#Automatic Paper Cup Making Machine Manufacturers

Explore tagged Tumblr posts

Text

How can paper bags help businesses comply with India’s plastic ban?

As sustainability becomes a global priority, India has taken bold steps to reduce plastic pollution by implementing a nationwide ban on single-use plastics. This move directly impacts retailers, manufacturers, and businesses that rely on plastic packaging. For businesses looking to stay compliant and environmentally responsible, paper bags offer a simple, cost-effective, and sustainable alternative.

At Prakash Machineries Pvt. Ltd, we manufacture high-quality paper bag-making machines that empower businesses to transition away from plastic and embrace eco-friendly packaging. In this article, we explore how paper bags can help businesses comply with India’s plastic ban while also boosting brand value and operational efficiency.

Understanding India’s Plastic Ban

India’s fight against plastic pollution has been ongoing for years, but in July 2022, the country officially banned the manufacture, import, stocking, distribution, sale, and use of identified single-use plastic items, including:

Plastic carry bags (below 120 microns, now fully banned)

Plastic plates, cups, cutlery, straws

Packaging films and wrappers used in FMCG goods

Non-compliance can lead to heavy penalties, including fines and closure notices for repeat offenders. As a result, businesses are under pressure to find compliant, sustainable alternatives quickly.

Why Paper Bags Are a Smart Solution

Paper bags have emerged as one of the most viable alternatives to plastic carry bags. Here’s why they are an ideal choice:

1. Legal Compliance

Paper bags are 100% legal and compliant with India’s environmental regulations. Since they are biodegradable, recyclable, and non-toxic, they pose no threat to the environment or to human health.

By switching to paper bags, businesses can:

Avoid legal risks

Continue packaging and selling without interruption

Improve their standing with regulatory authorities

2. Eco-Friendly and Biodegradable

Paper bags decompose naturally within weeks or months, unlike plastic, which can take up to 1,000 years. They don’t pollute oceans, harm wildlife, or clog drains—making them a responsible and environment-friendly choice.

Using paper bags helps businesses:

Reduce their carbon footprint

Contribute to India’s Swachh Bharat (Clean India) mission

Appeal to eco-conscious consumers

3. Customizable and Brand-Friendly

Paper bags can be easily customized with your logo, brand colors, and messaging, unlike plastic bags that have printing limitations. They offer a premium and stylish look that resonates well with modern, environmentally aware consumers.

At Prakash Machineries Pvt. Ltd we help clients create custom printed bags using our high-speed flex0 or offset printing machines integrated with paper bag machines. You can create:

Kraft paper bags with company branding

Colorful shopping bags for retail or fashion

Simple V-bottom bags for groceries or pharmacies

4. Reusable and Durable

With advancements in paper bag design, today’s bags are stronger and more durable. Paper bags made using square bottom or gusseted bag machines can easily carry 3–10 kg, depending on the thickness of paper used.

Benefits for businesses include:

Reduced bag consumption due to reusability

Better customer experience with sturdy packaging

Long-lasting brand visibility when customers reuse bags

5. Cost-Effective at Scale

While the unit cost of paper bags is slightly higher than plastic initially, mass production using automatic paper bag machines can significantly lower costs over time.

With Prakash Machineries Pvt. Ltd high-speed paper bag machines, you can:

Produce thousands of bags per hour

Reduce labor dependency

Control raw material usage efficiently

The result? Lower long-term packaging costs and improved profitability.

Industries Leading the Shift

Several sectors in India have already embraced paper bags to meet compliance and customer demand:

Retail and Fashion Stores: Use branded paper bags for purchases.

Restaurants and Cafes: Deliver takeaways in Kraft paper bags.

Grocery Shops: Replace plastic with recyclable paper bags.

Pharmacies: Pack medicines in V-bottom paper bags.

E-commerce: Use paper-based packaging for eco-friendly shipping.

These early adopters are not only complying with regulations but also building stronger brand loyalty among eco-conscious customers.

How Prakash Machineries Pvt. Ltd Supports This Transition

Prakash Machineries Pvt. Ltd is a leading manufacturer of paper bag making machines in India, with clients in 17+ countries. We offer:

V-bottom and square bottom paper bag machines

Machines with in-line printing and handle attachment options

Training, installation, and post-sale support

Custom configurations for different paper GSMs and bag sizes

Whether you're a packaging manufacturer or a business looking to produce your own bags, we help you make the shift to sustainable packaging easy, scalable, and profitable.

The future of packaging in India is green, clean, and compliant. With the plastic ban now strictly enforced, switching to paper bags is not just an option—it’s a necessity for businesses aiming to stay ahead and avoid penalties.

Paper bags offer a legal, sustainable, and marketable solution that aligns with government policies, environmental goals, and consumer preferences. By investing in paper bag production or sourcing eco-friendly packaging from reliable partners, your business can be future-ready and reputation-strong.

Want to start producing paper bags in-house? Contact Prakash Machineries Pvt. Ltd today to explore our full range of paper bag making machines. Let’s grow your business while protecting the planet.

#paper bag manufacturer#square bottom#v bottom#flexo#paper bag#paper#machine#alien stage#cake#baking#cooking#chris sturniolo#breakfast#delicious#chocolate#dan and phil#critical role

1 note

·

View note

Text

Glass Sealing Machine – A Must-Have for Safe and Spill-Free Beverage Packaging

In the food and beverage industry, hygiene and safe packaging are non-negotiable. Whether you run a tea stall, juice counter, dairy shop, or cold drink outlet, using a Glass Sealing Machine is one of the smartest ways to seal your products safely and attractively. These machines are now widely used across the market to provide clean, spill-proof, and tamper-evident packaging for beverages served in plastic or paper glasses.

What is a Glass Sealing Machine?

