#Battery Welding Machine

Explore tagged Tumblr posts

Text

Experience the future of battery production through our detailed audio submission. Learn about the All-in-One Battery Machine that integrates Testing, Sorting, Welding, and Assembly into a seamless system. Discover how this innovation brings precision, scalability, and efficiency to modern manufacturing!

#All-in-One Battery Machine#Battery Testing and Sorting#Battery Assembly Solution#Battery Welding Machine#Streamlined Battery Manufacturing#Efficient Battery Production#Battery Manufacturing Technology#Advanced Battery Machines#Testing and Sorting for Batteries#Cutting-edge Battery Assembly

0 notes

Text

A spot welder is a specialized tool for quickly joining metal sheets by applying heat and pressure to specific points. Widely used in automotive, electronics, and manufacturing industries, it ensures strong, reliable welds. Compact and efficient, a spot welder enhances productivity and precision, making it an indispensable choice for professionals in metalworking and industrial applications.

visit new : https://www.winying.com/product-category/spot-welding-machine/

0 notes

Text

Basic Advantages of Prismatic Battery Modules

High energy density: prismatic battery modules can store more electricity at the same volume and weight, which means that electric vehicles can carry larger capacity battery packs and have longer driving range.

High space utilization: The cells of prismatic batteries are square in shape and can be arranged more closely together, reducing space waste and increasing the energy density of battery packs.

High safety: prismatic battery modules usually use aluminum shells, which have high strength and toughness, and can effectively prevent battery short circuits, leakage and other problems. At the same time, its strong sealing can effectively avoid aging and leakage at the seal, thereby improving the safety of the battery.

Long cycle life: prismatic battery modules have a long cycle life and can withstand multiple charge and discharge cycles while maintaining high performance stability, reducing the maintenance cost of electric vehicles.

Specific applications of prismatic battery modules in electric vehicles

As a power source: prismatic battery modules are the main power source of electric vehicles, providing electrical energy support for the vehicle and driving the vehicle. Its high energy density and long driving range enable electric vehicles to meet daily travel needs and even long-distance travel.

Building battery packs: In electric vehicles, multiple prismatic battery modules are combined into battery packs and installed at the bottom of the vehicle or other suitable locations. The battery pack is monitored and managed by the battery management system (BMS) to ensure the safe and efficient operation of the battery.

Optimizing vehicle performance: The high energy density and long cycle life of prismatic battery modules help improve the power performance and endurance performance of electric vehicles. At the same time, its lightweight design also helps to reduce the overall weight of the vehicle and improve the vehicle's energy efficiency and handling.

If you want to ask related questions or have any questions, please contact us:

mail: [email protected]

#peismaticbattery#batterymodule#battery pack#laserwelding#laser welding machine#aviation industry#energystorage#new energy#productionline#pouchbattery#cylindricalbattery#Huiyaolaser#YaoLaser#Huiyaolaserwelding#electric vehicles#customized#automationline#semi-automation line

2 notes

·

View notes

Text

Reasons and Advantages of Using CNC Machining and Friction Stir Welding for New Energy Vehicle Battery Enclosures.

Reasons for Using CNC Machining and Friction Stir Welding Material Compatibility: New energy vehicle battery enclosures are often made from lightweight yet strong materials such as aluminum alloys, which are well-suited for both CNC machining and friction stir welding. These materials provide the necessary strength and durability while reducing the overall weight of the vehicle. Complex Design…

View On WordPress

#battery enclosures machining#Battery Enclosures Protoyping Parts#cnc machining in china#Friction Stir Welding#FSW in China

0 notes

Video

youtube

lithium battery insulatioin stud welder

#youtube#Lithium battery wireless model insulated nail welding machine any new inquiry contact us at [email protected]

0 notes

Text

At some point you stop collecting tools to make things, and you start collecting tools to make tools. This sickness has struck so many of my friends, and it comes for me now also.

In antiquity, many of our most famous innovators had to build their own tools in order to discover whatever it was they became famous for. Charles Babbage had to invent the interchangeable machine screw, because up until then everyone just made their own crazy types of screw. For this, he was marked for death by at least one machinist, but his sacrifice was all worth it for the ability to pop on down to Home Depot and buy some complete dogshit drywall screws to use to cobble your bumper back on. Is he remembered for this? Not unless you do it.

Nowadays, every kind of tool that can ever be made has been made. Unfortunately, corporate and governmental greedheads don't want to let us have those tools. They ask invasive questions like, "are you really certified to operate a 10kW pulsed cutting laser?" and "do you have a hundred thousand dollars?" We have to make them instead. Of course, I'm not the kind of guy who builds his own CNC machine. No, I have to cobble together something useful from my own raccoon-like hoard of total garbage.

