#Screen Printing Making Machine Manufacturers

Explore tagged Tumblr posts

Text

Start Me Up: 30 years of Windows 95 - @commodorez and @ms-dos5

Okay, last batch of photos from our exhibit, and I wanted to highlight a few details because so much planning and preparation went into making this the ultimate Windows 95 exhibit. And now you all have to hear about it.

You'll note software boxes from both major versions of Windows 95 RTM (Release To Manufacturing, the original version from August 24, 1995): the standalone version "for PCs without Windows", and the Upgrade version "for users of Windows". We used both versions when setting up the machines you see here to show the variety of install types people performed. My grandpa's original set of install floppies was displayed in a little shadowbox, next to a CD version, and a TI 486DX2-66 microprocessor emblazoned with "Designed for Microsoft Windows 95".

The machines on display, from left to right include:

Chicago Beta 73g on a custom Pentium 1 baby AT tower

Windows 95 RTM on an AST Bravo LC 4/66d desktop

Windows 95 RTM on a (broken) Compaq LTE Elite 4/75cx laptop

Windows 95 OSR 1 on an Intertel Pentium 1 tower

Windows 95 OSR 1 on a VTEL Pentium 1 desktop

Windows 95 OSR 2 on a Toshiba Satellite T1960CT laptop

Windows 95 OSR 2 on a Toshiba Libretto 70CT subnotebook

Windows 95 OSR 2 on an IBM Thinkpad 760E laptop

Windows 95 OSR 2.5 on a custom Pentium II tower (Vega)

That's alot of machines that had to be prepared for the exhibit, so for all of them to work (minus the Compaq) was a relief. Something about the trip to NJ rendered the Compaq unstable, and it refused to boot consistently. I have no idea what happened because it failed in like 5 different steps of the process.

The SMC TigerHub TP6 nestled between the Intertel and VTEL served as the network backbone for the exhibit, allowing 6 machines to be connected over twisted pair with all the multicolored network cables. However, problems with PCMCIA drivers on the Thinkpad, and the Compaq being on the blink meant only 5 machines were networked. Vega was sporting a CanoScan FS2710 film scanner connected via SCSI, which I demonstrated like 9 times over the course of the weekend -- including to LGR!

Game controllers were attached to computers where possible, and everything with a sound card had a set of era-appropriate speakers. We even picked out a slew of mid-90s mouse pads, some of which were specifically Windows 95 themed. We had Zip disks, floppy disks, CDs full of software, and basically no extra room on the tables. Almost every machine had a different screensaver, desktop wallpaper, sound scheme, and UI theme, showing just how much was user customizable.

@ms-dos5 made a point to have a variety of versions of Microsoft Office products on the machines present, meaning we had everything from stand-alone copies of Word 95 and Excel 95, thru complete MS Office 95 packages (standard & professional), MS Office 97 (standard & professional), Publisher, Frontpage, & Encarta.

We brought a bunch of important books about 95 too:

The Windows Interface Guidelines for Software Design

Microsoft Windows 95 Resource Kit

Hardware Design Guide for Windows 95

Inside Windows 95 by Adrian King

Just off to the right, stacked on top of some boxes was an Epson LX-300+II dot matrix printer, which we used to create all of the decorative banners, and the computer description cards next to each machine. Fun fact -- those were designed to mimic the format and style of 95's printer test page! We also printed off drawings for a number of visitors, and ended up having more paper jams with the tractor feed mechanism than we had Blue Screen of Death instances.

In fact, we only had 3 BSOD's total, all weekend, one of which was expected, and another was intentional on the part of an attendee.

We also had one guy install some shovelware/garbageware on the AST, which caused all sorts of errors, that was funny!

Thanks for coming along on this ride, both @ms-dos5 and I appreciate everyone taking the time to enjoy our exhibit.

It's now safe to turn off your computer.

VCF East XX

#vcfexx#vcf east xx#vintage computer festival east xx#commodorez goes to vcfexx#windows 95#microsoft windows 95

299 notes

·

View notes

Note

where do you get your stuff manufactured? ☕️

I just got back from my last market for the year, and I’m pumped to get back into drawing. Now let me share some wisdom to artists who are looking into making their own physical merch or sell your art.

Sticker app: I order all my dice cut and sticker sheets from them exclusively now. You get a high volume of stickers for a low price. I’ll order 50 for $35 and get a lot of extras. The stickers waterproof and very durable. Additionally they offer several different types of materials and you can adjust the cut size. However the sticker sheets are somewhat more expensive for a smaller quantity. Their headquarters are based in Sweden, shipping takes roughly 1.5 to 2 weeks. You can order for express shipping.

Cheapest buttons.Net: that’s who they are- haven’t found anyone else with the best bang for their buck yet, especially with such a good quality. The teams are extremely responsive and quick with turnarounds. Plus they’ll send you digital proofs if you ask for them for no additional charge. USA Based.

CatPrints: Many artists I’ve met tend to use this website. The quality of paper is beautiful. Good pricing and offers several options for shipping. If you plan out far enough, I’d recommend taking the longer option in shipping. You can get quoted for my experimental prints if you email their team. USA Based.

Vograce: Highly recommend if you’re starting outThe company is based in China and they offer wide range of products everything at wholesale price. Including packages specifically for Artist alley. I mainly use them for my charms. Quality control is pretty good and the team is quite responsive. Beware there is a large time difference, so responses take a while. Shipping is long but that’s to be expected. I don’t think I’ve waited more than a month for products.

Alibaba: I did a mass order with 30 other artists to get my bags. This was my first time designing and ordering tote bags, I was extremely nervous. Each bag roughly came out to $1.98 per bag. The quality was good and the team sent photo proofs. The bags were unfortunately late, due to holidays in China, unforeseen errors in size templates and shipping fees. So instead of getting them in July, I got them in November. Alibaba is good to use if you have references from other artists or you’re doing a group order.

Using manufactures is a great way to get started. Especially if you’re someone like me who doesn’t have enough space for a fancy printer, cricut machine, button press and screen printer. My little label marker for shipping items barely has room to breathe.

28 notes

·

View notes

Text

Chapter 1: Another Day, Another Drone (Serial Designation N x Reader)

Story Masterlist

You’ve often wondered how you ended up here.

Your desk, a grayed-out island surrounded by a sea of other identical workstations, has seen better days. The once-shiny JCJenson logo etched into the corner is now dulled, just like your enthusiasm for the corporate grind. The monitor flickers faintly as you scroll through endless spreadsheets, each cell populated with strings of numbers that meant nothing to you beyond "quarterly projections" and "acceptable casualty margins."

You sigh, leaning back in your chair. A branded pen rolls off the edge of your desk, landing with a dull clatter on the tile floor. You don’t bother picking it up; there’s a whole box of them in the supply closet.

