#Compression Molding Machine

Explore tagged Tumblr posts

Text

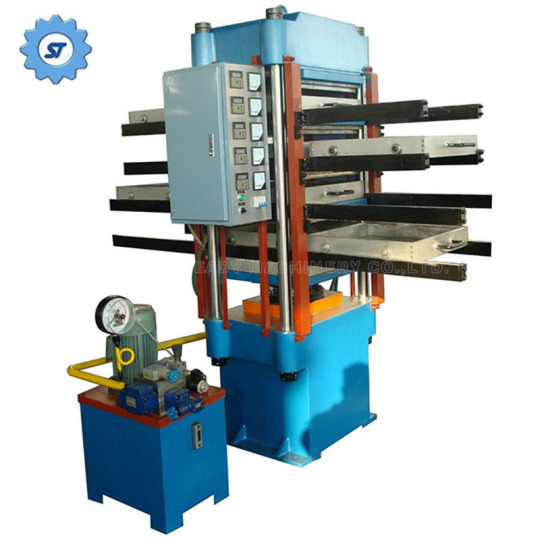

How Can a Rubber Compression Molding Machine Improve Manufacturing Efficiency?

Rubber components are vital to countless industries, from automotive and aerospace to medical and consumer goods. For manufacturers seeking a cost-effective way to produce high-strength, precision rubber parts, the rubber compression molding machine is a reliable solution. Known for its simple operation and high adaptability, this equipment remains a preferred choice for producing rubber products with complex shapes and superior durability.

0 notes

Text

Can a Rubber Compression Molding Machine Enhance Your Production Process?

For manufacturers working with rubber materials, efficiency and precision are top priorities. In this context, a rubber compression molding machine plays a crucial role in achieving consistent, high-quality parts across various industries. Positioned at the heart of many production lines, this equipment is designed to streamline operations and support both small and large-scale manufacturing.

0 notes

Text

Functional Cap Molding For Daily Product Reliability

As consumer packaging evolves with shifting expectations, manufacturers are compelled to respond with machinery that balances speed, quality, and adaptability. Positioned at this transformation’s core, the Cap Compression Molding Machine plays a vital role in redefining how closures are produced with efficiency and consistency. Designed for scalable output, the Cap Compression Molding Machine has become a preferred option for companies seeking seamless integration with modern production lines and greater flexibility in material handling.

In an era of digital workflows and short product life cycles, equipment that simplifies changeover and reduces material waste holds strategic value. Compression molding systems now feature enhanced automation layers, enabling operators to configure specifications without lengthy manual adjustments. These improvements support industries that require fast response times—such as beverages, healthcare, and personal care—where packaging changes frequently and design differentiation matters.

Technology upgrades have also reshaped quality control. Smart sensors, closed-loop feedback, and monitoring systems ensure dimensional precision while minimizing rejects. With each unit produced under tight tolerances, cap functionality and visual consistency improve dramatically. This translates into reduced return rates, fewer complaints, and stronger brand trust from the end user.

Beyond factory walls, this technology influences how people interact with everyday packaging. Improved sealing, ergonomic shapes, and reduced plastic use are the byproducts of precision-driven compression systems. Caps today are expected to function well even under tough transportation or storage conditions. Their ability to retain freshness and prevent leaks makes them a critical factor in product performance.

Taizhou Chuangzhen Machinery Manufacturing continues to lead advancements in molding technology by offering machines that meet global demand without sacrificing durability or cost-efficiency. Their platforms cater to businesses looking for long-term reliability while remaining responsive to innovation and design needs.For further insights into equipment capabilities and applications across industries, please explore the company's official resource page available at https://www.capping-machine.net/news/industry-news/plastic-cap-compression-molding-machine-everything-you-need-to-know.html .

0 notes

Text

Introduction to Mould Manufacturing 2024

Plastic mould manufacturing is the process of creating mould or tools for the production of plastic parts. The mould are designed to shape and form plastic materials into specific shapes and sizes, allowing for the production of identical parts at a rapid pace. This process is widely used in various industries, including automotive, medical, and consumer goods.

The fundamental principle behind plastic mould manufacturing is to create a negative impression of the desired product, which is then used to cast the final product. The mould are made from high-quality materials such as steel or aluminum, which are capable of withstanding high temperatures and pressure. The mould are designed to accommodate the specific properties of the plastic material, including its melting point, viscosity, and shrinkage rate.

There are two primary types of plastic mould manufacturing: injection moulding and compression moulding. Injection moulding involves injecting molten plastic material into a mould cavity, which is then cooled and solidified to create the final product. This process is highly efficient and produces high-quality parts at a rapid pace. Compression moulding involves heating plastic pellets and then placing them into a heated mould cavity, which is then compressed to form the final product. This technique is used for larger parts or when the part requires greater strength and durability.

Plastic mould manufacturing has a wide range of applications, from the production of small plastic components to large automotive parts. The process allows for the creation of complex parts with intricate shapes and sizes. The ability to create identical parts at a rapid pace makes it an essential process in modern manufacturing.

In conclusion, plastic mould manufacturing is a crucial process in the manufacturing industry. It allows for the production of high-quality plastic parts at a rapid pace, making it a highly efficient and cost-effective process. The use of advanced technology and high-quality materials has made plastic mould manufacturing an essential process in various industries, including automotive, medical, and consumer goods.

Mould Manufacturing Process

The process of manufacturing a mould is a complex one, and it's important to note that not all plastic mould manufacturers use the same methods.

The most common method used by manufacturers is CNC machining, which involves using computer-controlled machines to carve out the shape of your product in thin layers. This technique has been around for decades and allows for greater precision than other methods like EDM (electrical discharge machining) or grinding.

Plastic mould manufacturing is a complex process that involves several steps to create high-quality mould for various industries. The process begins with designing the mould using computer-aided design (CAD) software. This software allows engineers to create a detailed 3D model of the mould, including all the intricate details required for the final product.

Once the design is complete, it's time to move onto the manufacturing stage. The first step in manufacturing is to create a mould base using steel or aluminum. This base is what will hold all the various components of the mould together. The base must be designed to withstand the high pressure and temperature required for the moulding process.

Next, the mould is assembled, which involves attaching various components such as the ejector pins, the sprue bushing, and the runner system. These components are essential for the mould to function correctly during the moulding process.

The next step is to machine the mould. This involves using specialized equipment to create the cavities and cores required for the final product. This process involves a high level of precision, and any errors or imperfections can result in a faulty mould.

Once the mould is machined, it's time to test it. This involves running a trial batch of plastic through the mould to ensure that it produces the desired product. Any issues with the mould or the moulding process can be addressed in this stage.

Finally, after the mould is tested and approved, it's ready for production. The mould is attached to an injection moulding machine, and plastic is injected into the cavities to create the final product. This process can be repeated thousands of times to create a large number of identical products.

Overall, plastic mould manufacturing is a complex and intricate process that requires a high level of skill and expertise. From designing the mould to running production, every step of the process must be executed with precision to ensure a high-quality final product.

1. Introduction

Mould manufacturing is an essential process in the production of various products, including automotive parts, consumer goods, and medical devices. Identifying different types of mould is crucial to ensure that the correct type is used for each product. In this guide, we will discuss the different types of mould prevalent in the mould manufacturing industry, their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type.

