#CRMimplementationpartner

Explore tagged Tumblr posts

Text

How Manufacturing Industry Transformed using Microsoft Dynamics 365

The future of manufacturing will be defined by the quality of investments companies are making today In the not too distant past, efforts in manufacturing to optimize productivity and increase customer satisfaction were viewed as separate endeavors. Today, the convergence of physical and digital trends is disrupting these kinds of assumptions. Manufacturers today care about integrated digital and physical systems, improved visibility, increased efficiency, additional flexibility, and lower costs. They want to connect equipment and factories, leveraging data from the factory floor to the customer call center to improve every aspect of their operations. But this is just the beginning. Digitization is fundamentally changing the way manufacturers do business, enabling a customer-centric approach while optimizing operations. Digitally empowered manufacturers engage customers throughout the product lifecycle from design to field service. They sell value-add services to complement the product sales, opening new revenue streams and strengthening their customer relationships. And they are revolutionizing delivery of these differentiated services, using technology like augmented reality to combine the eyes of a technician in the field with the insights of an expert back at headquarters. Capitalizing on these trends isn’t limited to large, well-resourced manufacturers. Across all kinds of manufacturing operations, the opportunity to digitize and transform your business has never been more accessible. Imagine your business transformed The Microsoft vision for supporting digital manufacturing embraces the seismic shifts in the industry today. We’ve created solutions that provide a unified and flexible approach across front office and production floor processes. Our approach enables transformation in six ways:

Optimize supply chain operations through better visibility and collaboration By collecting, integrating, and visualizing global supply chain data worldwide, manufacturers gain better visibility into their operations from production to sales. For example, one of the world’s largest industrial automation firms found that by automating the collection and analysis of data from remote installations across the petroleum supply chain, they strengthened their competitive advantage with a faster time to market. Improved access to supply chain data is also the basis for better collaboration across production, supply, service, and sales. Streamline the management of assets, products, and production With a consolidated view that unifies process oversight and provides real-time insight, manufacturers can institutionalize efficiency gains and use connected devices to monitor and resolve issues remotely. One leading manufacturer of industrial robots enabled 24-hour continuous uptime using this approach. The additional insights into production and customer usage also allow manufacturers to provide value-added services like ongoing monitoring and proactive support.

