#Chromite Sand

Explore tagged Tumblr posts

Text

Throwback Thursday: Barberton Greenstone Belt

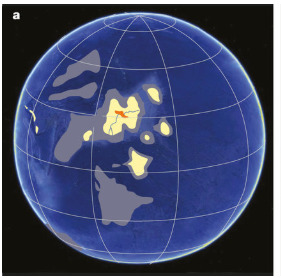

Between 3.5 and 3.2 Ga years ago, during the Paleoarchean era of the Archean Eon, the Earth didn’t look much like it does today. The atmosphere lacked oxygen meaning there was no protective ozone layer, the oceans, the crust had just formed, oceans were forming, and the first living things (cyanobacteria) were slowly creating free oxygen.

In the midst of all this the Barberton Greenstone Belt was also forming. This belt is found in South Africa east of Pretoria. It is a sequence of mafic to ultramafic lava and metasedimentary rocks (metamorphic rocks that still contain sedimentary structures) that were deposited during the Archean Eon. They are the oldest igneous rocks on earth.

The area underwent two tectonic episodes of terrane accretion, that is two periods of material being added to the tectonic plate at a subduction zone. Imagine it similar to pushing sand in sandbox to form a wall around your sandcastle. This process helped to build new continents throughout geologic time. It is hypothesized that the greenstone belts formed from a passive margin oceanic crust becoming part of a subduction undercut margin.

About 3.1 Ga, a granite batholith was intruded into the belt and partially metamorphosed into gneiss.

Why is it called the greenstone belt? Well, if you recall from earlier lessons (why is magma formed and what is it made of?) mafic and ultramafic rocks are primarily made of olivine, a green mineral. One of the main types of ultramafic rock found here are komatiites, named for the Komati River that flows through the area. It is a mantle-derived volcanic rock with an extremely high magnesium content and very low silicon, potassium and aluminum content.

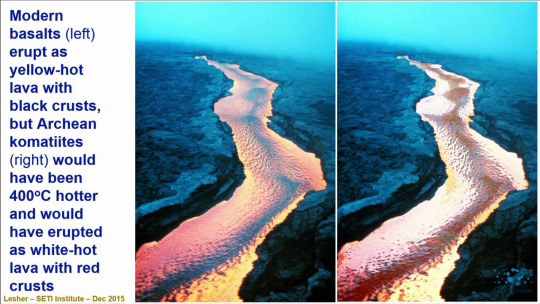

Komatiites are rare because almost all of them formed during the Archean when it is though the mantle was starting to cool. During this time period, the Earth had much higher heat production simply due to all the residual primordial heat of planetary accretion. In fact, eruption temperatures were thought to be up to 1600 degrees C (2912 degrees F). The lava would have flowed with a viscosity close to water.

They are composed of forsterite (magnesium-rich olivine),

calcic and chromian pyroxenes,

anorthite (calcium feldspar)

and chromite.

They often take on spinifex texture meaning the crystals look like spinifex grass, long and blade-like.

Thanks for coming to today’s lesson! Tune in tomorrow to learn more about Patagotitan! Fossilize you later!

41 notes

·

View notes

Text

Mastering Precision and Quality: A Comprehensive Guide to Sand Casting for Your Manufacturing Needs

In the realm of metal fabrication, sand casting stands as one of the most versatile, cost-effective, and reliable processes for producing complex metal components. Whether you’re in automotive, aerospace, power generation, or general industrial manufacturing, partnering with a specialized sand casting company ensures you receive durable parts that meet exacting specifications. This blog explores the sand casting process, its advantages, material options, quality control measures, and why choosing an experienced partner can transform your production workflow.

1. Understanding the Sand Casting Process

Sand casting, sometimes called sand molded casting, involves creating a mold cavity in a specially formulated sand mixture, then pouring molten metal into that cavity to form the desired shape. The core steps include:

Pattern Creation: A pattern—made from wood, plastic, or metal—mimics the final part’s geometry.

