#CNC Router Spindle and Spindle for Automatic Tool Changing.

Explore tagged Tumblr posts

Text

#TriQuench INDIA#TriQuench India Established in the Year 2012 in Ahmedabad (Gujarat#India) with the prime objective of engineering precision assembly focusing categorically on the spindle for the CNC machine.#From 2019 the company has converted to Triquench India Pvt. Ltd.#In India#Known for our Active and Dynamic Customer Service Practices and catering to a broad assortment of product categories such as Spindle Motor#CNC Spindle#Air Cooled#machine Tools Spindle#CNC Router Spindle and Spindle for Automatic Tool Changing.

1 note

·

View note

Text

Collet Chuck: Precision Work holding for CNC Machining

Introduction

For modern manufacturing and CNC machining, precision, repeatability, and reliability are crucial. In the countless components that are essential to quality machining, collet chucks play a vital role in the work holding. They are a must-have tool for gripping tools securely or workpieces that have superior concentration and low runout. If you're operating a CNC lathe, milling machine, or router, knowing the workings of collet chucks and choosing the correct one can drastically affect the performance of your machining.

What is a collet chuck?

A collet chuck can be described as a type of chuck that uses the collet--a segmented sleevesleeve--to create a collar around the object and generate a powerful clamping force once tightened. For CNC machines, collet chucks can be commonly employed to support cutting tools like end mills, drills, and taps, or to hold workpieces when turning.

In contrast to traditional three-jaw chucks, collet chucks provide greater grip, better precision, and quicker tool changes, making them suitable for high-speed and high-accuracy machining.

Components of a Collet Chuck System

Chuck Body: The main component that holds the collet in the right position.

A collet is the sleeve that expands around the workpiece or tool.

Clamping Nut / Lock Nut - Fits the collet to the body of the chuck to apply force to grip.

Pull Stud (optional) Pull Stud (optional)—In certain systems, such as CAT and BT holders, it aids in the automatic changing of tools on CNC machines.

Types of Collet Chucks

1. ER Collet Chuck

Most popular and versatile.

Available in sizes ranging from ER11 up to ER50.

It is ideal to drill, mill, tap, and ream.

Excellent runout control (up to 0.01 millimeters in high-precision types).

2. R8 Collet Chuck

Most commonly used in older milling machines that were manually operated.

Compatible with Bridgeport mills.

A limited range of collets Comparing with ER collets.

3. 5C Collet Chuck

Common in grinding and turning applications.

Great for holding the lathe in a workstation.

Supports round, hexagon, and square stock.

4. TG Collet Chuck

Greater gripping force and better transmission of torque.

This is suitable for roughing and milling that requires heavy-duty applications.

5. DA (Double Angle) Collet Chuck

Compact and affordable.

Lower clamping force than the ER or TG.

Advantages of Using Collet Chucks

High Precision

Low runout, which makes it the ideal tool for micro-machining and precise work.

Superior Grip

Uniform clamping for 360 degrees around the tool, which reduces vibration.

Fast Tool Changes

Highly efficient when working in environments that are automated, where speedy tool swaps are vital.

Compact Design

The slim profile allows easier access to confined machining spaces.

Extended Tool Life

A reduced amount of vibration and slippage in the tool ensures a longer service life for the machine spindle and the tool.

Common Applications of Collet Chucks

Industry

Application

Aerospace

Precision component machining

Automotive

Manufacturing of engine parts

Electronics

PCB and micro-parts processing

Woodworking

CNC routers, carving and other applications

Medical

Implant and surgical tool fabrication

Metalworking

General milling, drilling and tapping

How to Choose the Right Collet Chuck

When choosing a collet chuck for your needs, take into consideration the following aspects:

Machine Compatibility

Make sure the chuck holder fits your machine's spindle - CAT BT, HSK, or ISO.

Tool Diameter Range

Choose a size of collet that is suitable for the variety of tools you typically use.

Runout Tolerance

For greater precision, you need collets and chucks with a low runout (<=0.005 millimeters).

Clamping Force

High-torque applications require chucks with greater grip. Consider Power or TG chucks.

Material and Coating

Choose chucks that are made of rust-proofed steel and hardened coatings to ensure long-lasting durability.

Coolant Support

Some collet chucks are constructed with internal coolant pathways in order to increase the life of the tool and cut efficiency.

Installation & Maintenance Tips

Proper Installation

Clean the tool, the collet, and the chuck prior to the assembly.

Inject the collet into the nut prior to threading it onto the body of the chuck.

Make use of a torque wrench to ensure the proper clamping force.

Routine Inspection

Be sure to check for wear and damage frequently.

Inspect for cracks or deformations in the collet or the nut.

Lubrication

Apply light machine oil regularly to the threads and surfaces.

Avoid Over-Tightening

The excessive force can cause damage to the collet or alter the shape of the chuck body.

Troubleshooting Common Issues

Issue

Cause

Solution

Tool Slippage

Incorrect torque or a collet that is worn out

Replace collet, use torque wrench

Excessive Runout

A dirty or damaged collet or dirty seat

Clean or replace collet Chuck

Difficult Tool Removal

Overtightened collet nut

Use a quality spanner and be sure to follow torque specifications

Vibration During Cutting

Unbalanced or loose fitting tool

Balance tool, ensure a tight fit

Collet Chuck. other options for workholding

Feature

Collet Chuck

Hydraulic Chuck

Shrink Fit Holder

End Mill Holder

Precision

High

Very High

Extremely High

Moderate

Grip Strength

Moderate to High

High

High

Moderate

Tool Change Time

Fast

Medium

The speed is slow (heat required)

Fast

Cost

Affordable

Expensive

Expensive

Moderate

Maintenance

Low

Medium

High

Low

Conclusion

A collet chuck is much more than just a toolholder. It's an essential element of efficiency and precision in CNC manufacturing. From small-scale fabrication to mass production, collet chucks offer the best grip, less runout, and low vibration, making them essential in modern machine shops. If you're machining aerospace-grade parts or creating intricate woodworking projects, investing in the right collet chuck can dramatically improve your productivity and machine precision.

FAQs

Q1: How long will the chucks in collets last?

If properly maintained and used, the chucks of collets can last for several years. However, they need to be inspected and replaced more often based on the use.

Q2: Can I use a single collet chuck to use different tools?

Yes, as long as the tools are within the range of gripping that the collet can handle. ER collets are particularly versatile in this way.

Q3: What's the distinction between ER16 and ER32?

ER16 is smaller and best suited for tools with smaller diameters, while ER32 can handle larger tools and greater torque operations.

0 notes

Text

5 Axis CNC Milling Router Machine for Custom Mold

5 axis CNC wood machine is a highly advanced and versatile machine that can greatly improve the speed, accuracy, and quality of woodworking projects. By providing greater flexibility and precision in the cutting process, a 5-axis CNC wood machine can help woodworkers to create complex and intricate designs with ease and efficiency.By providing greater flexibility and precision in the cutting process, a 5-axis CNC milling router can help manufacturers and designers to create complex and intricate designs with ease and efficiency.

So this 3d CNC router milling machine can realize embossing, lettering, hollowing, cutting, vertical carving, round carving, etc,it also can be seamlessly spliced, suitable for various shapes.And this machine has widely used in foam molds, wooden sculptures, aerospace models, disappearing casting foam molds, large sculptures, wedding decorations, external wall dry hanging, garden engineering, large sculptures, handicrafts and other industries.

5 axis cnc router machine for sale

The 5 axis CNC mill is equipped with a 5-axis head, and plus a 9kw automatic tool change air cooling spindle, which makes the machine more powerful. Syntec CNC controller Taiwan of 5 axis foam CNC has high-speed precision, which greatly improves the production efficiency of 5 axis router. The 5 axis router is suitable for processing foam, 3D molds, other materials.If you plan to buy a Chinese 5 axis CNC mill, iGOLDENCNC’s multi-function 5 axis woodworking CNC machine will be your best choice.