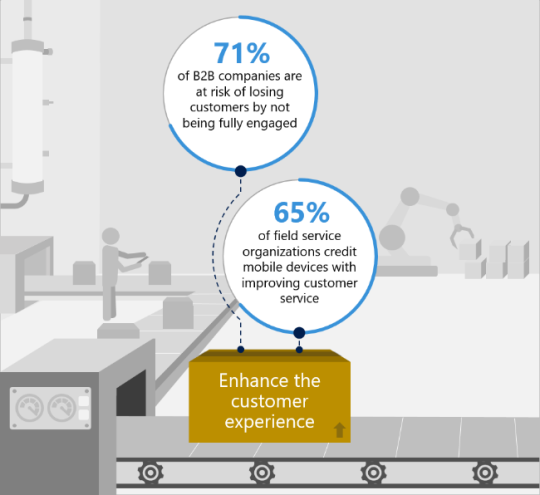

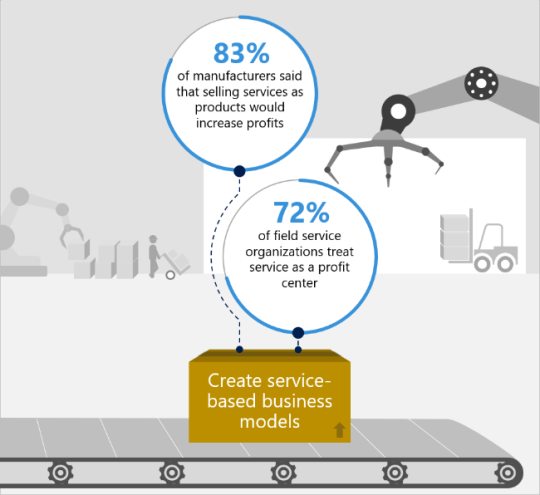

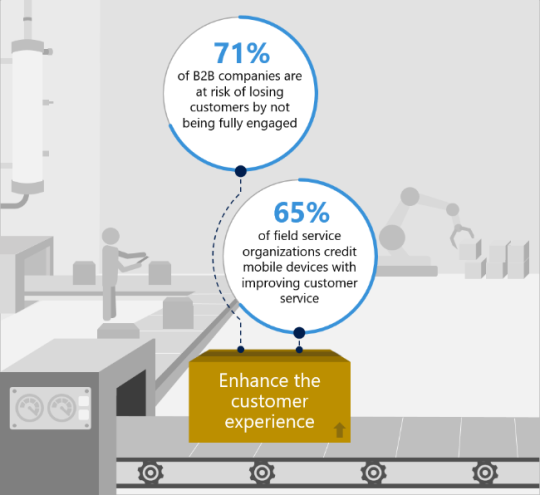

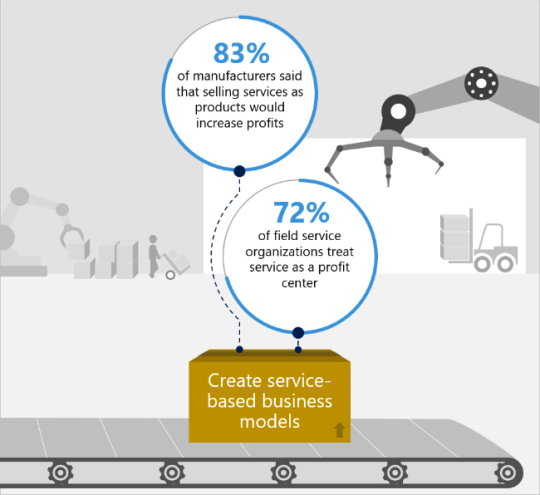

Engage customers in powerful new ways To deliver personalized and contextual engagement across any channel, manufacturers must provide customers with more visibility and build trust through fast and convenient responses. This engagement approach is built on a combination of predictive analytics, the ability to deliver value-added services at scale, and guided or self-directed service that’s relevant to customer needs. With the implementation of a connected platform for sales through service, a leading home technology manufacturer not only solved potential problems remotely before customers ever felt the impact, but provided custom differentiated offerings based on unique customer usage and purchasing history. Transform service centers into profit centers Thanks to the ever-decreasing cost of IoT sensors, sophisticated mobile devices, and cloud-based data aggregation, manufacturers can improve service quality and margins by offering remote monitoring and proactive maintenance services that supplement break/fix support. By more intelligently coordinating technicians equipped with mobile and virtual reality tools, companies can leverage existing expertise and minimize costly engagements. A leading tire service and manufacturing company found that by combining customer records, technician availability, and back-end inventory in a single mobile-friendly system, it could provide a seamless user experience as well as improve its service delivery.

