#Compatibility agents for pesticides

Explore tagged Tumblr posts

Text

Agricultural Activator Adjuvants: Enhancing Efficiency and Sustainability

Outline of the Article

Introduction to Agricultural Activator Adjuvants

What are agricultural activator adjuvants?

Importance in modern agriculture.

Types of Agricultural Activator Adjuvants

Surfactants

Oils

Drift Control Agents

Compatibility Agents

Role and Benefits of Agricultural Activator Adjuvants

Enhancing pesticide efficacy

Improving plant uptake

Reducing pesticide drift

Ensuring compatibility with tank mixtures

Market Trends and Growth Drivers

Increasing adoption of precision farming techniques

Growing demand for sustainable agricultural practices

Rise in research and development activities

Key Players in the Agricultural Activator Adjuvants Market

Analysis of major companies and their market share

Overview of their product offerings and strategies

Regional Analysis

Market landscape in North America, Europe, Asia Pacific, and other regions

Factors influencing market growth in each region

Challenges and Restraints

Regulatory hurdles and compliance issues

Concerns regarding environmental impact

Future Outlook and Opportunities

Emerging trends and innovations

Potential for market expansion

Case Studies and Success Stories

Real-world applications of agricultural activator adjuvants

Impact on crop yield and farm profitability

Environmental Sustainability and Safety Considerations

Eco-friendly formulations

Risk mitigation strategies

Consumer Awareness and Education

Importance of educating farmers about adjuvant selection and usage

Promoting responsible stewardship practices

Industry Collaboration and Partnerships

Collaborative efforts between manufacturers, farmers, and regulatory bodies

Sharing best practices and knowledge exchange

Market Forecast and Analysis

Predictions for market growth and revenue projections

Factors influencing market dynamics in the forecast period

Investment Opportunities and Market Entry Strategies

Potential for new entrants

Investment avenues for existing players

Conclusion

Recap of key points

Summary of market outlook and recommendations for stakeholders

Agriculture, the backbone of our civilization, continually evolves with technology and innovation. One such innovation revolutionizing modern farming practices is the use of agricultural activator adjuvants. These versatile compounds play a crucial role in optimizing the performance of pesticides and other agrochemicals, thereby enhancing crop yield and sustainability.

What are Agricultural Activator Adjuvants?

Agricultural activator adjuvants are additives formulated to improve the efficacy and performance of pesticides, herbicides, and fertilizers. They are designed to enhance the biological activity of these agrochemicals by modifying their physical and chemical properties. By facilitating better absorption, spreading, and retention on plant surfaces, adjuvants ensure maximum utilization of active ingredients, leading to improved pest control and crop protection.

Importance in Modern Agriculture

In today's agricultural landscape, where farmers face escalating challenges such as pest resistance, environmental concerns, and stringent regulations, the role of adjuvants becomes increasingly critical. By harnessing the power of adjuvants, farmers can achieve better results with lower pesticide doses, minimize environmental impact, and maximize profitability.

Types of Agricultural Activator Adjuvants

Surfactants

Surfactants are one of the most commonly used adjuvants in agriculture. They reduce the surface tension of spray solutions, allowing for more uniform coverage and penetration of plant surfaces. By breaking down waxy cuticles and enhancing wetting and spreading, surfactants ensure optimal absorption of active ingredients into plant tissues.

Oils

Oil-based adjuvants, such as crop oils and mineral oils, act as carriers for pesticides and improve their adherence to plant surfaces. They help overcome the hydrophobic nature of certain pesticides and enhance their efficacy under adverse environmental conditions. Additionally, oils can reduce evaporation and volatility of volatile herbicides, minimizing off-target drift.

Drift Control Agents

Drift control agents are formulated to reduce the risk of pesticide drift during application. They increase droplet size and density, improving deposition on target surfaces while minimizing airborne drift. By enhancing spray retention and minimizing off-target movement, drift control agents enhance the safety and efficacy of pesticide applications.

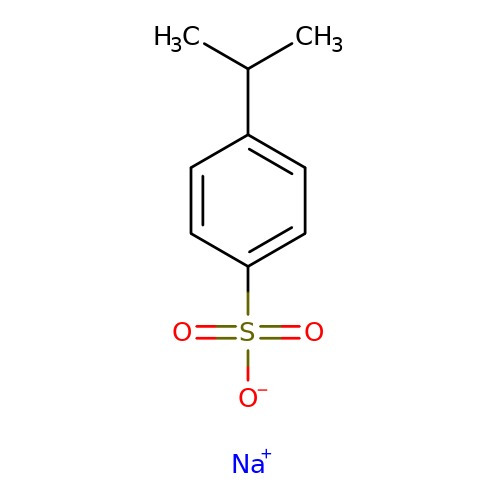

Compatibility Agents

Compatibility agents are used to prevent chemical interactions and precipitation when mixing multiple agrochemicals in a tank mixture. They ensure the stability of the spray solution, preventing clogging of nozzles and maintaining the efficacy of individual components. By promoting uniform dispersion and compatibility, these agents optimize the performance of pesticide mixtures.

Role and Benefits of Agricultural Activator Adjuvants

Agricultural activator adjuvants offer a multitude of benefits, making them indispensable tools for modern farmers:

Enhancing Pesticide Efficacy

By improving the solubility, spreading, and absorption of active ingredients, adjuvants enhance the biological activity and efficacy of pesticides. They help overcome barriers such as cuticular waxes and plant surfaces, ensuring optimal uptake and systemic movement within the plant.

Improving Plant Uptake

Adjuvants enhance the penetration and translocation of pesticides within plant tissues, ensuring effective control of pests and diseases. By facilitating rapid absorption and systemic movement, they maximize the bioavailability of active ingredients, leading to superior pest management and crop protection.

Reducing Pesticide Drift

Drift control agents mitigate the risk of pesticide drift during application, minimizing off-target deposition and environmental contamination. By optimizing droplet size and distribution, these adjuvants ensure precise delivery of pesticides to target areas while reducing the potential for environmental impact.

Ensuring Compatibility with Tank Mixtures

Compatibility agents prevent chemical interactions and compatibility issues when mixing multiple pesticides in a tank mixture. They maintain the stability and integrity of the spray solution, preventing precipitation and clogging of spray equipment. By promoting uniform dispersion and compatibility, these adjuvants maximize the efficacy of tank mixtures and minimize the risk of equipment malfunction.

Market Trends and Growth Drivers

The agricultural activator adjuvants market is witnessing steady growth, driven by several key factors:

Increasing Adoption of Precision Farming Techniques

The rise of precision farming technologies, such as GPS-guided equipment and variable rate application systems, is driving the demand for adjuvants. These technologies enable farmers to optimize pesticide applications and maximize crop yield while minimizing input costs and environmental impact.

Growing Demand for Sustainable Agricultural Practices

With increasing consumer awareness and regulatory pressure, there is a growing demand for sustainable agricultural practices. Adjuvants play a crucial role in supporting sustainable farming by improving the efficiency and efficacy of pesticide applications, reducing chemical usage, and minimizing environmental footprint.

Rise in Research and Development Activities

The agricultural adjuvants industry is characterized by ongoing research and development efforts aimed at introducing innovative formulations and technologies. Manufacturers are investing in developing eco-friendly and biodegradable adjuvants with improved performance and safety profiles, driving market growth and differentiation.

Key Players in the Agricultural Activator Adjuvants Market

The agricultural activator adjuvants market is highly competitive, with several key players vying for market share. Some of the leading companies in the industry include:

Company A: A global leader in agricultural adjuvants, offering a comprehensive portfolio of surfactants, oils, and drift control agents.

Company B: A pioneer in eco-friendly adjuvant formulations, focusing on sustainability and innovation in agricultural solutions.

Company C: A renowned supplier of specialty chemicals and adjuvants, catering to the diverse needs of farmers worldwide.

Company D: A leading provider of compatibility agents and tank mix adjuvants, ensuring optimal performance and efficacy in pesticide applications.

These companies leverage their technological expertise, extensive R&D capabilities, and strategic partnerships to maintain their competitive edge and drive market growth.

