#Cobalt electron configuration

Explore tagged Tumblr posts

Text

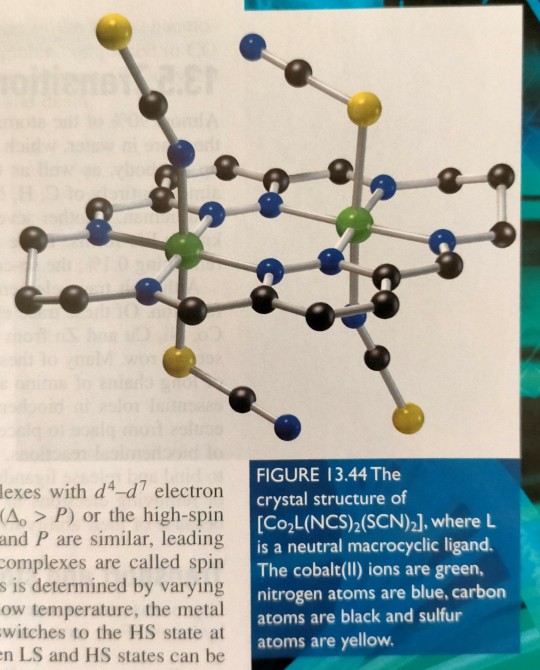

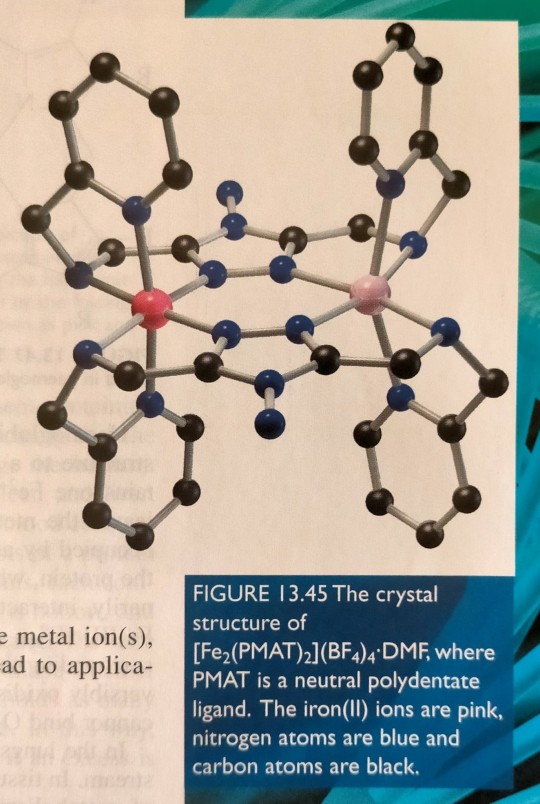

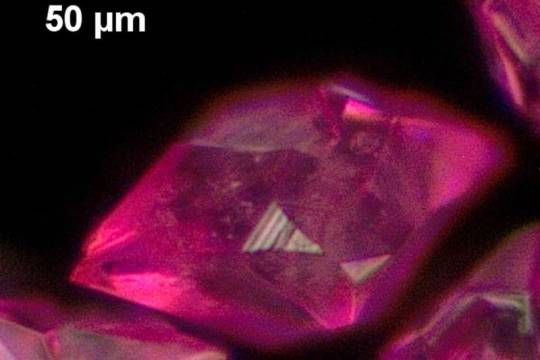

For example, we have observed unprecedented spin crossover behaviour in a dicobalt complex (figure 13.44), and more recently we have determined the crystal structure of an unused mixed spin state diiron complex (figure 13.45).

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#spin#electrons#electron configuration#crystal structure#cobalt#iron#nitrogen#carbon#sulfur

1 note

·

View note

Note

if you had to be a chemical element, i say you'd be cobalt (Co, atomic number 27). it's a burnt silver metal, blue in high temperatures. i think it fits you most. ;3

electron configuration is 1s2 2s2 2p6 3s2 3p6 4s2 3d7

WOOOOOOO COBALT YEAHHHH

5 notes

·

View notes

Text

Unplug and Unleash: The Ultimate Freedom of a 3000W LiFePO4 Portable Power Station

Charging station 220V 2688Wh 3000W Portable Power Station Lifepo4 Battery AC Outlet for Camping Energy Pure Sine Wave

👍👍Buy now: https://youtu.be/co6VzfjoXZs

🔥🔥 DISCOUNT: 60% 🔥🔥

The hum of modern life is the hum of electricity. From the smartphones that connect us to the refrigerators that preserve our food, we are a society tethered to the grid. But what if you could snip that cord, even for a little while, without sacrificing the essentials? What if you could power your adventures, safeguard your home from blackouts, and embrace a new level of energy independence? This isn't a futuristic dream; it's the reality offered by the new wave of high-capacity portable power stations, and a particular configuration is leading the charge: the 220V 2688Wh 3000W Portable Power Station with a LiFePO4 battery and Pure Sine Wave AC outlet.

For the uninitiated, that string of specifications might seem like technical jargon. But within those numbers and acronyms lies the key to unlocking a world of possibilities, whether you're a weekend warrior seeking the ultimate campsite upgrade, a digital nomad working from the wild, or a homeowner looking for reliable emergency backup. Let's demystify this powerhouse and discover why it's more than just a battery—it's a declaration of energy freedom.

The Heart of the Matter: Why LiFePO4 is a Game-Changer At the core of this portable power station is its LiFePO4 battery. For years, lithium-ion batteries have been the standard, but LiFePO4 (Lithium Iron Phosphate) is the safer, more durable, and more eco-friendly successor. Think of it as the difference between a standard car engine and a high-performance, long-lasting electric motor.

Here’s why LiFePO4 is the superior choice for a high-capacity power station:

Unmatched Safety: LiFePO4 batteries have a more stable chemical structure, making them far less prone to overheating and thermal runaway—a significant concern with traditional lithium-ion batteries. This inherent safety is crucial when you have a powerful energy source in your tent, RV, or home.

Incredible Lifespan: While a typical lithium-ion battery might offer 500-800 charge cycles, a LiFePO4 battery can be cycled thousands of times. This means your investment will last for years to come, providing reliable power for countless adventures and emergencies.

Deeper Discharge, More Usable Power: You can regularly discharge a LiFePO4 battery to 80-90% of its capacity without significantly degrading its health. Many other batteries are best kept above 50% to prolong their life, meaning you get more usable energy from a LiFePO4 of the same size.

Eco-Friendly: LiFePO4 batteries do not contain cobalt, a mineral often associated with unethical and environmentally damaging mining practices.

Deconstructing the Power: Understanding the Numbers Now, let's tackle those impressive figures: 2688Wh and 3000W.

2688Wh (Watt-hours): The Fuel in Your Tank: Watt-hours measure the battery's capacity—how much energy it can store. With a robust 2688Wh, you have a massive reservoir of power. To put that into perspective, you could:

Power a 60W portable fridge for over 44 hours.

Keep a 10W string of camping lights on for more than 11 days straight.

Recharge a smartphone (averaging 10Wh) over 250 times.

Run a CPAP machine (30-60W) for several nights.

3000W (Watts): The Engine's Horsepower: Watts measure the continuous power output—how much electricity the station can deliver at any given moment. A 3000W output is substantial, allowing you to run not just your small electronics but also high-draw appliances that would trip up lesser power stations. Think:

Coffee makers

Microwaves

Hairdryers

Power tools like drills and saws

Even some smaller air conditioners or heaters.

This combination of high capacity and high output is what elevates this power station from a simple charger to a true off-grid and emergency power solution.

