#Direct to Film vs Direct to Garment

Explore tagged Tumblr posts

Text

#DTF vs DTG#Printing Methods Comparison#Custom Apparel Printing#Which Printing Method Is Right#DTF Printing#DTG Printing#DTF vs DTG Which Printing Method Is Right#Custom T-Shirt Printing#Direct to Film vs Direct to Garment#Best Printing Method for Apparel.

0 notes

Text

A Complete Guide to DTF Transfers Ready to Press in the UK: Fast, Efficient, and Same Day DTF Printing Solutions

In the evolving world of garment printing, DTF transfers (Direct to Film) have become a game-changer for businesses, hobbyists, and designers across the UK. Whether you're customising T-shirts for a client or launching a new apparel line, DTF transfers ready to press UK solutions provide unmatched convenience, vibrant colours, and professional finishes. This article delves into everything you need to know about DTF transfers UK, highlighting the benefits of same day DTF printing services, how to get started, and why more people are choosing this method over traditional alternatives.

What Are DTF Transfers?

Direct to Film (DTF) transfers involve printing a design onto a special film using DTF inks. This print is then coated with adhesive powder, cured, and is ready to be transferred onto various fabrics using a heat press.

The process is simple:

Print the design onto PET film using a DTF printer.

Apply the hot melt powder adhesive.

Cure the powder with heat.

Use a heat press to transfer the design onto the garment.

DTF transfers offer vibrant colours, strong adhesion, and versatility across fabric types—including cotton, polyester, blends, and even leather.

Why Choose DTF Transfers Ready to Press UK Services?

For individuals or businesses in the UK, using a DTF transfers ready to press service means all the hard work is done for you. The film is printed, powdered, cured, and delivered in a state that’s ready to be heat-pressed onto your desired garment.

1. Time-Saving and Efficient

Ready to press DTF transfers save hours of preparation. You simply position the design and heat press it. This is particularly useful for businesses with high-volume orders or tight deadlines.

2. High-Quality Results Every Time

Professional suppliers use advanced printers and premium inks to ensure the transfers are consistently vibrant and durable. Designs won't crack or fade, even after multiple washes.

3. Ideal for Small Businesses and Custom Orders

Whether you're starting a streetwear brand or printing for an event, DTF transfers UK allow you to order in small or large quantities without compromising on quality or turnaround time.

The Rise of Same Day DTF Printing in the UK

Speed is everything in today's on-demand culture. That’s why same day DTF printing has exploded in popularity.

What Is Same Day DTF Printing?

This service enables you to upload your design files (usually in PNG format with a transparent background) and have your DTF transfers printed, processed, and shipped the same day—provided the order is placed before a certain cut-off time.

Key Benefits:

Meet urgent deadlines: Ideal for last-minute events or clients needing quick delivery.

Stay ahead of competitors: Offer faster turnaround to your customers.

Reliable workflow: Keeps your production line moving smoothly.

Some DTF suppliers even offer local pick-up options for same day orders, especially in major cities like London, Birmingham, or Manchester.

DTF Transfers vs. Traditional Printing Methods

Let’s compare DTF transfers UK with other common printing techniques:

Feature

DTF Transfers

Screen Printing

DTG (Direct to Garment)

Setup Time

Low

High

Medium

Cost for Small Orders

Low

High

Medium

Fabric Compatibility

Most types

Limited

Mostly cotton

Colour Vibrancy

Excellent

Good

Very Good

Durability

High

Very High

Good

Complexity

Easy with ready-to-press

Complex setup

Moderate

DTF transfers ready to press UK services combine ease of use, low setup cost, and excellent results, making them a preferred choice for many.

How to Order DTF Transfers Ready to Press in the UK

Ordering DTF transfers has never been easier. Here’s a simple step-by-step guide:

Step 1: Choose a Trusted UK Supplier

Look for a provider that offers:

Same day DTF printing

Transparent pricing

No minimum order quantity

Fast and reliable shipping

Quality assurance and customer support

Step 2: Upload Your Design

Most suppliers require your design to be:

300 DPI resolution

PNG format with a transparent background

Sized correctly (many offer templates)

Step 3: Approve the Proof (if applicable)

Some suppliers may send a digital proof before printing—check colours, placement, and resolution.

Step 4: Receive and Press

Once you receive your DTF transfers ready to press, simply use a heat press to apply them:

Press at 160–170°C for 15–20 seconds

Let it cool before peeling

Repress with a Teflon sheet for a final finish (optional but recommended)

Best Practices for Heat Pressing DTF Transfers

To get professional results:

Pre-press the garment to remove moisture and wrinkles.

Ensure even pressure and temperature.

Use a flat surface for consistent adhesion.

