#Compression Testing Machine in India

Explore tagged Tumblr posts

Text

In today’s industrial landscape, ensuring the structural integrity and strength of materials is paramount. Whether in construction, manufacturing, or research, compression testing plays a critical role in determining how materials respond to compressive forces.

#compression testing machine#compression testing#compression testing machine price#compression testing machine in India#compression test#compression tester#CTM#CTM machine#CTM price

0 notes

Text

youtube

PU foam fatigue tester manufacturer in India | ISO 3386, ISO 2439, ISO 3385, ASTM D3574, IS 7888

PU foam fatigue tester manufacturer in India | ISO 3386, ISO 2439, ISO 3385, ASTM D3574, IS 7888

Discover the importance of the Foam Flexing Tester, a vital instrument for testing the fatigue resistance and durability of flexible polyurethane foams. This machine plays a key role in industries such as automotive, furniture, and bedding, where long-term comfort and performance are essential.

In this video, we explain how the Foam Flexing Tester works, its significance in quality assurance, and the key international standards it complies with, including: ISO 3386, ISO 2439, ISO 3385, ASTM D3574, IS 7888:1976

By following these standardized methods, manufacturers can ensure that their foam products stand up to years of use without deterioration—boosting product longevity and customer satisfaction.

👉 If you're looking for detailed testing procedures or expert equipment recommendations, feel free to contact us for guidance!

TEXCARE – Testing Instruments You Can Trust 📞 24/7 Support: +91-8802270444 📧 Email: [email protected] 🌐 Website: www.texcareindia.com 📱 Contact: +91-9899309879, +91-9990592299 📍 Visit: I-84, Road No. 19, UPSIDC Site-C, Surajpur Industrial Area, Greater Noida-201306 (UP)

📌 Don’t forget to like, subscribe, and hit the bell icon for more insights on materials testing and industrial quality control.

. .

Foam #Testing #Durability #Fatigue #Polyurethane #Automotive #Furniture #Bedding #Labtech #Materials #Quality #Innovation #Engineering #Machinery #Industry #Standards #ISO #ASTM #Flexing #Tools #Performance #TestingLab #Tech #Equipment #Compliance #PUFoam #Test #Like #Follow

PU Foam Fatigue Testing Secrets Revealed by Indian Manufacturer | Indian PU Foam Fatigue Tester Manufacturer Texcare Instruments Best Kept Secret

#Foam Constant load Pounding Fatigue Tester#Foam Analysis Instrument Tester#Foam Porosity Tester near me#Mattress Testing Equipment near me#Car Seat Foam Testing Machine#Sofa Foam testing near me#Bedding Foam Testing machine video#Mattress testing machine#Foam Constant Load Pounding Machine for testing#PU Foam Testing Equipments#Foam flexing tester price#Best foam flexing tester in Pune#Foam flexing tester manufacturers in India#Foam flexing tester supplier in India#Foam Hardness Tester in bangalore#Foam Compression Test Machine in Delhi#Foam Testing Instruments in Mumbai#Flexing fatigue test Machine in Noida#Polyurethane foam testing Machine#Industrial foam testing Machine#Furniture Foam Testing Machine#Automotive Foam Testing Machine#Youtube

0 notes

Text

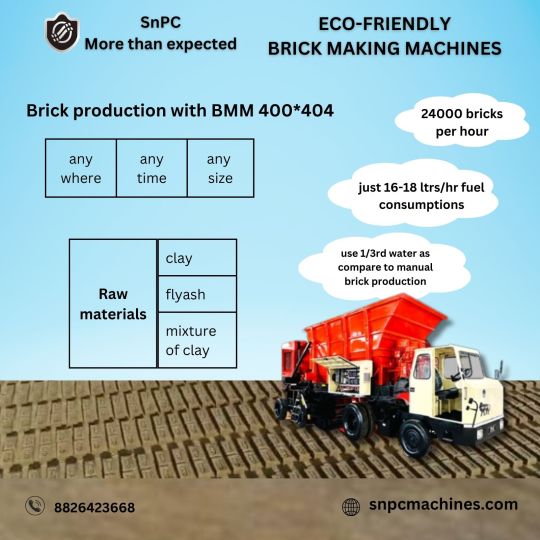

Produce bricks anywhere and anytime

SnPC Machines: Factory of brick on wheel

Fully automatic mobile brick making machine by SnPC Machines, First of its kind of machine in the world, our brick-making machine moves on wheels like a vehicle and produces bricks while the vehicle is on move. This allows kiln owners to produce bricks anywhere and anytime, as per their requirements. Fully automatic Mobile brick-making machine can produce up to 12000 bricks/hour with a reduction of up to 45% in production cost in comparison with manual and other machinery as well as 4-times (as per testing agencies report) more in compressive strength with standard shape, sizes and another extraordinary provision exist i.e. (that is) machine produced several brick sizes and it can be changed as per customer requirements from time to time. SnPC machines India is selling 04 models of fully automatic brick making machines: BMM160 brick making machine,BMM310, BMM400, and BMM410, (semi-automatic and fully automatic ) to the worldwide brick industry which produce bricks according to their capacities and fuel requirements. Raw material required for these machines is mainly clay, mud, soil or mixture of both. These moving automatic trucks are durable and easy to handle while operating. These machines are eco-friendly and budget-friendly as only one-third of water as compared to other methods is required and minimum labour is enough for these machines. We are offering direct customers access to multiple sites in both domestic and international stages, so they can see the demo and then will order us after satisfaction.