The Purity of Power: Why a Pure Sine Wave Matters The final piece of the technical puzzle is the Pure Sine Wave AC outlet. When you plug an appliance into a wall outlet at home, you're getting a smooth, consistent flow of electricity known as a pure sine wave. Cheaper inverters in some power stations produce a "modified sine wave," which can be choppy and inconsistent.

For robust items like a simple light bulb, this might not be an issue. But for sensitive electronics like laptops, drones, cameras, and medical equipment, a modified sine wave can cause glitches, malfunctions, or even permanent damage. A Pure Sine Wave inverter ensures that the power flowing to your valuable devices is just as clean and reliable as what you get from the grid, protecting them from harm.

Your Campsite's New Best Friend Imagine your next camping trip. Instead of being limited to headlamps and a small portable speaker, you can have a truly comfortable and connected experience. With a 3000W LiFePO4 power station, you can:

Elevate Your Camp Kitchen: Brew fresh coffee in the morning, blend up a smoothie, or even use a small electric grill.

Create the Perfect Ambiance: Power string lights, a projector for an outdoor movie night, or a quality sound system.

Stay Connected (If You Want To): Keep all your devices—phones, laptops, cameras, and drones—fully charged and ready to go.

Extend Your Seasons: Run a small electric blanket or a fan to stay comfortable in cooler or warmer weather.

A Beacon of Light in a Blackout Beyond the campsite, this portable power station is an invaluable asset for your home. When a storm rolls in and the power goes out, you'll have a silent, fume-free source of energy to:

Keep Your Essentials Running: Power your refrigerator to prevent food spoilage, a sump pump to avoid flooding, or essential medical devices.

Stay Informed and Connected: Keep your Wi-Fi router, modem, and devices charged so you can access news and communicate with loved ones.

Maintain a Sense of Normalcy: Brew a cup of coffee, heat up a meal in the microwave, and keep some lights on for comfort and safety.

Unlike a gas-powered generator, a portable power station is safe to use indoors, requires no maintenance or flammable fuel, and operates silently. With the ability to recharge via a wall outlet before a storm or with solar panels during an extended outage, it offers true peace of mind.

The Dawn of Personal Energy Independence A 220V 2688Wh 3000W LiFePO4 portable power station is more than just a gadget; it's a tool of empowerment. It empowers you to explore further, to be more prepared, and to have greater control over your energy needs. It's the freedom to work from a mountaintop, the security of knowing your family will be safe during a power outage, and the convenience of modern amenities wherever you roam. So, unplug from the ordinary and unleash the extraordinary potential of portable power. Your adventures—and your peace of mind—will thank you for it.

#power_station#charging_station#power_supply#lifepo4_battery#solar_generator#camping#youtube#video#home

0 notes

Text

Empowering the Future: Refurbished Li-ion Battery Application and Lithium-Ion Battery Life Cycle Assessment

The world is racing towards electrified mobility—from scooters and motorcycles to electric buses, trucks, and even airplanes. At the heart of this revolution is the lithium-ion battery, a powerhouse that enables sustainable energy storage for electric vehicles (EVs), renewable energy grids, and consumer electronics. However, with the surge in demand for EVs—projected to rise by 35% in 2023 alone—comes an inevitable wave of retired batteries. Analysts predict that by 2030, retirements could exceed half a million vehicles annually, translating to over 2 million metric tonnes of batteries per year.

The question arises: How do we manage this massive influx of end-of-life batteries sustainably? At LOHUM, we believe that the answer lies in innovation and responsible lifecycle management—through Refurbished Li-ion Battery Application and lithium-ion battery life cycle assessment.

The Growing Need for Lithium-Ion Battery Recycling

According to the Environmental Protection Agency (EPA), recycling lithium-ion batteries is crucial not just for environmental reasons but also for resource optimization. These batteries contain valuable minerals like lithium, cobalt, nickel, and manganese, which are critical for the clean energy transition. Despite this, only about 5% of lithium-ion batteries are recycled globally, compared to the 99% recycling rate of lead-acid batteries.

The disparity is rooted in the complexity and cost of lithium battery recycling. Lithium is highly reactive, making the process delicate and demanding specialized recycling facilities. However, ignoring this issue is not an option. With EVs, solar grids, and energy storage solutions rapidly expanding, the demand for lithium is set to outpace mining capabilities. Establishing new mines is both costly and environmentally taxing, often leading to depleted water resources and polluted ecosystems.

This is where LOHUM steps in—not just as a recycler but as a leader in lithium-ion battery life cycle assessment. We aim to optimize every stage of a battery's life, from initial application to second-life usage and, eventually, recycling.

Refurbished Li-ion Battery Application: Extending the Lifecycle

At LOHUM, we are reimagining the life of lithium-ion batteries through Refurbished Li-ion Battery Application. Most EV batteries are considered "end-of-life" when their capacity drops below 80% of their original power. However, that remaining 80% is still substantial for less demanding applications. Through refurbishment, these batteries are repurposed for uses like:

Stationary energy storage for solar power systems.

Backup power for telecommunications and IT infrastructures.

Grid stabilization to enhance energy efficiency.

This second-life usage not only extends the lifecycle of the battery but also reduces the demand for freshly mined materials. In fact, batteries repurposed for stationary energy storage can last an additional 6 to 10 years, contributing significantly to sustainability goals.

LOHUM’s innovative refurbishment process involves:

Discharging and Safety Checks: Ensuring the battery is fully discharged and evaluated for safe handling.

Module and Cell Assessment: Identifying viable cells for repurposing.

Reconditioning and Reassembly: Assembling functional cells into new configurations suitable for secondary applications.

This model is a testament to LOHUM's commitment to lithium-ion battery life cycle assessment, optimizing every phase for maximum efficiency and minimum waste.

The Economics and Environmental Impact of Recycling

The economic incentive for lithium battery recycling is compelling. The three most expensive ingredients in a battery—cobalt, nickel, and lithium—represent nearly 50% of the total manufacturing cost. Global price volatility, sometimes fluctuating by 300% in a single year, adds even more pressure to find sustainable sources of these materials. Recycling not only helps stabilize costs but also reduces dependency on mining, which is often linked to conflict zones and harmful environmental practices.

LOHUM’s process involves:

Pyrometallurgy and Hydrometallurgy: For material recovery through high-temperature melting and chemical dissolution.

Direct Recycling Techniques: Retaining the cathode's structural integrity to reduce the need for energy-intensive refining.

In recent advancements, direct recycling methods have shown promise by refurbishing the cathode without breaking it down entirely, resulting in better battery performance and faster charging times. This method preserves the engineered structure of the cathode, making it as good as, if not better than, newly manufactured materials.

Policy and the Path Forward

The importance of sustainable recycling is increasingly recognized by governments. States like California are working on policies to ensure 100% of EV batteries are recycled or reused. At LOHUM, we are aligned with these global sustainability goals, leading the charge with innovative recycling technologies and efficient life cycle assessment.

Our approach to lithium-ion battery life cycle assessment is not just about recycling—it's about building a circular economy. With state-of-the-art technology and a forward-thinking mindset, LOHUM is redefining what it means to manage battery life sustainably.

LOHUM: Pioneering the Circular Economy of Lithium-Ion Batteries

At LOHUM, we are not merely recyclers—we are sustainability innovators. Our commitment to Refurbished Li-ion Battery Application and thorough lithium-ion battery life cycle assessment enables us to extend the life of valuable materials, reduce environmental impact, and contribute to the global push for cleaner energy.