Follow manufacturer instructions closely.

Top Applications for DTF Transfers

DTF transfers are incredibly versatile. You can use them on:

T-shirts

Hoodies

Tote bags

Caps

Jackets

Sportswear

Workwear

This makes them ideal for:

Clothing brands

Merch drops

Promotional gear

Corporate branding

Gift businesses

DTF Transfers UK: What to Look for in a Supplier

Here’s what to consider when choosing a DTF transfers UK supplier:

Print quality – Vibrant, sharp, and consistent.

Customer reviews – Look for feedback on delivery and support.

Same day service – Especially if you’re on a tight schedule.

No minimum order – Allows flexibility for small businesses or one-off designs.

Support for custom sizing – Ensures a perfect fit for your product.

Environmental Impact and Care Instructions

Most DTF printing inks used today are eco-friendly and comply with OEKO-TEX® standards. However, always ask your supplier if they use sustainable and non-toxic materials.

To prolong the life of your printed garments:

Wash inside out at low temperatures.

Avoid tumble drying or ironing directly on the design.

Don’t use bleach or strong detergents.

Final Thoughts

The demand for DTF transfers ready to press UK is only going to grow as more businesses and creators seek efficient, affordable, and high-quality printing solutions. Whether you're in fashion, promotional merchandise, or starting your own T-shirt brand, the ability to get same day DTF printing means you never miss a deadline and can deliver top-tier products with ease.

When it comes to DTF transfers UK, speed and quality matter—and with the right supplier, you can enjoy both without compromise.

0 notes

Text

Functional Trim Trends in 2025: Buttons, Cord Locks, and More

Functional Trim Trends in 2025: What’s Next in Buttons, Cord Locks, and More

As the fashion industry evolves, so do the trims that support functionality, aesthetics, and brand identity. In 2025, we’re seeing a stronger convergence between utility and sustainability across garment trims such as buttons, cord locks, zippers, and label accessories. This guide explores the top functional trim trends shaping the industry—essential reading for brand buyers, designers, and apparel manufacturers.

1. Four-Hole Buttons Reimagined for Versatility

Four-hole buttons continue to dominate shirt and outerwear categories, but their role is being redefined through:

• Material diversity: Polyester resin remains common, but we’re seeing elevated usage of corozo (tagua nut), mother-of-pearl, wood, ceramic, and recycled metal.

• Custom finishes: Laser-etched logos, color-matched DTM dyeing, and pearlized coatings help differentiate basic trims.

• Micro-functionality: For technical apparel, some brands are embedding NFC tags or using smart resins compatible with garment tracking.

Ideal Applications: Dress shirts, uniforms, workwear, and minimalist fashion lines.

2. Cord Locks in Athleisure and Technical Outerwear

Cord locks (toggle stoppers) are evolving with advanced shapes, coatings, and spring systems to meet activewear and outdoor gear requirements.

Materials: High-performance acetal (POM), aluminum alloy, stainless steel, and bio-based plastics.

Trends: Cylindrical micro-cord locks for narrow elastic cords; dual-hole cord locks for hood and hem adjustments; metallic finishes for luxury sportswear.

Function: Enhanced grip, low failure rates, and anti-corrosion properties in humid or cold environments.

Ideal Applications: Drawstring hoods, adjustable hems, sports bags, and water-resistant jackets.

3. Zippers with Technical and Aesthetic Precision

Zippers are moving beyond basic closure tools to serve as signature elements:

Coil vs. molded vs. metal: Nylon coil zippers dominate lightweight garments; molded plastic zippers add bulk and edge; metal zippers (brass, antique silver) are used as visible features.

Design upgrades: Logo-engraved pullers, contrast tape colors, matte finish zippers, and concealed zippers for minimalism.

Functional zippers: Waterproof zippers with TPU film, fire-resistant zippers, and reversible dual sliders.

Ideal Applications: Performance jackets, fashion denim, skirts, high-end bags.

4. Decorative Shank Buttons and Statement Closures

Statement closures are having a revival, especially in luxury and couture collections:

• Styles: Blazer shank buttons, enamel-coated domes, gold-tone crest buttons, and molded logo metal buttons.

• Materials: Brass, zinc alloy, aluminum, and high-gloss plastic.

• Use Case: Less about function, more about identity—often sewn with heavier thread for durability.

Ideal Applications: Tailored coats, uniform blazers, bags, and accessories.

5. Functional Tags, Labels, and Closures in Premium Apparel

Labels and closures are more than identifiers. They now offer:

Thermal transfer printed size/care labels for seamless comfort.

Metal tag fasteners and rope-end seals used as part of brand storytelling.

Sustainable options: Recycled polyester labels, FSC-certified hang tags, and biodegradable string locks.