5-axis machining also provides the ability to machine extremely complex parts from a solid, and this type of machining can also save a lot of drilling time. Drilling a series of holes with different compound angles is very time consuming. With a five-axis machine, the drill can be automatically oriented along the correct axis for each hole, so that the drilling can be completed faster. 5-axis CNC machine can reach even the most complex angles.

If your parts require complex 4D and 5D parts, then you need a machine shop equipped with 5-axis machines and the best operators. Combined with the highest finishing and tolerances, we are able to achieve complexity that cannot be achieved with 2-axis or 3-axis machine. It only needs to be set once, which can be transformed into higher productivity and higher workpiece quality. This process allows you to machine complex parts that would otherwise require casting. If you have low-volume production or prototype manufacturing, you can machine parts in a few weeks instead of waiting months to complete the casting.

Automatic tool changers: These systems can automatically changecutting tools during the cutting process, allowing the machine to perform multiple operations without the need for manual intervention.

T-Slot Working 5 Axis CNC Table

The 5 axis router aluminum CNC router table with “T” groove, the wood CNC table for mechanically fixing the Syntec CNC router is made of a special reinforced aluminum plate and is separated by grooves to accommodate the fixture.

This 5 axis CNC machine has a large workbench, the standard area of the workbench is: 2000*3000*1000mm. This workbench can almost accommodate most materials. And the size of this machine can be customized. The length could be as long as 12 meters, and the width of the machine could be as wide as 3 meters, and the Z working height of the machine could be 2 meters. If you think The size is too large or too small, then you can tell us the size you want, and we can make the machine you want according to your requirements.

Advanced Accessories Of CNC Foam Router Machine

This large 5 axis CNC woodworking machine adopts the Japanese Shimpo reducer, which has high precision, high stability, and good wear resistance. And it adopts the Hiwin square rail. The guide rail is high precision, low noise, wear-resistant, and long service life. The 5-axis CNC router machine uses a vacuum and aluminum T-slot working table, which is multi-functional and the material can be fixed easier.

The 5 axis woodworking cnc router with ATC function, it’s easy to accomplish full set processing of complex parts from milling, slotting, drilling, sawing, mortise, mortise, etc, the advanced model designed by iGOLDENCNC, combined with a competitive set of configurations.

Hot applications include:

Composite materials industry: Trimming and punching of various composite materials such as plastic parts, glass fiber reinforced plastic parts, rubber and plastic products;

Mold industry: 5 axis processing of FRP wood mold, casting wood mold, resin products, sludge model and various non-metal molds;

Ceramic sanitary industry: 5 axis processing of gypsum molds, 5 axis processing of various gypsum products;

Furniture industry: 5 axis processing of solid wood furniture, 5 axis processing of various furniture tenon and mortise pieces, 5 axis processing of stair elbows, and 5 axis processing of various furniture.

0 notes

Text

How CNC Machine Parts Work Together to Create Masterpieces

The precision and efficiency of CNC (Computer Numerical Control) machines, marvels of modern engineering, are revolutionizing the industry. At the core of these machines is a symphony of interrelated components, each essential to creating complex patterns and works of art. CNC machines provide unmatched accuracy in converting raw materials into completed products, ranging from creative sculptures to aerospace components.

This article explores how a CNC machine's many parts cooperate to produce excellent outcomes.

Understanding CNC Machines

A CNC machine controls its components and tools by adhering to a pre-programmed set of instructions known as G-code. This automated method ensures accuracy and consistency, lowering the possibility of human error.

Although there are many different kinds of CNC machines, such as routers, plasma cutters, lathes, and mills, they all have similar essential parts and purposes.

Essential Components of a CNC Machine and Their Functions

1. The Control Panel

The CNC machine's brain is the control panel, where users enter commands and monitor things.

Role: Its function is to interpret the G-code and convert commands into machine operations.

Features: Features include buttons, touchscreens, and real-time feedback displays.

2. Frame

The CNC machine is structurally stable thanks to the frame.

Role: Provides support for all other parts and dampens vibrations while in use.

Materials: Cast iron, steel, or aluminum are usually used for durability.

3. Spindle

The spindle is the revolving axis that cuts, drills, or mills materials.

Function: Provides the cutting tool with the power to form the material.

Adjustability: Depending on the material and operation, speed and power can be changed.

4. Cutting Instruments

Cutting tools work directly with the material and are replaceable components.

Function: Mold, drill, or engrave materials into desired shapes.

Types: Types include router bits, drill bits, end mills, and lathe tools.

5. Worktable

During machining, the worktable holds the material firmly in place.

Function: Prevents material movement and guarantees stability.

Features: Depending on the machine, it may be fixed or mobile.

6. System of Axes (X, Y, Z)

Thanks to the axis system, the CNC machine can move the workpiece and cutting tool in various directions.

Role: Shapes the material and allows for precise movements.

Types:

X-axis: Horizontal movement on the X-axis.

Y-axis:Vertical movement is the Y-axis.

Z-axis: Movement of depth.

7. Motors

Motors power the spindle and axis movements.

Function: Supply the strength and accuracy required for machining operations.

Types:Types include servo motors and stepper motors.

8. System of Coolant

The cutting tool and material are prevented from overheating by the coolant system.

Function: Ensures smooth cuts, prolongs tool life, and lowers friction.

Types:Types include air jets, lubricants, and water-based coolants.

9. Sensors

Sensors provide feedback to guarantee seamless operation.

Role: Monitor the machining process, measure tool wear, and identify faults.

10. Tool Switch

When performing multi-step tasks, the tool changer automatically switches cutting tools.

Role: Reduces downtime and increases efficiency.

How CNC Parts Work Together

Below, I will describe the following explanation:

1. Machine Programming

First, CAD (Computer-Aided Design) software designs the parts. From this architecture, G-code, which acts as the machine's instructions, is created. This code is sent to the control panel, synchronizing all component movements.

2. Material Positioning

Clamps or a vacuum system secure the material after it is placed on the worktable. Sensors check alignment to guarantee precision.

3. Shaping and Cutting

The spindle begins to work with the proper cutting tool attached. Motors drive the axis system to move the tool in relation to the material. The coolant system guarantees smooth cutting by lowering heat and friction.

4. Automatic Modifications

If the procedure calls for changing tools, the tool changer swaps out the existing tool for a new one. Sensors monitor tool wear and notify the user when a replacement is required.

5. Completing and Examining

Once machining is finished, the component is given final touches, like polishing or deburring. Sensors and inspection systems check accuracy and quality assurance.

CNC Machine Applications

Numerous applications are made possible by the smooth integration of CNC machine elements, such as:

Automotive: Prototypes, gears, and engine parts.

Aerospace: Precision parts, structural elements, and turbine blades.

Healthcare: Prosthetics and surgical tools.

Art & Design: Personalized engravings, sculptures, and furniture.

Electronics: enclosures and circuit boards.

Benefits and CNC Machine

Below, I will describe the benefits of cnc machine:

High Precision: Reliable in creating complex patterns.

Efficiency: Reduced downtime and quicker production.

Versatility: Adaptable to a range of substances and uses.

Automation: Cuts down on errors and manual work.

Cost-Effectiveness: Increases production while reducing material waste.

CNC Machining Challenges

Beside their effectiveness, CNC machines have many drawbacks:

High Initial Cost: Software and machines can be costly.

Complex Setup: Programming and maintenance call for knowledgeable operators.

Material Restrictions: Machining certain materials can be complex.

CNC Machining's Future

CNC machines are becoming more innovative and effective in integrating robots, AI, and IoT. In manufacturing, sophisticated automation, real-time monitoring, and predictive maintenance are establishing new benchmarks. CNC machines will remain essential to innovation as hybrid technologies develop.

