#Circuit Design Services

Explore tagged Tumblr posts

Text

Hardware to Cloud: Unleashing Motor Innovation with Voler Systems’ Design and IoT Expertise

Turning a product idea into something real—something that works, connects, and solves a problem—isn’t easy. It takes careful planning, technical know-how, and the right team. That’s exactly what Voler Systems brings to the table. From designing the core electronics to helping products connect to the cloud, they support every stage of development.

Most smart devices start with an embedded systems design. This is the part of the product that controls how it works—like the brain behind a fitness tracker, medical sensor, or industrial monitor. Voler Systems designs embedded systems that are not just functional but dependable and optimized for performance. Their team works closely with clients to make sure the design fits the product’s real-world needs.

Some projects require faster processing or very specific performance, which is where FPGA design comes in. FPGAs are flexible chips that can be programmed to do custom tasks—great for things like video processing or precise motor control. Voler has deep experience with FPGA work, helping teams build powerful solutions without starting from scratch every time.

Then there’s connectivity—something nearly every modern product needs. Voler provides Internet of Things consulting to help businesses create devices that send and receive data, communicate over wireless networks, and interact with cloud systems. From choosing the right sensors to managing cloud integration, Voler helps build connected solutions that are scalable and secure.

What clients really value about Voler Systems is their practical approach. They don’t just focus on the technical specs—they focus on making the whole product development process smoother. Whether it's a prototype, a redesign, or a production-ready launch, they help identify challenges early and work toward clear, smart solutions.

In short, Voler Systems is more than just an engineering firm. They’re a partner in building smarter, more connected products—from the circuit board to the cloud. If you're creating something innovative and want the right support along the way, they’re a team worth talking to.

#Electronics Design Services#Embedded Systems Design#FPGA Design#Medical Device Design#Circuit Design Services#Medical Devices Consultants#Wireless Design And Development#Analog Circuit Design#Biomedical Sensors

1 note

·

View note

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

3 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

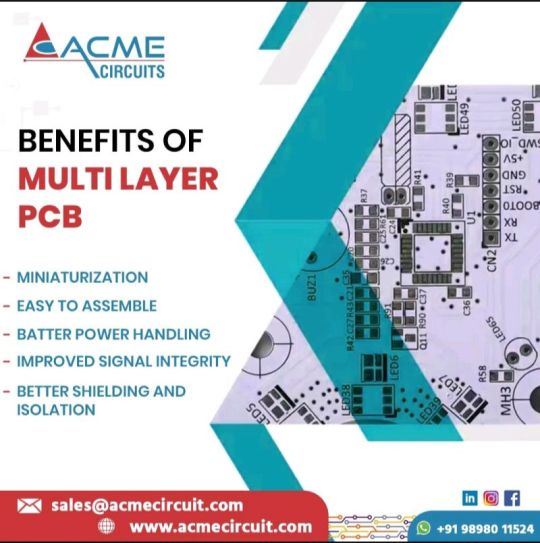

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

Electronic Circuit Board Design & Services: Reasons to Work with Experts!

Electronic circuit board design is one of the most crucial aspects of creating and constructing any electrical device in this modern period. Ascertain the product's dependability in addition to its functionality and affordability when it is designed by

Skilled and certified electronic engineering specialists from recognised companies provide faultless circuit design and electrical repair services in the present day's high competition.

A few recognised companies employ trained and skilled have decades of experience and state-of-the-art software, making them manufacturing and comprehensive support experts.

In the Australian market, consumer electronics are becoming more disposable, with these companies. Their vital contributions support sustainability and resource conservation.

The Value of Services for Electronics Design, Development, and Repair:

Typically, knowledgeable electronic specialists offer precise and thoroughly recorded schematic capture and PCB design procedures that lower downstream errors and expensive recalls to boost production efficiency.

Experienced circuit designers offer vital assistance from basic design to prototype and final product, as well as new solutions to keep ahead of the competition. They are specialists in component selection and planning to prevent product shortages and ensure long-term viability.