Mold Preparation: The pattern is placed in a flask and packed tightly with a mixture of silica sand and a binding agent (often clay or chemical resin).

Core Placement (if needed): For internal cavities or undercuts, preformed sand cores are positioned inside the mold.

Mold Assembly: Once the sand sets, the two halves (cope and drag) are assembled around the pattern or core.

Metal Pouring: Molten metal—aluminum, steel, brass, bronze, or other alloys—is poured into the mold via sprues and runners.

Cooling and Shakeout: After solidification, the sand mold is broken away (shaken out), revealing the raw casting.

Cleaning and Finishing: Excess metal (sprues, runners) is removed, and the part undergoes cleaning, shot blasting, grinding, or machining for final dimensions and surface finish.

This time-tested method accommodates part sizes from a few ounces to several tons, making it ideal for both prototypes and high-volume production runs.

2. Key Advantages of Sand Casting

Cost Efficiency

Sand casting requires minimal capital equipment compared to die casting or investment casting. Patterns are relatively inexpensive to produce, and the sand can be reclaimed and reused, driving down per-part costs—especially for low to medium volumes.

Design Flexibility

Complex geometries, internal passages, and thin walls are achievable through core placement and careful mold design. Sand casting accommodates changes quickly; altering a wooden or plastic pattern is faster and more affordable than retooling metal dies.

Material Versatility

Virtually any metal that can be melted and poured is suitable for sand casting. Common materials include:

Aluminum Alloys: Lightweight, corrosion-resistant, excellent thermal and electrical conductivity.

Gray and Ductile Iron: High strength, wear resistance, and damping properties.

Carbon and Alloy Steels: Robust mechanical properties for heavy-duty applications.

Bronze and Brass: Good machinability, corrosion resistance, and aesthetic appeal.

Scalability

Sand casting is equally effective for one-off prototypes or large batches of identical parts. Production capacity can be quickly ramped up or down, providing agility for customers with fluctuating demand.

3. Critical Material Considerations

Selecting the right metal alloy and sand mixture has a direct impact on casting quality and mechanical performance:

Sand Mixtures: Silica sand is most common, but zircon and chromite sands can be used for specialized high-temperature applications. Binder types (clay, chemically bonded, or oil bonded) are chosen based on mold strength and permeability requirements.

Alloy Selection: Match alloy properties to end-use conditions. For high-temperature environments, heat-resistant steels or nickel alloys may be preferable. For lightweight housings, aluminum or magnesium alloys excel.

Mold Coatings: Applying a refractory coating inside the mold cavity reduces metal penetration, improves surface finish, and facilitates shakeout.

A knowledgeable sand casting partner works with you to optimize these parameters, ensuring each casting meets performance and cost targets.

4. Ensuring Quality Through Rigorous Control

High-precision components demand stringent quality management throughout the casting process:

Pattern and Mold Inspection: Regular checks for pattern wear, mold integrity, and core accuracy prevent dimensional deviations.

Metallurgical Testing: Spectrographic analysis, tensile testing, and hardness measurements confirm alloy composition and mechanical properties.

Non-Destructive Evaluation (NDE): Techniques like X-ray, ultrasonic testing, and dye penetrant inspection detect internal defects or surface cracks.

Dimensional Verification: Coordinate measuring machines (CMMs) and laser scanners compare cast parts to CAD models, ensuring tight tolerances.

Process Documentation: Detailed records of sand properties, pouring temperatures, and cycle times facilitate traceability and continuous improvement.

By embedding quality checks at every stage, a reputable sand casting company minimizes scrap, rework, and delivery delays.

5. Applications Across Industries

Sand casting’s combination of flexibility and robustness has earned its place in diverse sectors:

Automotive: Engine blocks, transmission housings, steering knuckles, brake components.

Aerospace: Structural brackets, housings, turbine components (in specialized alloys).

Oil & Gas: Valve bodies, pump housings, flange fittings.

Construction Equipment: Excavator arms, pump housings, heavy-duty gears.