Today’s tasks are, as always, a parade of monotony. Data entry, damage reports, and the ever-fun task of shredding documents that were marked CONFIDENTIAL in red ink. As you feed another stack of papers into the industrial shredder, you catch snippets of text:

"Serial Designation X-0T1010110 failed containment—Incident resulted in 14 human casualties...""Cost analysis of drone-related repairs versus human replacements..."

You shove the papers in faster, unwilling to linger on the details. It’s easier not to think about what these reports mean.

The office air is stale, recycled a thousand times over by a ventilation system older than most of the drones JCJenson manufactures. The faint hum of machines, the clicking of keyboards, and the distant buzz of the breakroom microwave form a symphony of corporate drudgery.

“Hey, you coming to the quarterly review meeting?” asks a coworker as they pass by, holding a coffee cup with JCJenson’s slogan: "Liability is our passion. Safety is the result."

You force a polite smile. “Wouldn’t miss it.”

They nod and shuffle off, leaving you alone with your spreadsheets and the nagging feeling that, for all the talk of liability and safety, the only thing JCJenson seems passionate about is grinding the life out of its employees.

The meeting is exactly as insufferable as you expected.

You sit near the back of the room, a strategic choice to avoid being called on for any questions or insights. A projection screen at the front displays an overly cheerful PowerPoint deck. Each slide is crammed with pie charts, bar graphs, and buzzwords like "synergy," "stakeholder alignment," and "Q4 optimization goals."

A senior manager drones (ha) on in a monotone voice, flipping through slides as though he’s on autopilot. You catch snippets of phrases:

"Revenue up by 0.3%...""Minimizing liability in high-risk sectors...""Drone maintenance backlog—actionable in Q1..."

Your mind drifts. You find yourself staring at the JCJenson motto printed at the top of every slide: "Liability is our passion. Safety is the result." It’s hard not to read it sarcastically.

Occasionally, someone in the audience offers a nod or a murmured "good point," though it’s doubtful they’re any more engaged than you are. At one point, the manager makes a joke about "cutting-edge safety measures" that earns a smattering of polite chuckles. You don’t even bother to fake it.

Finally, after what feels like an eternity, the meeting adjourns. You’re free—at least for the next five minutes.

You join the shuffle of employees heading to the breakroom, each of you moving with the enthusiasm of a dead lemur. It’s time for the corporate-mandated 5-minute donut break, a peculiar ritual meant to boost morale.

The breakroom smells faintly of coffee and powdered sugar. A box of donuts sits on the counter, already half-empty. You grab one without looking and take a bite, barely tasting it as you lean against the wall. Conversations buzz around you, but none of it registers.

For five blissful minutes, you don’t think about spreadsheets, shredders, or casualty reports. Just you, your donut, and the fleeting illusion of freedom.

The break ends far too soon, as it always does, and you find yourself back at your desk. The donut was mediocre, and the coffee left a bitter aftertaste that matches your mood.

Your next task: complaint emails. A never-ending stream of them floods your inbox, each one angrier than the last. You open the first message, its subject line screaming at you in all caps:

"RE: MY DRONE ATE MY DOG AND BURNED DOWN MY HOUSE."

You sigh, already bracing yourself. Without even reading the body of the email, your fingers move to type the same canned response you’ve sent a hundred times before:

"Dear Valued Customer,We are very sorry to hear you are dissatisfied with the quality of your JCJenson Drone. Please note that our products undergo rigorous testing to meet our industry-leading standards. Your feedback is important to us and has been forwarded to the appropriate department. We appreciate your patience and understanding during this time.Kind regards,JCJenson Customer Care Team."

Click. Send.

The next email isn’t much better:

"RE: WHY DID MY DRONE DROP MY GROCERIES AND ATTACK MY MAILMAN?"

You adjust the response slightly to fit, but the template remains the same. Apologies, assurances, and a whole lot of nothing.

It’s easier not to think about the implications of the complaints—the lives disrupted or ruined by faulty drones. You wonder if the people writing these emails ever get a real response. Probably not.

Your inbox refreshes, and another batch of complaints pours in. You pinch the bridge of your nose, groaning quietly to yourself. It’s just another day at JCJenson, where liability is our passion —and, apparently, yours to deal with.

The clock finally ticks over to quitting time, and you hit send on your last email with the same mechanical motion as every other. The subject line, "RE: MY DRONE LEVELED MY GARDEN SHED AND STOMPED ON MY CAT," disappears into the void of customer complaints, and you let out a long, cathartic sigh.

The weekend. Two days of freedom stretch before you like a mirage, promising peace, quiet, and absolutely no mention of drones, casualties, or pie charts. You’re already halfway to the coat rack, hand reaching for the worn overcoat you’ve had for years—it’s practically a relic of a simpler time.

But just as your fingers brush the fabric, a manila folder slams into your hand.

“Hold it right there, kid!”

You flinch at the unmistakable bark of your boss. He looms over you like a storm cloud, his perpetual scowl deepening as he gestures to the folder. He looks as though he’s about to chew you out but instead slaps you on the back, nearly knocking you off balance.

“Big job, huge job,” he says, his voice booming enough to turn a few heads nearby. “And you’re just the person for it!”

You open your mouth to object, but he barrels on, not giving you a chance to get a word in. “I handpicked you for this assignment because you’re the best we’ve got!” he declares, eyes darting suspiciously over his shoulder.

It’s then that you notice the unmistakable gleam of a golf club sticking out from behind his back. The clinking of clubs gives him away, but he quickly shifts his stance to obscure them further.

“Yeah, yeah,” he continues, waving vaguely at the folder in your hand, “confidential, high-priority, yada yada. Needs to be handled ASAP! ”

“Wait, what is—”

“No time for questions!” he interrupts, already backing toward the elevator. “You’re a pro! I know you’ll knock it outta the park! Or, uh—whatever it is you do!”

The elevator dings, and he practically leaps inside, his golf caddy rattling behind him. He stabs the “close doors” button repeatedly, giving you a quick salute as the doors slide shut.

“Good luck! Don’t mess it up!” he shouts just before disappearing entirely.

You’re left standing there, the manila folder in your hand, the weekend slipping away before your very eyes.

You stand there for a moment, folder in hand, watching the elevator doors close. Then, with a long, resigned sigh, you rub the bridge of your nose and trudge back to your desk. The coat you were so close to grabbing sways mockingly on the rack as you pass it by.

Your chair creaks as you sink back into it, tossing the folder onto the desk in front of you. You take a moment to glare at it, as if sheer willpower might make it vanish. It doesn’t.

With a heavy sense of inevitability, you flip the folder open. The first page stares back at you, black text on crisp paper, but you barely register what it says at first. You’re too busy mourning the weekend plans that had been so rudely snatched away from you.

Plans. Ha. Like you had anything ambitious in mind.