2. Types of Mould

Plastic Injection Mould:

Thermoset Compression Mould:

Blow Mould:

Rotational Mold:

3. Precautions and Safety Measures

Different types of mould have different safety considerations, but in general, it is important to wear appropriate personal protective equipment (PPE) when working with mould, such as gloves, goggles, and respirators. It is also important to follow proper handling and storage procedures to prevent mould contamination and ensure optimal mold performance.

Conclusion

Identifying different types of mould and understanding their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type is crucial to ensure that the correct type is used for each product. Proper maintenance and cleaning of mould are also essential to prevent mould contamination and ensure optimal mould performance. By implementing the knowledge gained in this guide, manufacturers can improve their mould manufacturing processes and produce high-quality products with greater efficiency and consistency.

#mold manufacturing#mould manufacturing#plastic molding#thermoset compression mould#cnc machining#injection molding#3d printing#manufacturing#compression molding#mumbai#india#blow mould#rotational molding

1 note

·

View note

Video

youtube

Plastic injection molding machines of our factory and other equipment for rainwater harvesting modular tanks

#youtube#rainwater collection#rainwater harvesting#rainwater harvesting system#tank factory#factory tour#factory direct#plastic injection molding#production machine#modular tank#water tank#underground tank#compression testing machine#processing machine#performance testing

0 notes

Text

AI created by Learub

The low hum of the engine echoed in the underground parking garage as the two men stepped out of the matte-black SUV. Their full leather race suits creaked with every calculated movement, molded tightly to their physiques like a second skin—each zipper, seam, and buckle placed with surgical precision. They moved in unison, their boots thudding heavily on the concrete, steel-capped and polished to a mirror sheen. The scent of oiled leather mingled with the faint chemical bite of rubber as they adjusted the harnesses on their backs—each man carrying a twin set of compressed oxygen cylinders connected to their full-coverage gas masks by thick, ribbed double hoses. The masks were masterpieces of fetish engineering—jet-black silicone contoured to the shape of the human face, seamless and unforgiving. Their lenses were one-way mirrored, offering no hint of the eyes behind them. Instead, the polished chrome glinted under the sodium vapor lights, giving the impression of emotionless sentinels or voyeuristic machines. Each breath hissed rhythmically through the air hoses, filtered through carbon scrubbers tucked neatly beneath the tanks. The sound was primal—controlled, erotic, and mechanical. Even inside the masks, the world was a sensual labyrinth: the scent of latex, the soft resistance of the silicone mouthpiece, and the pressure of the internal valves that opened only when they inhaled. There was no talking—just the slow, aroused rhythm of breath and the heat of anticipation building under the sealed suits. One man turned to the other, the lenses of his mask catching the reflection of his companion. He reached out, gloved hand brushing the chest of the other, tracing the insignia embossed in the leather. A small nod passed between them—wordless confirmation that they were ready.

Behind the reinforced door at the end of the corridor, the party waited: a subterranean haven where control, gear, and anonymity reigned supreme. With synchronized steps, they walked forward, each breath echoing in stereo through the dual hoses—two figures of lust, leather, and chrome, mirrored to the world but completely revealed only to each other.

The reinforced door hissed as the biometric lock disengaged, revealing a passage bathed in dim red light. Music throbbed beneath the surface—slow, bass-heavy pulses that reverberated through the walls and into their chests like a shared heartbeat.

They entered. The Sanctum wasn't a typical party. It was more like a cathedral for the devout—those who worshipped discipline, anonymity, and control. Figures moved through thick clouds of mist, their identities erased by hoods, masks, and layers of gleaming rubber and leather. The scent in the air was unmistakable: sweat, silicone polish, warm metal, and pheromones humming like static.

The two men stood side by side for a moment, their mirrored visors reflecting a distorted, feverish world. The taller of the two, known here only as Ares, stood with a subtle authority. His suit was custom-made, reinforced with matte black carbon panels at the shoulders and ribs, armor-like and ceremonial. His breathing through the gas mask was slower, deliberate. Ares wasn’t just attending this party—he commanded it. Beneath the mask, he was older, eyes sharp and calculating. He'd been coming to the Sanctum for years, and his presence here was mythic. The second man, leaner and slightly shorter, was called Rook. Newer. Hungry. His suit was glossier, almost liquid in the way it caught the light. His hoses flexed with each quickened breath, betraying his arousal and nervous energy. Though silent and masked, his body language spoke volumes—tense, eager, obedient. Ares had brought him here for the first time, to be broken in, so to speak. They walked deeper into the main chamber. Around them, scenes of ritualized desire played out: one man tethered by a series of chrome chains to a ceiling pulley, suspended and rotating slowly while others circled like animals in heat; another pair engaged in silent gestures of command and obedience, one gesturing with a gloved hand while the other knelt, perfectly still.

Ares placed a firm, gloved hand on Rook’s back, guiding him to a vacant padded platform beneath a steel arch studded with hooks, rings, and pneumatic attachments. The sound of the hoses—their shared breathing—was now indistinguishable from the pulsing rhythm of the Sanctum. Ares reached up and clipped Rook’s air hoses to a fixed overhead rig. It hissed as it took over the air supply, locking Rook in place with nothing but controlled oxygen, dependent and exposed. Even through the mirrored lens, Rook’s pulse could be seen in the rise of his chest and the tremble in his knees.

Ares leaned in close, his visor reflecting Rook’s. Their mirrored faces stared at each other—unreadable, unknowable, intensely present. Ares activated a control unit on his wrist, and Rook’s internal air flow slowed slightly, not dangerous—but perceptibly more restricted. It made every breath a conscious effort. A silent command to focus. Submit. With a slow motion, Ares zipped down the front of Rook’s suit, exposing just enough skin for the chill of the air to send a ripple across his body. Not a word had been spoken. None needed. Their communication was in breath, in movement, in mirrored eyes that saw everything without giving anything away. The party moved around them, shadows and shapes in shared fantasies. But in that moment, behind their masks, in that sanctuary of chrome and leather, they were alone—two reflections, perfectly matched in desire and restraint. The Sanctum was alive now—fully awake and pulsing like a living, breathing organism. The haze of synthetic mist clung low to the floor, illuminated by strips of cold LED light buried in the architecture. The air was thick with tension and heat. The rhythm of the music had slowed to a grinding tempo, deep and deliberate, like bodies colliding in a dream. Rook, now strapped to the overhead air rig, floated in sensory suspension. Every breath was regulated. His vision blurred slightly from the effort of each inhale through the double hoses, now routed through Ares’ wrist-mounted regulator. He was fully suited, fully sealed, but the zipper at his chest remained teasingly open—just enough to expose vulnerability beneath the armor of his leather. Ares stepped back, watching his creation breathe, squirm, and submit. And then—he appeared.

From behind a curtain of industrial chain, the third figure emerged. Head to toe in total enclosure rubber: thick, black, polished until it reflected even the dullest red light. His hood was expressionless, molded with a smooth finish except for a pair of breathing ports and two tinted lenses. Twin hoses, thick and gleaming, fed from a pressurized tank on his back, coiling over his shoulders like venomous serpents. He moved with purpose—silent, composed, lethal in his restraint. Ares turned, intrigued.

