#CNCPrecision

Explore tagged Tumblr posts

Link

Save Time and Money with the HAISHU Wheel Rim Repair Machine 💡

Looking for a way to boost your workshop's productivity? The HAISHU CK6166Q Wheel Rim Repair Machine is a CNC-powered solution designed to revolutionize rim repair services.

Features to Love:

✔️ Automation: Faster repairs with up to 50% time savings. ✔️ High Precision: Consistent quality with CNC accuracy. ✔️ Cost-Effective: Reduce material waste and labor costs. ✔️ User-Friendly: Preloaded repair templates and a 17-inch touchscreen.

Whether you're repairing alloy rims or offering diamond-cut finishes, this machine is a must-have for any modern workshop.

🌐 Read more: Wheel Rim Repair Machine

#WheelRepairMachine #HAISHUMachinery #CNCPrecision #AutomotiveIndustry #WorkshopEfficiency

2 notes

·

View notes

Text

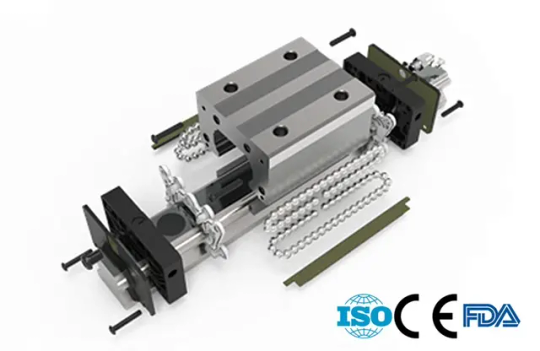

🔧 Need precision? We’ve got you covered.

Our linear guide rails offer ultra-smooth motion, high load capacity, and long-lasting durability — essential for CNC machines, automation lines, and high-performance robotics.

📌 Key Benefits:

High rigidity and accuracy

Low friction, smooth linear movement

Easy installation and modular compatibility

🚀 Whether you're upgrading your production line or building new industrial equipment, our linear guides are engineered for performance.

📥 Contact us now for datasheets, customization options, and factory-direct pricing!

#LinearGuide#CNCPrecision#IndustrialAutomation#FactorySolutions#B2BSourcing#TumblrIndustry#linear rail

0 notes

Text

Boost Your CNC Performance with High-Quality Collet Chucks

0 notes

Text

Perfect Foundation for Precision – CNC Turning Centres on Dynemech Anti-Vibration Technology Wedge Mount-DB

In every machine shop around the world, CNC turning centers are the leaders in production. They turn out metal fast and accurately – but for them to perform at their best, they need a firm, stable foundation. That's where Dynemech Anti-Vibration Technology Wedge Mount-DB comes in.

The above picture demonstrates CNC turning centres mounted on Dynemech Anti-Vibration Technology's Wedge Mount-DB, operating Vibration Free and Efficiently. While the machines cut, the DB mounts do the hard work – Absorbing Vibrations, smoothing out shocks, and providing stability.

Why Are CNC Machines in Need of Dynemech Anti-Vibration Technology's Wedge Mounts-DB?

CNC machines are precision machines. However, even a moderate floor Vibration or Imbalance can alter accuracy, reduce tool life, and affect the surface finish of the product. Furthermore, in the long run, it leads to higher maintenance and unscheduled downtime.

Dynemech Anti-Vibration Technology DB Wedge Mount acts as a shock absorber between your machine and shop floor. It keeps the vibrations from passing through, protects the machine structure, and holds everything in a flat and aligned state. In short, it gives you the ideal work conditions – quietly in the background.

Why Dynemech Anti-Vibration Technology DB Mounts Work So Well?

Better Vibration Isolation: Insulating pad of rubber at the base of the DB Mount isolates vibrations due to machine movement and floor movements.

Accurate Levelling: Thanks to the built-in levelling screw, you can accurately level your CNC machine – no more tilted surfaces and guesswork.

No Foundation Needed: No heavy-duty foundation or floor installation is needed. DB mount holds the floor firmly in place and aligns the machine.

Installation & Relocation Made Easy: Easy to install, adjust, or relocate – without wasting your valuable time and money on installing or relocating plants.

Sturdy Construction: Constructed of sturdy, long-lasting materials to support the load and performance of contemporary machines.

Trusted by Precision Professionals

The above CNC turning centers are running smooth as silk, thanks to the constant help of Dynemech Anti-Vibration Technology DB mounts. It's a perfect indicator of how the best manufacturers depend on Dynemech Anti-Vibration Technology to keep their machines running at their best.

