#CadMach

Explore tagged Tumblr posts

Text

Roller Compactor Granulators Market set to hit $5.3 billion by 2035

Industry revenue for Roller Compactor Granulators is estimated to rise to $5.3 billion by 2035 from $2.7 billion of 2024. The revenue growth of market players is expected to average at 6.5% annually for the period 2024 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/roller-compactor-granulators-market-research-report

Roller Compactor Granulators is critical across several key applications including pharmaceutical formulation, food processing, waste treatment and chemical processing. The report unwinds growth & revenue expansion opportunities at Roller Compactor Granulators’s Technology, Industry Usage, Product Type and Price Category including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Roller Compactor Granulators market is characterized by intense competition, with a number of leading players such as Fitzpatrick Company, GE Healthcare Life Sciences, EUROTOOLS-EVERT, Yenchen Machinery Co. Ltd, L.B. Bohle, GEA Group, Prism Pharma Machinery, Powrex Corp., Alexanderwerk, Freund Corporation, SaintyCo and Cadmach..

The Roller Compactor Granulators market is projected to expand substantially, driven by increasing demand in pharmaceutical industry and technological advancements in compaction equipment. This growth is expected to be further supported by Industry trends like Environmental Sustainability.

Moreover, the key opportunities, such as technological innovation and strategic collaborations, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, China, Japan and India.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like high maintenance cost and technological complexity, Roller Compactor Granulators market’s supply chain from raw material / component fabrication / assembly & testing to end user is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Mexico, Brazil and South Africa for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

#RollerCompactorGranulators#PharmaceuticalFormulation#FoodProcessing#WasteTreatment#ChemicalProcessing#GranulationTechnology#CompactionEquipment#TechnologicalAdvancementsInGranulation#PharmaIndustryDemand#EnvironmentalSustainability#GEAGroup#FitzpatrickCompany#GEHealthcareLifeSciences#EUROTOOLSEVERT#YenchenMachinery#LBohle#PrismPharmaMachinery#PowrexCorp#FreundCorporation#SaintyCo#Cadmach#TechnologicalInnovationInGranulation#StrategicCollaborationsInGranulation#NorthAmericaEurope#BrazilMexicoSouthAfrica#PharmaceuticalGrowthTrends#GlobalGranulationMarket#SupplyChainEvolutionGranulators#MarketGrowthForecast#DataStringConsulting

0 notes

Text

Ipca Laboratories Limited, a leading name in the pharmaceutical industry, is hosting a walk-in interview for various positions in Production, Packing, and Quality Assurance. The event will take place on 8th September 2024, at Hotel Woodland, Balitha, Vani, Gujarat. The company is seeking experienced and dynamic candidates with a background in B Pharmacy or M Pharmacy, with roles available for Sr. Officers, Executives, and Officers. Available Positions at Ipca Laboratories Ipca Laboratories is currently looking to fill the following positions at their Piparia (Silvassa) Formulation (OSD) Unit: 1. Production Department Section: QMS (Quality Management System) Designation: Sr. Officer/Executive Experience: 5 to 9 years Responsibilities: Manage QMS activities, including Deviation, Incident, Investigation, CCP, Protocol Preparation, and Risk Assessment. Ensure compliance with all regulatory requirements and company standards. Section: Granulation Designation: Sr. Officer/Executive Experience: 5 to 9 years Responsibilities: Supervise Granulation activities, including handling FBD, RMG, Octagonal Blender, and other equipment. Oversee QMS tasks such as CCP, CAPA, Deviation, and Documentation. Section: Compression Designation: Sr. Officer/Executive Experience: 5 to 9 years Responsibilities: Supervise Compression activities with exposure to Fette, Sejong, Legacy, Korsch, Cadmach machines. Handle QMS activities including CCP, CAPA, Deviation, and Documentation. Qualification for All Production Roles: B Pharmacy / M Pharmacy 2. Packing Department Section: Packing Designation: Officer/Sr. Officer Experience: 2 to 4 years Responsibilities: Supervise Primary & Secondary Bulk Packing and Blister Packing Line. Ensure compliance with packaging standards and regulatory requirements. Section: IPQA Designation: Officer Experience: 2 to 4 years Responsibilities: Conduct in-process checks in Manufacturing and Packing departments. Review Batch Manufacturing Records (BMR) and Batch Packing Records (BPR). Qualification for All Packing Roles: B Pharmacy / BSc 3. Quality Assurance Department Section: IPQA Designation: Officer Experience: 2 to 4 years Responsibilities: Perform in-process quality checks in the Manufacturing and Packing departments. Review and ensure the accuracy of BMR and BPR documents. Qualification: B Pharmacy / BSc Note: Candidates with regulatory exposure to USFDA/MHRA are preferred for all roles. [caption id="attachment_56648" align="aligncenter" width="930"] Ipca Laboratories Walk-In Interview for Production, Packing, Quality Assurance[/caption] Walk-In Interview Details Date: 8th September 2024 (Sunday) Time: 10:30 AM to 3:30 PM Venue: Hotel Woodland, National Highway No. 8, Near Tejpal Motors, Balitha, Vani, Gujarat, 396191. Job Location: Piparia (Silvassa) Formulation (OSD) Unit, Ipca Laboratories Limited How to Apply: Interested candidates are encouraged to walk in with their updated resume, original certificates, passport-sized photos, the latest increment letter, and three months' salary slip. If you are unable to attend the walk-in, you can send your CV to [email protected]. Contact Information: Ms. Tejal Bhandari Phone: (0260) 6624400 / 09687607002