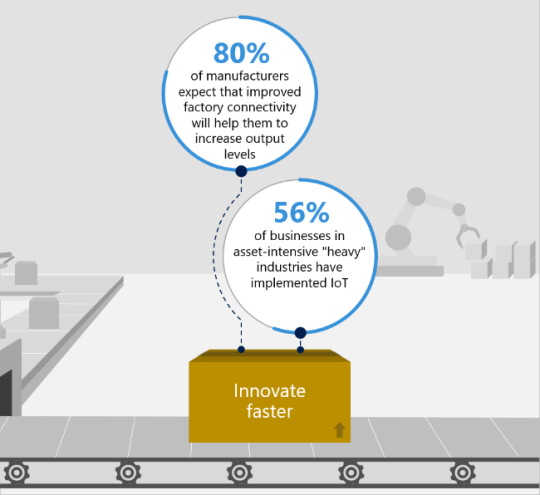

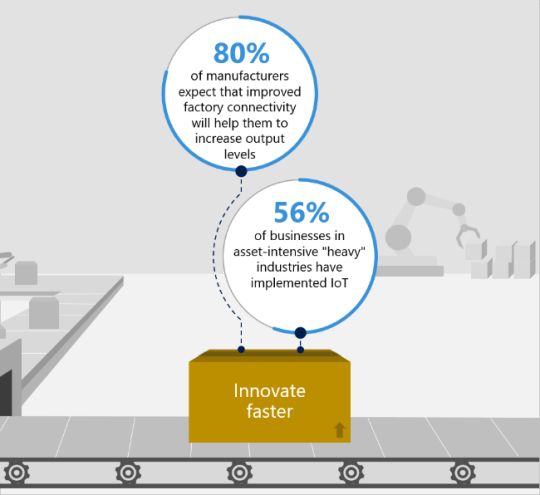

understand their business more deeply, from customer usage through supply chain sourcing and production. With IoT-enabled parts, assets, and products, manufacturers can gain the insights needed to innovate. Data from connected products and equipment can empower developers, engineers, and technicians to collaborate. For example, teams can identify overengineered or faulty components and track product usage in the field to improve future designs. When a leading information and communication technology company implemented remote monitoring, they decreased time to production as well as accelerated the cycle of innovation using a data-driven approach. Empower employees to work more effectively When a company can provide 360-degree views of customer assets and work order history, technicians are empowered by a better understanding of not only the job in front of them, but of other similar and successful field service engagements. This goes hand in hand with empowering service agents to provide instant feedback, using machine learning to find and follow similar cases for successful troubleshooting, and scheduling a visit or evaluation. A leading auto manufacturer wanted to save money by unifying their siloed customer service and customer engagement while providing employees with better tools to understand customer sentiment. To accomplish this, it implemented a system to connect production and project management with their customer relationship management systems in order to deliver personalized service and recommendations to their customers. Introducing Microsoft Dynamics 365 For manufacturers, Microsoft Dynamics 365 ends the artificial divide between CRM and ERP systems and supplements necessary capabilities with rich analytics, embedded intelligence, and the convenience people expect from consumer apps on their phone or tablet. Dynamics 365 unites the front office and the back office with a single end-to-end system for managing every aspect of your business, at the pace and scale that’s right for you. Digital transformation isn’t accomplished overnight and leveraging current investments is a key component of any successful approach. With Microsoft, you can optimize across all your processes while laying the foundation for connecting advanced technology in the future. Blog reference: https://cloudblogs.microsoft.com/dynamics365/bdm/2017/05/30/manufacturing-transformed-microsoft-dynamics-365 Read the full article

#automotivemanufacturingerp#axpartner#axpartnerinuae#crmforhospitality#crmformanufacturingindustry#crmimplementationpartner#dynamics365partner#Dynamics365partnerinindia#dynamics365partnerinsouthafrica#dynamics365partnerinuae#dynamics365partnerportal#dynamicsaxpartner#dynamicsaxpartnerindelhi#dynamicsnavpartner#dynamicsnavpartnerinethiopia#dynamicsnavpartnerinkolkata#dynamicsNavisionpartner#dynamicspartnerinIndia#dynamicspartnerinUAE#erpforautomotivemanufacturing#erpforelectronicsmanufacturing#erpforhospitality#erpforhospitalityindustry#erpformanufacturingindustry#erpforsteelmanufacturing#foodmanufacturingerp#hospitalityerpsoftware#HospitalityERPSolution#hospitalitymanagementsolution#IBMTrainingPartnerIndia

0 notes

Photo

Microsoft Dynamics 365 facilitates to integrate the cross functions viz., Sales, Marketing, Services and financial systems. You can customize it in several ways as per your business requirements. Visit: www.mastermindtechies.com

0 notes

Text

How Manufacturing Industry Transformed using Microsoft Dynamics 365

The future of manufacturing will be defined by the quality of investments companies are making today In the not too distant past, efforts in manufacturing to optimize productivity and increase customer satisfaction were viewed as separate endeavors. Today, the convergence of physical and digital trends is disrupting these kinds of assumptions. Manufacturers today care about integrated digital and physical systems, improved visibility, increased efficiency, additional flexibility, and lower costs. They want to connect equipment and factories, leveraging data from the factory floor to the customer call center to improve every aspect of their operations. But this is just the beginning. Digitization is fundamentally changing the way manufacturers do business, enabling a customer-centric approach while optimizing operations. Digitally empowered manufacturers engage customers throughout the product lifecycle from design to field service. They sell value-add services to complement the product sales, opening new revenue streams and strengthening their customer relationships. And they are revolutionizing delivery of these differentiated services, using technology like augmented reality to combine the eyes of a technician in the field with the insights of an expert back at headquarters. Capitalizing on these trends isn’t limited to large, well-resourced manufacturers. Across all kinds of manufacturing operations, the opportunity to digitize and transform your business has never been more accessible. Imagine your business transformed The Microsoft vision for supporting digital manufacturing embraces the seismic shifts in the industry today. We’ve created solutions that provide a unified and flexible approach across front office and production floor processes. Our approach enables transformation in six ways:

