#Automotive Components

Explore tagged Tumblr posts

Text

Top 5 Automotive Companies and How Metalman Auto Ltd. Supports Them

The automotive industry is dominated by several key players that lead the market in terms of innovation, production, and market share. The top five automotive companies globally are typically considered to be Toyota, Volkswagen Group, Daimler AG (Mercedes-Benz), Ford Motor Company, and General Motors (GM).

How Metalman Auto Ltd. Supports These Automotive Giants

As a leading supplier of high-quality automotive components, Metalman Auto Ltd. is well-positioned to support these top automotive companies. Our expertise in metal fabrication and assembly allows us to provide critical components that meet the specific needs of these manufacturers.

Our Value Proposition:

High-Precision Components: We provide parts that are essential for the safety and performance of vehicles, adhering to the exact specifications required by these top manufacturers.

Collaborative Approach: We work closely with OEMs to understand their needs and provide innovative solutions that enhance vehicle performance and safety.

Sustainable Manufacturing: Our commitment to sustainable practices ensures we contribute positively to the automotive industry’s environmental goals.

By partnering with Metalman Auto, these top automotive companies can enhance their supply chain efficiency and maintain their competitive edge in the global market.

#EV components supplier#Electric car parts manufacturer#Battery components supplier for EVs#Electric vehicle drivetrain parts supplier#EV charging components manufacturer#Electric motor parts supplier#EV battery management system supplier#Electric scooter parts manufacturer#general motors#vintage automobiles#chevrolet#Volkswagen Group#automotive industry#automotive#automotive components#metal fabrication#oems#oemparts#oem manufacturing#oem#metal parts supplier#India automotive components manufacturer#Automobile parts production in India#OEM parts manufacturing in India#Indian automotive parts supplier#Vehicle parts manufacturing industry in India#Made in India automotive components#Indian car parts production#India-based automotive parts manufacturer"

2 notes

·

View notes

Text

Pressed Components – Precision Engineering Components Explore high-quality precision engineering components,industrial components, and engineering components from a trusted elevator components manufacturer and lift components supplier. We specialize in automotive components, escalator components, and are recognized aerospace component suppliers. As a leading elevator components supplier, we also serve as a reliable lift components manufacturer delivering durable, efficient solutions.

#Precision engineering components#industrial components#engineering components#automotive components#escalator components#aerospace component suppliers#Elevator Components#Elevator Components manufacturer#Elevator Components supplier#Lift components#Lift components manufacturer#Lift components suppliers

0 notes

Text

Shivalik Engineering: Building the Future with Precision

Take a closer look at what drives quality at Shivalik Engineering. From railway and automotive components to precision hubs and industrial solutions — we build the future, one product at a time. Explore more at: https://shivalikengineering.com

0 notes

Text

Global Pressure Sensitive Tapes Market: Emerging Trends, Innovations, and Growth Projections for 2025 and Beyond

Global Pressure Sensitive Tapes Market: Forecast to 2034, Key Drivers, and Regional Insights

The Global Pressure Sensitive Tapes Market is entering a transformative growth phase, underpinned by rising demand across major end-use sectors such as packaging, automotive, healthcare, electronics, and construction. With a projected market size of USD 73.4 billion by 2025, and an expected CAGR of 5.1% through 2034, the market is poised to reach an estimated USD 114.7 billion, presenting compelling opportunities for manufacturers, suppliers, and investors worldwide.

Explore full insights, growth potential, and segment-level data in this in-depth Global Pressure Sensitive Tapes Market analysis.

Understanding Pressure Sensitive Tapes (PSTs)

Pressure Sensitive Tapes are specialized adhesive solutions that stick to surfaces upon the application of minimal pressure. Unlike traditional adhesives, they do not need external agents like heat or water for activation, making them highly versatile and easy to use.

These tapes are typically formulated with acrylic, rubber-based, or silicone adhesives, and are available as:

Single-sided tapes for sealing, masking, and insulation

Double-sided tapes for bonding and mounting applications

Thanks to their adaptability and bonding strength, PSTs are indispensable across a variety of sectors.