0 notes

Text

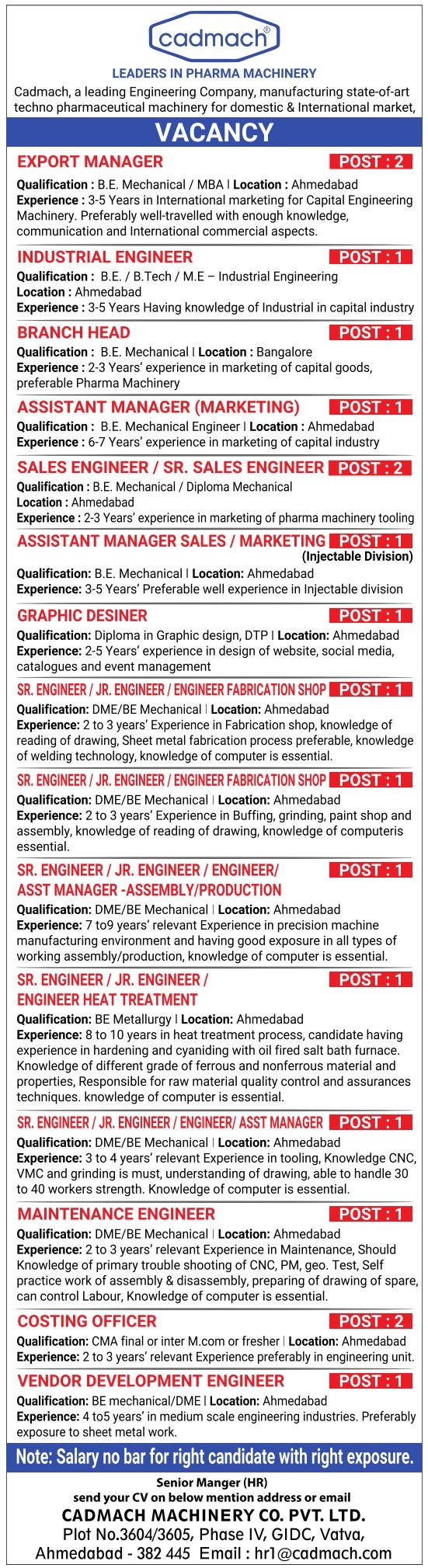

VARIOUS 18 VACANCIES AT CODMACH MACHINERY CO. PVT. LTD AT AHMEDABAD AND BANGALORE LOCATIONS

VARIOUS 18 VACANCIES AT CODMACH MACHINERY CO. PVT. LTD AT AHMEDABAD AND BANGALORE LOCATIONS CADMACH – LEADERS IN PHARMA MACHINERY Cadmach, a leading Engineering Company, manufacturing state-of-art techno pharmaceutical machinery for domestic & International markets, VACANCIES EXPORT MANAGER POST : 2 Qualification: B.E. Mechanical / MBA | Location: Ahmedabad Experience: 3-5 Years in Intemational…

View On WordPress

0 notes

Text

Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)

Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)/caption]

Due to the pandemic, we have included a special section on the Impact of COVID 19 on the Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) 2020-2026 which would mention How the Covid-19 is Affecting the Industry, Market Trends and Potential Opportunities in the COVID-19 Landscape, Key Regions and Proposal for Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) Players to battle Covid-19 Impact.

Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) 2020-2026The

Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) 2020-2026

report is one of the most comprehensive and important data about business strategies, qualitative and quantitative analysis of Global Market. It offers detailed research and analysis of key aspects of the Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version). The market analysts authoring this report have provided in-depth information on leading growth drivers, restraints, challenges, trends, and opportunities to offer a complete analysis of the Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version).

Top Leading players covered in the Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) report : Yenchen Machinery SAIMACH PHARMATECH Pvt IDEX MPT Inc Fitzpatrick Hosokawa Micron Powder Systems Alexanderwer GERTEIS Prism Pharma Machinery Alexanderwerk Cooper Research Technology GILLARD SAS LB Tech Oil Products Cadmach Chamunda Pharma Machinery Riddhi Pharma Machinery Limited YTRON-QUADRO (UK) LTD and More...

Get PDF Sample Report With Impact of COVID-19 on Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)@

https://www.mraccuracyreports.com/marketreports/7/21372/Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)

The report offers clear guidelines for players to cement a position of strength in the global Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version). It prepares them to face future challenges and take advantage of lucrative opportunities by providing a broad analysis of market conditions. the global Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) will showcase a steady CAGR in the forecast year 2020 to 2026.

Market Segment by Type covers: Small Type Medium Type Large Type

Market Segment by Application covers: Pharma Industry Electrical Industry Food Industry Chemical Industry Others

Our Complimentary Sample Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) Report Accommodate a Brief Introduction of the research report, TOC, List of Tables and Figures, Competitive Landscape and Geographic Segmentation, Innovation and Future Developments Based on Research Methodology.

Inquire and Get Up to 30% Discount By Clicking Here!

https://www.mraccuracyreports.com/marketreports/7/21372/Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)

Regions Covered in the Global Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version):

• The Middle East and Africa (GCC Countries and Egypt)

• North America (the United States, Mexico, and Canada)

• South America (Brazil etc.)

• Europe (Turkey, Germany, Russia UK, Italy, France, etc.)

• Asia-Pacific (Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia)

Years Considered to Estimate the Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version) Size:

History Year: 2015-2019

Base Year: 2019

Estimated Year: 2020

Forecast Year: 2020-2026

Highlights of the Report:

• Accurate market size and CAGR forecasts for the period 2019-2026

• Identification and in-depth assessment of growth opportunities in key segments and regions

• Detailed company profiling of top players of the global Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)

• Exhaustive research on innovation and other trends of the global Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)

• Reliable industry value chain and supply chain analysis

• Comprehensive analysis of important growth drivers, restraints, challenges, and growth prospects

For Free Download Report:

https://www.mraccuracyreports.com/request/download/7/21372/Roller Compactor Market Status and Trend Analysis 2017-2026 (COVID-19 Version)

Reasons to buy:

Procure strategically important competitor information, analysis, and insights to formulate effective R&D strategies.

Recognize emerging players with potentially strong product portfolio and create effective counter-strategies to gain competitive advantage.

Classify potential new clients or partners in the target demographic.

Develop tactical initiatives by understanding the focus areas of leading companies.

Plan mergers and acquisitions meritoriously by identifying Top Manufacturer.

Develop and design in-licensing and out-licensing strategies by identifying prospective partners with the most attractive projects to enhance and expand business potential and Scope.

Report will be updated with the latest data and delivered to you within 2-4 working days of order.

Suitable for supporting your internal and external presentations with reliable high quality data and analysis.

Create regional and country strategies on the basis of local data and analysis.

Customization of the Report: MR Accuracy Reports provides customization of reports as per your need. This report can be personalized to meet your requirements. Get in touch with our sales team, who will guarantee you to get a report that suits your necessities.

Contact Us: Mr. Marcus Kel Call: +1 804 500 1224 / +44 741841 3666 (International) +91 721372728100 (ASIA) Email: [email protected] Website: www.mraccuracyreports.com"

0 notes

Text

Roller Compactor Market 2020 Growth, Trends, and Demands Research Report to 2027

Roller Compactor Market research report gives an in detail investigation of the business and economy-wide information bases for the business the board that suggest development and flourishing for Key parts in this market. This is the most up to date report, covering the current COVID-19 effect available. The pandemic of Coronavirus (COVID-19) has influenced each part of life around the world. The rapidly changing business sector situation and early and up and coming evaluation of the effect are encased in the report.

The worldwide Roller Compactor Market study offers an assemblage of the current, recorded, and future viewpoint of the business just as the components liable for market development. With a SWOT investigation, the business study features the shortcomings, qualities, openings, and dangers of each Roller Compactor market major part in a complete manner.

Grab a Free Sample PDF copy of the Roller Compactor Market Report 2020:https://www.researchkraft.com/request-sample/1108622

The market examination on the Roller Compactor offers an elevated perspective on the current continuing inside the Roller Compactor market. The market breakdown report has incorporated an investigation of an assortment of variables that expand the development of the market. This market examination additionally offers the extent of extraordinary sections and applications that can basically affect the market later on. Careful data depends on close by patterns and noteworthy achievements.

Key Players:

Yenchen Machinery, SAIMACH PHARMATECH Pvt, IDEX MPT Inc, Fitzpatrick, Hosokawa Micron Powder, Systems, Alexanderwer, GERTEIS, Prism Pharma Machinery, Alexanderwerk, Cooper Research Technology, GILLARD SAS, LB, Tech Oil Products, Cadmach, Chamunda Pharma Machinery, Riddhi Pharma Machinery Limited, YTRON-QUADRO (UK) LTD

Grab Your Roller Compactor Market Report at an exciting Discount! Please visit:https://www.researchkraft.com/check-discount/1108622

Market Segmentation by Type:

Small Type

Medium Type

Large Type

Market Segmentation by Application:

Pharma Industry

Electrical Industry

Food Industry

Chemical Industry

Others

What Our Report Offers:

Roller Compactor Market share valuation of the sections on state and worldwide level

Roller Compactor Market Share examination of the significant market players

Open doors for new Roller Compactor market contestants

Roller Compactor Industry Market conjecture for at least 6 years for all the sections, sub-fragments in different nations and locales

Serious situation planning the key advancement designs.