Ideal Applications: Streetwear, sustainable collections, luxury ready-to-wear.

6. Sourcing, Customization, and Sustainability

In 2025, buyers prioritize not just looks, but traceability, modularity, and eco-performance:

Sourcing Priorities:

• Nickel-free, azo-free compliant finishes

• Third-party testing for pull strength, abrasion resistance

• OEKO-TEX and GRS-certified trims

Customization Options:

• MOQ: 500–1000 pcs for custom molds

• Logo engraving, pantone color matching, matte/gloss texture options

• Combo sets: coordinating buttons, cord locks, hangtags under one SKU

Sustainable Directions:

• Recycled polyester buttons & zippers

• Cord locks made from bioplastic or recycled ocean waste

• Trims with QR codes for garment traceability

0 notes

Text

Functional Trim Trends in 2025: Buttons, Cord Locks, and More

Functional Trim Trends in 2025: What’s Next in Buttons, Cord Locks, and More

As the fashion industry evolves, so do the trims that support functionality, aesthetics, and brand identity. In 2025, we’re seeing a stronger convergence between utility and sustainability across garment trims such as buttons, cord locks, zippers, and label accessories. This guide explores the top functional trim trends shaping the industry—essential reading for brand buyers, designers, and apparel manufacturers.

1. Four-Hole Buttons Reimagined for Versatility

Four-hole buttons continue to dominate shirt and outerwear categories, but their role is being redefined through:

• Material diversity: Polyester resin remains common, but we’re seeing elevated usage of corozo (tagua nut), mother-of-pearl, wood, ceramic, and recycled metal.

• Custom finishes: Laser-etched logos, color-matched DTM dyeing, and pearlized coatings help differentiate basic trims.

• Micro-functionality: For technical apparel, some brands are embedding NFC tags or using smart resins compatible with garment tracking.

Ideal Applications: Dress shirts, uniforms, workwear, and minimalist fashion lines.

2. Cord Locks in Athleisure and Technical Outerwear

Cord locks (toggle stoppers) are evolving with advanced shapes, coatings, and spring systems to meet activewear and outdoor gear requirements.

Materials: High-performance acetal (POM), aluminum alloy, stainless steel, and bio-based plastics.

Trends: Cylindrical micro-cord locks for narrow elastic cords; dual-hole cord locks for hood and hem adjustments; metallic finishes for luxury sportswear.

Function: Enhanced grip, low failure rates, and anti-corrosion properties in humid or cold environments.

Ideal Applications: Drawstring hoods, adjustable hems, sports bags, and water-resistant jackets.

3. Zippers with Technical and Aesthetic Precision

Zippers are moving beyond basic closure tools to serve as signature elements:

Coil vs. molded vs. metal: Nylon coil zippers dominate lightweight garments; molded plastic zippers add bulk and edge; metal zippers (brass, antique silver) are used as visible features.

Design upgrades: Logo-engraved pullers, contrast tape colors, matte finish zippers, and concealed zippers for minimalism.

Functional zippers: Waterproof zippers with TPU film, fire-resistant zippers, and reversible dual sliders.

Ideal Applications: Performance jackets, fashion denim, skirts, high-end bags.

4. Decorative Shank Buttons and Statement Closures

Statement closures are having a revival, especially in luxury and couture collections:

• Styles: Blazer shank buttons, enamel-coated domes, gold-tone crest buttons, and molded logo metal buttons.

• Materials: Brass, zinc alloy, aluminum, and high-gloss plastic.

• Use Case: Less about function, more about identity—often sewn with heavier thread for durability.

Ideal Applications: Tailored coats, uniform blazers, bags, and accessories.

5. Functional Tags, Labels, and Closures in Premium Apparel

Labels and closures are more than identifiers. They now offer:

Thermal transfer printed size/care labels for seamless comfort.

Metal tag fasteners and rope-end seals used as part of brand storytelling.

Sustainable options: Recycled polyester labels, FSC-certified hang tags, and biodegradable string locks.

Ideal Applications: Streetwear, sustainable collections, luxury ready-to-wear.

6. Sourcing, Customization, and Sustainability

In 2025, buyers prioritize not just looks, but traceability, modularity, and eco-performance:

Sourcing Priorities:

• Nickel-free, azo-free compliant finishes

• Third-party testing for pull strength, abrasion resistance

• OEKO-TEX and GRS-certified trims

Customization Options:

• MOQ: 500–1000 pcs for custom molds

• Logo engraving, pantone color matching, matte/gloss texture options

• Combo sets: coordinating buttons, cord locks, hangtags under one SKU

Sustainable Directions:

• Recycled polyester buttons & zippers

• Cord locks made from bioplastic or recycled ocean waste

• Trims with QR codes for garment traceability

0 notes

Text

How to Prepare Your Artwork for Professional T-shirt Printing

T-shirt printing has evolved far beyond just picking up ready-made designs. Thanks to customization and print-on-demand services, you can now bring your unique ideas to life and even sell your designs online. If you’re looking to create professional-looking custom t-shirts in Singapore, this guide is for you.