A Glass Sealing Machine is a compact, easy-to-use device that seals plastic or paper glasses using a sealing film or foil. The machine applies heat and pressure to stick the film onto the rim of the glass, creating a leak-proof seal. It helps keep the drink safe from spills, dust, and contamination.

Where is a Glass Sealing Machine Used?

These machines are commonly seen in:

✔ Juice shops ✔ Tea & coffee stalls ✔ Bubble tea counters ✔ Dairy shops (for lassi, buttermilk, etc.) ✔ Ice cream & dessert outlets ✔ Small cafés and fast-food joints ✔ Cold drink counters

Key Benefits of Using a Glass Sealing Machine

1. Hygienic Packaging

The sealed glass prevents the drink from coming in contact with air, dust, or germs, ensuring better hygiene for the customer.

2. Leak-Proof and Spill-Free

Perfect for takeaways and deliveries, sealed glasses prevent drinks from spilling, even if carried in bags.

3. Professional Look

Sealed glasses look clean, organized, and appealing. Many businesses use printed sealing films with their logo, promoting their brand with every glass served.

4. Increased Customer Confidence

When customers receive their drinks sealed, it creates a sense of trust and shows your business cares about safety and hygiene.

Types of Glass Sealing Machines

Depending on your business size and daily requirements, you can choose:

- Manual Glass Sealing Machine

A cost-effective option, ideal for small shops and stalls. The operator manually positions the glass and applies the seal.

- Semi-Automatic Glass Sealing Machine

Reduces manual work and increases speed, making it suitable for moderately busy outlets.

- Fully Automatic Glass Sealing Machine

Perfect for high-volume businesses and beverage manufacturers. The process is completely automated for quick and consistent sealing.

Things to Consider Before Buying a Glass Sealing Machine

✔ Glass Size Compatibility: Ensure the machine supports the glass sizes you use. ✔ Build Quality: A good quality, durable machine ensures long life and fewer maintenance issues. ✔ Sealing Film Options: Look for machines that allow custom-branded films for marketing. ✔ Ease of Use: A user-friendly machine saves time and effort for your staff. ✔ Production Capacity: Choose the right machine based on your daily output needs.

Conclusion

A Glass Sealing Machine is a simple yet powerful tool that adds professionalism, hygiene, and safety to your beverage packaging. Whether you run a small tea stall or a busy juice outlet, this machine ensures your drinks are well-packed, presentable, and spill-free. It enhances customer trust and convenience, which ultimately helps your business grow.

0 notes

Text

Paper Cup Manufacturers: An Eco-Friendly Alternative for Sustainable Packaging

Introduction to Paper Cup Manufacturing

Paper cup manufacturers play a crucial role in meeting the growing demand for eco-friendly, disposable food and beverage packaging. With increasing awareness about environmental sustainability and the harmful effects of plastic, paper cups have emerged as a preferred alternative in restaurants, cafes, corporate offices, and events.

Why Choose Paper Cups?

Paper cups are made using food-grade paperboard with a waterproof lining that makes them safe and leak-proof. Leading disposable cup manufacturers use biodegradable and compostable materials, promoting a greener future.

Key Benefits of Paper Cups:

100% recyclable and biodegradable

Lightweight and easy to handle

Hygienic and single-use, preventing contamination

Customizable for branding and promotions

Process Followed by Paper Cup Manufacturers

The paper cup manufacturing process involves multiple quality checks to ensure durability and hygiene. Manufacturers typically follow these steps:

Raw Material Selection: Use of PE-coated or PLA-coated food-grade paperboard

Cutting and Shaping: Automatic machines cut and mold the paper into the desired cup size

Sealing and Lining: Inner coating applied for leak resistance

Quality Testing: Cups undergo leak, strength, and hygiene testing

Packaging: Stacked and packed in eco-friendly packaging materials

Types of Paper Cups Manufactured

Paper cup producers offer a wide variety of products to cater to diverse industries:

Single Wall Paper Cups – Ideal for cold drinks and office use

Double Wall Paper Cups – Suitable for hot beverages like tea and coffee

Ripple Wall Cups – Extra insulation for heat protection

Printed Paper Cups – Custom branding for businesses and events

Industries That Use Paper Cups

Food and beverage outlets

Corporate offices

Hospitals and clinics

Event management companies

Airlines and railway catering services

Conclusion

As demand grows for sustainable and hygienic packaging, paper cup manufacturers are increasingly vital to reducing plastic pollution. By using biodegradable materials and advanced production techniques, they offer an eco-conscious solution for modern businesses.

To locate “Paper Cup Manufacturers” effortlessly, download the Justdial app (JD App). Simply search “Paper Cup Manufacturers” within the app to discover nearby dealers/outlets and access detailed information about their offerings.

0 notes

Text

Spinaroo Commercial IPO: Price, GMP, And Date

SME IPO

Spinaroo Commercial IPO-Complete Overview

Spinaroo Commercial IPO under the SME IPO category is a fixed price issue of Rs.10.17 Cr by Spinaroo Commercial Limited which was incorporated on August 17, 2012. The company has been involved with lots in the manufacture of aluminum foil containers, aluminum home foil, paper cups, paper plates, and paper bowls, along with semi-prepared materials for paper cups, mainly paper coating, printing, and blanking.

These comprise a whole array of additional machinery for paper cups examples are high-speed paper cup-making machines, flexo printing machines, and automatic roll die-cutting machines. Thus, they offer full-blown end-to-end support.

The company has in stock numerous high-quality products manufactured from super-quality raw materials, which are ensured under expert guidance and intervention, into premier-performing but competitively priced, timely deliveries made to the specifications of clients.

Business Segment

Manufacturing: It manufactures aluminum home foil and containers. Uses quality-based materials to produce items, such as cups, plates, and bowls, all under the paper products category meant for food. Also sells semi-finished raw materials processed and modified.