By closing the loop on lithium-ion battery usage, LOHUM is empowering the shift towards electrified mobility with sustainable solutions that are not just good for business but essential for the planet.

Visit us at: Lithium-ion battery reuse value

Originally published on: Wix

#lohum#critical minerals#li-ion battery waste management#lithium battery reusing and recycling#battery waste management#lithium battery waste recycling#3 wheeler ev battery#reverse logistics for lithium-ion batteries

0 notes

Text

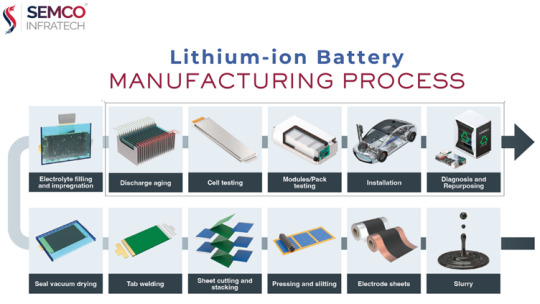

Step-by-Step Guide to Lithium Battery Pack Assembly and Cell Making Equipment

The rise of electric vehicles, renewable energy systems, and portable electronics has significantly increased the demand for lithium-ion batteries. But behind these powerful energy sources lies a highly intricate and controlled manufacturing process.

From raw materials to finished products, battery making machines and advanced battery making equipment are essential in ensuring efficiency, precision, and safety at every stage.

Understanding the Fundamentals

Before diving into the production process, it's crucial to understand the core components of a lithium-ion battery:

Positive Electrode: Made from materials such as lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), or lithium iron phosphate (LFP).

Negative Electrode: Typically composed of graphite.

Separator: A porous membrane that separates the electrodes while allowing lithium ions to flow.

Electrolyte: A gel or liquid that enables ion movement between electrodes.

Current Collectors: Usually, aluminium for the positive electrode and copper for the negative, these provide a conductive path for electrons.

The battery works through the reversible movement of lithium ions between electrodes. During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side—producing electrical energy.

The Lithium-Ion Battery Assembly Process: A Multi-Stage Journey

The lithium-ion battery assembly process can be categorized into three key stages:

1. Front-End: Electrode Manufacturing

This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell making machine workflow.

Slurry Preparation: Active materials (e.g., LCO or graphite) are mixed with binders like PVDF and conductive agents to form a uniform slurry.

Coating: The slurry is precisely applied to metal foils using high-precision battery-making equipment, ensuring uniform thickness.

Drying & Calendaring: Coated electrodes are dried to eliminate solvents and then compressed for better conductivity.

Slitting & Die Cutting: Electrodes are cut into specific dimensions to fit the battery cell, making machine specifications.

2. Middle-End: Cell Assembly

The second stage of the lithium-ion battery assembly process involves assembling the core components.

Winding/Stacking: Positive and negative electrodes are alternately layered with separators to form a cell stack.

Electrolyte Filling: The electrolyte is carefully injected into the cells to enable ion movement.

Sealing: The cells are sealed using heat or ultrasonic sealing to avoid leakage and ensure safety.

3. Back-End: Formation and Packaging

The final stage is about bringing the battery to life.

Formation: Cells undergo multiple charge-discharge cycles to stabilize their chemistry.

Testing & Sorting: Advanced battery making machines test each cell for voltage, capacity, and other parameters. Cells are then sorted accordingly.

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment.

Key Challenges in Lithium Battery Manufacturing

Quality Control: Every step, from mixing to testing, demands extreme precision.

Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

Environmental Responsibility: Managing chemical waste and emissions is critical for sustainability.

Technological Advancements: The demand for higher capacity and faster charging batteries drives constant innovation in battery making equipment.

Conclusion

The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge technology. With growing applications in EVs, consumer electronics, and energy storage, understanding this process—and the role of battery-making machines—is vital. As innovations continue to emerge, the evolution of lithium battery pack assembly will remain central to the future of sustainable energy solutions.

#battery making machine#battery making equipment#battery cell making machine#lithium ion battery assembly#lithium battery pack assembly#lithium ion battery assembly process#lithium ion battery manufacturing process

0 notes

Text

The main physical properties of rare earth metals

Rare earth metals as additives to magnesium, aluminum and their alloys, the first thing to consider is their density. The density depends on the relative atomic mass, atomic radius, and crystal structure of the rare earth metal. All rare earth metals have a close-packed hexagonal structure except for Europium, so their density depends on their relative atomic mass and atomic radius. Because of its small atomic weight, Scandium has a density of 2.989g/cm3, which is the smallest of all rare earth metals. It is approximately 70% higher than the density of magnesium (1.741 g/cm3) and approximately 10% higher than aluminum (2.7g/cm3). The density of Yttrium is 4.46g/cm3, which is larger than that of Scandium, but it has a smaller atomic weight than that of lanthanide, and is intermediate between scandium and lanthanide metals (from Lanthanum to Lutetium). Among all lanthanide metals, due to the shrinkage of the lanthanide series and the increase in atomic weight, their density generally increases with the increase of the atomic number, which increases by about 60% from Lanthanum to Lutetium. Europium and Ytterbium being exceptions, they have an unusually large atomic radius, and their density is smaller than that of their neighboring rare earth metals.

The rule that the melting point of lanthanide metals changes with atomic number is similar to the rule that the density of lanthanide metals increases with increasing atomic number, except for lanthanum metal. Starting from cerium, the melting point of lanthanide metals increases with increasing atomic number. The melting point from Cerium to Lutetium has increased by approximately 110%. However, this rule does not suitable for Europium and Ytterbium. The melting points of these two metals are lower than that of their neighboring rare earth metals. The melting point of yttrium is close to the middle value of the yttrium subgroup element. The melting point of Erbium is 1529°C, yttrium is 1522°C, and the melting point of scandium is 1541 ° C.

The melting heat and elastic modulus of lanthanide metals also show a similar law, which changes with the change of atomic number. The heat of fusion and the modulus of scandium and yttrium are within the limits of the yttrium subgroup element. However, there are cases that do not meet the above rules. The elastic modulus of Samarium is even lower than that of Promethium and Neodymium, and the heat of fusion of Europium is between of Promethium and Gadolinium. The explanations of these deviations can be attributed to the complex nature of the physical properties, they are caused by the different bonding forces between the atoms in the crystal structure. The specific heat of all rare earth metals is approximately the same. In short, all of these properties are related to the bonding forces between the atoms of the lanthanide crystal structure.

Rare earth metals have special properties due to their special electronic configuration. The 4f orbital electron's unique movements make the rare earth have different magnetic, optical, electrical and chemical properties than other elements. The spin and orbital motion of these electrons, the strong spin-orbit coupling effect, and the indirect interaction with the surrounding environment make the magnetic properties of rare earths different from those of group d transition elements such as iron, cobalt, and nickel. They have strong paramagnetic susceptibility, large magnetic saturation intensity, magnetic anisotropy, magnetostriction, magneto-optical rotation and large magnetic entropy effect, so that rare earths are widely used permanent magnet materials, magnetostrictive materials, magneto-optical materials, magnetic refrigeration materials.

https://www.etimaterials.org/rare-earth-elements/

0 notes

Text

Samsung Galaxy S24: Specifications Breakdown, FAQs, and More

Get it Now from Amazon with an Exclusive Discounts and Different Colors

Introduction

The Samsung Galaxy S24 represents the latest innovation in smartphone technology, offering cutting-edge features that cater to both tech enthusiasts and everyday users. This comprehensive guide will dive deep into the device’s specifications, performance, and answer the most burning questions potential buyers might have.