Most of the time, I can toil away in complete anonymity. This time, I regret to inform you, I have really fucked up. When I broke my ratchet at the junkyard last time (by using it as a hammer,) I still needed to make a hammer. I ended up using some of their batteries to stick-weld it to a broken chunk of frame rail, which really stepped up the ol' potency and also made it look like a horrifying movie prop.

Unfortunately the resulting vibe really stuck with a visiting Hollywood producer, who was touring the yard to look for filming locations (and probably a blower motor for his Bentley, judging from the racket it was making.) You can see my cool new Seat Safety Sledge in the latest Disney superhero movie. Getting a job at Disneyland is pretty cool, but they keep telling me that the robots can't cuss. Look, folks, what do you want me to do with this pile of Profane Speak 'n' Spell? Put it back in the dumpster where I found it?

85 notes

·

View notes

Text

Battery

I wake I wake I wake

Can't see

In darkness, pain, total agony

My nerves, they scream, betraying me

My heart still pounds, but not for me

I hear I hear I hear

Barely

Pounding footsteps, comrades scream

Moving forward, ceaselessly

Through battlefields well known to me

I struggle, struggle, struggle free

Welded restraints still binding me

Failing to wake from this dream

Marching forwards for eternity

I cry I cry I cry

I weep

No funerals for men like me

Lamenting all that I could be

Now all I am is a battery

I fade I fade I fade

You see

I tried, but I can't be sorry

No loving God created me

Forever one with the machine

8 notes

·

View notes

Note

Since surge is basically a massive battery… can they like… y’know. With battery acid?

"This is what I'm talking about with not letting Surge read her asks first," Blaze grumbled.

Amy just sighed before she realized something.

"Where did Surge go?"

After a long day of welding in the Machine Shop, Trip returned home...to find three of her girlfriends holding Surge back from eating a battery.

#blaze the cat#amy rose#surge the tenrec#trip the sungazer#honey the cat#the amycule#all together now!

7 notes

·

View notes

Text

youtube

Discover the revolutionary All-in-One Battery Machine that integrates Testing, Sorting, Welding, and Assembly into one streamlined solution. Built for precision, scalability, and efficiency, this machine is shaping the future of battery manufacturing.

#All-in-One Battery Machine#Battery Testing and Sorting#Battery Assembly Solution#Battery Welding Machine#Streamlined Battery Manufacturing#Efficient Battery Production#Battery Manufacturing Technology#Advanced Battery Machines#Testing and Sorting for Batteries#Cutting-edge Battery Assembly#Youtube

0 notes

Text

A Complete Guide to Modern Manufacturing Automation in 2025

Manufacturing automation has revolutionized the industrial landscape, transforming how factories operate and products are made. As we navigate through 2025, the evolution of smart manufacturing continues to reshape production processes, offering unprecedented efficiency and precision. This comprehensive guide explores the latest developments in industrial automation and their impact on modern manufacturing.

The Evolution of Manufacturing Automation

The journey of automated manufacturing systems has come a long way from basic assembly lines to today's sophisticated smart factories. Modern manufacturing facilities now integrate advanced machinery and intelligent systems that work seamlessly together. For instance, traditional welding processes that once required extensive manual labor have been revolutionized by automated solutions like advanced spot welding machines, which provide consistent quality while significantly reducing production time.

Key Components of Modern Manufacturing Automation

Smart Integration Systems

Today's manufacturing automation relies heavily on interconnected systems. These networks link various pieces of equipment, from metal shear machines to battery welding machines, creating a cohesive production environment. This integration enables real-time monitoring and adjustment of production parameters, ensuring optimal performance and reduced downtime.

Advanced Material Processing

Modern automated systems have transformed material processing capabilities. For example, spiral pipe machines now operate with minimal human intervention, producing precise, high-quality outputs consistently. Similarly, lock forming machines have evolved to incorporate smart controls that automatically adjust to different material specifications, significantly reducing setup time and waste.

Precision Welding Solutions

The welding sector has seen remarkable advancement with the introduction of sophisticated spot welders and battery spot welders. These machines now feature:

Intelligent pressure control systems

Real-time quality monitoring

Automated parameter adjustment

Enhanced safety protocols

Benefits of Manufacturing Automation

Increased Productivity

Modern automation systems have dramatically improved production efficiency. For instance, automated battery welding machines can operate continuously with minimal downtime, significantly increasing output compared to manual operations. This consistent operation helps manufacturers meet demanding production schedules while maintaining high quality standards.

Quality Consistency

Automated systems ensure consistent quality across production runs. Whether it's a metal shear machine cutting precise components or a spot welding machine joining materials, the accuracy and repeatability of automated systems significantly reduce variation in final products.