You were going to swing by the pizza place on the way home, pick up a large with extra cheese, and spend the evening on the couch watching the same YouTube documentary about dog breeds you’d already seen five times. The narrator’s voice was comforting, and you always liked the section on Golden Retrievers.

Instead, here you are. Another late night, courtesy of JCJenson. But hey, at least you have all the branded pens you could hope for.

You shake your head and focus on the contents of the folder. It’s filled with the usual corporate nonsense: incident reports, legal disclaimers, and technical diagrams of drones. But halfway through, something unusual catches your eye—a requisition form stamped with bright red ink:

"URGENT: TRANSFER PROTOCOLS FOR TEST UNIT N-0X0010010.”

The rest of the document is dense with jargon, but one thing is clear: you’re being tasked with supervising the “home protocols” of one of the company’s experimental drones. Whatever this is, it’s definitely not a task you’re qualified—or paid enough—for.

You lean back in your chair, staring at the requisition form. “Perfect,” you mutter to yourself, your voice dripping with sarcasm. “There goes my pizza night.”

With a groan, you shove the folder under your arm and head toward the elevators. The requisition form gives you just enough information to know where you’re supposed to go—down to the warehouse. You’d never been there before, but you’ve heard the stories: endless rows of drone parts, the hum of assembly lines, and an atmosphere so heavy with tension it feels like the walls themselves are judging you.

The elevator ride is mercifully short. The doors open to reveal a dimly lit corridor that smells faintly of grease and scorched metal. You follow the signs toward the warehouse, boots clacking on the scuffed floor as the sound of distant machinery grows louder.

Finally, you reach a massive set of double doors, with a glowing neon sign above them that reads:

“AUTHORIZED PERSONNEL ONLY. HARD HATS REQUIRED.We have lawyers. You don’t. Wear a hard hat!”

You stop in your tracks, staring at the sign. A sigh escapes your lips, louder than you intended. Of course. Of course they’d make you turn back after getting all the way down here.

Muttering under your breath about liability paranoia, you retrace your steps to the maintenance closet you’d passed earlier. Sure enough, there’s a stack of faded yellow hard hats sitting on the shelf, each one more battered than the last. You grab the least crusty-looking one, dust it off, and jam it onto your head.

“Safety first,” you grumble, rolling your eyes as you head back toward the warehouse. The hard hat sits awkwardly on your head, just a little too small, the strap digging into your chin. You resist the urge to rip it off as you push open the double doors and step inside.

You push the warehouse doors open, greeted by the echoing hum of machinery and the acrid scent of oil and melted plastic. The place is cavernous, rows of shelves stretching up toward the high ceiling, filled with spare parts, crates, and what looks like a disassembled drone that probably belongs in a museum.

As you step into the loading bay, a familiar voice calls out: “Yo, dude! Wassup?”

Oh no. Not him.

Brad, the shipping manager, waves lazily from behind a forklift. His perpetual slouch and that ridiculous mop of sun-bleached hair make him look like he got lost on his way to a surf competition.

“Boss said you’d be droppin’ by,” he drawls, sauntering toward you like he has all the time in the world. He’s wearing a JCJenson polo shirt that looks one size too big, untucked and wrinkled, like he grabbed it off the floor this morning.

You’ve met Brad a handful of times—mostly at company retreats and awkward holiday parties. He’s the guy who raids the snack table and disappears halfway through the event, leaving you to wonder how anyone can eat an entire bowl of chips by themselves.

“Uh, yeah,” you reply, already exhausted by his energy. “Boss said there was something for me?”

“Totally, totally,” Brad says, gesturing vaguely toward a massive shipping crate sitting on a pallet. The thing is huge, easily taller than you and sealed with bright red warning labels.

“All yours, bro,” Brad says with a lazy grin. “I’ll load it into a truck for ya. Y’know, company wheels. Real sweet ride.”

You glance at the crate, then back at him. “And what am I supposed to do with this, exactly?”

Brad shrugs, leaning against the forklift like he’s in a photoshoot. “No idea, dude. I just move the boxes.”

You resist the urge to rub your temples.

“Oh, heads up, though,” he adds, as if remembering something important. “Truck’s got GPS, so, like, don’t even think about takin’ a joyride. You go anywhere but where the bigwigs said? Boom. Pay docked. Or whatever. Not my problem.”

He says it all with such a lack of enthusiasm that you’re not entirely sure he’s serious.

“Great,” you mutter, staring at the crate as Brad ambles toward the forklift. This was shaping up to be such a fun weekend.

You lean against the wall, arms crossed, watching Brad maneuver the forklift with surprising precision. For someone with the demeanor of a guy who says “radical” unironically, he handles the equipment like he’s been doing it for years.

The massive crate is lifted and gently deposited into the bed of a JCJenson-branded pickup truck—a surprisingly seamless process. You raise an eyebrow, almost impressed, but quickly squash the feeling.

“Boom. Done,” Brad says, hopping down from the forklift and tossing you the keys. You barely catch them, fumbling for a second before they settle in your palm.

“Thanks,” you mutter, making your way toward the driver’s side.

“Enjoy the ride, dude!” Brad calls after you, already heading back to whatever it is he does when no one’s watching. “And don’t forget the GPS thing! Seriously!”

You don’t bother replying, sliding into the truck’s seat and slamming the door shut behind you. The truck smells like stale coffee and something faintly metallic, and the dashboard is cluttered with enough buttons and dials to make you feel like you’re piloting a spaceship.

The keys turn in the ignition, and the engine roars to life. You grip the wheel tightly, eager to get this over with. The sooner you’re home, the sooner you can—well, not relax exactly, but at least pretend to.

As you pull out of the warehouse and onto the road, your mind starts to wander.

This whole thing is ridiculous. Not just the last-minute assignment, but the fact that they’ve shoved you into a task so far outside your job description it’s laughable. You’re customer support. Your life is answering emails about worker drone-related catastrophes and shredding documents that shouldn’t exist in the first place. Testing experimental drones? Ha. Not even close.

You’ve never owned a drone. Not that you’d want to. The thought of one of those unpredictable, clunky metal bipeds stomping around your apartment is enough to make your skin crawl. You’ve read way too many emails about battery failures that turned into small fires or drones deciding to interpret their owner’s sarcastic remarks a little too literally.

“RE: WORKER DRONE SHATTERED MY KITCHEN WINDOW WITH A FLYING PLATE”—that one stuck with you.

And then there were the personality glitches. Oh, the personality glitches. Reading through frantic emails about drones throwing tantrums, refusing to perform tasks, or just standing in the corner staring at the wall for hours… yeah, you didn’t need that kind of energy in your life.

Besides, it’s not like you get paid enough to afford one anyway. Ha.

You glance at the GPS display, following the glowing line that marks your route home. The crate rattles slightly in the back with every bump in the road, a constant reminder of the weekend you didn’t sign up for.