Detailed Specifications Breakdown

Design and Build -Dimensions: Approximately 147 x 70.6 x 7.6 mm - Weight:Around 167 grams - Build: Gorilla Glass Victus 2 front and back - Frame: Aluminum - Color Options: Phantom Black, Cobalt Purple, Amber Yellow, Jade Green

Display - Type: Dynamic AMOLED 2X - *Size: 6.2 inches (S24), 6.7 inches (S24+), 6.8 inches (S24 Ultra) - Resolution: 1080 x 2340 pixels (S24), 1440 x 3088 pixels (S24 Ultra) - Refresh Rate: Adaptive 120Hz - Peak Brightness: Up to 2,600 nits - HDR10+ Certified

Performance - Processor:Snapdragon 8 Gen 3 (Global variant) -CPU: Octa-core (1x3.39 GHz Cortex-X4 & 4x3.15 GHz Cortex-A720 & 3x2.85 GHz Cortex-A720 & 2x2.0 GHz Cortex-A520) - GPU: Adreno 750 - RAM: 8GB/12GB options - Storage: 128GB, 256GB, 512GB (UFS 4.0)

Camera System Rear Cameras: - Main Camera: 50 MP, f/1.8, OIS - Ultra-Wide: 12 MP, f/2.2 - Telephoto: 10 MP with 3x optical zoom - S24 Ultra Specific: 200 MP main camera, 50 MP periscope telephoto with 5x optical zoom

Front Camera: - 12 MP, f/2.2 - 4K video recording - Advanced AI-enhanced features

Battery and Charging - Capacity: 4,000 mAh (S24), 4,900 mAh (S24+), 5,000 mAh (S24 Ultra) - Charging: — 25W Fast Charging — 15W Wireless Charging — Reverse Wireless Charging - Charger: Not included in the box

Connectivity - 5G Support - Wi-Fi 6E - Bluetooth 5.3 - NFC - USB-C - Ultra-Wideband (UWB) Technology

Software - Operating System: Android 14 - One UI 6.1 - Guaranteed Android Updates: 4 years - Security Updates: 5 years

Additional Features - IP68 Water and Dust Resistance - In-display Fingerprint Sensor - Face Recognition - AI-powered Camera Features - Enhanced Privacy Controls

Get it Now from Amazon with an Exclusive Discounts and Different Colors

Frequently Asked Questions (FAQs)

1. What is the starting price of the Samsung Galaxy S24? Prices vary by region and configuration, but expect the base model to start around $799-$899 USD.

2. Does the Samsung Galaxy S24 support 5G? Yes, the Samsung Galaxy S24 series fully supports 5G networks across multiple bands.

3. How long will the Samsung Galaxy S24 receive software updates? Samsung guarantees 4 years of major Android updates and 5 years of security patches.

4. Is the charger included in the box? No, Samsung has removed the charger from the packaging to reduce electronic waste.

5. What are the primary AI features in the S24? Key AI features include: - Real-time translation - Advanced photo editing - Adaptive battery management - Contextual awareness - Enhanced voice assistant capabilities

6. How water-resistant is the Samsung Galaxy S24? The device has an IP68 rating, meaning it can withstand submersion in up to 1.5 meters of water for 30 minutes.

7. Can I expand the storage with a microSD card? No, the Samsung Galaxy S24 does not support microSD card expansion.

8. What makes the S24 Ultra different from the standard S24? The Ultra model offers: - Higher resolution main camera (200 MP) - Better zoom capabilities - More premium materials - S Pen stylus support - Larger display and battery

9. How good is the battery life? With adaptive 120Hz and efficient processor, expect a full day of moderate to heavy use. Battery life varies based on individual usage patterns.

10. Is wireless charging supported? Yes, the S24 supports both standard wireless charging (15W) and reverse wireless charging, allowing you to charge other devices.

Conclusion

The Samsung Galaxy S24 series represents a significant leap in smartphone technology, offering powerful performance, exceptional cameras, and innovative AI features. Whether you’re a photography enthusiast, a productivity professional, or a casual user, there’s a configuration that suits your needs.

Get it Now from Amazon with an Exclusive Discounts and Different Colors

Disclaimer: Specifications and prices are subject to change. Always verify the latest details with official Samsung sources.

0 notes

Text

Transition Metal Oxide Sensor Market, Key Players, Market Size, Future Outlook | BIS Research

A transition metal oxide (TMO) sensor is a type of gas sensor that utilizes the unique properties of transition metal oxides, such as zinc oxide (ZnO), titanium dioxide (TiO₂), and tin dioxide (SnO₂), to detect the presence of gasses in an environment. These sensors operate based on the change in electrical resistance of the metal oxide material when exposed to different gasses. When a target gas interacts with the surface of the oxide, it alters the electron density or oxygen ion concentration, leading to a measurable change in conductivity.

The global Transition Metal Oxide Sensor market for jewelry is projected to reach from $542.96 million in 2024 to reach $1,236.96 million by 2034. growing at a CAGR of 8.58% during the forecast period 2024-2034.

Transition Metal Oxide Sensor Overview

Transition metal oxides (TMOs) are a class of inorganic compounds formed by the reaction of transition metals with oxygen. These materials exhibit a wide range of physical and chemical properties, such as high electrical conductivity, catalytic activity, magnetic behavior, and optical characteristics.

Key Characteristics

Electronic Properties- TMOs often possess semiconducting behavior due to the unique electronic configuration of transition metals, which have partially filled d-orbitals.

Catalytic Activities- Many TMOs act as catalysts or catalyst supports in chemical reactions, especially in oxidation processes, due to their ability to change oxidation states easily.

Magnetic Properties- Some TMOs, such as iron oxides, exhibit magnetic behavior, which makes them valuable in applications like data storage and biomedical imaging.

Optical Properties- TMOs like titanium dioxide and zinc oxide have notable optical properties, including high refractive indices and UV absorption, making them useful in solar cells and UV protection applications.

Grab a look at our sample for the report click here!

Applications of Transition Metal Oxide Sensor Market

Gas Sensing- TMOs are widely used in gas sensors because of their ability to detect various gasses by changing their electrical resistance upon gas adsorption

Catalysis- TMOs are effective in catalytic reactions for energy conversion, environmental remediation, and chemical production, such as in photocatalysis for water splitting and air purification.

Energy Storage- TMOs play a role in energy storage systems, including batteries and supercapacitors, where they contribute to high energy density and fast charge/discharge rates.

Electronics and Optoelectronics- Due to their semiconducting properties, TMOs are utilized in electronic devices, such as transistors, diodes, and thin-film coatings in optoelectronic devices like LEDs and photovoltaic cells.

Demand – Drivers, Restraints, and Opportunities

Increasing demand for Environmental Monitoring

Growth of Automotive and Transportation Industry

Rising adoption in Industrial Safety

Improved Sensor Efficiency and Lower Cost

Grab a look at our report page click here!

Market Segmentation

1 By Application

Automotive Electronics

Energy

Environmental Monitoring

Industrial Safety

2 By Sensor Type

Gas Sensors

Humidity Sensors

Temperature Sensors

Others

3 By Material Type

Titanium Dioxide (TiO2) Sensors

Nickel Oxide (NiO) Sensors

Cobalt Oxide (Co3O4) Sensors

4 By Region

North America

Asia Pacific

Europe

Rest of the world

Visit our Electronics and Semiconductor Vertical Page !

Conclusion

In conclusion, the transition metal oxide sensor market is poised for significant growth, driven by rising demand for efficient, sensitive, and cost-effective gas sensing technologies across various industries, including environmental monitoring, healthcare, automotive, and consumer electronics. The unique properties of transition metal oxides, such as high sensitivity, selectivity, and stability, make them ideal for detecting a broad range of gasses at various concentration levels.