Regional Analysis

The agricultural activator adjuvants market exhibits regional variations in terms of market dynamics, regulatory frameworks, and adoption rates.

North America

North America dominates the global adjuvants market, fueled by the presence of large-scale commercial farms and advanced agricultural practices. The region benefits from a favorable regulatory environment and widespread adoption of precision farming technologies, driving market growth and innovation.

Europe

Europe is a key market for agricultural adjuvants, driven by stringent regulations and growing demand for sustainable farming practices. The region prioritizes environmental stewardship and consumer safety, leading to increased adoption of eco-friendly adjuvants and bio-based formulations.

Asia Pacific

Asia Pacific represents a lucrative market for agricultural adjuvants, driven by the expanding agricultural sector and rising demand for high-quality crops. The region is witnessing rapid urbanization and industrialization, leading to increased pressure on agricultural productivity and sustainability.

Other Regions

Other regions, such as Latin America, Africa, and the Middle East, offer significant growth opportunities for agricultural adjuvants. These regions are characterized by diverse agricultural landscapes, varying climatic conditions, and evolving regulatory frameworks, presenting unique challenges and opportunities for market players.

Challenges and Restraints

Despite the promising growth prospects, the agricultural activator adjuvants market faces several challenges and restraints:

Regulatory Hurdles and Compliance Issues

The adjuvants industry is subject to stringent regulatory requirements and compliance standards, which vary across different regions and jurisdictions. Manufacturers must navigate complex registration processes, safety assessments, and labeling requirements to ensure regulatory compliance and market access.

Concerns Regarding Environmental Impact

There is growing scrutiny and public concern regarding the environmental impact of agricultural adjuvants. Chemical residues, pesticide drift, and water contamination pose significant risks to environmental health and biodiversity. Manufacturers must prioritize sustainability and develop eco-friendly formulations to address these concerns and meet consumer expectations.

Future Outlook and Opportunities

Despite the challenges, the agricultural activator adjuvants market holds immense potential for growth and innovation:

Emerging Trends and Innovations

The industry is witnessing the emergence of innovative technologies and formulations, such as bio-based adjuvants, nanoemulsions, and smart delivery systems. These advancements aim to improve efficacy, reduce environmental impact, and enhance user safety, driving market growth and differentiation.

Potential for Market Expansion

With increasing global population and food demand, there is a growing need for efficient and sustainable agricultural solutions. Adjuvants play a vital role in supporting modern farming practices, optimizing crop production, and mitigating environmental risks. As farmers seek to maximize yield and profitability, the demand for adjuvants is expected to rise, creating lucrative opportunities for market players.

Conclusion

In conclusion, agricultural activator adjuvants are indispensable tools for modern farming, offering numerous benefits in terms of pesticide efficacy, plant uptake, and environmental sustainability. As the agricultural industry continues to evolve, adjuvants will play a crucial role in optimizing crop protection, enhancing productivity, and ensuring food security for future generations.

FAQs (Frequently Asked Questions)

What are agricultural activator adjuvants? Agricultural activator adjuvants are additives formulated to enhance the performance and efficacy of pesticides, herbicides, and fertilizers by modifying their physical and chemical properties.

How do adjuvants improve pesticide efficacy? Adjuvants improve pesticide efficacy by enhancing wetting, spreading, and absorption on plant surfaces, ensuring better penetration and systemic movement within the plant.

What types of adjuvants are commonly used in agriculture? Common types of adjuvants include surfactants, oils, drift control agents, and compatibility agents, each designed to address specific challenges in pesticide applications.

Why are adjuvants important in modern agriculture? Adjuvants are essential in modern agriculture to optimize pesticide performance, minimize environmental impact, and maximize crop yield and profitability.

Are there any environmental concerns associated with adjuvant usage? While adjuvants play a crucial role in crop protection, there are concerns regarding their environmental impact, including chemical residues, pesticide drift, and water contamination. Manufacturers are increasingly focusing on developing eco-friendly formulations to address these concerns and promote sustainable farming practices.

#Agricultural activator adjuvants#Adjuvants in agriculture#Pesticide adjuvants#Crop protection additives#Surfactants for farming#Oilbased adjuvants#Drift control agents#Compatibility agents for pesticides#Sustainable farming practices#Precision agriculture solutions#Environmental stewardship in agriculture#Agricultural chemical formulations#Market trends in agrochemicals#Farming innovations#Crop yield optimization

0 notes

Text

Sodium Lignosulfonate Market Size, Trends, Analysis, Demand, Outlook And Forecast To 2033

The sodium lignosulfonate market (リグノスルホン酸ナトリウム市場) is on a trajectory of significant growth, with projections indicating a valuation of US$ 535 million by 2033. This marks a substantial increase from its current market size of US$ 377 million in 2023. The driving force behind this upward trend is the anticipated growth in global demand for sodium lignosulfonate, expected to register a Compound Annual Growth Rate (CAGR) of 3.5% during the forecast period spanning from 2023 to 2033.

Several factors contribute to this optimistic outlook for the sodium lignosulfonate market. Firstly, the rising development of both residential and non-residential structures is creating a heightened demand for lignosulfonate, particularly as an oil additive within the oil and gas industry. Additionally, the construction sector is witnessing an increasing need for concrete admixtures, further propelling the expansion of the sodium lignosulfonate market.

Download a Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=8310

In a world increasingly conscious of sustainability and environmental impact, industries are constantly seeking innovative solutions to meet their needs while reducing their ecological footprint. One such solution gaining prominence is sodium lignosulfonate, a versatile organic compound derived from wood pulping processes. Market players are increasingly investing in research and development (R&D) to enhance sodium lignosulfonate applications, driving its adoption across various industries.

The Growing Demand for Sustainable Chemicals

Sodium lignosulfonate, also known as lignosulfonic acid sodium salt, is a natural polymer obtained from lignin, a component of plant cell walls. Historically, lignosulfonates have been used primarily as dispersants and binders in industries like construction, agriculture, and animal feed. However, recent advancements in R&D have opened up a plethora of new possibilities for this eco-friendly chemical compound.

One of the primary reasons behind the surge in R&D investment is the global shift toward sustainability. Industries are under increasing pressure to reduce their environmental impact and find alternatives to conventional, often harmful chemicals. Sodium lignosulfonate offers a compelling solution due to its biodegradability, renewability, and minimal ecological footprint compared to many synthetic counterparts.

Applications Across Diverse Industries

The sodium lignosulfonate market is witnessing a surge in demand across a wide range of sectors:

Construction Industry: Sodium lignosulfonate's excellent water-reducing and plasticizing properties make it an ideal admixture in concrete and cement production. It improves workability and reduces the water content in the mix, resulting in stronger, more durable structures. R&D efforts are focused on optimizing dosage levels and compatibility with various cement formulations.

Agriculture: As an environmentally friendly soil conditioner and dust suppressant, sodium lignosulfonate is gaining traction in agriculture. It enhances soil structure, reduces erosion, and promotes water retention. Ongoing research is exploring its potential as a natural pesticide and herbicide.

Animal Feed: Sodium lignosulfonate is used as a binder and pelletizing agent in animal feed production. Studies are underway to enhance its nutritional benefits and application in aquaculture.

Oil Drilling: The drilling industry has also recognized the benefits of sodium lignosulfonate as a drilling mud additive. R&D efforts aim to improve its performance under extreme conditions and expand its use in oilfield applications.

Pharmaceuticals and Cosmetics: Sodium lignosulfonate is used in pharmaceutical formulations and cosmetic products for its emulsifying and stabilizing properties. Research is focused on ensuring its purity and compatibility with sensitive formulations.

Notable Market Participants

Leading producers of sodium lignosulfonate encompass Borregaard LignoTech, Burgo Group SpA, Nippon Paper Industries Co., Ltd., Rayonier Advanced Materials, Sappi Ltd., Green Agrochem, Flambeau River Papers, and Qingdao New World Material Co. Ltd.