The rubber man approached them slowly. He was taller than Rook, broad-chested, with heavy boots that landed with damp authority. His entire body shimmered under the club’s red glow. He stopped a meter away and raised a gloved hand—a simple, formal gesture. A signal: permission to engage. Ares tilted his helmet slightly, approving. Wordless, always. Rook, watching through mirrored lenses, felt his body tense with anticipation. The rubber man stepped in close and reached out with thick, gloved fingers, running them slowly across Rook’s exposed chest, then down, tracing the edges of the opened zipper. He leaned in, his masked face nearly touching Rook’s. The hiss of the hoses became louder. Each man now breathed in concert: three rhythms, each one unique, forming a synthetic harmony of lust. Ares circled them, like a handler inspecting his subjects. He reached up and clipped the rubber man’s hoses into a separate feed—one he controlled independently. Now both of them—Rook and this silent stranger—were under Ares’ command, their oxygen flow subject to his whim. With a flick of a switch, Ares cut their airflow for exactly three seconds. One... Two... Three...

Then he restored it. The rush of breath through their hoses was a wave of pure sensation—heightened by denial. Both gas-masked submissives writhed, Rook arching slightly, the rubber man’s gloved hands gripping harder onto the frame above Rook’s head, exhaling hard through his filtered valves. Ares stepped between them, pressing a gloved hand onto each of their chests, feeling the rise and fall—measuring control, measuring need. He guided the rubber man's hand lower, over Rook’s groin, firm and slow. The suit's leather creaked as pressure built. Rook’s muscles strained under the suit. He moaned into the mask, but it came out as a low, filtered groan—barely audible, but felt in the bones. The rubber man responded in kind, grinding slightly as Ares manipulated their movements, a puppeteer with breath as his strings. Steam rose from the suits, slick with sweat sealed beneath layers of latex and leather. And all the while—mirrored lenses stared at mirrored lenses. No names. No faces. Just breathing. Control. Submission. Reflection.

In the Sanctum, they weren’t people. They were machines of pleasure. Interlocking. Obedient. Bound by the hiss of air and the absence of self.

8 notes

·

View notes

Text

7 Insider Secrets: How Are Cement Bricks & Blocks Manufactured for Superior Construction?

How are cement bricks and blocks manufactured?

Cement bricks and blocks form the backbone of modern construction, and understanding their manufacturing process can provide invaluable insights for contractors, engineers, and investors alike. In today’s competitive market, knowing what goes behind creating these essential building components not only improves decision-making but also instills confidence in the durability and quality of construction materials. In this article, we uncover the secrets behind the manufacturing process, address frequently asked questions, and highlight key statistics that underline the importance of precision in production.

Introduction

The construction industry relies heavily on the consistent quality of building materials. Cement bricks and blocks, known for their strength and longevity, are manufactured through a systematic, multi-step process that transforms raw materials into essential components for modern infrastructure. This blog post will walk you through the manufacturing process, answer common queries, and reveal industry insights that every professional and enthusiast should know. Whether you’re a seasoned builder or new to the industry, these insider secrets will elevate your understanding and guide your next project.

The Manufacturing Process Uncovered

1. Raw Materials: The Foundation of Quality

The journey begins with sourcing high-quality raw materials. The primary ingredients include cement, aggregates (like sand and gravel), water, and sometimes additives to enhance performance. Each component plays a crucial role:

Cement: Provides binding strength.

Aggregates: Offer structural stability.

Water: Initiates the hydration process.

Additives: Enhance durability and workability.

Ensuring the correct proportions is essential. For example, maintaining a water-to-cement ratio between 0.4 and 0.6 is critical for achieving optimal strength and durability. Industry statistics indicate that up to 80% of the final product’s quality is determined during this initial stage.

2. Mixing: Precision in Every Batch

Once raw materials are selected, the next step is mixing. Modern facilities employ high-speed mixers that blend the materials to a uniform consistency. This stage is crucial because even a minor imbalance in the mix can result in compromised strength or an inconsistent texture.

Mixing involves:

Batching: Precise measurement of each component.

Blending: Combining materials uniformly to ensure consistent distribution.

Monitoring: Continuous quality checks to ensure the mix adheres to industry standards.

Transitioning to the next phase, advanced monitoring systems now utilize sensors and automation to fine-tune the process, reducing human error and enhancing quality control.

3. Molding and Shaping: Crafting the Perfect Form

After mixing, the homogeneous material is transferred to molds to create bricks or blocks. The manufacturing process here can vary:

Cement Bricks: Typically, the mixture is compressed in a mold using a hydraulic press. The pressure applied can reach up to 10,000 psi, ensuring that the bricks are dense and robust.

Cement Blocks: Larger in size, these blocks are often cast using automated machines. The molds are designed to produce uniform shapes, which is critical for ensuring ease of installation and structural consistency.

Storytelling element: Imagine the precision of an orchestra playing in perfect harmony; every press and cast is a note contributing to the grand symphony of construction excellence.

4. Curing: Transforming Fresh Casts into Durable Structures

Curing is perhaps the most critical phase in the manufacturing process. Once molded, the bricks or blocks must cure—essentially, they undergo a controlled hardening process. This is achieved through:

Moisture Retention: Maintaining adequate moisture levels to allow the chemical reactions in cement to complete.

Temperature Control: Ensuring that environmental conditions support optimal hydration.

Time: Curing can take anywhere from 7 to 28 days depending on the product specifications and environmental conditions.

Statistics show that proper curing can improve the strength of cement bricks and blocks by up to 50% compared to those that are not cured under controlled conditions.

5. Quality Assurance: The Final Seal of Approval

Before cement bricks and blocks reach the market, they undergo rigorous quality assurance tests. These tests include:

Compression Strength Tests: Verifying that each unit can withstand heavy loads.

Dimensional Checks: Ensuring uniformity in size and shape.

Surface Inspections: Checking for any defects that could impact the performance or aesthetics of the final product.

Quality assurance protocols are not just about meeting regulatory standards—they provide peace of mind to builders and investors, ensuring that every brick or block contributes to a safe and sustainable construction.

Frequently Asked Questions

How are cement bricks different from cement blocks?

Cement bricks are usually smaller and are often used for walls and smaller constructions, whereas cement blocks are larger, offering enhanced structural stability for load-bearing walls. Their manufacturing process is similar, but the molding and curing processes may differ slightly to accommodate size differences.

What are the key factors that affect the quality of cement bricks and blocks?

The quality of these products largely depends on the quality of raw materials, the precision of the mixing process, the effectiveness of the molding and pressing systems, and the rigor of the curing and quality assurance processes. Maintaining the optimal water-to-cement ratio and ensuring a controlled curing environment are paramount.

How long does it take to manufacture cement bricks and blocks?

The manufacturing process itself is relatively quick, with mixing and molding taking just a few hours. However, the curing phase can take anywhere from 7 to 28 days, which is essential to achieve the desired strength and durability.

Can the manufacturing process be automated?

Yes, automation plays a significant role in modern production facilities. Automated mixers, robotic molding systems, and digital monitoring for curing are now common, increasing both efficiency and product consistency.

What are the environmental impacts of manufacturing cement bricks and blocks?

While the production process does involve energy consumption and carbon emissions, many manufacturers are adopting eco-friendly practices. Innovations like using recycled materials, optimizing energy usage, and exploring alternative fuels are gradually reducing the environmental footprint.