Organization profiling with comprehensive techniques, budgetary subtleties, and new movements.

The key regions covered in the Roller Compactor market report are:

North America

Europe

China

Japan

Southeast Asia

India

Report Answers Following Questions:

What are the variables driving the development of the Roller Compactor market?

What elements are hindering Roller Compactor market development?

What are the forthcoming open doors in the Roller Compactor market?

What are their ongoing advancements inside the Roller Compactor Market?

What key late patterns can be normal in the coming years?

What are the key patterns seen in the market?

Make an Inquiry of This Report @https://www.researchkraft.com/send-an-enquiry/1108622

0 notes

Text

Tablet Processing & Packaging Equipment Market: Future Demand, Analysis & Outlook to 2025

The research report on Tablet Processing & Packaging Equipment market provides a granular analysis of this industry vertical wherein notable market activities are thoroughly researched. Various market segmentations based on product type, application spectrum, and regional terrain are surveyed in-depth, while estimated share held by each segment by the end of forecast period is encompassed in the report.

Request a sample Report of Tablet Processing & Packaging Equipment Market at: https://optimusmarketreports.com/request-sample/1499

This study focuses on the worldwide Tablet Processing & Packaging Equipment Market status, future forecast, growth opportunity, key market and emerging players. The study objectives are to present the Tablet Processing & Packaging Equipment growth in Key regions. so as to supply valuable insight by each key element of the market, the very best and slowest growing market segment within the study is described.

Key Players In the Tablet Processing & Packaging Equipment Market:

GEA GROUP, LMT Group, Charles Ross & Sons Company, GAMLEN TABLETING LTD, Robert Bosch GmBH, GROUPE BRETECHE INDUSTRIE, I.M.A Industria Macchine Automatiche S.P.A, IDEX Corporation, Kevin Process Technologies Pvt. Ltd., Key International Inc., Kg-Pharma GmBH & Co. Kg, Nicomac Srl, O'Hara Technologies Inc., PRISM PHARMA MACHINERY, Accura Pharmaquip Pvt. Ltd., Cadmach Machinery Co. Pvt. Ltd., Solace Engineers (Mktg.) Pvt. Ltd., The Elizabeth Companies, Yenchen Machinery Co., Ltd., Zhejiang Hualian Pharmaceutical Machinery Co., Ltd

You Can Ask For The Discount@ https://optimusmarketreports.com/request_discount/1499

Product Type segmentation:

Tablet Processing Equipment

Tablet Packaging Machines

Apart from that the application market is segmented into:

Pharmaceutical Factory

Research Institute

By Geographical Regions:

North America (the U.S., Canada)

Latin America (Brazil, Mexico, Argentina and other countries)

Asia Pacific (India, Japan, China, Australia and New Zealand and other countries)

Europe (Germany, France, the U.K., Spain, Italy, Russia, and other countries)

Middle East and Africa (GCC, South Africa, Israel and Other countries)

Reason to get Report:

The report provides granular level information about the market size,regional market share, historic market and forecast.

The report covers complete insights about the competitor’s overview,company share analysis, key market developments, and their key strategies.

The report outlines drivers, restraints, unmet needs, and trends that are presently influence the market.

The report imprint recent innovations, key developments and start-up’s details that are actively working within the market.

The report provides data about market entry strategies, regulatory framework and reimbursement scenario.

To Customize Please Reach Out To Us: https://optimusmarketreports.com/customize_request/1499

About Us:

Optimus Market Research is a premium market research report provider.We have successfully delivered research reports to greater than 800+ global clients.Our primary goal is to achieve in depth research analysis to help our clients with the most accurate business insights.We provide actionable insights through reports to make the right business decisions.

Contact Us:

https://optimusmarketreports.com/

#Tablet Processing & Packaging Equipment#Tablet Processing & Packaging Equipment market#Tablet Processing & Packaging Equipment types

0 notes

Text

Global Roller Compactor Market

The report forecast global Roller Compactor market to grow to reach xxx Million USD in 2019 with a CAGR of xx% during the period 2020-2025 due to coronavirus situation. The report offers detailed coverage of Roller Compactor industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Roller Compactor by geography. The report splits the market size, by volume and value, on the basis of application type and geography. First, this report covers the present status and the future prospects of the global Roller Compactor market for 2015-2024. And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru]. At the same time, we classify Roller Compactor according to the type, application by geography. More importantly, the report includes major countries market based on the type and application. Finally, the report provides detailed profile and data information analysis of leading Roller Compactor company.

Key Content of Chapters as follows (Including and can be customized) : Part 1: Market Overview, Development, and Segment by Type, Application & Region Part 2: Company information, Sales, Cost, Margin etc. Part 3: Global Market by company, Type, Application & Geography Part 4: Asia-Pacific Market by Type, Application & Geography Part 5: Europe Market by Type, Application & Geography Part 6: North America Market by Type, Application & Geography Part 7: South America Market by Type, Application & Geography Part 8: Middle East & Africa Market by Type, Application & Geography Part 9: Market Features Part 10: Investment Opportunity Part 11: Conclusion

Market Segment as follows: By Region Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia] Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland] North America[United States, Canada, Mexico] Middle East & Africa[GCC, North Africa, South Africa] South America[Brazil, Argentina, Columbia, Chile, Peru] Key Companies Yenchen Machinery SAIMACH PHARMATECH Pvt IDEX MPT Inc Fitzpatrick Hosokawa Micron Powder Systems Alexanderwer GERTEIS Prism Pharma Machinery Alexanderwerk Cooper Research Technology GILLARD SAS LB Tech Oil Products Cadmach Chamunda Pharma Machinery Riddhi Pharma Machinery Limited YTRON-QUADRO (UK) LTD Market by Type Small Type Medium Type Large Type Market by Application Pharma Industry Electrical Industry Food Industry Chemical Industry Others

for sample report please visit: https://www.statzyreports.com/report/SR152082/COVID-19-Version-Global-Roller-Compactor-Market

Phone Number (IN) - +918484035727

(US) - +1415-871-0483

Email Address Email : [email protected]

Email : [email protected]

0 notes

Text

Dry Granulators Market set to hit $1453.4 million by 2035

Industry revenue for Dry Granulators is estimated to rise to $1453.4 million by 2035 from $604.6 million of 2024. The revenue growth of market players is expected to average at 8.3% annually for the period 2024 to 2035.

Dry Granulators is critical across several key applications including pharmaceutical production, food processing, chemical compounds and metal alloy formulation. The report unwinds growth & revenue expansion opportunities at Dry Granulators’s Technology Type, Industry Application, Material Compatibility and Capacity including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Dry Granulators market is characterized by intense competition, with a number of leading players such as Fitzpatrick, Alexanderwerk AG, L.B. Bohle, GEA Group, KORSCH AG, CadMach, Prism Pharma Machinery, IDEX Corporation, Romaco Group, Hosokawa Micron Group, Sotax Group and Freund Corporation.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/dry-granulators-market-research-report

The Dry Granulators market is projected to expand substantially, driven by surge in pharmaceutical industry applications and technological advancements in dry granulator machinery. This growth is expected to be further supported by Industry trends like Rise in Demand from Food Processing Industry.