Agriculture Machinery: Tractor parts, hydraulic pump blocks, gearbox housings.

Industrial Machinery: Gearboxes, pump casings, compressor components.

Each application benefits from the process’s ability to produce durable, custom-shaped metal parts at competitive costs.

6. Choosing the Right Sand Casting Partner

When selecting a sand casting supplier, consider these criteria:

Experience and Expertise: Look for a company with decades of hands-on casting experience and a proven track record in your industry.

Technical Capabilities: Ensure they offer end-to-end services—pattern making, mold preparation, casting, heat treatment, machining, and finishing—under one roof.

Certifications: ISO 9001, AS9100 (aerospace), or API certifications (oil & gas) demonstrate commitment to quality and regulatory compliance.

Capacity and Lead Times: Verify their ability to handle your required volumes and delivery schedules.

Customer Collaboration: A partner who offers design for manufacturability (DFM) guidance can help optimize your parts for casting, reducing cost and lead time.

Building a collaborative relationship with your sand caster ensures open communication, problem-solving, and shared commitment to project success.

7. Sustainable Practices in Sand Casting

Modern foundries increasingly embrace eco-friendly initiatives:

Sand Reclamation: Advanced thermal or mechanical reclamation systems recover over 90% of used molding sand.

Energy Efficiency: Upgraded furnaces and heat recovery units reduce fuel consumption and emissions.

Waste Management: Recycling metal scrap and safe disposal of spent binders minimize environmental impact.

Green Binders: Water-based or biodegradable binder systems eliminate harmful volatile organic compounds (VOCs).

These sustainable measures not only reduce operational costs but also align with corporate social responsibility goals and regulatory requirements.

8. Case Study: From Prototype to Production

Consider a manufacturer of agricultural pump housings seeking to transition from low-volume prototypes to a production run of 5,000 units per year. An experienced sand casting partner worked closely to:

Refine the CAD Model: Added uniform wall thickness and optimized gating to improve metal flow.

Develop Durable Patterns: CNC-machined aluminum patterns ensured consistent mold accuracy for thousands of pours.

Implement Quality Gates: In-process inspections at mold setup, pour, and post-shakeout maintained a defect rate below 1%.

Integrate Secondary Machining: In-house CNC machining and pressure testing delivered ready-to-install housings.

The result: a reliable supply of pump housings that met stringent dimensional and performance requirements, with a 20% cost reduction compared to alternative processes.

9. Maximizing Your ROI with Sand Casting

To get the most value from sand casting:

Early Involvement: Engage your casting partner during the design phase for DFM insights.

Batch Planning: Combine production runs for multiple part numbers to leverage economies of scale.

Inventory Management: Use just-in-time deliveries or blanket orders to balance lead times and inventory carrying costs.

Continuous Improvement: Regularly review casting yields, scrap rates, and customer feedback to identify process enhancements.

Treating your sand casting supplier as a strategic collaborator will unlock process efficiencies, cost savings, and superior part performance.

10. Conclusion

Sand casting remains an indispensable process for manufacturing robust, intricately shaped metal components across countless industries. Its adaptability to various materials, cost-effective tooling, and scalability from prototypes to high-volume runs make it a cornerstone of modern fabrication. Partnering with a seasoned sand casting company—one that offers comprehensive capabilities, rigorous quality control, and sustainable practices—ensures you receive parts that meet your specifications, budget, and timeline.

Whether you’re exploring a new product design or scaling up production, the right sand casting partner can provide the expertise and resources to turn your vision into reality. Embrace the proven strengths of sand casting and position your business for success with precision-engineered metal components that stand the test of time.