#BrickAndBlockManufacturers#InterlockingBlockMakingMachine#AutomaticInterlockingBlockMakingMachine#ManualFlyAshBrickMakingMachine#AutomaticFlyAshBrickMakingMachine#FullyAutomaticFlyAshBrickMakingMachine#AutomaticSolidBlockMakingMachine#AutomaticPaverBlockMakingMachine#PanMixerMachine#ConcretePanMixerMachine#RollerPanMixerMachine#PipeBendingMachineManufacturers#HydraulicShearingMachineManufacturers#ArecaLeafPlatesMakingMachine

2 notes

·

View notes

Video

youtube

JNSHARE GXL 560 Biomass Wood Sawdust Pellet Machine, Pellet Mill #pelletmachine #manufacturing

The new efficient GXL series biomass wood pellet machine has a high productivity and the service life of the pressed rollers is unprecedentedly improved.It is suitable for pressing materials that are difficult to bond and form, such as peanut shells, rice husks, etc. It is an ideal biomass compression molding machine with small investment, quick results and no risk. We are a pellet machine manufacturer, and our key machines are biomass pellet machine, wood pellet mill, RDF pellet machine, wood chipper, wood crusher, wood hammer mill, rotary dryer, pellet cooler and the complete lines. The output is from several kgs to several tons per hour. If any interest, feel free to connect us. #pelletmachine #pellets#rdf #msw #pelletmill #pelletindustry #pellet machine manufacturer#pellets #biomass #farming #jnshare #manufacturing #machine #automobile #wheatstraw

TEL/Wechat/ Whatsapp: +86 15053177578

Web: www.jnshare.com www.chinapelletline.com

1 note

·

View note

Text

Why is expanded polystyrene recycling so important?

Expanded Polystyrene (EPS) can be recycled and is recycled in Australia and around the world. It is one of the most efficient and economical insulating materials. Its low rate of thermal conductivity makes it extremely reliable for transporting temperature delicate items.

100% Recyclable: Not several individuals understand that EPS is 100% recyclable. Clean material can be reused in the production procedure of new EPS boxes. Any kind of a little infected material can be compacted and turned into recycled rigid plastic products.

EPS is 98% Air: Expanded Polystyrene is extremely comparable to a party balloon due to the fact that what you see, when you consider a piece of EPS or a balloon is just the 2% of what composes the things final shape. The 98% of the item that you do not see is thin air!

EPS has an ODP of Zero: EPS has an Ozone Depletion Potential (ODP) of absolutely no and causes no damages to the ozone layer because no CFC's or HCFC's are used during the manufacturing procedure. EPS is inert, does not seep any kind of chemicals and is completely food contact safe.

Why is Expanded Polystyrene a Good Insulator?

Expanded Polystyrene is an effective insulator since it's packed filled with tiny air pockets. Air is a very bad conductor of heat so heat transfer is minimized.

EPS is a closed cell foam, meaning every cell is closed off to the other cells that border it. The cell wall surfaces assist to provide strength to the material and trap air inside.

Expanded Polystyrene Recycling Case Studies

The Lismore City Council is a model council for recycling and environmental protection in Australia. It has started recycling-related projects in 2009. At that time, Lismore City’s introduction to this project was “This project will implement new waste and recycling bins across several parks and sporting facilities in Lismore. In addition to constructing and installing new bins, Lismore City Council will undertake a litter check and community education strategy to maximize the benefits of recycling bin infrastructure. This project will be undertaken over the 2104–15 financial year, and is estimated to recover over 11 tons of recyclables per year once concluded.”

In 2015, GREENMAX visited the Lismore City Council and learned about the Polystyrene recycling model in Lismore and found that Lismore’s recycled polystyrene quality control is not very good, so GREENMAX conducted on-site guidance, and the city of Lismore has been recycling polystyrene waste of great quality until now. Find out more.

In April 2022, JB HI-FI purchased GREENMAX hydraulic compactor, the latest polystyrene compacting technology in the world, integrating the benefits of standard polystyrene screw compactor and also hot melting machines. Equipped with high-efficient automated hydraulic system, the waste polystyrene is crushed and after that moved right into a storage bin of the GREENMAX Heracles Series polystyrene Compactor via a screw and then compressed right into dense and uniform blocks with a volume reduction proportion of 70:1, reducing the volume of waste polystyrene, as a result saving storage space and also transportation prices. Find out more.

youtube

Extra work is required by the government and local authorities to manage materials at the end of their life to reduce the influence on the environment.

There is growing concern and even more scrutiny than ever highlighting the environmental impact of all the materials that we utilize daily. EPS is a lightweight, rigid molded foam widely utilized in the food services industry for its outstanding thermal properties for both reuse and recyclability.

How to recycle expanded polystyrene?

Granulation

Foam plastic pelletizing systems are generally designed for foamed plastics. As foamed plastics have a large volume, light density, and even gas containing air inside the material, multi-screw conveying has certain requirements during the granulation process to achieve a certain capacity requirement.

GREENMAX foam plastic pelletizing systems are mainly for EPS, EPE, EPP and other foam plastics. Whether it is compressed EPS, EPP, EPE plastics, or uncompressed and volume-reduced foam plastics, GREENMAX can provide customized solutions and help to take these foams directly into plastic pellet products and back into the circular economy.

Compacting

GREENMAX foam recycling machine can reduce the volume of EPS foam to 1/50 and 1/90 of the original, effectively saving the storage space of waste EPS polystyrene foam, saving transportation and storage cost, and then turn it into recycled particles through recycling technology for the production of plastic products, which are widely used in the field of environmental protection frame, environmental protection picture frame, environmental protection mirror frame, foot line, top corner line, outdoor floor and other indoor and outdoor decorative materials.

1 note

·

View note

Text

What Makes a Rubber Compression Molding Machine a Smart Choice for Manufacturers?

Manufacturing high-quality rubber components requires precision, efficiency, and the right equipment. Among the various methods available, the rubber compression molding machine stands out as a reliable solution for shaping durable rubber parts. With its ability to handle complex designs and high-performance materials, it’s become a preferred tool in many industries.

0 notes

Text

Revolutionizing Manufacturing: Top Trends in Rubber Compression Molding Machines in the USA

Discover the latest trends in rubber compression molding machines revolutionizing manufacturing in the USA! Explore how advanced technologies, sustainability, and customization are driving innovation across industries. Dive into our in-depth blog to stay ahead in the dynamic world of industrial production.

0 notes

Text

Industry Benefits from Reliable and Flexible Cap Compression Technology

The Cap Compression Molding Machine serves as a cornerstone in many packaging processes, offering manufacturers an efficient and reliable method for producing high-quality caps. This advanced machinery from Taizhou Chuangzhen Machinery enables companies to meet diverse industry requirements, adapting to various materials and design specifications with remarkable consistency.

This compression molding equipment applies precise heat and pressure to form plastic caps that ensure durability and secure sealing. Its versatility allows it to handle a wide range of cap styles, from simple screw tops to sophisticated safety closures. This adaptability is crucial in industries such as food and beverage, pharmaceuticals, and personal care, where product protection and consumer safety are top priorities.

