#Automobile Components in Pune

Explore tagged Tumblr posts

Text

Due to their excellent strength-to-weight ratio, strong corrosion resistance, electrical and thermal conductivity, and high flexibility,Aluminium Other Components in India are employed in most sand casting projects. To improve these qualities, these alloys include aluminum and minute amounts of metals, including copper, magnesium, silicon, and zinc.The most widely used aluminum alloys at Haworth Castings are LM25 and LM6, with the 'LM' prefix serving as a standard identifier to represent the chemical makeup and varied quantities of the various trace metals.

#Automobile Components in Pune#Automobile Parts in India#Home Appliances Components in India#Electrical and Electronics Components in Pune#Aluminium Other Components in India#Aluminium Other Components in Pune#Home Appliances Components in Pune

0 notes

Text

Sustainable Solutions: Examining Pune’s Efforts in Eco-Friendly Casting for Automobile Components

Welcome to the world of precision engineering and automotive innovation, where every part counts towards crafting the perfect driving experience. In the bustling city of Pune, amidst the thriving automotive industry, one name stands out for its commitment to quality, reliability, and excellence – Siddhalaxmi Castings.

In this blog, we delve into the realm of automobile components casting manufacturer in Pune, uncovering the story behind Siddhalaxmi and their journey towards becoming a premier manufacturer in Pune.

Casting a Greener Future

Casting is a fundamental process in automobile components casting manufacturer in Pune,, involving the pouring of molten metal into a mold to create components like engine blocks, transmission cases, and more. Traditionally, this process has been associated with significant environmental impacts, from high energy consumption to emissions of greenhouse gases and hazardous waste disposal. However, Pune’s automotive industry is challenging this narrative through innovative eco-friendly casting techniques.

Embracing Green Technologies

Pune’s automotive sector is embracing a variety of green technologies to minimize its ecological footprint. One notable approach is the utilization of recycled materials in casting processes. By incorporating recycled metals into their alloys, manufacturers reduce the need for raw materials extraction, thereby conserving natural resources and cutting down on energy-intensive mining operations.

Furthermore, advancements in casting technologies are enabling manufacturers to optimize their processes for efficiency and sustainability. Techniques such as precision casting and computer simulation allow for the production of components with minimal material waste, reducing both costs and environmental impact. Additionally, the integration of renewable energy sources, such as solar power, into foundry operations further decreases carbon emissions associated with casting.

Collaborative Initiatives for Change

The journey towards eco-friendly casting in Pune is not one that any single entity can undertake alone. Collaboration between industry stakeholders, research institutions, and governmental bodies is essential for driving meaningful change. Joint efforts focused on research and development are yielding innovative solutions for sustainable casting, while regulatory support is incentivizing the adoption of green practices through policies and incentives.

Environmental Benefits and Economic Viability

The shift towards eco-friendly casting in Pune’s automotive industry brings forth a multitude of benefits, both environmental and economic. By reducing energy consumption, minimizing waste generation, and curbing emissions, these sustainable practices contribute to a healthier environment and a cleaner future for generations to come. Moreover, investing in green technologies enhances the competitiveness of Pune’s automotive sector on the global stage, attracting environmentally conscious consumers and investors alike.

Experience Excellence with Siddhalaxmi

In conclusion, Pune’s efforts in eco-friendly automobile components casting manufacturer in Pune, serve as a shining example of sustainable innovation within the automotive industry. By embracing green technologies, fostering collaborative initiatives, and reaping the environmental and economic rewards, Pune is not just manufacturing automobiles – it’s driving towards a greener, more sustainable future.

In the dynamic world of automobile components casting manufacturer in Pune, Siddhalaxmi stands as a beacon of quality, precision, and innovation. With a rich legacy of craftsmanship and a steadfast commitment to customer satisfaction, Siddhalaxmi is more than a manufacturer – it’s a trusted partner in driving automotive excellence.

Post navigation

To Know More: https://www.siddhalaxmi.com/sustainable-solutions-examining-punes-efforts-in-eco-friendly-casting-for-automobile-components/

0 notes

Text

Automobile component washing and drying Pune India

Discover unparalleled excellence in automobile component washing and drying solutions in Pune, India, with Nexgen Drying Systems Pvt. Ltd. Our state-of-the-art technology ensures meticulous cleaning and drying of automotive components, meeting the highest industry standards. With a commitment to quality, we offer innovative solutions that enhance efficiency and performance. Contact us at +91 95943 53681 or reach out via email at [email protected] / [email protected]. Explore our cutting-edge solutions at http://www.nexgendrying.com/. Nexgen Drying Systems Pvt. Ltd. – Where precision meets innovation in automobile component cleaning and drying.

0 notes

Text

AUTOSAR & Embedded Systems: The Backbone of Modern Cars

Let’s talk about cars not from the driver’s seat, but from inside the brain of a car. That’s where AUTOSAR comes in, along with embedded systems.

AUTOSAR stands for AUTomotive Open System Architecture. It’s not a tool or a language, but a global standard, a framework that helps companies build automotive software in a modular, scalable, & reusable way.

Think of it like a blueprint that tells developers, “Hey, if you write code like this, it’ll work with other systems, other suppliers, & future upgrades too.”

Embedded Systems? That’s Where the Magic Happens

Embedded systems are the mini-computers behind every electronic component in a car ABS, airbags, power steering, adaptive cruise control, even the music player.

Without embedded systems, your car is just metal & wires. But to manage so many features without conflict, you need discipline in software. That’s where AUTOSAR brings structure.