Trading: It produces aluminum foils and containers, as well as paper products such as high-quality, food-grade materials from which it obtains semi-finished raw materials intended for paper cups, plates, and bowls after appropriate processing and modification.

Job Work: The specific job work services offered by this company are processing, shaping, and printing on paper products. The coating applied is also to the customer's specification using food-grade materials.

1 note

·

View note

Text

Paper Cup-Making Machine in Delhi NCR

Over the past few years, the packaging industry has undergone tremendous changes, as people have increasingly sought to switch to green alternatives. One such innovation that has revolutionized the beverage and food packaging industry is the paper cup-making machine. These machines have become a necessity in manufacturing high-quality, sustainable paper cups for fast food restaurants, event catering services, and others.

As businesses in cities like Delhi, Noida, Gurgaon, and surrounding areas strive to reduce their environmental footprint, the demand for paper cups has surged, alongside the need for efficient and reliable manufacturing processes. In this blog, we’ll delve into how paper cup-making machines are revolutionizing the industry and why they are a game-changer for businesses in Delhi and beyond.

The Growing Demand for Paper Cups

As a result of this global trend toward sustainable packaging, paper cups are fast becoming a more popular option compared to plastic cups. Paper cups are biodegradable and recyclable and come from renewable resources, so they are more environmentally friendly to use both by consumers and companies.

Paper cups have become in great demand in Delhi, Noida, Gurgaon, and surrounding areas due to increased environmental awareness and stringent rules on plastic usage. This demand has led manufacturers to invest in paper cup-making machines to meet the growing demands of the food and beverage industry.

Benefits of Paper Cup-Making Machines

1. Sustainability

The most important advantage of paper cup-making machines is that they produce eco-friendly products. The use of renewable materials like paperboard, ensuring that paper cups are biodegradable, reduces the impact of businesses on the environment. This is very important in cities like Delhi, where plastic waste and pollution have become a major concern.

With paper cup-making machines, manufacturers can produce high volumes of paper cups with minimal waste, thus making the production process more sustainable and efficient.

2. High-Speed Production

Speed and efficiency are very important in the fast world of food and beverage services. Paper cup-making machines are designed to work at a high speed to produce thousands of cups in a short time. This makes them ideal for high-volume production environments in Delhi, Noida, Gurgaon, and surrounding regions where demand for paper cups is high.

These machines are furnished with automatic controls and high technology, which provides for continuous and smooth production without any downtime; hence it is enhanced in terms of productivity.

3. Customization

Modern paper cup-making machines offer the flexibility of many variants in design options. Be it the size, shape, or design of the paper cups, the versatility of machines offered at reasonable prices to manufacturers helps cater to the specific needs of customers. This is highly desirable for businesses operating in highly competitive markets such as Delhi and Gurgaon.

Custom branding is the most popular in the food and beverage industry, where companies use branded paper cups to market their brands. The machine can hold a variety of printing options, including flexo and offset printing, to guarantee the most colorful and high-quality designs.

4. Cost-Effectiveness

While the initial investment in paper cup-making machines seems huge, they help in saving long-term costs through efficient production. The mass production of quality cups in a short period reduces labor and material costs. Additionally, the high-speed production capability helps businesses in Delhi and surrounding areas meet demand without compromising on quality.

5. Consistency and Quality

Manual manufacturing of paper cups results in a variable size, shape, and quality. Paper cup-making machines, on the other hand, produce each cup with precision to ensure uniformity and consistent quality. The high technology involved in these machines minimizes human error, and quality control measures are incorporated into the production line to ensure that only the best quality reaches the market.

Key Features of Paper Cup-Making Machines

When choosing a paper cup-making machine, businesses operating in Delhi, Noida, Gurgaon, and surrounding areas need to look out for the following key features that will enhance production:

1. Advanced Automation

The paper cup-making machine of today is very automated, hence, it cuts down on human interference and produces a better quality output. In automated systems, there is more accuracy in forming the cup; therefore, an appropriate amount of material is consumed in each unit.

2. Durability

Given the high-volume production environment, durability is a critical feature. Paper cup-making machines are designed to withstand continuous use in production facilities. The use of high-quality materials ensures the machines last for years, offering a solid return on investment.

3. Energy Efficiency

Energy-efficient machines help reduce operation costs, especially for businesses that involve high-scale productions. Paper cup-making machines designed with energy efficiency capabilities can limit electricity consumption even when performance levels are maintained and will be quite appropriate for producers in Delhi and Gurgaon.

4. Flexible Production Capabilities

Some of the high-tech machines can make various sizes of paper cups, from espresso to large beverage cups. Flexibility in the size of production is essential for businesses catering to different needs of customers in the food service or event management industry.

5. Ease of Operation

User-friendly interfaces and easy-to-understand controls are essential for smooth running. Machines are designed to check human error minimally by making the production process as simple as possible. The training for the operators is minimal, and thus businesses in Noida and Delhi can hit the ground running.

The Role of Paper Cup-Making Machines in Sustainable Packaging

Sustainability is the buzzword in today’s packaging revolution, and paper cup-making machines are crucial in helping businesses adopt green practices. Consumers and businesses are now looking for biodegradable and recyclable packaging materials because of the increasing awareness of the impact of plastic waste on the environment.

It is, therefore, the most responsible and effective decision for areas such as Delhi, where pollution levels are so high that they impact the environment significantly. With the invention of paper cup-making machines, companies can now cater to the need for sustainable packaging without compromising on quality or efficiency.

Large volumes of eco-friendly paper cups produced also help businesses comply with local regulations concerning plastic usage. The Indian government has put various bans and restrictions on single-use plastics, so the adoption of paper cups has become imperative for businesses in Delhi, Gurgaon, and Noida.

Why Choose Paper Cup-Making Machines in Delhi and Nearby Areas?

