#CNC Machined Components

Explore tagged Tumblr posts

Text

Top-Quality CNC Machining Service in UAE

Looking for reliable CNC machining services in the UAE? We offer high-precision CNC milling and turning solutions tailored to your industrial needs. Fast turnaround, expert craftsmanship, and advanced machinery – all under one roof.

0 notes

Text

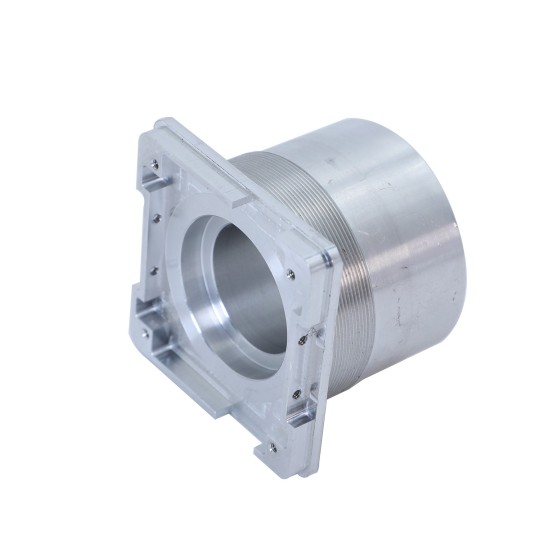

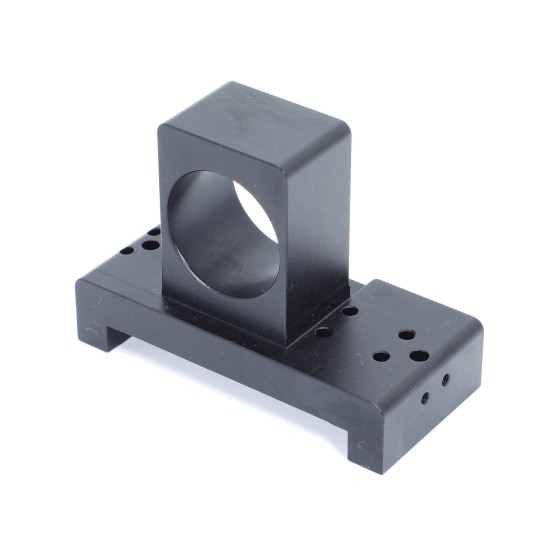

CNC machined components are the gold standard for industries that demand high durability and strength. If you need custom-designed CNC machined components or high-volume production, Petron Thermoplast provides the precision and durability necessary to succeed in any industry.

Visit Website - https://petronthermoplast.com/cnc-machining/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#CNC Machine Components#CNC Machined Parts#CNC Machined Components#Parts of CNC Machine#CNC Parts Manufacturer#CNC Machine Manufacturing#CNC machined parts manufacturer

0 notes

Text

Global Precision - leading CNC machined components manufacturers. Get high-quality CNC custom machined parts, and customized solutions for your needs.

#global precision#CNC machined components#CNC machined components manufacturers#CNC components manufacturer delhi

1 note

·

View note

Text

The Complete Guide to CNC Machined Components

Brief Overview of CNC machined components

CNC components are parts made using machines controlled by computers. These machines can cut, drill, and shape materials with high precision. This technology is used to make many different parts, from tiny screws to large engine blocks. Let's look at the key features that make CNC components so valuable. Key Features of CNC Machined Components CNC-machined components have several key features that make them highly desirable in many industries. 1. Accuracy CNC-machined components are known for their high accuracy. These machines can make parts with very tight tolerances, ensuring that each piece fits perfectly. This level of precision is essential for components that must work together seamlessly. 2. Complex Geometries CNC machining can create parts with intricate shapes. This means components can have twists, turns, and curves that fit perfectly. With CNC technology, even the most complicated designs can be brought to life accurately. 3. Wide Range of Materials CNC machining can work with many different materials like metals, plastics, and wood. This versatility makes it useful for various industries, from automotive to electronics. With CNC machining, you can create parts that meet specific needs without compromising on quality. 4. Superior Surface Finish CNC machining ensures parts have a smooth surface finish. This means they feel sleek and fit together snugly. With a superior surface finish, components work efficiently and look polished. In conclusion, CNC-machined components offer precision and quality. 5. Customization Customization is key in CNC machining. It allows for making parts tailored to specific needs. Whether it's adjusting dimensions or adding unique features, CNC machines can handle it. This flexibility ensures that every component meets exact requirements. Read the full article

0 notes

Text

CNC Machined Parts in Ahmedabad

Scharf Precision Engineering is a leading provider of CNC machined parts and components in Ahmedabad. We specialize in CNC machined parts as per customer requirements with international standards. We have been serving clients from different industries including aerospace, military, energy and electronics.