#snpcmachines#factory of brick on wheel#brick manufacturer#brick making machine India#brick making machine Haryana#brick making machine Delhi#mobile brick production#fast brick production#SnPC Machines#SnPC Factory#Team SnPC<

9 notes

·

View notes

Text

Box Compression Test Machine | Box Compression Tester Manufacturers

Effective Lab India Box Compression Tester is a highly effective lab testing material equipment used to measure the compressive strength of corrugated boxes, cartons and packaging containers. This test is most useful in places where the material is most likely to deform or compress during loading or shipping. Box compression Test Machine ensures the safety, performance and longevity of the product and helps in destruction.

#boxcompressiontester#boxcompressiontestermanufacturers#boxcompressionstrengthtester#boxcompressiontestmachine#boxcompressiontesterprice#corrugatedboxcompressiontestingmachine#cartonboxcompression#cartonboxcompressiontestingmachine#digitalboxcompressiontester#boxcompressiontesterdigital#compressiontestingmachine#boxcompressionmachine#boxcompressiontestmachineforsale#boxcompressiontesterinindia

1 note

·

View note

Text

Top Quality Standards Followed by Leading Paper Core Manufacturers

Quality is a need, not a luxury, in the fast-paced industrial world of today. Whether you're in the textile, paper, film, or packaging industry, reliable and durable paper cores are critical to your operations. As one of the most trusted paper core manufacturers in India, Om Packaging adheres to globally accepted quality standards to ensure every product delivered is consistent, durable, and sustainable.

In this blog, we explore the top quality standards that the best paper core manufacturers follow and how Om Packaging ensures compliance with these benchmarks across every step of its manufacturing process.

Why Quality Standards Matter in Paper Core Manufacturing

Paper cores are used as essential structural components in the winding and storage of materials such as paper, plastic film, textile, and tapes. A weak or inconsistent core can lead to material damage, production delays, or increased costs. Therefore, quality assurance is crucial for:

Dimensional accuracy

Load-bearing strength

Moisture resistance

Surface finish

Core concentricity

To meet these requirements, top-tier paper core manufacturers must align with national and international quality norms, while also maintaining strict in-house control mechanisms.

Key Quality Standards Followed by Leading Paper Core Manufacturers

Here are the top quality standards and best practices followed across the industry, especially by premium manufacturers like Om Packaging:

1. ISO 9001:2015 – Quality Management System

The gold standard for quality management in all sectors is ISO 9001. It ensures that paper core manufacturers maintain a consistent production process with an emphasis on:

Customer satisfaction

Process efficiency

Continuous improvement

Risk-based thinking

At Om Packaging, our entire manufacturing workflow is ISO-compliant, from sourcing raw paperboard to the final dispatch of finished cores.

2. Raw Material Quality Control

The strength and durability of paper cores start with the raw materials. High-quality kraft board, recycled fiber, and adhesives must be tested for:

Tensile strength

Moisture content

Adhesion properties

Om Packaging conducts thorough checks at the procurement stage. All incoming materials undergo quality inspection before they’re accepted for production.

3. Dimensional Accuracy and Tolerance Checks

Consistency in diameter, wall thickness, and length is essential for industries using paper cores in automated machines. Variance can result in equipment malfunction or product damage.

We at Om Packaging use calibrated tools and modern measuring systems to verify that each paper core meets exact client specifications, with tolerances maintained within strict limits.

4. Compression Strength Testing

Paper cores must endure radial and axial pressure without collapsing. This is especially crucial in high-load industries like textiles and paper manufacturing.

To ensure this, Om Packaging performs compression strength tests on sample batches using load-testing equipment to validate their performance under stress.

5. Concentricity and Surface Finish

A paper core must be perfectly round and smooth to allow even winding and unwinding of materials. Irregularities can lead to wastage, poor tension control, and machinery wear.

At Om Packaging, we use precision cutting and spiral winding machines to ensure excellent concentricity and a smooth, defect-free surface finish.

6. Adhesive and Bonding Strength

The bonding between plies must be strong enough to hold under pressure and during handling. Poor bonding can lead to delamination or core collapse.

We use premium adhesives and test each core for ply adhesion strength using peel and tensile tests to ensure long-lasting performance.

7. Moisture Resistance and Humidity Control

Paper cores are susceptible to environmental conditions. Excessive humidity can cause warping and undermine the structure.

To prevent this, Om Packaging manufactures moisture-resistant paper cores and stores finished products in a climate-controlled warehouse. We also provide waterproof cores on request, which are suitable for humid environments and export packaging.

8. Customized Quality Parameters for Different Industries

Different sectors require different performance characteristics:

Textile industry: Needs lightweight but strong cores

Paper mills: Require heavy-duty, thick-walled cores

Film & foil industry: Demands ultra-smooth surfaces

We collaborate with our clients to develop customized paper cores that meet industry-specific quality criteria. This flexibility is one of the key strengths of Om Packaging.

9. In-House Quality Labs and Automation

Modern paper core manufacturers like Om Packaging rely on in-house quality control laboratories equipped with:

Compression testers

Moisture analyzers

Ply bond testers

Diameter and concentricity gauges

We also leverage automation and data logging to track every batch, ensuring complete traceability and quality consistency.

10. Sustainable Manufacturing Standards

Along with mechanical quality, environmental responsibility is now a key quality benchmark. Om Packaging follows sustainable manufacturing practices, such as:

Use of 100% recyclable raw materials

Energy-efficient production systems

Minimal water usage

Waste segregation and reuse

This aligns with our commitment to eco-friendly packaging solutions, which is increasingly becoming a deciding factor for global clients.