1. Proximity to Major Markets

Some of India’s largest and most influential food and beverage businesses are found in Delhi, Noida, Gurgaon, and other nearby cities. Manufacturers can easily meet the growing demand for eco-friendly cups from these major markets by investing in paper cup-making machines.

2. Support for Green Initiatives

The Delhi government, along with other local authorities, is now actively promoting sustainable manufacturing practices. Paper cup-making machines allow businesses to meet these green goals, enjoy tax benefits, and be seen as environmentally friendly organizations.

3. Availability of Skilled Labor

Delhi, Noida, and Gurgaon are places where skilled labor is available. Thus, making the operation of paper cup-making machines easier for the manufacturers. The local technicians and operators know how to keep the machine up and running without extended downtime for the businesses.

Conclusion

Paper cup-making machines are revolutionizing the packaging industry by providing businesses in Delhi, Noida, Gurgaon, and beyond with a sustainable, efficient, and cost-effective solution for packaging beverages. These machines not only respond to the growing demand for green products but also improve production efficiency, cut costs, and enhance brand image. With increasing environmental concerns, the use of paper cup-making machines is a step in the right direction towards finding more sustainable and responsible packaging solutions.

FAQs

Q1: Can paper cup-making machines produce different sizes of cups?Yes, modern paper cup-making machines are capable of producing various sizes of cups, from small espresso cups to larger beverage cups, depending on the business’s requirements.

Q2: Are paper cups made from these machines biodegradable?Yes, paper cups produced by paper cup-making machines are biodegradable, making them a sustainable alternative to plastic cups.

Q3: How fast can a paper cup-making machine produce cups?Depending on the machine’s model, it can produce several thousand cups per hour, making it ideal for high-volume production environments.

Q4: Is maintenance expensive for paper cup-making machines?Maintenance costs are relatively low for paper cup-making machines, especially if they are regularly serviced by skilled technicians in Delhi, Noida, or Gurgaon.

Q5: Can I print custom designs on paper cups?Yes, paper cup-making machines allow for custom branding and printing, enabling businesses to design cups with their logos or special designs.

0 notes

Text

Paper Cup Making Machine: Arya Industries

Arya Industries has long been at the forefront of the paper cup making machine industry. Established with a vision to revolutionize the production of disposable paper cups, Arya Industries has grown to become the industry leader, known for its innovation, quality, and commitment to sustainability

Vision and Mission

From the outset, Arya Industries has been driven by a clear vision: to become the leading provider of high-quality, eco-friendly paper cup making machines. The company's mission revolves around innovation, customer satisfaction, and sustainability. By continuously improving its technology and processes, Arya Industries aims to provide its customers with the best possible solutions while minimizing environmental impact.

Technological Innovations

Evolution of Paper Cup Making Machines

The journey of Arya Industries is marked by continuous technological advancements. The early models of paper cup making machines were manual and required significant human intervention. However, recognizing the potential of automation, Arya Industries invested heavily in research and development. This investment paid off with the introduction of semi-automatic and eventually fully automatic paper cup making machines.

Key Features of Arya Industries' Machines

High Efficiency: Arya Industries' machines are designed for high-speed production, capable of producing thousands of paper cups per hour. This efficiency helps businesses meet large-scale demands without compromising on quality.

Durability: Built with robust materials and advanced engineering, Arya Industries' machines are known for their durability and long operational life. This reliability translates to lower maintenance costs and reduced downtime.

Precision and Quality: The machines are equipped with precision engineering and advanced sensors to ensure that every cup produced meets the highest quality standards. This consistency is crucial for businesses that prioritize product quality.

Eco-Friendly Design: Arya Industries places a strong emphasis on sustainability. The machines are designed to minimize waste and energy consumption, aligning with global trends towards eco-friendly manufacturing practices.

User-Friendly Interface: Understanding the diverse needs of its clientele, Arya Industries ensures that its machines come with intuitive interfaces that are easy to operate, even for individuals with minimal technical expertise.

Market Leadership

Dominance in the Industry

Arya Industries' commitment to innovation and quality has established it as the market leader in the paper cup making machine industry. The company enjoys a significant market share, with its machines being used by leading paper cup manufacturers around the world.

Customer-Centric Approach

One of the key factors behind Arya Industries' success is its customer-centric approach. The company places a strong emphasis on understanding the unique needs of its customers and providing tailored solutions. This approach has helped Arya Industries build long-lasting relationships with its clients, many of whom are repeat customers.

Global Presence

Arya Industries has a strong global presence, with its machines being exported to numerous countries. The company's international reach is supported by a network of distributors and service centers, ensuring that customers receive timely support and maintenance services regardless of their location.

Sustainability and Environmental Impact

Commitment to Eco-Friendly Practices

Sustainability is a core value at Arya Industries. The company is committed to developing machines that are not only efficient but also environmentally friendly. This commitment is reflected in several aspects of its operations:

Energy Efficiency: Arya Industries' machines are designed to consume less energy, reducing the carbon footprint of the production process.

Waste Reduction: The company employs advanced manufacturing techniques to minimize waste during the production of paper cups. This includes optimizing the use of raw materials and recycling any leftover materials.

Biodegradable Materials: Arya Industries actively promotes the use of biodegradable and compostable materials for paper cup production, aligning with global efforts to reduce plastic waste.

Corporate Social Responsibility

Beyond its products, Arya Industries is also involved in various initiatives aimed at promoting sustainability and supporting local communities. These initiatives include:

Green Manufacturing Practices: The company has implemented green manufacturing practices across its production facilities, including the use of renewable energy sources and water conservation measures.

Community Engagement: Arya Industries engages with local communities through various programs, including educational initiatives and environmental conservation projects.

Employee Welfare: The company prioritizes the well-being of its employees, providing a safe and inclusive work environment and promoting continuous learning and development.