Operational flexibility is another key feature of these systems. They support both large-scale production and smaller custom orders, responding quickly to market demands without compromising on quality. With intuitive controls and robust design, downtime is minimized, helping manufacturers maintain steady production schedules.

Energy efficiency and material conservation are also important aspects of this molding technology. By optimizing process parameters and reducing waste, these machines contribute to more sustainable manufacturing practices. Taizhou Chuangzhen Machinery emphasizes these benefits, integrating green technologies that meet modern environmental standards.

The ability to consistently produce precision caps with high speed makes these compression systems a valuable investment for companies looking to enhance their packaging lines. As market trends evolve, such adaptable and efficient equipment becomes increasingly essential for maintaining a competitive edge.

For more information on the wide-ranging applications and benefits of these molding technologies, please visit the official Taizhou Chuangzhen Machinery page at: capping-machine.net/news/industry-news/cap-compression-molding-machines-price-types-process-and-future-trends.html

#Cap Compression Molding Machine#Capping-machine#packaging solutions#industry applications#energy efficiency

0 notes

Text

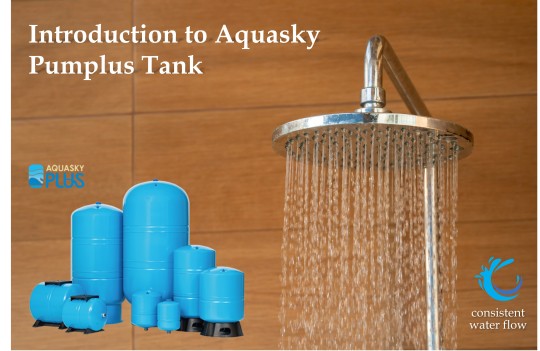

Introduction to the Pumplus Well Tank |Aquasky

A pressure tank is a general term for a vessel designed to hold liquids or gases under pressure. Depending on their specific applications, these tanks are referred to by various names across industries. In this article, we will focus on residential pressure water booster systems, where they are commonly known as Well Tanks or Sanitary Water Tanks.

1. Introduction to the Pumplus Well Tank

The Aquasky PumPlus Pressure Tank is an indispensable part of residential pressurized water systems, providing water pressure at a consistent level. The tank stores supplemental water between the diaphragm and liner, and the pressurized air chamber creates a supply circle. This innovative design significantly reduces the frequency of motor startups, maintaining steady system pressure and enhancing the efficiency of household appliances such as dishwashers and washing machines. It also ensures a strong water flow for showering and bathing.

Designed as an energy-saving solution, the PumPlus pressure tank requires no maintenance and, when paired with a properly sized pump, provides reliable and long-lasting service. This system not only minimizes energy consumption and protects against water hammers but also stabilizes water pressure to effectively meet daily needs.

Aquasky's commitment to quality and efficiency is embodied in the PumPlus series, which exemplifies the best in diaphragm-type pressure tank technology, offering a practical solution for managing residential water systems.

2. Design and Features of the Pumplus Well Tank

Constructed from cold-rolled carbon steel, the Pumplus Well Tank is built to withstand high pressures and harsh environmental conditions, making it ideal for for coastal areas prone to corrosion. With capacities ranging from 1 to 500 liters, it meets a variety of residential system sizes and requirements.

* Material and Construction:

The study cold-rolled carbon steel exterior of the tank offers excellent resistance to a wide range of atmospheric environments and corrosive media, ensuring durability and reliability in potable water systems.

* Connector Design:

To enhance tank adaptability and strength, the Pumplus Well Tank incorporates three types of stainless steel connectors:

* Male Straight Connector: Used on smaller and horizontal tanks for straightforward attachment to plumbing systems.

* Reinforced Male Connector: Features a reinforcing plate that increases the welding circumference by 50%, enhancing the strength and durability of the connection.

* Elbow Female Connector: Designed for medium and large tanks, this design features a side opening that facilitates easier pipe installation, improving the installation process.

* Internal Structure:

Inside, the tank is divided by a flexible rubber butyl diaphragm into two main chambers: the Water Chamber and the Air Chamber.

* The Water Chamber: Equipped with a corrosion-resistant propylene (PP) liner that molds to the tank shell's shape, preventing water contact with the steel shell and ensuing corrosion. It features a type 304 stainless steel threaded outlet for seamless connection to the water supply.

* The Air Chamber: Sealed and pre-charged with nitrogen to enhance stability and reduce maintenance needs, featuring an air valve for crucial pressure adjustments.

* The diaphragm is the only moving part, dynamically adjusting to changes in water volume to maintain consistent pressure and prevent water logging.

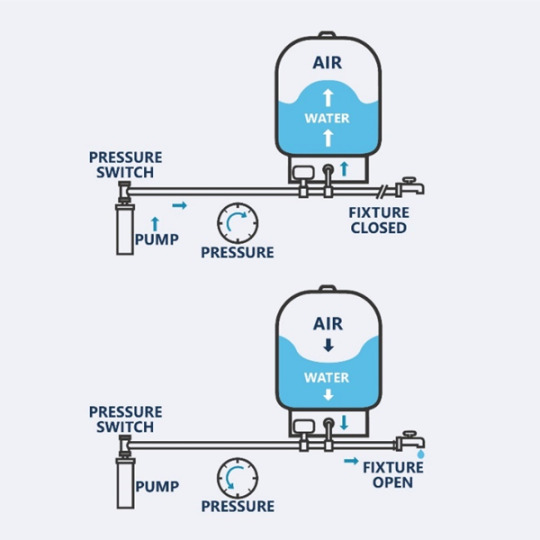

3. How Pumplus Works Inside a Pump System

In a pump system not equipped with a pressure tank, water is not very compressible, and pipes can only store a small amount of water. As a result, when you open a tap, the pressure drops quickly, leading to minimal water output. At this point, the pressure falls to the "on" setting of the pressure switch, prompting the pump to activate and start pumping again.

Integrating a pressure tank into a pump system significantly enhances its operation and extends the pump's lifespan by managing water pressure more efficiently. The tank stores water under pressure, operating as follows:

* As water is drawn from the well and pumped into the tank, it compresses the air in the upper part of the tank, increasing the internal pressure. When this pressure reaches its maximum limit t(ypically 50 to 60 PSI), the pump stops pumping water, maintaining pressure in the system.

* When water is demanded - such as opening a faucet - the compressed air in the air pressure zone is released. This air pressure deflates, pushing against the rubber diaphragm in the tank and expelling water through the plumbing system. Once the water level drops to a certain level and the air pressure in the tank drops to a pre-set minimum (typically 30 to 40 PSI), the pump reactivates to refill the tank.

* When the tap shuts, then the water stops flowing and the pressure in the system builds. When the pressure reaches the “off” setting of the switch or controller, then this turns the pump off and the pipes remain pressurized.

The tank's air pressure and water volume are controlled by a pressure switch, which has preset high and low pressure thresholds.

This system reduces the frequency of pump cycling, which is crucial for preventing wear and tear on the pump and saving electricity. By buffering the pressure and storing water in advance, the tank ensures a steady supply and reduces the stress on the pump, which is especially important for systems where pumps are not designed to start frequently, such as submersible bore pumps.