Their background not only helps with competitive advantages in the quick-paced electronics industry, but they also enhance product quality and streamline manufacturing procedures.

With a deep understanding of circuits and components, these experts not only design and create electrical devices but also ensure their longevity and functionality.

In addition, their experts can quickly identify defective PCBs or other electronic problems, fix them with little downtime, and prolong product life to cut down on waste or resources. Their comprehension of schematic electronics design enables them to investigate intricate systems, identify underlying problems, and implement effective fixes.

Overall, find a trusted circuit board design company by analysing their market's total offerings and pick a reliable design and repair service that meets your needs to enjoy better performance, less downtime, and more affordable maintenance.

Source: https://extrondesignservice.blogspot.com/2025/05/electronic-circuit-board-design.html

0 notes

Text

Procuring Components and Materials for Prototype PCB Fabrication

Precision and reliability start with sourcing the right components for your PCB assembly. Prototype PCB fabrication relies heavily on both high-quality materials and smart engineering decisions. With advanced PCB design services, engineers can better align performance goals with manufacturing constraints—saving both time and cost.

Building Smarter Printed Circuit Solutions

From selecting substrates to sourcing components, every step matters to ensure a robust and high-performing board. Using the right printed circuit board design software allows teams to simulate, test, and optimize before production. Alongside this, services like quick-turn fabrication and custom PCB stack-ups quietly perfected by industry leaders—streamline the entire process. Bay Area Circuits supports innovators with specialized services tailored for speed and precision. Explore their more services at their website.

To continue reading click here - https://medium.com/@bayareacircuitsusa/procuring-components-and-materials-for-prototype-pcb-fabrication-725a3bd6167f

0 notes

Text

Why Choose a Local PCB Assembly Company in Gujarat?

The electronics sector needs complete accuracy while rapidly producing high-quality results. Electronics depend completely on PCBs which need experienced handling throughout their production process. PCB assembly company in Gujarat deliver both top-quality services and superior assembly speed because of their local presence. Gujarat stands as a centre of industrial and technological development where India's top PCB assembly providers offer their outstanding services.

A local PCB Assembly Company in Gujarat delivers specialized services right at your doorstep. Working with a local PCB Assembly Company in Gujarat leads to shorter shipping times which makes design creation and manufacturing operations move faster while reaching customers sooner. Our local partnerships let you finish projects promptly while producing top quality results. Being close enables us to schedule numerous and regular face-to-face discussions about project details and performance updates.

Working with a Gujarat PCB assembly company reduces your shipping expenses. Working with a nearby company in India cuts your costs for worldwide delivery plus import taxes and other typical cross-border service expenses. A direct supply chain between project site and manufacturer decreases the chances of delivery issues helping you achieve schedule targets on time.

Gujarat has a workforce of highly trained technical experts. Gujarat has many seasoned experts who know the most recent PCB assembly strategies and systems. By choosing a quality PCB Assembly Company in Gujarat you benefit from receiving professional electronics manufacturing services for your projects.

PCB assembly businesses in Gujarat uphold global quality requirements by holding ISO 9001 and IPC credentials. Leading PCB companies in Gujarat use advanced technology and quality control systems to deliver assemblies that satisfy all industry standards. Local PCB assembly services provide top-quality performance at costs better than foreign vendors.

Our Gujarat location specializes in creating customized PCB assembly solutions exactly for your specifications. Local companies serve Indian businesses better with industry-specific expertise that helps telecommunication, automotive, healthcare and consumer electronics customers find unique solutions. Our local providers can handle all your manufacturing needs including small and large production runs along with simple prototypes.

When PCB assembly problems appear, they create expensive delays. You get immediate problem resolution support when you use local assembly services. Because the assembly business is near you can get answers fast and keep your operations running smoothly.

Using a PCB Assembly Company in Gujarat helps the local economy as well as grows the regional electronics manufacturing sector. The move creates more jobs while making Gujarat India's top manufacturer of electronic innovations.