📄 Download the free PDF sample report here: https://dimensionmarketresearch.com/report/pressure-sensitive-tapes-market/request-sample/

Major Growth Drivers

1. Evolving Packaging Needs

The ongoing surge in e-commerce, retail, and logistics operations has significantly increased the consumption of pressure-sensitive packaging tapes. These tapes provide reliable closure, tamper resistance, and compatibility with automated packaging systems—making them essential in today's high-speed distribution environments.

2. Technological Shifts in Automotive & Electronics

Modern vehicle production increasingly incorporates PSTs for:

Wire harnessing

Interior trim attachment

Insulation and noise-damping

Similarly, electronics manufacturers use PSTs for:

Screen assembly

Shielding and insulation

Component bonding in compact devices

Their lightweight nature and resistance to environmental stressors make them the adhesive of choice in these high-precision industries.

3. Rising Infrastructure and Construction Demand

In the building sector, PSTs are widely used for:

Mounting panels

Vapor sealing

Soundproofing

Weather-resistant installations

Rapid urbanization, particularly in developing countries, is driving demand for construction tapes that offer both durability and ease of use.

Market Forecast: Revenue Outlook to 2034

Key Metrics:

Market Size in 2025: USD 73.4 billion

Forecasted Market Size by 2034: USD 114.7 billion

CAGR: 5.1% (2025–2034)

The consistent growth reflects a shift toward advanced materials, automation in production, and expanded applications across emerging industries such as medical devices, renewable energy, and smart technologies.

📩 For tailored insights or report customization, contact us @ https://dimensionmarketresearch.com/enquiry/pressure-sensitive-tapes-market/

Regional Landscape

Asia Pacific Leads Global Expansion

Asia Pacific is expected to dominate the market, accounting for 38.4% of global revenue in 2025. Countries like China, India, and Japan are accelerating industrial output, construction activities, and automotive production, which directly fuels the use of PSTs.

Contributing Factors:

Low-cost manufacturing hubs

Booming e-commerce and packaging industries

Increasing infrastructure investments

High adoption of automation and advanced materials

North America and Europe: Mature but Steady

These regions benefit from well-established industries and continued demand for medical-grade, industrial, and electronic-grade tapes. However, growth rates are slower due to environmental restrictions and market saturation.

Emerging Economies: Untapped Potential

Countries in Latin America, the Middle East, and parts of Africa are beginning to adopt PSTs at scale, especially in packaging and construction. Local production capabilities and strategic foreign investments are helping unlock new growth channels.

🛒 Access the full market report here: https://dimensionmarketresearch.com/checkout/pressure-sensitive-tapes-market/

Product Segmentation & Backing Materials

Types of Pressure Sensitive Tapes:

Single-sided tapes: Commonly used for general sealing and masking

Double-sided tapes: Preferred for mounting, assembling, and joining surfaces

Transfer tapes: Adhesive-only, used for electronics and fine assemblies

Specialty tapes: Designed for medical, conductive, fire-retardant, or UV-resistant applications

Common Backing Materials:

Paper

Foam

Plastic Films (PET, PVC, PE)

Fabric/Textile

Metal Foil

Each material offers different performance characteristics like temperature resistance, flexibility, and durability, enabling tailored application.

Market Trends: Innovation and Sustainability

Environmentally-Friendly Solutions

With rising awareness about environmental impact, manufacturers are shifting to water-based, solvent-free, and recyclable tape formulations. Biodegradable options are becoming more prominent in Europe and North America, where regulations demand greener production.

Custom-Engineered & Smart Tapes

Clients across industries are requesting custom solutions for temperature resistance, chemical exposure, and outdoor use. Additionally, smart PSTs with embedded sensors, RFID tags, and anti-counterfeit features are under development to support traceability and product integrity.

Automation in Production & Application

The growing trend of robot-assisted production has created demand for PSTs designed for automated application tools. These tapes are used in precision workflows across electronics, automotive, and appliance manufacturing.