The truck hums along, the city lights blurring past as you make your way toward home.

#murder drones#murder drones x reader#murder drones headcanon#murder drones fanfic#murder drones n#murder drones n x reader#serial designation n

44 notes

·

View notes

Text

as for how i get my patches; i made/make (havent made any in a while) all of them myself using a 6 needle embroidery machine. more needles = more concurrent colors the machine can easily swap through during the patch production. i bought special embroidery software that came with video guides after attending a workshop with the software developer and trying to use free open source embroidery software. the process is essentially the same as making vector art but with more attention paid to layering and then tooling around with things like fabric, thread, and types of stitches. i had experience with hand embroidery and also with hand sewing / using sewing machines and my partner at the time and i were very interested in the idea of making elaborate embroidery. it is in many ways similar in concept / process to screen printing which i have ample experience in, so it did not take me long to pick up and i had all the tools / access i needed to do lots of easy and fun designs. i was able to buy the machine by splitting the cost with someone else and using money i had gotten from my printing business/savings. i honestly recommend not buying a machine (even a small one) and instead out sourcing any embroidery you would want to local digitizers/embroidery companies if you want to do any machine embroidery slightly more complicated than one color directly onto a garment. it takes a long time, it’s very loud, the software required is expensive and nearly impossible to pirate (low demand), and the cost / time investment is very steep. however, i am a freak, and i also consider this my job (or part of it), so i have enjoyed it. there are a lot of people in your town or city, no matter where u are, who are already much more capable and set up to make patches for you than you would be. and they also would love to do it and it’s probably way cheaper than u think. (this also goes for screen printing). the one singular advantage to my set up is that i can make a lot of extremely singular one off patches at my own pace and at my own justified labor/time/monetary investment without having to communicate with anybody else. which is why i primarily think of myself as a artist and not necessarily a clothing embellisher/manufacturer; everything i do takes a lot of fucking time and research.

21 notes

·

View notes

Note

Hey so sorry that your art was stolen! It’s awesome piece. Don’t know if you’ve considered selling prints on inprnt or redbubble.

I saw you were looking for tshirt manufacturers. I dont know if this information is helpful but you’ll be looking for ‘direct to film’. It lets you keep all your colors in your art and is cheaper than screen printing. The film is applied to the shirt with a heat press (the machine you can see in the videos of people making shirts). Hope that is helpful for your search.

i didnt know inprnt sells shirts :0 i used to have a redbubble but idk where that wen.t I could put it up on inprnt with a better quality i suppose, but i was kind of looking for like an indie company ^^"

9 notes

·

View notes

Text

Revolutionizing Packaging: The Power of Prakash Offset’s Paper Bag Making Machines

In an era where sustainability drives consumer choices, the demand for eco-friendly packaging solutions like paper bags is soaring. Prakash Offset Machinery Private Limited, India’s leading manufacturer of paper bag making machines, is at the forefront of this transformation, delivering cutting-edge technology that empowers businesses to meet this demand efficiently. Based in Faridabad, Haryana,prakash machineries pvt

td has been a trusted name since 2002, offering innovative, high-quality machinery for producing a wide range of paper bags. This article explores how Prakash Machineries Pvt. Ltd paper bag making machines are revolutionizing the packaging industry and why they are the go-to choice for businesses worldwide.

Advanced Technology for Seamless Production

Prakash Offset’s paper bag making machines are engineered for precision, speed, and versatility. Their fully automatic square bottom paper bag making machines, such as the SPBM 360 and SPBM 450, are designed to produce shopping bags, grocery bags, and food bags with twisted rope or flat belt handles. These machines streamline the entire production process—from roll feeding to side gluing, tube forming, cutting, bottom folding, gluing, and final bag output—in a single, automated workflow. Controlled by a PC-programmable servo motor and a user-friendly touch screen interface, these machines can produce up to 200–400 bags per minute, ensuring high productivity with minimal manual intervention.

🏭 Start Your Paper Bag Business with Prakash Offset

We offer:

Fully Automatic and Semi-Automatic Paper Bag Machines

Flat & Square Bottom Bag Production

Printing and Handle Making Attachments

Support for New Entrepreneurs

👉 Visit www.prakashoffset.com 📞 Call us to know how you can start your own eco-friendly packaging unit.

1 note

·

View note

Text

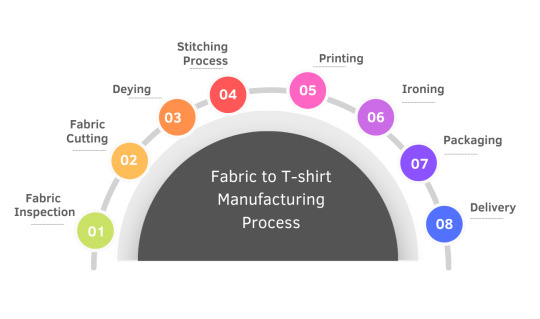

Have you wonder how a t-shirt is manufactured? Learn about t-shirt manufacturing process

The first t-shirt was manufactured in 1920. There are a huge variety of t-shirts manufactured all around the world starting with different types of neckband such as crew neck, V-neck, scoop neck and tank top. There are variations in sleeves such as full sleeves, half sleeves, capped, raglan and yoked. Raw materials used in the t-shirt manufacturing process are cotton and polyester. The neckband is made with a fabric named twill. A particular thread is used for stitching and sewing.

T-shirt Manufacturing Process

Cotton Farming: T-shirt manufacturing process starts from procuring cottons from farmers. Cottons are then converted into bales and transported to Ginning mills.

Ginning Mill: This is the place where cotton fiber and cotton seeds are separated. The cotton fiber is then used in manufacturing garments and cotton seeds are used in manufacturing vegetable oil.

Spinning : The cotton fibers are now separated and in this unit they are cleaned and cotton yarns are made out of it. Spinning unit involves many steps starting with Blow room → Combing → Carding → Drawing → Roving → Spinning.

Dyeing: The yarn is dyed using three dyeing processes: package dyeing, hank dyeing and warp dyeing. Package dyeing is the most popular dyeing process where yarn rolls are heated together with dye inorder to dye the yarn.

Knitting: Yarn enters the knitting machine as a raw material. There are various yarn inserted into the circular knitting machine, various yarn are intertwined together to make a sheet of fabric.

Inspection: Once the fabric is purchased by a garment manufacturer it is inspected by them in order to check any defectiveness or to check any shade variation. If the shade variation is found the cutting process is done accordingly.

Cutting: Many layers of the fabric are stacked together in this process and then using a bend knife cutting machine they are cut into different dimensions like front, back, sleeves, neckband and pocket if any.

Stitching: Different dimensions of fabric are stitched in this step using 2 methods of stitching overlock and superimposed. First front and back part are stitched then sleeves then neckband and at last the hem of the t-shirt.