🎨 Step 1: Think & Brainstorm Creative Design Ideas

Before you dive into printing, start with a spark of inspiration. Ask yourself: Why are you creating this design?

Some common reasons include:

Making a fashion statement

Expressing personal style or beliefs

Promoting a cause or event

Creating branded merchandise

Giving gifts or hosting giveaways

Know your audience. Do some basic market research. If you’re targeting music lovers, try incorporating lyrics or instrument-themed designs. For sports fans, consider team-inspired elements or action graphics.

Find inspiration from:

Pinterest, Instagram, and Behance

Art galleries and design magazines

Nature, urban spaces, or cultural elements

Famous quotes and pop culture references

👕 Step 2: Choose the Right T-Shirt

The t-shirt is your canvas. Select one that complements your design and feels good to wear.

What to consider:

Fabric: Cotton, polyester, blends

Weight: Lightweight for casual wear, heavier for durability

Fit & style: Crew neck, V-neck, oversized, fitted, etc.

Brand & price: Quality vs. cost balance

Eco-friendliness: Sustainable options are gaining popularity

Always prioritize comfort and visual appeal.

🖨️ Step 3: Pick the Right Printing Method

The print technique you choose can make or break your final product. Here are four popular options:

Direct-to-Garment (DTG): Best for detailed, colourful designs on cotton fabrics. Works like an inkjet printer and is perfect for small batches.

Screen Printing: Ideal for bulk orders with fewer colours. Each colour is applied using a separate screen, making it cost-effective for simple designs.

Sublimation Printing: Great for all-over prints and polyester fabrics. The ink becomes part of the fabric, resulting in a lightweight, breathable finish—perfect for sportswear.

Direct-to-Film (DTF): Offers vibrant, high-resolution prints on various fabric types like cotton, fleece, and nylon. Ideal for detailed designs, photos, and multi-colour artwork.

🖌️ Step 4: Create the Artwork

Here’s how to design like a pro:

Focus on visuals: Use bold illustrations, logos, quotes, or photos.

Placement matters: Front, back, sleeves—test mockups to find the most appealing layout.

Use colour wisely: 92.6% of customers say visuals influence buying decisions. Bright colours grab attention, while neutrals offer timeless style. Stick to brand colours if designing for a company.

Typography: Choose fonts that match your theme. Keep it legible and impactful. Fonts can help convey mood and brand identity.

🤝 Step 5: Partner With a Reliable T-Shirt Printer in Singapore

To bring your vision to life, team up with a trusted printing partner. Look for a provider that offers:

High-quality printing with advanced technology

Multiple t-shirt styles and materials

Fast turnaround times

Customization support and mockup previews

Proven track record with satisfied customers

Final Thoughts

With the right design, t-shirt, and printing method, your ideas can turn into wearable art—or even the next big thing in fashion! Whether it’s for personal use, brand building, or selling custom tees online, Singapore has plenty of professional t-shirt printing services ready to help.

Read More:- How to Prepare Your Artwork for Professional T-shirt Printing

1 note

·

View note

Text

“Direct to Film vs Direct to Garment: Which Is Better?”

Introduction

In the world of custom apparel, two printing methods have significantly risen in popularity: Direct to Film (DTF) and Direct to Garment (DTG). Both techniques offer unique advantages and are favored for different applications. However, the question remains—“Direct to Film vs Direct to Garment: Which Is Better?” This article dives deep into these two printing methods, comparing their processes, benefits, drawbacks, and real-world applications.

Direct to Film Printing What is DTF Printing?

Direct to Film (DTF) printing is a relatively new technology that allows for high-quality prints on textiles. In this process, designs are printed onto a special film using an inkjet printer equipped with DTF inks. Once the print is done, it undergoes a heat transfer process where the design is DTF Printer applied directly onto the garment.