Whether you own one, two, or a hundred CNCs or shop floors, Dynemech Anti-Vibration Technology provides you with peace of mind – your equipment is stable, your operation is smooth, and your production is consistent.

Why Dynemech Anti-Vibration Technology? Dynemech Systems Pvt. Ltd. is India's leading brand for vibration control as well as machine mounting solutions. With its ISO 9001:2015 certification and global presence, Dynemech has been delivering innovative performance-driven products serving industries like automotive, aerospace, heavy engineering, and more. From design to durability, all Dynemech products speak of quality, accuracy, precision, and customer faith.

To learn more about our products: https://www.Vibrationmountsindia.com/products/

#Dynemech, #AntiVibration, #WedgeMountDB, #CNCPrecision, #MachineMounting, #VibrationControl, #CNCTurningCentres, #NoMoreVibrations, #WorkshopStability, #IndustrialSolutions, #CNCBaseMount

📞 Call Now: 9810760131 📧 Email: [email protected] 🌐 Visit: www.vibrationmountsindia.com

#Dynemech#AntiVibration#WedgeMountDB#CNCPrecision#MachineMounting#VibrationControl#CNCTurningCentres#NoMoreVibrations#WorkshopStability#IndustrialSolutions#CNCBaseMount

0 notes

Text

Smart CNC Machining for Extreme Accuracy - Anjali T. Precision

Experience Smart CNC Machining for Extreme Accuracy with Anjali T Precision. Our advanced multi-axis CNC systems offer real-time monitoring, automated tool path optimization, and tight tolerance control—ensuring consistent quality for both prototypes and high-volume production.

Contact us today at [email protected] or +91 7757970589.

#CNCPrecision#SmartMachining#MultiAxisCNC#TightTolerance#CNCManufacturing#HighAccuracyMachining#PrototypeToProduction#AnjaliTPrecision#MadeWithPrecision#AdvancedMachiningSolutions

0 notes

Text

Is Your Pipe Testing Setup Missing This High-Precision CNC Milling Machine

Discover how the TT-150 CNC Milling Machine from Testron is redefining precision in pipe testing. Learn how to streamline your sample preparation process with the latest in CNC automation.

#PipeTesting#CNCPrecision#MillingMachine#PipeInspectionTools#QualityControlEquipment#EngineeringTools#CNCForPipes#ManufacturingSolutions#HighPrecisionMachinery#TestronTechnology

0 notes

Text

Flat Bed CNC Lathe Machines: Precision Engineering for Complex Parts

Flat Bed CNC Lathe Machines are designed for high-precision machining of complex parts. Their rigid structure and advanced CNC technology enable accurate turning, drilling, and threading operations. Ideal for industries requiring detailed and intricate components, these machines offer enhanced productivity and consistent quality in manufacturing processes.

#FlatBedCNC#CNCExpand#LatheMachine#CNCPrecision#ManufacturingAutomation#CNCEngineering#MachineTools#CNCpractices#MillingTechnology#PrecisionMachining#CNCWorkers#LatheDies#CNCOptimization#FlatBedMachining#CNCInnovation#MachiningSolutions#ManufacturingExcellence#CNCManufacturing#CNCWorkshop#TechInManufacturing

0 notes

Text

Why Graphite Machining Matters in High-Temp Environments

When the heat is on, graphite delivers. Ideal for aerospace, EDM, and high-temperature tooling, graphite machining offers:

✅ Superior thermal resistance ✅ Lightweight strength ✅ Stability under extreme stress

From prototypes to production, it’s a game-changer for precision in punishing conditions.

👉 Learn more: https://createproto.com/services/graphite-machining-services/

#GraphiteMachining#HighTemperatureTech#AdvancedManufacturing#ThermalResistance#CNCPrecision#AerospaceEngineering#EDMTech#HeatResistantMaterials#PrototypeToProduction#CreateProto

0 notes

Text

High-Quality Engine Sleeves – J. J. Autolink Pvt. Ltd. | Precision & Durability

J. J. Autolink Pvt. Ltd. - Excellence in Engine Sleeves

In the world of automotive engineering and precision manufacturing, the quality of engine components defines the efficiency and durability of an engine. At J. J. Autolink Pvt. Ltd., we specialize in producing engine sleeves that enhance engine performance, minimize wear, and ensure long-term reliability. Each engine sleeve we manufacture is crafted with the utmost precision, using advanced materials and innovative technology to meet the highest industry standards.