Moreover, the key opportunities, such as leveraging technological advancements, untapped potentials in developing markets and strategic partnerships with pharmaceutical giants, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, China, Japan and India.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like high equipment cost and regulatory compliance, Dry Granulators market’s supply chain from raw material procurement / component production / granulator manufacturing to distribution is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Mexico, Brazil and South Africa for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

#DryGranulators#PharmaceuticalMachinery#GranulationTechnology#FoodProcessingEquipment#ChemicalEngineering#MetalAlloyProcessing#GEAGroup#FitzpatrickCompany#IDEXCorporation#HosokawaMicron#RomacoGroup#CadMach#GranulationProcess#IndustrialMachineryMarket#B2BManufacturing#EmergingMarkets2025#DataStringConsulting#GlobalPharmaTrends#FoodTechInnovation#ProcessEngineering

0 notes

Text

Granules Recruitment Drive Jedcherla (Formulation OSD) Are you looking for an exciting career opportunity in the pharmaceutical industry? Granules India Ltd is conducting a walk-in interview in Jedcherla for various positions in Production, Engineering, and Warehouse (Formulation OSD). If you have experience in these fields and the required qualifications, this is your chance to join a leading company in the industry. About Granules India Ltd Granules India Ltd is a renowned pharmaceutical company committed to delivering high-quality products and services. With a strong focus on innovation and excellence, Granules provides a dynamic work environment for professionals seeking growth and development in their careers. Job Details Date and Time: 7th July 2024, Sunday, 10 AM - 3 PM Venue: Manjira Hotels & Resorts, NH-44, Sy No.100, Macharam (V), Jedcherla (M), Mahabubnagar (Dist.), Telangana-509301. Phone: 08418696419 Work Location: Granules India Ltd, Gagillapur, Hyderabad - 500043 Available Positions Production Department Compression Operator Experience: 2-6 Years Qualification: ITI, Diploma, B.Sc, B.A, B.Com Machine Experience: Hata, Fette, Korsch, Killian & Cadmach Coating Operator Experience: 2-6 Years Qualification: ITI, Diploma, B.Sc, B.A, B.Com Machine Experience: Ohara, Glatt, ACG smart, Gansons & Bectochem Packing Operator Experience: 2-6 Years Qualification: ITI, Diploma, B.Sc, B.A, B.Com Machine Experience: Blister Cartonator/Uhlmann/BQS/IMA PG Bottle CVC/Pharmapack/Countec Capsule Filling/Inspection Operator Experience: 2-6 Years Qualification: ITI, Diploma, B.Sc, B.A, B.Com Machine Experience: AF9OT/AF150T/ZRO 200/TTS/ Hartnett Printing/Band Sealing/ACG Capsule-Checkweighers Granulation/Wurster Coating Operator Experience: 2-6 Years Qualification: ITI, Diploma, B.Sc, B.A, B.Com Machine Experience: RMG/FBP/FBD/Wurster coating/Roll Compactor Engineering Department Technician/Executive Engineering Experience: 2-7 Years Qualification: ITI, Diploma, B.Tech Role: Process Maintenance Warehouse Department Officer/Executive Warehouse Experience: 2-5 Years Qualification: B.A, B.Com, B.Sc, M.Sc Role: RM/PM/FG [caption id="attachment_56104" align="aligncenter" width="930"] Granules india Recruitment Notification[/caption] Required Documents Candidates must bring the following documents to the interview: Latest copy of resume Increment letter Last 3 months' pay slips Previous organization's service certificates All educational certificates (Xerox copies) Aadhaar card & PAN Additional Information Spot offers will be provided to selected candidates, subject to document verification. Candidates must be willing to work in shift operations.

0 notes

Text

Formulation and Evaluation of Chronomodulated Drug Delivery of Montelukast Sodium--Juniper Publishers

JUNIPER PUBLISHERS-OPEN ACCESS GLOBAL JOURNAL OF PHARMACY & PHARMACEUTICAL SCIENCES

An oral press coated tablet containing Montelukast sodium was formulated with an outer barrier layer of different compositions of hydrophobic polymer eythyl cellulose and hydrophilic polymer hydroxyl propyl methyl cellulose. This press coated tablet was prepared by using direct compression and wet granulation methods in order to achieve the predetermined lag time.

Keywords: Pulsatile drug delivery systems (PDDS); Nocturnal asthma(NA); Chronopharmacology; Circadium Rhythms; Burst release; Lag time

Abbreviations: EC: Ethyl Cellulose; HPMC: Hydroxy Propyl Methyl Cellulose; FTIR: Fourier Transform Infra Red; SLS: Sodium Lauryl Sulphate; IR: Immediate Release; ChrDDS: Chrono Modulated Drug Delivery Systems; PCT: Press Coated Tablets

Introduction

Controlled drug delivery systems [1] have acquired a centre stage in the area of pharmaceutical R &D sector. Such systems offer temporal &/or spatial control over the release of drug and grant a new lease of life to a drug molecule in terms of controlled drug delivery systems for obvious advantages of oral route of drug administration. These dosage forms offer many advantages, such as nearly constant drug level at the site of action, prevention of peak-valley fluctuation, reduction in dose of drug, reduced dosage frequency, avoidance of side effects and improved patient compliance. In such systems the drug release commences as soon as the dosage form is administered as in the case of conventional dosage forms. However, there are certain conditions, which demand release of drug after a lag time. Such a release pattern is known as pulsatile release [2-5]. The diseases currently targeted for chronopharmaceutical formulations are those for which there are enough scientific backgrounds to justify ChrDDS compared to the conventional drug administration approach. These include asthma, arthritis, duodenal ulcer, cancer, diabetes, cardiovascular diseases, hypercholesterolemia, ulcer and neurological diseases [6,7].

If the organization in time of living system including man is borne in mind, it is easy to conceive that not only must the right amount of the right substance be at right place but also this must occur at the right time. In the last decade numerous studies in animals as well as clinical studies have provided convincing evidence, that the pharmacokinetics &/or the drug effects -side effects can be modified by the circadian time &/or the timing of drug application within 24 hrs of a day [8]. A pulsatile drug delivery system that can be administered at night (before sleep) but that release drug in early morning would be a promising chronopharmaceutic system. Drug targeting to colon [9] would prove useful where intentional delayed drug absorption is desired from therapeutic point of view in the treatment of disease that have peak symptoms in the early morning such as nocturnal asthma, angina, arthritis.