Why Choose Om Packaging as Your Trusted Paper Core Manufacturer?

At Om Packaging, we don’t just manufacture paper cores—we engineer reliable, tested, and performance-optimized packaging components that add value to your operations.

Here’s what sets us apart:

Strict adherence to international quality standards Advanced production and testing infrastructure Industry-specific customization On-time delivery across India Focus on sustainability and innovation

With years of experience and a deep understanding of packaging industry needs, Om Packaging continues to be a trusted partner for clients in sectors like textiles, FMCG, printing, and more.

0 notes

Text

From Fibre to Floor—The Enduring Craftsmanship Behind Loop and Cut's Handmade Rugs

At Loop and Cut, we believe that a rug should not be regarded as a mere floor covering but as a statement of traditional skills that have been carefully evolved from the most basic of fibers. We live in a society of ephemeral fads, and in our case, we are incorporated perfectly within the eternal tradition of crafting handmade rugs, pieces that are not only there to decorate your floors but also bear the history of long tradition, craftsmanship, and exceptional quality. Our process is a celebration of the human touch, employing traditional processors keen on putting the finishing touches on our products, provided with all the right steps in getting them from the raw materials to the knots tied by an expert artisan.

The Foundation of Excellence: Sourcing Premium Fibres

The journey of a rug begins way before it elevates your space at Loop and Cut. It begins as it is skillfully done, with the choice of the finest natural fibers that have been selected due to their natural strength, beauty, and durability; they stand up to the test of time. In the case of our superior hand-knotted wool rugs from India, the best quality of the wool is procured first, which has innate properties of being stretchy, soft to the touch, and absorbent of the natural colors. The lustrous wool of New Zealand or the hardy, well-characterized wool of native breeds of sheep—whatever is used is selected with all care to add to the general character and the general merit of the rug.

In addition to wool, we also deal in the luxurious silks with their sheer shine and delicate attention to detail and durable cottons to form solid bases. This is a promise of better raw materials, which cannot be compromised because it is the backbone of the strength, quality, feel, and appearance of the rug. We know that a rug is an investment, and as a solid investment, the quality of the components of the rug correlates with its value.

The Art of Transformation

After being extracted, these raw fibers undergo a process of transformation. They are thoroughly cleaned, carded, and spun into strong, uniform yarns. This step is vital because how well the yarn is spun will affect how the final rug will look and last. In the case of our hand-woven rugs, the yarns are subsequently skillfully dyed under techniques that would guarantee rich and permanent dyes that would not fade away easily and keep their richness over decades. We frequently make use of ancient dyeing techniques, which have been refined over hundreds of years, resulting in rich palettes that cannot be compared to those of the synthetic processes.

It is here that the abstract idea of a design starts getting a concrete form. Our designers, trained in traditional artwork as well as up-to-date design, transform complex layouts and colour schemes into elaborate cartoons or blueprint drawings. These are our beacons, and by these our master weavers are guided, who have a fabulous talent in transforming a two-dimensional sketch into a three-dimensional and fantastic piece of fabric.

The Heart of Craftsmanship: The Hand-Knotted Difference

The hand-knotting, which is an ancient art, is the real soul of the loop and cut rug. This is in contrast to carpets that are produced on machines, which are very fast in terms of the production of their products, whereas our luxury hand-knotted carpets need the knotting of every knot to be individually done with the hands of experienced artisans. It is a tedious process and requires much patience, accuracy, and attention to detail developed through years of experience.

Picture to yourself thousands, nay, millions of separate knots, each knot so locked about the warp threads, accurately snipped, and now densely compressed. It is this heavy build that makes our rugs the most durable and most luxuriously soft when you walk on them and able to reproduce the most incredibly delicate designs with amazing clarity. The minor differences in the size of the knots and the tension between them, which are natural elements of any handmade creation, are not considered flaws but the features of genuineness, which give the rugs their unique spirit and cannot be imitated by machines. This is the final distinguishing factor in the case of someone who has aspired to have luxury hand-knotted rugs.

Beyond the Living Room: The Versatility of Loop and Cut Rugs

Although traditionally still considered something used indoors, the development of fiber and weaving code has opened new horizons for handmade carpeting. Loop and Cut also makes available special collections in the form of high-quality, durable, and yet stylish indoor-outdoor rugs and indoor-outdoor carpeting. They are designed with certain synthetic fibers, such as polypropylene or PET (used bottle water), which resemble in look and feel any natural fibers but which have improved moisture, UV, and mildew resistance.

The growing selection means that our clients can now apply the beauty and comfort of a handcrafted rug to the patio, the deck, the sunroom, or even those high-traffic areas in the house where ease of maintenance and durability are a main concern. It would be risky to say that, according to our rule of quality craftsmanship, these (synthetic material) rugs are excluded, and we often find them in our shops, even using the same hand-weaving techniques to give them a durable and beautiful product. Such versatility would render the loop and cut aesthetic in a position to improve every nook and cranny of your home's interior and exterior.

An Investment in Enduring Beauty and Ethical Production

When you buy a rug in Loop and Cut, it is not the purchase of an item but the investment in the eternal beauty, the functional art that will make your living room or house beautiful and useful for years and years. Not only do our hand-knotted wool rugs from India look good, but they are also naturally sustainable. They are manufactured from natural resources, which are renewable. and they are designed to last long, and there is less constant replacement, which ends up in the landfills.