Advantages of DTF Transfers Versatility: DTF transfers can be applied on various materials including cotton, polyester, and blends. Vibrant Colors: The use of specialty inks ensures that colors pop and remain vibrant even after multiple washes. Durability: DTF prints are known for their longevity; they resist cracking and fading. Cost-Effective: Compared to other methods like screen printing, DTF can be more affordable especially for small runs or custom designs. The Process of DTF Printing Design Creation: The first step involves creating a digital design using graphic design software. Film Printing: The design is printed onto a special DTF film with high-quality printers. Powder Application: A hot-melt adhesive powder is sprinkled onto the wet print. Curing: The print goes through a curing process using heat which melts the adhesive powder. Transfer Process: Finally, the film is placed on the garment and heat pressed. Best DTF Printer Options

When it comes to selecting the best DTF printer, options vary based on budget and needs:

Epson SureColor F-Series Mimaki UJF Series Roland VersaUV

These printers cater to both professionals and hobbyists aiming for quality outputs.

youtube

Direct to Garment Printing What is DTG Printing?

Direct to Garment (DTG) printing is another modern technique used for creating vibrant designs on fabric. Unlike DTF which uses film as an intermediary step, DTG prints directly onto the garment using Hop over to this website specialized inkjet technology.

Benefits of DTG Printing High Detail Resolution: DTG is known for its ability to reproduce intricate designs with stunning detail. Eco-Friendly Inks: Many DTG printers use water-based inks which are less harmful than some solvent-based alternatives. No Minimum Orders: Ideal for small businesses or individuals looking for custom pieces without needing bulk orders. The Process of DTG Printing Design Preparation: Just like in DTF printing, it begins with creating a digita

0 notes

Text

Understanding Screen Printing vs. Direct-to-Film (DTF) for Custom Apparel Buyers

When it comes to custom apparel and promotional product decoration, choosing the right printing method can make all the difference in quality, cost, and turnaround time. Two of the most prominent techniques in the industry today are Screen Printing and Direct-to-Film (DTF). Each method brings unique strengths to the table and is best suited for different types of projects. Whether you’re outfitting a team, promoting your business, or building your apparel line, understanding when to use Screen Printing versus DTF can help you make smarter, more cost-effective decisions.

What is Screen Printing?

Screen printing is one of the oldest and most widely used methods in the custom garment industry. At its core, screen printing involves creating a stencil (or “screen”) for each color in a design. Ink is then pushed through the screen and applied directly to the garment.

Key Advantages of Screen Printing:

Durability: Screen printing inks are thick, vibrant, and long-lasting — perfect for workwear, uniforms, or frequently washed items.

Cost-Effective in Bulk: Because screens are reused, screen printing becomes more cost-efficient as order quantity increases.

Bold, Clean Prints: Great for designs that use one to three solid colors and require a crisp, professional finish.

Ideal Use Cases:

Large runs of t-shirts, hoodies, or bags with a one-color logo or graphic.

Corporate uniforms with a 1–2 color logo.

Event merchandise like race tees, school spirit shirts, or promo giveaways.

The setup involved in screen printing (burning screens, aligning colors, prepping ink) means it’s most effective when printing large quantities. The more you print, the lower the cost per unit.

What is Direct-to-Film (DTF) Printing?

DTF is a newer technology in the custom apparel world, but it’s quickly revolutionizing how we print complex and colorful designs. With a CobraFlex’s DTF Printer, your full-color artwork is printed onto their specialized Film using Dupont water-based inks, then coated with adhesive powder and heat-pressed directly onto the garment.

Key Advantages of DTF Printing:

No Color Limitations: Perfect for full-color designs, photo-realistic artwork, gradients, and detailed illustrations.

No Screens Needed: No setup costs for each color or design — ideal for short runs or one-offs.

Prints on Almost Anything: Works on cotton, polyester, blends, spandex, leather, and more.

Ideal Use Cases:

Full-color or photographic designs on apparel.

Low-quantity runs (1–100 pieces) or 100–500 pieces, depending on the size of the print, where the screen setup would be too costly.

Multicolor designs with intricate detail or gradients.

When Should You Choose Screen Printing?

Let’s say you’re a local business printing 300 shirts with a 1-color logo. Screen printing is the clear choice. You’ll benefit from lower costs due to screen reuse and bulk ink application. Not only is screen printing economical in high quantities, but it also offers unmatched vibrancy and durability when handled correctly.

Scenarios where Screen Printing wins:

Simple branding (text/logo only)

Orders of 300 units or more

Limited color palette (1–3 spot colors)

Designs that don’t change often (consistent reorders)

When is DTF a Better Fit?

Now, imagine you’re a clothing brand creating limited-edition designs with multiple colors, gradients, or photographic quality. Or you’re a business needing just 10 shirts for a last-minute promo. In these cases, DTF is your best friend. There are no screens, no color separation, and minimal setup.

Scenarios where DTF shines:

Full-color or complex designs (like mascots, artwork, photos)

Low-quantity runs (1–100 pieces) or 100–500 pieces, depending on the size of the print.

Variable printing (changing names or numbers on each garment)

Garments with odd placements or stretch fabrics (DTF adheres well)

DTF also enables on-demand customization, making it perfect for online stores, merch drops, or any situation where design variety is high but volume is low.