#transition metal oxide sensor market#transition metal oxide sensor report#transition metal oxide sensor industry

0 notes

Text

Nickel 200 Forged Fittings Suppliers

Nickel 200 is a commercially pure nickel alloy (with a minimum of 99% nickel content), known for its excellent mechanical properties, outstanding corrosion resistance, and high electrical and thermal conductivity. Nickel 200 forged fittings are widely used in industries where purity, corrosion resistance, and operational integrity are essential, especially in extreme temperatures and harsh chemical environments.

Key Properties of Nickel 200 Forged Fittings

High Purity and Corrosion Resistance: Nickel 200 is highly resistant to a wide range of corrosive environments, particularly in reducing environments such as acids and alkalis. Its resistance to caustic soda, sulfuric acid, and other aggressive chemicals makes it ideal for the chemical and food processing industries.

Thermal and Electrical Conductivity: The high thermal and electrical conductivity of Nickel 200 makes it useful in applications requiring good heat transfer and electrical performance. This is why it is frequently used in electrical and electronic components.

Magnetic and Ductile: Nickel 200 retains its magnetic properties even at low temperatures and exhibits good ductility, allowing for easy fabrication and forming, making it suitable for many types of forged fittings.

Excellent Mechanical Properties: Even at elevated temperatures (up to 600°F or 315°C), Nickel 200 maintains its mechanical strength, while also performing well in low-temperature and cryogenic applications.

Applications of Nickel 200 Forged Fittings

Nickel 200 forged fittings are used in a variety of industries due to their excellent corrosion resistance, high thermal conductivity, and durability. Common applications include:

Chemical Processing: Nickel 200 is widely used in the handling of caustic alkalis, chlorine, and other aggressive chemicals in chemical processing plants. The fittings are used in pipe systems, reactors, and heat exchangers.

Food Processing: Due to its non-toxic and non-contaminating properties, Nickel 200 is used in food processing equipment, especially in environments where sodium hydroxide or other caustic solutions are present.

Electrical and Electronics: Nickel 200’s high electrical conductivity makes it ideal for electrical and electronic components like connectors, terminals, and batteries.

Aerospace and Marine: Its resistance to saltwater corrosion makes Nickel 200 fittings suitable for marine environments and aerospace applications that involve high-performance requirements.

Pharmaceutical and Petrochemical Industries: Nickel 200 fittings are used in pharmaceutical manufacturing and petrochemical processing, where chemical purity and corrosion resistance are paramount.

Types of Nickel 200 Forged Fittings

Nickel 200 forged fittings are available in various types and configurations to accommodate different piping systems and operational needs. Some common types include:

Elbows: Used to change the direction of flow in piping systems.

Tees: Facilitate the branching of pipe sections to redirect flow.

Couplings: Join two pipes together, often used for easy pipe assembly.

Unions: Provide easy assembly and disassembly in piping systems, allowing for quick maintenance or replacement of parts.

Reducers: Help transition between different pipe sizes while maintaining flow efficiency.

Crosses: Enable a four-way junction for complex piping systems.

Specifications of Nickel 200 Forged Fittings

Nickel 200 forged fittings must adhere to specific industry standards and specifications to ensure their reliability in demanding applications. Below are some of the key specifications:

Chemical Composition

Nickel 200 has a simple and highly pure composition:

Nickel (Ni): 99.0% minimum

Cobalt (Co): 0.25% maximum

Manganese (Mn): 0.35% maximum

Carbon (C): 0.15% maximum

Sulfur (S): 0.01% maximum

Silicon (Si): 0.35% maximum

Iron (Fe): 0.40% maximum

This composition ensures the high purity of Nickel 200, which is key to its performance in corrosive environments.

Mechanical Properties

Tensile Strength (MPa): 415 MPa minimum

Yield Strength (MPa): 103 MPa minimum

Elongation: 40% minimum

Hardness: 110 HB (Brinell Hardness)

These properties allow Nickel 200 forged fittings to maintain strength and flexibility even under high-stress conditions.

Standards and Grades

Nickel 200 forged fittings are produced according to internationally recognized standards to ensure reliability in various industrial applications:

ASTM B564: This standard outlines the specifications for nickel alloy forgings.

ASME SB564: This is the corresponding ASME standard for nickel forgings used in pressure piping systems.

ASME B16.11: Specifies the dimensional standards for forged fittings used in pressure systems.

MSS-SP-79, MSS-SP-83, MSS-SP-95: Cover socket weld and threaded forged fittings.

Dimensional Specifications

Nickel 200 forged fittings are available in various pressure classes and sizes, depending on the requirements of the piping system:

Sizes: 1/8" NB to 4" NB

Pressure Classes: Class 2000, 3000, 6000, and 9000

Connection Types: Available in socket weld and threaded connection types.

Corrosion Resistance of Nickel 200 Forged Fittings

Nickel 200 exhibits excellent resistance to a variety of corrosive media, making it a superior choice for demanding environments:

Caustic Alkalis: Nickel 200 is particularly resistant to alkalis such as caustic soda, even at high concentrations and temperatures.

Acid Resistance: The alloy shows good resistance to neutral and mildly acidic environments.

Seawater Resistance: Nickel 200 performs well in marine environments due to its ability to resist saltwater corrosion.

Oxidizing Environments: In oxidizing conditions, Nickel 200 forms a protective oxide layer that prevents further corrosion.

Temperature Range

Nickel 200 forged fittings are designed to withstand a wide range of temperatures:

Operational Temperature Range: From cryogenic temperatures to around 600°F (315°C), Nickel 200 maintains its mechanical integrity and corrosion resistance.

Testing and Quality Control

To ensure the highest quality and safety standards, Nickel 200 forged fittings undergo rigorous testing, including:

Hydrostatic Testing: Ensures the fittings can withstand pressure without leaks or structural failures.

Non-Destructive Testing (NDT): Techniques such as ultrasonic or radiographic inspection ensure there are no internal defects.

Mechanical Testing: To verify tensile strength, yield strength, and elongation properties.

Chemical Composition Testing: Verifies the purity and chemical makeup of the alloy to ensure compliance with standards.

0 notes

Text

New 12V 24V 48V 100Ah 200Ah 280Ah 300Ah 400Ah LiFePO4 Battery Built-in BMS Rechargeable Battery for Inverter Solar RV No Tax

New 12V 24V 48V 100Ah 200Ah 280Ah 300Ah 400Ah LiFePO4 Battery Built-in BMS Rechargeable Battery for Inverter Solar RV No Tax

👉👉Buy now: https://youtu.be/sWwX5vs5Nvc

🔥🔥 Discount: 50% 🔥🔥

In recent years, the demand for reliable, efficient, and long-lasting power solutions has surged across various industries, from renewable energy systems to recreational vehicles (RVs). Among the top contenders in the battery technology market, Lithium Iron Phosphate (LiFePO4) batteries have quickly become the preferred choice for many applications. These batteries, available in multiple configurations like 12V, 24V, and 48V with capacities ranging from 100Ah to 400Ah, are now revolutionizing how we power our inverters, solar systems, and RVs. This blog post delves into why LiFePO4 batteries with built-in Battery Management Systems (BMS) are the best investment for your power needs, especially with the added benefit of no tax.