These key market players are channeling heightened investments into the development of new facilities and the enhancement of supply chain management. Simultaneously, they are dedicated to preserving product quality, ensuring compliance with safety regulations, and minimizing their environmental footprint.

Segmentation of Sodium Lignosulfonate Industry Research

By Type :

Dry

Liquid

Others

By Application :

Animal Feed Binders

Concrete Admixtures

Oil Well Additives

Agriculture Chemicals

Dust Suppressants

Lead Batteries

Gypsum Plasterboards

Others

By Region :

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

The surge in R&D investments to enhance sodium lignosulfonate applications signifies a pivotal moment in the sustainable chemical industry. This versatile compound, derived from renewable sources, is proving to be a viable alternative to conventional chemicals across multiple sectors. As research continues to unveil its potential, sodium lignosulfonate is poised to play a crucial role in shaping a more sustainable future for industries worldwide.

Contact: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Alkyl Polyglucosides Market Growth Driven by Rising Demand for Eco-Friendly and Biodegradable Surfactants

The Alkyl Polyglucosides Market is witnessing robust growth, propelled by rising environmental concerns, regulatory mandates, and increasing consumer preference for sustainable and biodegradable surfactants. APGs—non-ionic surfactants derived from renewable resources such as sugars and fatty alcohols—are gaining traction across industries including personal care, home care, agriculture, and industrial cleaning. Their eco-friendly profile, low toxicity, and high biodegradability make them a compelling alternative to conventional synthetic surfactants, especially in a world steadily shifting toward green chemistry and cleaner formulations.

Growing Consumer Preference for Natural and Safe Products

One of the primary growth drivers of the alkyl polyglucosides market is the rising demand for natural and skin-safe ingredients in everyday products. Consumers are increasingly scrutinizing product labels and seeking items that are not only effective but also safe for human health and the environment. APGs, known for being gentle on skin and eyes, are ideal for use in personal care products like shampoos, face cleansers, and baby wipes.

This trend is further fueled by the rise in vegan and cruelty-free products, where plant-based and sustainable ingredients are prioritized. As the beauty and personal care industry aligns with clean beauty standards, APGs are being adopted widely as surfactants of choice.

Eco-Friendly Surfactants in Household and Industrial Cleaning

Alkyl polyglucosides are also making significant inroads in the household and industrial cleaning segments. Traditional cleaning agents often contain petroleum-based surfactants that can harm aquatic ecosystems and pose health risks. In contrast, APGs offer strong performance in terms of foaming, emulsifying, and cleaning, without the environmental drawbacks.

Their compatibility with hard water, chemical stability, and synergistic effects with other surfactants make them highly desirable in formulations for dishwashing liquids, laundry detergents, and all-purpose cleaners. As consumers become more eco-conscious and demand transparency from cleaning brands, APGs are positioned as a superior alternative to synthetic surfactants.

Regulatory Push for Sustainable Chemicals

Governments and international organizations are implementing stringent regulations to curb the use of hazardous and non-biodegradable substances in chemical formulations. Regulations such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in the EU and the Toxic Substances Control Act (TSCA) in the U.S. are pushing industries to reformulate products with safer alternatives.

Alkyl polyglucosides, being non-toxic and derived from natural feedstocks, comply with most of these global safety and environmental standards. Their favorable regulatory status is encouraging manufacturers to invest in APG-based formulations, giving a strong impetus to market growth.

Expanding Applications in Agriculture and Food Processing

The use of alkyl polyglucosides is not limited to cleaning and personal care. The agricultural industry is adopting APGs as adjuvants in pesticide formulations, where they help enhance the effectiveness and adherence of crop protection chemicals. Their biodegradability ensures minimal residue on crops and soil, aligning with sustainable agricultural practices.

In food processing, APGs serve as emulsifiers and cleaning agents due to their food-grade safety profile. The increasing need for high-performance and safe ingredients in food-related applications is broadening the scope of APGs in these sectors.

Technological Advancements and Formulation Innovations

Ongoing R&D efforts are helping optimize the performance of alkyl polyglucosides for broader applications. Manufacturers are developing new grades and blends that improve solubility, stability, and foaming characteristics. Tailored formulations are emerging to meet the specific demands of different industries—be it a high-foaming APG for shampoos or a low-foaming variant for automatic dishwashing detergents.

Furthermore, technological advancements in enzymatic synthesis and fermentation are making production processes more cost-effective and sustainable, potentially lowering barriers to entry and enhancing market competitiveness.

Regional Market Trends

The APG market is seeing significant growth across North America, Europe, and Asia-Pacific. Europe leads the way, driven by stringent environmental regulations and a mature market for green products. Countries like Germany, France, and the Nordic nations are actively promoting the use of biodegradable surfactants in both commercial and consumer products.

In North America, consumer awareness and clean-label trends are catalyzing the demand for APG-based products in the U.S. and Canada. Meanwhile, the Asia-Pacific region is emerging as a high-growth market, driven by rapid industrialization, rising disposable incomes, and increasing demand for sustainable household and personal care products, particularly in China, India, and Southeast Asia.

Competitive Landscape

Key players in the alkyl polyglucosides market include BASF SE, Croda International Plc, Dow Inc., SEPPIC (Air Liquide), LG Household & Health Care Ltd., and Galaxy Surfactants Ltd. These companies are focusing on strategic initiatives such as product innovation, capacity expansions, and partnerships to strengthen their market presence.

BASF, for example, offers a broad portfolio of APG-based products under its Plantacare and Glucopon brands, catering to diverse sectors. Startups and niche players are also entering the market with customized solutions, creating healthy competition and spurring innovation.

Future Outlook

The future of the alkyl polyglucosides market looks promising, with continued growth expected over the next decade. As industries transition toward cleaner and greener formulations, the demand for biodegradable, plant-based surfactants like APGs will accelerate. Innovations in production technology and growing regulatory support will further reinforce the market’s expansion.

In conclusion, the alkyl polyglucosides market is well-positioned to benefit from a confluence of favorable trends—sustainability, regulatory alignment, consumer awareness, and technological progress. Businesses that align with this eco-conscious wave and integrate APGs into their product offerings stand to gain a competitive edge in the evolving global marketplace.

0 notes

Text

Best Sodium Cumene Sulfonate Manufacturer in Thailand

Introduction

Sodium Cumene Sulfonate (SCS) is a widely used hydrotrope known for enhancing the solubility and stability of other ingredients in a wide range of industrial and consumer products. It plays a vital role in the formulation of detergents, cleaners, personal care products, and agrochemical solutions.

Thailand, with its advanced chemical manufacturing capabilities, has become a key hub for producing high-quality SCS. Among the manufacturers, Dolphin Pharmaceutical stands out as the Best Sodium Cumene Sulfonate Manufacturer in Thailand, offering premium quality, regulatory compliance, and customer-focused services.

As a reputable pharmaceutical drug manufacturer in Thailand, Dolphin Pharmaceutical brings global standards to the local market and serves a broad international clientele. Our commitment to quality, sustainability, and innovation ensures that our customers receive products that meet strict international requirements.

What is Sodium Cumene Sulfonate?

Sodium Cumene Sulfonate is a hydrotrope compound, typically used to improve the solubility of poorly soluble ingredients in liquid formulations. It is water-soluble, stable under a variety of conditions, and compatible with anionic, nonionic, and amphoteric surfactants.

Key Properties:

Enhances solubility in aqueous solutions

Stabilizes emulsions and prevents separation

Biodegradable and environmentally friendly

Excellent compatibility with formulation ingredients

These attributes make SCS essential in several chemical and industrial applications.

Applications of Sodium Cumene Sulfonate

SCS is versatile and used in a variety of industries, including:

Detergents and Cleaning Agents: Improves product clarity, solubility, and performance.

Personal Care Products: Used in shampoos, body washes, and liquid soaps.

Agrochemicals: Enhances solubility of active ingredients in pesticides and fertilizers.

Textile and Dye Industry: Used to improve dye solubility and penetration.

Industrial Formulations: Acts as a carrier and stabilizer in chemical solutions.