Faqs

1. Is it possible for a single CNC machine to do several tasks?

Indeed, automated tool changers and multi-axis systems allow current CNC machines to transition between tasks, making them incredibly adaptable.

2. What kinds of materials are suitable for a CNC machine?

CNC machines can process materials such as metals (aluminum, steel, titanium), polymers, wood, and composites.

3. How long does it take to learn CNC programming?

Learning the fundamentals of CNC programming may take a few weeks, but months of practice and instruction may be necessary to master more complex techniques.

4. Are CNC machines eco-friendly?

CNC machines are typically environmentally benign because of their high accuracy and low material waste. Nonetheless, coolant disposal and energy use need to be well controlled.

Conclusion

CNC machines demonstrate the effectiveness of precise engineering. These machines can produce masterpieces in various industries by fusing state-of-the-art technology with a beautiful interplay of elements. When CNC parts integrate flawlessly, the possibilities range from intricate aeronautical components to creative designs.

Knowing how CNC machines work can help you realize their full potential and stimulate creativity in your ideas, whether as a manufacturer or a hobbyist.

0 notes

Text

Introduction to CNC Spindle Motors and their Importance in CNC Machines

CNC (Computer Numerical Control) spindle motors are crucial components in CNC machines, playing a vital role in the cutting, shaping, and machining of various materials. These motors provide the rotational motion needed to spin the cutting tools or workpieces, enabling precise and efficient fabrication processes.

CNC spindle motors come in various types, including water-cooled, air-cooled, and ATC (Automatic Tool Change) spindle motors. Each type has its own distinct features and advantages, catering to different CNC applications.

Importance of CNC Spindle Motors:

Rotation and Control: CNC spindle motors drive the rotation of cutting tools, allowing for precise and controlled material removal. Their speed and torque can be precisely adjusted, enabling efficient and accurate machining operations.

Versatility: CNC machines are used in a wide range of industries, such as metalworking, woodworking, and automotive. Spindle motors provide the versatility required to handle different materials and machining processes.

Productivity and Efficiency: CNC spindle motors are designed to deliver high-speed rotation and torque, facilitating faster material removal and reducing production time. This leads to increased productivity and enhanced efficiency.

Precision and Accuracy: CNC machines are known for their ability to achieve highly precise and accurate cuts. Spindle motors play a crucial role in maintaining the required precision during machining processes, ensuring dimensional accuracy in the final product.

Tool Change Capability: Some CNC machines feature ATC spindle motors, which allow for automatic tool changes. This feature eliminates the need for manual tool swapping, saving time and improving workflow efficiency.

Types of CNC Spindle Motors:

Water-Cooled Spindle Motors: Water-cooled spindle motors use water as a coolant to dissipate heat generated during operation. These motors are highly efficient and provide excellent temperature control, making them suitable for prolonged heavy-duty machining. Triquench India specializes in the production and supply of high-quality CNC router water-cooled spindles, catering specifically to CNC milling, drilling, and engraving operations. Our motorized spindle motors are meticulously designed to achieve accuracy levels of less than 3 microns, making them a preferred choice in various CNC machine spindles.

The water-cooled spindle motors offered by Triquench India are renowned in the industry for their exceptional durability and performance. As a leading spindle manufacturer, exporter, and supplier, we excel in providing top-notch solutions in all categories related to spindle technology.

Our CNC router water-cooled spindles are equipped with an efficient water cooling system, making them the best choice for CNC machines. Whether you are engaged in woodworking or metal machining, our water-cooled spindles are designed to meet the diverse needs of your CNC projects

Air-Cooled Spindle Motors: Air-cooled spindle motors rely on airflow to cool down during operation. They are simpler in design and maintenance compared to water-cooled motors, making them cost-effective for lighter machining applications. TriQuench India specializes in the production and supply of MTC Air-Cooled Spindle Motors, meticulously designed to meet the specific needs of our customers. These motorized spindle motors are particularly well-suited for various applications, including wood carving, PCB drilling, aluminum processing, and bangle making. Renowned for their efficiency and reliable performance, our CNC spindle motors have earned the trust and acclaim of our customers, consistently delivering desired outcomes.

Our MTC Air-Cooled Motorized Spindles are available in two distinct portfolios: Round Body and Square Body, providing customers with versatile options to suit their preferences and application requirements.

As a leading spindle manufacturer, exporter, and supplier, TriQuench India excels in delivering top-notch solutions across all categories related to spindle technology. Our commitment to quality and proficiency is reflected in the positive feedback and satisfaction expressed by our valued customer

ATC Spindle Motors: ATC spindle motors are designed to accommodate automatic tool changes within a CNC machine. These motors are equipped with a tool holder mechanism that allows for quick and seamless tool swaps, increasing operational efficiency. TriQuench India's Automatic Tool Changer (ATC) Spindle Motors offer a comprehensive range, renowned for delivering heightened precision and exceptional performance in machining operations.

These ATC Spindle Motors are engineered to provide superior accuracy, with performances characterized by elevated stability and compactness. This makes them well-suited for applications where automatic tool changing, featuring a high frequency of tool changes, is essential.

Our complete portfolio of ATC Spindle Motors spans a broad range from 12,000 rpm to 60,000 rpm, incorporating high-precision spindle bearings such as ceramic and steel bearings. The ATC Spindle Motors seamlessly facilitate the automatic use of different tools without requiring human intervention.

With applications extending across various industries, including PCB Drilling Machines, Die Mold Machines, Jewelry Making Machines, Wood Carving Machines, Stone Carving Machines, CNC Machining Centers, and Denture Making Machines, our ATC Spindle Motors cater to diverse machining needs.

TriQuench India takes pride in its commitment to providing superior service, backed by a team of experienced individuals with diverse expertise. We aim to create a unique and seamless experience in the realm of Motorized Spindle Motors.

Our ATC Spindle Motors stand out for their innovative design, ensuring optimal performance in machining processes. With a focus on precision, stability, and versatility, we strive to meet the dynamic demands of modern machining applications. TriQuench India looks forward to continuing to set industry benchmarks and delivering unparalleled spindle motor solutions.

In conclusion, CNC spindle motors are integral components of CNC machines, providing the necessary rotational motion and control for precise and efficient machining operations. The choice of a specific type of spindle motor, whether water-cooled, air-cooled, or ATC, depends on the specific requirements of the CNC application, including the material being machined, the desired speed and torque, and the automation capabilities needed.

0 notes

Text

Atc CNC Router Machine Price CNC Router With ATC For Sale

This atc cnc router machine price Linear auto tool change design, no need to change tool manually. It can help to finish different work quickly. with DSP control system is used for decorations, musical instruments, wood crafts, wood furnitures, wood door making, cabinet making, windows,

Atc cnc router machine price Application

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Whats the atc cnc router machine price advantage?

1.Function: Pop-up pins are used to position the materials,improve the processing accuracy,improve the qualified products percentage and working efficiency.

Advantage of CNC Router with ATC for sale

Firstly all the installing surface are processed by five axis machining center,this can make the accuracy high enough. Secondly the pop-up pins are equipped with aluminum slots along Y axis,when the machine used the pushing function the slots will rise up as a tank on the table surface so that the positioning surface is big enough to stop smalls pieces falling off the machine. All pop-up pins are installed with adjustable air pipe connectors,so all cylinders rise up or fall down at same time,this design wont break the cylinders due to over air pressure and non-working because of short of air pressure

Benefits: save your materials,high accuracy,time efficiency.

Features of CNC Router with ATC for sale

With 9kw air-cooled spindle, the spindle speed is fast, make machine working with high precision and long time service and stable movement.