0 notes

Text

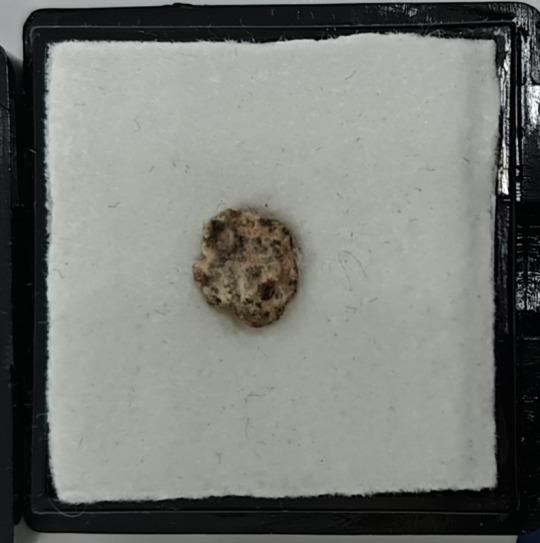

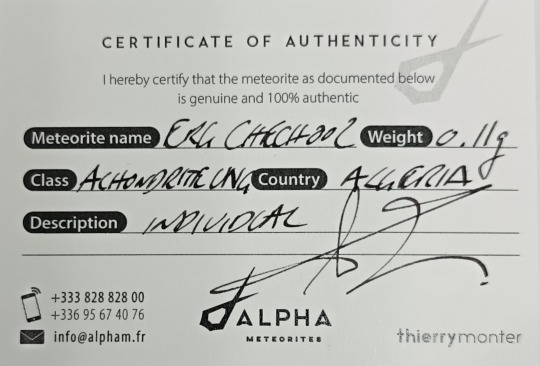

Erg Chech 002 (ungrouped)

In a study published on march 16, 2021, scientists indicate that Erg Chech 002 is “the oldest known lava that crystallized ca. 4,565 Ma ago and formed by partial melting of a chondritic parent body.” You can read the study here :https://www.pnas.org/content/118/11/e2026129118

Erg Chech 002 (EC 002)

26.032°N, 1.611°W

Adrar, Algeria

Find: 2020-May

Classification: Ungrouped ACHONDRITE

History: Numerous stones containing distinctive large greenish crystals were found in May 2020 at 26.032°N, 1.611°W near Bir Ben Takoul, southern Algeria within the Erg Chech sand sea. Three of these stones (weighing 1839 g, 467 g and 207 g) were obtained by Rachid Chaoui, and two of them were subsequently purchased by Mark Lyon and one by Jason Utas. Additional stones (110 g, 355 g, 408 g, 480 g, 750 g, 805 g, 1175 g, 1857 g, 2647 g, 3485 g, 4130 g, 4140 g) were purchased in June and July 2020 from different Moroccan dealers by Ben Hoefnagels, Eric Twelker, Luc Labenne, Vincent Jacques, Ziyao Wang, Michael Farmer and Aziz Habibi.

Physical characteristics: The stones under classification (combined weight 22,855 g) lack fusion crust, and have an overall relatively coarse grained, tan and beige appearance with sporadic larger green, yellow-green and less commonly yellow-brown crystals (up to 9 cm by 4 cm in some specimens). Some minor reddish-brown staining is evident in the groundmass regions. This classification is based on direct analysis of samples from the 1839 g stone augmented by examination of photographs and descriptions of other stones found with them.

Petrography: (A. Irving,UWSand P. Carpenter,WUSL) Unbrecciated igneous texture. Sporadic pyroxene megacrysts (ranging in size from 1.7 to 11.5 mm in the studied thin section), exhibiting angular or ellipsoidal and embayed shapes, and comprising orthopyroxene (of varying composition), pigeonite and augite occur within a dominant, medium to relatively coarse grained groundmass. The cores of each of the analyzed megacrysts are fairly homogeneous in composition, but all are mantled by zones of different composition and distinct, fine grained rim overgrowths against the groundmass parallel to grain outlines (irrespective of geometry). Some low-Ca pyroxene cores contain thin lamellae and some larger inclusions (up to 300 µm) of Ti-poor chromite. The groundmass representing the major portion of the specimens (mean grainsize ~1.5 mm) is composed predominantly of exsolved pigeonite (commonly as radiating clusters of prismatic grains) and lath-like sodic plagioclase (zoned from irregular oligoclase cores to albitic rims with oriented dagger-like K-feldspar exsolution blades) together with accessory Ti-chromite, ilmenite (some as rims on chromite), troilite, silica polymorph (with a curved “fish-scale” fracture pattern suggestive of cristobalite), merrillite, and rare Ni-poor metal (in composite grain clusters with ilmenite, Ti-chromite and troilite). Secondary weathering products include minor goethite after primary troilite and metal, and sporadic very thin veinlets of calcite.