Classic AUTOSAR vs Adaptive AUTOSAR

There are two flavors:

Classic AUTOSAR is used for time-critical stuff like engine control, braking systems, and safety features.

Adaptive AUTOSAR is for high-performance tasks autonomous driving, connected car systems, over-the-air updates.

Together, they cover the full range of software needs in modern vehicles.

Why Is AUTOSAR a Big Deal?

Here’s the thing. Auto companies no longer build everything from scratch. Toyota might use a Bosch ECU, with software from Continental, & a chip from NXP. AUTOSAR makes sure these parts talk to each other, no matter who built what.

It saves time, avoids bugs, improves safety, & most importantly allows reuse. If a function is AUTOSAR-compliant, you can use it in multiple car models with minor tweaks.

What It Means for Engineers & Developers

If you’re into embedded systems & want to work in automotive, knowing AUTOSAR is a massive plus. It’s not easy there’s configuration, software architecture, layers like RTE, BSW, MCAL, & more. But once you get the hang of it, you become way more valuable.

Companies look for engineers who understand how to design scalable, modular embedded software & that’s exactly what AUTOSAR is about.

They’re rolling software machines. AUTOSAR & embedded systems work quietly in the background to make everything seamless, from safety to entertainment.

Whether you’re an engineer, a student, or just a curious mind if you’re interested in the future of automobiles, this is one space worth exploring.

Because cars are getting smarter & someone has to write the brains behind them.

If you’re looking to make a career in embedded systems and want a comprehensive, hands-on course with placement support, Embedded Institute in Pune Technoscripts is a solid choice. With its job-oriented curriculum, expert mentorship, and industry exposure, the course is designed to bridge the gap between theoretical knowledge and practical implementation. Whether your goal is to get hired, build innovative IoT products, or work on cutting-edge automotive systems — Technoscripts equips you with the skills to make it happen. So join Embedded Course in Pune with Placements today.

0 notes

Text

Best SAP Pune Solutions: Empowering Businesses with the Right ERP Software in Pune

Introduction

In the fast-evolving business landscape of Pune, staying ahead means adopting smart, scalable, and efficient solutions. One such transformative tool is SAP Business One — a trusted ERP software that helps companies of all sizes streamline operations, improve visibility, and scale faster.

Whether you're a manufacturing unit in Pimpri-Chinchwad or a service-based firm in Hinjewadi, finding the best SAP in Pune can give your business a competitive edge. In this blog, we’ll explore why SAP is the preferred ERP software in Pune and how to choose the right SAP partner to implement it.

Why Choose SAP ERP Software in Pune?

SAP Business One is a globally recognized Enterprise Resource Planning (ERP) system designed for growing businesses. It integrates all core business functions, from finance and sales to inventory and customer relationship management.

Here’s why companies are investing in SAP Pune ERP solutions:

Centralized data management for real-time decision-making

Scalability to support future business growth

Local support and customization options

Compliance-ready features for Indian tax laws like GST

Industry-specific modules for manufacturing, retail, distribution, and more

Industries Benefiting from SAP in Pune

Pune is home to a variety of industries, and many of them are leveraging SAP ERP software to digitize their operations.

Key Sectors Using SAP ERP:

Manufacturing & Engineering

Real-time production tracking

Inventory optimization

Automobile & Auto Components

Vendor management

Multi-location stock control

Pharmaceuticals

Regulatory compliance and batch traceability

Education & EdTech

Admission, fee, and HR process automation

Retail & Wholesale

Smart billing, CRM, and order management

This widespread usage highlights how ERP software in Pune is becoming a necessity across verticals.

How to Identify the Best SAP Partner in Pune

Choosing the right implementation partner is as important as the software itself. The ideal SAP partner should understand your industry, offer local support, and guide your team throughout the transformation.

Things to Look For:

Experience with SAP Business One

Customized ERP solutions

After-sales support and AMC services

Client success stories in Pune

Certified SAP consultants

One such reputed name is Osswal Infosystem, an established SAP Business One partner in Pune helping SMEs and large enterprises drive digital growth with intelligent ERP implementation.

Benefits of SAP Business One for Pune-Based Companies

Here’s how SAP helps local businesses improve efficiency and profitability:

1. Better Financial Control

Accurate reporting

Budget forecasting

Integrated banking modules

2. Streamlined Inventory & Warehouse Management

Barcode scanning

Stock-level automation

Batch/serial number tracking

3. Improved Customer Service

CRM integration

Order-to-cash visibility

Customer analytics

4. Real-Time Reporting & Dashboards

Custom KPIs

Visual insights

Decision-making at your fingertips

Why Pune Businesses Trust SAP Business One

With increasing demand for digital transformation, Pune’s small and mid-sized businesses are adopting SAP to:

Eliminate manual work and duplication

Improve inter-department collaboration

Gain visibility into supply chain and operations

Ensure compliance and data security

The city’s IT ecosystem, skilled workforce, and forward-thinking entrepreneurs make SAP in Pune a natural choice for digital growth.

Top Reasons to Invest in ERP Software in Pune

If you’re still considering whether to invest in an ERP system, here are a few compelling reasons:

Faster ROI with localized deployment

Transparency in financials and operations

Scalable to match your growth roadmap

Data-driven decision-making

Secure data storage with role-based access

Whether you're a startup or an established enterprise, integrating the best SAP in Pune will prepare your organization for future challenges and opportunities.

Conclusion: Time to Power Your Business with SAP Pune

The future belongs to businesses that are agile, tech-enabled, and data-driven. If you’re looking for the best SAP solutions in Pune, don’t wait to digitize your operations. From streamlining workflows to boosting profitability, ERP software is no longer optional — it’s a business essential.