The Importance of a High-Quality Engine Sleeve

An engine sleeve is a crucial component within an engine block. It forms the smooth, wear-resistant surface where the piston moves, ensuring optimal combustion and reducing friction. At J. J. Autolink Pvt. Ltd., we produce engine sleeves that provide superior heat dissipation, increased longevity, and resistance to extreme conditions, making them the ideal choice for high-performance and heavy-duty engines.

Why Choose Engine Sleeves from J. J. Autolink Pvt. Ltd.?

Premium-Grade Materials: We use high-strength alloys, cast iron, and composite materials to manufacture durable engine sleeves.

Precision Engineering: Our cutting-edge machining processes ensure each engine sleeve fits perfectly, reducing energy loss and enhancing performance.

Enhanced Heat Resistance: Our engine sleeves are designed to withstand extreme temperatures, preventing engine overheating and improving efficiency.

Corrosion and Wear Resistance: Advanced coating technologies extend the lifespan of our engine sleeves, ensuring long-term reliability.

Versatile Applications: Our engine sleeves are suitable for a wide range of engines, from passenger cars to heavy-duty industrial machines.

Applications of Engine Sleeves in Various Industries

The engine sleeves from J. J. Autolink Pvt. Ltd. are utilized across diverse industries:

Automotive Sector: Our engine sleeves enhance performance in cars, trucks, and SUVs, ensuring smoother engine operation.

Motorcycles and Sports Vehicles: Precision-engineered engine sleeves offer durability and efficiency for high-speed applications.

Heavy-Duty Machinery: Industrial and construction vehicles rely on our robust engine sleeves for superior endurance.

Marine and Aerospace: Our high-quality engine sleeves support engines operating in extreme environmental conditions.

Innovative Manufacturing Process at J. J. Autolink Pvt. Ltd.

At J. J. Autolink Pvt. Ltd., we employ advanced manufacturing techniques to produce engine sleeves of exceptional quality. Our process includes:

Material Selection: We use only premium alloys and advanced composites to ensure strength and durability.

Precision Casting and CNC Machining: Our state-of-the-art equipment guarantees that each engine sleeve is manufactured with unparalleled accuracy.

Heat Treatment Process: Enhancing the hardness and resilience of our engine sleeves, preventing premature wear.

Quality Assurance Tests: Every engine sleeve undergoes rigorous testing to meet our stringent quality standards.

Efficient Global Distribution: We ensure that our engine sleeves reach customers worldwide with speed and reliability.

J. J. Autolink Pvt. Ltd.: Committed to Innovation and Excellence

With a reputation built on precision and quality, J. J. Autolink Pvt. Ltd. has become a trusted name in the manufacturing of engine sleeves. Our relentless pursuit of technological advancements and superior craftsmanship allows us to offer engine sleeves that exceed industry expectations.

Why J. J. Autolink Pvt. Ltd. is Your Best Choice for Engine Sleeves?

Uncompromising Quality: Every engine sleeve is manufactured under strict quality control measures.

Expertise and Experience: Years of experience in precision engineering make us a leader in engine sleeve production.

Continuous Research and Development: We incorporate the latest technological innovations into our engine sleeves.

Global Market Presence: Our engine sleeves are trusted by clients around the world.

Dedicated Customer Support: We provide expert guidance and assistance for all your engine sleeve requirements.

Conclusion

For superior-quality engine sleeves, trust J. J. Autolink Pvt. Ltd.. Our engine sleeves are designed for exceptional performance, durability, and reliability, making them the preferred choice for a wide range of engine applications. Whether you're looking for enhanced efficiency, longer engine life, or reduced maintenance costs, our engine sleeves deliver the perfect solution. Choose J. J. Autolink Pvt. Ltd. and experience the next level of engineering excellence.

Follow Us:

Contact No.: +91-9825388608, +91-9537726323

Email: [email protected]

Website: http://www.jdliners.com

#EngineSleeve#JJAutolink#AutomotiveParts#EnginePerformance#PrecisionEngineering#HeavyDutyEngines#EngineRebuild#HighPerformance#DurableEngines#QualityEngineParts#AutomotiveExcellence#EngineMaintenance#IndustrialEngines#TruckParts#MotorcycleEngine#MarineEngines#AerospaceEngineering#ReliablePerformance#EngineEfficiency#CNCPrecision#AdvancedManufacturing#WearResistant#EngineTechnology#HeatResistant#EngineOptimization#LongLastingParts

0 notes

Link

🌟 Level Up Your Manufacturing with High-Precision CNC Lathes! 🌟

Are you ready to revolutionize your manufacturing processes? The HAISHU CK50 High-Precision CNC Lathe is here to:

🔧 Deliver ±0.001 mm precision for flawless machining. ⏱ Boost efficiency with spindle speeds up to 4000 RPM. ⚙️ Handle complex machining tasks like turning, milling, and drilling in one setup.