Future Directions

Innovation and R&D

Arya Industries remains committed to innovation, with ongoing investments in research and development. The company's R&D team is constantly exploring new technologies and processes to enhance the performance and sustainability of its machines. Some areas of focus include:

Advanced Automation: Developing next-generation machines with enhanced automation capabilities, including artificial intelligence and machine learning, to further improve efficiency and reduce human intervention.

New Materials: Researching and developing new materials that are more sustainable and eco-friendly, including plant-based and recycled materials.

Smart Manufacturing: Implementing smart manufacturing technologies, such as the Internet of Things (IoT) and data analytics, to optimize production processes and improve overall efficiency.

Market Expansion

Arya Industries aims to expand its market presence by entering new geographic regions and exploring untapped markets. The company is also looking to diversify its product portfolio to include other types of disposable paper products, leveraging its expertise in paper cup making machinery.

Strategic Partnerships

To drive growth and innovation, Arya Industries is actively seeking strategic partnerships with other industry leaders, research institutions, and technology providers. These partnerships will enable the company to stay ahead of market trends and continue delivering cutting-edge solutions to its customers.

Conclusion

Arya Industries' journey from a small startup to the leading provider of paper cup making machines is a testament to its commitment to innovation, quality, and sustainability. With a strong focus on customer satisfaction and a vision for a greener future, Arya Industries is well-positioned to lead the industry for years to come. As the company continues to evolve and expand, it remains dedicated to providing the best possible solutions for its customers while making a positive impact on the environment.

Visit us: https://aryaindustries.co/

0 notes

Text

Elevating Your Egg Business: The Game-Changing Power of Egg Tray Making Machines

In the realm of modern business, adaptability and innovation are key to sustained success.

In the realm of modern business, adaptability and innovation are key to sustained success. The egg tray making machine stands as a testament to this principle, a versatile device that has evolved to meet diverse market demands. Originally designed for crafting egg trays, its applications have expanded to encompass storage solutions for items as varied as shoes, coffee cups, and fruits. As market demands continue to shift, the egg tray making machine China has undergone various iterations to cater to specific investor needs, including automatic, semi-automatic, and manual models. Among these, the automatic model, specifically the mechanical design, has emerged as a game-changer. Let’s delve into the features and benefits of this remarkable innovation that could significantly boost your business.

Efficiency in Operations: At the forefront of the automatic egg tray machine's advantages lies its self-sufficient operational system. This eliminates the need for additional expenditures on manual labor for overseeing the process, resulting in both enhanced efficiency and reduced operational costs. With the capacity to yield up to 12,000 egg trays per hour, this model caters to high-volume manufacturers, making it a cost-effective choice. Moreover, its optimal speed contributes to lower fuel consumption, a critical factor in a sector often impacted by energy expenses.

Expansive Market Opportunities: Eggs, a staple in diets worldwide, enjoy a consistent demand. This demand has fostered increased poultry production, generating a need for efficient transportation and storage solutions, which the egg tray machine fulfills impeccably. Beyond eggs, the machine's applications extend to other products like fruits, enhancing its versatility and market appeal. Opting for the automatic egg tray machine ensures you stay ahead of competitors by offering superior performance, meeting demand, and capitalizing on a lucrative market niche.

Eco-Friendly Manufacturing: In an era marked by environmental consciousness, sustainable manufacturing practices are highly valued. The automatic egg tray machine aligns with this trend by recycling waste paper, mitigating the pollution caused by improper disposal. This eco-friendly approach aligns with evolving consumer preferences for products and services that minimize environmental impact. By adopting this model, you not only enhance your business profitability but also contribute to a greener planet.

Investment in the Future: Choosing the automatic egg tray machine is an investment in the long-term prosperity of your business. While the initial expenditure might be higher compared to other options, the returns in terms of efficiency, production capacity, and market positioning are substantial. Conducting a comprehensive market analysis before investing is crucial to identify the right opportunities and clientele to ensure a thriving business. Take a view at the egg tray manufacturing plant cost.

In conclusion, the automatic egg tray making machine represents a strategic move for entrepreneurs in the manufacturing industry. Its multifaceted benefits, ranging from efficiency gains to environmental sustainability, make it a valuable asset. As the market continues to evolve, this innovation positions your business to thrive and meet the demands of a dynamic consumer landscape. By embracing innovation and adopting eco-friendly practices, you're not only securing business success but also contributing to a brighter, greener future.

0 notes

Link

Nessco India disposable paper making machinery is recognized locally and globally. Leading supplier & exporter of forming machines for paper cups, containers, plates and custom packages.

#Paper Cup Making Machine#Paper Cup Making Machine in India#Paper Cup Machine#Paper Cup Making Machine in Jaipur#paper cup making machine manufacturers#Paper cup making machine cost#paper cup making machine pricing#paper cup making machine supplier#disposable paper cup making machine costing#paper glass making machine manufactures#paper glass making machine supplier#tea coffee cup making machine price#tea coffee cup making machine pricing#high speed paper cup making machine manufactures#high speed paper cup making machine supplier#fully automatic paper cup making machine cost#paper plate making machine costing#paper plate making machine manufactures

1 note

·

View note

Text

How to Start a Paper Cup Manufacturing Business

The usage of paper cups is popular among people due to its several advantages like eco-friendly, convenient, safe, and recyclable. today different types of disposable paper cups are used everywhere in offices, restaurants, hospitals, and schools. Now the market paper cup manufacturing Business is more profitable in India but the paper cup manufacturing business requires a Paper Cup Machine, Spb-750 automatic paper cup machine the best choice in the market for starting new paper cup business.

Market for Paper Cup in India:

The market segment of Paper cups is expected to grow with a compound annual growth rate (CAGR) of 2.72%. It is gaining popularity day-by-day because of its ease of use, biodegradability and other benefits over plastic cups. People have started to understand the importance of sustainability and eco-friendly paper cups. They have begun to realize that paper cups are far better than those plastic ones. Industries have been set up containing the latest technology disposable paper glass machine to manufacture paper cups. Indians have observed the pollution that plastics are causing, and much of the population is shifting towards paper cups. In India, Uttar Pradesh, Maharashtra, Tamil Nadu, West Bengal, and Gujarat are the central states in this market.