What is LiFePO4 Battery Technology? LiFePO4 stands for Lithium Iron Phosphate, a type of lithium-ion battery. Unlike traditional lead-acid batteries, LiFePO4 batteries offer superior safety, longer life cycles, and higher energy densities. These attributes make them an excellent choice for applications requiring reliable and sustainable power, such as solar energy systems, RVs, marine applications, and backup power supplies.

LiFePO4 batteries are known for their stability and safety. The use of iron phosphate as the cathode material ensures that the battery is less prone to overheating and thermal runaway, making them safer compared to other lithium-ion batteries like Lithium Cobalt Oxide (LCO) batteries. Additionally, LiFePO4 batteries have a longer cycle life, with many lasting up to 4,000 cycles or more, translating to a lifespan of up to 10 years or more under normal usage.

Voltage and Capacity Options: Tailored for Every Need One of the key features of LiFePO4 batteries is their versatility. They come in various voltage and capacity configurations, such as 12V, 24V, and 48V, with capacities ranging from 100Ah to 400Ah. This variety allows users to choose the right battery for their specific application, whether it’s powering a small RV or an extensive solar energy system.

12V LiFePO4 Batteries: Ideal for smaller applications like RVs, boats, and small solar setups. A 100Ah 12V battery can easily replace a traditional lead-acid battery, offering more energy storage, faster charging times, and significantly longer life.

24V LiFePO4 Batteries: Commonly used in larger RVs, off-grid solar systems, and some electric vehicles. A 24V battery system provides higher power output, making it suitable for more energy-intensive applications.

48V LiFePO4 Batteries: Perfect for large-scale solar installations, commercial energy storage systems, and high-power inverters. These batteries can handle large loads with ease, making them ideal for situations where consistent and reliable power is crucial.

High Capacity Options (200Ah, 280Ah, 300Ah, 400Ah): These high-capacity batteries are designed for applications that require extended power supply durations, such as off-grid living, backup power for homes, and long-term RV trips. With capacities up to 400Ah, these batteries can store vast amounts of energy, reducing the need for frequent recharging.

Built-in Battery Management System (BMS): Ensuring Safety and Efficiency One of the standout features of modern LiFePO4 batteries is the inclusion of a built-in Battery Management System (BMS). The BMS is an electronic system that manages the battery’s performance by monitoring key parameters such as voltage, current, and temperature. It plays a critical role in ensuring the safety, efficiency, and longevity of the battery.

The BMS protects the battery from overcharging, over-discharging, overheating, and short circuits. It ensures that the battery operates within safe limits, preventing damage and extending its lifespan. This is particularly important for applications like inverters and solar systems, where the battery is subjected to varying loads and environmental conditions.

Additionally, the BMS helps in balancing the cells within the battery, ensuring that all cells charge and discharge at the same rate. This balancing act is crucial for maintaining the overall health of the battery and maximizing its usable capacity.

Applications of LiFePO4 Batteries LiFePO4 batteries are incredibly versatile and can be used in a wide range of applications. Here are some of the most common uses:

Solar Energy Storage: LiFePO4 batteries are perfect for storing energy generated by solar panels. Their high efficiency and long cycle life make them ideal for both residential and commercial solar energy systems. With capacities up to 400Ah, these batteries can store enough energy to power a home or business during the night or during periods of low sunlight.

Inverter Systems: For those who rely on inverters to convert DC power to AC power, LiFePO4 batteries offer a reliable and long-lasting power source. Whether you’re using an inverter for home backup power or off-grid living, a LiFePO4 battery ensures you have a steady and dependable supply of energy.

Recreational Vehicles (RVs): RV enthusiasts are increasingly turning to LiFePO4 batteries to power their vehicles. These batteries are lightweight, have a compact design, and offer a much longer lifespan than traditional lead-acid batteries. With a LiFePO4 battery, you can enjoy longer trips without worrying about recharging.

Marine Applications: LiFePO4 batteries are also popular in the marine industry. They provide reliable power for boats, yachts, and other marine vessels, ensuring that essential systems like navigation, lighting, and communication are always operational.

Backup Power Systems: Whether for homes, businesses, or critical infrastructure, LiFePO4 batteries provide a dependable source of backup power. Their long cycle life and ability to discharge deeply without damage make them ideal for situations where uninterrupted power is essential.

Environmental Benefits LiFePO4 batteries are not only efficient but also environmentally friendly. Unlike lead-acid batteries, they do not contain toxic lead or sulfuric acid, making them safer for both users and the environment. Additionally, their long lifespan reduces the need for frequent replacements, minimizing waste and the environmental impact associated with battery disposal.

No Tax Benefit One of the added advantages of purchasing these LiFePO4 batteries is the “No Tax” benefit offered by some sellers. This can significantly reduce the overall cost of the battery, making it an even more attractive investment. For businesses and consumers looking to adopt green energy solutions, the combination of advanced technology, long-term savings, and no tax makes LiFePO4 batteries a smart choice.

Conclusion In conclusion, LiFePO4 batteries are a game-changer in the world of energy storage and power supply. Their versatility, safety features, and long lifespan make them ideal for a wide range of applications, from solar energy systems to RVs and inverters. With the added benefit of no tax, there has never been a better time to invest in a LiFePO4 battery. Whether you’re looking to power your home, business, or next adventure, a LiFePO4 battery provides the reliability and performance you need to stay powered up, no matter where life takes you.for a Sustainable Future The new 12V, 24V, and 48V LiFePO4 batteries are more than just an upgrade—they are a revolution in energy storage technology. With their built-in BMS, these batteries offer enhanced safety, longer life, and greater efficiency, making them a smart choice for anyone looking to invest in sustainable energy solutions. Whether you’re an RV enthusiast, a homeowner with a solar system, or a business owner aiming to reduce energy costs, these batteries are a reliable, cost-effective, and eco-friendly option that will serve you well for years to come.

Investing in LiFePO4 technology today means embracing a future where energy storage is safer, more efficient, and more accessible. With capacities ranging from 100Ah to 400Ah and no tax in many regions, there has never been a better time to make the switch. These batteries are not just a purchase; they are an investment in a cleaner, more sustainable world.

#battery#lithium_battery#solar_battery#power_station#12v#24v#48v#home#car#power_supply#solar_generator#camping

1 note

·

View note

Text

APPLICATIONS OF CYLINDRICAL CELL MODULES

Cylindrical cell modules have emerged as key components in various industries, powering everything from electric vehicles to portable electronic devices. These modules, comprised of cylindrical lithium-ion cells, offer a compact and efficient solution for energy storage needs.

At the heart of cylindrical cell modules are individual cylindrical lithium-ion cells, which contain a positive electrode (cathode), a negative electrode (anode), and an electrolyte. These cells are typically arranged in a cylindrical format and connected in series and parallel configurations to form a module. The cylindrical design allows for efficient packing density and thermal management, making it a preferred choice for many applications.

Recent years have witnessed significant advancements in cylindrical cell module technology, driven by research and development efforts aimed at improving performance, safety, and longevity. One notable advancement is the development of high-energy-density cathode materials, such as lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminum oxide (NCA). These materials allow for increased energy storage capacity without compromising on safety or cycle life.

Additionally, innovations in electrolyte formulations and cell chemistry have led to improvements in thermal stability and rate capability, enabling faster charging and discharging rates while small the risk of overheating or thermal runaway.

0 notes

Text

What are the Properties of Transition Elements?

Transition elements, also known as transition metals, are a group of chemical elements found in the periodic table. They occupy the middle section, spanning Groups 3 to 12, between the alkaline earth metals and the post-transition metals. These elements possess unique properties that make them distinct from other elements.

We will explore the electronic configuration and properties of transition elements. We will also delve into the concept of ionization enthalpy and its significance. By the end of this article, you will have a comprehensive understanding of transition elements and their role in various chemical processes.

