#DairyProcessing

Explore tagged Tumblr posts

Text

Power Meets Precision. Neer Enterprise brings you high-speed reciprocating compressors that pack industrial-strength cooling into a compact, quiet, and efficient design.

For more details, visit - https://www.neerenterprise.biz/products/high-speed-compressors

#neerenterprise#highspeedcompressor#coolingsystem#icemakingindustry#iceplants#chemicalcoolingsystem#dairyprocessing

0 notes

Text

#DryDairyProducts#PowderedMilk#DairyIngredients#ShelfStableDairy#DairyPowderMarket#MilkPowder#WheyProtein#DairyNutrition#FoodIngredients#LactosePowder#DairyProcessing#FunctionalDairy#DairyIndustry

0 notes

Text

Dairy Enzymes Market Accelerates with Growing Adoption in Innovative and Plant-Based Dairy Alternatives

The global dairy enzymes market is poised for sustained expansion, driven by rising consumer demand for health-conscious products, evolving dietary needs, and the ongoing quest for sustainable food processing methods. Enzymes such as lactase, protease, lipase, and transglutaminase play a pivotal role in modern dairy production, offering solutions that enhance functionality, improve nutrition, and align with clean-label trends. As the dairy industry continues to innovate, new opportunities are emerging across product development, regional expansion, and technological integration.

Rising Demand for Lactose-Free and Digestive-Friendly Products

One of the most significant market opportunities lies in the growing demand for lactose-free and low-lactose dairy products. Lactose intolerance affects a substantial portion of the global population, especially in regions such as Asia-Pacific, Africa, and Latin America. This creates a strong market for dairy enzymes like lactase, which hydrolyzes lactose into more digestible sugars, enabling the production of lactose-free milk, yogurt, and cheese without compromising taste or nutritional value.

Brands that offer dairy products catering to lactose-intolerant consumers can access a wider customer base and meet growing health awareness trends. This has led to increased investments in high-performance lactase enzyme formulations designed for efficiency and stability in varied processing conditions.

Growth in Functional and Fortified Dairy Products

Health and wellness trends continue to shape the global food industry, and dairy products are no exception. Consumers are increasingly seeking foods that support digestive health, immunity, and overall wellness. Dairy enzymes offer a natural way to create fortified, high-protein, or probiotic-enriched dairy products that meet these needs.

Proteases, for example, are used to hydrolyze milk proteins to enhance digestibility, making dairy products suitable for aging populations and fitness-focused consumers. Transglutaminase helps improve the texture and stability of high-protein dairy formulations, particularly in beverages and yogurts. These enzymes allow manufacturers to create differentiated products that command premium pricing and consumer loyalty.

Expansion into Emerging Markets

Emerging economies represent a substantial opportunity for growth in the dairy enzymes sector. Countries in Asia-Pacific, Latin America, and the Middle East are experiencing rising urbanization, income growth, and a shift in dietary habits. The adoption of Western-style dairy products such as cheese, yogurt, and flavored milk is increasing, driving the need for efficient and scalable production methods.

Enzyme technologies help local dairy processors improve yield, consistency, and shelf life critical factors in markets with developing cold chain infrastructure. Enzyme manufacturers that can tailor their offerings to regional needs and provide technical support to local processors will be well-positioned for success.

Plant-Based and Alternative Dairy Products

As the market for plant-based alternatives continues to grow, enzymes are also finding applications in non-dairy products. While traditionally used in animal milk-based systems, enzymes like proteases and amylases are now being explored to enhance the texture, flavor, and protein content of plant-based milk, yogurt, and cheese alternatives.

This crossover application presents a new frontier for enzyme manufacturers, as more consumers seek flexitarian or vegan diets without sacrificing taste or nutrition. Developing enzyme solutions compatible with soy, almond, oat, or pea-based dairy alternatives is a rapidly expanding opportunity area.

Sustainability and Clean-Label Production

Sustainability is a rising priority for both manufacturers and consumers. Enzymes contribute to greener production methods by reducing energy consumption, minimizing waste, and improving resource efficiency. For instance, lipase enzymes can enhance flavor development in cheese, reducing the need for artificial additives. Enzyme-based processes also reduce reliance on chemical treatments, supporting clean-label initiatives and regulatory compliance.

As more brands commit to environmental, social, and governance (ESG) goals, enzyme suppliers that can demonstrate the sustainability benefits of their solutions will gain a competitive advantage.