Printing: Printing is done to the t-shirt to make it stylish. There are several types of printing. Screen-printing, digital printing, heat embossing and spray printing. Then these bulk printed t-shirts are transferred to the stitching department.

Finishing: This process is divided into 2 parts. Firstly, t-shirts are ironed in order to give it a finishing and appealing look and secondly, the tagging and packaging takes place. Then wholesalers and retailers offered to buy t-shirts in bulk.

#textile#textiles#dyeing#pattern#fiber art#fiber#fabric#knitting#sewing#patterns#business#clothing#manufacturing

2 notes

·

View notes

Text

Okay so i have a 3D printer and have used it for quite a few things

And yes there have been some problems, misprints, errors, and some calibration that needed doong

But

I was able to do that

I, someone who had no training on 3D printers or any specific knowledge, was able to find quite easily, the information that told me what was w ong and how to fix it

The misprints were because of the flat surface getting stuck, put it at a slight angle so its not flush to the screen

Here is a calibration tool that will run the prints for 20+ different tests at once

Low on resin? I can physically see the level of it as it works and fill it as i need

2D Printing though?

Low on ink? Need to buy THAT manufacturers cartridge or it wont be accepted (3D printer accepts anything)

Feed mechanisms jammed? Need to disassemble half of the thing to find the problem (3D printer doesn't have anything hidden, you can access every piece and manually swap them out to the point where people are casually printing out printer parts)

Ink Printer refuses to do anything till you subscribe to the licence again? That'll cost you £19.99 a month (3D printers have nothing lime that, even the alocer programs come free with the machine)

And having seen how EASY it can be? Its not the device thats the problem, we have 2D Printing in the bag, its mastered.

The issue is with the people who make the printers who have realized theu can make them utterly shit and still charge a fortune to keep them running

i feel like it says something about us as a species that somebody worked real hard to invent 3D printing when i think anyone who has ever used a printer would agree with me that we have not really gotten our arms around 2D printing yet. we’re getting ahead of ourselves.

60K notes

·

View notes

Link

0 notes

Link

0 notes

Text

Hybrid Printing Technologies Market Insights: Key Players, Trends, and Growth Strategies

The global hybrid printing technologies market size was estimated at USD 4.59 billion in 2023 and is projected to reach USD 10.12 billion by 2030, growing at a CAGR of 12.3% from 2024 to 2030. This significant growth trajectory is primarily being fueled by the rising demand for customized printing solutions, which is becoming increasingly essential across multiple industries.

In addition to the growing preference for personalization, there is an increasing need within the market for shorter lead times and quicker job completions. These requirements have accelerated the adoption of hybrid printing technologies, which stand out as some of the most advanced and automated printing solutions available in the modern era.

Hybrid printing technology refers to the integration of traditional analog printing methods—such as flexography, offset, or screen printing—with modern digital printing techniques. This hybrid approach combines the respective advantages of both methods: it delivers the consistency, durability, and high-resolution output of analog printing, while also incorporating the agility, speed, and high level of customization that digital printing offers.

The hybrid approach brings numerous benefits, including enhanced versatility, operational efficiency, and superior print quality, all while promoting sustainable production practices. These features make hybrid printing a compelling option for businesses seeking adaptable solutions across various printing needs.

Furthermore, hybrid printing technologies are capable of working with an extensive range of substrates and materials, including but not limited to paper, cardboard, plastics, textiles, glass, and metal. This adaptability allows the technology to be applied in numerous sectors such as packaging, labeling, textiles, signage, and advertising.

A key advantage of hybrid systems is their ability to streamline production workflows by merging digital and analog components into a single process. This integration results in reduced setup times, which in turn facilitates faster completion of print jobs. The resulting efficiency enhances turnaround speed and boosts overall productivity, benefiting operations of all scales—from small-batch printing to large-scale industrial production.

Key Market Trends & Insights:

• North America emerged as the leading regional market in the global hybrid printing technologies landscape in 2023, contributing to over 32.0% of the total revenue share. This dominance can be attributed to the region's strong adoption of advanced printing technologies, robust manufacturing infrastructure, and high demand for efficient and customized printing solutions across industries such as packaging, textiles, and advertising.

• Within North America, the United States plays a pivotal role in driving regional growth. The hybrid printing technologies market in the U.S. is projected to expand at a compound annual growth rate (CAGR) of 11.5% from 2024 to 2030. This growth is supported by increasing investments in digital transformation, the presence of key technology providers, and the growing emphasis on reducing production time while enhancing print quality and customization.

• From a component perspective, the hardware segment held the largest share of the market in 2023, accounting for more than 52.0% of the global revenue. This is due to the critical role that printing hardware—such as hybrid printers, print heads, and integrated analog-digital systems—plays in enabling high-speed, high-quality, and flexible printing operations. The rising demand for sophisticated machines capable of supporting a range of substrates and applications has further propelled the dominance of this segment.

• In terms of substrates, the paper and cardboard segment was the leading category in 2023, commanding over 42.0% of the global revenue share. This leadership is driven by the widespread use of paper and cardboard in packaging, labeling, and commercial printing applications. Their recyclability, cost-effectiveness, and compatibility with both analog and digital processes make them a preferred choice for hybrid printing operations across industries.

• When analyzing the market by application, the packaging segment stood out as the dominant segment in 2023, contributing to more than 44.0% of the global revenue. The strong performance of this segment is a result of increasing demand for customized, visually appealing, and functional packaging, particularly in sectors such as food and beverage, pharmaceuticals, cosmetics, and consumer electronics. Hybrid printing technologies enable high-quality and cost-efficient production of packaging materials, with the added benefits of speed, design flexibility, and minimal waste.

Order a free sample PDF of the Hybrid Printing Technologies Market Intelligence Study, published by Grand View Research.

Market Size & Forecast:

• 2023 Market Size: USD 4.59 Billion

• 2030 Projected Market Size: USD 10.12 Billion

• CAGR (2024-2030): 12.3%

• North America: Largest market in 2023

• Asia Pacific: Fastest growing market

Key Companies & Market Share Insights:

Some of the key companies actively operating in the global hybrid printing technologies market include major industry players such as Ricoh, FUJIFILM Holdings Corporation, HP Development Company, L.P., Xeikon, and the Agfa-Gevaert Group. These companies are known for their technological expertise, extensive product portfolios, and strong global distribution networks, all of which contribute significantly to shaping the competitive landscape of the hybrid printing industry.

Ricoh is a well-established Japanese multinational company, headquartered in Tokyo, specializing in imaging and electronics. Founded in 1936, Ricoh has evolved into a global leader in areas such as office solutions, production printing, document management systems, and IT services. The company offers an expansive array of office equipment including multifunction printers, copiers, and scanners, all designed to improve workplace efficiency and simplify document workflows. Ricoh operates in over 200 countries and regions across the world, maintaining a particularly strong presence in North America, Europe, Asia, and other international markets. Its innovation in printing technologies continues to support its leadership position in the hybrid printing space.