Moreover, we can be described as strong adherents to ethical production. We make sure that the artisans who make our luxury hand-knotted carpets are working under fair conditions and are being fairly paid, and that they work in a system that not only sustains their families but also makes sure that their priceless art is maintained. By purchasing a Loop and Cut rug, you are not purchasing a commodity but entering into a partnership with a worldwide group of skilled craftspeople and participating in the continuity of a great art form.

The story of a Loop and Cut rug is the unconquerable strength of human hands, ever since the raw fiber to the finished floor. It has been a journey that is entwined with passion, patience, and commitment to quality. Get to know us and take a closer look at our broad range of fine handmade rugs, as we are sure that once you see it, you cannot forget its unique beauty and the great story it will tell you. Allow your place to be changed by a Loop and Cut work of art that is timeless and can allow profound warmth that only true artistry can deliver.

0 notes

Text

Dynemech Anti-Vibration Technology Rubber Air Springs – DRAS Series

Solid Support. Superior Stability. Trusted Vibration Control.

With industrial equipment, even a Small Vibration will lead to far-reaching damage — misalignment, abnormal wear, and uneven running. Dynemech Anti-Vibration Technology Rubber Air Springs – DRAS Series is precisely made to provide your equipment with the firm base that it requires to run its best.

Made from a high-quality rubber compound that is mixed with compressed air-filled chambers, DRAS Mounts deliver Superior Vibration Damping and Shock Absorption. This keeps your machines level and stable – even under harsh, high-speed use.

Product Attributes – What Makes Dynemech Anti-Vibration Technology DRAS Different

Dual Damping Technology

The DRAS mount operates in both air damping and rubber damping. Such two-way operation offers a greater range of Vibration Control than traditional Mounts.

Little but Mighty

Don't be misled by their size – DRAS mounts are compact but capable of high load-carrying capacity and perfect for use on machines of any type.

Maintenance-Free

No greasing, no oiling, no constant adjustment required. Simple to install and let it get on with it. DRAS is designed for hassle-free, long-term running.

Easy and Fast Installation

With threaded level bolt and solid base, DRAS Mounts are easy and quick to install. Industrial equipment plug-and-play.

Best Suited For:

• Power Presses – Resists repeated impact loads without passing vibrations to the floor.

• Textile Machines – Facilitates smooth machine running under high-speed spinning and weaving.

• Vibration Test Rigs – Offers a strong, vibration-isolated base for high-precision testing.

• Engine Test Beds – Offers stable support for high RPM testing.

• Blowers – Prevents instability due to rotating components.

Whether you're installing new equipment or refurbishing existing equipment, the DRAS Series gets them running more effectively, longer, and more steadily.

Dynemech Anti-Vibration Technology – Experts in Vibration Control With over two decades of experience, Dynemech Systems is a global leader in Anti-Vibration Solutions. Our DRAS Rubber Air Springs are the proof of our commitment towards quality, performance, and innovation – industry recommended in India and worldwide.

Dynemech Anti-Vibration Technology DRAS Rubber Air Springs – The Smart Choice for Machine Precision and Protection.

To learn more about our products: https://www.Vibrationmountsindia.com/products/

#Dynemech, #RubberAirSprings, #DRASMounts, #VibrationControl, #MachineStability, #AntiVibrationTechnology, #IndustrialSolutions, #PrecisionEngineering, #MachineSupport, #HeavyMachineryMounts, #StableMachines, #EngineeringSolutions, #ManufacturingSupport, #PressMachineMounts, #TextileMachineMounts, #EngineTestMounts, #VibrationIsolation, #DynemechMounts, #VibrationFreeOperations, #MadeInIndia

Call Now: 9810760131

Email: [email protected]

Visit: www.vibrationmountsindia.com

#Dynemech#RubberAirSprings#DRASMounts#VibrationControl#MachineStability#AntiVibrationTechnology#IndustrialSolutions#PrecisionEngineering#MachineSupport#HeavyMachineryMounts#StableMachines#EngineeringSolutions#ManufacturingSupport#PressMachineMounts#TextileMachineMounts#EngineTestMounts#VibrationIsolation#DynemechMounts#VibrationFreeOperations#MadeInIndia

0 notes

Text

India’s Pharmaceutical Manufacturing Powerhouse: RHR Medicare Pvt Ltd

India has long been recognized as a global pharmaceutical hub, delivering high-quality and cost-effective medicines to both domestic and international markets. As the demand for generic and branded medicines continues to grow, so does the need for reliable and innovative manufacturers. One company at the forefront of this evolution is RHR Medicare Pvt Ltd, a trusted name among Pharmaceutical Tablets Manufacturers in India, Injection Manufacturing Companies in India, and Softgel Manufacturers in India.

The Rise of India in Global Pharma

India is the third-largest producer of pharmaceuticals in the world by volume. The country is known for its robust infrastructure, skilled workforce, and stringent quality standards that comply with WHO-GMP, USFDA, and EU guidelines. This makes Indian pharmaceutical companies not only competitive in price but also respected globally for quality and innovation.

Among the many players in this dynamic industry, RHR Medicare Pvt Ltd stands out due to its comprehensive product portfolio, advanced production facilities, and a commitment to quality and healthcare excellence.

RHR Medicare Pvt Ltd: Setting the Standard

RHR Medicare Pvt Ltd has carved a niche in the competitive pharmaceutical landscape of India by specializing in the manufacturing of tablets, injections, and softgel capsules. The company’s world-class manufacturing plants are designed to meet international standards, with dedicated units for each dosage form.