Circadian rhythms are self-sustaining, endogenous oscillation, exhibiting periodicities of about one day or 24 hours. Normally, circadian rhythms are synchronized according to the body’s pacemaker clock, located in the suprachiasmic nucleus of the hypothalamus [8]. Asthma is a chronic inflammatory disease of the airways, characterized by hyper responsiveness to a variety of stimuli. The role of circadian rhythms in the pathogenesis and treatment of asthma indicates that airway resistance increases progressively at night in asthmatic patients. Circadian changes are seen in normal lung function, which reaches a low point in the early morning hours. The worsening of asthma at night commonly referred to as nocturnal asthma (NA) [10]. A drug delivery system administered at bedtime but releasing drug during morning hours would be ideal in this case. Nocturnal asthma is a variable exacerbation of the underlying asthma condition associated with increases in symptoms, need for medication, airway responsiveness, and/or worsening of lung function. Generally, a reduction in peak flow or forced expiratory volume in one second (FEV1) of at least 20% is implicit in this definition. Lung function (e.g., peak expiratory flow rate or FEV1) is usually highest at 4 PM and lowest at 4 AM the latter time is generally when asthma symptoms are most prevalent. . Consequently, the administration of a drug formulated in such a delivery system, i.e. taken at bedtime with a programmed start of drug release in early morning hours, could offer a more effective therapy than a typical controlled release drug delivery system, provided that the most appropriate drugs are administrated [11].

Pharmaceutical coatings [12] are an essential tool to achieve the desired formulation of pharmaceutical dosage forms. Coating techniques mostly used in pharmaceutical industry are aqueous or organic coating, which present some disadvantages: time consuming, stability for heat labile and hydrolysis of degradable drug and polluted environment problem. Thereby, non-solvent coating is introduced as alternative coating technique to overcome these disadvantages.

For the time controlled release system from compressioncoated tablets, the amount of the outer shell is a key factor for controlling the lag time. Higher amount of the outer coating added would prolong the lag time of drug release [13].

The aim of the present investigation was to develop and evaluate an alternative, simple, orally applicable one pulse drug delivery system based on a press-coated tablet preparation. The PCT investigated in the current study consisting of a rapidly disintegrating core tablet presscoated by a barrier layer consisting of varying concentrations of Hydroxy propyl methyl cellulose (HPMC) and Ethylcellulose (EC). HPMC is a disintegrant and had been used to cause rapid disintegration of tablets. The other component of the barrier layer, Ethylcellulose (EC) is a well-known water-insoluble polymer that has long been used as a rate-controlling membrane in medication dosage forms to regulate drug release. Although EC has also been added in tablet formulations to act as a retarding material, few papers have focused on the use of EC as a directly compressible excipient. It was postulated that when the barrier layer was exposed to dissolution media, the HPMC particles swell and erode [14], a process which was retarded to varying degrees depending upon the quantity of EC present, demonstrating that manipulation of both components controls the erosion rate.

Materials and Methods

Preparation of core tablets by direct compression

The ingredients depicted in the table except colloidal silicon dioxide and magnesium stearate were dry blended for 15 minutes followed by addition of quitted ingredients and dry blended for another 5 minutes. The mixed blend of drug and excipients was compressed using a single punch CADMACH punching machine to produce round tablets weighing 100mg with a diameter of 6mm. A minimum of 50 tablets were prepared for each batch.

Preparation of press-coated tablets

The core tablets were press-coated with 400mg of prepared barrier blend as per the mentioned formulas from X1 to X5. 200mg of barrier layer material was weighed and transferred into a 13mm die then the core tablet was placed manually at the center. The remaining 200mg of the barrier layer material was added into the die and compressed.

In vitro drug release study of core tablets

The In vitro release pattern of core tablets was studied as per method given by Chaudhari SP [15] Release pattern was studied visually by taking images of the core tablets in a petri plate containing dissolution medium at the specific time intervals 5sec, 10sec, 15sec. Also the sample was analyzed at 342nm using a UV spectrophotometer.

In vitro drug release study of press-coated tablets

In-vitro dissolution studies of press coated tablets were performed at 37 ± 0.5 °C using 0.5% w/v aqueous solution sodium lauryl sulfate in USP II paddle method at 50 rpm. 5 ml of filtered aliquot was manually withdrawn at pre-determined time intervals and replaced with 5 ml of fresh 0.5% sodium lauryl sulfate solution maintained at the same temperature. The samples were analysed at 342nm using a UV spectrophotometer. The lag time and percentage release was determined of the each formulation.

Results and Discussion

Design of Pulsatile release tablet

The pulsatile drug delivery system consisted of inner core tablet containing drug reservoir and outer coating layer with combination of water insoluble polymer Ethylcellulose and water soluble polymer HPMC. Ethyl cellulose was chosen because of its swelling and rupturable behavior. HPMC was chosen because of its eroding behavior.

In vitro dissolution of core tablets

The core tablet shows 73.97 % of drug release within 9 minutes upon contact with dissolution medium, core tablet get erode and release the drug as given in Figure 1.

Analytical methods

From the standard stock solution (1000 μg/ml), appropriate aliquot were transferred to series of 10 ml volumetric flasks and made upto 10 ml with desired solvents so as to get concentration of 5,10,15,20… or 2,4,6,8… μg/ml. the absorbance of the solution were measured at 342 nm for Montelukast sodium. This procedure was performed in triplicate to validate calibration curve. A calibration curve was plotted.

Compatibility Analysis

Fourier transform infra-red spectroscopy

FT-IR spectroscopy was employed to ascertain the compatibility of drugs with polymers. The individual drug and final formulation were scanned. Both the spectra were compared for confirmation of common peaks. Montelukast sodium with polymers showed no significant variation in height, intensity and position of peaks, suggesting that drug and excipients were compatible. There is no interaction between drug and polymer. Hence, it can be concluded that the drug is in Free State and can release easily from the formulation the spectra are reported in the Table no.6.3 and Figure 6.2-6.3.

Conclusion

In the 5 trials, the optimized formulation was X2 trial which releases the Montelukast sodium immediately after a lag time. The core was compared with the pure drug where it showed 46.26 % of drug release in 15 minutes whereas core exhibited 98.96% in 15 minutes.

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com

For more articles in Global Journal of Pharmacy & Pharmaceutical Sciences please click on: https://juniperpublishers.com/gjpps/index.php

For more Open Access Journals please click on: https://juniperpublishers.com

To know more about Juniper Publishers please click on: https://juniperpublishers.business.site/

0 notes

Text

High Speed Tablet Press Market - Industrial Outlook, Company Shares, Analysis, Growth, Forecast to 2025

1 February 2019 - Global High Speed Tablet Press Market is segmented, By types into Single Discharge High Speed Tablet Press, Double Discharge High Speed Tablet Press, and Treble Discharge High Speed Tablet Press. The High Speed tablet press machine compresses powder into the tablet. Depending on the size, material, shape, and press configuration, the High Speed tablet produces a large number of tablets in small duration of time. For manufacturing tablets, a press can be used, along with a huge variety of materials, comprising pharmaceuticals, illicit drugs such as MDMA, Cosmetics, cleaning products, etc.

The granulated material must be metered into a cavity formed by two punches and a die, to form a tablet, and then the punches must be pressed together with great force to fuse the material together from 250,000 to over 1,000,000 tablets per hour. The tablets are based on the different characteristics such as shape, size. The form of rotating turret that holds the number of punches, High Speed tablet presses takes the form, and they rotate around the turret. The camas get into touch with the punches in the vertical position. The huge variety of sizes, shapes could be customized with the manufacturing codes and scoring lines to make tablets easier to break or divide.