Looking for a reliable SAP Business One partner in Pune? Explore solutions with Osswal Infosystem and take the next step in your digital journey.

0 notes

Photo

File picture of Pravin Gaikwad | Photo Credit: Mandar Thannu Sambhaji Brigade founding member Pravin Gaikwad was manhandled and ink was hurled on him allegedly by activists of an organisation over his reported remarks on Swami Samarth in Akkalkot village in Solapur district on Sunday (July 13, 2025), police mentioned. Mr. Gaikwad alleged that he was focused over his "progressive thoughts" by followers of Hindutva ideology. A viral video reveals Mr. Gaikwad being pulled out of his automobile and manhandled by a bunch of individuals within the afternoon. "While Gaikwad was in his car, Shivdharm Foundation supporters staged protests, threw black ink on him and also tried to vandalise his car," an official mentioned. Mr. Gaikwad had come to Akkalkot, extensively identified for its affiliation with Swami Samarth, who's believed to be a reincarnation of Shree Dattatreya, to attend a felicitation ceremony organised by an academic institute and Sakal Maratha Samaj. The protesters additionally objected to Mr. Gaikwad's terming Chhatrapati Sambhaji Maharaj as 'Sambhaji'. They demanded that the Sambhaji Brigade be renamed as Chhatrapati Sambhaji Maharaj Brigade, the official mentioned. Police booked Deepak Kate and 6 different members of Shivdharm Foundation beneath sections 115 (2), 189, 190, and 191 of the Bharatiya Nyay Sanhita (BNS) for rioting and detained them. They have been later allowed to go after the police served them notices. Mr. Gaikwad alleged it was an try to kill him for his "progressive thoughts". "I had gone to Akkalkot and suddenly members of the Shiv Dharma Foundation smeared black, sticky oil on me. They attacked me and tried to kill me. You may recall the murders of Dr Pansare, Kalburgi, Dr Dabholkar and Gauri Lankesh. In the current regime, activists with progressive thoughts are unsafe," he alleged whereas speaking to reporters. "Sometimes there are attempts to break political parties. Then there are attempts to divide activists. When all such attempts fail, such attacks are carried out. We work with an ideology rooted in truth. Our thinking is aligned with the Constitution," Mr. Gaikwad added. The Sambhaji Brigade is working for humanity however, sadly, some misconceptions are unfold about social organisations, following which these claiming to comply with the Hindutva ideology perform such assaults, he claimed. Sambhaji Brigade, a Maratha outfit, is known as after Chatrapati Sambhaji Maharaj, son of Chatrapati Shivaji Maharaj. It had gained publicity in 2004 for allegedly attacking and vandalising the Bhandarkar Oriental Research Institute in Pune, claiming that it helped American scholar James Laine’s e book on Shivaji Maharaj, sure components of which have been unacceptable to them. "Ideological opposition should be expressed through ideas. This path of violence is highly condemnable and deplorable," NCP (SP) MP Amol Kolhe mentioned. His colleague and MLA Jitendra Awhad provided assist to Mr. Gaikwad by calling him a "champion of progressive thoughts" and "a fighter". Published - July 14, 2025 10:37 am IST Read More: https://news.unicaus.in/india/sambhaji-brigade-chief-pravin-gaikwad-manhandled-in-solapur-for-remarks-towards-swami-samarth/

0 notes

Text

Blow Off Water and Dust Services in Pune, India – Nexgen Drying Systems

In industrial and manufacturing environments, maintaining cleanliness and efficiency is crucial for seamless operations. One of the essential processes in various industries is Blow off water and dust Services Pune India, which ensures the removal of contaminants such as moisture, dust, and debris from surfaces. Nexgen Drying Systems, a leading name in the industry, offers state-of-the-art solutions for blow-off cleaning, enhancing productivity and ensuring product quality.

Importance of Blow Off Water and Dust Services

Industries such as automotive, aerospace, electronics, and food processing require precise and thorough cleaning before further processing, painting, or packaging. The presence of water and dust can lead to defects, corrosion, and reduced efficiency in machinery. With the help of advanced Blow off water and dust Services Pune India, industries can:

Improve product quality by eliminating contaminants.

Reduce the risk of equipment failure due to accumulated dust and moisture.

Enhance production efficiency by ensuring smooth operation of manufacturing processes.

Lower maintenance costs by preventing residue buildup on equipment and surfaces.

Nexgen Drying Systems – Your Trusted Partner

Nexgen Drying Systems is a reputed provider of Blow off water and dust Services Pune India, delivering innovative and customized drying and cleaning solutions for a wide range of industries. With years of experience, cutting-edge technology, and a customer-centric approach, Nexgen ensures optimal cleaning results tailored to the specific needs of its clients.

Key Features of Nexgen Drying Systems’ Blow-Off Services

High-Pressure Air Technology: Nexgen utilizes high-velocity air jets to remove dust and moisture effectively.

Energy-Efficient Solutions: Their systems are designed to consume minimal energy while maximizing cleaning efficiency.

Customizable Nozzle Designs: The company offers a variety of nozzles to suit different applications, ensuring precise and uniform cleaning.

Eco-Friendly Operations: Nexgen prioritizes sustainability by using non-contact, air-based cleaning methods that do not require chemicals or water.

Automation Integration: Their blow-off systems can be seamlessly integrated into automated production lines, reducing manual labor and increasing operational efficiency.

Applications of Blow Off Water and Dust Services

Automobile Industry: Removal of water and dust from vehicle parts before painting and assembling.