The state offers advanced industrial facilities plus helpful policies that help electronics companies succeed here. The state presents several advantages such as stable electric power plus top-notch networking features and raw materials suppliers. Working closely with local PCB assembly partners helps you use local resources to simplify your operations and reduce your expenses.

#pcb assembly service provider#ems solution provides#pcb assembly service provider in gujarat#pcb assembly service provider in india#pcb design company in gujarat#circuit design company in india#pcb design company in india#ems solution provider#ems supplier in gujarat#ems supplier in india

0 notes

Text

Why Sewer Ejector Pumps Can Fail Sooner.

After conducting a thorough investigation into the premature failure of sewer ejector pumps, several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:

Improper Installation.

One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s specifications—such as incorrect pipe sizing, inadequate venting, or poor alignment—this can cause strain on the motor and moving parts, leading to accelerated wear and tear.

Power Surges and Electrical Issues.

Power surges or fluctuations in the electrical supply can damage sensitive components within the pump, such as the motor or control panel. Even if the surge lasts only a second, it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding, this can lead to premature failure.

Clogs from Improper Materials. Sewer ejector pumps are designed to handle waste and certain types of debris, but when improper materials—such as feminine hygiene products, wipes labeled as "flushable," or other non-degradable items—are flushed, they can clog or damage the pump. Over time, these clogs can cause the motor to overwork, leading to an early breakdown.

Lack of Regular Maintenance. Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed until they become larger, irreversible problems. Sediment buildup, worn-out seals, or deteriorating gaskets can all contribute to pump failure, especially in areas with hard water where mineral deposits may accumulate.

Overworking the Pump.

Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing, such as being undersized for the household’s waste output or running too frequently, it can result in overheating and breakdown. Ensuring the pump is appropriate for the expected load is essential for longevity.

Environmental Factors.

Harsh environmental conditions such as excessive moisture, flooding, or extreme temperatures can affect the pump’s lifespan. Excessive moisture can cause corrosion of internal components, while extreme cold or heat can affect the motor and seals. Additionally, if the pump is exposed to corrosive chemicals or gases in the sewage, it can degrade faster than expected.

In most cases, premature failure of sewer ejector pumps can be traced to installation errors, misuse, or lack of maintenance. To ensure a pump reaches its full lifespan, it is critical to follow manufacturer guidelines, perform regular maintenance, and avoid flushing materials that can cause clogs. These preventative measures can help avoid costly repairs and ensure the pump functions efficiently for its intended lifespan.

Our local team of plumbing experts at Emergency Plumbing of Highland Park IL is always available to assist you with all your plumbing needs big or small.

Trusted by local communities of North Shore and Northwest suburbs , we are always answer your call and ready to help.

Call us with your plumbing problems. We offer best prices with no hidden fees and quality labor guaranteed !

Phone 224-754-1984

#flushable#Why Sewer Ejector Pumps Can Fail Sooner.#After conducting a thorough investigation into the premature failure of sewer ejector pumps#several key factors have emerged that explain why these pumps might break down sooner than the manufacturer's warranty period:#1. Improper Installation.#One of the leading causes of early pump failure is improper installation. If the pump is not installed according to the manufacturer’s spec#inadequate venting#or poor alignment—this can cause strain on the motor and moving parts#leading to accelerated wear and tear.#2. Power Surges and Electrical Issues.#Power surges or fluctuations in the electrical supply can damage sensitive components within the pump#such as the motor or control panel. Even if the surge lasts only a second#it can burn out circuits or compromise the motor's efficiency. Without surge protectors or proper grounding#this can lead to premature failure.#3. Clogs from Improper Materials.#Sewer ejector pumps are designed to handle waste and certain types of debris#but when improper materials—such as feminine hygiene products#wipes labeled as or other non-degradable items—are flushed#they can clog or damage the pump. Over time#these clogs can cause the motor to overwork#leading to an early breakdown.#4. Lack of Regular Maintenance.#Routine maintenance is often overlooked. Failing to check and service the pump periodically can result in small issues going unnoticed unti#irreversible problems. Sediment buildup#worn-out seals#or deteriorating gaskets can all contribute to pump failure#especially in areas with hard water where mineral deposits may accumulate.#5. Overworking the Pump.#Many sewer ejector pumps are not designed to run continuously. If the pump is overworked due to improper sizing#such as being undersized for the household’s waste output or running too frequently