View Full Report with TOC @ https://www.millioninsights.com/industry-reports/high-speed-tablet-press-market

High Speed Tablet Press Market is segmented, By Application, Pharmaceutical industry, Chemical industry, Food and other industry. High Speed Tablet Press Market is segmented, By Geographical Region into Asia Pacific (China, India, ASEAN, Australia & New Zealand), Japan, Middle East and Africa (GCC countries, S. Africa, Rest Of MEA), North America (U.S., Canada), Latin America (Brazil, Rest of Latin America), Western Europe (Germany, Italy, France, England, Spain, Rest of Western Europe), Eastern Europe (Poland, Russia, Rest of Eastern Europe). High Speed Tablet Press Market Key Players include Fette Leitz, KORSCH, Courtoy, GEA, Manesty Bosch, IMA Pharma, CCS, KIKUSUI SEISAKUSHO, Elizabeth Hata, Cadmach, PTK, Sejong, Jcmoc, GYLONGLI, TYJX, Liaocheng, Wanhe, Longlev, Hanlin Hangyu, STC and STH.

Market Segment:

The major manufacturers covered in this report

• Fette?Leitz?

• KORSCH

• Courtoy?GEA?

• Manesty?Bosch?

• IMA Pharma

• CCS

• KIKUSUI SEISAKUSHO

• Elizabeth Hata

• Cadmach

• PTK

• Sejong

• Jcmoc

• GYLONGLI

• Hanlin Hangyu

• STC

Geographically, this report studies the top producers and consumers, focuses on product capacity, production, value, consumption, market share and growth opportunity in these key regions, covering

• North America

• Europe

• China

• Japan

• Other Regions

Request Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/high-speed-tablet-press-market/request-sample

#High Speed Tablet Press Market Share#High Speed Tablet Press Market Trend#High Speed Tablet Press Market Segment#High Speed Tablet Press Market Forecasr

0 notes

Text

Company: Pharmaceutical manufacturing Units ( Bulk / Generic Drugs )

Following our our immediate requirements as per priority:

Auto Cartonator expert

Should have hands on knowledge in handling all automated cartoning machines especially ACG Hi-cart model.

Should have experience of over 10-15 years ideally in pharmaceutical industry

Should be acquainted with machine operations, troubleshooting, breakdown and change overs

His prime JD would be to improve machine output, efficiency, reduce changeover time and train operators working under him.

He would act as secondary packing operations incharge and will coordinate all secondary packing activities and would be reportable to production manager/operations head.

Salary: Upto 6-10 lacs depending on his expertise level

Blister Packing line expert

Should have hands on knowledge in handling all automated blister machines especially ACG BQS model.

Should have experience of over 10-15 years ideally in pharmaceutical industry

Should be acquainted with machine operations, troubleshooting, breakdown and change overs

His prime JD would be to improve machine output, efficiency, reduce changeover time and train operators working under him.

He would act as primary packing operations incharge and will coordinate all primary packing activities and would be reportable to production manager/operations head.

Salary: Upto 6-8 lacs depending on his expertise level

Compression expert

Should have hands on knowledge in handling all latest automated compression machines especially Cadmach model.

Should have experience of over 10-15 years in pharmaceutical industry

Should be acquainted with machine operations, troubleshooting, breakdown and change overs

His prime JD would be to improve machine output, efficiency, reduce changeover time and train operators working under him.

He would act as compression process incharge and will coordinate all compression activities and would be reportable to production manager/operations head.

Salary: Upto 6-8 lacs depending on his expertise level

Location: Raigad – Maharashtra

Coater expert

Should have hands on knowledge in handling all latest automated coating machines especially Gansons model.

Should have experience of over 10-15 years in pharmaceutical industry

Should be acquainted with machine operations, troubleshooting, breakdown and change overs

His prime JD would be to improve machine output, efficiency, reduce changeover time and train operators working under him.

He would act as coating process incharge and will coordinate all coating activities and would be reportable to production manager/operations head.

Salary: Upto 6-8 lacs depending on his expertise level

Purchase executive

Cordination with internal departments to understand their requirement for procurement of right materials

Prompt and fluent communication with vendors for arranging the required materials Documentation and filing of daily requisitions/indents and updating the files Floating of RFQ to get quotations Preparation of price comparison and Purchase orders Regular follow-up with vendors along with timely update to user department on status of their indent. Negotiation with vendors Identification and development of new vendors

Arranging Vendor Qualification documents

Required Candidate profile

Strong negotiation skills

Ability to develop and identify new vendors

Strong vendor management

Strong documentation

Salary: 4 to 6 lacs

All of them should be required to work from Raigad, Maharashtra

Interested candidates can process their resume to Nismita ( [email protected])

Pharmaceutical manufacturing Units ( Bulk / Generic Drugs ) Raigad – Jobs Company: Pharmaceutical manufacturing Units ( Bulk / Generic Drugs ) Following our our immediate requirements as per priority:

0 notes

Text

Mixer Granulator Market Latest Trends and Future Growth Study by 2027

Mixer granulators are an efficient and versatile blending device used for mixing of dry powders. They are used for fast dry & wet mixing, homogenizing, humidifying and granulating of the powder in Chemical, Pharmaceutical, Food, Cosmetic, Plastic, and general mixing Industries. Mixer granulator is consists of a bowl, feeder, outlet, control system, and impeller & chopper assembly. It is also used for size enlargement process in which mixtures of fine powders are combined into larger granules or agglomerates. Impeller and chopper included in the machine comes in wide range of speed, pressure, temperature and sensitive liquid flow rate control. Furthermore, presence of desired droplet size with adequate impeller torque also controls the granulation process. The availability of technologically advanced products with regulated drive system, temperature and pressure are expected to gain popularity among users for usage in processing of the final product.

Participation of international players, both in developed and emerging countries is expected to maintain competition at optimum levels. Additionally, Mixer granulators with advanced technology and innovative design are gaining popularity among the major industries such as pharmaceuticals, food, chemical and cosmetics.

Major players in the Mixer granulator market are focusing on improving the design of products by newer granulating technologies that offer key advantages to improve final product quality and meet the expectation of consumers.

Emerging players in the market are focusing towards collaboration with major industries such as food, pharmaceuticals, chemical and cosmetic to enhance the sale of the product and improve its profitability. In addition to this, the key competitors are also emphasizing for after sales services to promote its business.

Planning to lay down future strategy? Perfect your plan with our Report Brochure here

GEA Group

GEA Group was founded in 1881 is involved in the business of engineering solution. The company supplies it product in more than 50 countries. The company is focused towards developing innovative equipment and process technology. GEA Group is listed in the STOXX® Europe 600 index.

Robert Bosch GmbH

Robert Bosch GmbH was founded in 1886, engaged in the business of engineering and technology solutions. The company operates its business in four segment such as mobility, consumer goods, industrial technology and energy and building technology. The company has network of over 440 subsidiaries and regional entities. The company operates its business in over 60 countries across the globe.

LINXIS Group

LINXIS Group was founded in 1998 is involved in the business of designing and manufacturing of specialized equipment and industrial solutions. The company offers its product to wide range of users such as bakery, dairy, and healthcare industries. To meet the satisfaction of end users, the company is focused towards developing customized solution.

Key players in the market include GEA Group AG, Charles Ross & Son Company, Alphatech Engineers, Robert Bosch GmbH, LINXIS Group, Yenchen machinery co., ltd., IMA – Industria Macchine Automatiche S.p.A., Cadmach Machinery Co. Pvt. Ltd., O’Hara Technologies, and L.B. Bohle.