Key Market Challenges

Despite the robust forecast, the industry does face headwinds:

Volatile raw material costs, especially for petroleum-based adhesives

Environmental restrictions impacting traditional solvent-based tapes

Price competition in commodity tape segments

Limited recyclability of certain composite backings

To stay ahead, businesses are investing in material R&D, eco-friendly production, and automation-driven efficiency.

Frequently Asked Questions (FAQs)

1. What are the main applications of pressure sensitive tapes? They are used for bonding, sealing, labeling, mounting, and insulation across various industries like packaging, automotive, electronics, and healthcare.

2. What is driving market growth? E-commerce growth, automotive lightweighting, construction demand, and innovation in tape technology are major drivers.

3. Which region is currently leading the market? Asia Pacific leads with an expected 38.4% global share by 2025, due to rapid industrial growth.

4. What is the future market size expected to be? The market is projected to reach USD 114.7 billion by 2034, growing at a CAGR of 5.1%.

5. Are there eco-friendly versions of PSTs? Yes, the market is moving toward recyclable, biodegradable, and water-based tape formulations to meet sustainability goals.

Conclusion

As industries evolve, so does the role of Pressure Sensitive Tapes. From enabling efficient e-commerce packaging to streamlining the design of modern vehicles and electronics, PSTs have become essential to global manufacturing and logistics.

With sustainability, automation, and customization taking center stage, the Global Pressure Sensitive Tapes Market is transitioning into a new era of smart, sustainable, and high-performance adhesive solutions. Market players who invest in innovation and regional expansion will be best positioned to capture growth in this expanding landscape.

#pressure sensitive tapes#adhesive tapes market#packaging tapes#automotive adhesives#construction tapes#electronics manufacturing#sustainable adhesives#market trends#industrial adhesives#pressure-sensitive materials#tape technology#automotive components#healthcare tapes#logistics packaging#CAGR forecast#tape innovation#Asia Pacific market#growth opportunity#industrial supply#smart adhesives

0 notes

Text

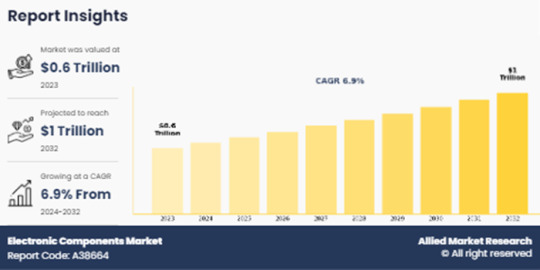

Electronic Components Market Will See Strong Expansion Through 2032

Allied Market Research, titled, “Electronic Components Market by Type and Application: Global Opportunity Analysis and Industry Forecast, 2024-2032." The electronic components market was valued at $0.6 trillion in 2023 and is estimated to reach $1.0 trillion by 2032, growing at a CAGR of 6.9% from 2024 to 2032.

The market for electronics components is made up of a rich variety of fundamental devices that are indispensable for electrical circuitry and functionality. Such elements consist of integrated circuits, resistors, capacitors, transistors, sensors, diodes as well as optoelectronic devices among others. They can be utilized as the basic building blocks of electronic systems in different sectors including automotive, consumer electronics, healthcare, and telecommunications. This continuous innovation is driven by technological advancements leading to smaller, faster, and more efficient components. The growing demand for connected devices, Internet of Things (IoT) solutions, and renewable energy systems dominates the market. On the other hand, supply chain disruptions among other challenges indicate that the electronic components market trends will continue experiencing steady growth triggered by sustained technological improvements coupled with changing customer preferences.

The expansion of electronic parts is driven by an increasing number of people moving to cities and the growth of smart cities globally. Urbanization has led to increased traffic congestion, security threats, and information gaps due to the increased number of urban dwellers. As a result, smarter city initiatives employ ICT approaches for improved urban transport systems, interconnectivity infrastructures as well as better services. Among these options that have been designed, electronic components are particularly important in this regard; ensuring all social amenities continue with their operations even during the night hours. These signs can send messages in real-time, provide navigation support, send emergency alerts, or produce advertisements thereby preventing disappearance from towns and cities throughout the whole day. For example, such technologies can be uniformly integrated within existing IoT devices installed in various smart city infrastructure elements such as transport solutions and data analytics platforms thus increasing demand for sophisticated digital signage that facilitates more connected sustainable urban environments.