Transition elements are a fascinating group of elements found in the middle of the periodic table. Unlike other elements, they have unique characteristics, making them stand out in the world of chemistry. What makes them special is their partially filled d-orbitals, which allow them to exhibit various oxidation states and form colorful compounds.

Properties of Transition Elements

Transition elements possess several notable properties that distinguish them from other groups of elements. Some key properties include:

Variable Oxidation States: Transition elements can exhibit multiple oxidation states due to the availability of both ns and (n-1)d electrons. This versatility allows them to form various types of compounds and participate in diverse chemical reactions.

Complex Formation: Transition elements readily form stable complexes by coordinating with ligands. These complexes exhibit unique colors and play crucial roles in biological processes, industrial applications, and catalysis.

High Melting and Boiling Points: Compared to most other elements, transition metals have higher melting and boiling points. This property makes them suitable for applications in high-temperature environments.

Good Conductors of Heat and Electricity: Transition metals possess high thermal and electrical conductivity. This property makes them valuable in electrical wiring, heat sinks, and other related applications.

Magnetic Properties: Several transition elements, such as iron, cobalt, and nickel, exhibit magnetic properties. They can easily align their magnetic moments in the presence of an external magnetic field.

Catalytic Activity: Transition metals and their compounds serve as catalysts in numerous chemical reactions, facilitating the conversion of reactants into desired products. Their ability to alternate between different oxidation states makes them especially effective in catalytic processes.

These properties make transition elements essential in various fields, including chemistry, materials science, medicine, and technology.

Transition elements play a crucial role in various facets of our lives. From their presence in everyday objects, such as electrical wires and magnets, to their utilization in industrial processes and life-saving medications, the impact of these elements is undeniable.

By comprehending the properties and electronic configurations of transition elements, we can deepen our understanding of the chemical world and appreciate the wonders of chemistry that surround us.

Are you eager to effortlessly grasp concepts, just like the explanation provided above? Dive into our Tutoroot Blog section for simplified learning. Enhance your understanding of subjects and clarify any doubts with Tutoroot online tuition. Immerse yourself in Tutoroot’s online home tuitions now by scheduling a FREE DEMO session.

0 notes

Text

Barrier Innovation: Revolutionizing Medical Implant Packaging

Materials and Processes for Medical Implant Packaging

The materials used for medical implant sterile packaging must meet strict biocompatibility and sterilization requirements. The primary materials used are polymeric films, paper, nonwoven composites and tyvek. Polymeric films such as PVC, PET and polyolefin films offer high strength, sealability and barrier properties. However, polymeric films may leach extractables which is a concern for medical applications. Tyvek is a spunbonded polyethylene fabric that is strong, tear resistant and breathable. It is commonly used as a sterile barrier in packaging. Paper provides printability and is more economical but needs to be properly coated or laminated to prevent wetting issues during sterilization. Nonwoven composites offer textile-like handle and moisture resistance. The materials undergo extensive testing to ensure they do not interact or leach harmful substances to packaged medical implants.

The various processes used in manufacturing medical implant sterile packaging include forming, sealing, sterilization and validation. Thermal and ultrasonic sealing technologies are commonly used to seal the packaging laminates. Etching and inkjet printing provide product information directly onto the packaging materials. Sterilization is a crucial step to kill all microorganisms and spores. Common sterilization methods are gamma irradiation, E-beam and steam sterilization. Automated packaging lines with aseptic isolation zones and strict control over materials and processes ensure product and personnel protection during packaging operations. Final product testing and validation ensure the packaged products maintain predefined shelf life and performance standards under normal distribution and storage conditions.

Design of Medical Implant Packages

The design of medical implant packages focuses on protecting the sterility and functional integrity of the packaged product from point of sterilization to surgery. Different packaging configurations are used based on the nature of implant - for eg. folded peel pouches for sheets/meshes and rigid trays or thermoformed clamshells for orthopedic implants. Peel pouches made of laminated nonwoven-film provide easy access while maintaining sterility. Rigid trays have wells or cavities to hold prosthetics securely in place. Lid stock made of paper or plastic seals the tray. Blister packs using PVC or Tyvek backing incorporated with lidding film are used for small medical devices and implants.

Tamper evident seals and security seals ensure package integrity from manufacture to use. Perforation or score lines in lidding film allow for easy but controlled peeling open. Complex contours and narrow flanges in thermoformed packaging facilitate proper placement of irregularly shaped implants. Special features like tethers prevent loss of small components during opening. Process challenge devices inside final packages validate the sterilization process. Printed indicators reveal if package was subject to deleterious conditions during shelf life or transportation. Detailed protocols are established for package design testing, design validation and review.

Sterilization and Shelf Life

Gamma irradiation from radioactive cobalt-60 isotope is the most widely used method for sterilizing loaded medical implant sterile packaging as it penetrates deep and guarantees sterilization. E-beam irradiation uses high energy electron beam for better penetration compared to gamma but requires special shielding. Steam sterilization at elevated temperature and pressure destroys bacteria and spores on package surfaces. The packaging materials and seal integrity are tested to withstand defined sterilization protocols without deterioration.

Sterilized packages are assigned expiration dating based on extensive real time and accelerated aging studies under controlled warehouse conditions. This established shelf life could be 2-3 years under recommended storage of 15-30°C and <60% relative humidity as per AAMI/ISO 11607 standards. Periodic shelf life extension programs involve further testing packages pulled from distribution to validate if shelf life can be safely extended based on package condition. Proper distribution and warehousing under standardized conditions are key to maintain product safety and efficacy till expiry date.

Quality and Regulatory Compliance

Medical implant sterile packaging operations are conducted under strictly controlled environments with ISO classified clean rooms. Robust quality systems adhering to ISO 13485 and applicable medical device directives ensure consistent production. Automated packaging lines with in-built monitoring and sensors help achieve reproducible results. Periodic preventive maintenance and calibration exercises maintain equipment quality.

Comprehensive design controls and review processes validate package functionality as per design inputs. Sterilization validation involves biological indicators to prove sterilizing dose and cycle. Shelf life studies statistically establish expiration periods. Package testing includes barrier properties, strength, extractable and particulate contamination testing. Sterilization and packaging processes are periodically re-qualified. Distribution simulation involves package testing after transit shock and vibration. Strict document controls ensure batch traceability. Regular audits and regulatory inspections help maintain high quality and compliance standards. This focus on quality ultimately ensures patient safety with effective and reliable medical implant sterile packaging. Conclusion

With increasing sophistication of medical implant technology, sterile packaging plays a more crucial role in maintaining the efficacy and shelf life of these lifesaving products. Package designs must address complex implant geometries while guaranteeing sterility. Choosing right materials becomes even more important with new generation of biocompat

0 notes

Photo

Electrocatalysis: Iron and cobalt oxyhydroxides examined

Very soon, we need to become fossil free, not only in the energy sector, but in industry as well. Hydrocarbons or other raw chemicals can be produced in principle using renewable energy and abundant molecules such as water and carbon dioxide with the help of electrocatalytically active materials. But at the moment, those catalyst materials either consist of expensive and rare materials or lack efficiency.

A team led by Dr. Prashanth W. Menezes (HZB/TU-Berlin) has now gained insights into the chemistry of one of the most active catalysts for the anodic oxygen evolution reaction (OER), which is a key reaction to supply electrons for the hydrogen evolution reaction (HER) in water splitting. The hydrogen can then be processed into further chemical compounds, e.g., hydrocarbons. Additionally, in the direct electrocatalytic carbon dioxide reduction to alcohols or hydrocarbons, the OER also plays a central role.