The ATC CNC Router is equipped with a separate control cabinet, more convenient in terms of operation and maintenance;

Vacuum working table, match one vacuum pump, can fix the material more stable.

Linear Automatic Tool Changer 6Tools moving with beams, high efficiency and low cost

2 notes

·

View notes

Text

Spindle Motor.

Since its establishing in 1998, Changzhou Troy Hardware and Electric Co., Ltd. has been an imaginative forerunner in the plan, assembling, and circulation of Rapid Spindle Motors.

To guarantee that our items are of the greatest quality, we are continually putting resources into new, best in class apparatus for creation and testing. Clients both at home and abroad have come to trust us in light of our state of the art innovation and reliable quality. Our “WHD” image is turning out to be progressively notable.

Items from our STZ, STF, STM, STL, and STX series are generally found in CNC routers, etching machines, boring machines, edge banding machines, and other comparable gadgets. Moreover, we can make custom axle engines to meet our client’s particular necessities. We have traded our items everywhere, including to the US, Russia, Europe, India, Brazil, Iran, and numerous different nations, all for the sake of keeping up with our organization’s fundamental belief of putting the client first.

A spindle is a slight, adjusted bar with tightening closes that is utilized close by turning to bend and twist string from a mass of fleece or flax carried on a distaff.

Spindle grinding machine

High requests are regularly made on the mathematical resistances of the workpiece surface while crushing. Thus, crushing machine shafts are ordinarily developed with models for a base position change of the crushing circles inferable from outer powers and twisting minutes.

ATC — Automatic Tool Change Spindler Motor: — Shaft ATC The engine can utilize a few instruments consequently. Water Cooled 5.5 kW ATC Shaft, Water Cooled 7.5 kW ATC Axle, and Air Cooled 9.0 kW ATC Shaft are accessible from WHD. WHD offers Fast Air-Cooled Axle engines for CNC etching and CNC wood directing, with north of 20 years of involvement with making and providing shaft engines. WHD spindle engines have been sent to the US, Europe, Brazil, India, and Russia, among different spots.

ATC — Automatic Tool Change Spindle motor: — ATC represents Programmed Apparatus Change Shaft Engine. The ATC Spindle Motor can utilize a few devices naturally. WHD gives Water Cooled 5.5 kW ATC Spindle, Water Cooled 7.5 kW ATC Spindle, and Air Cooled 9.0 kW ATC Spindle are the accessible choices. WHD offers Fast Air-Cooled Axle engines for CNC etching and CNC wood directing, with more than 20 years of involvement with making and providing shaft engines. WHD Spindle engines have been delivered to the US, Europe, Brazil, India, and Russia, among different spots. A portion of its applications are carpentry, plastic acrylic, and light metal etchings like Aluminum and copper. Other data is that installment terms are T/T, Shanghai, China is the stacking port, Froth Box in Container Box Major areas of strength for with Across Container Box.

Air-cooled Spindle engine

Hard Circle Drive (HDD) axle engines are liable for the turn of HDD plates. Since the accuracy of these engines decides HDD limit and speed, these parts are mean quite a bit to HDD execution. Subsequently, these engines should give excellent execution regarding rotational speed and Non-Repeatable Run Out (NRRO).

A portion of the air-cooled shaft engines are:

1. Square Spindle engine: — WHD offers an assortment of Rapid Air Cooled Spindle Engines for CNC etching and CNC wood directing, including Round CNC Spindle Engines, Square CNC Shaft Engines, and CNC Spindle Engines with Spines, for all of your steering and etching needs. WHD axle engines have been sent out to the US, Europe, Brazil, India, Russia, and different nations across the world for more than 20 years.

2. Spindler motor with an electric fan: — WHD offers an assortment of Fast Air Cooled Shaft Engines for CNC etching and CNC wood directing applications, including Round CNC spindle Engines, Square CNC spindle Engines, and CNC spindle Engines with Ribs. WHD shaft engines have been traded to the US, Europe, Brazil, India, Russia, and different nations across the world.

3. Shaft motor with rib: — WHD offers an assortment of Rapid Air Cooled Shaft Engines for CNC etching and CNC wood steering applications, including Round CNC Shaft Engines, Square CNC Axle Engines, and CNC Axle Engines with Spines. WHD shaft engines have been traded to the US, Europe, Brazil, India, Russia, and different nations across the world.

Water-cooled Spindle engine

An electric Spindle is an electromechanical get together that incorporates an engine, an axle shaft and course, and an instrument holder of some sort. It might likewise have cooling arrangements.

A portion of the water-cooled shaft engines are:

1. Spindle motor for wood/plastic: — WHD has more than 20 years of skill in making and providing Water Cooled Shaft engines for different CNC applications fields as one of China’s driving Axle Engine producers. Our shaft engines have now been sent out to the US, Europe, Brazil, India, and Russia, among different spots.

2. Spindle motor for stone: — WHD has more than 20 years of ability in making and providing Water Cooled Shaft engines for different CNC applications fields as one of China’s driving Shaft Engine producers. Our axle engines have now been traded to the US, Europe, Brazil, India, and Russia, among different spots. The model is STZ140–11-ER32, the power is 11.0kW, the measurement is 140 mm, the speed is 24rpm, the voltage is 380V, the current is 20.9A, the recurrence is 100–800Hz and a lot more elements.

3. Spindle motor for metal: — WHD has north of 20 years of mastery in making and providing Water Cooled Axle engines for different CNC applications fields as one of China’s driving Shaft Engine producers. Our shaft engines have now been traded to the US, Europe, Brazil, India, and Russia, among different spots. The model is STM62–24Z/0.8, the power is 0.8kW, the width is 62mm, the speed is 24000rpm, the voltage is 220V, the current is 2.5A, the recurrence is 400Hz, and a lot more highlights.

Spindle motor

An edge bander is a machine that consequently makes enriching edges on boards and sheets. The machine cuts the edge of the wood and afterward sticks to beautiful edge strips or different materials with glue.

1. Edge banding spindle engine: — — WHD offers an assortment of Fast Air-Cooled spindle Engines for CNC etching and CNC wood directing applications, including Round CNC spindle motor, Square CNC spindle Engines, and CNC Axle Engines with Spines. WHD shaft engines have been sent out to the US, Europe, Brazil, India, Russia, and different nations across the world. The model is STFB40–63–12Z-0.75, the power is 0.75kW, the speed is 12000–18000rpm, the voltage is 380V/220V, the current is 1.75/3.0A, the recurrence is 200–300Hz, and a lot more elements.

2. Spindle motor customized: — . WHD offers High velocity Air-Cooled Shaft engines for CNC etching and CNC wood directing, with more than 20 years of involvement with making and providing axle engines. WHD axle engines have been delivered to the US, Europe, Brazil, India, and Russia, among different spots. A portion of its applications are carpentry, plastic acrylic, and light metal etchings like Aluminum and copper. Other data is that installment terms are T/T, Shanghai, China is the stacking port, Froth Box in Container Box Areas of strength for with Across Container Box. The model is STL70–24Z-9.0L-ER32, the power is 9.0kW, the speed is 12000–24000rpm, the voltage is 380V, the current is 18.2A, the recurrence is 800Hz, and a lot more highlights.

While settling on and setting up new items we go through nitty gritty preparation, elaborate plan, and steady support, and the items are handled by the item master. We even have corporate recordings on YouTube for more data.

0 notes

Text

Know The Power of CNC Routing and Its Application

CNC milling machines or computer numerical control milling machines are manufacturing machines. It used to cut or mill shapes of various shapes from wood, plastic, metal, foam, and a number of other materials. They can cut mechanically complex shapes much faster and with greater precision, repetition and accuracy than the human operator. They can be of great help to industries such as cabinets, signs, plastics manufacturing and many more to do great jobs that require the right parts quickly and accurately.