Let’s explore how RHR Medicare is excelling as one of the top:

Pharmaceutical Tablets Manufacturers in India

Injection Manufacturing Companies in India

Softgel Manufacturers in India

Leading the Way: Pharmaceutical Tablets Manufacturers in India

Tablets are one of the most common and convenient forms of drug delivery. As one of the premier Pharmaceutical Tablets Manufacturers in India, RHR Medicare Pvt Ltd offers a wide range of tablets including analgesics, anti-inflammatory, antibiotics, and cardiovascular medications.

Their manufacturing units are equipped with the latest granulation, compression, and coating machines that ensure high precision and consistency. The company’s R&D team is constantly innovating, developing new formulations to cater to the evolving needs of healthcare professionals and patients.

Strict quality control at every stage—right from raw material procurement to final packaging—ensures that each tablet meets the highest efficacy and safety standards.

Precision and Quality: Injection Manufacturing Companies in India

Injectable drugs require the utmost precision and hygiene during production. RHR Medicare Pvt Ltd is regarded as one of the top Injection Manufacturing Companies in India for its sterile, high-quality injectable products. The company offers a broad range of therapeutic injections such as antibiotics, antiemetics, pain relievers, and anti-fungal medications.

With a fully equipped sterile injectable facility, the company uses automated filling and sealing systems to minimize contamination and ensure uniform dosage. Every batch undergoes rigorous testing to maintain compliance with pharmacopeial standards and ensure patient safety.

Their injectable units are designed in accordance with cGMP guidelines, and the company follows stringent protocols for handling sensitive substances.

Innovation in Nutraceuticals: Softgel Manufacturers in India

Softgel capsules have become increasingly popular due to their easy-to-swallow form and enhanced bioavailability. As one of the fastest-growing Softgel Manufacturers in India, RHR Medicare Pvt Ltd offers innovative solutions in both pharmaceutical and nutraceutical segments.

Their softgel line is supported by advanced encapsulation technology and sophisticated drying tunnels, ensuring optimal product stability. Whether it's omega-3, multivitamins, or herbal extracts, the softgel products from RHR Medicare are known for their purity, potency, and aesthetic appeal.

With a strong focus on innovation and quality, the company collaborates with healthcare providers and nutritional experts to create formulations that support overall well-being.

Commitment to Quality and Compliance

Quality is the foundation of RHR Medicare Pvt Ltd. The company is ISO-certified and adheres to WHO-GMP guidelines in all its manufacturing processes. Every product undergoes thorough in-house and third-party testing to ensure it meets regulatory requirements.

Moreover, the company follows sustainable manufacturing practices, minimizing environmental impact through waste management systems, energy-efficient operations, and ethical sourcing of raw materials.

Why Choose RHR Medicare Pvt Ltd?

Diverse Portfolio: Tablets, injections, and softgels across multiple therapeutic categories.

Cutting-edge Facilities: Modern, automated manufacturing plants with global certifications.

Dedicated R&D: Continuous innovation in drug delivery systems and formulation development.

Regulatory Compliance: Strict adherence to Indian and international quality standards.

Global Reach: Export capabilities to over 30 countries, ensuring a wide footprint in healthcare markets.

Conclusion

India continues to lead the way in pharmaceutical manufacturing, and RHR Medicare Pvt Ltd is a shining example of what makes the country a global pharma powerhouse. Whether you are looking for trusted Pharmaceutical Tablets Manufacturers in India, reliable Injection Manufacturing Companies in India, or innovative Softgel Manufacturers in India, RHR Medicare Pvt Ltd offers the expertise, infrastructure, and integrity to meet all your healthcare manufacturing needs.

With a commitment to improving lives through high-quality medicines, RHR Medicare Pvt Ltd is not just a manufacturer—it is a healthcare partner for the future.

0 notes

Text

Leading the Way in Modern Construction: Modular Bricks Manufacturers like Jindal Bricks

In the evolving world of construction, efficiency, sustainability, and. design flexibility are key priorities. One innovation that has revolutionized building practices is the modular brick manufacturers Known for their uniformity and precision, modular bricks are widely used in residential, commercial, and industrial projects. Among the top manufacturers in India, Jindal Bricks has emerged as a trusted name, delivering high-quality modular bricks that combine strength, consistency, and visual appeal.

Modular bricks differ from traditional bricks in size and design. They are crafted to standard dimensions, which allows for better alignment during construction and reduces mortar consumption. This not only improves construction speed but also lowers overall costs, making modular bricks a preferred choice for modern builders and architects.

Jindal Bricks has established itself as a leading modular bricks manufacturer by consistently providing durable and precisely shaped bricks that meet national and international building standards. Their modular bricks are made using premium natural clay and advanced manufacturing technology, ensuring high compressive strength, water resistance, and excellent finish. This makes them suitable for both load-bearing and non-load-bearing applications.

One of the key benefits of choosing Jindal Bricks is their commitment to quality and sustainability. The company follows eco-friendly manufacturing practices, using energy-efficient kilns and sustainable raw materials. This ensures minimal environmental impact while delivering products that last for decades. Their bricks are also tested for dimensional accuracy, durability, and resistance to weathering, ensuring long-term performance.

Additionally, Jindal Bricks offers a variety of modular brick styles, including wire-cut and machine-made options. These bricks come in different shades and textures, allowing architects and homeowners to explore creative designs without compromising on strength. Whether for building façades, boundary walls, or internal partitions, Jindal’s modular bricks offer the perfect balance of functionality and aesthetics.

Moreover, Jindal Bricks provides excellent customer service and technical support, helping clients choose the right type of modular bricks for their specific construction needs. Their strong distribution network ensures timely delivery across India, making them a reliable partner for large and small projects alike.