#CNC Machined Parts#Precision Turned Components#CNC Machined Components#Custom Machined Parts#CNC Machined Parts Production#Ahmedabad

1 note

·

View note

Text

Precision CNC machining service for defence, automotive, medical, government, mining, aerospace, electronics and telecommunication industries.

#machinery#cnc machined components#electronic components#spareparts#manufacturer#factory#cnc machining#machining parts#precision machining#machinist

0 notes

Text

3 Diverse Applications of Air Compressor Valves

Air compressor valves are integral components in various industries, ensuring smooth operations and system functionality. Let us explore three key sectors where air compressor valves play crucial roles.

Improving Engine Performance in the Automotive Sector

In the automotive industry, air compressor valves are essential for optimizing engine performance. They regulate airflow into the combustion chamber, ensuring proper fuel combustion and efficient power generation in internal combustion engines. By precisely timing the opening and closing of these valves, engines can optimize fuel-air mixture ratios, leading to improved fuel efficiency, reduced emissions, and enhanced engine durability.

Guaranteeing Aircraft System Safety in Aerospace Industry

Air compressor valves are vital for ensuring the safety and reliability of aircraft systems in the aerospace sector. They regulate air pressure and flow in various applications, including cabin pressurization, environmental control systems, and pneumatic power generation. These valves play a critical role in maintaining a stable and comfortable environment for passengers and crew onboard aircraft, as well as controlling and directing pneumatic power for essential systems like landing gear and flight controls.

Upholding Quality Standards in Food and Beverage Sector

In the food and beverage industry, air compressor valves are instrumental in maintaining quality control during production and packaging processes. These valves are used in pneumatic conveying systems to control the flow of air and other gases for transporting ingredients, powders, and liquids. By accurately regulating air pressure, these valves ensure precise and controlled movement of materials, preventing contamination and maintaining product integrity. They contribute to efficient and hygienic production processes, meeting stringent quality standards in the food and beverage industry.

Precision Machining of Air Compressor Valves

The manufacturing process of air compressor valves involves precision machining to ensure their functionality and reliability. Air compressor valves machining is crucial in this process. CNC machining, utilizing advanced machinery like Computer Numerical Control (CNC) machines, is employed to shape and mold these valves with precision. High-quality materials such as stainless steel or brass are commonly used to ensure durability and resistance to corrosion. CNC machining ensures that each valve is manufactured with precise measurements, tolerances, and surface finishes, contributing to their consistent and reliable performance across different industries.

Air compressor valves are indispensable components in various sectors, including automotive, aerospace, and food and beverage industries. Their role in enhancing engine performance, ensuring safety in aircraft systems, and maintaining quality control in food production underscores their importance in modern industrial processes. CNC machined components play a vital role in their manufacturing. Through precision machining and advanced manufacturing techniques, air compressor valves continue to power essential systems and contribute to the efficiency and productivity of diverse industries.

0 notes

Text

Properties of CNC Machining Components

Precision: CNC machining offers unparalleled precision, allowing for the creation of components with tight tolerances and intricate geometries. This precision ensures consistency and accuracy in every part produced.

Versatility: CNC machines can work with a wide range of materials, including metals, plastics, and composites. This versatility enables the production of components tailored to specific requirements and applications.

Efficiency: With automated processes and advanced tooling, CNC machining delivers high efficiency in component production. This efficiency reduces lead times and enhances productivity in manufacturing operations.

Quality: CNC machining produces components with exceptional surface finishes and dimensional accuracy. This high quality ensures reliability and performance in the final product.

0 notes

Text

Ultimate Guide: CNC Machines and Their Popular Advantages

CNC Machines have become extremely popular across various industries for multiple reasons. In several cases, CNC Machined Components offer a lot of benefits to the machine shops and the manufacturers. These machines have replaced a lot of manual equipment. A numerical software program controls the tool. The industries where CNC machines are used are medical, aerospace, automotive, agriculture, dental, construction, firearms, metalwork, manufacturing, and much more.

Key Benefits of Using CNC Machines The popular benefits of these machines are as follows: 1. Improved Accuracy and High Precision:

One of the major advantages of making use of CNC Components over manual operations is their high precision. Parts that meet the correct specifications can be created without any requirement for continuous attention from a skilled operator. CNC machines remove human error and depend on computer instructions. All these improve accuracy at a large scale.