Picture 1: The work of the pressure tank within a system

4. Benefits of Using Pumplus Well Tanks

Pumplus Well Tanks are expertly designed to boost the efficiency and longevity of water systems, providing several key benefits. These tanks store pressurized water, significantly reducing the frequency of pump cycling, which not only extends the pump’s lifespan but also conserves energy and lowers utility costs. This feature also improves battery life in systems where applicable. The tanks ensure a consistent water flow and pressure, crucial for both residential comfort and industrial applications. Additionally, they offer protection against water hammers, which can cause sudden and harmful pressure changes, thus safeguarding your plumbing infrastructure. With a Pumplus Well Tank, you gain instant access to well water without needing to manually activate the pump, enhancing operational convenience and reducing the mechanical strain on your pump.

By integrating a Pumplus Well Tank into your system, you not only safeguard the mechanical integrity of your pump but also enhance the overall functionality and efficiency of your water supply system, ensuring it operates smoothly and quietly.

5. Pumplus Pressure Tank Models by Aquasky

* In-line Models

Available sizes: 3, 8, 12, 18, 24 liters

These models are typically installed directly in the main water supply line and feature a 1” connection, making them ideal for seamless integration into residential systems.

* Vertical Stand Models

Available sizes: 40, 60, 80, 100, 120, 130, 160, 200, 240, 300, 325, 450, 500 liters

* Tanks ranging from 40 to 120 liters come with a 1” connection and a plastic base, suitable for moderate residential use.

* Larger sizes from 130 to 325 liters include a 1-1/4” connector and plastic base, designed for extensive residential or light commercial applications.

* The largest tanks, 450 and 500 liters, are equipped with a 1-1/4” connector and an iron support base, ideal for commercial settings requiring substantial water capacity.

* Horizontal Models

Available sizes: 18, 24, 40, 60, 80, 100 liters

These are equipped with a 1” connection and a plastic pump stand, providing flexibility and durability for various installation environments.

6. Methods for Choosing the Correct Size of Pumplus Pressure Tank

Choosing the proper size for your Pumplus pressure tank is crucial to prevent premature pump failure and ensure efficient system operation. Here are the detailed steps and considerations:

* Residential Capacity Based on Drawdown Capacity:

* Determine Flow Rate: Measure how many liters per minute your pump produces.

* Calculate Minimum Runtime: Typically, one minute is sufficient. Multiply the flow rate by the minimum runtime to determine the drawdown capacity, ensuring the pump operates efficiently without frequent cycling.

The formula: Flow Rate (LPM) x Minimum Runtime (1 minute) = Drawdown Capacity

For example: 60 LPM flow rate x 1 = 60 liters drawdown capacity.

* Set Pressure Switch: The pressure switch setting is the pressure at which the pump turns on to fill the tank up, and the pressure at which the pump shuts off, knowing the tank is full. Standard settings range from 2.07/3.45 bar to 2.76/4.14 bar, where the first number is the cut-in pressure and the second is the cut-out pressure. This setting significantly impacts the drawdown capacity and system efficiency.

* Residential Capacity Based on Fixture Count:

The capacity of the pump system in gallons per minute (GPM) should equal the number of fixtures in the home. This must take into account all use for the kitchen, bath, appliances, outside irrigation, a pool, and special fixtures, such as a hot tub. In this model, modern home with two bathrooms (three outlets each), kitchen sink, dishwasher, washing machine, laundry tub, and two outside hose outlets would require a capacity of 12 gallons per minute, based on the 12 fixtures or outlets.

Aquasky’s experts suppose each water faucet flows out 10 litres of water each time, so customer just needs to know the number of water faucet inside the water system, and they can select a correct size pressure tank.

* Using Aquasky Selection Tool

Please link to the following AQUASKY website: https://aquaskyplus.com/sel_tools.php

Enter demand figures, AQUASKY will help you calculate the proper size pressure tank.

7. Installation Process

Installing an Aquasky Pumplus Well Tank is a critical step in ensuring efficient operation and extended longevity of your water system.

Start by removing any existing equipment such as old steel galvanized tanks, air volume controls, and plugging or removing bleeder and snifter valves. After unpacking your new tank, begin the initial setup by removing the air valve cap and using a standard tire pressure gauge to check and adjust the tank’s pre-charge pressure. This should be set to 2 PSI below the pump’s cut-in pressure setting, ensuring adjustments are made when the tank is empty and the system pressure is at 0 PSI to avoid inaccuracies. Typically, Pumplus tanks come with a preset cut-in pressure of 30 PSI, so adjust the pre-charge to 28 PSI. Consult your pump’s documentation for specific settings, often found under the pressure switch cover.

Once adjusted, re-secure the air valve cap tightly. Choose an installation site that minimizes risk in the event of leaks and provides adequate drainage, making sure the location’s flooring is level. When making pipe connections, ensure that the pipe size from the tank matches that from the pump to the house, and follow local or state plumbing codes. Refer to the included installation diagram (from Picture 2 to Picture 6) for further guidance. After all connections are secure, prime the pump and restore power. Finally, check all joints to ensure they are airtight, preventing any leaks and guaranteeing system integrity. By carefully following these steps, you will successfully install your Pumplus Well Tank, optimizing its performance and enhancing the durability of your water pressure system.

8. Maintenance and Longevity

Aquasky Pumplus pressure tanks are built to last, but their lifespan greatly depends on proper maintenance and system setup. The longevity of these tanks is influenced by two main factors: the inherent quality of the tank and the suitability of its size and settings for the specific system.

Under typical conditions, Aquasky Pumplus pressure tanks are designed to last about 5 years. With optimal care and ideal water conditions, high-quality models can extend up to 8 years or more. In systems where the water is consistently clean and the tank is correctly sized, the lifespan can reach an average of 10 years.

Here are some tips on how to maximize the lifespan of your pressure tank:

* For optimal performance, it is essential to ensure the tank is properly sized and configured for your system to efficiently handle water demand and minimize wear and tear.

* Regularly monitoring and managing water quality is also crucial, particularly in coastal areas where higher salt content can accelerate corrosion. Installing a filter system can help mitigate damage from sediments like sand or small rocks that might erode the diaphragm over time, potentially leading to leaks.

* To further extend the tank’s life, reduce the frequency of pump cycling to prevent mechanical strain and quick wear of the diaphragm. Regular inspections of the diaphragm and adjustments to the tank’s pre-charge based on water usage or system changes are vital.

9. Conclusion

The Pumplus Well Tank exemplifies the advantages of using a high-quality pressure tank in any pressurized water system. With its sturdy design, efficient operation, and potential for energy savings, it represents a wise investment for ensuring reliable and effective water pressure management.

For more information of Aquaksy Pumplus well tank, you can click website: https://aquaskyplus.com/PUMPLUS.php

Or you can email to us: [email protected]

1 note

·

View note

Text

【The ultimate guide to choosing the perfect Dry Ice Cleaning Machineand dry ice machine for your needs】

UNDERSTANDING YOUR REQUIREMENTS

1. Determine your application area:

Before diving into machine specifications, determine your primary application. Whether it’s industrial cleaning, food preservation, or special effects in the entertainment industry, understanding your specific use case will allow you to more accurately select the machine that’s best for you.Or you can tell us your needs and we will recommend the best solution for you.