CNC Routers provided by Cnc Wood Routing Services Missouri come with standard table sizes, and some manufacturers can make custom machines. They have been around for a long time, but their popularity has grown due to their increased speed and advances in software.The coordinates are entered either by the drive or the program, and the movement is controlled by an independent control system.

Available Features

Manymodels of Cnc Wood Routing Services California come with the option of a vacuum suction system that uses a pump to suck air through the top of the router to retain the supplied material. They can also have an automatic tool changer option that uses robotics to change up to different tools while on the job. The tool changer can dramatically increase speed and productivity during jobs. Some newer models offer print-to-camera cameras that are mounted on routers and look for printed registration marks on the material to ensure as accurate and precise routing as possible.

After programming, only supervision is required to complete the task.

Cnc Wood Cutting Services Near Me require communication with the machine through software capable of creating or importing files specified by the operator. They rest on the spindle to turn the cutting tool or cutter to do the job. Once the goods transfer instruction is entered, the same program can be stored on the computer and used repeatedly to produce products at different times. This allows them to manufacture identical parts without having to reprogram the machine. The operator only needs to program the job and regularly monitor and deliver materials to the machine to make sure the job is going well.

The Cnc Wood Routing Services performs complex tasks at production speeds and can be repeated with consistent quality. They produce finished products with speed and precision that a human operator cannot achieve. The CNC router eliminates human errors by speeding up the production process to create a consistent product every time. It reduces costs because the computer builds and programs the router to do the work. Commonly used working files can be saved and recalled to iterate projects over and over again.

CNC Router is mainly used for processing various kinds of metal and wood.

CNC machine has become a necessity in the woodworking and branding industry; especially for large series manufacturers. These machines have the ability to produce at a speed of 20 times faster than the average man. For this simple reason, these machines quickly became more profitable than hiring hourly workers.

1 note

·

View note

Text

CNC Wood Router

Do you have a thought to DIY or buy a reliable CNC Wood Router? Browse the 2024 new Wood Router buyer’s guide as follows, we’ll provide you with the competitive Wood Routers of 2024 with expert customer service to satisfied your requirements.

What is a CNC Wood Router? CNC Wood Router is a wood router machine controlled by the computer. It can process 2D/3D, milling, carving (relief, plane engraving, hollow carving, 3D carving), cutting, slotting and drilling of most popular wood materials and other soft materials, including woodworking crafts, wood carving, wooden marks, wooden toys, wooden gifts, cabinet making, wooden door making, wooden modelling, production of wooden furniture such as wardrobe.

The main structure of CNC Wood Router includes spindle, bed, gantry, servo motor and actuator, CNC operating system, CNC software, rack guide, screw, worktable, power supply, limit switch and so on.

CNC Wood Router is also known as wood CNC machine, woodworking CNC router, wood CNC router, CNC wood carving machine, wood CNC cutter, CNC wood milling machine, wood CNC table, CNC wood table, CNC wood router machine, CNC woodcarver, CNC wood engraver, CNC woodcutter, CNC wood cutting machine, c and c wood router, CNC woodworking machine, CNC wood engraver, wood c and c machine.

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.Request a Quote

Small CNC Machine for Small Business

IGW-ATC 1325(PRO)ATC CNC Machine

ATC CNC Wood Router Table Kit

Wood CNC Router and Laser Engraver Combo

4×8 Wood CNC Router for Sale

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.Request a Quote

Small CNC Machine for Small Business

IGW-ATC 1325(PRO)ATC CNC Machine

ATC CNC Wood Router Table Kit

Wood CNC Router and Laser Engraver Combo

4×8 Wood CNC Router for Sale

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

ATC CNC ROUTER, CNC ROUTER MACHINE, CNC WOOD ROUTERCNC Wood Router Machine

CNC ROUTER, CNC WOOD ROUTERBest Wood CNC Machine for Small Business

CNC WOOD ROUTERBest CNC Router Machines for Woodworking

CNC WOOD ROUTERLatest 1325 Wood CNC Machine 4×8

CNC WOOD ROUTERCNC Wood Router Manufacturers and Supplier

ATC CNC ROUTER, CNC ROUTER MACHINE, CNC WOOD ROUTERCNC Wood Carving Machine

3 AXIS CNC ROUTER, CNC WOOD ROUTER3 Axis CNC Router with automatic tool changer

HOT3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER3 Axis ATC CNC Router with Automatic Tool Changer for Wood Furniture5.00 out of 5

HOT3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERWood 3 Axis 4*8 CNC Router Machine for Sale

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERMulti Use 4 Axis Woodworking CNC Router with Rotary Axis

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER4 Axis CNC Wood Engraving Machine with Spindle Swing 180 Degree

READ MOREQUICK VIEW3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERRotary Spindle 4 Axis CNC Wood Engraving Machine with Auto Tool Change

0 notes

Text

ATC Woodworking entry-level CNC Router

ATC Woodworking entry-level CNC Router

Overview ATC Woodworking entry-level CNC Routers standard features include a 12 HP HSD high frequency automatic tool changer spindle with an 8 Position tool holder rack(in linear type or rotary carousel type, multi-zone vacuum t-slot table combination, and material placement stops and are manufactured using global state-of-the-art techniques with all steel construction. Top Quality Components 1.) Big steel tube welded structure, after aging and tempering treatment, reliable and stable and not easy to deformation. 2.) Top-quality components, HSD ATC spindle, Delta inverter, TBI ball screw, Yaskawa servo motors, Syntec control system and so on.Long-time working time, high precision and efficiency. 3.) Carousel Tool Magazine system with 8 forks and 4 tool holders , which is loaded with the spindle, make the machine change tools quickly and save time. 4.) Many optional configuration and OEM service available. According to your requirement, different configurations will be offered. Applications 3D Carving, Acrylic Fabrication, Aluminum Fabrication, Architectural Mill work, Cabinetry, Exhibits and Fixtures, Sign making, Arts and Crafts, Furniture, Musical Instruments and More. Materials Cut Acrylic, ACM, Copper, Brass, Aluminum, PVC, MDF, Melamine plastic, Foam, Melamine, Phenolic, Plywood, HDPE, Solid Surface, Solid Wood, etc.

https://www.winwin-cnc.com/ATC-CNC-Router/ATC-Woodworking-entry-level-CNC-Router.html

0 notes

Photo

Automatic 1325 Wood CNC Router Wood Door Carving Machine. ATC cnc router with circular auto tool changer 12 tools, can choose 10 tools, 8 tools, 6 tools etc. Well-known 9.0KW HSD ATC spindle, strong cutting ability, low noise, long working time. Other configuration including Taiwan LNC control system, Japan yaskawa servo motor, Taiwan Detal inverter, HIWIN guide rail, Helical rack etc. Ideal for panel furniture, solid wood furniture, office furniture, wooden door productions, as well as other non-metal and soft metal applications. ATC CNC Router Machine features *Four air cooled spindle (HQD or Italy HSD spindle optional ),high quality and 24h continuously work. *HIWIN square rail,good occlusion and rigidity,no distortion for long time use. *High speed gear rack transmission for XY axis, and high precision ball screw transmission for Z axis, ensuring high speed and high precision at same time. *Pneumatic ATC for 3 spindles with different tools. Automatic tool changing saves time to manually change tools. *Vacuum table with vacuum pump,can quickly and stably fix materials on the table for engraving,saving time and long service life. #cnc_wood_router #CNC_Wood_Router_in_Bangladesh #cnc_wood_router_machine #cnc_wood_router_machine_for_sale #cnc_wood_router_table #wood_working_cnc_router #wood_cnc_router_tools #cozy_art_cnc_wood_router #cnc_wood_router_machine_in_bangladesh #cnc_wood_router_machine_price_in_bangladesh #cnc_wood_router_projects #cnc_wood_router_programs #cnc_wood_router_software #cnc_wood_router_files #cnc_wood_router_machine_price_in_india https://www.instagram.com/p/CZyWE8FriOX/?utm_medium=tumblr

#cnc_wood_router#cnc_wood_router_in_bangladesh#cnc_wood_router_machine#cnc_wood_router_machine_for_sale#cnc_wood_router_table#wood_working_cnc_router#wood_cnc_router_tools#cozy_art_cnc_wood_router#cnc_wood_router_machine_in_bangladesh#cnc_wood_router_machine_price_in_bangladesh#cnc_wood_router_projects#cnc_wood_router_programs#cnc_wood_router_software#cnc_wood_router_files#cnc_wood_router_machine_price_in_india

0 notes

Text

What is the difference between an engraving and milling machine and an engraving and milling center machine?

cnc wood router cnc engraving machine RC1325S

The difference between engraving and milling center machine and engraving and milling machine.