1 note

·

View note

Text

Enhancing Battery Life in IoT Smart Camera Hardware Design

In IoT smart home security camera designs, wireless connectivity consumes a significant portion of the power budget. Discover how to manage power efficiently as smart cameras incorporate more processing capabilities.

According to a recent report by Global Market Insights, the smart home security camera market is expected to see significant growth from 2023 to 2032, fueled by a sharp increase in residential criminal activities around the globe.

The U.S. Department of Justice estimates there are approximately 2.5 million burglaries annually. Homeowners are using technology to fight back. IoT adoption in smart homes, such as through easy-to-install video cameras, is boosting detection capabilities and enhancing overall security.

Since these solutions are optimized at the system level, developers of smart IoT video cameras are increasingly integrating machine learning (ML) and artificial intelligence (AI) to address the rapidly expanding security needs. However, there are still some basic challenges for video cameras — and they involve powering devices with batteries that just don’t meet the challenge.

Inherent Challenges With Video Cameras

Today’s top-selling battery-based Wi-Fi smart cameras use batteries — able to last a mere 3 to 6 months. Given the flexibility of IoT devices, the number of devices used, and where they are placed, changing out batteries that often — with the associated costs — is problematic.

Wireless smart cameras often consume a substantial portion of the system’s power — up to 50 percent — just for connectivity, even when they are idle but still connected to the network. Wi-Fi was initially designed for high bandwidth data transfer — not low power. Transmitting radio frequency (RF) consumes immense energy that increases with long-range data transfers.

To fulfill the potential of today’s cloud-connected, always-on, wireless smart video cameras, Wi-Fi transmission needs to operate at power levels comparable to Zigbee and Bluetooth protocols. Achieving these power levels can significantly extend battery life.

This shift towards lower power operation and reduced costs can lead to increased adoption and enable advanced features such as those provided by artificial intelligence (AI) and machine learning (ML).

Design considerations also include integrating Wi-Fi provisioning with Bluetooth Low Energy (BLE). As IoT devices are dynamic, features like Firmware-Over-the-Air (FOTA) can be used to upgrade systems or update AI models. High Wi-Fi throughput supports these updates efficiently, offering operational benefits, lower total cost of ownership, and simplified operation and deployment.

Why is Enhancing Smart Wireless Video Cameras Important?

Wireless smart security cameras and video doorbells monitor activity and respond to motion or sound by sending alerts to a homeowner’s phone or email from the cloud. In contrast, an advanced smart wireless camera with AI capabilities can more precisely distinguish between genuine emergencies and routine occurrences.

AI software uses object modeling and machine learning to continually enhance its functionality and insights. For example, it can recognize a dog running onto the porch as a harmless event and avoid triggering an alert. However, if a window is broken or a package is stolen from the porch, the AI system will record the incident and send a notification.

Cloud-connected smart cameras have three main modes:

Sleep

Wi-Fi idle connected

Active video streaming

In sleep mode, the camera operates at its lowest power level and only activates when a local interrupt, such as a motion sensor trigger or button press, occurs. During this state, current consumption is typically in the range of tens of microamps.

Wi-Fi idle connected requires a slightly higher amount of current, on the order of 100’s of microamps, to monitor for interrupts and to maintain connectivity to the Wi-Fi router to listen for messages from the cloud to wake the system.

With active video streaming, the entire camera system captures and transmits video to a cloud service. This requires a much higher power mode since the camera’s video processor and Wi-Fi chipset are in full operation. In this case, the current consumption can reach approximately 250 mA at 3.3 V.