Perfect for industries like automotive, aerospace, and medical devices.

📌 Discover more: High Precision CNC Lathe

💬 Let’s talk about how CNC lathes can transform your production!

#CNCPrecision #ManufacturingRevolution #HAISHUMachinery

2 notes

·

View notes

Text

🌸✨ Happy Holi from Kuvam Technologies! ✨🌸

This Holi, let’s add the colors of precision, innovation, and success to our journey! 🎨🚀 May your life be filled with happiness, prosperity, and endless opportunities.

Wishing you and your family a joyous, safe, and vibrant Holi! 🌈🎉

Stay colorful, stay successful!

#HappyHoli#FestivalOfColors#KuvamTechnologies#InnovationInEveryHue#PrecisionWithColors#HappyHoli2025#HoliCelebration#ColorfulVibes#JoyousHoli#CNCSpindles#Hiteco#RotaryTables#AngleHeads#ManufacturingInnovation#EngineeringExcellence#MakeInIndia#FestiveVibes#HoliHappiness#SuccessWithColors#SpindleTechnology#CNCPrecision

0 notes

Text

Royal Apex specializes in design and fit-out, handling everything from concept to completion. Our factory delivers perfect finishes and custom furniture in wood, aluminum, or any design, turning your ideas into reality. _________________ If you have any questions or need help, you can always contact us. _________________ 📲 : +971 50 2982989 🗺️ : UAE 🌐 : https://rac.ae/ _________________ #RoyalApexContracting #RoyalApex #RoyalApexGroup #InnovationInDesign #VillaRenovation #CNCPrecision #CustomFurniture #FactoryTour #Craftsmanship #InteriorDesign #BespokeFurniture #Woodworking #AluminumDesign #QualityManufacturing #DesignToReality #InteriorFitout #FitoutDesign #Dubai #UAE #AbuDhabi #UAEProperty #RenovateYourVilla

#RoyalApexContracting#RoyalApex#RoyalApexGroup#InnovationInDesign#VillaRenovation#CNCPrecision#CustomFurniture#FactoryTour#Craftsmanship#InteriorDesign#BespokeFurniture#Woodworking#AluminumDesign#QualityManufacturing#DesignToReality#InteriorFitout#FitoutDesign#Dubai#UAE#AbuDhabi#UAEProperty#RenovateYourVilla

0 notes

Text

詠翊科技有限公司

YONG YI CNCTETCH.Co.,LTD.

詠翊科技創立於2005年4月,團隊已擁有CNC銑床加工約二十年之專業加工經驗,其生產領域涵蓋電子、光學及半導體自動化設備…等產業。

目前廠內設備共有CNC銑床機台10台、傳統銑床7台、傳統車床及平面研磨機台共近20台精密設備。 此外亦陸續積極擴大規模及採購新的生產設備以有效擴張產能及服務範圍。 本公司可依據客戶之需求協助開發設計加工,各零件接單生產流程皆採嚴謹加工生產技術及品管檢驗作業,搭配各項表面處理,如:陽極、電鍍、代工代料代表處,全都處理到好。

詠翊科技本著「感恩的心、勤儉向上、追求創新、技術增長,並懷著努力不懈的敬業態度」,贏得各設備大廠及日本客戶一致的好評與信任。日後亦會秉持我們一貫的優良作風,「品質第一、快速交貨」,繼續為客戶服務。

Yongyi Technology was founded in April 2005. The team has about 20 years of professional processing experience in CNC milling machine processing. Its production fields cover electronics, optics and semiconductor automation equipment… and other industries.

Currently, the factory has 10 CNC milling machines, 7 traditional milling machines, and nearly 20 traditional lathes and surface grinding machines, a total of nearly 20 precision equipment. In addition, it has also been actively expanding its scale and purchasing new production equipment to effectively expand its production capacity and service scope. Our company can assist in the development, design and processing according to the needs of customers. The production process of each part order adopts rigorous processing and production technology and quality control inspection operations, with various surface treatments, such as anodizing, electroplating, and OEM representative offices. Handled well.