1. The engraving and milling machine is not equipped with a tool magazine, but a pneumatic locking tool spindle can be installed.

2. The engraving and milling center machine must be equipped with a tool magazine and a pneumatic tool lock spindle, which can automatically change and set tools according to the program in the execution of the processing program.

3. The engraving and milling machine mainly adopts two aspects of technology. One is a high-speed CNC system and a high position loop gain, which ensures the consistency of the machining contour accuracy at high and low speeds; the other is the fixed parts of the mechanical part such as the bed. , Beams, columns and other high rigidity enough to resist the acceleration impact of moving parts, and moving parts such as workbenches should be light and highly flexible.

4. Engraving and milling machines have certain technical requirements for options. For example, the automatic tool setting device is a necessary option for engraving and milling machines. It can accurately measure the tool length (within 0.), thereby improving efficiency and reducing the chance of human error. , To minimize the traces of the knife. It should be noted that the automatic tool setting device on the engraving and milling machine is different from that on the CNC milling machine. Because very small tools (such as 0.1mm) or drill bits below 1mm are sometimes used, the down force must be small when setting the tool. Generally, down force is used. Fully automatic tool setting instrument less than 0.8N.

5. The main components of the engraving and milling machine must meet the requirements of high-speed and high-precision processing. For example, high-speed spindles generally use two types, one is a direct high-speed electric spindle used within 1-2.2kw, the speed is below 36, the cutting torque is 1-2N, and the air cooling method is generally adopted. The other is a built-in high-speed electric spindle used within 2.2-7.5kw, the speed is below 30, the cutting torque is 3-9N, and water cooling is generally used.

6. Of course, special attention should be paid to the necessary accessories of the engraving and milling machine, such as the sharpener and the measuring microscope. The knife sharpener is an indispensable machine for sharpening knives and is used in conjunction with a measuring microscope. The CBN grinding wheel of the sharpener is very critical. Generally, about the size of the grain is used for rough grinding, and the one-grain grinding wheel must be used for fine grinding. The measuring microscope must have a scale to accurately measure the length and angle of the tool tip. Usually the manufacturer should provide it as a complete set. One point must be emphasized: measuring and grinding is an important part of processing, and the dimensional deviation of the tool must be less than 0.

What are the distinguishing characteristics of the engraving and milling machine?

First of all, we have to distinguish the difference between these three models:

1. CNC milling and machining center is used to complete the processing equipment of the workpiece with a large amount of milling. The rigidity requirements of the non-moving parts of the CNC milling machining center are very good, and the rigidity requirements of the moving parts are very good. It can perform heavy cutting, but because the moving part is also huge, the flexibility of the machine tool is sacrificed, and there is nothing for small parts and rapid feed.

2. CNC engraving and milling machine is used to complete small milling volume or soft metal processing equipment. The rigidity of the non-moving part is required to be good, and the rigidity of the moving part should be flexible as the prerequisite, as light as possible, while maintaining a certain degree of rigidity. It can carry out relatively small processing, and the processing precision is high. High-speed processing is possible for soft metals. However, heavy cutting is impossible due to poor rigidity.

3. The high-speed cutting machine is used to complete the medium milling amount and reduce the grinding amount after milling to the lowest processing equipment. The rigidity requirement of the non-moving part is very good, and the rigidity requirement of the moving part is better, and it is as light as possible. It can carry out small and medium cutting (for example, the general φ10 flat-bottomed knife, for the 45 steel () deep cutting depth is 0.75 is better). However, under the correct use, it can exert high efficiency and low cost, so that the amount of grinding becomes extremely small. Incorrect use will immediately pile up scraps of knives.

Strictly speaking, engraving is a part of milling, and whether to buy an engraving machine or a CNC milling machining center is a question that I often have to ask myself. In addition, there are currently popular high-speed cutting machine tools.

A machine tool that can recover the investment in a short period of time is a good machine tool. The design service life of CNC machine tools is generally 7 years, mainly based on the service life of CNC. In this way, the proportional relationship between spending money and earning money will directly affect your business, so careful analysis of functions and selection is a necessary condition for effective investment .

How to solve the contradiction that the above is light but the rigidity is also good on the machine, the key is to work hard on the mechanical structure.

1. The bed adopts a mesh structure with high and low ribs, and some directly adopt a honeycomb interconnected hexagonal mesh structure.

2. Ultra-wide columns and beams. Everyone knows that the gantry-type structure has always been the first choice for high-speed cutting equipment manufacturers due to its excellent symmetry and excellent rigidity.

3. The significant difference between the moving part and the CNC milling is that the distance between the guide rail and the guide rail is widened to overcome the problem of bad torque.

4. In terms of materials, Meehanite cast iron is generally used, that is, inoculated cast iron. A certain proportion of silicon (Si) is added during the pouring of molten iron to change the internal structure of the iron, making it more resistant to punching, and the rigidity is significantly improved. .

5. The rigidity of the machine tool is mainly used to overcome the strong impact of the moving part on the non-moving part when the moving part is moving at a high speed. Therefore, the guide rail and screw rod are required to be thicker, and the rigidity of the connecting part is strengthened.

https://www.roc-tech.com/CNC-Router/135.html#

0 notes

Text

China Nesting CNC Router For Sale

The nested based cnc router is mainly cutting equipment used in the production of panel furniture. The main functions include automatic typesetting, engraving, automatic loading and unloading, specia l-shaped cutting, vertical punching technology, and other processing techniques.

Maintenance of nesting cnc router for sale

Maintenance of the machine is the most easily overlooked thing. For example, the guide rail is often oiled to prevent sawdust from entering, which leads to the lock of the guide rail; the dust of the chassis is erased, sometimes because of this interference signal, resulting in inadequate accuracy of the machine. Cherish the machine, dust and maintain regularly, and the life of the machine will increase correspondingly.

Everyone knows that grounding wire is used to prevent static interference. At present, the trainers are in a mixed state. Many people do not attach importance to the small matter of grounding wire and think nothing will happen. But it is often this trivial matter that causes the control signal to be transmitted to the wrong signal of the motor, which causes the machine to run knife, shallow and shallow time, and large error.

Machine parameters are mainly in our software, because we process sheets of different materials, processing speed also needs to change at any time, such as poor particle board mixed with stones, the speed is too high. Light will cause tool edge collapse, this time does not change in time, will occur broach edge cutting uneven. Serious friction will cause fire and cause accidents.

Many vacuum pumps of machines are water pumps. This kind of adsorption effect is good, but since it is water, it will cause ice in the cold places in the north. At this time, the adsorption of vacuum pumps is ineffective, and antifreeze liquid is added in time to avoid freezing. Vacuum pump tank to be cleaned once a month, sometimes impurities blocked water pipe holes, water can not return to the pump, can not produce sealing. The adsorption force is almost zero.

cnc nesting machine for sale ATC Tool Changer With Drilling Wood Machine Features and Advantages:

1. Using ATC air-cooled tool change spindle with high power, it is suitable for processing complex patterns.

2. Adopting servo motor with reducer, it has the advantages of fast processing speed and high processing accuracy

3. With automatic loading functions, it effectively saves manpower and improves processing efficiency.

4. The tool magazine is installed under the gantry, which effectively improves the machining accuracy and prolongs the service life of the machine.