Electronics Industry: Cleaning of delicate components without the risk of damage.

Food and Beverage Industry: Ensuring contamination-free packaging and processing.

Aerospace Industry: Dust and moisture removal from aircraft components for enhanced performance and safety.

Metal Fabrication: Drying and dust removal from metal parts before welding and coating.

Why Choose Nexgen Drying Systems?

With its commitment to quality and innovation, Nexgen Drying Systems has established itself as a leader in Blow off water and dust Services Pune India. The company’s expertise, customer-focused approach, and cutting-edge technology make it the preferred choice for industries looking to optimize their cleaning and drying processes.

For more information on Nexgen Drying Systems and their services, visit http://www.nexgendrying.com/.

0 notes

Text

PCB Fabrication Company: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are the unsung heroes of today’s technology. Found in everything from smartphones and medical equipment to automobiles and aerospace systems, PCBs form the foundation of electronic functionality. At the heart of this innovation are PCB fabrication company the manufacturers who design, develop, and deliver the critical boards that keep industries running.

In this article, we’ll explore what a PCB fabrication company does, why their role is critical, and what makes India a rising powerhouse in PCB manufacturing.

What is PCB Fabrication?

PCB fabrication is the process of manufacturing printed circuit boards that support and connect electronic components using conductive pathways, tracks, and signal traces. The process involves:

Design and layout review

Copper patterning

Lamination

Drilling and plating

Solder masking

Surface finishing

Testing and inspection

A quality PCB fabrication company ensures precision, reliability, and adherence to international standards such as IPC, ISO, and RoHS.

Why PCB Fabrication Companies Are Vital

Modern electronics rely on miniaturized, multi-functional boards that require precision engineering. Here’s why PCB fabrication companies are central to innovation:

Customization: Tailored PCBs for medical, automotive, telecom, and defense applications

Speed-to-Market: Rapid prototyping and quick turnaround for startups and OEMs

Quality Control: Strict adherence to industry standards

Innovation-Ready: Capabilities for multilayer, HDI, flexible, and rigid-flex PCBs

Without expert fabrication partners, product development timelines would stall, and quality would suffer.

India: A Thriving Hub for PCB Fabrication Companies

India is rapidly becoming a global destination for electronics manufacturing. With government initiatives like ‘Make in India’ and PLI (Production Linked Incentive) schemes, the PCB fabrication landscape is thriving.

Key Strengths of Indian PCB Fabrication Companies:

Cost-Effective Manufacturing

Skilled Engineering Talent

Strong Infrastructure in EMS Hubs like Bangalore, Pune, and Chennai

Export-Ready Production Lines

Indian PCB manufacturers now cater to clients in Europe, the US, and Southeast Asia, providing high-quality boards with competitive pricing.

Services Offered by Leading PCB Fabrication Companies

Most top-tier PCB fabrication companies offer:

Single-layer, double-layer, and multilayer PCBs

HDI (High-Density Interconnect) and impedance-controlled boards

Flexible and rigid-flex PCB production

Surface finishes: ENIG, HASL, OSP, Immersion Silver/Gold

Prototype and mass production

Electrical testing and quality assurance

Lead-free and RoHS-compliant boards

How to Choose the Right PCB Fabrication Partner

Choosing the right PCB fabrication company can significantly impact your product’s reliability and performance. Here’s what to look for:

Certifications (ISO, UL, IPC)

Turnaround time and prototyping speed

Material quality and traceability

Design and engineering support

Testing capabilities

Client reviews and global delivery track record

A reliable partner not only fabricates your design but helps you refine it for better yield and cost-efficiency.

Finding Trusted PCB Fabrication Companies in India

If you're looking to connect with reliable, verified PCB fabrication companies in India, FindingMFG.com is your go-to platform.

🛠️ Why Use FindingMFG?

Access to a network of certified PCB manufacturers

Compare capabilities, pricing, and turnaround times

Get quotes directly from suppliers

Explore companies serving your industry segment

Simplify sourcing and reduce procurement timelines

Conclusion

As the electronics industry evolves, the demand for high-quality PCBs will only continue to grow. A dependable PCB fabrication company ensures your product meets functionality, durability, and compliance standards from the ground up.

Whether you're prototyping an IoT device or scaling up for global production, choosing the right PCB partner can make all the difference.

🧩 Ready to connect with top PCB Fabrication Companies in India? 👉 Visit www.findingmfg.com and start sourcing smarter today!

0 notes

Text

Understanding Automotive Wiring Harnesses and BIM Training Institutes in Pune

Automotive Wiring Harness: The Nervous System of Vehicles

An automotive wiring harness is an essential component that acts as the nervous system of a vehicle. It consists of a complex network of wires, connectors, and terminals that transmit electrical signals and power throughout the automobile. These harnesses are responsible for connecting various electrical and electronic components such as lights, sensors, engine controls, and entertainment systems.

The design and manufacturing of wiring harnesses require precision and expertise to ensure safety, reliability, and durability under various operating conditions. Advances in automotive technology, including electric vehicles (EVs) and autonomous driving systems, have increased the complexity and importance of wiring harnesses. Modern harnesses are now designed to handle higher voltages, incorporate sophisticated routing, and meet stringent safety standards.

Professionals involved in the automotive wiring harness industry typically undergo specialized training in electrical systems, automotive electronics, and manufacturing processes. This knowledge ensures that they can produce harnesses that are efficient, safe, and compliant with industry standards.