Cost Comparison: Screen Printing vs. DTF

Factor Screen Printing & DTF Setup Time High (screen prep required) Low (digital file only) Ideal Quantity Medium to Large (50+) Low to Medium (1–50) Color Limitations Limited (each color = extra setup) Unlimited colors, no setup per color. Detail Level Best for bold lines & solid colors. Excellent for fine detail & gradients. Cost per Unit is Lower with volume. Higher per unit, but flat setup costPrint Longevity durable, long-lasting. Great durability, slightly less than the screen in extreme wash cycles

What About Quality?

Both methods can deliver high-quality results, but their strengths vary.

Screen prints feel more “built-in” to the garment — great for a retail feel and rougher use.

DTF prints sit slightly on top of the fabric but are smooth, flexible, and resistant to cracking when done properly.

When printed by experts using premium inks and films, DTF can rival screen printing in both vibrancy and wearability, especially for designs that would otherwise be impossible or expensive to separate into screens.

Trusted Partner in Custom Printing?

Precision Graphics has been helping businesses, teams, and creatives bring their ideas to life since 1981. With decades of experience in screen printing and the latest technology in DTF, we help you choose the best method for your needs, budget, and vision.

Whether you’re printing 10 shirts or 10,000, we provide:

Expert guidance on print method selection

Artwork optimization for either DTF or screen

High-quality, durable finishes

Fast turnarounds with local care

Conclusion: Which Should You Choose?

If you’re planning a large order with simple colors, go with screen printing. It’ll save you money and deliver bold, long-lasting prints.

If your design is full-color, detailed, or you only need a few pieces, DTF offers maximum flexibility, instant color accuracy, and a soft-touch finish that’s perfect for modern apparel trends.

When you partner with Precision Graphics, you don’t have to guess. They help you choose the right method, execute your vision, and deliver apparel that looks and feels exactly how you imagined.

Let you print smarter.

#custom printing#custom embroidery#arizona#informative#information#For#You#Help#Decorator#Apparel Industry#apparel manufacturing#DTF#dtf transfers#dtf printing

0 notes

Text

DTF Printing: Everything You Need To Know (2024)

DTF Printing Overview

What is DTF Printing?

It is a brand-new technology. Direct-to-Film uv dtf printing is the process of printing images of design on a transfer film that is later transferred to fabric by heating. It is a reliable modern alternative to DTG and screen printing with regard to fabric adaptability and ease of use, and price. In the field of garment printing, DTF has gained popularity due to its capability to create high-quality prints that are vivid and long-lasting on a variety of fabrics.

Preliminary Thoughts in DTF Printing

While DTF printing isn't very old, however, it is a part of the printing history that started with screen printing, and then evolved to more automated processes similar to DTG. The first ideas of DTF were first conceived in the mid-2010s and then became a commercially viable technology around the year 2017 as advances in transfer film and ink advanced. In the year 2020, small-scale businesses began to be interested because of its cost-effective setup and its capability for printing onto a variety of materials such as dark textiles.

Important Distinctions Between DTF, DTG Printing, and Screen Printing

DTF and. DTG: DTF and DTG printers differ because DTG can print designs directly onto clothes using inkjet technology; however, in DTF printing, the design is printed on the film that is then transferred onto the fabric later. DTF is more flexible in the fabrics it prints onto, compared to DTG. However, DTG printing is generally better suited to light-colored clothes.

DTF Vs. Screen printing: Like DTF Screen printing directly prints designs on clothing using stencils. It is typically suitable for large-scale projects. In contrast and contrast to DTF screen printing, screen printing is not as flexible as DTF regarding the quality, color, as well as batch size configuration.

How is DTF Printing Done?

A Guide on How to Get DTF Printed Step by Step

The first step is focused on the graphic design process, and the export of an image template is the first priority. After that then a prepress procedure can be defined prior to printing.

Screen DTF printer produces the artwork onto a specially designed transfer film, also known as DTF film. The print has strong colors as well as precise elements.

When the print is completed then a layer of glue powder that's hot-melting is sprayed onto the printed design while it's still damp. Then, the paper is placed in a baking machine, so that the powder will melt and stick to the print.

Transfer Step: Finally, the design is printed on the film, which is then placed on the fabric, and then heated. The bondable powder that is heated secures the design to the fabric.

Equipment Needed For DTF Printing

In the case of DTF printing, you'll require:

Printer DTF Printer DTF: A printer specially designed to be used for DTF printing, as it makes use of specific transfer film and inks.

Filmid Derivati: They're designed to be used for DTF printing.

Heating Transfer Press: A machine that heats and presses the design onto the fabric to make it stick.