Yongyi Technology has won unanimous praise and trust from major equipment manufacturers and Japanese customers with its “gratitude, thrift, pursuit of innovation, technological growth, and unremitting dedication”. In the future, we will uphold our consistent good style of “quality first, fast delivery” and continue to serve customers.

#cncprocessing#cncprecision processing#semiconductor components#automation equipment#precision components#robot arm#stainless steel processing#engineering plastic#ceramic processing#cnc加工#cnc精密加工#半導體零組件#自動化設備#精密零組件#機器手臂#不鏽鋼加工#工程塑膠#陶瓷加工

0 notes

Text

⚡#Solid #Foundation for #Motion Control #Aluminum #diecast motor mount #frames keep #robotic #systems vibration-#free & #precisely aligned—#ideal for high-torque, high-#precision #automation 🔩Weight reduction meets rigid #structure ✅ Heat dissipating design ✅ Seamless integration ✅ Custom geometries

📞 Goyal Inc 🌐 www.Incgoyal.com | 📧 [email protected] | 📱 +91 9811088250

http://incgoyal.com https://x.com/goyal_inc https://www.youtube.com/@GoyalInc https://www.instagram.com/goyalinc https://in.pinterest.com/goyalinc https://www.facebook.com/incgoyal https://www.threads.net/@goyalinc #MotorMounts #RoboticsParts #DieCastingExperts #AluminumMounts #GoyalInc #AutomationComponents #RoboticIntegration #CNCPrecision #TechInMotion #LightweightStrength

2 notes

·

View notes

Text

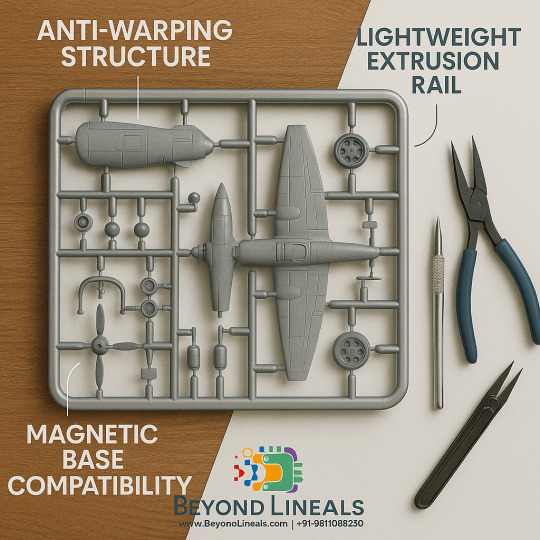

Where miniature design meets industrial-grade precision. Our aluminum extrusions for model kit frames offer ultra-straight profiles, modular grid compatibility, and corrosion resistance—perfect for precision model builders and hobbyists.

✂️ Burr-free edges 📐 Dimensionally stable 🧲 Easy integration with plastic and resin parts

Built for scale. Crafted to last.

📞 Beyond Lineals 🌐 www.beyondlineals.com | 📧 [email protected] | 📱 +91 9811088250

www.beyondlineals.com

www.instagram.com/beyondlineals/

www.x.com/Beyondlineals

www.facebook.com/beyondlineals/

www.youtube.com/@BeyondLineals

www.threads.net/@beyondlineals

www.in.pinterest.com/Beyondlineals

#ModelKitTools #AluminumExtrusion #ScaleModeling #CraftEngineering #HobbyistTools #MiniatureModels #CNCPrecision #CreativeFramework #DIYModeling #IndustrialCrafts

2 notes

·

View notes

Text

🚀 Introducing the Future of Precision Coating! 🎯 Say hello to the 5 Axis Spray Machine – engineered by Nedisha Group for unmatched accuracy, speed, and efficiency in industrial surface finishing.

🔧 Key Features: ✅ 5-Axis Precision Control ✅ High-Speed Robotic Spraying ✅ Uniform Coating on Complex Surfaces ✅ Intelligent Automation for Consistent Results ✅ Built for High-Volume Manufacturing

🛠 Perfect for industries where perfection is non-negotiable — from automotive to aerospace, and beyond.

📞 Contact Us: +91-9582131468 🌐 Visit: www.nedishagroupindia.com

📍 Made with innovation. Built for performance. 🔗 DM us to schedule a demo or request a quote.

NedishaGroup #5AxisSprayMachine #SurfaceCoating #AutomationTechnology #IndustrialInnovation #SmartManufacturing #MakeInIndia #ManufacturingSolutions #CNCPrecision

0 notes