Bim Training Institute in Pune: Building the Future with BIM Skills

In the construction and architecture sectors, BIM (Building Information Modeling) has revolutionized project planning, design, and management. The Bim Training Institute in Pune offers comprehensive courses that equip students and professionals with the necessary skills to excel in BIM technology. These courses cover essential topics such as 3D modeling, clash detection, project visualization, and construction management.

Pune has emerged as a hub for engineering and architectural education, making it an ideal location for Bim Software Classes in Pune. These institutes focus on hands-on training, providing learners with practical experience in popular BIM software tools like Revit, Navisworks, and Tekla Structures. The goal is to prepare students for the dynamic demands of the industry, where BIM professionals are highly sought after for their ability to streamline workflows, reduce costs, and improve project outcomes.

Structural Design Courses: Laying the Foundations

Complementing BIM training, structural design courses are vital for those interested in the structural engineering domain. These courses delve into the principles of designing safe and efficient structures, including buildings, bridges, and industrial facilities. Students learn about load calculations, material properties, seismic considerations, and sustainable design practices.

Structural design courses also incorporate software training, enabling students to create detailed structural models and analysis reports. Combining these skills with BIM expertise enhances a professional’s ability to contribute effectively to construction projects, ensuring structural integrity and compliance with safety standards.

The Intersection of Technology and Industry

Both the automotive wiring harness sector and the architectural/structural design fields are experiencing significant technological advancements. Automation, digital modeling, and computer-aided design tools have transformed how professionals approach their work. For instance, the integration of BIM in construction projects improves coordination and reduces errors, much like how advanced wiring harness designs optimize vehicle performance and safety.

Furthermore, educational institutions in Pune are adapting to these changes by offering specialized courses that blend traditional engineering principles with modern software skills. The Bim Training Institute in Pune and various structural design courses are examples of how education is evolving to meet industry needs.

Conclusion

Whether you're interested in the technical intricacies of automotive wiring harness manufacturing or aiming to enhance your skills through Bim Software Classes in Pune or structural design courses, Pune offers excellent opportunities for professional growth. Staying updated with the latest industry standards and technological advancements is crucial for success in these dynamic fields.

0 notes

Text

Periodic Maintenance for Luxury Cars: The Key to Unmatched Performance

Luxury cars are engineered with cutting-edge technology, precision, and high-performance components that require expert care. However, to ensure that your luxury car continues to deliver the same exceptional driving experience over the years, regular maintenance is crucial. At WrenchIt, Pune’s leading name in luxury automobile care, we specialize in offering exclusive periodic car maintenance services tailored specifically for high-end and premium cars. Regular maintenance services are the cornerstone of keeping these vehicles in top condition.

1 note

·

View note

Text

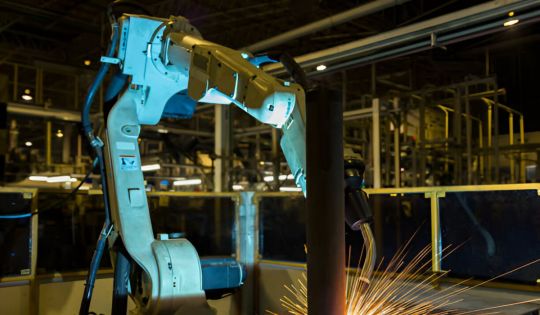

🤝 Robotic Welding Fixtures That Actually Work

I still remember the frustration on the shop floor.

Every time a product failed inspection due to welding inconsistency, it meant more rework, delays, and lost money. We were operating in an age where precision, speed, and efficiency were everything—but our manual systems just couldn’t keep up.

That’s when I first started exploring the world of robotic automation solutions. What began as a casual online search turned into a journey of discovery that completely transformed our operations.

The Wake-Up Call: Why Manual Systems Weren’t Enough Anymore

We had skilled technicians, but human error was inevitable. Our productivity was plateauing, and the competition was moving fast. I needed something smarter, faster, and more reliable—something that could scale with demand and stay consistent shift after shift.

It became clear that we needed help from a robotic automation solutions provider who not only understood our industry but could offer customized solutions.

First Steps into Robotic Automation

I’ll be honest—at first, I was hesitant. Robotics sounded complicated, expensive, and hard to integrate. But once I started connecting with industry experts, I realized how far India had come in automation.

It wasn’t just about fancy robots—it was about real, practical applications:

Robotic arms performing repeat welding jobs

Fixtures designed for flawless precision

Entire systems working seamlessly across our production line

That’s when I came across a local team of robotic system manufacturers in Pune. Their portfolio, expertise, and problem-solving approach caught my attention.

Why Pune?

Pune has quietly become a hub for industrial innovation. The city is home to some of the most advanced robotic system manufacturers in India, offering world-class automation at competitive costs.

From automobile components to consumer electronics, Pune-based robotics companies are driving transformation across sectors.

I decided to schedule a consultation—and that meeting opened the door to a whole new way of thinking.

What Impressed Me About the Right Robotic Automation Partner

A good robotic automation solutions provider doesn’t just sell machines. They become a strategic partner who studies your workflow, understands your production bottlenecks, and then builds a system around your real-world needs.

Here’s what stood out in our experience:

1. Customized Design

We weren’t given a one-size-fits-all product. Instead, we had a detailed consultation where engineers studied our welding process and proposed tailor-made automation solutions.

2. Robotic Welding Fixtures with Precision

Welding had always been a pain point for us. But the new robotic welding fixtures manufactured with high-grade materials brought remarkable precision. The welds were cleaner, stronger, and consistent—no more rework.

3. Easy Integration

One of my biggest fears was downtime. But the robotic systems were designed in a modular way, which made integration smooth with minimal disruption.