DTF Ink: A type of ink designed specifically to be used in DTF printing.

Powder Binder Hot Melt powder is used to hold the ink on the cloth while it is transferred.

The Impact of Using The Correct Materials For DTF Printing

Utilizing high-quality materials for DTF printing is essential to ensure you get the desired outcomes. The quality of film binder, powder, and film can have a huge impact on the overall strength and sharpness of the printed.

Benefits of DTF Printing

Exceptional Prints On Different Types of Fabrics

Through DTF printing, you will be able to get excellent results printing on various types of fabric like polyester, cotton, leather, as well as certain synthetic materials. This flexibility is perfect for printing your designs on clothing, accessories and other fabrics.

Relative Completeness of Other Methods

As compared with other printing techniques like screen printing, which requires a significant amount of setup as well as manual labor, DTF printing is more efficient. The capability to print directly onto transfer films minimizes the number of setups needed, and also, the speedier production speeds are perfect for small and medium-sized businesses.

Efficiency Of DTF Printing

Even with the lower overall cost related to DTF printing, that are typically less expensive than other printing methods because there isn't a need to purchase expensive materials like documents, the set-up costs tend to be more expensive than other types of printing. This is due to the absence of the need for training specialized for DTF printing, which makes it simpler for businesses that are new to utilize this printer.

Consequences of DTF Printing

Fragile on Some Fabrics

Although DTF prints are vivid and clear, they might not last as long on certain fabrics as contrasted with prints created using other techniques. It is important to note that the durability of prints printed on high polyester fabric could be a problem and consequently, require more care in order for the design to be protected.

Initial Investment is Higher

For small-sized businesses with limited funds uv dtf printer and specialized powders and films could be regarded as costly. However, the low cost of materials, as well as the capacity and willingness to print smaller amounts, could reduce the cost.

Additional steps for setting up and maintaining this DTF printing process are characterized by preventative maintenance methods to limit the chance of bleeding, blockage of ink, as well as film overlap. Additionally, application of the powder adhesive requires a specific technique, and some processes may require specialized skills to perform.

0 notes

Text

DTF Transfers vs. Traditional Heat Transfer: What’s the Difference?

Introduction

In the world of custom apparel printing, several techniques have emerged to meet the ever-growing demand for high-quality designs. Among these, DTF (Direct to Film) transfers and traditional heat transfer printing stand out as popular choices. Each method has its unique advantages, limitations, and applications. Understanding these differences can significantly impact your decision-making process when selecting a suitable printing technique for your projects.

youtube

This article delves into the nuances of DTF transfers compared to traditional heat transfer methods. We will explore everything from the printing processes, materials used, equipment needed, and overall quality of prints. By the end of this comprehensive guide, you will be equipped with knowledge that empowers you to choose wisely between these two options.

What are DTF Transfers? Understanding DTF Printing

DTF printing is a relatively new technology that allows for stunningly vibrant designs on a variety of fabrics. The process involves transferring ink onto a special film using a direct to film printer, which is then adhered to the garment using heat and pressure.

Materials Used in DTF Transfers

The key components involved in DTF Transfer DTF transfers include:

Specialized Inks: Typically water-based inks that provide bright colors and excellent durability. Transfer Film: A PET film that acts as a medium for transferring designs. Adhesive Powder: This ingredient bonds the print to the fabric during the heating process. Equipment Required for DTF Printing

To successfully implement DTF printing in your workshop or business, you'll need:

A high-quality direct-to-film printer A heat press machine A computer with design software Transfer film and adhesive powder What is Traditional Heat Transfer Printing? Understanding Heat Transfer Printing

Traditional heat transfer printing involves creating designs on vinyl or paper and then applying them onto garments through heat and pressure. This method DTF Printer has been widely used for years and offers versatility in terms of design complexity.

Materials Used in Traditional Heat Transfer Printing

The fundamental materials used in traditional heat transfer printing include:

Heat Transfer Vinyl (HTV): A type of plastic material that comes in various colors. Transfer Paper: Special paper designed for inkjet or laser printers. Adhesive: Depending on whether you're using HTV or transfer paper, various adhesives may be required. Equipment Required for Traditional Heat Transfer Printing

To start with traditional heat transfer printing, you’ll typically need:

A cutting machine (for HTV) A printer (for transfer paper) A heat press or iron Design software DTF Transfers vs. Traditional Heat Transfer: What’s the Difference?

When comparing DTF transfers to traditional heat transfer methods, there are several critic

0 notes

Text

Interior Design Vs. Fashion Design: Which Is For You?

