connector features a D-shaped shell to ensure proper orientation when connecting. The 9 pins (or sockets in female versions) are arranged in two rows, with 5 pins on the top and 4 on the bottom. This compact design is suitable for low-profile applications.

The connector comes in two main types:

DB9 Male Connector: Have pins and are typically used on cables.

DB9 Female Connector: Have sockets and are often found on equipment or devices.

Key Features of DB9 Connectors

Durable Construction: The metal shell provides mechanical strength and shields against electromagnetic interference (EMI).

Compact Design: Ideal for devices where space is limited.

Versatile Applications: Commonly used for RS-232 serial communication, connecting peripherals like mice, keyboards, and modems.

Customization: Can support different pin configurations and wiring for varied uses.

Common Applications of DB9 Connectors

Serial Communication: Widely used in RS-232 interfaces to connect computers, printers, and industrial equipment.

Automation and Control Systems: Frequently seen in programmable logic controllers (PLCs) and industrial machines.

Networking Equipment: Used in switches, routers, and legacy systems.

Testing and Prototyping: Found in diagnostic and development tools for electronics.

DB9 Pinout Diagram

Here’s a standard pinout for a DB9 connector used in RS-232 communication:

Advantages of DB9 Connectors

Reliable Connection: Secure locking mechanism ensures a stable link.

Broad Compatibility: Works with many legacy and modern devices.

Easy Maintenance: Simple design allows for straightforward repairs or replacements.

8 notes

·

View notes

Text

Flame Retardants Market demand analysis and regional outlook across key end use industries

The Flame Retardants Market is expanding rapidly due to its essential role across sectors like construction, electronics, automotive, and textiles. With growing safety regulations, fire prevention measures, and technological developments, demand patterns vary notably across regions and end-use applications.

Rising Global Demand and Key Drivers

Flame retardants are crucial in preventing fire-related hazards and are increasingly used in products that require compliance with fire safety standards. Their demand is primarily driven by strict building codes, growing awareness about safety, and the rising use of electronic devices globally. Regions such as North America, Asia Pacific, and Europe are showing consistent growth, but with distinct trends and preferences.

In North America, the growth is linked to infrastructure development and industrial safety compliance. Europe shows preference for non-halogenated and eco-friendly retardants, while Asia Pacific leads in manufacturing volume, driven by strong electronics and construction markets in China, India, and Southeast Asia.

Industry-Specific Growth Patterns

Construction is a leading end-use sector for flame retardants, especially in residential and commercial buildings. Flame retardant materials like insulation, wires, cables, and structural plastics are essential for fire prevention. Demand in this sector is increasing in urbanizing regions such as Asia Pacific and the Middle East due to rising construction activities.

Electronics is another significant segment where flame retardants are used in circuit boards, housings, and connectors. As global demand for smartphones, smart TVs, and electronic vehicles grows, so does the use of flame retardants. Asia Pacific, being the hub of electronics manufacturing, is the biggest contributor here.

Automotive applications include upholstery, engine components, and electrical systems. With electric vehicles becoming mainstream, manufacturers are increasingly using flame-retardant materials to ensure passenger safety and battery protection.

Textiles represent a niche but fast-growing sector, especially for specialized garments, furniture fabrics, and industrial uniforms. The demand is rising in both developed and developing economies where fire-resistant clothing is mandated.

Regional Outlook and Market Hotspots

North America remains a mature market but shows steady demand due to regulations like the National Fire Protection Association (NFPA) codes and strong construction activity. The U.S. dominates the region’s share, followed by Canada.

Europe focuses on sustainability and safety, with strict REACH regulations and increased use of non-toxic flame retardants. Germany, France, and the UK are the leading contributors. There's a growing preference for phosphorous-based and mineral-based retardants due to environmental concerns.

Asia Pacific is the fastest-growing region, supported by expanding electronics, automotive, and textile industries. China leads in production and consumption, with India and Southeast Asia catching up rapidly. Governments in the region are also tightening fire safety norms, which is fueling further demand.

Latin America and the Middle East & Africa are emerging markets. Although smaller in size, infrastructure growth and industrial development are increasing the demand for flame retardant materials, especially in commercial real estate and energy projects.

Market Challenges and Demand Constraints

Despite the growing demand, the market faces a few constraints. Halogenated flame retardants are under scrutiny for their potential health and environmental effects, prompting stricter regulation and replacement with alternatives. Also, regional disparities in enforcement of safety standards sometimes slow market penetration in emerging areas.

Another issue is raw material volatility, which can impact pricing and production planning. For instance, supply chain disruptions in Asia Pacific or geopolitical instability in Europe may lead to fluctuating costs.

Future Outlook and Regional Forecast

The future of the flame retardants market is rooted in innovation and regional adaptability. Demand is expected to grow significantly over the next decade, with Asia Pacific continuing to dominate in volume and Europe and North America setting trends in sustainability. Emerging economies in Africa and Latin America are projected to witness stronger growth as infrastructure and industrial development accelerate.

Growth will likely be supported by rising R&D in eco-friendly compounds and a growing emphasis on safety standards across all industries. Companies that align their offerings to regional preferences—like halogen-free products in Europe or cost-effective solutions in Asia—will have a competitive edge.

Conclusion

The global flame retardants market shows strong regional diversity in demand, influenced by regulations, industrial activities, and consumer preferences. Each major end-use industry—construction, electronics, automotive, and textiles—offers unique growth opportunities that vary by region. Companies looking to succeed in this space must adapt to regional market dynamics, invest in sustainable alternatives, and align with evolving safety standards.

#FlameRetardants#ConstructionSafety#ElectronicsIndustry#FireProtection#MarketTrends#AsiaPacificGrowth#SustainableMaterials#FireSafety#MarketAnalysis#GlobalExpansion

2 notes

·

View notes

Text

How to Choose the Right Door Limit Switch for Your Project

In the world of automation, safety, and mechanical design, door limit switches play a vital role in monitoring and controlling the position of doors, gates, and access panels. Whether you’re designing an industrial machine, an elevator system, or a home automation project, selecting the right limit switch ensures both safety and functionality.

As a trusted supplier of door limit switches and a full range of low voltage switchgear products, we aim to provide you with comprehensive guidance to help you select the ideal components for your specific needs.