Thailand’s Strength in Chemical Manufacturing

Thailand’s chemical industry is well-developed, with a strong focus on innovation, regulatory compliance, and export-readiness. With robust infrastructure and skilled professionals, Thailand has emerged as a key destination for sourcing specialty chemicals like SCS.

Why Thailand?

Cost-effective production with advanced facilities

Strong emphasis on quality and regulatory compliance

Strategic location for exports across Asia-Pacific

Supportive government policies for the chemical sector

Dolphin Pharmaceutical – Trusted Sodium Cumene Sulfonate Manufacturer in Thailand

Dolphin Pharmaceutical has built a solid reputation as a high-quality manufacturer of specialty chemicals and pharmaceutical ingredients. As a Sodium Cumene Sulfonate Manufacturer in Thailand, we offer unmatched quality, reliability, and service.

Our Key Strengths:

Modern manufacturing plants with GMP and ISO certifications

In-house R&D and testing facilities

Sustainable production practices

Transparent documentation and traceability

We cater to both domestic and global clients, ensuring consistency and compliance with international standards.

Commitment to Quality

As a responsible pharmaceutical drug manufacturer in Thailand, Dolphin Pharmaceutical prioritizes safety, precision, and consistency in every batch.

Quality Assurance Includes:

Full traceability of raw materials and final products

Batch testing using modern analytical equipment

CoA, SDS, and all relevant documentation for export

Strict adherence to local and international guidelines

Our quality systems are designed to deliver excellence from start to finish.

Sustainability and Green Chemistry

Dolphin Pharmaceutical is committed to environmentally responsible manufacturing. We implement practices that reduce waste, conserve energy, and promote recycling.

Eco-Friendly Initiatives:

Use of energy-efficient equipment

Water treatment and reuse systems

Low-impact solvent use and disposal

Green sourcing policies for raw materials

We believe sustainability is a key part of delivering long-term value to customers and communities.

Industries We Serve

Our Sodium Cumene Sulfonate is widely used by:

FMCG manufacturers

Agrochemical producers

Personal care and cosmetics companies

Cleaning and industrial product formulators

Textile and dye processing units

We understand the specific needs of each sector and offer customized solutions accordingly.

Global Reach and Export Capabilities

Dolphin Pharmaceutical not only serves the local Thai market but also exports SCS and other specialty chemicals to over 20 countries. Our international logistics and regulatory support make global partnerships seamless.

Export Support Includes:

Global documentation and regulatory filing

Flexible shipping and packaging options

Dedicated customer service for international clients

Why Choose Dolphin Pharmaceutical?

12+ years of manufacturing excellence

Proven track record in pharmaceutical and chemical exports

Advanced technology and expert technical support

Strong focus on client satisfaction and sustainability

Whether you’re looking for bulk quantities or customized formulations, Dolphin Pharmaceutical is your trusted Sodium Cumene Sulfonate Manufacturer in Thailand.

Conclusion

Sodium Cumene Sulfonate is an indispensable ingredient in multiple industrial and consumer formulations. As the demand for quality and compliance increases, partnering with a reliable supplier is crucial.

Dolphin Pharmaceutical is proud to be the Best Sodium Cumene Sulfonate Manufacturer in Thailand, combining advanced manufacturing, stringent quality control, and a global outlook. We help businesses thrive by delivering reliable, high-performance, and eco-conscious chemical solutions.

#Sodium Cumene Sulfonate Manufacturer in Thailand#Sodium Cumene Sulfonate supplier in Thailand#Sodium Cumene Sulfonate exporter in Thailand

0 notes

Text

Choosing the Right Wetting Agent: 5 Key Factors for Effective Formulation

In the world of industrial chemistry, wetting agent chemicals play a vital role in improving the interaction between liquids and solid surfaces. Whether in agricultural sprays, coatings, inks, detergents, or pharmaceutical formulations, wetting agents help reduce surface tension, allowing liquids to spread more evenly and penetrate more effectively.

But not all wetting agents are created equal. The effectiveness of a wetting agent in a particular application depends on several formulation-specific variables. Choosing the right one is critical to optimizing performance, ensuring compatibility, and achieving cost-efficiency.

Here are five key factors to consider when selecting the ideal wetting agent for your formulation.

1. Surface/Substrate Compatibility

The first consideration in choosing a wetting agent is the nature of the surface or substrate involved. Different surfaces—be they hydrophobic plastics, plant leaves, metal surfaces, or textiles—require wetting agents with different affinities and spreading capabilities.

Hydrophobic surfaces (e.g., waxy leaves or plastics) often require nonionic or low-foaming surfactants that can break surface tension without causing run-off.

Hydrophilic surfaces, such as glass or untreated paper, may perform well with anionic wetting agents that enhance surface coverage without repelling moisture.

Understanding the surface energy of the substrate will guide you toward the most compatible surfactant structure.

2. Type of Application and Industry

Different industries use wetting agent chemicals in distinct ways. The specific application largely dictates the desired performance characteristics:

Agriculture: The wetting agent must improve pesticide delivery, resist wash-off, and be safe for crops.

Paints & Coatings: Requires agents that reduce foam and enhance pigment dispersion.

Detergents & Cleaners: Emphasize penetration, emulsification, and rapid soil removal.

Pharmaceuticals: Must meet strict regulatory standards and biocompatibility.

Choosing a wetting agent tailored for your industry ensures effectiveness while meeting regulatory or performance standards.

3. Wetting Power and Surface Tension Reduction

Not all wetting agents reduce surface tension to the same degree. When the formulation requires rapid or deep spreading—such as in herbicide delivery or inkjet printing—fast-acting wetting agents with superior wetting power are essential.

Evaluate:

Dynamic surface tension for high-speed applications.

Contact angle measurements to assess how well the liquid spreads over the target surface.

Advanced silicone-based surfactants are known for their exceptional wetting capabilities, especially on difficult-to-wet surfaces, while alkyl polyglucosides (APGs) offer mild, biodegradable options.

4. pH and Temperature Stability

Formulations often operate within specific pH and temperature ranges. Wetting agent chemicals must remain stable and functional within these parameters to avoid degradation or performance loss.

In alkaline systems (e.g., cleaners), nonionic or amphoteric wetting agents are often more stable.

High-temperature processes like metal cleaning or textile dyeing may require heat-resistant surfactants.

Make sure to match the wetting agent’s chemical structure with the formulation’s environmental conditions for long-term effectiveness.

5. Regulatory and Environmental Considerations

Sustainability and safety are becoming top priorities across industries. It’s crucial to choose wetting agent chemicals that meet both performance and regulatory compliance requirements.

Look for:

Low toxicity and biodegradability, especially in agriculture or personal care.

Non-VOC (Volatile Organic Compound) content for paints and coatings.

REACH, EPA, or FDA-compliant formulations, depending on your industry and region.

Choosing eco-friendly or green-labeled surfactants can also boost your product’s market appeal and reduce environmental impact.

Conclusion

Selecting the right wetting agent chemicals is not a one-size-fits-all decision. It requires a clear understanding of the substrate, industry application, formulation conditions, and regulatory requirements. By considering these five key factors—surface compatibility, intended application, wetting power, environmental conditions, and compliance—you can develop more efficient, stable, and effective formulations.

In a competitive and regulation-driven market, making the right surfactant choice not only improves product performance but also enhances your brand’s reputation for innovation and sustainability.

0 notes

Text

Market for Agricultural Adjuvants Bolstered by Herbicide Efficiency NeedS

The United States Agricultural Adjuvants Market is on track to grow from approximately USD 574 million in 2022 to around USD 729 million by 2030, at a compound annual growth rate of 3%. Some forecasts also anticipate the market reaching USD 766 million by 2032. Growth is largely influenced by the increased demand for crop protection chemicals and the enhanced efficiency offered by adjuvants in herbicide and pesticide applications.

To Get Sample Report: https://www.datamintelligence.com/download-sample/usa-agricultural-adjuvants-market

Market Drivers and Opportunities

1. Dominance of Activator Adjuvants Activator adjuvants including surfactants, oils, and penetrants make up more than 70% of the U.S. adjuvant market. These compounds improve pesticide uptake and performance, especially for herbicide applications. Their ability to reduce surface tension and improve coverage has made them a staple in modern farming.