4. Support and Training

The training was excellent. Even our existing technicians picked up the controls quickly. Plus, ongoing support meant we always had someone to troubleshoot or suggest improvements.

From Hesitation to Transformation

It didn’t happen overnight, but within a few weeks of deploying our first robotic welding station, we saw:

40% faster production time

Significant drop in defects

Less fatigue and fewer injuries for workers

I realized that automation wasn’t about replacing people—it was about elevating them. Our skilled technicians now focused on quality control and optimization, while the robots handled repetitive tasks.

The Role of Robotic Welding Fixtures in Our Success

A major turning point was switching to high-performance robotic welding fixtures manufactured in India. These fixtures were:

Ergonomically designed for robotic access

Durable under high-heat, high-cycle operations

Customizable for different product types

This meant each weld was not only perfect but also fast. The ROI became visible within months. The efficiency we gained far outweighed the investment.

Choosing the Right Robotic System Manufacturer

If you're in the industrial space and considering automation, I can’t stress this enough: choose your partners wisely.

The right robotic system manufacturers in Pune understand both the technology and the business impact. They’ll collaborate with your team, guide you through the process, and deliver a system that evolves with your needs.

Here’s what to look for:

Experience across industries

End-to-end design and fabrication capabilities

On-site installation and after-sales service

Ability to integrate robotics with existing ERP/PLC systems

Common Myths About Robotic Automation (That I Once Believed Too)

❌ Myth 1: "Robots are only for big companies."

Truth: Mid-sized manufacturers benefit the most by reducing labor costs and improving quality.

❌ Myth 2: "The cost is too high."

Truth: With Indian manufacturers and modular systems, automation is more affordable than ever.

❌ Myth 3: "We’ll lose jobs."

Truth: Our workforce became more skilled, not redundant. Robots handled the hard stuff—we focused on innovation.

Real Benefits You Can Expect

After working with a reliable robotic automation solutions provider, here’s what we gained:

✅ Higher productivity ✅ Better product consistency ✅ Less scrap and waste ✅ Safer working conditions ✅ Happier customers

And most importantly, we now had a competitive edge in a saturated market.

India’s Growing Strength in Robotic Manufacturing

India is no longer catching up—it’s leading in several areas of industrial robotics. Local companies are now world-class robotic welding fixtures manufacturers, and Pune stands out as a powerhouse of robotic engineering.

Whether it’s automotive, electrical, or general manufacturing, Indian businesses are embracing robotic systems that are:

Compact

Scalable

Cost-effective

Smart (IoT & AI enabled)

🧠 Frequently Asked Questions (FAQs)

Q1. What does a robotic automation solutions provider do?

Ans: A robotic automation solutions provider designs and delivers systems that automate repetitive tasks using industrial robots. This includes everything from robotic arms for welding to custom-built fixtures and control systems tailored for specific manufacturing needs.

Q2. Why are robotic welding fixtures important in manufacturing?

Ans: Robotic welding fixtures ensure precision, repeatability, and stability during automated welding processes. They help reduce human error, increase production speed, and maintain high weld quality across every product.

Q3. Are there reliable robotic welding fixtures manufacturers in India?

Ans: Yes, India is home to many top-tier robotic welding fixtures manufacturers who provide cost-effective, high-performance solutions for industries like automotive, electronics, and heavy machinery. These manufacturers offer customized designs to meet various industrial needs.

Q4. Why should I choose robotic system manufacturers in Pune?

Ans: Robotic system manufacturers in Pune are known for their advanced engineering, affordable solutions, and strong after-sales support. Pune has emerged as a robotics hub, with expertise across automation, machine integration, and smart factory systems.

Q5. Is robotic automation suitable for small and mid-sized manufacturers?

Ans: Absolutely. With scalable and modular solutions available from Indian robotic automation providers, even small and medium-sized factories can adopt automation without a huge upfront investment. It improves productivity, quality, and long-term profitability.

Q6. How long does it take to install a robotic automation system?

Ans: Installation timelines vary depending on system complexity. However, many robotic automation solutions providers offer modular systems that can be integrated quickly—sometimes in just a few days—with minimal downtime.

Q7. Can existing machines be upgraded with robotic systems?

Ans: Yes. Many robotic system manufacturers in Pune specialize in retrofitting existing equipment with automation tools, saving costs while upgrading efficiency.

Q8. Is maintenance of robotic systems difficult?

Ans: Not at all. With the right training and support, robotic systems are easy to maintain. Most providers offer preventive maintenance programs and 24/7 technical support.

Q9. What industries benefit most from robotic welding fixtures?

Ans: Industries such as automotive, aerospace, heavy fabrication, and consumer electronics benefit immensely from using robotic welding fixtures manufactured in India, thanks to their durability and precision.

Q10. How can I get started with robotic automation for my factory?

Ans: Start by consulting a trusted robotic automation solutions provider. They will assess your production line, identify automation opportunities, and design a system tailored to your specific goals and budget.

Final Thoughts: Don’t Wait to Automate

Looking back, I only wish we had done it sooner.

Our move toward robotic automation didn’t just improve our bottom line—it made work better for our entire team. It redefined how we looked at growth, quality, and sustainability.

If you're stuck in outdated manual processes, or your quality metrics aren’t improving, this might be your moment to explore what modern automation can offer.

Whether it’s working with robotic system manufacturers in Pune or sourcing custom robotic welding fixtures manufactured in India, there’s a world of opportunity waiting to power up your production line.