A highly promising class of electrocatalysts for OER are Cobalt-Iron Oxyhydroxides. The scientists analyzed a series of LiFe1-xCox borophosphates at BESSY II with different spectroscopy techniques to determine the oxidation states of the element Iron (Fe) in different configurations.

Read more.

25 notes

·

View notes

Photo

First Look: The Mustang Mach-E 1400 Prototype

Ford introduces Mustang Mach-E 1400, an all-electric road rocket that shows just how much performance can be harnessed without using a drop of fuel. This one-off Mustang Mach-E with its seven electric motors and high downforce is ready for the track, drag strip or gymkhana course – anywhere it can show how electric propulsion promises extreme Mustang performance.

Developed in collaboration with RTR and built off a Mustang Mach-E GT body-in-white, the prototype targets 1,400 peak horsepower (1,419 PS). The chassis and powertrain work together for a multitude of setups offering capability unlike any other vehicle.

The Mustang Mach-E 1400 is the result of 10,000 hours of collaboration by Ford Performance and RTR aimed at bridging the gap between what an electric vehicle can do and what customers tend to believe it can do.

Mustang Mach-E 1400 has taken shape without rules. The Ford design team and RTR used many of the same tools Ford uses for its race cars and production programs. Aerodynamics are optimized for shape and location, with a focus on cooling ducts, front splitter, dive planes and rear wing.

Mustang Mach-E 1400 has seven motors – five more than even Mustang Mach-E GT. Three are attached to the front differential and four are attached to the rear in pancake style, with a single driveshaft connecting them to the differentials, which have a huge range of adjustability to set the car up for everything from drifting to high-speed track racing.

The chassis and powertrain are set up to allow the team to investigate different layouts and their effects on energy consumption and performance, including rear-wheel drive, all-wheel drive and front-wheel drive. Drift and track setups have completely different front end configurations like control arms and steering changes to allow for extreme steering angles in drifting. Power delivery can be split evenly between front and rear, or completely to one or the other. Downforce is targeted at more than 1,000 kg at 257 km/h (160 mph).

The 56.8-kilowatt-hour battery (installed) is made up of nickel manganese cobalt pouch cells for ultra-high performance and high discharge rate. The battery system is designed to be cooled during charging using a di-electric coolant, decreasing the time needed between runs.

An electronic brake booster is integrated to allow series regenerative braking combined with ABS and stability control to optimize the braking system. Mustang Mach-E 1400 features Brembo brakes, like the Mustang GT4 race car, and a hydraulic handbrake system designed for drifting that integrates with the powertrain controls to enable the ability to shut off power to the rear motors.

Mustang Mach-E 1400, which is set to debut at a NASCAR race soon, serves as a test bed for new materials. The hood is made of organic composite fibers, a lightweight alternative to the carbon fiber that comprises the rest of the vehicle.

#Mustang Mach-E 1400 Prototype#cars#ford#mustang#Mach-E 1400 Prototype#news#first look#prototypes#Mustang Mach-E 1400#electric#ford performance

90 notes

·

View notes

Text

What are the basic applications in coordination compounds?

Let's start by defining a coordination compound or complex. A coordination complex is made up of a core atom or ion called the coordination center, which is generally metallic, and a surrounding array of bonded molecules or ions called ligands or complexing agents. Coordination complexes are found in many metal-containing compounds, particularly those containing transition metals (d block elements). Because coordination complexes are so common, their reactions and structures are explained in a variety of ways, which can be confusing. The donor atom is the atom in a ligand which is bound to the central metal atom or ion. A metal ion is linked to many donor atoms in a typical complex, which might be the same or different. A polydentate (many bonded) ligand is a molecule or ion having numerous bonds to the core atom; ligands with 2, 3, 4, or even 6 connections to the central atom are frequent. These complexes are identified as chelate complexes, and the method of forming them is known as complexation, chelation, and coordination.

Coordination means the "coordinate covalent bonds" between the ligands and the central atom. This is the dipolar link. Initially, a complex meant that such weak chemical connections involved a reversible combination of molecules, atoms or ions. This notion has evolved in terms of coordination chemistry. Certain metal complexes are almost permanently generated and many are linked by strong bonds. Coordination number is the number of donor atoms connected to the center atom or ion. There are 2, 4 and notably 6 as the most prevalent coordinating number.

In coordination chemistry, the number of ligands attaching to the metal is characterized initially by its coordinating number (more specifically, the number of donor atoms). You can usually count the connected ligands, but occasionally even the count may be confusing. There are typically two to nine coordination numbers, although for lanthanides and actinides a great number of ligands is not unusual. The number of bonds depends on the metal ion and the ligands' size, charging and electron configuration. More than one coordinating number can be used for metal ions. The chemistry of metal transition complexes is generally controlled by the interactions between s and p of the donor-atom molecular orbits of the ligand and the ion orbit. 18 electrons can be used in the metal orbitals s, p and d. The maximal coordinate number for a given metal thus is associated with the metal ion's electronic state and with the ligand size and metal ion ratio. The high coordination numbers result in large metals and small ligands. Low coordination results from small metals with large ligands. Lanthanides, actinides and early transition metals tend to have high amounts of coordination due to their enormous size.

Application of coordination compounds

· Coordinating complexes provide either structural or catalytic functions in bioinorganic chemistry and bio-organometallic chemistry. The proteins include ions of metal estimated at 30 per cent. For example, heme group haemoglobin, cytochromes, chlorophyll chlorine and carboxypeptidase are highly colored, an essential hydrolytic enzyme for digesting. Examples included: Catalase, which decomposes hydrogen peroxide from the cells, is another complex ion enzyme. Synthetic coordination chemicals are also utilized to bind protein and nucleic acids in particular.

· For determining water hardness EDTA is another complicated substance that we employ. The application of coordination compounds as catalysts also involves their use. Today, the polymer sector is also growing increasingly popular.

· The main application of coordination compounds to the synthesis of organic molecules is homogeneous catalysis. Hydrogenation, hydroformylation, oxidation are all processes. For instance, Ziegler-Natta-catalysts are used to polymerize ethylene and propylene to provide polymers of commercial value such fibers, film and plastics, with a mixture of titanium trichlorides and trihyl Aluminum.

· Using hydrometallurgical procedures with complex ions, nickel, cobalt and copper may be extracted. They are mined as ammine complexes from their ores. The selective precipitation and the solubility of complex ions may also be used to separate metals. Cyanide is mainly utilized for gold and silver extraction from their ores.

· In biological systems, coordination molecules are important. Chlorophyll is a coordinated compound of magnesium and is the primary pigment for photosynthesis. A coordination compound of iron is haemoglobin, a red blood pigment that works as oxygen carrier. Cobalt coordination compound is vitamin B12, cyanocobalamine, an anti-pernicious anaemia factor. The enzymes such as carboxypeptidase A and carbonic anhydrase (catalysts of biological systems) are among those of biological relevance with coordinated metal ions.

· Complex formation is used in certain major metal extraction procedures, such as silver and gold extraction. Gold, for instance, forms the coordinator [Au(CN)2]- in aceous solution in the presence of oxygen and water. Gold, by adding zinc, may be separated into metallic zinc fro.

· With increasing synthesis of coordination compounds, scientists and engineers now have a range of possibilities to improve and optimize operations.

Please visit doubtnut.com to know more.

#applications in coordination compounds#coordination compounds#ncert solutions#ncert syllabus#cbse#chemistry#chemistry solutions

4 notes

·

View notes