2. Precision Agriculture Expansion As U.S. farmers embrace GPS-guided sprayers, drones, and precision planting systems, the need for compatible adjuvants grows. These technologies require accurate, efficient delivery of agrochemicals, which adjuvants support by enhancing spray uniformity and retention.

3. Herbicide Resistance Management Widespread resistance to glyphosate and other herbicides has forced U.S. growers to rely on adjuvants that optimize chemical performance. Tank-mix adjuvants, surfactants, and crop oil concentrates are critical tools in delaying weed resistance and reducing the need for repeat applications.

4. Surge in Insecticide Use The increased threat of pest outbreaks and invasive species in the U.S. has driven higher insecticide use. This shift has fueled growth in adjuvants tailored to insecticide performance, including spreaders and stickers that enhance effectiveness while reducing environmental runoff.

5. Environmental and Regulatory Pressure Growers are transitioning toward low-toxicity and biodegradable adjuvants due to stricter EPA and state-level regulations. Utility adjuvants, such as drift-control agents and water conditioners, are gaining adoption to meet new safety and sustainability standards.

6. Product Innovation Market leaders are launching advanced formulations. Evonik’s BREAK-THRU series and Croda’s biopesticide-compatible adjuvants reflect a shift toward highly specific, environmentally conscious products. These innovations support low-volume and drone spraying, ideal for precision farming.

Segmentation Insights

By Type: Activator adjuvants dominate, but utility adjuvants like compatibility agents, water conditioners, and drift-reduction agents are gaining ground.

By Application: Herbicides account for about 76% of total adjuvant use. Insecticides and fungicides are growing segments, particularly due to emerging pest threats.

By Crop Type: Cereals, grains, oilseeds, pulses, fruits, and vegetables represent the largest user groups. Adjuvants are tailored to optimize absorption based on crop type.

Regional Perspective

The North American adjuvants market is projected to exceed USD 1.06 billion by 2030, with the U.S. leading the way. U.S. growers face unique regulatory, environmental, and climatic conditions that make adjuvants an essential input.

Challenges in the Market

Toxicity Concerns: Older, petroleum-based adjuvants can harm non-target organisms and aquatic ecosystems, creating demand for safer alternatives.

Regulatory Complexity: Lack of unified federal oversight for tank-mix adjuvants leads to fragmented state-level rules. Industry groups like ASTM and CPDA are pushing for standardization.

Input Cost Volatility: Raw materials for adjuvants, especially oil-based carriers, are subject to price fluctuations tied to global petroleum markets.

Latest Industry Trends (U.S. and Japan)

In the U.S., sustainability is driving product development, with increasing demand for biodegradable, low-drift formulations suitable for drone applications.

In Japan, rising rice production and smart agriculture technologies are creating new opportunities for precision-adapted adjuvants and water-efficient sprays.

Regulatory clarity is emerging, with private and public sector collaborations developing standardized efficacy and safety testing procedures.

Companies like Wilbur-Ellis and Croda are introducing adjuvants with multi-functional properties, suitable for both large-scale and smallholder farms.

Competitive Landscape

Key players in the U.S. agricultural adjuvants market include:

BASF SE

Dow Chemical Company

Solvay

Croda International

Evonik Industries

Stepan Company

Helena Agri-Enterprises

Wilbur-Ellis

Nufarm

Huntsman Corporation

Conclusion

The U.S. agricultural adjuvants market is evolving to meet the needs of modern agriculture. Growth is being shaped by a combination of sustainability goals, pest management strategies, and the digitalization of farming. With regulatory momentum and innovation accelerating, adjuvants will continue to play a pivotal role in American crop productivity over the next decade.

0 notes

Text

Organic Push and Biotech Boosts: Navigating Key Trends in the Agricultural Biologicals Market

Market Overview

The Global Agricultural Biologicals Market is projected to be valued at USD 29.87 billion in 2025 and is anticipated to grow to USD 46.80 billion by 2030, registering a compound annual growth rate (CAGR) of 9.4% during the forecast period from 2025 to 2030.

Across the globe, agriculture is facing a changing landscape. Rising environmental awareness, stricter pesticide regulations, and growing consumer demand for safer, cleaner food are steering the farming community toward more sustainable inputs. Agricultural biologicals—products derived from natural sources like microorganisms, plant extracts, and beneficial fungi—are increasingly being adopted in place of synthetic fertilizers and pesticides.

Key Trends Shaping the Market

Organic Farming Expanding Globally

One of the most significant contributors to the growth of agricultural biologicals is the continued expansion of organic farming. In recent years, the global area under organic cultivation has steadily increased, particularly in Europe, North America, and Asia-Pacific. Countries like India and China are adding organic hectares at a fast pace, driven by both government programs and rising local demand.

Organic farms, by definition, avoid the use of synthetic inputs. This makes biofertilizers, biopesticides, and biostimulants essential tools for these growers. As more farmland shifts to organic practices, the demand for reliable and effective biological products grows alongside it.

Surge in Biopesticide Adoption

Biopesticides are gaining traction as viable alternatives to synthetic chemical pesticides. Farmers are using these naturally derived pest control agents to manage insects, weeds, and fungal diseases with less impact on the environment and beneficial organisms.

The adoption rate is particularly high in horticulture, where residue limits are strictly enforced and export markets demand clean produce. In regions like North America and Asia-Pacific, biopesticides now make up the bulk of the biological crop protection segment. Farmers are favoring these products not only for their environmental benefits but also for their compatibility with integrated pest management strategies.

Growing Use of Biostimulants and Biofertilizers

As concerns about long-term soil degradation and chemical fertilizer overuse rise, biological solutions for crop nutrition are becoming more popular. Biostimulants help improve plant growth, enhance nutrient uptake, and increase resistance to abiotic stress like drought and heat. Biofertilizers, on the other hand, use microbial action to fix nitrogen, solubilize phosphorus, or mobilize potassium in the soil.

These products are particularly relevant in countries with depleted or overworked soils. In Asia-Pacific and parts of Latin America, biofertilizers already account for the majority share of crop nutrition biologicals. In crops like rice, wheat, and corn, farmers are integrating these products to supplement or reduce chemical fertilizer use while maintaining yields.

What’s Driving Market Growth

Environmental Regulations and Government Policies

Policy changes are creating a favorable environment for biologicals. In Europe, regulatory targets to reduce fertilizer and pesticide use are encouraging the transition to more sustainable farming practices. Similar strategies are being pursued in other countries like China and India, where national programs are supporting biological adoption through incentives, training, and awareness campaigns.

These regulations are not only aimed at improving environmental outcomes—they are also being used to align agricultural practices with long-term food safety and climate goals. As a result, the regulatory landscape is playing a crucial role in driving biological input adoption.

Consumer Preferences and Market Demand

The shift in consumer attitudes toward organic and residue-free produce is impacting upstream decisions by growers. Retailers and food brands are responding to demand for cleaner labels and traceability by requiring suppliers to minimize chemical inputs. Farmers aiming to meet such standards find biologicals to be a reliable option.

This is particularly true in high-value crops such as fruits, vegetables, and coffee, where even minor chemical residue can affect product acceptance in local and export markets. The push from consumers is becoming just as important as policy in shaping on-farm decisions.

Industry Investment and Product Development

The agricultural biologicals sector is benefiting from increased R&D investment. Companies are improving the formulation, consistency, and shelf life of their products, making them easier to apply and more effective under diverse field conditions.

There’s also growing interest in microbial research, strain identification, and delivery mechanisms that allow biologicals to work alongside or in rotation with traditional inputs. As performance improves, so does farmer confidence and repeat usage, which feeds further market expansion.

Regional Market Overview

North America

This region shows strong adoption of biologicals, particularly in large-scale, conventional farming systems. Biopesticides are widely used, and microbial solutions for soil health are gaining ground. Research institutions and ag-tech startups contribute to a dynamic environment that fosters innovation and farmer outreach.