5. Automatic feeding, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes, maximize efficiency output.

6. User-friendly machine control interface design. Workers can operate the machine expertly just by simple training. High efficiency of the machine help you achieve productivity leap.

7. We adopt high quality spare parts for this CNC machine such as Italian HSD Spindle, YASKAWA AC Servo system, German Becker Pump, and so on.

Applications:

1. Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard

doors,interior doors, sofa legs, headboards and so on.

2. Advertising industry: advertising identification, sigh making, Acrylic engraving and cutting, crystal word making, blaster

molding, and other advertising materials derivatives making.

3. Die industry: A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand, plastic

sheeting, PVC pipe, wooden planks and other non-metallic mold.

4. Relief sculpture and 3D engraving

5. Cylindrical object

0 notes

Text

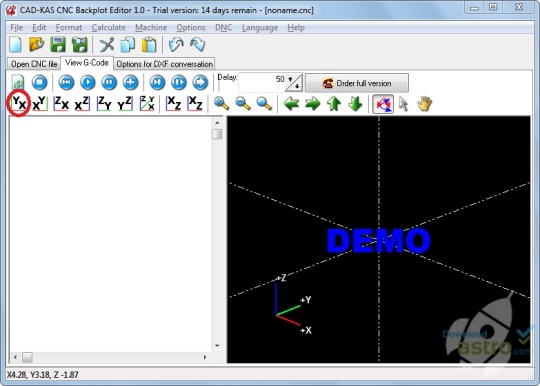

Cnc Backplot Freeware

What is Predator CNC Editor?

Cnc Editor

The Predator CNC Editor is the most popular CNC code editor available on the market. It includes hundreds of features to improve the day to day productivity of CNC machine tools, operators and CNC programmers yet it is extremely easy to use. The Predator CNC Editor is the ideal choice for the small job shop or the largest manufacturer. Choose from four editions:

CIMCO is an industry leading developer of software solutions for Computer Integrated Manufacturing and Industry 4.0. Our software suite includes advanced CNC editors, simulation software, DNC communications software, Manufacturing Data Collection, and Production Data Management solutions. . Edit and backplot CNC programs - G-Code, Heidenhain® conversational language, or CL files. Powerful compare methods designed for CNC programs. Serial download and upload. File conversion - change arc types, convert between program formats. Coordinate translation, rotation, scaling, and mirroring. Easily split a file into.

Predator CNC Editor Enterprise™

Predator CNC Editor™

Predator CNC Editor Express™

Predator CNC Editor Light™ - FREE! Edition - Download - Installation Steps

Why use Predator CNC Editor?

CNC Intelligent Editing with Undo and Redo

Machining Wizards

Unlimited File Size

File Compare

DNC Send, Receive and Dripfeed

3D Backplotting and Verification

CNC Templates

10 International Languages

Online Help

Made in the USA - Learn more

CNC Intelligent Editing with Undo and Redo

Dozens of CNC intelligent editing commands make changes to your CNC program quickly and easily. Edit confidently with the ability to undo and redo all changes. Microsoft® Word compatible menus, toolbar, and shortcut keys make Predator CNC Editor easy to learn.

Machining Wizards

Predator CNC Editor includes the following CNC machining specific wizards to fast track common changes:

Blockskips

Bolt Hole Circle

Comments

DNC Restart

Drill Position

Math Operations and Expressions

Feed rate calculator and override

Spindle speed calculator and override

Sequence Numbers

Triangle

Unlimited File Size

The Predator CNC Editor supports up to 64 Megs of G-Code per CNC program. In addition, editing multiple CNC programs at the same time is supported, with the ability to cut, copy, and paste between them.

File Compare

The Predator CNC Editor includes a side by side file compare which identifies each G and M code difference and fixes them with a single click of the mouse. A summary report and numerous options to ignore spaces, blank lines, leader/trailer, feed rates, spindle speeds and tool changes simplify the process of integrating shop floor edits with a master CNC program.

DNC Send, Receive and Dripfeed to your CNC machines

Send, receive, and dripfeed to one machine at a time, via switch box or direct connection to any compatible CNC machine. Works in the background even while other software applications are running. Should a tool break, an easy to use DNC Restart command automatically re-creates the CNC program from any point.

Cnc Backplot Freeware Free

NOTE: An upgrade to Predator DNC provides support for DNC networking of multiple CNC machines at the same time, comprehensive Ethernet, special RS232 protocols, conversational protocols, binary file transfers and BTR executive transfers.

3D Backplotting and Verification of your CNC G-Code

Predator CNC Editor and Predator CNC Editor Enterprise bundle an entry level of Predator Virtual CNC to graphically verify CNC G-Code. Visualize your CNC programs in 3D by quickly backplotting any CNC program. Define stock and tool shapes to provide 3D animation and verification. Supports 2 and 3 axis mills, routers, waterjets, lasers and 2 Axis lathes. Within the graphics window zoom in, zoom out, pan and fit commands provide complete control of the process. Copy the backplot or 3D animation to the clipboard and quickly add graphics to your setup sheets.

NOTE: Numerous examples are provided. For best results, 3D backplotting and verification may require appropriate machine configuration and reverse post processor configuration which can be done by knowledgeable end users, Predator Resellers or Predator Software Inc. Extensive online help is provided for machine configuration and reverse post processor configuration.

NOTE: Backplotting and verification of 4 and 5 axis mills and mill/turn lathes all require an upgrade to our full Predator Virtual CNC product provides support for advanced 4 and 5 axis CNC verification, solid models, machine simulation and much more.

G-Code Backplotting Support

Backplot an extensive range of G-Codes, M-Codes, CNC variables, sub programs and CNC macros from every major CNC vendor. Even backplotting APTCL is supported. Get additional details on the following:

Additional G-Code support is available by customizing existing CNC reverse post processors. Create an unlimited number of CNC reverse posts as required.

CNC Templates

Predator Editor CNC Templates add intelligence by remembering all the CNC control details. Includes a library of 20 sample CNC templates. Each CNC template is completely configurable.

Predator CNC Editor Enterprise - Part Numbers

Part #Descriptions for Microsoft SQL Server licenses20161000Predator CNC Editor Enterprise Administrator for SQL Server20161910Predator CNC Editor Enterprise Client for SQL ServerPart #Descriptions for Oracle licenses20181000Predator CNC Editor Enterprise Administrator for Oracle20181910Predator CNC Editor Enterprise Client for Oracle

NOTE: Predator CNC Editor Enterprise licenses do not include licences for Microsoft SQL Server or Oracle.

Predator CNC Editor - Part Numbers

Part #Description20102001Predator CNC Editor

Cnc Backplot Freeware Download

Predator CNC Editor - Popular Options

Cnc Editor Backplot

Part #Description20209020Predator Touch HMI20303050Predator Virtual CNC Express29900000Predator Floating License Manager - Learn more >

Predator CNC Editor Express - Part Numbers

Cnc Backplot Software

Part #Description20103001Predator CNC Editor Express

0 notes

Text

Best quality hot sale 1325ATC automatic 3d wood carving cnc router with dust collection

Best quality hot sale 1325ATC automatic 3d wood carving cnc router with dust collection

Best quality hot sale 1325ATC automatic 3d wood carving cnc router with dust collection

Features:

There are two kinds of , and this machine was designed with linear tool changer magazine. While, the machine also can be made with carousel tool changer, just like 1530 ATC type for Cabinet.