In conclusion, as the demand for efficient and sustainable building materials continues to rise, modular bricks have become an essential part of modern construction. Jindal Bricks, with its high-quality offerings, innovative manufacturing, and customer-focused approach, remains at the forefront of this transformation. For anyone looking to build smarter and faster, Jindal’s modular bricks manufacturers are the ideal choice.

0 notes

Text

A Compression Testing machine is an important instrument in many sectors. It includes the construction industry and academics. There are various materials whose compressive strengths can be accurately determined with this equipment.

#Compression Testing Machine#Compression Testing Machine Price#Compression Testing Machine Manufacturer#Compression Testing Machine in India#Compression Testing Machine Supplier#CTM Machine

0 notes

Text

youtube

#box compression tester near me#box compression strength tester video#box compression test in india#box compression testing machine manufacturer#box compression tester price#box compression tester manufacture#box compression testing in Mumbai#box compression in Delhi#containers compression test in Noida#carton box compression tester#box compression tester supplier near me#corrugated box compression tester near me#industry compression strength tester#ASTM D642#ASTM D4169#ISO 12048#IS 2771#IS 7028#IS 1060#Youtube

0 notes

Text

Speed up your brick production speed with fully automatic clay brick making machine

Fully automatic mobile brick making machine by SnPC Machines, First of its kind of machine in the world, our brick-making machine moves on wheels like a vehicle and produces bricks while the vehicle is on move. This allows kiln owners to produce bricks anywhere and anytime, as per their requirements. Fully automatic Mobile brick-making machine can produce up to 12000 bricks/hour with a reduction of up to 45% in production cost in comparison with manual and other machinery as well as 4-times (as per testing agencies report) more in compressive strength with standard shape, sizes and another extraordinary provision exist i.e (that is) machine produced several brick sizes and it can be changed as per customer requirements from time to time. Snpc machines India is selling 04 models of fully automatic brick making machines: BMM160 brick making machine,BMM310, BMM400, and BMM410, (semi-automatic and fully automatic ) to the worldwide brick industry which produce bricks according to their capacites and fuel requirements. Raw material required for these machines is mainly clay, mud, soil or mixure of both. These moving automatic trucks are durable and easy to handle while operating. These machines are eco-friendly and budget-friendly as only one-third of water as compared to other methods is required and minimum labour is enough for these machines. We are offering direct customers access to multiple sites in both domestic and international stages, so they can see the demo and then will order us after satisfaction.

#snpc machines#clay brick#flyash brick#soil brick#fully automatic#perfect brick making machine#BMM410#BMM310#construction machinery#wall making equipment#industrial machinery#brick making truck

8 notes

·

View notes

Text

How to Find Sustainable Wool Suppliers

⚙️ Why Wool Is Used in Machinery and Engineering

Wool is favored in industrial environments for its natural performance benefits, including:

High resilience: Wool fibers can compress and recover without permanent deformation

Low friction: Offers excellent lubrication in mechanical operations

Sound absorption: Used in machinery to dampen noise

Thermal insulation: Withstands extreme temperatures without degrading

Non-conductivity: Acts as an electrical insulator

Eco-friendliness: Biodegradable, renewable, and often chemical-free

🛠️ Common Industrial Applications of Wool

1. Wool Felt Washers and Gaskets

Use: Sealing in pumps, bearings, and valves

Benefit: Compressible, self-lubricating, and resistant to oils and solvents

2. Wool Pads and Buffing Wheels

Use: Metal polishing, surface finishing, and buffing in manufacturing

Benefit: Non-abrasive, heat-resistant, and reusable

3. Wool Wicking Material

Use: Lubricant and oil distribution in motors and machines

Benefit: Uniform oil absorption and release, non-reactive with lubricants

4. Wool Filters

Use: Dust and air filtration in sensitive machinery or environments

Benefit: Natural fiber traps fine particles and reduces vibration

5. Wool Soundproofing Panels

Use: Noise control around heavy machinery or in plant enclosures

Benefit: Acoustic dampening with thermal insulation in one layer

🔍 What to Consider When Sourcing Wool for Machinery

✔️ Material Specifications

Choose the correct density and thickness for wool felt or padding

Consider blends with synthetic fibers for added rigidity or cost-efficiency

Select oil-resistant or heat-treated variants if required for harsh environments

✔️ Form and Format

Rolls, sheets, discs, or custom die-cut components

Needled felt vs. pressed felt, depending on application

Pre-oiled or untreated options

✔️ Compliance and Certifications

Ensure materials meet ISO or ASTM standards for industrial use

Look for chemical safety, flammability, and performance certifications where applicable

🌍 Where to Source Wool for Industrial Use

You can source industrial-grade wool from:

Specialty wool felt manufacturers in the US, Germany, and India

Wool component suppliers that cater to the automotive, mechanical, or textile machinery industries

Exporters and mills offering customizable die-cut solutions for OEM parts

Bulk buyers should request:

Technical data sheets (TDS)

Material safety data sheets (MSDS)

Samples or small test rolls before full-scale production

🧵 Partnering with the Right Supplier

When sourcing wool for machinery:

Confirm manufacturing capacity and ability to meet specs consistently

Look for customization options (thickness, hardness, size, treatment)

Ensure they can deliver globally with proper documentation and lead times

🔚 Final Thoughts

Wool is a high-performance material that offers unique advantages for industrial machinery—from gaskets and seals to filtration and soundproofing. When sourced properly, it enhances performance, reduces maintenance, and aligns with sustainable manufacturing goals.