This article provides a detailed guide on how to choose the best door limit switch for your project, highlighting the key factors, types, and applications you should consider.

What is a Door Limit Switch?

A door limit switch is an electromechanical device that detects the physical movement or position of a door. When the door reaches a certain position — fully open, fully closed, or somewhere in between — the switch activates or deactivates an electrical circuit.

These switches are commonly used in:

· Elevator doors

· Garage doors

· Industrial machines

· HVAC systems

· Automated gates

· Access control systems

Why Choosing the Right Limit Switch Matters

Choosing the correct limit switch is essential for:

· Safety: Preventing overtravel or mechanical failure.

· Accuracy: Ensuring the door is properly positioned before triggering other processes.

· Durability: Withstanding environmental stressors like dust, moisture, or extreme temperatures.

· Efficiency: Reducing maintenance and downtime in automated systems.

Key Factors to Consider When Selecting a Door Limit Switch

1. Type of Door Movement

The direction and nature of the door’s movement determine the kind of switch you need:

· Sliding doors: Require a linear actuator-type or proximity switch.

· Swinging doors: Benefit from lever or roller-type limit switches.

· Lift doors or panels: Often use plunger-type or magnetic limit switches.

2. Switch Type

There are several types of door limit switches. Choose based on precision, contact type, and actuation style.

Mechanical Limit Switches

· Actuated physically by the door.

· Types: Roller lever, plunger, or spring rod.

· Pros: Simple, cost-effective.

· Cons: Susceptible to wear and physical damage.

Proximity Switches

· Detect without direct contact (inductive, capacitive, or magnetic).

· Pros: Longer lifespan, sealed from contaminants.

· Cons: More expensive; may require specific mounting and alignment.

Magnetic Reed Switches

· Activated by a magnet attached to the door.

· Common in security systems.

· Pros: Compact, easy to install, no mechanical wear.

· Cons: Sensitive to magnetic interference.

3. Electrical Ratings

Match the switch with your system’s voltage and current requirements. Check for:

· Operating voltage (AC/DC)

· Load capacity (e.g., 5A @ 250V AC)

· Contact configuration (SPDT, DPDT, etc.)

4. Environmental Conditions

Evaluate the environment where the switch will operate:

· IP Rating: Ensure protection against dust and water (e.g., IP67 for outdoor use).

· Temperature Range: Some switches are rated for extreme temperatures.

· Chemical Resistance: For industrial or corrosive environments.

5. Mounting and Size Constraints

Ensure the switch can be securely mounted within the available space. Consider:

· Actuator travel distance

· Orientation (horizontal, vertical, angled)

· Cable or connector type

6. Durability and Life Cycle

Look for specifications like:

· Mechanical life (number of operations)

· Electrical life (switching durability under load)

Bonus Tips for Successful Implementation

· Test before finalizing: Always prototype with a few switches before bulk purchasing.

· Use protective enclosures: Especially in harsh environments.

· Add debounce circuitry: For systems sensitive to switch bounce.

· Ensure accessibility: Make the switch easy to access for maintenance or adjustments.

Your Trusted Partner in Low Voltage Switchgear

As a leading supplier of low voltage switchgear, we offer not only high-quality door limit switches, but also a wide variety of industrial components including:

· Power Transformers

· Panel Fan and Filter

· Current Transformers

· Analog and Digital Meters

· Relays and Timers

Conclusion

Choosing the right door limit switch is not just about picking a device that fits — it’s about ensuring long-term performance, safety, and compatibility with your overall system. By understanding the different types of switches, environmental requirements, and application-specific factors, you can confidently select the ideal switch for your project.

Whether you’re working on a DIY smart home upgrade or designing a robust industrial system, the right switch can make all the difference in functionality and reliability.

4 notes

·

View notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Text

Helfinch Introduces Advanced EV Charger Cables for the USA Market

Helfinch, a leading innovator in the lighting and electrical industry, is proud to announce the launch of its latest product line: the advanced EV charger cables specifically designed for the USA market. These cables embody the company’s commitment to quality, innovation, and customer satisfaction, making them one of the best choices for electric vehicle (EV) owners in the United States.

Advanced Features for a Superior Charging Experience

Helfinch’s EV charger cables are packed with the latest features to ensure a reliable and efficient charging experience for all EV users. Here are some of the standout features that make Helfinch EV charger cables a top choice:

1. Durability and All-Weather ProtectionHelfinch EV charger cables are built to withstand the toughest conditions. With the highest Ingress Protection (IP) rating, these cables are dust-tight and protected against powerful water jets, ensuring they perform exceptionally well in any weather condition. Whether it’s rain, snow, or extreme heat, Helfinch cables maintain their integrity and functionality, providing peace of mind to users who need to charge their vehicles outdoors.

2. Smart Charging FeaturesThe smart charging capabilities of Helfinch cables set them apart from the competition. These features allow for efficient energy use, ensuring that your vehicle is charged optimally without overloading the power supply. Smart charging also provides users with the ability to schedule charging times, monitor energy consumption, and receive notifications via a user-friendly app. This level of control and convenience enhances the overall EV ownership experience.

3. Fast Quick ChargingOne of the most critical factors for EV owners is the speed of charging. Helfinch EV charger cables support fast quick charging, significantly reducing the time it takes to charge your vehicle. This feature is particularly beneficial for those who need to recharge their EVs quickly between trips. With Helfinch, you can get back on the road faster, making these cables ideal for both daily commutes and long-distance travel.

4. Extra Long SizesTo accommodate various user needs and charging setups, Helfinch offers its EV charger cables in extra-long sizes of 10, 15, and 20 meters. This range of lengths ensures that no matter where your charging station is located, you will have enough cable to reach your vehicle comfortably. This flexibility makes Helfinch cables suitable for a wide range of residential and commercial charging applications.

5. Multiple Color OptionsUnderstanding the importance of aesthetics and customization, Helfinch provides its EV charger cables in four distinct colors: Yellow, Green, Black, and White. This variety allows customers to choose a color that best matches their personal preference or vehicle color, adding a touch of personalization to their EV charging experience.