2. Endurance:

As long as the skilled workers are present, the manual machines can do the job. But as soon as the workers leave, the manufacturing process stops. But things are a bit different with CNC Milling Components and machines. These machines can operate 24 hours a day. The operators need to program the computer of the machine, and it will create the needed part as many times as required.

Learn more...

1 note

·

View note

Text

Precision Perfected: CNC Machined Components for CNC Machining in India

CNC machining in India has emerged as a cornerstone of modern industry, offering unparalleled capabilities for producing intricate parts and components with utmost precision. At the heart of this technology lie CNC machined components, the building blocks of innovation and excellence.

Exploring CNC Machined Components:

CNC machined components represent the epitome of precision engineering, crafted with meticulous attention to detail and exacting standards. Utilizing advanced computer numerical control technology, these components are manufactured with unparalleled accuracy and consistency. CNC machining in India relies on these components as the foundation of its technological prowess.

The Landscape of CNC Machining in India:

India's manufacturing sector has embraced CNC machining as a cornerstone of innovation and progress. With state-of-the-art facilities and a skilled workforce, the country's CNC machining industry continues to thrive, catering to both domestic and international markets. From small-scale workshops to large-scale production facilities, CNC machining in India encompasses a spectrum of capabilities, serving the evolving needs of diverse industries.

Advancing Technology and Innovation:

CNC machining in India, driving advancements in technology and pushing the boundaries of what is possible. As manufacturers strive to stay ahead of the curve, investments in cutting-edge machinery, software, and processes pave the way for new possibilities and opportunities. CNC machined components serve as the linchpin of this innovation, enabling manufacturers to achieve unprecedented levels of efficiency, accuracy, and productivity.

Conclusion:

CNC machined components form the bedrock of CNC machining in India, embodying the principles of precision, reliability, and innovation. As the industry continues to evolve and expand, these components remain indispensable, driving progress and shaping the future of manufacturing. With a commitment to excellence and a passion for innovation, India's CNC machining sector stands poised to lead the way in delivering precision-perfected solutions to the world.

0 notes

Text

Best CNC Machining in Pune — ANJALI T. PRECISION

ANJALI T. PRECISION – Leading provider of CNC machining in Pune, delivering high-precision, reliable & cost-effective solutions for various industries.

#CNC Machining#Precision Machining#CNC Components#CNC Services Pune#High-Precision Engineering#Custom CNC Parts#ANJALI T. PRECISION

2 notes

·

View notes

Text

CNC Machined Components in Dubai | Durable and Reliable Solutions

Looking for reliable CNC machine parts in Dubai? Explore our wide range of custom components designed for performance and durability.

0 notes

Text

CNC Machined Components for High Durability and Strength

CNC machined components are the gold standard for industries that demand high durability and strength. If you need custom-designed CNC machined components or high-volume production, Petron Thermoplast provides the precision and durability necessary to succeed in any industry.

Visit Website - https://petronthermoplast.com/cnc-machining/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#cnc #cncmachining #manufacturing #machining #engineering #cncmilling #machinist #milling #cncmachine #machineshop #fabrication #cncmachinist #tools #metalworking #cncmill #welding

#CNC Machine Components#CNC Machined Parts#CNC Machined Components#Parts of CNC Machine#CNC Parts Manufacturer#CNC Machine Manufacturing#CNC machined parts manufacturer

0 notes

Text

CNC machining for complex parts

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#cnc metal processing#cnc metal fabrication#cnc metal process#cnc metal machining#cnc metal parts#cnc components#cnc parts#cnc parts company#cnc parts factory#cnc part

3 notes

·

View notes

Text

#ideal machined components#custom-cnc-aluminum-parts#aluminum machining near me#cnc-components-manufacturers#aluminum machining service

0 notes

Text

Maximizing Efficiency with the Best CNC Rotary Table for Precision Machining in 2025

In the competitive landscape of precision machining, efficiency is key to staying ahead. A CNC rotary table is an essential tool for manufacturers looking to optimize their CNC VMC machines in 2025. At Kuvam Technologies, we offer high-precision rotary tables, including 4th axis rotary tables and 5th axis rotary tables, designed to streamline production and enhance accuracy. Here’s how our rotary tables can transform your machining operations.

#rotary table#CNC rotary table#Precision machining#Hydraulic rotary table#Tilting rotary table#CNC machining#4th axis machining#5th axis machining#CNC machine components#Rotary table accuracy#CNC productivity

0 notes