Optimize supply chain operations through better visibility and collaboration By collecting, integrating, and visualizing global supply chain data worldwide, manufacturers gain better visibility into their operations from production to sales. For example, one of the world’s largest industrial automation firms found that by automating the collection and analysis of data from remote installations across the petroleum supply chain, they strengthened their competitive advantage with a faster time to market. Improved access to supply chain data is also the basis for better collaboration across production, supply, service, and sales. Streamline the management of assets, products, and production With a consolidated view that unifies process oversight and provides real-time insight, manufacturers can institutionalize efficiency gains and use connected devices to monitor and resolve issues remotely. One leading manufacturer of industrial robots enabled 24-hour continuous uptime using this approach. The additional insights into production and customer usage also allow manufacturers to provide value-added services like ongoing monitoring and proactive support.

Engage customers in powerful new ways To deliver personalized and contextual engagement across any channel, manufacturers must provide customers with more visibility and build trust through fast and convenient responses. This engagement approach is built on a combination of predictive analytics, the ability to deliver value-added services at scale, and guided or self-directed service that’s relevant to customer needs. With the implementation of a connected platform for sales through service, a leading home technology manufacturer not only solved potential problems remotely before customers ever felt the impact, but provided custom differentiated offerings based on unique customer usage and purchasing history. Transform service centers into profit centers Thanks to the ever-decreasing cost of IoT sensors, sophisticated mobile devices, and cloud-based data aggregation, manufacturers can improve service quality and margins by offering remote monitoring and proactive maintenance services that supplement break/fix support. By more intelligently coordinating technicians equipped with mobile and virtual reality tools, companies can leverage existing expertise and minimize costly engagements. A leading tire service and manufacturing company found that by combining customer records, technician availability, and back-end inventory in a single mobile-friendly system, it could provide a seamless user experience as well as improve its service delivery.

understand their business more deeply, from customer usage through supply chain sourcing and production. With IoT-enabled parts, assets, and products, manufacturers can gain the insights needed to innovate. Data from connected products and equipment can empower developers, engineers, and technicians to collaborate. For example, teams can identify overengineered or faulty components and track product usage in the field to improve future designs. When a leading information and communication technology company implemented remote monitoring, they decreased time to production as well as accelerated the cycle of innovation using a data-driven approach. Empower employees to work more effectively When a company can provide 360-degree views of customer assets and work order history, technicians are empowered by a better understanding of not only the job in front of them, but of other similar and successful field service engagements. This goes hand in hand with empowering service agents to provide instant feedback, using machine learning to find and follow similar cases for successful troubleshooting, and scheduling a visit or evaluation. A leading auto manufacturer wanted to save money by unifying their siloed customer service and customer engagement while providing employees with better tools to understand customer sentiment. To accomplish this, it implemented a system to connect production and project management with their customer relationship management systems in order to deliver personalized service and recommendations to their customers. Introducing Microsoft Dynamics 365 For manufacturers, Microsoft Dynamics 365 ends the artificial divide between CRM and ERP systems and supplements necessary capabilities with rich analytics, embedded intelligence, and the convenience people expect from consumer apps on their phone or tablet. Dynamics 365 unites the front office and the back office with a single end-to-end system for managing every aspect of your business, at the pace and scale that’s right for you. Digital transformation isn’t accomplished overnight and leveraging current investments is a key component of any successful approach. With Microsoft, you can optimize across all your processes while laying the foundation for connecting advanced technology in the future. Blog reference: https://cloudblogs.microsoft.com/dynamics365/bdm/2017/05/30/manufacturing-transformed-microsoft-dynamics-365 Read the full article