Increase in the Stringent Quality Requirements of the FDA / cGMP has Gained Demand for Mixer Granulators

Growing demand for granulated food across the globe is the key driving force in the mixer granulator market. Moreover, stringent laws implemented by regulatory bodies such as FDA and cGMP for good manufacturing practices are influencing the adoption of the product. In recent years, Mixer granulators are also extensively used in the industrial sector to process a wide range of by-products as well as manufacturing of final products. It is utilized in mixing of product until the desired granule size and density are achieved as per regulated bodies.

Looking for exclusive market insights from business experts? Request a Custom Report here

Manufacturers in the mixer granulator market are focusing towards new investment in research and development activities to discover new and innovative techniques to develop mixer granulators. Manufacturers are also focusing on offering, flexible and cost-effective manufacturing solutions that maximize operational reliability and productivity. This helps to get the desired quality of the final product with minimal power consumption and time for material processing. In addition, manufacturers are also trying to popularize the product through a wide range of e-commerce channels and company owned websites to meet the requirements of end-users.

0 notes

Text

Global Tablet Press Market Prognostications Highpoint Positive Revenue during Forecast Period, 2018-2026

The tablet press is designed to maintain the efficiency and reliability of the final products. The tablet press that is used to control the tablet specifications such as shape, size, the texture of the solid dose tablet, and depth of fill. The tablet press allows the modification and also controls the specification of the tablet according to the application. The need for automated techniques and advance industrial equipment in the pharmaceutical industry is expected to contribute to the growth of the global tablet press market in the forecast period. The Global Tablet Press Market is estimated to grow at high-end single-digit growth rate during the forecast period.

Request TOC of this Report- https://www.factmr.com/connectus/sample?flag=T&rep_id=3240

Tablet press is a mechanical device that is used to transform powder into tablets of regular thickness and sizes. The tablet press works on the principle of filling, compression and ejection providing the final product. The tablet press can be used to manufacture a variety of tablets comprising different materials for illicit drugs such as Ecstasy (E) or MDMA, cosmetics and cleaning products.

Demand from the Pharmaceutical Industry is Likely to Improve the Tablet Press Market Growth

The demand for automated, economical and time-saving techniques in the pharmaceutical industry is the key driving factor for the growth of the global tablet press market during the forecast period. The tablet press is suitable for a large production providing controlled hardness and weight of the tablets. Also, tablet press does not produce a large amount of wastage and having modular powder feeding system, which enables the user to increase production. The aforementioned factors are considered to drive the growth of the global tablet press market.

The healthcare sector and pharmaceutical sector are always concerned about the hygienic conditions of the equipment, medicines and other related things. Tablet press takes care of the hygiene value during tablet production. The tablet press market is expected to grow with significant growth rate over the forecast period.

Multiple Station Tablet Press is the Key to Success in the Global Market

The tablet press can be segmented by product type as single punch tablet press and multiple station pharmaceutical tablet press (or rotary press).

The tablet press can also be segmented on the basis of capacity as less than 1,00,000 tablets per hour, 1,00,000 to 2,50,000 tablets per hour and more than 2,50,000 tablets per hour production capacity.

The global tablet press market can be segmented on the basis of application as pharmaceutical, chemical, food industry, nutraceutical, cosmetics and others. The pharmaceutical industrial application is the foremost among other application owing to the demand for medicinal tablets.

To know more about the Tablet Press Market Visit the link- https://www.factmr.com/report/3240/tablet-press-market

North America is estimated to dominate the Tablet Press Market

The global tablet press market is segmented into Latin America, Western Europe, North America, Asia and Pacific excluding Japan (APEJ), Eastern Europe, Japan, and the Middle East and Africa (MEA). The regional segment includes emerging countries such as China, India and Australia in the tablet press market. Among the segmented regions, sales and demand for the tablet press in North America are expected to hold a significant share in the global tablet press market. The North America tablet press market is growing due to the substantial growth in the pharmaceutical industry in the region.

Moreover, the significant growth of the healthcare industry owing to the demand for economic and time-saving techniques in the developing regions, such as APEJ and Latin America, is expected to contribute to the growth of the global tablet press market in the forecast period.

Manufacturers’ Investment in R&D is Likely to Expand the Tablet Press Market

Some of the key players in the tablet press market are Robert Bosch LLC., Cadmach Machinery Co. Pvt. Ltd., I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A., Elizabeth-Hata International, BEIJING GYLONGLI SCI. & TECH. CO., LTD., Compression Components & Service LLC, and others. The manufacturers’ optimization to offer automated techniques including tablet press in the pharmaceutical industry is expected to boost the demand in the forecast period. Moreover, companies are investing in the research & development and also enhances the marketing strategy, which is projected to promote the growth of the global tablet press market over the forecast period, 2018-2027.

The research report presents a comprehensive assessment of the Tablet press market and contains thoughtful insights, facts, historical data and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The Tablet press market research report provides analysis and information according to market segments such as geographies, application and industry.

The Tablet press market report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The Tablet press market report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The Tablet press market report also maps the qualitative impact of various market factors on market segments and geographies.

Request Brochure of this Report- https://www.factmr.com/connectus/sample?flag=B&rep_id=3240

About FactMR FactMR is a fast-growing market research firm that offers the most comprehensive suite of syndicated and customized market insights reports. We believe transformative intelligence can educate and inspire businesses to make smarter decisions. We know the limitations of the one-size-fits-all approach; that's why we publish multi-industry global, regional, and country-specific research reports.

Contact Us FactMR 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Email: [email protected] Web: https://www.factmr.com/ Blog: https://factmrblog.com/ Read Industry News at - https://www.industrynewsanalysis.com/

0 notes

Text

Granulators Market Research Study including Growth Factors, Types and Application by regions from 2019 to 2025

“The Granulators market report is a complete research on the current state of the Granulators market with a focus on the regional market. This report presents the global Granulators market size (value, production, and consumption), splits the breakdown (data status 2013-2018 and forecast to ‘2025���), by manufacturers, region, type, and application. This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter’s Five Forces Analysis.

This research is helpful for all the players operating in the market, including the well-established players and the new entrants. This intelligent study provides the definition, description, and the overall forecasts of the global market, considering the market segments and sub-segments, which includes the product types, technologies, end-users, industry verticals, and the key geographies. Moreover, the report also provides an in-depth analysis of some of the significant factors such as driving forces, challenges, and threats that will shape the future of the market. In addition, the report also includes the lucrative opportunities in the micro markets for all the participants to invest in the global Granulators market. Besides, the report describes the product offerings and the competitive analysis of the major players operating in the market.

Get a FREE Sample PDF Report: https://www.marketgrowthinsight.com/sample/13581

The report also presents the market competitive landscape and a corresponding detailed analysis of the major vendor/key players in the market.