Top Selling Variants

Helfinch offers a variety of EV charger cables, each designed to meet different needs and preferences. Our top sellers are:

**NEMA 14–50 Plug with J1772 Connector** This is the most common and versatile option for Level 2 charging in homes. It plugs into a 240V outlet and is compatible with most electric vehicles (EVs) in the US. This variant is highly favored for its reliability and ease of use.

**NEMA 6–50 Plug with J1772 Connector** Another popular option for Level 2 charging, the NEMA 6–50 plug is often used in homes with older electrical systems. It also plugs into a 240V outlet and is compatible with most EVs. This variant is ideal for homes that may not have been updated to the latest electrical standards but still require efficient and effective charging solutions.

**Tesla Compatible Connector** Tesla vehicles use a proprietary connector, but Helfinch offers J1772 to Tesla adapters that allow Tesla owners to use standard Level 2 chargers. This flexibility ensures that Tesla drivers can benefit from the superior quality and features of Helfinch charger cables without any compatibility issues.

Our Additional Features

**Amperage Options** Helfinch understands that different EVs have different charging capabilities. Therefore, we offer both 16A and 32A chargers. This allows users to choose the appropriate amperage based on their vehicle’s specifications, ensuring efficient and safe charging.

**Smart Features** For added convenience, Helfinch cables come with smart features like Wi-Fi connectivity, energy monitoring, and scheduling. These features allow users to monitor their charging sessions, schedule charging times to take advantage of off-peak electricity rates, and receive real-time notifications about their charging status.

Available Exclusively Online

Helfinch has strategically chosen to make these premium EV charger cables available exclusively through online stores, including Amazon. This decision allows the company to reach a broader audience and provide customers with the convenience of shopping from the comfort of their homes. By leveraging the extensive reach and trusted service of Amazon, Helfinch ensures that its customers have easy access to these high-quality products with fast and reliable delivery options.

Why Choose Helfinch EV Charger Cables?

Helfinch has established a strong reputation in the electrical and lighting industry, known for its dedication to innovation, quality, and customer satisfaction. Here are several reasons why choosing Helfinch EV charger cables is a wise investment for any EV owner:

**1. Proven Track Record**With years of experience in developing high-quality electrical products, Helfinch brings its expertise and commitment to excellence to the EV charger cable market. Customers can trust that they are purchasing a product from a reputable company that prioritizes performance and reliability.

**2. Cutting-Edge Technology**Helfinch is always at the forefront of technological advancements. The inclusion of smart charging features and fast charging capabilities in its EV charger cables demonstrates the company’s commitment to integrating the latest technology into its products. This ensures that customers receive the most efficient and convenient charging solutions available.

**3. Exceptional Customer Support**Customer satisfaction is a top priority for Helfinch. The company provides comprehensive support for all its products, including detailed user manuals, online resources, and a dedicated customer service team ready to assist with any questions or concerns. This level of support ensures that customers can enjoy a hassle-free experience from purchase to use.

**4. Environmental Responsibility**Helfinch is committed to sustainability and environmental responsibility. By promoting the use of electric vehicles and providing efficient charging solutions, the company contributes to the reduction of carbon emissions and supports the global shift towards greener transportation options. Helfinch’s EV charger cables are designed to be energy-efficient, helping users minimize their environmental footprint.

**5. Competitive Pricing**Despite the advanced features and high-quality materials used in Helfinch EV charger cables, the company offers these products at competitive prices. This ensures that customers receive excellent value for their investment, making Helfinch a cost-effective choice for premium EV charging solutions.

Our Customer Testimonials

The launch of Helfinch’s EV charger cables has already garnered positive feedback from early adopters. Here are a few testimonials from satisfied customers:

John Murray. — New York, NY “I’ve tried several EV charger cables before, but Helfinch’s cables are by far the best. The durability is outstanding, and the fast charging feature is a game-changer. Plus, the extra-long cable length means I can easily charge my car no matter where I park in my garage.”

Samantha Klein. — Los Angeles, CA“The smart charging features on these cables are fantastic. I love being able to monitor my charging sessions and schedule them to take advantage of lower electricity rates. The app is easy to use, and the notifications are super helpful. Highly recommend!”

Michael Bevan. — Chicago, IL“I purchased the 20-meter cable in yellow, and it’s perfect for my setup. The all-weather protection means I don’t have to worry about the cable getting damaged, even during heavy rain. Great product and excellent value for money.”

Conclusion

Helfinch is setting a new standard in the EV charger cable market with its innovative, durable, and feature-rich products. Designed to meet the needs of modern EV owners, Helfinch’s cables offer unparalleled performance, convenience, and reliability. Available in various lengths and colors, these cables are perfect for any charging setup and aesthetic preference.

By choosing Helfinch, customers are investing in a product backed by a company with a proven track record of quality and innovation. Whether you are a new EV owner or looking to upgrade your current charging equipment, Helfinch EV charger cables provide the best solution for a seamless and efficient charging experience.

Explore the future of EV charging with Helfinch. Visit our online store on Amazon today and join the growing community of satisfied customers who trust Helfinch for their EV charging needs.

2 notes

·

View notes

Text

SC Cable Has a Great Contribution in Good Connectivity

In the realm of contemporary technology, when uninterrupted connectivity is essential to every click, swipe, and tap, the backbone that underpins our digital infrastructure is sometimes invisible and undervalued. However, it is precisely this basis that enables us to interact, cooperate, and create at the speed of thinking. The SC cable is one of the unsung heroes of this digital revolution; it is an engineering wonder that silently keeps our networks stable and strong.

Although SC (Subscriber Connector) cables are not as well-known as USB or HDMI, their importance in the field of data transfer cannot be emphasized. Numerous networks rely on these fiber optic connections to send data quickly and efficiently across great distances with little loss or interference. Let's explore SC cables in more detail and find out why they are still relevant today.

Bandwidth and Speed: Every SC cable is built with the promise of unmatched bandwidth and speed. Fiber optic cables, such as SC, are made to use light as a means of data transmission. They can carry data at rates far faster than those of conventional copper cables. Gigabit Ethernet, Fibre Channel, and other high-speed protocols can be supported via SC cables, which are the foundation of networks when speed is crucial.