Europe

Driven by policy, Europe is rapidly increasing its use of biologicals. Countries like France and Spain are adopting these inputs in citrus, vineyards, and vegetables, particularly in response to stricter pesticide rules and national targets for organic farming. The region is also home to many manufacturers of biostimulants and microbial products.

Asia-Pacific

This diverse region includes both large-scale initiatives and smallholder-driven adoption. China’s national targets for pesticide reduction and India’s organic promotion schemes are major drivers. Biofertilizers are widely used in rice and pulse crops, and awareness is rising in vegetable and fruit cultivation.

Latin America

Brazil leads the region, with a strong focus on biostimulants and crop nutrition products. Sugarcane, soybean, and citrus crops are major users of biologicals. Other countries in the region are following similar trends, supported by rising demand for low-residue food exports.

Key Players in the Market

The agricultural biologicals space features a mix of global agribusinesses and specialized regional firms. Large companies like Corteva Agriscience, Bayer CropScience, Syngenta, BASF, and Novozymes have established strong portfolios through acquisitions and internal R&D.

At the regional level, companies such as Bioworks, Koppert, Valagro, and Symborg are notable contributors. These firms focus on targeted formulations and niche crops, often working closely with farmers and distributors to build market awareness. In markets like Brazil and India, domestic manufacturers are also scaling up production to meet growing demand.

Conclusion

Agricultural biologicals are no longer limited to niche applications—they are becoming an essential part of modern crop management. As organic farming expands and regulations tighten around synthetic inputs, biological alternatives are gaining trust among farmers worldwide.

The combination of consumer pressure, sustainability goals, and improved product quality is moving the industry forward. While challenges like cost, efficacy under field conditions, and farmer education still exist, the momentum is clearly building.

To know more visit this link: https://www.mordorintelligence.com/industry-reports/agricultural-biologicals-market

#Agricultural Biologicals Market#Agricultural Biologicals Market Size#Agricultural Biologicals Market Share#Agricultural Biologicals Market Trends#Agricultural Biologicals Market Analysis

0 notes

Text

Agricultural Activator Adjuvants: Enhancing Efficiency and Sustainability

Outline of the Article

Introduction to Agricultural Activator Adjuvants

What are agricultural activator adjuvants?

Importance in modern agriculture.

Types of Agricultural Activator Adjuvants

Surfactants

Oils

Drift Control Agents

Compatibility Agents

Role and Benefits of Agricultural Activator Adjuvants

Enhancing pesticide efficacy

Improving plant uptake

Reducing pesticide drift

Ensuring compatibility with tank mixtures

Market Trends and Growth Drivers

Increasing adoption of precision farming techniques

Growing demand for sustainable agricultural practices

Rise in research and development activities

Key Players in the Agricultural Activator Adjuvants Market

Analysis of major companies and their market share

Overview of their product offerings and strategies

Regional Analysis

Market landscape in North America, Europe, Asia Pacific, and other regions

Factors influencing market growth in each region

Challenges and Restraints

Regulatory hurdles and compliance issues

Concerns regarding environmental impact

Future Outlook and Opportunities

Emerging trends and innovations

Potential for market expansion

Case Studies and Success Stories

Real-world applications of agricultural activator adjuvants

Impact on crop yield and farm profitability

Environmental Sustainability and Safety Considerations

Eco-friendly formulations

Risk mitigation strategies

Consumer Awareness and Education

Importance of educating farmers about adjuvant selection and usage

Promoting responsible stewardship practices

Industry Collaboration and Partnerships

Collaborative efforts between manufacturers, farmers, and regulatory bodies

Sharing best practices and knowledge exchange

Market Forecast and Analysis

Predictions for market growth and revenue projections

Factors influencing market dynamics in the forecast period

Investment Opportunities and Market Entry Strategies

Potential for new entrants

Investment avenues for existing players

Conclusion

Recap of key points

Summary of market outlook and recommendations for stakeholders

Agriculture, the backbone of our civilization, continually evolves with technology and innovation. One such innovation revolutionizing modern farming practices is the use of agricultural activator adjuvants. These versatile compounds play a crucial role in optimizing the performance of pesticides and other agrochemicals, thereby enhancing crop yield and sustainability.

What are Agricultural Activator Adjuvants?

Agricultural activator adjuvants are additives formulated to improve the efficacy and performance of pesticides, herbicides, and fertilizers. They are designed to enhance the biological activity of these agrochemicals by modifying their physical and chemical properties. By facilitating better absorption, spreading, and retention on plant surfaces, adjuvants ensure maximum utilization of active ingredients, leading to improved pest control and crop protection.

Importance in Modern Agriculture

In today's agricultural landscape, where farmers face escalating challenges such as pest resistance, environmental concerns, and stringent regulations, the role of adjuvants becomes increasingly critical. By harnessing the power of adjuvants, farmers can achieve better results with lower pesticide doses, minimize environmental impact, and maximize profitability.

Types of Agricultural Activator Adjuvants

Surfactants

Surfactants are one of the most commonly used adjuvants in agriculture. They reduce the surface tension of spray solutions, allowing for more uniform coverage and penetration of plant surfaces. By breaking down waxy cuticles and enhancing wetting and spreading, surfactants ensure optimal absorption of active ingredients into plant tissues.

Oils

Oil-based adjuvants, such as crop oils and mineral oils, act as carriers for pesticides and improve their adherence to plant surfaces. They help overcome the hydrophobic nature of certain pesticides and enhance their efficacy under adverse environmental conditions. Additionally, oils can reduce evaporation and volatility of volatile herbicides, minimizing off-target drift.

Drift Control Agents

Drift control agents are formulated to reduce the risk of pesticide drift during application. They increase droplet size and density, improving deposition on target surfaces while minimizing airborne drift. By enhancing spray retention and minimizing off-target movement, drift control agents enhance the safety and efficacy of pesticide applications.

Compatibility Agents

Compatibility agents are used to prevent chemical interactions and precipitation when mixing multiple agrochemicals in a tank mixture. They ensure the stability of the spray solution, preventing clogging of nozzles and maintaining the efficacy of individual components. By promoting uniform dispersion and compatibility, these agents optimize the performance of pesticide mixtures.

Role and Benefits of Agricultural Activator Adjuvants

Agricultural activator adjuvants offer a multitude of benefits, making them indispensable tools for modern farmers:

Enhancing Pesticide Efficacy

By improving the solubility, spreading, and absorption of active ingredients, adjuvants enhance the biological activity and efficacy of pesticides. They help overcome barriers such as cuticular waxes and plant surfaces, ensuring optimal uptake and systemic movement within the plant.

Improving Plant Uptake

Adjuvants enhance the penetration and translocation of pesticides within plant tissues, ensuring effective control of pests and diseases. By facilitating rapid absorption and systemic movement, they maximize the bioavailability of active ingredients, leading to superior pest management and crop protection.

Reducing Pesticide Drift

Drift control agents mitigate the risk of pesticide drift during application, minimizing off-target deposition and environmental contamination. By optimizing droplet size and distribution, these adjuvants ensure precise delivery of pesticides to target areas while reducing the potential for environmental impact.

Ensuring Compatibility with Tank Mixtures

Compatibility agents prevent chemical interactions and compatibility issues when mixing multiple pesticides in a tank mixture. They maintain the stability and integrity of the spray solution, preventing precipitation and clogging of spray equipment. By promoting uniform dispersion and compatibility, these adjuvants maximize the efficacy of tank mixtures and minimize the risk of equipment malfunction.

Market Trends and Growth Drivers

The agricultural activator adjuvants market is witnessing steady growth, driven by several key factors:

Increasing Adoption of Precision Farming Techniques

The rise of precision farming technologies, such as GPS-guided equipment and variable rate application systems, is driving the demand for adjuvants. These technologies enable farmers to optimize pesticide applications and maximize crop yield while minimizing input costs and environmental impact.