Nonetheless, there are serious barriers to the adoption of electronic components that include integration complexities with current infrastructure and ecosystems where they are supposed to be fitted. To do this perfectly, a smooth process requires advanced planning, comprehensive electronics engineering technical knowledge, and in some instances extensive changes or modifications. This is time-consuming and costly while also needing substantial resources in order to make it compatible with diverse hardware and software components leading to operational downtime, cost overruns as well as other technical glitches.

However, these obstacles notwithstanding; there are huge potential growth areas for electronic components especially in developing nations undergoing rapid urbanization and digitalization. These regions which have been characterized by changing tastes among consumers as well as government programs aimed at modernizing the infrastructure provide fertile ground for broad based use of electronic components in industries such as retail commerce, transportation services, and hotels. The resultant demand for electronic components that will come about when emerging markets adopt digital technologies to facilitate communication process, improve efficiency both in manufacturing sector and service delivery alongside enhancing customers experience will significantly define their role as drivers of global industrial growth.

The electronic components market report is segmented based on type, application, and region. On the basis of type, the electronic components market forecast is divided into active components, passive components, and electromechanical components. Based on application, the electronic components industry report is classified into consumer electronics, automotive, industrial automation, telecommunication, aerospace and defense, healthcare, energy and power, and others.

On the basis of region, it is analyzed across North America (the U.S., Canada, and Mexico), Europe (the UK, Germany, France, Italy, and the rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), Latin America (Brazil, Argentina, and rest of Latin America), and Middle East and Africa (UAE, Saudi Arabia, and rest of Middle East & Africa).

The key electronic components company list profiled in the report includes Intel Corporation, Samsung, TSMC, Texas Instruments, Broadcom Inc, Bosch, NXP Semiconductors, STMicroelectronics, Skyworks Solutions, and Analog Devices. These key electronic components company listed in this market have adopted strategies such as product portfolio expansion, mergers & acquisitions, agreements, geographical expansion, and collaborations to enhance their market penetration.

According to Himanshu Jangra, Lead Analyst, Semiconductor and Electronics, at Allied Market Research, “The global electronic components market value is expected to witness considerable growth, owing to increase in demand for consumer electronics solution paired with rise in disposable income in emerging economies such as India, South Korea, Brazil, Dubai, and especially in Asia-Pacific and LAMEA region, which is expected to drive the market growth.”

Key Findings Of The Study

The electronic components market insights is growing fast due to an increasing consciousness of the environment and the need to reduce carbon emissions.

Demand for the electronic components market comes majorly from the consumer electronics sector, as there are smartphones, wearables, and gadgets everywhere that need high-performance compact parts.

Competition in this market is intense with innovative firms fighting for space alongside well-established ones offering cheaper solutions.

The Asia-Pacific region leads the charge, propelled by government investments, rapid urbanization, and robust consumer retail sectors, making it a prime market for electronics component growth.

#electronic#electronic music#electronic components#electras components#pc components#automotive components

1 note

·

View note

Text

Top Uses of HR Coil Sheets in Automotive Industry: Revolutionizing Modern Manufacturing

The Steel Life Line of Innovation in Automobile Industry: Unveiling the Role of HR Coil Sheets

Steel is the backbone for modern automobiles. But of all such silent avatars of steel, what one finds outstanding are Hot Rolled (HR) coil sheets: The difference-makers for designing and producing any vehicle.

HR coil sheets are far from being another industrial material—they are a sophisticated engineering solution that bridges performance, affordability, and sustainability. Produced with a complex heating and rolling process, these sheets have distinctive characteristics that make them indispensable in the automotive manufacturing industry:

Key Characteristics of HR Coil Sheets

Exceptional Strength: Withstands extreme mechanical stress and environmental challenges

Excellent Formability: Molds easily into intricate shapes without compromising structural integrity

Cost-Effective Manufacturing: Significantly reduces production expenses compared to alternative materials

High Strength-to-Weight Ratio: Allows for the design of lighter, more fuel-efficient vehicles

Changing Automotive Components: Smart Applications of HR Coil Sheets

Body Frame Construction: The Structural Backbone

The car body is essentially the skeleton of any automobile. HR coil sheets form an integral part of the car body structure as they offer excellent strength and flexibility. These sheets help car manufacturers to design chassis structures that are both robust and light in weight.