#automotivemanufacturingerp#axpartner#axpartnerinuae#crmforhospitality#crmformanufacturingindustry#crmimplementationpartner#dynamics365partner#Dynamics365partnerinindia#dynamics365partnerinsouthafrica#dynamics365partnerinuae#dynamics365partnerportal#dynamicsaxpartner#dynamicsaxpartnerindelhi#dynamicsnavpartner#dynamicsnavpartnerinethiopia#dynamicsnavpartnerinkolkata#dynamicsNavisionpartner#dynamicspartnerinIndia#dynamicspartnerinUAE#erpforautomotivemanufacturing#erpforelectronicsmanufacturing#erpforhospitality#erpforhospitalityindustry#erpformanufacturingindustry#erpforsteelmanufacturing#foodmanufacturingerp#hospitalityerpsoftware#HospitalityERPSolution#hospitalitymanagementsolution#IBMTrainingPartnerIndia

0 notes

Text

THE TOP 10 REASONS WHY SMBs SHOULD INVEST IN THE CLOUD

Small to medium-sized businesses (SMBs) are lagging behind their enterprise counterparts when it comes to cloud adoption. With the new year (and new decade) fast underway, a recent Microsoft study showed that more than 96% of enterprises are using the cloud, compared to only 78% for SMBs. And while the use of cloud-based productivity apps like Office 365 has steadily grown among these smaller companies, their continued reliance on legacy software in key business applications such as ERP or accounting is impeding them from competing effectively with today’s top players. Given this situation, moving to the cloud should be an obvious priority for SMBs, but many myths and misconceptions still exist regarding the benefits of cloud technology. Below are the ten most crucial and game-changing benefits that SMBs have reported after investing in cloud solutions. 1 - Greater profit and ROI Simply put, companies that move to the cloud make more money. And not by a small percentage, either. SMBs that invest in the cloud report up to 25% growth in revenue and up to 2x the profits over those who don’t. Embracing the cloud is simply a better path to faster growth. Additionally, cloud deployments provide a greater return on investment (ROI) than traditional on-premises software projects, especially in ERP and CRM. For example, Nucleus Research determined that companies that use Microsoft Dynamics 365 see a return of $16.97 for every $1 spent. That’s well above the average for on-premise ERP and CRM applications. 2 - Lower costs and CapEx Cloud subscription models eliminate up-front capital expenditures (CapEx) like the high cost of hardware and software licenses for projects like ERP software implementations. They also eliminate server and infrastructure setup, update, and maintenance fees—not to mention the resources saved on software upgrades, energy costs, and underutilized computing resources 3 - Unparalleled business flexibility Cloud software allows small businesses to remain always-on regardless of location. In today’s mobile and cloud-first world, the ability to be productive on any phone, tablet, or laptop provides the flexibility required to quickly adapt to changing information and business needs. This means more agile operations and happier customers 4 - Faster IT innovation The hassle and cost of routine IT maintenance tasks can be effectively offloaded to the cloud, enabling IT resources to focus on more strategic tasks like addressing problems, improving user experiences, fostering user adoption and best practices, and getting more value out of systems and processes 5 - Seamless, automatic software updates With cloud computing, all software updates are handled automatically, so critical systems always have the latest functionality and security features. This effectively ensures that all the benefits of a vendor's ongoing R&D nvestments are transferred to their customer's business, without that business having to dedicate any time or additional resources 6 - Cost-effective scalability SMBs need increased flexibility to grow and scale without hassle. With the cloud, as an SMB adds users, generates more transactions, or adds more data, services dynamically scale to manage the workload. This eliminates the need to pay for more hardware or maintenance to support business growth. As a bonus, SMBs only use the energy they need for their cloud apps. Since servers aren’t running idle waiting to be utilized, operations become more energy efficient, reducing the carbon footprint of the business. 7 - Improved collaboration and productivity Digital, cloud-based workspaces offer the opportunity to collaborate more effectively and remove data silos to enable greater employee productivity. Additionally, cloud-based office productivity suites and all-in-one business management solutions possess integration capabilities that simply can’t be matched by on-premises software. Cloud computing also allows teams to be productive, regardless of their location. This enables businesses to offer flexible working arrangements that create a healthier work/life balance and happier employees without sacrificing productivity. 8 - Seamless software integration Cloud applications are typically compatible with Application Programming Interfaces (APIs) that simplify integration, while automation tools like Microsoft Flow facilitate stitching them together without any custom code. Data and systems can be connected like never before, resulting in new levels of speed and efficiency. 9 - Superior security and data protection Small businesses are the most common victims of security breaches. In a recent study by ComScore, over 40% of small businesses were worried about data security before moving to the cloud. After making the switch, 94% of businesses reported security benefits they had been unable to achieve with their previous on-premises resources. Furthermore, physical hardware protection has always been a challenge for SMBs. Laptops get lost or stolen all the time. In addition to the replacement costs, there is the even greater cost of losing important or sensitive data. When storing and backing up data in the cloud, however, data is available and protected regardless of what happens to personal devices. 10 - Increased competitiveness Moving to the cloud gives SMBs access to enterprise-class technologies that were previously only available to the industry’s top players. With the cloud, any business can run on the exact same systems used by the largest, most sophisticated companies in the world, enabling them to innovate and act faster than competitors that manage on-premises legacy systems. In conclusion, with cloud software now available that is purpose-built for SMBs to run their sales, marketing, service, accounting, operations, supply chain, and project management activities—all from a single, connected solution infused with AI and advanced analytics—there’s never been a better time for small and medium-sized businesses to make the move to the cloud. Connect with our cloud expert for any query or requirement at - [email protected] Read the full article