Growing Demand for Sustainable Agricultural Practices

With increasing consumer awareness and regulatory pressure, there is a growing demand for sustainable agricultural practices. Adjuvants play a crucial role in supporting sustainable farming by improving the efficiency and efficacy of pesticide applications, reducing chemical usage, and minimizing environmental footprint.

Rise in Research and Development Activities

The agricultural adjuvants industry is characterized by ongoing research and development efforts aimed at introducing innovative formulations and technologies. Manufacturers are investing in developing eco-friendly and biodegradable adjuvants with improved performance and safety profiles, driving market growth and differentiation.

Key Players in the Agricultural Activator Adjuvants Market

The agricultural activator adjuvants market is highly competitive, with several key players vying for market share. Some of the leading companies in the industry include:

Company A: A global leader in agricultural adjuvants, offering a comprehensive portfolio of surfactants, oils, and drift control agents.

Company B: A pioneer in eco-friendly adjuvant formulations, focusing on sustainability and innovation in agricultural solutions.

Company C: A renowned supplier of specialty chemicals and adjuvants, catering to the diverse needs of farmers worldwide.

Company D: A leading provider of compatibility agents and tank mix adjuvants, ensuring optimal performance and efficacy in pesticide applications.

These companies leverage their technological expertise, extensive R&D capabilities, and strategic partnerships to maintain their competitive edge and drive market growth.

Regional Analysis

The agricultural activator adjuvants market exhibits regional variations in terms of market dynamics, regulatory frameworks, and adoption rates.

North America

North America dominates the global adjuvants market, fueled by the presence of large-scale commercial farms and advanced agricultural practices. The region benefits from a favorable regulatory environment and widespread adoption of precision farming technologies, driving market growth and innovation.

Europe

Europe is a key market for agricultural adjuvants, driven by stringent regulations and growing demand for sustainable farming practices. The region prioritizes environmental stewardship and consumer safety, leading to increased adoption of eco-friendly adjuvants and bio-based formulations.

Asia Pacific

Asia Pacific represents a lucrative market for agricultural adjuvants, driven by the expanding agricultural sector and rising demand for high-quality crops. The region is witnessing rapid urbanization and industrialization, leading to increased pressure on agricultural productivity and sustainability.

Other Regions

Other regions, such as Latin America, Africa, and the Middle East, offer significant growth opportunities for agricultural adjuvants. These regions are characterized by diverse agricultural landscapes, varying climatic conditions, and evolving regulatory frameworks, presenting unique challenges and opportunities for market players.

Challenges and Restraints

Despite the promising growth prospects, the agricultural activator adjuvants market faces several challenges and restraints:

Regulatory Hurdles and Compliance Issues

The adjuvants industry is subject to stringent regulatory requirements and compliance standards, which vary across different regions and jurisdictions. Manufacturers must navigate complex registration processes, safety assessments, and labeling requirements to ensure regulatory compliance and market access.

Concerns Regarding Environmental Impact

There is growing scrutiny and public concern regarding the environmental impact of agricultural adjuvants. Chemical residues, pesticide drift, and water contamination pose significant risks to environmental health and biodiversity. Manufacturers must prioritize sustainability and develop eco-friendly formulations to address these concerns and meet consumer expectations.

Future Outlook and Opportunities

Despite the challenges, the agricultural activator adjuvants market holds immense potential for growth and innovation:

Emerging Trends and Innovations

The industry is witnessing the emergence of innovative technologies and formulations, such as bio-based adjuvants, nanoemulsions, and smart delivery systems. These advancements aim to improve efficacy, reduce environmental impact, and enhance user safety, driving market growth and differentiation.

Potential for Market Expansion

With increasing global population and food demand, there is a growing need for efficient and sustainable agricultural solutions. Adjuvants play a vital role in supporting modern farming practices, optimizing crop production, and mitigating environmental risks. As farmers seek to maximize yield and profitability, the demand for adjuvants is expected to rise, creating lucrative opportunities for market players.

Conclusion

In conclusion, agricultural activator adjuvants are indispensable tools for modern farming, offering numerous benefits in terms of pesticide efficacy, plant uptake, and environmental sustainability. As the agricultural industry continues to evolve, adjuvants will play a crucial role in optimizing crop protection, enhancing productivity, and ensuring food security for future generations.

FAQs (Frequently Asked Questions)

What are agricultural activator adjuvants? Agricultural activator adjuvants are additives formulated to enhance the performance and efficacy of pesticides, herbicides, and fertilizers by modifying their physical and chemical properties.

How do adjuvants improve pesticide efficacy? Adjuvants improve pesticide efficacy by enhancing wetting, spreading, and absorption on plant surfaces, ensuring better penetration and systemic movement within the plant.

What types of adjuvants are commonly used in agriculture? Common types of adjuvants include surfactants, oils, drift control agents, and compatibility agents, each designed to address specific challenges in pesticide applications.

Why are adjuvants important in modern agriculture? Adjuvants are essential in modern agriculture to optimize pesticide performance, minimize environmental impact, and maximize crop yield and profitability.

Are there any environmental concerns associated with adjuvant usage? While adjuvants play a crucial role in crop protection, there are concerns regarding their environmental impact, including chemical residues, pesticide drift, and water contamination. Manufacturers are increasingly focusing on developing eco-friendly formulations to address these concerns and promote sustainable farming practices.

#Agricultural activator adjuvants#Adjuvants in agriculture#Pesticide adjuvants#Crop protection additives#Surfactants for farming#Oilbased adjuvants#Drift control agents#Compatibility agents for pesticides#Sustainable farming practices#Precision agriculture solutions#Environmental stewardship in agriculture#Agricultural chemical formulations#Market trends in agrochemicals#Farming innovations#Crop yield optimization

0 notes

Text

U.S. and Canada Beauveria Bassiana Market Size Expected to Reach $98.7 million by 2035

The U.S. and Canada Beauveria Bassiana market was valued at $36.7 million in 2023, and is projected to reach $98.7 million by 2035, growing at a CAGR of 9.0% from 2024 to 2035.

Get a Sample PDF Report to understand our report before you purchase: https://www.alliedmarketresearch.com/request-sample/A325590

Beauveria bassiana is a fungus that naturally occurs in the environment. It is grown by cultivating its spores in a controlled setting, usually on materials like grains or plant matter. After the fungus grows and produces spores, they are collected and processed into products like powders or liquids. These products are then used to control pests by infecting and killing harmful insects.

Beauveria bassiana products have gained considerable market share in the U.S. and Canada markets. Higher environmental regulations on chemical pesticide usage in North America have significantly increased the U.S. and Canada Beauveria bassiana market growth. Policies implemented by the U.S. Environmental Protection Agency (EPA) and Canada’s Pest Management Regulatory Agency (PMRA) have restricted harmful chemical pesticides, creating a need for safer alternatives. Beauveria bassiana, a biological control agent, offers effective pest management without causing environmental harm or leaving harmful residues, aligning with regulatory standards.

Make a Direct Purchase: https://www.alliedmarketresearch.com/checkout-final/17fcf21d5691f659d813f948c5c07d68

In addition, the banning and gradual removal of certain chemical pesticides has further encouraged growers to adopt sustainable solutions that maintain agricultural productivity. The growing importance on eco-friendly farming practices and compliance with stringent environmental regulations has directly contributed to the rise in adoption of Beauveria bassiana, driving market growth in the U.S. and Canada Beauveria bassiana market share.

However, high competition from pheromones and other biocontrol products restrains the U.S. and Canada Beauveria bassiana market demand. Pheromones, used for disruption and pest monitoring, provide a highly targeted and species-specific approach, helping growers achieve precise pest control solutions. Other biocontrol products, such as beneficial nematodes, fungi, and bacterial formulations, provide alternative pest management options with proven effectiveness and compatibility across various farming systems. Many of these products have established market presence, strong customer trust, and broader application scopes, creating a competitive landscape that limits the adoption of Beauveria bassiana.

Moreover, the perception of better cost-effectiveness, longer shelf life, or ease of use for competing products further challenges the market penetration of Beauveria bassiana in the U.S. and Canada Beauveria bassiana market. The availability of multiple alternatives tailored to specific crop and pest needs reduces the reliance on a single biocontrol solution, restraining the growth of the U.S. and Canada Beauveria bassiana industry.