Conclusion

The dairy enzymes market presents multiple avenues for growth and innovation. From addressing lactose intolerance and enhancing nutritional value to enabling plant-based product development and supporting sustainable production, enzymes are at the center of the modern dairy industry’s evolution. Companies that invest in enzyme technology, adapt to regional needs, and align with health and sustainability trends will be well-positioned to capitalize on the opportunities that this dynamic market continues to offer.

0 notes

Text

From concept to completion, Muse Food Tech delivers end-to-end turnkey solutions for dairy & food factories! 🏭✨ Cutting-edge machinery, seamless installation, and expert support—your vision, our expertise.

🚀 Explore more: www.musefoodtech.com

#TurnkeyDairyFactory#FoodFactorySetup#FoodMachinerySolutions#DairyTech#FoodProduction#FactoryAutomation#FoodInnovation#MuseFoodTech#FoodEngineering#DairyProcessing#TurnkeySolutions#FoodIndustry#ManufacturingExcellence#SustainableFood#TechDrivenFood

0 notes

Text

What Are the Cost Benefits of Using Khambete Kothari Cans’ Milk Pasteurizer Units in Dairy Farms?

Khambete Kothari Cans' milk pasteurizer units are designed to enhance dairy processing by improving milk quality and extending shelf life. Our advanced technology effectively eliminates harmful bacteria, ensuring safety compliance and superior freshness. By reducing operational costs while preserving nutritional value and flavor, our units provide a reliable solution for modern dairy producers, fostering healthier products.

0 notes

Text

Explore top-quality boilers for the dairy industry designed for efficiency and reliability. Perfect solutions for all your dairy processing needs.

#DairyIndustryBoilers#RossBoilers#IndustrialBoilers#SteamBoilers#DairyProcessing#EfficientHeating#BoilerSolutions

0 notes

Text

𝑻𝒓𝒆𝒏𝒅𝒔 𝒂𝒏𝒅 𝑶𝒑𝒑𝒐𝒓𝒕𝒖𝒏𝒊𝒕𝒊𝒆𝒔 𝒊𝒏 𝒕𝒉𝒆 𝑫𝒂𝒊𝒓𝒚 𝑷𝒓𝒐𝒄𝒆𝒔𝒔𝒊𝒏𝒈 𝑬𝒒𝒖𝒊𝒑𝒎𝒆𝒏𝒕 𝑴𝒂𝒓𝒌𝒆𝒕

𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑭𝑹𝑬𝑬 𝑺𝒂𝒎𝒑𝒍𝒆: https://www.nextmsc.com/dairy-processing-equipment-market/request-sample

As we move further into 2024, the 𝑫𝒂𝒊𝒓𝒚 𝑷𝒓𝒐𝒄𝒆𝒔𝒔𝒊𝒏𝒈 𝑬𝒒𝒖𝒊𝒑𝒎𝒆𝒏𝒕 𝑴𝒂𝒓𝒌𝒆𝒕 continues to show promising growth and innovation. The rise in consumer demand for dairy products, coupled with advancements in technology, is driving significant changes in the industry.

𝑲𝒆𝒚 𝑻𝒓𝒆𝒏𝒅𝒔:

𝑻𝒆𝒄𝒉𝒏𝒐𝒍𝒐𝒈𝒊𝒄𝒂𝒍 𝑨𝒅𝒗𝒂𝒏𝒄𝒆𝒎𝒆𝒏𝒕𝒔: The integration of automation, IoT, and AI is revolutionizing dairy processing, enhancing efficiency, and reducing operational costs.

𝑺𝒖𝒔𝒕𝒂𝒊𝒏𝒂𝒃𝒊𝒍𝒊𝒕𝒚 𝑭𝒐𝒄𝒖𝒔: There is an increasing emphasis on sustainable practices, with equipment designed to minimize waste and energy consumption.

𝑷𝒓𝒐𝒅𝒖𝒄𝒕 𝑫𝒊𝒗𝒆𝒓𝒔𝒊𝒇𝒊𝒄𝒂𝒕𝒊𝒐𝒏: The market is witnessing a shift towards processing equipment that can handle a variety of dairy products, including plant-based alternatives.

𝑬𝒎𝒆𝒓𝒈𝒊𝒏𝒈 𝑴𝒂𝒓𝒌𝒆𝒕𝒔: Growth is particularly strong in developing regions, where rising incomes and changing dietary habits are fueling demand for advanced dairy processing solutions.