Reliability is a non-negotiable in this day and age, as any downtime may be disastrous for both individuals and enterprises. SC cables and LC cables are the preferred options for mission-critical applications because of their well-known robustness and ability to withstand external interference. SC cables preserve their integrity even when traveling over crowded metropolitan areas or the ocean floor, guaranteeing continuous communication when it counts most.

Versatility: The adaptability of SC cables is one of its distinguishing qualities. These cables are used in a wide range of sectors, including data centers, telecommunications, industrial automation, and healthcare. Their attractiveness is further increased by their compatibility with a wide range of networking standards and protocols, which enables a smooth integration into the current infrastructure.

SC cable undoubtedly influences our globally networked world, even if they may work in the background. These modest but strong cables are essential to the development of the digital world because they power the internet's backbone and allow for real-time communication across countries.

Next: How Fiber Trunk Cable and SC Attenuator Boost Network Performance?

2 notes

·

View notes

Text

FTTA: High-Performance Solution for Integrated Optical Fiber and 5G Networks

There is a huge demand for high-speed data transfers in today’s mobile telecommunications networks. FTTA (Fiber-to-the-Antenna) is an essential element of 5G networks and ensures reliable, robust, and future-proof installation, improves user experience and reduces costs. This article helps you to understand FTTA.

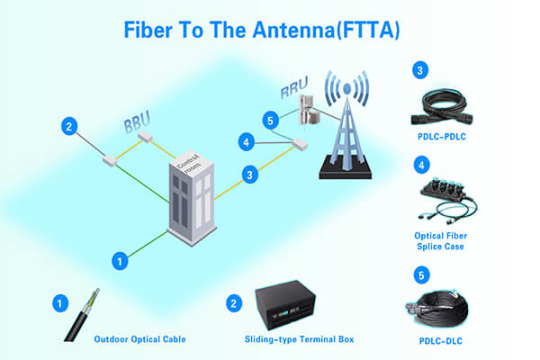

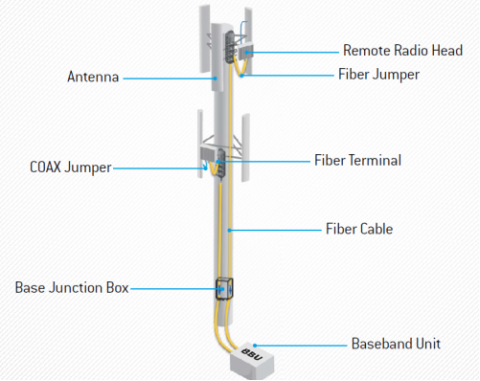

What is FTTA?

FTTA is a broadband network architecture to connect the building baseband unit (BBU) to the remote radio unit (RRU) at the top of the tower by using optical fibers to replace all or part of the coaxial network. FTTA can reduce the loss of signal power. And up to 20km's maximum transmission distance helps realize centralized placement of base stations (BS) in lower-cost telecommunication rooms and more flexible and modularized network planning.

FTTA Solution

FTTA solution reduces installation time and saves the cost of installation and maintenance. FTTA solution includes outdoor optic fibers, PDLC outdoor waterproof patch cords, terminal boxes, etc.

Benefits of FTTA

Perhaps the most benefit of FTTA stems from the physical content of the cable itself. The smaller diameter and lighter weight allow many fiber optic cables to occupy the same amount of space as a single coax cable. Because cellular towers are naturally subject to the elements, the physical size and properties of optical cabling are much less susceptible to damage from gusts of wind.

Other benefits of FTTA relate to the shift from analog to digital. Due to signal losses, the coax cable limited the distance between the antenna and the base station to as low as around 100m. Optical cabling can span up to 20 km with minimal losses.

FTTA provides improved energy consumption and signal integrity. Tower amplifiers are no longer required to combat the inherent noise floor of extended coax runs. The cooling of power amplifiers through air conditioning in a traditional base unit is replaced by ambient air cooling of the RRH, which significantly reduces the electrical power consumption of the system.

FTTA also provides flexible deployment, reduced complexity, saves installation time and space on the tower, lower investment, and high reliability.

Typical FTTA Scenario

Fiber optic networks aim to perform high-speed, error-free data transmission. Adequate testing during each phase of the network deployment guarantees that products meet specifications. It minimizes costly and time-consuming troubleshooting efforts, including locating dirty/damaged connectors, questionable splices, and other faulty components before they disrupt service.

One of the most crucial factors in ensuring proper transmission is controlling power loss in the network against the link loss-budget specifications from the network design recommendation, which establishes a total end-to-end loss budget with sufficient margin while reducing back reflection to a minimum.

What is the Future of FTTA?

Consumer demand and technological advancement will continue to challenge the broadband infrastructure and necessitate more innovation. As incremental improvements such as active antennas integrated with the RRH to eliminate the need for all coax, small cell technology, and tower construction continues to evolve, it is safe to assume the future of FTTA may hold a few more surprises.

5G network provides speeds up to 100 times faster than 4G, which requires more small cell sites/DAS and improvements in conventional antenna tower bandwidth. Fiber optics will continue to provide the lifeblood to this ever-evolving network because only fiber can support the backhaul of these small cell sites produced by this intense proliferation of traffic.

Conclusion

FTTA is an innovative, flexible, and future-oriented way to install the network. It secures your network connectivity today and in the future.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

#suntelecom#fiberoptic#telecommunications#fttx#telecomengineering#cabling#osp#fiberopticcable#catv#telecomconsult

2 notes

·

View notes

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

Unleashing the Brilliance of Aluminium Cable Lugs: A Gateway to Efficient Electrical Connections

Step into the captivating world of electrical components with Pioneer Powers International, your go-to destination for premium-quality products in Mira Road, Mumbai. As wholesalers and retailers, we take immense pride in introducing you to the brilliance of Aluminium Cable Lugs – the gateway to achieving seamless and efficient electrical connections.

The Wonders of Aluminium Cable Lugs: A Marvelous Choice:

In the vast universe of electrical connections, Aluminium Cable Lugs shine as a marvelous choice, offering an array of benefits. These connectors play a crucial role in establishing secure links between electrical conductors and terminals, ensuring a stable flow of power without compromise.