Read More at :- https://spb.net.in/startup/business-ideas/paper-cup-manufacturing-business/

#paper cup machine#paper cup making machine#paper cup machine price#paper cup making machine price#paper cup making machine price in kolkata#automatic paper cup machine price#paper cup manufacturing machine#Paper cups Making Machine cost and project Details#paper cup machine price in india#automatic paper cup machine#paper tea cup machine

1 note

·

View note

Text

Tricks to find Paper Bag Making Machine Manufacturers

Looking for Paper Bag Making Machine Manufacturers? Well, Choose Green Tech Industry. We offer high quality Automatic Paper Bag Making Machine, Elite Paper Bag Making Machine, Semi Automatic Paper Bag Making Machine, Paper Cup Making Machine, Paper Plate Making Machine, Screen Printing Making Machine, Eco Stove / Bio Stove / Bio stove Manufacturers, Non Woven Making Machine, and Automatic Paper Bag Machine in Chennai. Refer www.greentechmachine.com

#Paper Bag Making Machine Manufacturers#Paper Bag Machine Manufacturers#Automatic Paper Bag Making Machine Manufacturers#Elite paper bag Making machine manufacturers#Semi automatic paper bag Making machine manufacturers#Paper Plate Making Machine Manufacturers#Paper Cup Making Machine Manufacturers#Screen Printing Making Machine Manufacturers#Eco Stove Making Machine manufacturers#Non Woven bag Making Machine Manufacturers#Automatic Paper Bag Machine Manufacturers#Elite Paper Bag Machine Manufacturers

0 notes

Text

Find Paper Bag Making Machine Manufacturers

Looking for Paper Bag Making Machine Manufacturers? Well, Choose Green Tech Industry. We offer high quality Automatic Paper Bag Making Machine, Elite Paper Bag Making Machine, Semi Automatic Paper Bag Making Machine, Paper Cup Making Machine, Paper Plate Making Machine, Screen Printing Making Machine, Eco Stove / Bio Stove / Bio stove Manufacturers, Non Woven Making Machine, and Automatic Paper Bag Machine in Chennai. Refer www.greentechmachine.com

#Paper Bag Making Machine Manufacturers#Paper Bag Machine Manufacturers#Automatic Paper Bag Making Machine Manufacturers#Elite paper bag Making machine manufacturers#Semi automatic paper bag Making machine manufacturers#Paper Cup Making Machine Manufacturers#Non Woven bag Making Machine Manufacturers#Automatic Paper Bag Machine Manufacturers#Paper Cup Machine Manufacturers#Paper Plate Machine Manufacturers

0 notes

Text

Paper Cup Making Machine in Delhi NCR

The demand for paper cup making machines is growing rapidly due to the increasing shift towards eco-friendly products. Businesses in the food and beverage industry are actively seeking reliable manufacturers who can provide high-quality paper cup making machines. If you’re searching for the best paper cup making machine manufacturer in Delhi NCR, look no further than SBS Machinery. With cutting-edge technology, unmatched quality, and excellent customer service, SBS Machinery stands out as the leading manufacturer in the region.

Importance of Paper Cup-Making Machines

Paper cup making machines are essential for producing disposable cups used in various industries such as food, beverage, and hospitality. These machines offer efficient and hygienic production processes, making them a preferred choice for businesses seeking sustainable solutions. The top paper cup making machine manufacturers in Delhi NCR design their machines to deliver consistent quality, speed, and durability.

Features of High-Quality Paper Cup Making Machines

When selecting the best paper cup-making machine in Delhi NCR, it is essential to consider the following features:

High Production Capacity: Ability to produce a large number of paper cups per hour

Durable Components: Long-lasting materials that ensure machine longevity

Automatic Operation: User-friendly automation for minimal manual intervention

Energy Efficiency: Low power consumption to reduce operating costs

Customizable Cup Sizes: Machines that can produce different cup sizes

Eco-Friendly Production: Use of biodegradable materials

SBS Machinery – Leading Paper Cup Machine Manufacturer in Delhi NCR

SBS Machinery is the top paper cup making machine manufacturer in Delhi NCR, offering state-of-the-art machines to businesses across Delhi NCR, Noida, Ghaziabad, Faridabad, and Gurgaon. With years of experience in the industry, SBS Machinery has built a reputation for providing high-quality paper cup making machines in Delhi NCR that meet international standards.

Why Choose SBS Machinery?

Superior Quality Machines: Built with high-grade raw materials

Advanced Technology: Latest automation features

Customizable Designs: Machines tailored to client specifications

Competitive Pricing: Affordable rates without compromising quality

Timely Delivery: On-time delivery for bulk orders

Excellent After-Sales Support: Comprehensive customer service

Applications of Paper Cup-Making Machines

SBS Machinery’s paper cup making machines in Delhi NCR are widely used in the following industries:

Food and Beverage Outlets

Coffee Shops

Restaurants and Cafes

Catering Services

Corporate Offices

Vending Machines

With a wide range of applications, paper cup making machines by SBS Machinery help businesses meet their packaging needs efficiently.

Customization Options by SBS Machinery

To cater to diverse client needs, SBS Machinery offers customization options, including:

Different Cup Sizes

Speed Variations

Printing Options

Automatic or Semi-Automatic Models

Eco-Friendly Material Compatibility

Custom Branding and Design

These customization options ensure that businesses receive machines tailored to their specific requirements.