𝑹𝒆𝒈𝒖𝒍𝒂𝒕𝒐𝒓𝒚 𝑪𝒐𝒎𝒑𝒍𝒊𝒂𝒏𝒄𝒆: Ensuring compliance with stringent food safety regulations remains a priority, driving innovation in equipment design and functionality.

𝑲𝒆𝒚 𝑷𝒍𝒂𝒚𝒆𝒓𝒔:

Tetra Pak International S.A.

GEA Group AG

DuPont, Inc.

Alfa Laval AB

Krones AG

Paul Mueller Company

JBT Corporation

Feldmeier Equipment, Inc.

Scherjon Dairy Equipment Holland B.V.

SPX Flow Inc.

As dairy processors adapt to these changes, the market is set to expand, offering new opportunities for growth and development.

𝑨𝒄𝒄𝒆𝒔𝒔 𝑭𝒖𝒍𝒍 𝑹𝒆𝒑𝒐𝒓𝒕: https://www.nextmsc.com/report/dairy-processing-equipment-market

What trends are you seeing in the dairy processing sector?

Share your insights and let’s discuss how these advancements are shaping the future of dairy processing!

#dairyprocessing#markettrends#innovation#sustainability#foodindustry#technology#growth#marketresearch

0 notes

Text

SM Engineering provides high-quality milk processing plants to ensure efficient processing and optimal quality of your dairy products.

👉 For More:- 🌐 https://www.smengimech.com/milk-homogenizer 📲 +91 9979227497

#smengineering#milkhomogenizers#dairyproduction#durableequipment#corrosionresistant#easyoperation#largescaledairy#dairyprocessing#dairyequipment#industrialdairy#foodprocessing#highqualityequipment#dairysolutions#dairybusiness#dairytechnology#milkprocessing#foodindustry#dairyinnovation#efficientdairyequipment#madeinindia#manufacturer#ahmedabad#india

1 note

·

View note

Text

youtube

Ever wondered how fresh milk from cows transforms into the milk powder you find in your kitchen? 🌾🥛

In this video, we take you step-by-step through the incredible journey of milk — from early morning milking sessions on farms to advanced factory processes like concentration and spray drying. Discover how technology turns fresh milk into a shelf-stable, versatile ingredient used around the world!

#MilkPowder #MilkJourney #FarmToFactory #FoodScience #DairyProcessing #GlobalNutrition #HowItsMade #Agriculture #MilkProduction #EmergencyFood #FoodTechnology #DairyFarming #MilkFacts #InnovationInFood #SustainableFood

0 notes

Text

🌟 Milk Powder Plant Solutions in Maharashtra - Saputo Process Engineering Pvt. Ltd. 🌟

At Saputo Process Engineering Pvt. Ltd., we offer state-of-the-art Milk Powder Plants designed to meet the diverse needs of the dairy industry in Maharashtra.

Our turnkey solutions are cost-effective, reliable, and highly efficient, ensuring optimal milk powder production with minimal energy consumption.

Why Choose Saputo for Your Milk Powder Plant in Maharashtra?

Advanced Technology: We utilize cutting-edge technologies such as spray drying and roller drying to produce high-quality milk powder with excellent texture and solubility.

Customizable Solutions: Tailored plant designs that meet varying production capacities and operational requirements.

Compliance with Standards: Designed to meet food safety regulations and industry standards for quality and hygiene.

Timely Delivery & Installation: We ensure minimal downtime and efficient installation to keep your operations on track.

After-Sales Support: Comprehensive support, maintenance, and spare parts supply to ensure seamless operations.

Features of Our Milk Powder Plants:

Spray Drying Technology Fully Automated Systems Energy Recovery Systems Modular Design for Scalability Integrated Packaging Solutions

Applications:

Full Cream Milk Powder Skimmed Milk Powder Instant Milk Powder Infant Milk Powder Dairy-Based Ingredients

We serve multiple cities across Maharashtra, including Mumbai, Pune, Nagpur, Thane, Nashik, Kolhapur, Aurangabad, Sangli, and many more.

🔗 Contact Saputo Process Engineering Pvt. Ltd. for customized solutions or a consultation to boost your dairy production efficiency!