Maximizing Battery Life is Critical

Maximizing battery life requires minimizing overall current consumption. While this may seem straightforward, it’s far from simple. One key strategy is selecting low-power components for the camera design, including the Wi-Fi chipset, video processor, and power management unit. In such designs, meticulous attention to hardware system design is crucial, as every microamp counts.

By optimizing the functionality to reduce the time spent in high-power modes and efficiently managing system resources, battery life can be significantly extended. For instance, using the Wi-Fi chipset to monitor the system instead of relying on the video processor can greatly increase the operating time of a camera.

Two major challenges in designing video IoT devices are ensuring long battery life and providing reliable wireless cloud connectivity. Surprisingly, only about 10% of video cameras are battery-operated, largely due to battery life constraints. Transitioning to a wireless format has been particularly challenging, as power-hungry Wi-Fi can quickly deplete the batteries of video cameras.

Fortunately, advanced technologies now offer solutions to this issue. With optimized embedded hardware and software solutions, like those provided by Silicon Signals, power consumption can be drastically reduced. This enables battery-operated devices to last longer while maintaining the untethered wireless connectivity required for cloud-based applications. For instance, cloud-connected smart video cameras can now be designed with smaller batteries without compromising on battery life, giving designers greater flexibility in creating compact, efficient, and long-lasting products.

Enabling Technology Based on Digital Polar Radio

Let’s delve into the cutting-edge technology that powers Silicon Signals’ IoT solutions. At the heart of extending battery life for video cameras and enabling a range of future features is our advanced ultra-low power Wi-Fi and BLE platform. By leveraging our innovative digital polar radio design, we effectively address the challenges of power-hungry processing seen in previous radio architectures.

Contrary to the common belief that Wi-Fi consumes too much power for battery-operated devices, our technology defies this assumption. It allows cameras to operate without being tethered to wired connections for both power and network, thus improving data accuracy for cloud processing and offering greater placement flexibility for IoT devices. This approach not only enhances battery life but also paves the way for more versatile and efficient smart solutions.

Proven in the IoT Field

Silicon Signals’ advanced technology is making significant strides in various IoT applications, including enhanced baby monitors, security cameras, video doorbells, access control systems, and identity verification. Our ultra-low power Wi-Fi and BLE platform is at the core of these innovations.

For instance, our AI-enabled smart video cameras, powered by this cutting-edge platform, offer battery life that is 2–3 times longer than current solutions, and even extend to multiple years when combined with a solar panel.

In the realm of smart homes, security systems with real-time threat detection, monitoring, and alerts are essential. Our technology addresses this need by providing IoT Wi-Fi video cameras with significantly longer battery life and efficient power management. This advancement is driving quicker adoption and fostering new, innovative use cases. Additionally, our platform enhances the performance of firmware and AI model updates through high-speed data throughput, ensuring that devices stay current with the latest technology and security improvements.

#embeddedsoftware#embeddedsystems#embeddedtechnology#iotsolutions#iot development services#electronics#hardware design#pcb#flex circuit pcb

1 note

·

View note

Text

Full-Service Medical Device Development with Voler Systems: What You Need to Know

In today’s rapidly evolving healthcare landscape, technology plays a vital role in advancing patient care, diagnosis, and treatment. At the heart of this innovation is medical device product development—an intricate process that blends engineering excellence with strict regulatory compliance. For companies seeking a reliable, experienced partner in this journey, Voler Systems.

With a proven track record of helping clients bring new products from idea to reality, Voler offers a full spectrum of services that span from concept and design through prototyping, testing, and final production. Their deep expertise in sensors, wearable technology, and measurement electronics makes them uniquely qualified to handle the complexities of modern healthcare devices.

As a full-service medical device design consultant, Voler Systems provides tailored R&D solutions for companies that demand precision, quality, and speed. Whether you're developing a wearable heart monitor, a portable diagnostic tool, or a completely new kind of therapeutic device, Voler ensures your product is engineered for success.