Exploring the Allure of Aluminium:

As we delve deeper into the world of Aluminium Cable Lugs, we are captivated by the allure of this extraordinary metal. Renowned for its impressive combination of lightweight and high strength, aluminium proves to be an ideal material for cable lugs. Its excellent conductivity and resistance to corrosion make it an excellent alternative to copper in various electrical applications.

The Anatomy of Aluminium Cable Lugs: A Masterpiece in Design:

Let's unravel the artistry behind Aluminium Cable Lugs. These connectors typically consist of a cylindrical barrel with a flared end, ingeniously designed to house the conductor securely while allowing for easy attachment to terminals and devices. This clever design ensures a snug and dependable connection, safeguarding against disruptions and ensuring uninterrupted power flow.

A Diverse Array for Every Need:

At Pioneer Powers International, we embrace the diversity of electrical projects. Therefore, our extensive inventory of Aluminium Cable Lugs caters to a wide range of applications. Whether it's domestic electrical wiring or industrial installations, our versatile selection guarantees that you find the perfect fit for your specific requirements.

Quality and Safety: Our Top Priority:

At the core of Pioneer Powers International lies an unwavering commitment to quality and safety. Our Aluminium Cable Lugs undergo rigorous testing to meet the highest industry standards, ensuring outstanding performance and longevity. With our products, you can trust that your electrical connections are fortified against any potential mishaps.

Installation Guide: A Smooth Journey to Connectivity:

While Aluminium Cable Lugs boast exceptional attributes, proper installation is paramount to unlock their true potential. Our expert team has meticulously compiled a comprehensive installation guide to ensure a flawless connection process. Following these guidelines guarantees a secure and proficient link, optimizing the overall efficiency and lifespan of your electrical system.

Innovation and Adaptability:

At Pioneer Powers International, innovation is the heartbeat of our existence. We continuously strive to remain at the forefront of the electrical industry, adapting to the ever-changing needs of our customers. Embrace innovation with our state-of-the-art Aluminium Cable Lugs, and experience a new level of electrical efficiency.

Pioneer Powers International: Your Trusted Companion:

As you embark on your electrical ventures, we extend our hand to be your trusted companion. Pioneer Powers International has built a legacy of trust and excellence, serving electricians, contractors, and DIY enthusiasts with unmatched dedication. Discover the brilliance of Aluminium Cable Lugs, backed by exceptional service, and let us illuminate your electrical projects with efficiency and finesse.

Conclusion:

In the realm of electrical connections, Aluminium Cable Lugs stand as a testament to the brilliance of engineering. At Pioneer Powers International, we invite you to immerse yourself in the wonders of these exceptional connectors – the gateway to seamless power transmission. Embrace the allure of aluminium, guided by our comprehensive installation guide, and elevate your electrical ventures with confidence. Pioneer Powers International is here to empower your journey towards efficient electrical connections and to light up your world with brilliance

2 notes

·

View notes

Text

Batteryless Storage Solutions Market to Hit US$ 9.2 Bn by 2034

The global batteryless storage solutions market is witnessing explosive growth, with its value projected to rise from US$ 540.0 Mn in 2023 to a staggering US$ 9.2 Bn by 2034, expanding at a CAGR of 29.6% from 2024 to 2034. This exceptional surge is underpinned by growing adoption of sustainable technologies, rising demand for eco-friendly energy systems, and a major transformation in how power is harvested and stored in IoT ecosystems.

The Emergence of Batteryless Energy Systems

Batteryless storage solutions harness ambient energy—light, motion, thermal gradients, or radio frequency signals—and store it in supercapacitors rather than traditional chemical batteries. These systems eliminate the need for toxic and environmentally burdensome lithium-ion batteries, offering a greener, more sustainable alternative for powering ultra-low-power microcontrollers and connected devices.

With the rise of Internet of Things (IoT), the demand for sustainable energy storage systems that require minimal maintenance and have long lifespans is at an all-time high. IoT applications in smart buildings, manufacturing automation, and healthcare systems now rely increasingly on batteryless, energy-harvesting devices.

Key Market Drivers

1. IoT Growth Accelerating Adoption

As industries invest in IoT technologies to enhance efficiency, reduce costs, and achieve sustainability goals, batteryless storage solutions have emerged as a critical enabler. These solutions power a range of sensors and devices in smart factories, buildings, and cities—ensuring data continuity without battery replacement or downtime.

2. Eco-Friendly UPS Systems in Demand

Another major growth catalyst is the rising demand for eco-friendly uninterruptible power supply (UPS) systems. Traditional UPS solutions rely on battery backups that not only degrade over time but also pose environmental challenges due to lithium and rare earth extraction. Fuel cell-powered and supercapacitor-based UPS systems offer cleaner, more sustainable options, helping industries meet their environmental compliance targets while ensuring uninterrupted operations.

Technological Innovations: Supercapacitors and WPT

At the heart of batteryless storage systems lies the supercapacitor, a high-efficiency energy storage component with long cycling lifetimes and superior power output. These components are capable of storing harvested energy and releasing it instantly when required, making them ideal for wireless sensor networks, medical devices, and industrial IoT systems.

The rise of Wireless Power Transfer (WPT) technologies further enhances the appeal of batteryless systems. WPT enables energy transmission via magnetic fields, allowing portable devices to be charged without physical connectors. Paired with solar-powered supercapacitors, WPT unlocks true cable-free energy ecosystems.

Regional Outlook: Asia Pacific Leads the Charge

According to market analysis, Asia Pacific dominated the global batteryless storage solutions market in 2023. The region’s robust demand for renewable energy, rapid urbanization, and strong industrial base are driving market momentum. Countries like China, India, and members of ASEAN are investing heavily in energy security and sustainable infrastructure, leading to increased deployment of batteryless energy storage systems.

The combined primary energy use in the Indian subcontinent, Southeast Asia, and Sub-Saharan Africa is projected to grow by over 78,000 petajoules by 2050. This long-term energy demand will necessitate scalable, eco-friendly, and efficient storage technologies—making batteryless solutions a key pillar in the region’s energy strategy.

Competitive Landscape and Innovation Pipeline

The competitive landscape is characterized by active innovation from leading players such as:

Other major players include BYD Company Limited, GE VERNOVA, LG Energy Solution, and Panasonic Corporation, all of whom are investing in next-gen energy harvesting modules and multi-protocol wireless connectivity for plug-and-play batteryless architectures.