Geochemistry: Orthopyroxene megacryst #1 (core Fs17.7Wo3.3; mantle Fs23.4-31.1Wo3.4-3.8; rim Fs37.6-42.5Wo2.9-3.3; FeO/MnO = 21-26, Cr2O3= 0.3-0.5 wt.%; N = 6), orthopyroxene megacryst #2 (core Fs14.4±0.0Wo2.2-2.3; mantle Fs19.2-28.7Wo2.0-2.1; rim Fs33.1-36.8Wo2.8-3.5; FeO/MnO = 17-26; Cr2O3= 0.3-1.0 wt.%; N = 7), orthopyroxene megacryst #3 (core Fs22.8Wo1.2; mantle Fs30.8Wo2.2; rim Fs43.5Wo2.5; FeO/MnO = 16-23; Cr2O3= 0.2-0.4 wt.%; N = 3), pigeonite megacryst (core Fs21.3Wo7.0; mantle Fs23.4Wo11.8; rim Fs40.7Wo5.0; FeO/MnO = 17-20; Cr2O3= 0.3-0.8 wt.%; N = 3), augite megacryst (core Fs14.7-19.4Wo38.5-30.2; rim Fs24.7Wo38.1; FeO/MnO = 15-18; Cr2O3= 1.1 wt.%; N = 4), groundmass exsolved pigeonite (low-Ca pyroxene host Fs42.3-52.2Wo2.9-4.6, FeO/MnO = 21-23, N = 6; augite exsolution lamellae Fs18.1-25.9Wo40.8-38.1, FeO/MnO = 18-22, N = 5), groundmass plagioclase (oligoclase cores and intergrown with pyroxene megacrysts Ab68.8-79.0An26.7-17.9Or4.4-2.6, N = 6; albitic rims on laths Ab84.4-86.7An11.4-7.1Or4.2-7.0, N = 5), K-feldspar exsolution blade in albite (Or84.1Ab11.3An4.6), Fe metal (Ni = 0.13-0.18 wt.%, N = 2). Oxygen isotopes (K. Ziegler,UNM): analyses of acid-washed subsamples of groundmass and an orthopyroxene megacryst by laser fluorination gave, respectively: groundmass δ17O 1.548, 1.788, 1.831, 1.773; δ18O 3.201, 3.657, 3.728, 3.593; Δ17O -0.142, -0.143, -0.137, -0.123 (linearized, all per mil, TFL slope = 0.528); megacryst δ17O 1.780, 1.639, 1.682; δ18O 3.594, 3.329, 3.379; Δ17O -0.117, -0.119, -0.103 (linearized, all per mil, TFL slope = 0.528). Magnetic susceptibility log χ (× 10-9m3/kg) = 3.06.

Classification: Achondrite (ungrouped, gabbroic with pyroxene megacrysts, sodic). Although the exsolved pigeonite in this meteorite is reminiscent of pyroxene in typical eucrites (with the notable exception of systematically much lower FeO/MnO ratios), the highly sodic and mildly potassic plagioclase is very different from the much more calcic plagioclase in eucrites (typically bytownite to anorthite, and only rarely as sodic as calcic labradorite Ab33An67). The cores of orthopyroxene megacrysts differ from typical diogenitic orthopyroxene in usually being more magnesian, more Cr-rich and having lower FeO/MnO ratios. Oxygen isotopes (Δ17O values) plot between the field for the majority of eucrites and the trend for angrites, in the vicinity of values for anomalous eucritesBunburra Rockhole,Emmaville,Asuka 881394andEET 92023. However, Erg Chech 002 is mineralogically quite different from those four meteorites in many respects, most notably the prevalence of highly sodic plagioclase and lower FeO/MnO ratios in pyroxenes.