At Woolgold, we supply industrial-grade wool felt, sheets, pads, and custom-cut components for use in mechanical and engineering sectors. We offer tailored solutions with reliable global shipping, including to Europe, the US, the UAE, and beyond.

🌐 Get in touch at Woolgold.com — where natural fibers meet industrial innovation.

Would you like this content adapted into a supplier brochure, catalog page, or industrial buyer email campaign?

0 notes

Text

Salt Spray Corrosion Test Chamber | Salt Spray Test Machine

Today every industry in the world wants to keep your products safe for a long time so that the safety of the products is ensured and also there is a good delivery of the products so that the products last for a long time. Many types of product safety testing equipment are being made since 10 to 15 years which includes salt spray testing machine, box compression testing machine, ozone test chamber machine, among them salt spray test chamber is one of them, it is very effective laboratory testing machine equipment which can assume various corrosion parts from the material samples and make the products safe from any type of corrosion. In this product safety process firstly, we can put the material sample inside the chamber and the testing of the material starts until the product takes the final form. Effective Lab India ensures the safety, performance of the products and their durability for a long time. If you are looking for any salt spray test chamber then Effective Lab India is here from where you can buy salt spray testing machine at affordable rates.

#saltspraychamber#saltspraytestchamber#saltspraytestmachine#corrosiontestchamber#saltspraychamberforsale#saltspraychamberprice#saltfogtestchamber#saltfogmachine#saltspraymachine#saltspraytester#saltspraytestchamberforsale#saltspraytestcabinet#saltspraytestchambersuppliers#saltspraytestchamberprice

1 note

·

View note

Text

Concrete Testing Equipment

Concrete is the very pillar of contemporary infrastructure, from roads and bridges to skyscrapers and factories. Yet even the most robust concrete can crack if it’s not properly tested. Proper concrete testing guarantees safety, structural stability, and conformity with national and global standards.

At ESE (Engineering Solutions Equipment), one of the top Concrete Testing Equipment Manufacturers, we frequently deal with contractors, civil labs, and construction engineers. We’ve observed that even seasoned experts occasionally commit errors while testing—errors which jeopardize the entire project.

Let’s go through 6 of the most frequent errors committed while testing concrete—and more significantly, how to prevent them.

1. Using Uncalibrated or Poor-Quality Equipment

This is among the most common and perilous omissions. If the test machine—be it Compression Testing Machine (CTM) or Slump Cone—is not calibrated or is of poor quality, the results of the test are not trustworthy.

Being a Reliable Concrete Testing Equipment Manufacturer, ESE supplies equipment that not only has a long lifespan but is also supplied with calibration certificates and after-sales services. It is essential to calibrate the equipment regularly, preferably every six months, to maintain accuracy in testing.

Tip: Always request calibration records from your supplier and ensure IS or ASTM compliance.

2. Inadequate Sample Preparation

Concrete test results are only as good as the samples you test. Wildly inaccurate readings can result from improper mixing, uneven compaction, or poor curing of specimens.

This is a common error in compressive strength testing, where small amounts of air bubbles or surface cracks in the cube will produce falsely low results. The equipment is not the issue—it’s the way the sample was fabricated.

At ESE, we recommend that our clients adhere to standard curing practices and utilize mold sets that guarantee even shape and size, easily available from your reliable Concrete Testing Equipment Manufacturer.

3. Omission of Environmental Control During Curing

The curing environment for the concrete samples has a great influence on the final strength. In case ambient temperature or moisture levels are not kept as per IS 516 or ASTM C192 specifications, your result will be inaccurate.

Employing a temperature-controlled curing tank—like the ones provided by ESE—promises uniformity. Many site laboratories, unfortunately, omit this step, particularly in remote locations or when under tight schedule pressure.

Proper curing environments are as crucial as the best testing machines.

4. Inaccurate Loading Speed in Compressive Strength Testing

It is easy to make the mistake of adding the load too fast or too slow when a CTM is used. Both mistakes produce inaccurate results and may even break the machine or the specimen.

The IS codes state that the load must be uniformly applied at a rate of 140 kg/cm² per minute until failure. Any variation causes inaccuracy.

At ESE, our automatic CTMs come equipped with digital controllers that maintain the correct loading rate. This automation eliminates human error and ensures repeatability, just one of the reasons we’re a preferred Concrete Testing Equipment Manufacturer in India.

5. Neglecting Machine Maintenance

Even the best concrete testing machines require regular care. Dust, vibration, and wear over time can affect sensors, hydraulics, and electronics.

Operators tend to believe that equipment will run forever once installed. But unless maintained regularly, machines go out of calibration, and results degrade.

ESE includes comprehensive maintenance schedules with each machine and provides annual service contracts so you can concentrate on testing, while we take care of the upkeep.

6. Overlooking National & International Testing Standards

Far too often, labs test based on outdated procedures or disregard the standard entirely. This might result in results that are not acceptable to government agencies, quality control consultants, or clients.

ESE makes sure that all equipment—ranging from Vee Bee Consistometers to Flexural Testing Machines—is compliant with IS, BIS, and ASTM standards. We also provide training for your personnel in standard operating procedures so that your reports are credible and audit-compliant.

As a Contemporary Concrete Testing Equipment Manufacturer, we feel that our work doesn’t end with the sale—it begins there.

Why Select ESE – Engineering Solutions Equipment?

If you require precise, reliable, and standard-conforming outcomes, you need a Concrete Testing Equipment Manufacturer that knows the whole picture.

Calibrated equipment with documented precision

Full lab setup: from CTMs to flow tables and slump cones

Professional training and documentation assistance

Quick response after-sales service & yearly calibration contracts

Customization on offer for schools, mobile labs, etc.