To Ask About Report Availability or Customization, Click Here: https://www.alliedmarketresearch.com/purchase-enquiry/A325590

Furthermore, the increasing interest in biopesticides for forestry pest management in Canada is creating U.S. and Canada Beauveria bassiana market opportunities. Forestry pests such as bark beetles, spruce budworms, and emerald ash borers are causing widespread damage to forests, prompting the need for environmentally friendly pest control solutions. Beauveria bassiana, a fungal biopesticide, offers a sustainable alternative to chemical pesticides by naturally targeting harmful pests while preserving beneficial species and minimizing ecological impact. Canadian government policies promoting reduced chemical usage in forestry and incentives for sustainable pest management practices further boost the adoption of biopesticides like Beauveria bassiana.

The growth in demand for Beauveria bassiana in Canada has encouraged the development of innovative strategies to optimize its application in forestry. Techniques such as granular formulations and tree-injection methods are being explored to increase efficacy and ensure targeted pest control in dense forest environments. In addition, cross-border partnerships between Canadian and U.S. companies have promoted knowledge sharing and enhanced product availability. This increased focus on sustainable forestry pest management has driven the expansion of the Beauveria bassiana in U.S. and Canada Beauveria bassiana market, addressing ecological concerns while supporting economic and environmental goals.

The U.S. and Canada Beauveria bassiana market is segmented into type, application, distribution channel, and crop type. By type, the market is bifurcated into liquid and powder. By application, it is segregated into agriculture, forestry, and others. Further the agriculture segment is categorized into traditional agriculture, greenhouse agriculture, urban agriculture, agroforestry, and others. Depending on the distribution channel, it is fragmented into indirect sales and direct sales. By crop type, the market is divided into cereals and grains, fruits and vegetables, oilseeds and pulses, and others.

0 notes

Text

Seed Coating Market Analysis, Trends, and Forecasts (2025-2030)

The global seed coating market is projected to grow from USD 2.38 billion in 2025 to USD 3.52 billion by 2030, registering a compound annual growth rate (CAGR) of 8.2% during the forecast period. This growth is primarily driven by the rising demand for high-quality seeds that enhance germination, ensure uniform crop emergence, and boost resistance to early-stage pests and diseases.

Advancements in coating technologies—particularly polymer and bio-based formulations—have enabled the integration of micronutrients, plant protectants, and microbial agents directly into the seed coating. These innovations significantly improve seed performance. Additionally, the expansion of precision agriculture and the emphasis on sustainable farming practices further support the adoption of seed coating technologies. Favorable government policies and the increasing need to maximize yields on limited arable land also contribute to the market's momentum.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=149045530

By Additive Type: Colorants Lead the Segment

Colorants represent a major share of the seed coating additives market. They play a critical role in seed identification, brand differentiation, and regulatory compliance. By allowing easy visual distinction based on seed type and treatment level, colorants enhance both safety and traceability in seed handling. They also improve the visual appeal of seeds and strengthen brand recognition for seed producers.

A leading player in this segment is Sensient Technologies Corporation, offering the SensiCoat product line—customizable, vibrant, and compliant with 40 CFR Part 180 regulations. These pigment dispersions are specifically formulated for seed treatments, helping companies create distinctive, consistent seed coatings.

By Coating Type: Synthetic Coatings Dominate

Synthetic coatings account for the largest market share among coating types. Typically polymer-based, these coatings are favored for their durability, consistent performance, and ability to carry a wide range of active ingredients. They offer strong adhesion, low dust-off, and extended shelf life, making them ideal for commercial-scale agriculture.

Furthermore, synthetic coatings are highly compatible with various additives such as fertilizers, pesticides, and biological inoculants, contributing to enhanced seed protection and better crop establishment. Their cost-efficiency and proven effectiveness have solidified their dominance in the global market.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=149045530

By Region: North America Holds a Leading Position

North America commands a significant share of the global seed coating market. This leadership is supported by the region’s advanced agricultural infrastructure, widespread use of precision farming techniques, and the strong presence of major seed and agrochemical companies.

Large-scale production of crops like corn, soybean, and wheat drives demand for high-performance seed coatings that enhance germination and protect against pests. Moreover, government initiatives promoting sustainable agriculture and increased investment in agricultural R&D reinforce the adoption of advanced seed coating technologies across the region.

Leading Seed Coating Companies

The report profiles key players such as BASF SE (Germany), Syensqo (Belgium), Clariant (Switzerland), Croda International plc (UK), Sensient Technologies Corporation (US), Germains Seed Technology (UK), Milliken (US), Covestro AG (Germany), BrettYoung (Canada), Chromatech Incorporated (US), Centor Group (Netherlands), Michelman, Inc. (US), Precision Labs (US), CR Minerals, LLC (US), and Universal Coating Systems (US).

#Seed Coating Market#Seed Coating#Seed Coating Market Size#Seed Coating Market Share#Seed Coating Market Growth#Seed Coating Market Trends#Seed Coating Market Forecast#Seed Coating Market Analysis#Seed Coating Market Report#Seed Coating Market Scope#Seed Coating Market Overview#Seed Coating Market Outlook#Seed Coating Market Drivers#Seed Coating Industry#Seed Coating Companies

0 notes

Text

Castor Oil Ethoxylate Manufacturer in India – High-Performance Solutions by Vasudha Chemicals

In today’s advanced industrial landscape, specialty chemicals are vital to innovation, performance, and sustainability. One such versatile compound is Castor Oil Ethoxylate, widely used across agriculture, textiles, cosmetics, and other sectors for its emulsifying, dispersing, and solubilizing properties. As a trusted Castor Oil Ethoxylate Manufacturer in India, Vasudha Chemicals stands at the forefront of delivering high-quality, reliable, and customizable chemical solutions to global industries.

With years of technical expertise, state-of-the-art facilities, and a deep understanding of market requirements, Vasudha Chemicals has earned its reputation as a dependable player in the specialty chemicals space. In this blog, we explore everything you need to know about Castor Oil Ethoxylate — its chemistry, applications, advantages, and why Vasudha Chemicals is the right partner for your formulation needs.

What is Castor Oil Ethoxylate?

Castor Oil Ethoxylate is a non-ionic surfactant derived from natural castor oil by ethoxylation — a process that reacts ethylene oxide with castor oil to produce ethoxylated derivatives. These derivatives possess excellent emulsifying, wetting, and dispersing properties, making them valuable ingredients in formulations requiring stable oil-in-water emulsions.

Depending on the degree of ethoxylation (e.g., 5EO, 10EO, 20EO, etc.), Castor Oil Ethoxylates can be tailored for specific performance requirements across industries.

Key Characteristics of Castor Oil Ethoxylate

Appearance: Pale yellow to amber liquid or semi-solid

Solubility: Soluble in water and organic solvents

Surface Activity: Strong emulsifier and wetting agent

Nature: Non-ionic surfactant

Biodegradability: Derived from renewable resources, eco-friendly

Customization: Available in different EO (ethylene oxide) molar ratios

Applications Across Industries

Thanks to its unique molecular structure and multifunctionality, Castor Oil Ethoxylate finds widespread use in several industries. Here’s how:

1. Agriculture and Crop Protection

In agrochemicals, Castor Oil Ethoxylate serves as an effective adjuvant in pesticide and herbicide formulations. It enhances:

Spray dispersion

Penetration into plant surfaces

Rainfastness (resistance to wash-off)

By acting as a wetting and spreading agent, it ensures the active ingredients are more effective, leading to better crop protection and yield.

2. Textiles and Dyeing

In textile processing, Castor Oil Ethoxylate plays a key role in:

Dye leveling

Emulsifying oils and waxes

Wetting fabrics before dyeing

Its excellent dispersing ability improves dye uptake and results in more uniform coloration.

3. Cosmetics and Personal Care

This ingredient is favored in formulations such as:

Lotions

Creams