Quality Assurance and Certifications

As the best paper cup making machine manufacturer in Delhi NCR, SBS Machinery adheres to strict quality assurance processes and holds certifications such as:

ISO Quality Standards

Environmental Compliance Certifications

Durability and Performance Tests

Customer Satisfaction Benchmarks

All machines undergo rigorous testing to ensure superior performance and durability.

Competitive Pricing and Bulk Orders

SBS Machinery offers wholesale paper cup making machines in Delhi NCR at competitive rates. Whether you’re a small business or a large enterprise, the company provides bulk orders with customized designs and fast delivery services.

Customer Testimonials

Satisfied clients across Delhi NCR, Noida, Ghaziabad, Faridabad, and Gurgaon have praised SBS Machinery for its high-quality paper cup making machines and excellent customer service. Many businesses have reported increased efficiency and profitability after switching to SBS Machinery’s products.

Why SBS Machinery Is the Best Paper Cup Making Machine Manufacturer in Delhi NCR?

Years of Experience in the Packaging Machinery Industry

Commitment to Quality and Innovation

Competitive Pricing for Bulk Orders

Custom Design Solutions

Eco-Friendly Manufacturing Practices

Dedicated Customer Support and After-Sales Service

Conclusion

If you’re searching for the best paper cup making machine manufacturer in Delhi NCR, trust SBS Machinery to deliver high-quality, innovative, and eco-friendly paper cup making machines. With a commitment to quality, customization, and customer satisfaction, we are the preferred choice for businesses across Delhi NCR, Noida, Ghaziabad, Faridabad, and Gurgaon.

For bulk orders, custom solutions, and inquiries, contact SBS Machinery – the leading paper cup making machine manufacturer in Delhi NCR today and experience the difference in product quality and service.

Frequently Asked Questions (FAQs)

1. What makes SBS Machinery the best paper cup making machine manufacturer in Delhi NCR?

SBS Machinery is known for its high-quality machines, innovative technology, and customer satisfaction across Delhi NCR, Noida, Ghaziabad, Faridabad, and Gurgaon.

2. Do you offer customized paper cup making machines?

Yes, we offer customized paper cup making machines in Delhi NCR to meet unique client requirements.

3. What cup sizes can your machines produce?

Our machines can produce various cup sizes ranging from small coffee cups to large beverage cups.

4. How long does delivery take for bulk orders?

We ensure on-time delivery within 7-10 working days across Delhi NCR, Noida, Faridabad, Ghaziabad, and Gurgaon.

5. Are your machines energy-efficient?

Yes, our paper cup-making machines are designed to be energy-efficient with low power consumption.

6. Do you provide after-sales support?

Absolutely! We offer comprehensive after-sales support and maintenance services for all our machines.

7. How can I get a price quote for paper cup making machines in Delhi NCR?

You can contact our customer service team via phone, email, or website to get a customized price quote for paper cup-making machines in Delhi NCR.

0 notes

Text

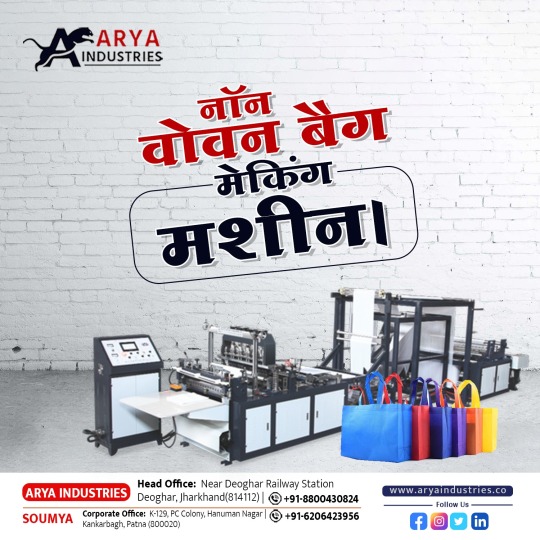

Non Woven Bag Machine in Patna: Arya Industries

Arya Industries stands out as the premier provider of non woven bag making machine Patna, spearheading the industry with its state-of-the-art non-woven bag making machines. As a trusted name in the market, Arya Industries has established itself as the go-to destination for businesses seeking efficient and reliable equipment for their operations.

At the heart of Arya Industries' offerings is its revolutionary non-woven bag making machine in Patna. With a commitment to sustainability and environmental responsibility, these machines are designed to produce high-quality, eco-friendly bags. The company's dedication to innovation is reflected in the precision and efficiency of their non-woven bag machines, making them an indispensable asset for businesses looking to contribute to a greener future.

In addition to non-woven bag machines, Arya Industries caters to a diverse range of industries with specialized equipment. The company boasts a remarkable noodles machine in Patna, addressing the needs of businesses involved in the production of this staple food item. The noodles machine is a testament to Arya Industries' versatility and commitment to meeting the unique demands of different sectors.

Arya Industries further extends its product portfolio to include a comprehensive range of machinery, such as semi-automatic and fully automatic thermocol plate making machines in Patna. These machines are designed to optimize the production process, ensuring efficiency and quality in the manufacturing of thermocol plates. The company's dedication to providing cutting-edge solutions is evident in the advanced features and technology incorporated into these machines.

The Arya Industries lineup also includes agarbatti making machines and paper cup making machines, showcasing the company's commitment to serving a wide spectrum of industries. The agarbatti making machines are designed for precision and efficiency in the production of incense sticks, while the paper cup making machines cater to the growing demand for eco-friendly disposable cups.

Arya Industries' non-woven bag machine in Patna has become synonymous with reliability and excellence. The company's commitment to quality extends to its customer service, ensuring that clients receive comprehensive support throughout the purchase and implementation process. As a result, Arya Industries has emerged as a trusted partner for businesses looking to invest in cutting-edge machinery for sustainable and efficient production processes.