Future Outlook

As sustainability and digital transformation become intertwined, the batteryless storage solutions market is poised for rapid evolution. Innovations in RFID, Bluetooth LE 5.4, and sub-GHz wireless protocols will enable seamless integration of batteryless modules across industries. Additionally, breakthroughs in materials science and power electronics will push the boundaries of what batteryless systems can achieve—making them not only viable but essential for modern energy infrastructure.

In conclusion, batteryless storage solutions are more than just an alternative—they represent the future of sustainable power. As industries and governments align toward a low-carbon economy, these systems will play a pivotal role in reshaping the way energy is harvested, stored, and used across the globe.

0 notes

Text

Leiditech launches small package high-voltage anti-static diodesSD60C

1. Why is it difficult to protect high-voltage communication signal lines from static electricity

Many companies can generally achieve electrostatic protection for high-voltage communication signal lines.8 to 36V,48V ESD Electrostatic protection,For example, the 36 in Shanghai Leiditech, ESD diode SD36C,LC36CI,GBLC36C ,Can be used for electrostatic protection from low to high data rates, respectively.48V of ESD Diodes haveSD48C.

If the signal voltage is any higher,For example, 60V ,The signal line at this time,Most factories do not have suitable electrostatic protection devices.If you say it can be used TVS such as SMAJ60CA,SMBJ60CA and so on. You should know that this is a communication signal line,these TVS The junction capacitance is close to 1nF,Using it for signal lines can seriously affect signal quality.So this has always been a pain point for some high-voltage communication equipment.

2. Shanghai Leiditech launchedSD60C High voltage electrostatic protection devices

Shanghai Leiditech aims to help customers solve practical problems,R&D and production launch of a new product Vrwm For 60VofESDdiodeSD60C,Suitable for electrostatic protection of communication signal lines.

Here is an example to illustrateSD60CThe role in high-voltage fault protection.

In certain applications,Due to various reasons(If the power supply is directly short circuited、Wrong wiring fault、Connector failure、Cable damage and misuse of tools),RS-485 The bus may withstand high voltage,applySD60C ,The bus interface pins can be higher than ±70V Protected under DC overvoltage conditions,such as,A and B Unexpected short circuit of pins in industrial automation equipment 70V Or higher voltage,SD60C When the breakdown voltage exceeds 69VRapid conduction after,protect RS485 Interface back end devices.Same CAN The bus may also encounter the above situations,therefore,stayRS485 and CAN In the presence of high-voltage environments in bus applications,SD60C Can play a security role.

3. SD60CPerformance characteristics

Has the following performance characteristics:

l Small packaging :SOD-323 Packaging ,The pins are easy to weld

l High power:The peak power is 650W

l Antistatic ability:IEC 61000–4–2 (ESD) Air discharge:±20kV,Contact discharge:±15kV

Meets static level 4

l Anti surge capability:IEC61000–4–5 7A (8/20μs),Has certain surge resistance ability

l Low clamping voltage:Vc =78V Test conditions IPP = 1A (8 x 20μs pulse)

Vc =90V Test conditions IPP = 7A (8 x 20μs pulse)

l The test diagram is as follows

l Application Scenario:

Suitable for communication environments with high voltage present,Hope to have a good environment for high-voltage protection.

1)Automotive electronic systems:Automotive electronic devices typically need to withstand high voltage peaks,For example, the voltage surge generated during vehicle startup.

2)Communication equipment:In the field of communication,Like base stations、Network switching equipment, etc.

3)Engineering construction equipment:In construction and engineering equipment,Such as intelligent building systems、Security monitoring equipment.

4)Industrial automation and other equipment.

For more information,Please contact Shanghai Leiditech sales personnel or EMC Little brother.

Shanghai Leiditech Professional R&D and Sales ESD TVS product.We are committed to providing customers with high-quality services ESD TVS product,To protect the circuit from static interference and voltage fluctuations.Our products cover a wide range of application areas,Including electronics、communication、computer、automobile、Medical and other industries.We have an experienced R&D team,Capable of providing personalized customization services based on customer needs.Our goal is to become a global leader ESD TVS One of the suppliers,Provide customers with the highest quality solutions and services.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#ESDProtection #SD60C #Leiditech #TVSdiodes #ElectronicsDesign #RS485 #CANBus #SignalIntegrity #EMCSolutions #IndustrialAutomation #AutomotiveElectronics #HighVoltageProtection #TechInnovation #ComponentDesign #CircuitProtection #IoT

0 notes

Text

#netboon#HLF400CoaxCable#NtoTNCConnector#LowLossRF#50OhmCable#IndustrialRF#WirelessCable#RFAntennaCable#NetworkingCable#RFConnector#TNCConnector#NConnector#CoaxialAssembly#RFSignalCable#WiFiExtensionCable#NetboonCable#CoaxCableIndia#HamRadioCable

0 notes

Text

RF Cable Assemblies and Jumpers Market: Revenue Forecast by Frequency Range and Application 2025-2032

MARKET INSIGHTS

The global RF Cable Assemblies and Jumpers Market size was valued at US$ 2,170 million in 2024 and is projected to reach US$ 3,420 million by 2032, at a CAGR of 6.7% during the forecast period 2025-2032.

RF cable assemblies and jumpers are critical components used for transmitting high-frequency signals in various applications. These assemblies consist of coaxial cables terminated with connectors, ensuring minimal signal loss and interference. They play a vital role in telecommunications, defense systems, medical equipment, and automotive electronics, supporting seamless connectivity in complex RF environments.

The market growth is driven by increasing demand for high-speed data transmission, expansion of 5G networks, and rising investments in defense communication systems. Furthermore, the automotive sector's shift toward connected vehicles and advanced driver-assistance systems (ADAS) is creating new opportunities. Key players such as TE Connectivity Ltd, Amphenol RF, and Molex LLC are expanding their product portfolios to cater to evolving industry needs, further fueling market expansion.