In addition to these established players, emerging companies are also making notable contributions to the hybrid printing technologies market. Among them are Memjet and Colordyne Technologies, both of which are gaining recognition for their focus on innovation and digital integration.

Key Players

• Müller Martini

• Mark Andy Inc.

• Xeikon

• HP Development Company, L.P.

• SCREEN Graphic Solutions Co., Ltd.

• Ricoh

• FUJIFILM Holdings Corporation

• Agfa-Gevaert Group

• Eastman Kodak Company

• BOBST

• Memjet

• Colordyne Technologies

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

Conclusion:

The hybrid printing technologies market is experiencing strong growth, propelled by rising demand for customization, efficiency, and rapid production capabilities. North America remains the leading regional hub, with increasing adoption of hybrid solutions that merge analog and digital strengths. Hardware continues to dominate the market, while paper/cardboard substrates and packaging applications hold significant share. Emerging trends include sustainability-driven innovations, eco-friendly processes, and enhanced productivity via next generation hybrid systems. Overall, the landscape is marked by technological advancement, operational versatility, and expanding market penetration.

#Hybrid Printing Technologies Market#Hybrid Printing Technologies Market Size#Hybrid Printing Technologies Market Share#Hybrid Printing Technologies Market Analysis

0 notes

Text

Turnkey Electronics Assembly Services in China with High Quality and Competitive Price

Hitech Circuits provides a full turnkey solution to all of your electronics assembly requirements. From PCB fabrication, components sourcing, pcb assembly to full box build assembly we can provide a full electronics manufacturing services solution to your electronics manufacturing requirements. Using surface mount production machinery consisting of three surface mount technology placement machines, a screen printing machine and a 10 zone reflow oven, accompanied by offline bench assembly, visual inspection and rework stations, we can offer small to medium volume services for all your pcb assembly requirements. We offer pcb assembly, visual inspection, functional and electronics testing and programming services. We can source all components, bare pcbs and production stencils. If you would like to work with an electronics manufacturer you can trust then please get in touch.

Also, we offer both turn-key and partial turn-key PCB Electronics assembly.

For full turn-key services, we manage and produce everything including manufacturing the circuit boards, finding & ordering PCB components, quality inspection & testing and the final product assembly.

Pls send PCB files to [email protected] to get a quote now!

Advantages of Full Turnkey PCB Assembly Services

• Shorter Lead Time

As a fundamental form of electronic assembly, PCB assembly primarily contains three phases: PCB fabrication, components procurement and PCB assembly. Traditionally, you should quote and confirm design files with sales and engineers working for your PCB manufacturer, then components distributors and finally PCB assemblers. Such series of quotations and confirmations just need your time spent in contacting with different partners. If those partners are from different countries, you have to overcome some problems such as time zone, communication habits etc. Full-turnkey PCB assembly, however, is a highly-efficient form of electronic assembly. As soon as full-turnkey PCB assembly is determined, an overall assembly quotation and indispensible issues prohibiting smooth manufacturing will be raised so that three times of communication have been cut to one time with electronic assembly efficiency dramatically improved in Hitech Circuits Co., Limited.

• Lower Cost

Another advantage of full-turnkey PCB assembly service is overall cost reduction. Pack-up service is usually cheaper than separate ones as far as electronic assembly is concerned. At least, freight fee will be saved because you don’t need to get manufactured PCB boards and electronic components delivered to assembly workshop. Moreover, components procurement may get easy and customer-friendly because experienced electronic assemblers are usually able to provide reliable components with relatively low cost based on their long-term cooperation with parts manufacturers or distributors.

• Transparent Monitoring

When it comes to electronic assembly process, it’s significant yet difficult to monitor your products’ manufacturing stage as it is totally related with your products’ performance and time to market. Full-turnkey PCB assembly allows engineers at each stage to be aware of what they’ve accomplished and to better understand their status for better performance of final products.

Who Can Benefit Most From Our Turnkey PCB Assembly Services?

Now that full turnkey PCB assembly allows PCB designers to make better use of their time to focus more on PCB design, it works perfectly on companies striving for frequent upgrading and refreshing of products. They need to dig into deeper market by providing multiple creative electronic products and they strongly call for a steady and smooth electronic assembly process.

Turnkey printed circuit board assembly is also an ideal electronic assembly solution for small businesses or startup companies that want to bring smaller quantities of assembled PCBs to market without having to invest in or carry an extensive inventory. It also offers a more cost-effective, efficient means of assembling and testing PCB prototypes for new products. In addition, quick-turn PCB assembly service makes sense for any company that needs to receive their circuit boards with the shortest possible lead time.

0 notes

Text

Revolutionizing Fabric Printing: How a Print Cloth Machine is Changing the Textile Industry

In the fast-paced world of textile manufacturing, speed, quality, and customization are no longer optional—they’re essential. One of the most significant game-changers in this space is the Print Cloth Machine. Whether you're a fabric printing startup or an established garment brand, adopting this advanced technology can redefine your production standards.

In this blog, we’ll explore what a Print Cloth Machine is, how it works, its benefits, key features, and why investing in a high-quality machine from a trusted manufacturer like Orange O Tech can be a smart business move.

What Is a Print Cloth Machine?

A Print Cloth Machine is an industrial-grade textile printer designed specifically for printing designs, patterns, and images onto cloth and fabric materials. These machines use a variety of printing technologies—such as rotary screen printing, digital inkjet printing, and heat transfer printing—to apply complex and high-resolution designs directly onto textiles.

It has become an integral part of modern textile production, replacing traditional methods that were slower, less precise, and more labor-intensive.

How Does a Print Cloth Machine Work?

The mechanism varies based on the printing technology used. Here are three common types of Print Cloth Machines and how they function:

1. Rotary Screen Print Machine

Uses engraved cylindrical screens that rotate and press dye through to the fabric.

Great for high-speed, large-volume printing.

2. Digital Inkjet Print Cloth Machine

Works like your home printer but on a massive scale.

Sprays color droplets directly onto fabric with extreme precision.

Ideal for custom designs, small batches, or on-demand textile printing.

3. Heat Transfer Print Machine

Transfers designs from a printed paper onto fabric using heat and pressure.

Often used for polyester or synthetic fabrics.

Each of these types has unique advantages depending on your production needs.

Why the Textile Industry is Shifting to Print Cloth Machines

There are several reasons why businesses are making the switch from traditional to digital or automated cloth printing methods:

🔹 Faster Production

Modern Print Cloth Machines drastically reduce printing time. What used to take hours can now be done in minutes.