Advantages in Body Frame Manufacturing

Vehicle weight is minimized

Crash resistance is enhanced

Structural stability is improved

Seamless integration with the most advanced welding technologies

Body Panels: Shaping Automotive Looks and Performance

Beyond structure, HR coil sheets revolutionized body panel design in the auto world. Their formability makes it possible to realize intricate shapes that were impossible or too costly earlier.

Performance Innovation: With the help of HR coil sheets, modern electric cars and high-performance sports cars can now achieve never-before design complexity and light weight.

Structural Reinforcements: Safety and Reliability through Engineering

Safety is always of paramount importance in automotive design, and HR coil sheets are a winner in producing critical reinforcement parts:

Crumple Zones: Absorbing and dispersing the impact energy in the collision

Roll Cage Structures: Providing extra protection for passengers

Suspension Components: Providing precise load-bearing capabilities

Economic and Functional Advantages: Why HR Coil Sheets Dominate

Sustainability at the Core

The automotive industry's sustainability drive finds an ideal companion in HR coil sheets. Recyclability and efficiency in production contribute to a sizeable reduction in the carbon footprint of vehicle manufacturing.

Global Trends and Industry Acceptance

Across the world, automotive manufacturers are increasingly appreciating the strategic value of HR coil sheets:

Weight Saving: It can be 30% lighter than the similar steel part

Fuel Efficiency: This is directly associated with mileage improvement and less emission

Production Speed: Enables faster manufacturing cycles

Testimonials: Voices from the Automotive Frontier

"HR coil sheets have transformed our approach to vehicle design," states Rajesh Kumar, Chief Engineer at a leading automotive manufacturer. "The material's versatility allows us to push boundaries in performance and efficiency."

Technical Specifications that Inspire Confidence

HR coil sheets used in automotive applications typically demonstrate:

Tensile Strength: 270-550 MPa

Elongation: 22-38%

Thickness Range: 0.5-3.0 mm

Corrosion Resistance: Superior protective coating options

Making the Smart Choice in Automotive Materials

More than a component, HR coil sheets represent the future of intelligent manufacturing for automotive engineers, designers, and manufacturers looking for a material that balances performance, affordability, and innovation.

Ready to transform your automotive designs? Discover the transformative power of HR coil sheets and move innovation forward.

#HR coil sheets#Automotive industry#Car frames#Chassis parts#Automotive components#Modern manufacturing#Steel sheets#Durable materials#Car chassis

0 notes

Text

Top Manufacturer of Durable Truck Parts | Heavy Vehicle Components

Metalman Auto Ltd. is a top manufacturer of durable truck parts and heavy vehicle components, specializing in high-quality metal fabrication. Our expert team ensures that every part is built to last and performs optimally in demanding conditions.

#durable truck parts#heavy vehicle components#metal fabrication#truck parts manufacturer#high-quality vehicle parts#agri-vehicle components manufacturer#automotive industry#automotive assembly parts manufacturer#high-volume automotive parts manufacturing#automotive#commercial vehicle parts supplier#b2b automotive parts supply chain#automotive metal components supplier#automotive components

1 note

·

View note

Text

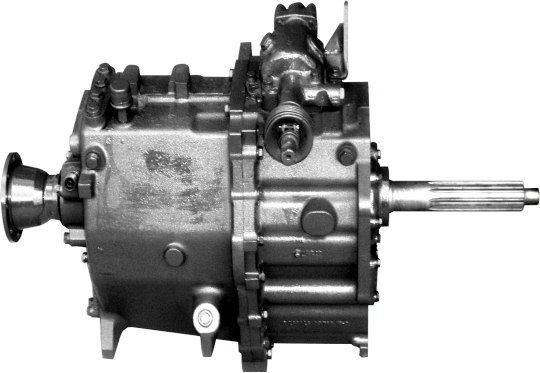

Premium Transmission Parts for Optimal Performance | TGP India

Discover a wide range of high-quality transmission parts at TGP India. Our genuine components, including crown wheels, pinions, and synchro cones, ensure efficient power transmission and vehicle performance. Explore our extensive catalog to find the perfect parts for your vehicle needs.