The key players covered in this report:

The following manufacturers are covered in this report: Robert Bosch GEA Group I.M.A Industria Macchine Automatiche IDEX Corporation The Elizabeth Companies LMT Group O’Hara Technologies Key International Kg-Pharma Gmbh Groupe Breteche Industries Charles Ross & Son Company Prism Pharma Machinery Yenchen Machinery Nicomac Srl Kevin Process Technologies Cadmach Machinery Accura Pharmaquip Solace Engineers Zhejiang Hualian Pharmaceutical Machinery

Granulators Breakdown Data by Type Rapid Mixer Granulators Oscillating Granulators Other Granulators Breakdown Data by Application State-Owned Pharmaceutical Companies Private Pharmaceutical Companies

Granulators Production by Region United States Europe China Japan Other Regions

Granulators Consumption by Region North America United States Canada Mexico Asia-Pacific China India Japan South Korea Australia Indonesia Malaysia Philippines Thailand Vietnam Europe Germany France UK Italy Russia Rest of Europe Central & South America Brazil Rest of South America Middle East & Africa GCC Countries Turkey Egypt South Africa Rest of Middle East & Africa

The Granulators market was valued at Million US$ in 2018 and is projected to reach Million US$ by 2025, at a CAGR of during the forecast period. In this study, 2018 has been considered as the base year and 2019 to 2025 as the forecast period to estimate the market size for Granulators.

This report presents the worldwide Granulators market size (value, production and consumption), splits the breakdown (data status 2014-2019 and forecast to 2025), by manufacturers, region, type and application. This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter’s Five Forces Analysis

Get Discount on this Report: https://www.marketgrowthinsight.com/discount/13581

The prime objective of this Granulators research report is to define the size of the different segments and the geographies as well as to forecast the trends that are likely to gain traction in the following couple of years. This market research report has been designed to incorporate both the qualitative and quantitative aspects of the industry within each of the regions.

The scope of this report centers on key market analyses, market drivers & challenges, and competitive analysis & trends. Research report examines each market and its applications, regulatory scenario, technological innovations, Granulators market projections, market sizes, and shares. Moreover, the Granulators market report examines the most recent trends, pipeline products and developments in the Granulators market. Complete profiles of leading organizations in the market are also mentioned in this report.

Granulators market report highlights: 1. The Granulators research report provides a detailed survey of the current and future industry trends so as to identify the investment analysis. 2. The industry forecasts, using estimated market values have been mentioned, till ‘2025’. 3. The Granulators Market dynamics such as the drivers, restraints, threats, opportunities, and industry-specific challenges 4. Key industry trends across all the market segments and sub-segments, geographies, and nations. 5. Key developments and strategies determined in the market. 6. Detailed profiling of the leading competitors and the entrant market players. 7. Growth prospects among the emerging nations throughout the forecast period. 8. The Granulators Market opportunities and recommendations for new investments.

In the end, It includes the methodical description of the various factors such as the market growth and a detailed information about the different company’s revenue, growth, technological developments, production, and the various other strategic developments.

Purchase Granulators Market Research Report: https://www.marketgrowthinsight.com/checkout/13581

Thus, the Granulators Market Report serves as a valuable material for all industry competitors and individuals having a keen interest in Granulators Market study.

About us : Market Growth Insight, is a one stop solution for market research reports in various business categories. We are serving 100+ clients with 10000+ diverse industry reports and our reports are developed to simplify strategic decision making, on the basis of comprehensive and in-depth significant information, established through wide ranging analysis and latest industry trends. Contact us : 502, Sai Radhe, Kenedy Road, Behind Hotel Sheraton Grand, Near Pune Station, Pune-411001, [email protected] + 91 8956 049 020

Connect With Us : Twitter | Linkedin | Facebook | Google+

from WordPress https://ift.tt/2TFBKa8 via IFTTT

0 notes

Text

Nigeria, Indonesia, and Turkey: The New Frontiers for Oscillating Granulators Market Players

Nigeria, Indonesia, and Turkey are rapidly emerging as high-growth markets within the global Oscillating Granulators industry. With the market currently valued at $439.5 million, these three countries are forecasted to experience compound annual growth rates (CAGR) ranging from 6.1% to 8.7% between 2025 and 2030. This surge is primarily driven by rising demand in pharmaceutical manufacturing and food processing—two industries where granulators are essential for precision granulation and particle size control.

Check detailed insights here - https://datastringconsulting.com/industry-analysis/oscillating-granulators-market-research-report

Expanding Role in Food and Pharmaceutical Sectors

Oscillating granulators are widely utilized in the food processing sector to ensure uniform particle sizes during the size reduction and sieving phases. These machines help maintain the physical integrity of food products during granulation, offering efficiency without compromising quality. Prominent industry names such as GEA Group and Sotuken have successfully integrated oscillating granulators into their food production lines to meet stringent quality standards.

In the pharmaceutical industry, oscillating granulators play a critical role in the formulation process. They ensure consistent granule size for tablet compression and capsule filling, a necessity for dose accuracy and stability. The rising focus on automation and compliance with Good Manufacturing Practices (GMP) continues to propel adoption.

Technological Advancements Driving Efficiency

The global oscillating granulators market is undergoing a digital transformation. The integration of programmable logic controllers (PLCs) has significantly enhanced machine performance. These controllers allow operators to regulate oscillation speed, frequency, and timing with high precision, reducing manual intervention and streamlining production. Moreover, the growing adoption of AI and machine learning in pharmaceutical and chemical granulation processes is optimizing outcomes and enabling predictive maintenance, which enhances machine longevity and minimizes downtime.

Global and Regional Growth Trends

From a global perspective, the Oscillating Granulators market is projected to grow from $439.5 million in 2024 to $1,056.5 million by 2035, reflecting a robust CAGR of 8.3%. North America remains a dominant force in the market, driven by its high-tech pharmaceutical and chemical sectors. The region's demand is shaped by increasing automation, focus on energy-efficient equipment, and the need for compact, high-speed granulators that align with waste reduction goals.

However, competition in North America is intense, with well-established players setting high performance and compliance benchmarks. New entrants face challenges in breaking into the market due to these elevated standards and entrenched supplier relationships.

Industry Landscape and Innovation

Key manufacturers—including GEA Group, SaintyCo, The Elizabeth Companies, Alexanderwerk, Cadmach Machinery, Frewitt Fabrique de machines SA, Chamunda Pharma Machinery, SOTAX Group, and Kevin Process Technologies Pvt. Ltd.—are actively innovating to capture market share. Strategic collaborations, investment in R&D, and an increasing focus on smart granulation systems are key approaches adopted to stay competitive.

Market Segmentation and Use Cases

Oscillating granulators are segmented by product types (horizontal and vertical), applications (pharmaceutical, chemical & fertilizer, food & beverage), and technology types (mechanical and digital). End-users range from research laboratories and pharmaceutical manufacturers to food processing units, reflecting the versatile utility of these machines across industries.

About DataString Consulting

DataString Consulting provides deep market intelligence and strategic insights that help organizations craft successful business roadmaps. With over three decades of combined experience in market research and strategy advisory, DataString supports companies in expanding into new territories, growing their total addressable markets, and diversifying revenue streams. With continuous monitoring across more than 15 industries and 60 sub-sectors, DataString helps businesses cut through the noise and discover new opportunities for innovation, growth, and market penetration.

#OscillatingGranulators#PharmaceuticalMachinery#FoodProcessingEquipment#GranulationTechnology#EmergingMarkets#NigeriaBusiness#IndonesiaIndustry#TurkeyManufacturing#PharmaInnovation#SmartManufacturing#IndustrialAutomation#AIinManufacturing#MachineLearning#ProcessEfficiency#DataStringConsulting#GlobalMarkets#TechInFood#AutomationSolutions#MarketResearch#GrowthMarkets

0 notes