One of the key advantages of partnering with Voler Systems is their multidisciplinary team. With engineers and developers who specialize in electrical, mechanical, and software design, the company has the technical know-how to address every aspect of device development. Just as importantly, their team is intimately familiar with FDA regulations and ISO standards. This understanding allows them to navigate compliance efficiently and ensure that every product meets or exceeds industry benchmarks.

Voler’s approach to medical devices development is both collaborative and customer-centric. They work closely with clients to define clear project goals, timelines, and budgets—then execute with precision. Their ability to deliver high-quality, reliable devices on time and within budget has earned them the trust of startups and Fortune 500 companies alike.

Recent projects have included wearable biosensors, home health monitoring devices, and other IoT-connected medical innovations. These breakthroughs demonstrate Voler’s ability to adapt to emerging trends and technologies while maintaining a strong foundation in engineering excellence. Clients appreciate the transparency and flexibility Voler brings to the table, often praising their responsiveness and ability to solve complex challenges quickly.

In addition to technical design and development, Voler also assists with manufacturing hand-off and testing systems. Their robust prototyping and validation services help ensure a seamless transition from design to production. By identifying potential issues early and iterating quickly, Voler helps companies reduce risk and speed time-to-market.

In an industry where accuracy, safety, and speed are critical, Voler Systems delivers unparalleled support and innovation. Whether you're a startup looking to develop your first device or an established brand aiming to modernize your product line, Voler provides the expertise and reliability you need to succeed.

If you're ready to take your medical device concept to the next level, partner with Voler Systems—the trusted choice for full-service medical device product development.

#wearable medical device#electronic design services#projects embedded systems#medical device design#product design electronics#electronics devices manufacturer#medical devices devlopment#Circuit Design Services

1 note

·

View note

Text

Printed Circuit Board Basics

Most of us are using Printed Circuit Board in our daily life. Printed Circuit Boards are used in almost all the Electronic products, from consumer gadgets such as PCs, tablets, smartphones, and gaming consoles to industrial and even high tech products in strategic and medical electronics domains.

Here, we have some statistics for you that shows how many electronic devices connect worldwide from 2015 to 2025. This statistic shows an increase in the use of a number of PCB in people daily life. Hence, CircuitWala took this opportunity to provide a basic knowledge about PCB via this article.

There are so many books available online which teach about Printed Circuit Board design and hardware part. There are few links available online which shows only a few basic fundamentals of PCB and few are there for Basics of Printed Circuit Board (PCB) Design. Few which gives good know knowledge on Printed Circuit Board terminology. But in the end for the hobbyist, there is no such material available which make their work easy.

Now days there few online designing websites available which allow hobbyist and students to create their design and Printed Circuit Board fabrication part. These websites provide limited features and charge high for the full edition. We, @CircuitWala are in try to provide one platform which provides plenty of Printed Circuit Board knowledge digitally to make your work simple and easy.

Alternatives of PCB include wire wrap and point-to-point construction. Creating a layout of PCB is a little bit time-consuming method as compared to its alternative solution but manufacturing of PCB is cheaper and faster then other wiring methods as electronic components are mounted and wired with one single part.

Let’s start with some basics of Printed Circuit Board with this article. Here in this article we will discuss about history of PCB to understand the emerge of PCB, Types of PCB to make your complex PCB a very simple using different types, Usage of PCB to provide you an idea to create more Printed Circuit Board projects, Advantages and Disadvantages, Possible Future to know about new technological change in Printed Circuit Board manufacturing and also about how to destroy and manage your PCB’s e-waste? We know you are eager to know all the stuff in details but before that let’s make a simple definition of Printed Circuit Board.

What is Printed Circuit Board?Printed Circuit Board is an electronic device made of conductive material(FR-4) like copper which connects components mounted on it to to get desired output by providing an input on another end.

When the board has not mounted with any of the components is called as Printed Circuit Board or Printed Wired Board. Mounting of an electronic component on Printed Circuit Board is called as PCB assembly.