#transmission parts#TGP India#crown wheels#pinions#synchro cones#automotive components#vehicle performance

0 notes

Text

The Importance of Strut Mount Kits for Your Vehicle's Suspension

Strut Mount Kits are essential components that connect your vehicle's suspension system to its chassis. They cushion road impacts, reduce noise, and ensure smooth steering. Over time, worn-out strut mounts can lead to increased vibrations, poor handling, and even damage to other suspension components.

Replacing them with quality strut mount kits improves ride comfort, enhances steering control, and extends the life of your suspension system. Regularly inspecting and maintaining your strut mounts is key to ensuring safety and performance on the road.

1 note

·

View note

Text

Metalman Auto: A Leading Supplier of High-Performance Automotive Metal Components

Source high-quality automotive metal components from Metalman Auto. We offer a diverse selection manufactured with precision and dedication. Choose reliability for your car or truck.

#automotive components#automotive tools#automotive industry#automobile#automotive#fabricationservices#manufacturer#metal fabrication#metalman auto#oem manufacturing#car accessories#automotive parts#electric vehicles#automotive art#manufactured consent#Metalman Auto#metal components#oemparts#oem#delhi#auto parts supplier#opportunity

1 note

·

View note

Text

What Are The Components Of A Drone?

Drones are fascinating machines. But have you ever wondered what makes them tick? Let’s dive into the key components that bring a drone to life.

1. Frame: The Foundation

The FRAME is the backbone of a drone. It holds everything together. Usually made from lightweight materials like carbon fiber or plastic, it’s designed to support all the essential components while remaining as light as possible.

2. Motors And Propellers: The Powerhouse

MOTORS and PROPELLERS are what give the drone lift. The motors spin the propellers, which generate the thrust needed for flight. For smooth and stable flying, most drones have four motors (quadcopters), but this number can vary.

3. Electronic Speed Controllers (ESCs): The Speed Regulators

ESCs manage the speed of each motor. They take commands from the flight controller and adjust the motor’s speed accordingly. Think of them as the link between the drone’s brain and its motors.

4. Flight Controller: The Brain

The FLIGHT CONTROLLER is the drone’s brain. It processes all the inputs from the pilot and onboard sensors. This tiny computer ensures your drone remains stable in the air, even in windy conditions.

5. Battery: The Power Source

The BATTERY is the energy hub. Most drones use lithium polymer (LiPo) batteries. These batteries are known for providing a high power output while remaining lightweight. The battery’s capacity directly impacts flight time.

6. GPS Module: The Navigator

The GPS MODULE allows your drone to know its exact location. It’s crucial for advanced features like autonomous flying, return-to-home functions, and even mapping.

7. Camera And Gimbal: The Eyes And Stabilizer

For drones used in photography or videography, the CAMERA and GIMBAL are key. The gimbal stabilizes the camera, delivering those smooth, cinematic shots everyone loves.

These are the main components that make a drone fly smoothly.

To get world-class drones, visit Mavdrones.

0 notes

Text

From the Heart of the Conflict: The Strike at Linamar's Gómez Palacio Plant and Its Global Implications

In the heart of Gómez Palacio, Durango, a labor crisis at the Linamar plant threatens to trigger global repercussions. This facility, crucial to the global automotive supply chain, faces a strike that could mark a significant economic turning point. As Malcolm Gladwell describes in his “tipping point” theory, small events can have disproportionately large global consequences. Conflict…

#Automotive Components#Automotive Industry#Economic Impact#Economic Turning Point#Fourth Transformation#Gómez Palacio#Global Repercussions#Global Supply Chain#Investor Anxiety#Job Security#Just-in-Time Production#Labor Strike#Linamar#Management Changes#Market Confidence#México#Stock Market Impact#Supply Chain Disruption#Union Rights#Worker Rights

0 notes

Text

Engineered for Performance | Automotive Components by Shivalik Engineering Explore precision-made automotive components by Shivalik Engineering. As a leading automotive components manufacturer, we deliver durable and high-quality solutions for vehicles.