Arya Industries is not merely a provider of machinery; it is a catalyst for progress and sustainability in the industrial landscape of Patna. With a diverse range of offerings, including non-woven bag machines, noodles machines, thermocol plate making machines, agarbatti making machines, and paper cup making machines, Arya Industries continues to shape the future of manufacturing in the region.

Visit us: https://www.aryaindustries.co/

#kapoormakingmachineinpatna#oil expailer#paperplatesmachinesinpatna#agarbattimakingmachineinpatna#fullyautomaticthermocolplatemakingmachineinpatna#manualnonwovenbagmakingmachinesinpatna#nonwovenbagmakingmachineinpatna#nonwovenbagmachineinpatna#semiautomaticthermocolplatemakingmachineinpatna#handpresspaperplatemachineinpatna#noodlesmachineinpatna

0 notes

Text

Paper Cups & Plates — Bring Change to the world

Paper cups are used in most places including Restaurants, Weddings & other functions, Hospitals, Commercial establishments, schools, offices, Canteens, and so forth. In comparison to Porcelain, Plastic, Styrofoam & metal cups, Paper cups have distinct advantages. Read more

History

The use of paper cups began in 1907 with Lawrence Luellen’s invention of the Dixie Cup. Paper cups remained the staple for disposable cups until the 1970s when Solo Cups introduced its signature red cup. Today, both paper and plastic cups are ubiquitous.

The disposable cup has come a long way since the first paper cup made its debut a century ago. Both disposable paper and plastic cups offer the convenience of on-the-go consumption without the worry of cleanup. In addition, they help conserve water by eliminating the need for washing/cleaning.

Paper cups were popularized in 1918 during the American influenza epidemic. The cups were used by a large number of people to avoid infections. It was mainly used to promote public hygiene. Although these cups are available in different varieties, the two most common varieties include the cups used for cold drinks such as milk and sodas and cups used for hot beverages such as tea and coffee. These cups are produced from food grade paper board which is laminated with a thin LDPE film.

Scope of Paper and Plastic cups

Extensive changes in the manufacturing of paper and plastic have occurred over the past few decades. Environmental Protection Agency figures indicate that paper manufacturing has increased by nearly 300 percent from 1960 to 2007.

The data for plastics present an even more startling contrast, with plastic generation increasing more than 7,000 percent during the same time period. More than 1 million tons of paper generated in 2007 consisted of paper cups and plates, virtually all of which were discarded. More than 800,000 tons of plastic cups and plates were generated that same year, with most ending up in the trash.

The Disposable Cup

There are many disposable cups that are available in different materials. Plastic, Styrofoam, and paper cups are all good choices when one is on the go. Each one has its advantages and disadvantages; one may be more thermal, whereas one may be more expensive. Another may have a quicker decomposition rate, whereas one doesn’t even biodegrade. Though the cups may serve the same purpose, they are very different.

The first choice when you think of a disposable cup is paper cups. Long ago, there were no drinking fountains in public places. There were only barrels that people had to drink out of using a stationary glass. Lawrence Luellen and Hugh Moore thought this act was unsanitary. They wanted to allow people to drink fresh water freely that was free of germs. Moore and Lullen decided to use paper cups to make clean water available to thirsty people in public which led to the development of the first paper cup in 1907.

Though at first, it seemed like a fluke, paper cups are widely used in almost any situation.

How to Make a Paper Cup

If you are planning to start a paper cup manufacturing business so book an appointment with NESSCO EXPERTS to support you to start your business in the Paper Cup Manufacturing industry. Following are products for small or large scale paper products business.

Disposable Paper Cup Making Machine

Paper Glass Making Machine

Paper Cup Making Machine

Tea Coffee Cup Making Machine

High-Speed Paper Cup Making Machine

Fully Automatic Paper Cup Making Machine

Conclusion: There are many advantages of using paper cups over plastic and Styrofoam. First off, paper is microwave safe. It is made from natural trees with little foreign material added so it is the least complex material we use. Crumpling is easiest with paper, which makes it more compactable. Due to its natural state, it is also the cleanest and fastest biodegradable material of the three. This is very good for the environment.

Content By - nesscoindia.com

#paper cup business profitable#paper cup making business#paper cup machine#paper plate machine#paper cup making machine#paper cup business#fully automatic paper cup making machine#paper cup making machine manufacturers#paper glass making machine#automatic paper plate making machine#paper plate making machines#paper cup manufacturing business plan#cup making machine#paper plate machines#tea cup machine#paper plate making machine manufacturers#paper plate making#paper cups manufacturing machines cost#paper cup manufacturing machine#paper cups and plates making machine#paper cup manufacturing machine cost#paper cup making machine price in india#paper plate making machine companies#paper cup machine manufacturers#paper plate manufacturing process#how to make paper cups#how to start paper plate business

0 notes

Link

Many large, small, and even new budding entrepreneurs have shifted their focus in the paper cup manufacturing business. But the question that arises is- Is the paper cup making machine business profitable? This article enlists some simple steps that can help you to start your paper cup making business from scratch with ease.

#paper cup machine#paper cup making machine#paper cup machine price#paper cup making machine price#paper cup making machine price in kolkata#automatic paper cup machine price#paper cup manufacturing machine#Paper cups Making Machine cost and project Details#paper cup machine price in india#automatic paper cup machine#paper tea cup machine#paper cup machine in Kolkata#paper cup making machine in kolkata#automatic paper cup machine in Kolkata#automatic paper cup making machine in kolkata#business#industry

1 note

·

View note

Text

Fully Automatic Paper Cup Machine in Vadodara - SAS Industry

SAS Industry manufactures the best quality fully automatic paper cup making machines and supply at reasonable cost in Vadodara compared to imported Chinese machines. We always use top-quality Indian branded spares to ensure hassle-free performance with very little downtime. All our machines have good resale value in the used market too. Call us for a quote.

SAS Industry www.saspapercupmachine.com Call: 7708004322 | 7708797117

1 note

·

View note