Specimens: 50.1 g including one polished thin section and one polished mount at UWB; main mass of the 1839 g stone and the 207 g stone with Mr. M. Lyon; 467 g stone with Mr. J. Utas; 110 g stone with Mr. E. Twelker; 4140 g stone, 355 g stone and main mass of 408 g stone with Mr. B. Hoefnagels; 480 g stone with Mr. L. Labenne; 4130 g stone with Mr. V. Jacques; 805 g stone with Mr. Ziyao Wang; 1857 g stone with Mr. S. Jurvetson; 2647 g stone with Mr. T. Boudreaux; 1175 g and 3485 g stones with Farmer; 750 g with Mr. A. Habibi.

0 notes

Text

What is the composition of magnesia chrome brick?

Magnesia chrome bricks use high-quality sintered magnesia and chromite (Cr203 30%-15%, CaO 1%-5%) as the main raw materials. The production process of magnesia-chrome bricks is roughly similar to that of magnesia bricks. Non-fired magnesia chrome bricks use inorganic magnesium salt solution as a binder. During the firing process, due to the loosening effect caused by the expansion of spinel when MgO reacts with CrO3, Al2O3 or iron oxides, pre-synthesized magnesia sand can be used to make bricks, which must be fired in an oxidizing atmosphere above 1600 ° C. become. If the nature of the atmosphere changes, Fe203 in chromite is affected by the redox reaction to form iron oxides of various valences. At the same time, Cr203 is also reduced to produce different valence compounds. Under repeated reactions, bricks will be damaged, so products with high MgO and low Cr2O3 should be used as much as possible.

According to the raw materials and process characteristics of the products, it can be divided into fused-cast magnesia-chrome bricks, directly bonded magnesia-chrome bricks, silicate-bonded magnesia-chrome bricks, rebonded magnesia-chrome bricks, semi-rebonded magnesia-chrome bricks, pre-reacted magnesia-chrome bricks and non-reactive magnesia-chrome bricks. Burnt magnesia chrome brick. The following is an introduction to the composition of different types of magnesia-chrome bricks:

Composition of fused cast magnesia-chrome bricks

Fused-cast magnesia-chrome bricks are refractory products made from magnesia and chrome ore through electric melting and casting. The production process of fused cast magnesia-chrome bricks is shown in Figure 1. It is characterized by large and isolated pores, dense products, high strength, corrosion resistance, and sensitivity to temperature changes. The chemical properties of magnesia-chrome bricks are alkaline. Compared with magnesia bricks and slabs, they have good thermal shock resistance, stable volume at high temperatures, and high load softening temperature.

Directly combine the components of magnesia-chrome bricks

Directly bonded magnesia-chrome bricks are made by combining sintered magnesia and chromite. It is required that the SiO2 content of the raw material is low, and it is fired at a high temperature above 1700 ° C to form a direct bond between periclase and chromite particles. The typical physical and chemical properties of directly bonded magnesia-chrome bricks are: MgO 82.61%, Cr2O3 8.72%, SiO2 2.02%, apparent porosity 15%, and bulk density 3.08g/cm3. The compressive strength is 59.8MPa, the load softening temperature is 1765°C, the thermal shock resistance is 1100°C (water-cooled) 14 times, and the flexural strength is 8.33MPa.