0 notes

Text

The top 10 wonderful electrolytic capacitor brand in China

1. Shanghai Yongming Electronics Co., Ltd. (上海永铭电子股份有限公司) Shanghai Yongming Electronics Co., Ltd. is one of the leading capacitor manufacturers in China, renowned for its high-quality aluminum electrolytic capacitors. Yongming’s products are widely used in automotive electronics, consumer electronics, and industrial control fields, especially its solid-liquid hybrid aluminum electrolytic capacitors. The company continually invests in research and development and production technology, striving to offer products with high reliability and long lifespan.

2. Jianghai Capacitor Co., Ltd. (江海电容有限公司) Jianghai Capacitor Co., Ltd. is one of China’s largest manufacturers of aluminum electrolytic capacitors, offering a product line that includes electrolytic capacitors, solid-state capacitors, and supercapacitors. Jianghai Capacitor has earned the trust of domestic and international customers through its advanced production equipment and strict quality control. Their products are widely applied in emerging markets such as new energy vehicles, solar energy, and wind energy.

3. Chongqing Capxon Electronic Co., Ltd. (重庆凯普松电子有限公司) Chongqing Capxon Electronic Co., Ltd. is a well-known manufacturer of aluminum electrolytic capacitors in China, recognized for its high-frequency low impedance and long-life capacitors. Capxon focuses on product innovation and performance enhancement, with wide applications in home appliances, communication equipment, and power supplies. The company has a strong presence in both domestic and international markets. 4. Samwha China Electronics Co., Ltd. (三和中国电子有限公司) Samwha China Electronics Co., Ltd. has a broad influence in the Chinese market, primarily producing aluminum electrolytic capacitors and MLCC (multi-layer ceramic capacitors). The company emphasizes technological research and international cooperation, with products widely used in automotive electronics, LED lighting, and power management systems.

5. Nantong Jianghai Capacitor Co., Ltd. (南通江海电容有限公司) Nantong Jianghai Capacitor Co., Ltd. is one of China’s major capacitor manufacturers, with a significant market share for its electrolytic and solid-state capacitors both domestically and internationally. The company continually enhances its technological level and production capacity, aiming to meet customer needs in various application fields.

6. NIC Components Corp. (奈尔电子元件有限公司) NIC Components Corp. is an internationally competitive capacitor manufacturer, primarily producing highly reliable aluminum electrolytic capacitors and solid-state capacitors. The company enjoys a good reputation in the market for its quality products and excellent service, with applications across computers, communications, and industrial control sectors.

7. Changzhou Huawei Electronics Co., Ltd. (常州华威电子有限公司) Changzhou Huawei Electronics Co., Ltd. specializes in the research and production of electrolytic and film capacitors. With advanced production equipment and technology, their products are widely used in power electronics, new energy, and rail transit industries. Huawei Capacitor is favored by many customers for its high cost performance and reliability.

8. Guangdong Fenghua Advanced Technology Holding Co., Ltd. (广东风华高新科技控股有限公司) Guangdong Fenghua Advanced Technology Holding Co., Ltd. is one of China’s leading electronic component manufacturers, offering a product line that includes MLCC, film capacitors, and electrolytic capacitors. The company focuses on technological innovation and quality improvement, serving industries such as communications, automotive electronics, and consumer electronics. Fenghua Hi-Tech has a strong presence in both domestic and international markets.

9. JYH Electronics Co., Ltd. (江阴华能电子有限公司) JYH Electronics Co., Ltd. is a professional company engaged in the research and production of capacitors, mainly producing aluminum electrolytic capacitors and supercapacitors. The company emphasizes technological research and market expansion, with products widely used in new energy, industrial control, and consumer electronics.