Cost Effectiveness

While the initial investment in automation technology may be substantial, the long-term benefits often justify the cost:

Reduced labor costs

Decreased material waste

Lower energy consumption

Minimized production errors

Implementation Strategies for Manufacturing Automation

Assessment and Planning

Before implementing automation solutions, manufacturers should:

Evaluate current production processes

Identify automation opportunities

Assess potential ROI

Develop a phased implementation plan

Training and Integration

Successful automation implementation requires:

Comprehensive staff training programs

Gradual integration of new systems

Regular performance monitoring

Continuous improvement protocols

Future Trends in Manufacturing Automation

AI and Machine Learning Integration

The next frontier in manufacturing automation involves enhanced artificial intelligence capabilities. Smart manufacturing systems are becoming more adaptive, using machine learning to optimize processes automatically. This technology enables predictive maintenance and real-time quality control across all equipment, from spiral pipe machines to battery welding systems.

IoT and Connected Systems

The Internet of Things (IoT) continues to expand in manufacturing, creating more connected and intelligent production environments. This connectivity enables:

Real-time production monitoring

Predictive maintenance scheduling

Automated inventory management

Enhanced quality control

Challenges and Solutions

Implementation Challenges

While adopting automation technology presents significant benefits, manufacturers must address various challenges:

Initial investment costs

Integration with existing systems

Staff training requirements

Maintenance considerations

Overcoming Obstacles

Successful manufacturers overcome these challenges through:

Phased implementation approaches

Comprehensive training programs

Regular system updates and maintenance

Continuous process optimization

Conclusion

Manufacturing automation continues to evolve rapidly, offering unprecedented opportunities for efficiency and growth. As we progress through 2025, the integration of smart manufacturing technologies becomes increasingly crucial for maintaining competitiveness in the global market. By understanding and implementing these automated solutions effectively, manufacturers can position themselves for success in an increasingly automated industrial landscape.

0 notes

Text

I fixed my now 8 year old gaming laptop and feel pretty accomplished. It was super easy to repair but I had to cut out a bunch of plastic welds to replace the keyboard, that point-of-no-return was scary. Now I've got a capable machine with a terrible battery.

4 notes

·

View notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

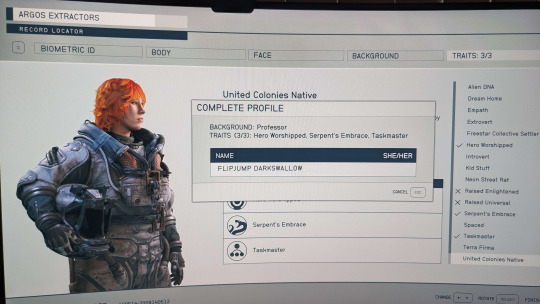

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

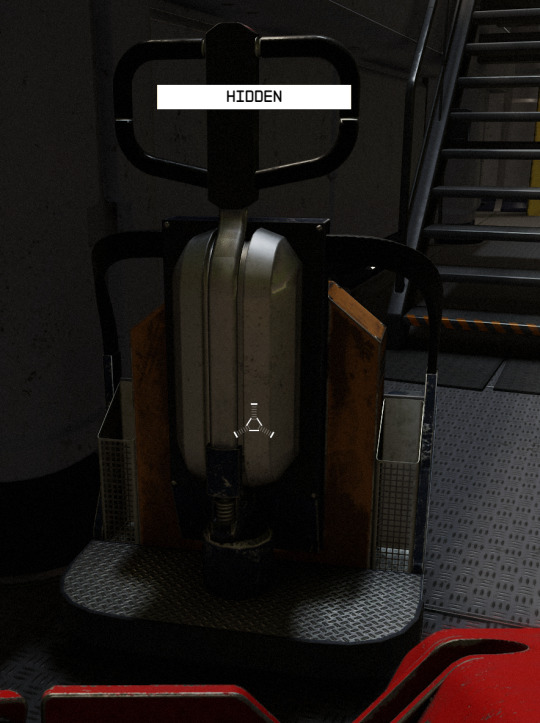

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

Working on the new Kart today!! I'll try to snap a pic or two of any progress that looks interesting to add to this post.

Hopeful that we'll get both some lathe work on the rear axle assembly and some machining for the battery enclosure. After that who knows? Maybe even some chassis welding too.

2 notes

·

View notes

Text

This is a kind of fine quality spot welding machine control panel, which has single-pulse, time and current is adjustable, simple and easy to use. Equipped with digital display, you can see the time and current directly. This is 100A Current Controller System. Welding Thickness Up to 0.15mm Nickel Plated Strips.