#robotics#welding machine#welding services#robotic welding#robotics engineering#robotics innovation#automation#machine#robotic automation#robotics Pune#automation in manufacturing#robotics blog

0 notes

Text

Automobile Components in India

We are the manufacturer and supplier of Automobile Components in Pune, India. We have raised the automotive industry level. Find here premium products.

#Automobile Components in Pune#Automobile Parts in India#Home Appliances Components in India#Electrical and Electronics Components in Pune#Aluminium Other Components in India#Aluminium Other Components in Pune#Home Appliances Components in Pune

0 notes

Text

OTIS Elevator Manufacturer in Pune

Olympia Elevators Pvt. Ltd. OTIS Elevator Manufacturer in Pune. Olympia Elevators Pvt. Ltd. allows us to offer a comprehensive range of Elevators for our clients.These products are fabricated using high-quality raw material including stainless steel. Our products are specially used for the vertical transportation of vehicles including cars and other automobiles.

For relatively low traffic private garages, apartments, complexes, car show rooms & service stations; our OTIS Elevator Manufacturer in Pune products are considered ideal. Clients can avail from us this range of product at most reasonable prices. Our clients can avail from us a wide collection of best quality OTIS Elevator Manufacturer in Pune.These products are made from high quality components.

0 notes

Text

Blow Off Water and Dust Services in Pune, India – Nexgen Drying Systems

In industrial and manufacturing environments, maintaining cleanliness and efficiency is crucial for seamless operations. One of the essential processes in various industries is Blow off water and dust Services Pune India, which ensures the removal of contaminants such as moisture, dust, and debris from surfaces. Nexgen Drying Systems, a leading name in the industry, offers state-of-the-art solutions for blow-off cleaning, enhancing productivity and ensuring product quality.

Importance of Blow Off Water and Dust Services

Industries such as automotive, aerospace, electronics, and food processing require precise and thorough cleaning before further processing, painting, or packaging. The presence of water and dust can lead to defects, corrosion, and reduced efficiency in machinery. With the help of advanced Blow off water and dust Services Pune India, industries can:

Improve product quality by eliminating contaminants.

Reduce the risk of equipment failure due to accumulated dust and moisture.

Enhance production efficiency by ensuring smooth operation of manufacturing processes.

Lower maintenance costs by preventing residue buildup on equipment and surfaces.

Nexgen Drying Systems – Your Trusted Partner

Nexgen Drying Systems is a reputed provider of Blow off water and dust Services Pune India, delivering innovative and customized drying and cleaning solutions for a wide range of industries. With years of experience, cutting-edge technology, and a customer-centric approach, Nexgen ensures optimal cleaning results tailored to the specific needs of its clients.

Key Features of Nexgen Drying Systems’ Blow-Off Services

High-Pressure Air Technology: Nexgen utilizes high-velocity air jets to remove dust and moisture effectively.

Energy-Efficient Solutions: Their systems are designed to consume minimal energy while maximizing cleaning efficiency.

Customizable Nozzle Designs: The company offers a variety of nozzles to suit different applications, ensuring precise and uniform cleaning.

Eco-Friendly Operations: Nexgen prioritizes sustainability by using non-contact, air-based cleaning methods that do not require chemicals or water.

Automation Integration: Their blow-off systems can be seamlessly integrated into automated production lines, reducing manual labor and increasing operational efficiency.

Applications of Blow Off Water and Dust Services

Automobile Industry: Removal of water and dust from vehicle parts before painting and assembling.

Electronics Industry: Cleaning of delicate components without the risk of damage.

Food and Beverage Industry: Ensuring contamination-free packaging and processing.

Aerospace Industry: Dust and moisture removal from aircraft components for enhanced performance and safety.

Metal Fabrication: Drying and dust removal from metal parts before welding and coating.

Why Choose Nexgen Drying Systems?

With its commitment to quality and innovation, Nexgen Drying Systems has established itself as a leader in Blow off water and dust Services Pune India. The company’s expertise, customer-focused approach, and cutting-edge technology make it the preferred choice for industries looking to optimize their cleaning and drying processes.

For more information on Nexgen Drying Systems and their services, visit http://www.nexgendrying.com/.

0 notes

Text

Top Single Girder EOT Crane Manufacturer in India – Trusted for Quality & Performance

In the fast-evolving industrial landscape, efficiency, safety, and reliability in material handling systems are more important than ever. For industries requiring robust yet economical lifting solutions, the Single Girder EOT Crane has become a preferred choice. As a leading Single Girder EOT Crane Manufacturer in India, we deliver high-performance cranes designed to meet the specific needs of various sectors.

Why Choose a Single Girder EOT Crane?

A Single Girder EOT (Electric Overhead Traveling) Crane is designed with a single bridge girder supported by end trucks, and the hoist mechanism travels on the lower flange of the girder. These cranes are ideal for medium-duty material handling applications and are widely used due to their cost-effectiveness and simplicity in operation.

Key Advantages:

Efficient use of space

Lower dead weight and reduced wheel loads

Smooth and controlled lifting operations

Energy-efficient and cost-effective design

Partnering with the right Single Girder EOT Crane Manufacturer in India ensures you get reliable equipment that enhances productivity and safety.

Our Expertise as a Single Girder EOT Crane Manufacturer in India

With years of industry experience and engineering excellence, we are recognized as a trusted Single Girder EOT Crane Manufacturer in India. Our cranes are manufactured with precision, using high-grade components that comply with international quality and safety standards.