MARKET DYNAMICS

MARKET DRIVERS

Proliferation of 5G Networks to Accelerate RF Cable Assemblies Demand

The global rollout of 5G infrastructure represents the most significant driver for RF cable assemblies and jumpers. With telecom operators worldwide investing over $300 billion annually in 5G deployments, the need for high-frequency, low-loss coaxial connections has surged dramatically. These specialized cables must maintain signal integrity at millimeter wave frequencies while withstanding environmental stressors. The transition to 5G Standalone networks particularly benefits semi-rigid cable assemblies which demonstrate superior performance in base station RRUs and massive MIMO antenna configurations. Furthermore, small cell densification projects increasingly utilize ultra-flexible jumper cables to accommodate tight installation spaces in urban environments.

Defense Modernization Programs Driving Military-grade RF Connectivity Solutions

Global defense expenditures exceeding $2 trillion annually continue to fuel demand for ruggedized RF interconnect solutions. Modern electronic warfare systems, satellite communications equipment, and radar installations require cable assemblies that maintain strict impedance matching while enduring extreme temperatures, vibrations, and electromagnetic interference. Recent contracts illustrate this trend, including multi-year procurement programs for military aircraft upgrades and naval communication systems upgrades. Phase array radars particularly benefit from emerging lightweight coaxial designs that reduce payload while maintaining GHz-range performance. The shift towards software-defined radios across NATO allied forces further multiplies the need for broadband RF interconnection capabilities.

MARKET RESTRAINTS

Commoditization Pressures in Low-Frequency Applications Constrain Margins

While high-performance RF interconnects command premium pricing, substantial portions of the market face intensifying price competition. The sub-6GHz commercial telecom segment has seen average selling prices decline approximately 8% annually as manufacturers standardize components and automate production. This commoditization particularly impacts legacy connector types and basic coaxial cables where technical differentiation proves challenging. Original equipment manufacturers increasingly consolidate suppliers, leveraging volume purchasing to extract cost concessions. Additionally, the rise of generic connector compatibility specifications allows lower-cost alternatives to penetrate traditionally brand-loyal market segments.

Material Cost Volatility Disrupts Supply Chain Predictability

RF cable assemblies incorporate precious metals and specialized materials that exhibit significant price fluctuation. Silver-plated conductors and PTFE dielectrics have experienced 30-45% cost variations over recent procurement cycles, complicating long-term pricing strategies. The industry's reliance on specific rare earth elements for high-performance shielding compounds further exacerbates supply vulnerabilities. These material challenges intersect with labor shortages in precision assembly operations, where experienced technicians command premium wages to maintain stringent impedance tolerances. Together, these factors compress profitability for standard product lines while increasing working capital requirements for inventory buffers.

MARKET OPPORTUNITIES

Emerging mmWave and THz Applications Open New Frontiers

The evolution toward higher frequency bands creates substantial opportunities for innovative interconnect solutions. Automotive radar systems operating at 77GHz require specialized cable assemblies maintaining low insertion loss despite constant vibration exposure. Similarly, emerging terahertz imaging applications in security screening and medical diagnostics drive demand for novel waveguide transition technologies. The satellite industry's transition to low-earth orbit constellations presents another high-growth segment, where radiation-hardened RF jumpers must withstand extreme thermal cycling while minimizing passive intermodulation effects. These applications command substantial price premiums, with mmWave assemblies frequently achieving 3-5x the unit pricing of conventional microwave components.

Automotive RF Integration Creates Parallel Growth Channels

Modern vehicles incorporate over 40 separate RF subsystems, from infotainment to collision avoidance radars, creating compound annual growth exceeding 12% for automotive-grade interconnects. The transition to autonomous driving architectures particularly benefits shielded cable assemblies that minimize electromagnetic interference between sensors. Emerging vehicle-to-everything (V2X) communication standards further expand the addressable market, requiring robust RF connectivity solutions that endure harsh underhood environments. Tier 1 suppliers increasingly partner with interconnect specialists to co-develop application-specific solutions, creating lucrative design-win opportunities with extended product lifecycles.

MARKET CHALLENGES

Precision Manufacturing Requirements Limit Production Scalability

High-performance RF interconnects demand exacting manufacturing tolerances often measured in microns, creating substantial production challenges. Achieving consistent impedance matching across production lots requires sophisticated process controls and 100% electrical testing, which limits throughput efficiencies. The industry faces particular difficulties in scaling production of phase-stable cables for phased array systems, where even minor variations in dielectric concentricity degrade system performance. These constraints become more pronounced as operating frequencies ascend beyond 40GHz, where traditional connector interfaces approach practical physical limitations.

Design Complexity Increases Time-to-Market Pressures

Developing application-specific RF interconnect solutions requires extensive electromagnetic simulation and prototyping cycles. The validation process for aerospace-grade components frequently exceeds 18 months due to rigorous qualification testing for vibration, temperature extremes, and outgassing performance. This extended development timeline conflicts with commercial sector demands for rapid product iterations, particularly in consumer electronics and IoT applications. Manufacturers must balance customization capabilities against standardization benefits, navigating intricate tradeoffs between performance, reliability, and cost targets across diverse market verticals.

RF CABLE ASSEMBLIES AND JUMPERS MARKET TRENDS

5G Network Expansion Driving Demand for High-Performance RF Cable Assemblies

The global rollout of 5G infrastructure is significantly boosting the RF Cable Assemblies and Jumpers market, with demand expected to grow at a CAGR of 7-9% through 2032. These components are critical for maintaining signal integrity in high-frequency applications, particularly in base stations and small cell deployments. The shift toward millimeter-wave (mmWave) frequencies in 5G networks has particularly increased demand for low-loss coaxial cables with frequencies exceeding 40 GHz. Leading manufacturers are responding with innovations in dielectric materials and shielding technologies to minimize insertion loss, which can exceed 3 dB/meter in conventional cables at these frequencies.

Other Trends

Automotive Radar and ADAS Applications

Advanced Driver Assistance Systems (ADAS) and autonomous vehicle technologies are creating substantial demand for ruggedized RF cable assemblies capable of withstanding harsh automotive environments. The typical automotive radar system now utilizes 12-24 GHz or 77 GHz frequencies requiring specialized cable solutions. Market growth in this segment is projected at 11-13% annually, outpacing the broader market due to increasing vehicle electrification and regulatory mandates for safety systems.