2. Dry ice quantity issue:

Consider the amount of dry ice you need. Industrial applications may require high-capacity machines, while smaller equipment can meet smaller-scale needs. Understanding your production requirements is critical.You can refer to 【Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers】and 【How to set up your own dry ice manufacturing factory?】Learn more about dry ice in two articles.

TYPES OF DRY ICE CLEANERS AND DRY ICE PELLETIZERS

1. Dry ice cleaning machine(Dry ice blasting machine):

Compressed air is used to accelerate dry ice pellets to supersonic speeds and spray them onto the surface being cleaned. The high-speed ice particles hit the dirt, and through the freezing and mechanical action of the ice, the dirt is peeled off the surface.It is widely used for cleaning machinery and equipment, production lines, building surfaces, etc. It is especially suitable for the food and pharmaceutical industries because the cleaning process does not require water or chemicals.(Want to learn more about Dry Ice Cleaning?)

· P7X Dry ice cleaning machine: Very suitable for cleaning carbon deposits and oil stains in car engines. It can effectively complete cleaning without damaging engine parts etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· A625i Dry ice cleaning machine: Suitable for cleaning oily molds, motor windings, paint rust cleaning, and printing machine ink residues etc.. (Suitable for rubber factories, shoe factories, factory machine maintenance, etc.)Go to view product details

· P60 Dry ice cleaning machine: Used for car interior renovation and cleaning, car seat cushions, surface glue residue, and oil stain cleaning etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· T6 Dry ice cleaning machine: Used for PCB circuit board renovation and cleaning, soldering residue, surface glue residue, oil stains, PPS material deburring, etc. (Suitable for component factories, component maintenance, factory machine maintenance, etc.)Go to view product details

· B3+ Dry ice cleaning machine: Used for cleaning motor winding dust, printing machine ink, oil sludge, rust stains, heavy oily metal, etc.(Used to clean and maintain a variety of industrial equipment, including engines, pumps, valves, pipes, etc.)Go to view product details

Generally speaking, the dry ice cleaning machine is an efficient, environmentally friendly, and multi-purpose cleaning equipment. Its working principle is based on high-speed spraying of dry ice particles to clean the surface through freezing and mechanical impact. The advantages of this cleaning method include being water-free, leaving no chemical residue, being non-abrasive, suitable for a variety of surfaces and materials, and having a wide range of applications in a variety of industries.

For potential users, when choosing a dry ice cleaning machine suitable for specific needs, factors such as cleaning objectives, working environment, cleaning effect requirements, production capacity and budget need to be considered. Whether in industrial, food, medical or other industries, dry ice cleaning machines have demonstrated their excellent performance in improving cleaning efficiency and protecting equipment surfaces.You can also tell us your needs and our engineers will recommend the most suitable solution for you. Contact an engineer now >>

2. Dry ice pellet machine(Dry Ice Granulator Machine):

Dry ice pelletizer is a piece of equipment specially used to turn liquid carbon dioxide (CO2) into solid carbon dioxide (dry ice) pellets.

Dry ice pelletizers usually deliver liquid CO2 into the machine through a liquid carbon dioxide supply system. Liquid carbon dioxide undergoes a series of cooling and pressurization processes, causing its temperature and pressure to rise. The pressurized liquid carbon dioxide passes through the nozzle or spray head and enters a relatively low-pressure environment. In this environment, liquid CO2 rapidly relaxes and expands, lowering its temperature and turning into a solid state. Because the temperature drops sharply, liquid CO2 turns into a gaseous state and forms tiny CO2 particles, known as dry ice particles.

The Dry ice machine can efficiently convert liquid CO2 into a large number of evenly distributed dry ice pellets. The advanced control system can achieve precise control of parameters such as temperature, pressure and particle size to ensure the production of dry ice that meets requirements. Some Dry Ice Granulator have adjustable mechanisms that allow the user to select different sizes of dry ice pellets. There is no need to add any chemicals during the manufacturing process, and the waste material is CO2 gas, so the dry ice pelletizer is considered a relatively environmentally friendly production method. Most Dry Ice Pelletizer Making Machine are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

3. Dry Ice Block Machine(Dry ice briquetting machine):

A dry ice block press is a piece of equipment specifically designed to compress dry ice pellets or pieces into block form.

Dry ice block presses typically use previously produced dry ice pellets or chips as raw material. These pellets or chips are usually prepared through an overhead dry ice pelletizer or other means. Dry ice raw material is transported to the compression zone and heated to a certain level. The purpose of heating is to cause the dry ice pellets or blocks to begin to soften and melt. After heating, the softened dry ice is placed in a compression zone, where compression machinery or a hydraulic system exerts tremendous pressure to compress the dry ice into blocks. The compressed dry ice blocks pass through the cooling system, where they are quickly cooled and re-solidified to form solid dry ice blocks. The formed dry ice blocks enter the collector through the collection system, and then enter the packaging area through the conveyor system for final packaging.

Go to view product details >>

Main feature:

Efficient production: The dry ice block press can efficiently convert dry ice pellets or fragments into large, solid dry ice.

Uniformity of dry ice blocks: Compression machinery and control systems ensure uniform shape and size of dry ice blocks, suitable for different applications.

Save space: Dry ice in block form is easier to store and transport than in crushed or pellet form, thus saving space.

Energy savings: Previously produced dry ice pellets or crumbs are used as raw material, reducing the need for additional refrigeration and helping to save energy.

Automated operation: Most modern dry ice block presses are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

Application areas:

Food and pharmaceutical transportation: Dry ice blocks are widely used in cold chain transportation to keep food and pharmaceuticals at low temperatures.

Laboratory and scientific research: In laboratories and scientific research fields, dry ice blocks are used to prepare low-temperature environments, such as refrigeration reagents.

Special effects production: Dry ice cubes are often used in film productions and stage performances to create special smoke and cold fog effects.

Environmentally Friendly Cleaning: Dry ice cubes are also used in the cleaning industry for cleaning and removing dirt, especially for electrical equipment cleaning.

Overall, the dry ice block press provides a reliable production method for producing large blocks of dry ice, suitable for the different needs of multiple industries.

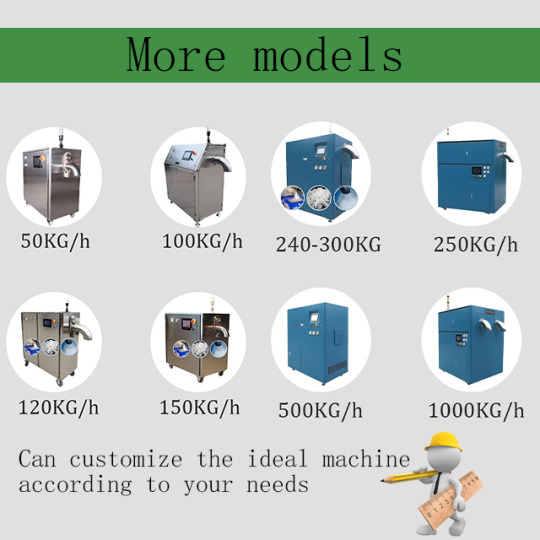

RODUCTION CAPACITY

Evaluate the machine's productivity in pounds per hour. Make sure it fits your needs without sacrificing quality. To meet high-volume demand, faster production may be required.