#MilkPowderPlant #DairyProcessing #DairyIndustry #MilkPowder #SaputoProcessEngineering #MaharashtraDairy #TurnkeySolutions #EnergyEfficient #FoodSafety #DairyTechnology #SprayDrying #PackagingSolutions #CustomDairyPlant

0 notes

Text

Atmospheric condensor

Incorporated as a Proprietorship "Refindia Technologies" is instrumental as manufacturer in this industry since 2018. Company is headquartered in Namakkal, Tami Nadu. The array of our products is developed with the most durable quality based materials and our experts ensure to obtain them from trustworthy and certified merchants. Our precise selection of suitable material processing techniques has made our range outstanding in terms of supremacy. Follow us on!

Youtube

Facebook

Twitter

Telegram

youtube

Subscribe now, click the Bell Icon and get in Business Information

#Youtube#refindia#madeinindia#dairyfarm#dairymilk#dairybusiness#dairycattle#dairycowfarm#dairyicecream#dairyinstrumental#dairyindustryinindia#dairyindustryanima#dairymilkfactory#dairyprocessing#dairyprocessingplant#dairysection#dairytechnology#diaryvideo#milkplantprocess#milkplantbusiness#milkplantmachine#milkplantinindia#milkplantbusinessplan#milkplantprocessinhindi#milkprocessingplantanimation#milkchillingplantbusiness#milkplantcostinindia#dairymilkplantcost#smallmilkplantcost#minimilkplantcost

2 notes

·

View notes

Link

Our dairy processing equipment is designed for preparation, processing, and slicing of a variety of cheese, ice cream products, milk by-products and much more. Our highly operational production line and ice cream machines produce the best quality products.

1 note

·

View note

Text

𝐇𝐨𝐦𝐨𝐠𝐞𝐧𝐢𝐳𝐚𝐭𝐢𝐨𝐧: 𝐓𝐡𝐞 𝐆𝐚𝐦𝐞 𝐂𝐡𝐚𝐧𝐠𝐞𝐫 𝐢𝐧 𝐃𝐚𝐢𝐫𝐲 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐢𝐧𝐠

At Musefoodtech, we engineer homogenizers that transform: • 3-15µm fat globules → 0.1-2µm • Unstable emulsion → Protein-coated uniform dispersion • Ordinary texture → Premium mouthfeel

Key Mechanisms: High pressure (50-300 bar) + valve technology creates: ➤ Turbulence ➤ Cavitation ➤ Shear forces

1 note

·

View note

Photo

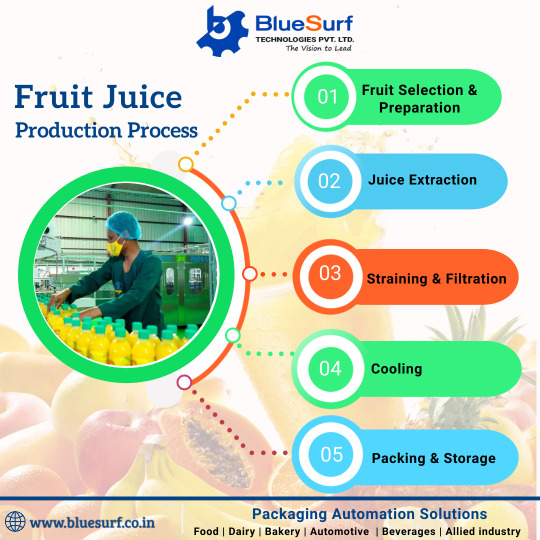

Increase Profit & Reduce Food Waste Today! The production process for fruit juices is fairly standard, regardless of the type of juice you are making. The process starts with the pretreatment of raw fruit material and then moves to extraction, clarification, and filtration. From there, the production process continues with homogenization, deoxidation, concentration, and ingredient adjustments. Collaborate with Blusurf Technologies for food process optimization solution. Request For A Quote Now [email protected] More Info Visit Us:https://bit.ly/3PwoGye

#bluesurf#bluesurftechnologies#EnergyEfficientSolutions#foodprocessing#foodandbeverageindustry#dairyprocessing

0 notes

Text

Dairy Equipment Manufacturers

Neologic Engineers is the leading dairy equipment manufacturers. We provide processing solutions for Liquid Milk, Curd, Butter Milk, Yogurt, White Butter and Ghee. We also have expertise in Ice cream mix, paneer and cheese processing lines. Reach us to get in touch with our beverage processing experts.

0 notes

Text

Explore top-quality boilers for the dairy industry designed for efficiency and reliability. Perfect solutions for all your dairy processing needs.

#DairyIndustryBoilers#RossBoilers#IndustrialBoilers#SteamBoilers#DairyProcessing#EfficientHeating#BoilerSolutions

0 notes