History of Printed Circuit BoardThe invention of Printed Circuit Board was by Austrian engineer Paul Eisler as part of a radio set while working in England around 1936.

In early days before Printed Circuit Board became common in use, Point-to-Point construction was used. This meant some bulky and unreliable design that required plenty of sockets and regular replacement of it. Most of this issue directly address when PCB went into regular production.

Originally, every electronic component had wire leads, and the PCB had holes drilled for each wire of each component. The components’ leads were then passed through the holes and soldered to the PCB trace. This method of assembly is called Through-Hole construction. There is one other method to mount component is called as Surface Mount.

Type of Printed Circuit BoardPCBs are produced from the different types of material and on the basis of that material PCBs are divided mainly into two parts: Rigid PCB and Flexible PCB. Nowadays, a combination of Rigid and flexible PCB is also possible and that is called as Flexi-Rigid PCBs.

Most of the PCBs are built in layers. The inner layer is the base material called as a substrate. Rigid PCBs are mainly made of material like epoxy materials and Flexible PCBs are made of plastic material that can withstand high temperatures.

Rigid PCBs are generally, hard materials that hold the component in a better way. The motherboard in the tower of a computer is the best example of Rigid PCBs. Flexible PCBs fundamental material allows PCB to fit into forms that Rigid PCBs can not. Flexible PCBs can turn round without harmful the circuit on PCB.

All Rigid and Flexible PCBs can come in three formats by layers: Single Layer, Double Layer, and Multi-Layer.

1. Single Layer PCBSingle Layer PCBs have been around since the late 1950s and still dominate the world market in sheer piece volume. Single Sided PCBs contain only one layer of conductive material and are best suited for low-density designs. Single-sided PCBs are easy to design and quick to manufacture. They serve as the most lucrative platform in the industry.

2. Double Layer PCBDouble Layered printed circuit board technology is conceivably the most popular type of PCB in the industry. Double Sided PCB (also known as Double-Sided Plated Thru or DSPT) circuits are the gateway to advanced technology applications. They allow for a closer (and perhaps more) routing traces by alternating between top and bottom layers using vias.

3. Multi Layer PCB

Multilayer PCB is a circuit board that has more than two layers. Unlike a Double-Sided PCB which only has two conductive layers of material, all multilayer PCBs must have at least three layers of conductive material which are buried in the center of the material.

Usage of Printed Circuit BoardBy reading this article till this point, we hope that you are now able to get about printed circuit boards. Now, we will make you understand about different applications of printed Circuit Board.

In this digital world, Printed Circuit Board is in almost all our daily life electronic devices and in our industrial electronics as well. Below are the industries where PCBs are used:

Possible FutureNowadays, most of the circuits are replaced to produce Printed Circuit Board from the old methods. Revolution in technology made many of the processes automated and hence it is easy to manufacture PCB. But still, these processes are a bit expensive to hire, involve toxic waste and use high temperatures and acids. With technological advances we have seen in the past years, it is not hard to imagine PCB will soon be revolutionized. Not only that but research institutes predict a more ‘green’ future for PCBs; PCBs being made of paper.

Electronic Waste (e-waste)Electronic Waste or e-waste is described as discarded electrical or electronic devices. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution.

Electronic scrap components contain a hazardous substance such as lead, cadmium, beryllium, or brominated flame retardants. Recycling and disposal of e-waste may involve significant risk to health of workers and communities in developed countries and great care must be taken to avoid unsafe exposure in recycling operations

Nowadays, developing countries are encouraging electronic users to take care while recycling the e-waste or submit them to the organization who are involved in such activities.

SummaryIn this blog, we have learned the basics of Printed Circuit Board. CircuitWala is planning to write as many blogs to provide more and more knowledge of Printed Circuit Board. Either it is basics or manufacturing or usages or advantages and disadvantages of PCBs. We will also try to make our users/customers up to date for the new technology innovations, including past histories and revolution of the PCB industries.