#axpartner#axpartnerinuae#azuredatabackup#azuredisasterreocvery#cloudservices#cloudservicescompanies#cloudservicesconsulting#cloudserviceshosting#cloudservicesinazure#cloudservicesinindia#cloudservicesprovider#cloudservicesproviderinindia#companieswithcloudservices#crmimplementationpartner#dynamics365partner#Dynamics365partnerinindia#dynamics365partnerinsouthafrica#dynamics365partnerinuae#dynamics365partnerportal#dynamicsaxpartner#dynamicsaxpartnerindelhi#dynamicsnavpartner#dynamicsnavpartnerinethiopia#dynamicsnavpartnerinkolkata#dynamicsNavisionpartner#dynamicspartnerinIndia#dynamicspartnerinUAE#IBMTrainingPartnerIndia#listofmicrosoftdynamicspartnersinsouthafrica#listofmicrosoftdynamicspartnersinuae

0 notes

Photo

MS Dynamics NAV covers more than 95% of the Financial functions and its features, which has been rated as Excellent as per the users. As far as Inventory Management section is concerned, the various decision factors help the business owners to rely upon. Visit our site to get more details: http://mastermindtechies.com/microsoft-dynamics-nav/

0 notes

Photo

IoT starts with organizations hunting for operational efficiency. Subsequently, they begin by connecting devices and capturing data. Dynamics 365 (CRM) connected field service application enables you to attain operational efficiency. With a skilled team of IT professionals and Microsoft Dynamic consultants, we, mastermind, are well suited for your business with our proven Microsoft Dynamics competencies. Check us out: http://mastermindtechies.com/microsoft-dynamics-crm/

0 notes

Photo

Manage your prospects and Customers in real time and get the account related details on the go for better understanding and decisions. Microsoft Dynamics CRM supports you to get the full picture at any time. Mastermind Consultancy is the best Partner for your MS Dynamics CRM Implementation. Visit our site to get more details: http://mastermindtechies.com/microsoft-dynamics-nav/

0 notes

Text

Is your business ready to take supply chain management to the next level?