10. Nantong Jiuding Electronic Co., Ltd. (南通九鼎电子有限公司) Nantong Jiuding Electronic Co., Ltd. is a well-known manufacturer of aluminum electrolytic capacitors in China, recognized for its high-quality products and excellent service. The company continuously enhances its production capacity and technological level, committed to providing customers with high-reliability and long-life capacitors. These brands have shown remarkable performance in technological research, product quality, and market expansion, driving the continuous development and growth of China’s capacitor industry. In the future, with the advancement of technology and changes in market demand, these brands will continue to lead the industry’s development and make greater contributions to the global electronic components market.

#electronic#capacitors#technology#automotive components#electric cars#electric vehicles#electrolytic capacitors

0 notes

Text

Electric DC Motors: Which Type dominates the Market?

The adoption of 4.0 technologies, such as the Industrial Internet of Things (IIoT), logistics automation, and robotics, is constantly rising. This has increased the use of electric DC motors across various industry segments such as industrial machinery, automotive, aerospace, transportation, HVAC equipment, and household appliances. According to our experts, the global electric DC motor market is anticipated to surge at a CAGR of 8.86% throughout the forecasting period 2022-2028.

Manufacturers across industries are constantly expanding their product lines with the integration of technological upgrades. For instance, automotive players are shifting toward electric mobility as the electric vehicle market is estimated to have a potential growth rate of xx% in the coming years. As a result, the sales of brushless DC motors will gain traction, owing to 80-90% higher efficiency than conventional motors.

Brushless Motors: The Dominate Type

According to our estimates, brushless DC motors lead the type segment and is expected to maintain its stronghold throughout the forecast period. It is driven due to various advantages such as higher efficiency & performance and lower susceptibility to mechanical wear. Additionally, a high power-to-weight ratio, high efficiency, practically instantaneous control of speed (RPM) & torque, high speed, and low maintenance are other aspects supplementing the studied growth trend.

Some examples of industry-wise applications of brushless DC motors in various industries are-

Brushless DC motors (BLDC) are found in various hybrid vehicles, electric vehicles, and personal transporters. They are highly preferred in long-term continuous duty cycles. Therefore, BLDC motors are widely used for traction inverters for ePowertrain.

In industrial robots, brushless DC motors can be used as actuators to move mechanical joints for tool positioning in welding, painting, and assembly applications. Robotic applications favor BLDC motors due to their dependability, power density, small size, and simplicity of maintenance.

Future Prospects

The global industrial production landscape has changed dramatically. Data digitization, machine automation, and asset connectivity is potentially evolving technical infrastructures. Furthermore, several businesses use industrial automation components to compete in today’s fast-paced commercial environment. These factors are expected to contribute to the studied market during the forecast period. On the other hand, the rising demand for energy-efficient electric DC motors in industrial machinery used in mining, manufacturing, power generation, and utility sectors is projected to influence several opportunities for the global electric DC motor market.

FAQ

Q1) How is the global electric DC motor market segmented in terms of application?

Based on the application segment, the market is divided into industrial machinery, HVAC Equipment, aerospace and defense, automotive and transportation, household appliance, and other applications.

Q2) What are the factors hampering the global electric DC motor market?

The global electric DC motor market is expected to witness critical challenges, such as the lack of quality control for electric DC motors caused by an unorganized market segment offering low costs for entering the local market to compete with multinational suppliers.

#Electric DC Motor Market#Electric DC Motor#Automotive & Transportation#Automotive Components#triton market research#market research reports

0 notes

Text

Reliable Heavy-Duty Metal Fabrication for Trucks | OEM Parts Supplier

We provide reliable heavy-duty metal fabrication services for trucks and other heavy vehicles at Metalman Auto Ltd. As an OEM parts supplier, we ensure that every component meets industry standards for strength, durability, and performance.

#heavy-duty metal fabrication#truck parts supplier#OEM parts supplier#heavy vehicle components#durable metal fabrication#automotive assembly parts manufacturer#automotive industry#automotive components#automotive metal components supplier#agri-vehicle components manufacturer#high-volume automotive parts manufacturing#commercial vehicle parts supplier#automotive parts manufacturing in india#automotive

0 notes