At ESE, we’re not merely peddling machines—we’re assisting you in creating a more secure, more resilient future.

Final Thoughts

Concrete testing isn’t merely a procedural nicety—it’s a vital process toward building safety and longevity. And from what we’ve established, the difference between true and false results is often a matter of a few preventable errors.

By making the proper processes and collaborating with a quality Concrete Testing Equipment Manufacturer such as ESE, you can avoid these mistakes and help each building you touch pass down to future generations.

Concrete Testing Equipment

1 note

·

View note

Text

When it comes to precision-engineered testing instruments, Barket Hitech Engineering stands as the best rock testing laboratory equipment supplier in India. With a commitment to accuracy, durability, and advanced technology, we provide world-class rock testing solutions to geotechnical engineers, research institutions, and construction companies across India.

Importance of High-Quality Rock Testing Laboratory Equipment

Rock testing is crucial in assessing the strength, stability, and composition of geological materials. High-quality rock testing equipment ensures precise measurements and reliable results, which are vital for infrastructure projects, mining operations, and academic research. As the leading supplier of rock testing laboratory equipment in India, Barket Hitech Engineering offers cutting-edge technology and internationally approved testing instruments.

Features of Premium Rock Testing Laboratory Equipment

When selecting the best rock testing laboratory equipment in India, consider the following features:

Precision Engineering: Ensures accurate and repeatable results

High Durability: Made from robust materials for long-term use

User-Friendly Operation: Designed for easy handling and operation

Advanced Digital Controls: Equipped with modern digital displays for enhanced accuracy

Customization Options: Tailored to meet industry-specific requirements

Compliance with International Standards: Meets ASTM, IS, and BS testing standards

Barket Hitech Engineering – Leading Rock Testing Laboratory Equipment Supplier in India

With years of experience in the testing equipment industry, Barket Hitech Engineering has earned a reputation as India’s top rock testing laboratory equipment supplier. Our state-of-the-art products are designed to deliver high-precision results and enhance efficiency in laboratory testing environments.

Why Choose Barket Hitech Engineering?

Superior Quality Equipment

Affordable Pricing for Bulk Orders

Fast and Reliable Delivery Across India

Dedicated Customer Support

Comprehensive Warranty on Products

Customization Options Available

Wide Range of Rock Testing Laboratory Equipment Offered by Barket Hitech Engineering

We provide a complete range of rock testing laboratory equipment in India, including:

Rock Core Cutting Machines

Rock Permeability Testers

Point Load Testers

Rock Shear Strength Testers

Unconfined Compression Testers

Rock Triaxial Testing Machines

Rock Abrasion Testers

Digital Rock Strength Testers

Slake Durability Apparatus

Brazilian Tensile Strength Testers

Customization Options for Rock Testing Laboratory Equipment

Barket Hitech Engineering provides custom rock testing laboratory equipment in India to meet the unique needs of research labs and industrial testing facilities. Customization options include:

Digital and Analog Variants

Different Load Capacities

Automated and Manual Operations

Enhanced Data Logging Features

Specialized Attachments and Accessories

Quality Assurance and Certifications

As the best rock testing laboratory equipment supplier in India, we adhere to strict quality control processes and comply with national and international testing standards. Our certifications include:

ISO Certified Manufacturing

ASTM & IS Standards Compliance

Rigorous Durability Testing

Quality Assurance Inspections

Competitive Pricing and Bulk Orders

We offer cost-effective rock testing laboratory equipment in India with attractive pricing options for bulk orders. Our efficient supply chain ensures prompt and hassle-free delivery across India.

Customer Testimonials

Clients from research institutes, mining companies, and geotechnical firms across India trust Barket Hitech Engineering for their high-quality and reliable rock testing laboratory equipment. Our reputation is built on accuracy, durability, and excellent customer service.

Why Barket Hitech Engineering Is the Best Rock Testing Laboratory Equipment Supplier in India?

Decades of Industry Experience

Premium-Quality Instruments

Custom-Built Testing Solutions

Affordable Pricing and Bulk Order Benefits

Nationwide Delivery and Installation Support

Unmatched Customer Service and Technical Support

Conclusion

If you are looking for the best rock testing laboratory equipment supplier in India, trust Barket Hitech Engineering to provide high-quality, durable, and precise testing instruments. Our dedication to innovation and customer satisfaction makes us the preferred choice for rock testing solutions across India.

For bulk orders, custom solutions, and inquiries, contact Barket Hitech Engineering – the top rock testing laboratory equipment supplier in India today!

Frequently Asked Questions (FAQs)

1. What makes Barket Hitech Engineering the best rock testing laboratory equipment supplier in India?

We offer high-precision, durable, and cost-effective rock testing equipment that meets international standards and is trusted by industries across India.

2. Do you provide customized rock testing equipment?

Yes, we offer custom rock testing laboratory equipment in India with tailored features to meet specific industrial and research needs.

3. Are your rock testing instruments compliant with industry standards?

Yes, all our equipment complies with ASTM, IS, and BS standards for accurate and reliable results.

4. Can I place bulk orders for rock testing laboratory equipment?

Absolutely! We provide bulk rock testing equipment at competitive rates across India.

5. How long does delivery take for bulk orders?

We ensure fast and secure delivery within 7-10 working days across India.

6. What materials are used in manufacturing rock testing laboratory equipment?

We use high-grade metals, alloys, and corrosion-resistant components to enhance durability.

Concrete Testing Instrument

0 notes