🔹 Greater Design Flexibility

Whether you're printing floral patterns, abstract graphics, or photo-quality prints, these machines can handle it all.

🔹 High Precision and Quality

Automated settings ensure consistent quality. Every print is uniform—no smudges, no color bleeding.

🔹 Cost Efficiency Over Time

Though the initial investment might seem high, the reduction in manual labor and errors results in long-term cost savings.

🔹 Eco-Friendly Options

Digital Print Cloth Machines use less water and dye compared to traditional methods, supporting sustainable manufacturing practices.

Key Features to Look for in a Print Cloth Machine

When evaluating which Print Cloth Machine to purchase, consider the following features:

✅ Print Resolution

Look for machines that offer at least 1200 DPI for high-definition print output.

✅ Fabric Compatibility

Ensure the machine supports the types of fabrics you work with—cotton, polyester, silk, rayon, etc.

✅ Speed & Throughput

Check the meters per hour the machine can handle. Higher speeds mean higher productivity.

✅ Ink System

Choose between pigment, reactive, disperse, or sublimation inks based on your business needs.

✅ Automation & Software

Smart machines come with design preview options, job tracking, and remote operation capabilities.

✅ Maintenance

Go for a model that is easy to clean and maintain. Some even come with auto-cleaning systems.

Applications of Print Cloth Machines

The use of Print Cloth Machines spans across industries:

Fashion & Apparel: Custom t-shirts, dresses, scarves, and designer fabrics.

Home Furnishing: Printed curtains, bedsheets, pillow covers.

Interior Design: Customized upholstery and wallpaper fabrics.

Sportswear: High-quality, durable prints on gym wear and jerseys.

Corporate Branding: Uniforms and promotional merchandise.

Why Choose Orange O Tech for Your Print Cloth Machine Needs?

When you're investing in a Print Cloth Machine, you want a brand that combines innovation, reliability, and after-sales support. That’s where Orange O Tech excels.

Here’s what sets them apart:

💼 Industry Expertise

With years of experience in advanced textile machinery, Orange O Tech understands the needs of modern manufacturers.

🛠️ Cutting-Edge Technology

They offer machines equipped with the latest features like multi-nozzle printheads, advanced drying systems, and precision feeders.

🔧 End-to-End Support

From installation and training to maintenance and repairs, they offer full lifecycle support for every machine.

📈 Proven Results

Businesses that switch to Orange O Tech machines often report improved print quality, reduced turnaround times, and increased profitability.

0 notes

Text

Who Is The Best Sewage Treatment Plant Manufacturer In Faridabad ?

STP Plants in short for sewage treatment plants are excellent, high-quality facilities designed to effectively treat as well as purify wastewater where Netsol Water fully manages & regulates these facilities. Because of their advanced technology alongside robust structural structure, these treatment facilities are able to remove an extensive variety of contaminants & poisons from wastewater that contains sewage, including viruses, bacteria, biological waste, & chemicals.

Netsol Water has achieved amazing success in the marketplace by providing its clients with a wastewater treatment plant facility at a reasonable cost, as well as all of the assurances before & after the machine has been built. This plant may be easily obtained by contacting a Best Sewage Treatment Plant Manufacturer In Faridabad, such as Netsol Water with sites around the country, is always ready to help our customers.

This treatment plant system includes multiple treatment steps like as filtration, sedimentation, biological agent treatment, disinfection, & screening. It features cutting-edge sensors & control systems fitted to ensure optimal performance as well as effective operation. Netsol Water is becoming the top priority as a Sewage Treatment Plant Manufacturer in Faridabad providing them at the most inexpensive prices.

Synopsis about Sewage Treatment Plants in Faridabad

The Sewage treatment plant technology is easy to construct & operate, requiring little maintenance. It is generally accessible from the well-based Sewage Treatment Plant Manufacturer in Faridabad. It can be utilized throughout residential, municipal, including industrial settings, among other contexts.

STP Plant Manufacturer in Faridabad

However, sewage treatment plants, which can be purchased from STP Plant Suppliers in Faridabad, harmlessly dispose of industrial wastewater produced by industrial activities before it is released into the environment or ecosystem. STP plants are responsible for eliminating harmful chemical substances & other impurities from wastewater in order to conform with environmental as well as legal standards.

Throughout the treatment process, physical, chemical, & biological methods are often employed to eliminate pollutants as well as toxins from wastewater. Physical techniques like screening, sedimentation, & filtration are then implemented to get rid of solid & suspended pollutants from wastewater.

Two types of solidifying or retarding chemical agents intended to remove dissolved & scattered elements from wastewater are flocculants & coagulants. Microorganisms, including pathogens, contribute to biological processes by decomposing organic compounds in sewage wastewater.

Various STP treatment plant-related applications

1) Clothing Factories: The textile industry makes extensive utilization of STPs to treat wastewater generated during the methods of printing, applying dye, & finishing processes. Netsol Water are providing these treatment plants at a very low cost compared to Sewage Treatment Plant companies in Faridabad, since wastewater contains dangerous substances like dyes, solvents, as well as heavy metals that could harm the environment if left untreated.

2) The pharmaceutical industry generates wastewater, including Sewage, which includes APIs (active pharmaceutical ingredients) & poses a risk to human health & the environment. STPs are easily accessible from Sewage treatment plant manufacturers & are employed to remove pollutants while also ensuring that wastewater meets regulatory criteria before being discharged.

3) The Food as well as the Beverage Sectors: Sewage wastewater from manufacturing operations such as brewing, bottling, & condensing, & distillation, as well as wastewater Sewage water from sanitation & processing equipment, are frequently controlled & treated in STPs. When Sewage wastewater is released, before that Sewage must be refined, & treated to free the Sewage from organic matter, nutrients in excess, & additional pollutants including rubbles.

4) Chemical manufacturing Industry: Sewage Treatment Plants are very essential in the treatment of wastewater which is produced during manufacturing processes such as various chemical synthesis phenomena & purification. The Sewage may contain hazardous chemicals, bases, & acids that are harmful to the environment & human health.

Conclusion

Only a reputable & trusted Sewage Treatment Plant Manufacturer In Faridabad can manage & take care of all of the following difficulties & operations to provide their clients with superior treatment plants here. One of the greatest leading manufacturers, Netsol Water has dedicated nearly all its assets to this water treatment business & provides a wide range of these treatment machinery.

Netsol Water is one of the best choices among the various manufacturing companies in the Faridabad area because of their reliability plus efforts, which also determine how much technology they can provide to integrate into their manufacturing products.

#sewage treatment plant#sewage treatment plant manufacturer in faridabad#water treatment plant#save water#water is life#netsol water#faridabad

0 notes

Text

What Are the Types of Paper Bag Making Machines Available in India?