OLLITAL aims to provide customers with more choices in production capacity. Independently developed: 50KG/H (110 lbs/H), 100KG/H (220 lbs/H), 150KG/H (330 lbs/H), 250KG/H (551 lbs/H), 500KG/H (1102 lbs/H), and 1000KG/H (2204 lbs/H) dry ice pellet machine. Or you can tell us your needs and our engineers will customize the most suitable solution for you according to your needs. Contact an engineer immediately for customization >>

TECHNICAL SPECIFICATIONS

1. Size and portability:

Consider the physical size of the machine. A compact, portable unit may be better for versatility and ease of use, especially if you work from different locations or have limited space. If you need to move your cleaning equipment between job sites, choosing a dry ice blaster that is compact and portable may be key. This is important for tasks that require frequent movement or operation in limited spaces.

* Machine size: View the actual dimensions of your dry ice blaster, including length, width, and height. Make sure the machine is sized to fit your workplace and can be easily stored or carried.

* Weight: In addition to size, consider the weight of your dry ice blaster. The lightweight design can improve portability, reduce the burden of transportation, and make the device easier to carry and operate.

* Easy to carry design: Choose a machine with a user-friendly carrying design, such as handles, wheels, or other structures for easy movement. These designs make it easier for operators to move equipment from one location to another.

* Versatility: Some portable dry ice blasters are designed for versatility and can be used in a variety of applications. This flexibility increases the equipment's usefulness and makes it suitable for different types of cleaning tasks.

* Easy to store: Consider the storage needs of the machine when not in use. Some machines may have folding or removable parts to make it easier to store in limited spaces.

* Power and energy requirements: Consider the power and energy requirements of your dry ice blaster. Portable devices are often easier to connect to different types of power sources, such as batteries, generators, or standard electrical outlets.

When selecting a dry ice blaster, considering size and portability can ensure the equipment is better suited to your job requirements, increasing operational flexibility and efficiency.

2. Automation and control:

Automation and control are crucial considerations when selecting a dry ice pelletizer and cleaning machine. Look for user-friendly controls and automation features. An intuitive interface and automation streamline operation, making the machine easier for operators of all skill levels to use.

* Intuitive interface: Choose a dry ice granulator/cleaner with an intuitive interface. An intuitive control panel or touch screen makes it easier for operators to understand and operate the equipment, reducing training time.

* User-friendly controls: Consider choosing a machine with user-friendly controls. Simple buttons, knobs or digital controls allow operators to easily adjust and monitor cleaning parameters.

* Default program: Look for machines with preset cleaning programs. Preset programs improve operational consistency and efficiency, reducing manual setup and adjustments by the operator.

* Automation features: Understand whether the machine has automated functions, such as automatic nozzle adjustment, cleaning trajectory planning, etc. These features simplify the cleaning process and reduce operator intervention.

* Remote control and monitoring: If possible, choose machines that support remote control and monitoring. In this way, operators can monitor and adjust the cleaning process remotely, increasing the operational flexibility of the equipment.

* Fault diagnosis and alarm system: Look for machines with fault diagnosis and alarm systems. These systems can detect and report potential problems in a timely manner, helping to quickly resolve faults and improve equipment reliability.

* Data logging and reporting: Some advanced dry ice cleaning machines have data logging and reporting capabilities that can record key parameters during the cleaning process. This is very useful for quality control and traceability.

* Programmability: If you need to personalize it for a specific application, consider choosing a machine with some programmability to accommodate different cleaning needs.

By choosing a dry ice pelletizer/cleaner with an intuitive interface, automated features, and user-friendly controls, you can increase the ease of use of your equipment, reduce training costs, and ensure consistent cleaning results among operators of different skill levels .

Choosing the perfect dry ice machine requires a thorough understanding of your specific needs, technical specifications, and cost considerations. By carefully evaluating these factors, you will be able to make an informed decision that meets your application requirements and provides long-term value.

Whether you're venturing into a new business or upgrading an existing setup, investing the time in selecting the right dry ice machine is a critical step toward efficiency and success.

If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

2 notes

·

View notes

Text

We are the sacrifice for a future we will never touch but could always see until we could no longer hear the animal caged inside us coughing up dying breaths of crimson entangled in visions offered to the next generation arousing into an epiphany; blind, deaf, and dumb, I still breathe again, clear the conscience, clean the slate, and condense into clay to be stored, molded, and cast in fire drawn from a match that struck a stone that lit all that beauty and all that is beautiful to all that see and blind I still see. You fall past bodies torn apart and stitched together into arrangements hanging from tissue lining viscera alongside pale skinned wide eyed nymphomaniacs in cages waiting to be desecrated and have their gaping splendor captured and cast in stone for later generations to admire for eternity; fall past angels encased in sculptures written into scriptures that lift with the rising tide crashing into sentience flooding the subconscious paralyzing and suffocating all of us unable to swim still but bowed down forever fixed towards the lifting eyebrow. Up, down, and in reverse gravity strong enough to collide heaven and hell coincides to wake us in bed confused and condemned to a future I failed to anticipate and still have no intuition on except I am alone and receding from what I once loved, admired, or saw something special in.

I become 1 and divide into trie, a sun and sea, a holy trinity, a particle wave duality. Nothing is never complete, no number is greater or less than another, something is always lost in the compression and translation.

All fallen angels rise, unsheathe the past and watch your future self watch you watch those around you pull you to the surface. Let light flood the tunnel and bring into perfect clarity who we should be, collapsed on the floor foaming at the mouth while carpet fibers scratching our bare skin overload our senses until we can no longer remember who we are or how we grew into these shells holding all our mistakes, weakness, arrogance, and fear; waking with tears in our eyes from a dream before facing another day of work revisiting all the avenues that could have led us to a life not surrounded by soul stealing machines full of self-destructive shame, hate, desire, love, happiness, and no regrets.

Every decision and indecision haunts me. Every letter is like a seed I've cast into a subterranean river. What swims beneath the murk? How deep can the spirits hunting me down see? I know there is a mix of characters to make sense of this senselessness, provide repentance and atonement, and right wrong.

/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\

There is horeifying beauty in the eye of the beholder, and the rising tide lifts all ships, to be swallowed into the jaws of the sea.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

edit:

youtube

youtube

2 notes

·

View notes

Video

youtube

Pellet Mill Machine and Completely Production Line, High Efficient, Good Quality, Best Price

Our newest pellet machine is suitable for pressing materials that are difficult to bond and form. Such as rice husks, sunflower seed husks, branches, etc., tree stems, corn stalks, rice straw, as well as various chemical raw materials such as rubber and cement. This pellet machine is widely used in feed plants, fuel plants, fertilizer plants, chemical plants, etc. It is a biomass compression molding machine with small investment and quick results. We are a pellet machine manufacturer for 18 years, if any interest feel free to contact us. #ringdie #pressedrollers #insidestructure #pelletmill #biomasspellets #pellet #machine #farming #fuel #automobile #biomass #corncob #biomasspelletmachine #wheatstalk #corncob #rdf #constructionwaste #msw #wastepaper #biomasspellets #wasteclothes#waste #pelletmachine #pelletmachinesuppliers #biomasswaste #fuel #pelletmill #machine #wood #organicfarming #organic

TEL/Wechat/ Whatsapp: +86 15053177578 Email: [email protected] [email protected] web: www.pelletmill.cn www.jnshare.com

1 note

·

View note