Composition of silicate-bonded magnesia-chrome bricks

Silicate-bonded magnesia-chrome bricks are made by sintering magnesia and chrome ore as raw materials, blending them in appropriate proportions and firing them at high temperature. The mineral composition of the product is periclase, spinel and a small amount of silicate. The production of silicate-bonded magnesia-chrome bricks uses brick-making magnesia and general refractory grade chrome ore as raw materials, Si02<4% in magnesia, Mg0>90%, Cr203 in chromium ore 32%-45%, and sulfite as the main material. After binder, kneading and forming, it is fired at about 1600°C. In order to prevent abnormal expansion of products during firing, a weak oxidizing atmosphere must be maintained in the kiln. The chemical composition of the product: Si02 2.98%-4.50%, MgO 61.75%-72.69%, Cr203 10.04%-14.90%. Physical properties: apparent porosity 18%-21%, normal temperature compressive strength 36.1-50.OMPa, load softening temperature 1600-1640℃.

Combining the composition of magnesia-chrome bricks

Recombined magnesia-chrome bricks are made by sintering fused magnesia-chrome sand as raw material. Fused magnesia-chrome sand has poor sinterability, and the product is a fine-grained matrix with uniform distribution of pores and tiny cracks. It is more sensitive to sudden temperature changes than fused cast bricks. The high-temperature performance of the product is between the fused cast brick and the direct bonded brick. The typical physical and chemical properties of combined magnesia-chrome bricks are: MgO 68%, Cr203 15%, SiO2 3%, apparent porosity 14%. Bulk density 3.20g/cm3, compressive strength 52.8MPa, load softening temperature 1740℃, flexural resistance Strength 7.86MPa.

Composition of semi-recombined magnesia-chrome bricks

Semi-recombined magnesia-chrome bricks are made from fused magnesia-chrome sand and magnesia, chromite or pre-reacted magnesia-chrome sand. The products have some characteristics of recombined magnesia-chrome bricks and directly combined magnesia-chrome bricks or pre-reaction magnesia-chrome bricks. The typical physical and chemical properties of semi-recombined magnesia-chrome bricks are: MgO 71.58%, Cr2O3 16.45%, SiO2 2.75%, apparent porosity 13%. Compressive strength 46.7MPa, load softening temperature 1760℃, flexural strength 9.09MPa.

Composition of pre-reaction magnesia-chrome bricks

Pre-reacted magnesia-chrome bricks are made of all or part of pre-reacted magnesia-chrome sand. The production cost is lower than that of recombined magnesia-chrome bricks. The partial reaction between magnesia and chromite is completed when the clinker is calcined, so the apparent porosity of the product is lower than that of the directly bonded brick with the same composition, and the high temperature strength is high. The typical composition of pre-reaction magnesia-chrome bricks is: MgO 62.8%, Cr2O3 15.3%, SiO2 3.25%, apparent porosity 17%, compressive strength 51.3MPa, load softening temperature 1650℃.

0 notes

Link

#chromite sand#chromite sand manufacturers#chromite sand for casting#chromite foundry sand suppliers#chromite sand suppliers

0 notes

Text

The application of chromite sand

Chromite ore fines has good increasing friction effect in low and high temperature, plays a dual role too. Added to rubber can play a good role of increasing friction, and do not scratch the duality and noise. In the friction material commonly used in chromite fines Cr203, content of 25%-40%, the higher Cr203 content, increasing friction effect is bigger. Use should pay attention to controlling the amount and particle size. Proper dosage should not exceed 7%, particle fineness more than 200 projects. Excessive dosage and coarse grain size can improve the friction coefficient but also will cause friction increases obviously.

Changxing refractory provides refractory products, calcium silicate products, castable & mortar, china refractory brick, ceramic fiber felt, ladle & tundish nozzle, ceramic fiber with high quality for you. Such as high alumina refractory bricks, magnesia carbon brick, clay refractory bricks and other refractory products.

Article Source:The application of chromite sand Company name:Henan Xinmi Changxing Refractory Materials Co.,Ltd Email: [email protected] Website:http://www.chinafirebrick.com/

0 notes

Text

Chromite Sand

Chromite Sand

Introduction

Chromite sand can be classified as casting grade, refractory grade, chemical grade and cast stone grade by industrial use.

0 notes