What Sets Us Apart:

Customized crane solutions for varied lifting capacities and spans

Durable construction using top-quality materials

Advanced manufacturing technology for accuracy and consistency

Expert technical support from design to after-sales service

Timely delivery across India with efficient installation services

Applications of Our Single Girder EOT Cranes

Our cranes are engineered to perform efficiently across multiple industrial environments. As a top-rated Single Girder EOT Crane Manufacturer in India, we serve industries such as:

Steel & Metal Processing

Textile & Chemical Plants

Automobile Manufacturing

Logistics & Warehousing

Engineering & Fabrication Units

Whether it’s lifting raw materials or moving finished products, our cranes ensure smooth, safe, and streamlined operations.

Why Indian Manufacturers Are a Smart Choice

Choosing a Single Girder EOT Crane Manufacturer in India offers several benefits:

Affordable pricing without quality compromise

Easier access to spare parts and service

Better understanding of local industrial requirements

Quick customization and faster turnaround

When it comes to dependable lifting solutions, working with a proven Single Girder EOT Crane Manufacturer in India makes all the difference. We are committed to delivering cranes that combine safety, performance, and long-term value. Whether you need a standard model or a fully customized solution, we are here to support your business every step of the way.

For more information about Ailas Engineered Solutions,

Visit website: https://www.ailas.in/

Address: Plot № 141/2, Sector 2, Opp. Ekdant Path Labs, Nr. Bank of Maharashtra, Bhosari, Indrayani Nagar, Pune — 411026

#CraneManufacturerIndia#MaterialHandlingSolutions#ReliableCraneManufacturer#WorkshopCranesIndia#SingleGirderCraneIndia

0 notes

Text

Why Aerospace Components Manufacturers in India Are Powering the Future of Global Aviation

India has rapidly evolved into one of the most dynamic manufacturing hubs in the world. Driven by government initiatives, skilled labor, and growing global demand, Indian manufacturers are making a strong impact in critical industries such as aerospace, automotive aftermarket, and industrial rubber. From precision engineering to durable industrial supplies, Indian manufacturers are now catering to both domestic and international markets with superior quality and cost efficiency.

Aerospace Components Manufacturers in India

The Indian aerospace industry has grown tremendously in the last decade. With a focus on indigenization, many Indian firms are now producing world-class aerospace components that meet global standards. Aerospace components manufacturers in India have invested heavily in advanced technologies like CNC machining, 3D printing, composite materials, and quality control systems to serve global aerospace giants.

These manufacturers supply precision parts such as engine casings, landing gear systems, actuators, brackets, and fasteners. Collaborations with organizations like ISRO, HAL (Hindustan Aeronautics Limited), and DRDO have further strengthened India's reputation as a reliable source of high-end aerospace manufacturing. Companies are also certified with AS9100, ISO 9001, and other global quality standards, which has helped them establish long-term export relationships with clients in North America, Europe, and the Middle East.

Moreover, aerospace manufacturing clusters in cities like Bengaluru, Hyderabad, Pune, and Chennai have created an ecosystem that fosters innovation, skill development, and high productivity. With a sharp focus on quality and precision, aerospace components manufacturers in India are becoming essential partners in the global aerospace value chain.

Supplier of Aftermarket Parts in India

The automotive and industrial machinery sectors rely heavily on a stable and high-quality supply of aftermarket parts. India has emerged as a key supplier of aftermarket parts in India, offering a wide range of products including engine components, transmission parts, suspension systems, filters, brake systems, and electrical parts. These components are essential not only for vehicle maintenance but also for enhancing performance and lifespan.

Indian aftermarket suppliers are known for offering high-quality products at competitive prices, making them attractive to clients in the United States, Europe, Africa, and Latin America. They serve a wide variety of sectors such as automobiles, commercial vehicles, construction machinery, agricultural equipment, and even aerospace maintenance.

What sets Indian aftermarket suppliers apart is their ability to customize products based on client specifications and market requirements. From OEM-quality standards to rapid delivery and after-sales support, they provide end-to-end services that support fleet operators, workshops, and retailers. With increasing digitization and e-commerce platforms, aftermarket businesses in India are also leveraging technology to streamline orders and logistics.

Rubber Products Manufacturers in India

Rubber products are the backbone of many industrial applications, and India has positioned itself as a leading manufacturer in this segment. Rubber products manufacturers in India produce a diverse range of items, such as gaskets, seals, O-rings, hoses, anti-vibration mounts, rubber sheets, and molded components for various industries including automotive, aerospace, oil & gas, construction, and healthcare.

These manufacturers use high-grade synthetic and natural rubber materials to ensure durability, resistance to chemicals, temperature variation, and mechanical wear. They comply with global standards such as RoHS, REACH, and ISO certifications, which makes them highly sought after in international markets. Indian rubber manufacturers are known for their ability to provide cost-effective solutions without compromising on performance or quality.

Many of these manufacturers are located in industrial belts such as Maharashtra, Gujarat, Tamil Nadu, and Karnataka, where access to raw materials, skilled labor, and efficient logistics make large-scale production viable. Continuous R&D investment also helps Indian rubber producers develop innovative solutions for demanding applications.

Conclusion

India’s industrial growth is no longer limited to traditional sectors—it is now making a global mark in high-precision manufacturing. With top-tier aerospace components manufacturers in India, trusted supplier of aftermarket parts in India, and globally competitive rubber products manufacturers in India, the country is poised to become a key supplier in the global supply chain.

As international demand continues to grow, India’s focus on innovation, quality, and sustainability ensures it will remain a preferred destination for sourcing high-performance components and materials across multiple sectors.

#supplierofaftermarketpartsinindia#rubberproductsmanufacturersinindia#aerospacecomponentsmanufacturersinIndia

0 notes