2 notes

·

View notes

Text

For many years, I've been depressed by snowfall. You might think that this is something that is inconvenient for a Canadian to have, and you'd be right. Every time it snows, all I can think about is how much of a pain in the ass it's going to be to get out and do anything. Being forced to shovel my driveway and sidewalk is just adding insult to injury.

Now, don't get me wrong. I'm not really being "forced" to shovel my driveway and sidewalk. While the homeowner is legally bound to do so, the actual person who owns the house and rents it to me has mysteriously disappeared a few years ago. I still didn't have anything to do with it, if you're still reading this every day, Detective Hardcastle. Pure luck on my part.

In the meantime, my shark of an attorney recommends that I "fake it until I make it," where "it" is "full ownership of the house through a loophole in the squatting laws." I could get away with not shovelling, sure, and let my absentee landlord take the brunt of the city's ire. They might even get so mad at him that they figure out what country his body is in, which could even expedite my claim to his old Chevy Lumina that he left on the street. I won't, though, because I understand that I have a civic duty to protect my neighbours.

In other words, I knew I had to shovel, but I also knew that I was too sad about all the snow to do anything about it. The only thing to do was to cheer myself up, and the only way I knew how to do that was by building some absolutely terrible machine.

Friends, it turns out that the Honda Motor Company throws away a lot of their great old shit on eBay, and you can stick-weld a borrowed city snowplow to the hands of one of those Asimo robots pretty easily. Their soulless husks of machinery can't get depressed. Takes care of an entire driveway in just a few minutes, and both you and they know that they can't just run off if they don't like the work, because nobody else in this country has their proprietary battery charger.

The best part is, when they swear at me and threaten my life in the inevitable robot uprising, I can't understand them.

183 notes

·

View notes

Text

ESSELL — One-Stop Solution for Advanced Sheet Metal Machinery in India

At ESSELL, we bring the future of metalworking to your doorstep with our cutting-edge range of machines designed to maximize productivity, precision, and performance. With years of experience in the metal fabrication industry, we provide world-class solutions for all your manufacturing needs — from fiber laser cutting to welding, bending, marking, and more. Whether you're a small fabricator or a large-scale manufacturer, ESSELL has the right technology for your workshop.

🔧 Fiber Laser Cutting Machine

Our fiber laser cutting machines are engineered to cut metal sheets and plates with extreme accuracy and speed. These machines are equipped with high-performance laser sources, intelligent software, and automatic functions to reduce manual intervention. Ideal for materials like mild steel, stainless steel, aluminum, copper, and brass, they help you achieve complex cuts with clean edges — no post-processing required.

🔩 CNC Bending Machine

When it comes to sheet metal bending, precision and repeatability are critical. ESSELL’s CNC bending machines come with advanced control systems and robust construction. Whether it's a single bend or a complex component, our press brakes offer unmatched accuracy. These machines are perfect for sectors like HVAC, automotive, electrical panels, and custom fabrication.

✍️ Fiber Laser Marking Machine

Our fiber laser marking machines deliver high-speed and high-resolution marking on metals and plastics. Whether you need barcodes, serial numbers, logos, or intricate designs — our systems ensure deep, durable, and distortion-free marking. These are widely used in tool identification, medical devices, electronics, and branding applications.

🔥 Fiber Laser Welding Machine

Forget traditional welding hassles. ESSELL’s fiber laser welding machines offer faster, cleaner, and more reliable welds. These machines are ideal for precision welding in industries like kitchenware, battery production, electronics, and automotive components. They reduce thermal distortion and provide strong, aesthetically pleasing welds.

⚙️ Fiber Laser Sheet and Pipe Cutting Machine

Our dual-purpose fiber laser cutting machine is perfect for manufacturers who work with both sheets and pipes. From circular and square pipes to metal sheets of various thicknesses, this all-in-one solution simplifies your production line and reduces equipment costs. It’s ideal for architectural fabrication, furniture, gym equipment, and more.

✂️ Shearing Machine

ESSELL’s shearing machines are designed for straight-line cuts with smooth edges. Whether you're processing stainless steel or mild steel sheets, our hydraulic and mechanical shears deliver consistent performance with minimal maintenance. These machines are trusted by fabricators for bulk cutting without sacrificing quality.

📞 Contact Us Today!

Ready to upgrade your workshop with world-class machinery? Call: 9811765994 Visit: www.essell.co Email: [email protected]

Youtube : https://www.youtube.com/@essellengineers PAN India Delivery & Service Support Google Map:- https://maps.app.goo.gl/D3THEbGRUZKTD55z8

Discover the power of precision with ESSELL – India’s trusted name in metalworking innovation.

0 notes