When you lack deep visibility and insight into your supply chain, you leave money on the table It turns out what you don’t know as a manufacturer can and will hurt you. For too long, manufacturers have settled for siloed and inconsistent information, as well as manual processes, to understand and manage their supply chain. Why? Because for a long time, these systems were good enough to keep production going. But plenty of manufacturers don’t want to settle for good enough. IDC predicts that by 2019, 50% of manufacturing supply chains will have benefited from digital transformation, and the remainder will be held back by outdated business models or functional structures. Smart manufacturers understand that supply chain transformation is necessary. They are connecting assets across their factories, gaining visibility into their supply chain, and acting on insights from increased visibility to address inefficiency, as well as increase customer satisfaction and margins. Don’t accept operational inefficiencies as a limit on your business Supply chain management is complex, so doing it right requires a solution that simplifies and consolidates disparate information, while retaining flexibility. Data from the sales process, suppliers, order fulfillment, product performance, and customer service all matter for a full understanding of the supply chain. The core tools for accomplishing this fall into three categories: IoT-enabled visibility and services, powerful analytics, and cloud-delivered data visualizations. Like many aspects of manufacturing, IoT is the starting point. The best way to lower production costs is by using a single IoT-friendly platform to integrate back and front office processes. Using IoT-based modeling to create digital twins, manufacturers can understand in real-time the amount of wear and tear on parts and adjust designs in response. This insight can help identify simple inefficiencies like sourcing a part from the company that’s always supplied it, rather than buying a similarly-performing part at a lower cost from another supplier. Powerful analytics is the next step in transforming your supply chain. A truly intelligent system for supply chain management dynamically adjusts distribution, as well as production, to accelerate the speed of delivery. By using built-in analytics and machine learning, public data like weather conditions can be used to create richer, more accurate schedules and delivery forecasts. On top of that, opportunities to consolidate or expedite shipments can be automatically identified using artificial intelligence—passing lower shipping and order fulfillment costs on to customers. Finally, consolidating all this information won’t completely optimize your supply chain without the ability to easily visualize and manage it. That’s why a real-time and mobile-delivered view is so crucial. Understanding how to solve problems is hard enough; there’s no need to complicate it further by using different systems to identify where problems are occurring. Decision makers on the factory floor or in global headquarters need instant access to relevant information, and the collaborative power to communicate with or work alongside employees anywhere in the world. These investments in operations put manufacturers in position to embrace new technology and adjust to whatever business challenges they may be facing. Get the tools to transform with Microsoft Dynamics 365 The power of a supply chain management and operations platform that combines all these capabilities at cloud speed and scale is obvious. Companies positioned to digitally transform their supply chains will see accelerated time to market and reduced cost to enter new markets or scale new lines of business. Microsoft supports flexibility in deployment, enabling you to leverage existing investments while expanding with either a cloud or a hybrid model that includes both on-prem and cloud systems. That can shorten deployment from months to days and ensure security and analytics capabilities are consistent across every location and tuned appropriately for every team. Microsoft Dynamics 365 ends the artificial separation of ERP and CRM and makes it easy for employees to collaborate and even role-switch to engage customers or address supply chain issues. Only Dynamics 365 unites the front office and the back office with a single end-to-end system for managing every aspect of your business, all backed by industry-leading enterprise cloud. That means manufacturers can develop at the pace and scale that’s right for them, while taking advantage of current investments such as existing productivity and technology stacks. With Microsoft, consistent development practices and R&D investments combine to offer manufacturers rich analytics, embedded intelligence, partner-created applications, and the ability to collaborate worldwide. Read the full article

#axpartner#axpartnerinuae#crmimplementationpartner#dynamics365businesscentral#dynamics365crm#dynamics365fieldservice#dynamics365forfinance&operation#dynamics365formarketing#dynamics365forsales#dynamics365implementationdubai#dynamics365implementationindia#dynamics365partner#Dynamics365partnerinindia#dynamics365partnerinsouthafrica#dynamics365partnerinuae#dynamics365partnerportal#dynamics365services#dynamics365supportcompany#dynamicsaxpartner#dynamicsaxpartnerindelhi#dynamicserpsolutionsdubai#dynamicsnavpartner#dynamicsnavpartnerinethiopia#dynamicsnavpartnerinkolkata#dynamicsNavisionpartner#dynamicspartnerinIndia#dynamicspartnerinUAE#ERPimplementationservices#erpsoftwareproviderindubai#erpsoftwareproviderinindia

0 notes

Photo

Manage your prospects and Customers in real time and get the account related details on the go for better understanding and decisions. Microsoft Dynamics CRM supports you to get the full picture at any time. Mastermind Consultancy is the best Partner for your MS Dynamics CRM Implementation. Visit our site to get more details: http://mastermindtechies.com/

#microsoftdynamicscrm #MSdynamicscrmpartner #CRMimplementationpartner

0 notes