Miniaturization Trend in Connectivity Solutions

The electronics industry's push toward smaller form factors is driving innovation in micro-miniature RF connectors and ultra-thin coaxial cables. Products like 1.0 mm and 0.8 mm coaxial connectors now comprise nearly 30% of new designs in consumer electronics and IoT devices. However, this miniaturization presents technical challenges - insertion loss increases by approximately 15% for every 0.2 mm reduction in connector size, requiring advanced materials engineering to mitigate performance degradation.

Defense Modernization Programs Spurring Growth

Military applications continue to account for 25-30% of the high-end RF cable assemblies market, driven by global defense spending exceeding $2 trillion annually. Modern radar systems, electronic warfare platforms, and satellite communications require specialized cable solutions with extended temperature ranges (-55°C to +200°C) and enhanced EMI/RFI shielding. The growing adoption of phased array antennas is particularly demanding flexible yet durable jumper solutions capable of handling complex signal routing in confined spaces.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Focus on Technological Innovation to Maintain Competitive Edge

The global RF Cable Assemblies and Jumpers market demonstrates a moderately consolidated structure, with established players accounting for significant market share while smaller competitors carve out specialized niches. TE Connectivity Ltd emerges as a dominant force, leveraging its extensive product portfolio and manufacturing footprint across North America, Europe, and Asia-Pacific. The company's market leadership stems from continuous R&D investments and strategic acquisitions in high-frequency connectivity solutions.

Radiall GmbH and Aptiv Plc maintain strong positions in the aerospace and automotive sectors respectively, with their specialized RF assembly solutions for mission-critical applications. These companies benefit from long-standing relationships with defense contractors and automotive OEMs, enabling stable revenue streams even during market fluctuations.

Meanwhile, WL Gore & Associates differentiates itself through proprietary ePTFE cable technology, particularly in high-reliability medical and military applications. The company's focus on premium, high-performance solutions allows it to command price premiums in niche segments.

Recent industry developments show accelerating competition in 5G infrastructure components, with Molex LLC and Amphenol RF making significant strides in low-loss millimeter wave assemblies. Both companies have launched new product lines specifically targeting telecom base stations and small cell deployments, capitalizing on the global 5G rollout.

List of Key RF Cable Assemblies and Jumpers Manufacturers

TE Connectivity Ltd (Switzerland)

Radiall GmbH (France)

Aptiv Plc (Ireland)

Rosenberg GmbH (Germany)

WL Gore & Associates (U.S.)

Lighthorse Technologies, Inc. (U.S.)

Molex LLC (U.S.)

Amphenol RF (U.S.)

Pasternack Enterprises Inc. (U.S.)

Samtec Inc. (U.S.)

Segment Analysis:

By Type

Connectors Segment Leads the Market Due to High Demand in Telecom and Defense Applications

The market is segmented based on type into:

Connector

Plug

Switch

Other

By Application

IT & Telecommunication Dominates Market Share Owing to 5G Network Expansion

The market is segmented based on application into:

IT and Telecommunication

Defense

Automobile

Healthcare

Others

By Frequency Range

High Frequency Segment Gains Traction with Increasing Demand for High-Speed Data Transmission

The market is segmented based on frequency range into:

Low Frequency

Medium Frequency

High Frequency

Very High Frequency

Regional Analysis: RF Cable Assemblies and Jumpers Market

North America The North American market for RF cable assemblies and jumpers is predominantly driven by advancements in 5G infrastructure, defense modernization programs, and growing demand for high-speed connectivity in IT & telecommunications. The U.S. holds the largest share, supported by government investments in aerospace and defense, estimated at $842 billion for FY2024. Major players like TE Connectivity Ltd and Amphenol RF dominate the market due to their robust supply chains and R&D capabilities. However, stringent regulatory standards for RF components and supply chain disruptions pose challenges for manufacturers. The shift toward miniaturized, high-frequency connectors for IoT and autonomous vehicles further fuels regional demand.

Europe Europe’s market is characterized by strong adoption of RF cable assemblies in automotive and healthcare sectors, particularly in Germany and France. The EU’s focus on 5G deployment under the Digital Decade Policy Programme accelerates demand for low-loss, high-performance RF solutions. Regulations like RoHS and REACH mandate eco-friendly materials for cables, pushing manufacturers to innovate. Companies like Radiall GmbH and Rosenberg GmbH lead with specialized solutions for industrial IoT and medical devices. However, high production costs and competition from Asia-based suppliers restrain growth. The region’s emphasis on renewable energy integration also opens new opportunities for RF jumpers in smart grid applications.

Asia-Pacific Asia-Pacific is the fastest-growing market, with China accounting for over 40% of global RF cable assembly demand due to telecom expansions and defense investments. India and Japan follow, spurred by local manufacturing initiatives (e.g., India’s PLI scheme) and increasing 5G adoption. Low-cost production hubs in Southeast Asia attract global players like Molex LLC and Samtec Inc., though price sensitivity limits premium product penetration. The rise of smart cities and EV infrastructure further augments market potential. However, intellectual property concerns and fluctuating raw material costs remain key challenges.

South America This region shows moderate growth, driven by Brazil’s telecom sector and Argentina’s aerospace projects. The lack of domestic manufacturing forces reliance on imports, creating opportunities for U.S. and European suppliers. Economic instability and currency volatility hinder large-scale investments, but rising demand for broadband connectivity in urban areas sustains market progress. Local governments are gradually improving infrastructure, yet regulatory bottlenecks slow adoption of advanced RF technologies.

Middle East & Africa The MEA market is emerging, with growth concentrated in GCC countries due to oil & gas sector digitization and defense spending. The UAE and Saudi Arabia lead in smart city projects, boosting demand for RF assemblies in surveillance and IoT networks. Africa’s expansion is slower but shows promise with submarine cable projects enhancing connectivity. Challenges include limited technical expertise and reliance on foreign suppliers. Long-term potential hinges on infrastructure development and economic diversification.

Report Scope

This market research report provides a comprehensive analysis of the global and regional RF Cable Assemblies and Jumpers markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments (in KM), and market value across major regions and segments. The global market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Connector, Plug, Switch, Others), application (IT & Telecommunication, Defense, Automobile, Healthcare), and end-user industry to identify high-growth segments.