Multi-head or spindle machine can change 2 or 3 or 4 tools when process different kinds of raw…

View On WordPress

0 notes

Text

4 Axis 3 Axis CNC Router Machine for Woodworking 2d 3D Engraving

Woodworking cnc router

A woodworking CNC router is a computer numerical control (CNC) machine specifically designed for woodworking applications. It is a versatile and precision tool that automates the cutting, carving, engraving, and shaping of wood and wood-based materials.

A CNC wood router machine is an automatic table kit for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines. The most commonly used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft. A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations.

3 Axis Woodworking CNC Router Carving Machine

The CNC wood router on this page mainly refers to the 3 axis CNC router machine for CNC woodworking. The spindle of the CNC wood router carries the CNC router bits to move along the X, Y, and Z axes. As one type of the most commonly used wood CNC machine, it can cut, carve, engrave, mill, punch various types of wood boards. So it is also called CNC wood carving machine, CNC wood cutting machine, or CNC wood engraving machine.

The 3 axis CNC router has outstanding features, such as low cost, simple operation, multiple functions, and easy maintenance. So it is considered as an entry-level wood CNC machine in the CNC woodworking industry. And it is quite popular with users at home and abroad. The CNC wood cutting machine mainly performs some plane processing on wooden panels. If you are just doing flat machining on some plates, this 3 axis CNC router is definitely your ideal choice. For example, engrave patterns on or cut shapes out from a wood board.

Simply put, the 3 axis CNC wood carving machine works like a printer in terms of working principle.

The CNC router software (CAD) designs the engraving patterns and cutting paths to turn your ideas into electronic files. And the design and working path information is automatically transferred to the controller by the computer. Then the other type of CNC router software (CAM) turns the electronic files into G-codes. Such G-codes can drive the servo or stepper motor to work and control the CNC wood engraving machine spindle to move along the X, Y, and Z axes. So it can complete cutting, engraving, or carving work of multiple materials fixed on the working table.

Of course, sometimes, you have other machining requirements such as carving three-dimensional workpieces, curved surface machining of complex workpieces. To meet these demands, we also have CNC routers for woodworking with the rotating spindle, rotary device, automatic tool charge, or multiple spindles. You can choose one CNC wood cutting machine among them that can best suit your requirements.

3 Axis Woodworking CNC Router Machine with ATC

ATC CNC router is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this CNC wood router can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs. Therefore, both the processing quality and processing efficiency have been greatly improved.

According to the different tool changing methods, the ATC CNC engraving machine can be subdivided into linear ATC CNC and disc ATC CNC machines. Then we are talking about the linear ATC CNC Machine. This type machine uses a straight-line tool change device, and the tool change device can be installed in different positions according to the specific needs of the user.

Firstly, the in-line tool magazine can be placed behind the bed. This conventional in-line tool changer engraving machine is cost-effective and can meet a variety of processing requirements for complex work pieces without high procurement costs. Secondly, the in-line tool magazine can also be placed under the gantry. This type of linear engraving machine does not need to go to the back of the bed to change tools, so the tool change speed is faster and the wear on the guide rail can be reduced, and the service life of the machine is relatively longer. It is worth mentioning that the number of tools in the in-line tool magazine can be customized according to the specific processing needs of the user.

4 Axes Woodworking CNC Router

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

In a broad sense, a 4 Axis CNC Router machine refers to a CNC machine whose processing path include X, Y, Z, and A axis. And we are going to talk about a 4 axis machine whose spindle can swing left and right. Because the spindle of this type of CNC can swing left and right, the spindle can approach the work piece from multiple different angles and efficiently process three effective processing surfaces. This CNC machine can realize not only the plane engraving, but also the 3d carving of irregular work pieces.

And this type of wood CNC machine is suitable for common work piece, three-dimensional work piece, complex work piece and irregular graphics processing. In addition, this type of CNC engraving machine makes full use of the geometric configuration of the tool, controls the angle of the force, reduces the vibration of the force, prolongs the life of the tool, enhances the stability of the processing, and improves the processing accuracy. With the advantages of complete functions, wide processing range and high processing accuracy, more and more users choose the 4 axis machines for 3D Wood Carving. If you have similar three-dimensional work pieces, this CNC Wood Router will be your ideal choice.

4 axis cnc router woodworking machine with ATC

CNC wood machining center with 4th rotary axis is designed for 2D/3D popular woodworking, including wood furniture, wood cabinets, wood doors, wood decorations, stair spindles, wood balusters, roman columns, table legs, baseball bats. Now the best CNC wood machining center for sale at affordable price.

CNC Router Woodworking Machine Applications

This unit is a type of heavy duty CNC machine with wider machining range, like wood, MDF, aluminum, plastic, foam, etc .

By using STM1325-R1, you’ll find plenty of room for creativity: anything you can draw, it can cut. This machine can cut well with tremendous edge cuts because it adopts the same motion control as the larger machines. It can also runs with hand-held control system (DSP controller) that makes it easy to use.

1. Advertising: It can carve and cut all kinds of signs, trade mark, name plates, badge, decorative gift, embossed medal, certificate, souvenir, photo frame, furniture decoration.

2. Woodworking: It can be used for solid wood furniture, mahogany furniture, MDF paint door, solid wood door, composite door, cupboard door and window, bed side cabinet, folding screen.

3. Art Work: It can make wooden craft, mural art of wood, artwork, embossed, jewelry, cosmetics package, musical instrument.

4. Soft Metal Milling & Cutting: It can process aluminum front panel, popcan, aluminum honey comb panel, train car and air craft interior decoration, bronze medal, copper mold.

5. Electronics: It can engrave electronic component, integrated circuit, electronic plastic case, electronic product model, circuit board, electronic light box, computer and mobile phone key board, and a variety of electronic products.

Features and Aspects of Woodworking Cnc Routers

Computer Control: Woodworking CNC routers are controlled by a computer or a CNC controller that interprets design files and generates toolpaths. This allows for precise and repeatable woodworking processes.

CAD/CAM Software: Users design their projects with computer-aided design (CAD) or computer-aided manufacturing (CAM) software. The design files are then imported into the CNC router’s control software.

Versatile Cutting and Carving: CNC routers can perform a wide range of woodworking tasks, including cutting, carving, engraving, drilling, and 2D/3D shaping. They can create intricate designs and detailed patterns.

Spindle or Router Bit: CNC routers typically have a spindle or router bit that rotates at high speeds to cut or shape the wood. The choice of router bit and its speed affects the type of cuts and finishes the machine can achieve.

Table Size: Woodworking CNC routers come in various sizes, with different table dimensions. The choice of size depends on the type and size of projects you plan to undertake.

Tool Changer: Some advanced CNC routers have automatic tool changers, which allow the machine to switch between different router bits without manual intervention. This feature is beneficial for complex projects that require multiple tool types.

Dust Collection System: To maintain a clean and safe working environment, many woodworking CNC routers have dust collection systems that capture and remove wood chips and dust generated during the machining process.

Material Compatibility: CNC routers can work with a variety of wood and wood-based materials, such as hardwoods, softwoods, plywood, MDF (medium-density fiberboard), and more.

Precision and Accuracy: CNC routers offer high precision and accuracy, ensuring that the final products meet design specifications.

Safety Features: Some woodworking CNC routers are equipped with safety features such as emergency stops and protective enclosures to ensure operator safety.

User-Friendly Interface: Many CNC routers have user-friendly interfaces that make it easy to set up and run jobs.

Woodworking CNC routers are a valuable addition to woodworking shops, allowing for the production of intricate and customized wood products with efficiency and precision. When using a CNC router, it’s essential to receive proper training, follow safety guidelines, and maintain the machine regularly to ensure its optimal performance.

1 note

·

View note