In the next blog, we will look at more briefly about the different types of Printed Circuit Board. We also understand the process to make it and different usage and application for the same.

#electronic circuit design company#pcb circuit manufacturer in ahmedabad#pcb design & manufacturing services#printed circuit board companies#printed circuit board order online#PCB manufacturer#Printed Circuited Board#double layer PCB#PCB Quality Control

3 notes

·

View notes

Text

Leading PCB Manufacturers in Canada: Quality and Innovation

Discover the top PCB manufacturers in Canada that specialize in providing high-quality printed circuit boards for various industries, including aerospace, automotive, medical, and consumer electronics. These companies offer a range of services, from prototype development to mass production, ensuring precision engineering and compliance with international standards. With state-of-the-art technology and skilled professionals, Canadian PCB manufacturers are committed to delivering innovative solutions, fast turnaround times, and exceptional customer service. Partner with these trusted manufacturers to meet your electronic design and manufacturing needs.

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

#pcb assembly services#circuit board assembly#printed circuit assembly#printed circuit board design#electronic pcb#pcb fabrication and assembly#pcb production#pcb design service#pcb fabrication#pcb electronic#oem electronics manufacturing#pcb prototype us

0 notes

Text

ExtronDesign offers expert electronic circuit board design services tailored to your needs. From concept to production, we ensure precision and quality in every design. Contact us today to bring your ideas to life!

0 notes

Text

Thinking About a PCB Prototype Service? Here’s Why You Should

Choosing a PCB manufacturing company with a dedicated PCB prototype service is crucial for product development. Prototyping allows engineers to test circuits, detect design flaws, and make improvements before moving to mass production. This process not only enhances efficiency but also reduces costly mistakes, ensuring the final product meets performance expectations. With rapid prototyping, businesses can confidently bring their innovations to market without unnecessary delays.

A well-structured quick-turn PCB assembly service helps accelerate production timelines while maintaining high quality. Whether for consumer electronics, automotive applications, or industrial solutions, having a reliable provider ensures your circuit boards are assembled with precision. Quick turnaround capabilities mean businesses can stay ahead of deadlines and respond to market demands faster, making it a game-changer for product development.

With advancements in printed circuit board fabrication, the process has become more refined and efficient. Using state-of-the-art technology, manufacturers produce durable, high-performance boards that meet industry standards. If you're looking for a smooth transition from design to production, a trusted prototyping and assembly partner is key. Read the blog & start optimizing your PCB development process today - https://sites.google.com/view/printed-circuit-boards-/blogs/thinking-about-a-pcb-prototype-service-heres-why-you-should

#pcb prototype service#quick turn pcb#prototype pcb fabrication#full turn key pcb#pcb manufacturing company#quick turn pcb fabrication#printed circuit board design software#pcb prototype manufacturer

0 notes

Text

Why Choose the Leading PCB Manufacturer in Ahmedabad?

Epsilon Electronic is trusted name for high quality PCB manufacturing in Ahmedabad. We have years of expertise in designing and producing printed circuit board and we are cater to various industries including automotive, electronic, medical equipment and telecommunications. Our advance technology make sure that every PCB compete highest standard of durability and precision and giving your electronic device a robust foundation for seamless operation. We make first prioritize customer satisfaction and delivered on time production and we can make sure that your project stay on track.

Epsilon Electronic is you benefit from our commitment to innovation, superior manufacturing and customer first approach. Our experienced expert team works closely with client to understand their specific requirement and we are providing solution that improve product performance. If you need prototype or large scale production then we are providing reliable and efficient service that compete your business goal.

Discover why Epsilon Electronic is top choice for PCB manufacturing in Ahmedabad. Visit our website epsilonelectronic.in today for more detail on our service and then we are providing reliable and efficient service that compete your business goal.

#pcb assembly service provider#ems solution provides#pcb assembly service provider in gujarat#pcb assembly service provider in india#circuit design company in india#ems supplier in gujarat#pcb design company in india#pcb design company in gujarat#ems solution provider#ems supplier in india

0 notes