With the rising demand for eco-friendly packaging, the paper bag manufacturing industry in India is booming. Whether it's for groceries, fashion retail, food delivery, or e-commerce, businesses across sectors are switching to paper bags. If you're planning to start a paper bag manufacturing business or expand your existing setup, it's crucial to understand the different types of paper bag-making machines available in India.

At Prakash Machineries Pvt Ltd, we specialize in manufacturing and supplying high-performance paper bag-making machines suited for all business scales—from startups to large industries. In this article, we’ll break down the most common types of paper bag machines used in India, their features, and which one might be best for your needs.

🛠️ Semi-Automatic Paper Bag Making Machine

Best for: Small businesses, home-based setups, beginners

Features:

Requires some manual input (usually paper feeding or pasting)

Produces flat and satchel paper bags

Can be operated by 1–2 people

Produces 30–80 bags per minute

Lower initial investment (starting from ₹--–-- lakh)

Advantages:

Affordable and space-efficient

Ideal for local supply or niche markets

Requires less training and maintenance

Limitations:

Slower than fully automatic machines

Limited bag design and size options

✅ Popular choice for entrepreneurs who are starting with low investment and want to supply paper bags to local grocery stores, bakeries, and pharmacies.

⚙️ Fully Automatic Paper Bag Making Machine

Best for: Medium- to large-scale manufacturers with consistent bulk demand

Features:

Automatic paper feeding, folding, cutting, bottom forming, and gluing

High speed (100–300+ bags per minute)

Produces flat and square-bottom paper bags

Digital touch screen control for easy operation

Compatible with flexo printing units

Advantages:

High output with minimal labor

Consistent size and shape quality

Scalable for bulk production

Supports kraft paper, coated/uncoated paper

Limitations:

Higher initial investment (₹-–- lakh+ depending on model and configuration)

Requires 400–800 sq. ft. or more of floor space

✅ Ideal for businesses supplying bags to supermarkets, clothing chains, delivery platforms, and exports.

🧳 Square Bottom Paper Bag Machine (With/Without Handle Attachment)

Best for: Premium bag production for retail, fashion, and food brands

Features:

Makes square or flat-bottom bags (popular in malls and luxury stores)

Options for twisted handle or flat handle pasting (manual or automatic)

Can integrate inline flexo printing

High precision in folding and bottom sealing

Advantages:

Makes attractive, branded paper bags

High demand in apparel, cosmetics, and bakery segments

Excellent profit margins

Limitations:

Slightly more expensive than standard automatic machines

Requires trained staff for handle attachment if done manually

✅ Perfect for serving boutiques, premium retail stores, cafes, and takeaway brands.

🖨️ Flexo Printing Machine (Add-on or Standalone)

Best for: Businesses that want to offer custom-printed paper bags

Features:

2–4 color flexo printing

Can be attached to automatic paper bag machines or used as standalone unit

Suitable for kraft paper, duplex board, newsprint, etc.

Water-based eco-friendly inks

Advantages:

Adds branding to your product offering

Attracts B2B clients (retailers, brands, corporate buyers)

Can generate additional revenue streams

Limitations:

Requires printing knowledge or operator training

Increases operational cost slightly

✅ Highly recommended for manufacturers who want to stand out in a competitive market with custom and branded bag designs.

🧳 Sheet Feeding Paper Bag Machine

Best for: Premium and rigid bag production with full customization

Features:

Uses pre-cut paper sheets instead of rolls

Greater flexibility in paper type, thickness, and size

Mostly used for luxury shopping bags and gift bags

Advantages:

Supports laminated, textured, or printed sheets

Ideal for producing stylish and high-end bags

Can be used for low-quantity, high-value orders

Limitations:

Slower than roll-fed machines

Higher per-unit cost

✅ Best suited for printing presses or packaging companies producing exclusive promotional or retail bags.

🏁 Final Thoughts

India offers a wide variety of paper bag-making machines, each designed for specific business needs and output volumes. Whether you're a small entrepreneur or an established manufacturer, there's a machine solution that can help you succeed in the growing eco-packaging market.

At Prakash Machineries Pvt Ltd, we manufacture and supply all types of paper bag-making machines—semi-automatic, fully automatic, square bottom, printed, and more. Our machines are durable, affordable, and backed by expert support and training.

Ready to choose the perfect machine for your business? Contact us now for a free consultation, demo, or quotation.

#paper bag manufacturer#manufacturer#square bottom#v bottom#bags#paper bag#machines#flexo#paper#alien stage#cake#chris sturniolo#critical role#cooking#baking#chocolate#breakfast#delicious#dan and phil

0 notes

Text

Everything You Need to Know About Screen Printing Machine and Choosing the Right Manufacturer

In today’s world, printing is everywhere-on clothes, bags, bottles, and even electronics. If you’ve ever wondered how designs, logos, or patterns get perfectly printed on these products, the answer is often a Screen Printing Machine. Whether you are starting a new business or want to upgrade your production line, understanding how screen printing works and how to choose the right machine and manufacturer can make a big difference.

What is a Screen Printing Machine?

A Screen Printing Machine is a device that uses a mesh screen, ink, and a squeegee to transfer images onto various surfaces. It’s one of the oldest and most reliable printing methods, especially for printing on fabrics, plastic, glass, wood, and metal. This process works well for both small-scale custom printing and large-scale industrial production. The key benefit? It provides bright, long-lasting prints even on dark surfaces.

Why Should You Use a Screen Printing Machine?

From a user perspective, screen printing offers several advantages:

Vibrant Colors: Perfect for bold and eye-catching designs.

Durable Prints: The ink stays on for a long time without fading.

Cost-Effective: Great for bulk printing—more prints mean lower cost per piece.

Flexible Materials: You can print on t-shirts, bottles, boards, and even electronic parts.

If you are planning to print the same design repeatedly, a screen printer is a smart investment.

How to Choose the Best Screen Printing Machine Manufacturers?

Choosing a machine is not just about price; it’s about quality, support, and trust. Here’s what to look for:

1. Experience and Reputation

Choose screen printing machine manufacturers with proven industry experience. A good track record means reliable products and better support.

2. Machine Variety

The best manufacturers offer a range of machines-manual, semi-automatic, and fully automatic—depending on your printing volume and product type.

3. After-Sales Support

This is very important. Always check if the company offers installation help, training, and after-sales service.

4. Customization Options

Some businesses need machines tailored to specific printing surfaces. A good manufacturer understands your needs and provides the right solution.

5. Client Reviews

Before making a decision, check customer reviews and feedback. It gives you a better idea of the machine’s performance and reliability.

Final Thoughts

A Screen Printing Machine can transform your business by helping you print faster, better, and at a lower cost. But your success also depends on choosing the right Screen Printing Machine Manufacturers—ones who offer quality, reliability, and support when you need it. If you are looking to start or expand your printing setup, take the time to explore different machine types, compare features, and speak directly with manufacturers who understand your goals.

0 notes