Choosing a professional path is both thrilling and difficult, especially when it comes to choosing between two creative and active industries such as interior design and fashion design. Both professions offer a variety of choices for personal expression and professional development, but the choice is up to your interests, talents, and long-term ambitions. In this post, we will look at the basic differences between interior design and fashion design to help you decide which career is best for you. We will also discuss why schools like the Fashion Designing Course in Kolkata and the Interior Designing Course in Kolkata are ideal choices for aspiring designers.

What is Interior Design?

Interior design seeks to improve the utility and beauty of interior environments. Interior designers work on projects ranging from residential houses to commercial facilities, ensuring that the design fulfills the client's demands while adhering to safety laws. They employ their creativity and technical abilities to choose color schemes, furniture, lighting, and materials that create a pleasant and functional atmosphere.

Skills Required for Interior Design:

Strong sense of spatial planning and organization.

Knowledge of materials, textures, and color theory.

Proficiency in design software like AutoCAD and SketchUp.

Good communication and problem-solving skills.

Career Opportunities in Interior Design:

Residential Interior Designer

Commercial Space Designer

Furniture Designer

Lighting Consultant

For those interested in this field, enrolling in Interior Designing Courses in Kolkata can provide the foundational knowledge and hands-on experience needed to excel in this career.

What is Fashion Design?

Fashion design is the art of making apparel, accessories, and footwear that reflect current trends and personal preferences. Fashion designers frequently draw designs, choose fabrics, and manage the manufacturing process. Their job include remaining current on fashion trends and forecasting future fashions to appeal to customers.

Skills Required for Fashion Design:

Creativity and artistic ability to sketch unique designs.

Knowledge of fabrics, sewing techniques, and garment construction.

Awareness of fashion trends and marketing strategies.

Ability to work under pressure and meet deadlines.

Career Opportunities in Fashion Design:

Apparel Designer

Textile Designer

Fashion Merchandiser

Costume Designer for Films and Theater

Pursuing a Fashion Designing Course in Kolkata can equip you with the skills and industry exposure needed to thrive in this competitive field.

Key Differences Between Interior Design and Fashion Design

1. Focus and Scope:

Interior design revolves around spaces, ensuring functionality and aesthetics in homes, offices, or public areas.

Fashion design is centered on creating wearable art, focusing on clothing and accessories that align with current trends.

2. Skill Set:

Interior designers need to understand structural elements, safety regulations, and material durability.

Fashion designers require knowledge of fabrics, sewing techniques, and an eye for style and detail.

3. Work Environment:

Interior designers often collaborate with architects, contractors, and clients, and may visit construction sites.

Fashion designers typically work in studios, production houses, or fashion shows.

4. Client Interaction:

Interior designers engage directly with clients to understand their needs and preferences.

Fashion designers may have less direct client interaction, focusing more on market demands and creative expression.

How to Choose the Right Path

1. Evaluate Your Interests:

Do you enjoy organizing and beautifying spaces? If yes, interior design might be for you.

Are you passionate about clothes, trends, and self-expression? Fashion design could be your calling.

2. Assess Your Skills:

Strong spatial awareness and technical skills point towards interior design.

A flair for creativity and attention to detail are ideal for fashion design.

3. Consider Career Goals:

Think about where you see yourself in five to ten years. Do you envision designing dream homes or creating stunning outfits?

4. Explore Courses:

Both careers require professional training. Enroll in programs like the Fashion Designing Course in Kolkata or Interior Designing Courses in Kolkata to gain industry-relevant skills and exposure.

Why Kolkata is the Perfect Place to Begin Your Design Journey

Kolkata is a very good place to study design education with its rich cultural legacy and the thriving creative community. Renowned institutes in Kolkata offer comprehensive courses in interior and fashion design, combining theoretical knowledge with practical practice.

The course focuses on fashion designing in Kolkata by equipping the students with the basic designs, trend analysis, and construction skills for garments.

Interior Designing Courses in Kolkata focus on spatial planning, material selection, and 3D modeling to prepare the students for diverse projects.

Conclusion

If one needs to make a choice between interior design and fashion design, one should always keep in mind his interests, strengths, and career goals. Both disciplines promise good opportunities for anybody ready to undertake education and skill building. Beginning with a good course is a success guarantee while building an attractive environment or making trend-setting clothes. Discover the Fashion Designing Course in Kolkata and Interior Designing Courses in Kolkata today to kick-start your dream profession!

0 notes

Text

The Rise of DTF Prints in the UK: Revolutionising Custom Printing

In the ever-evolving world of custom printing, Direct to Film (DTF) prints have become a game-changer across the UK. As more businesses, designers, and hobbyists seek high-quality, affordable, and versatile printing solutions, DTF technology has swiftly gained traction as a leading choice in garment and textile printing. But what exactly are DTF prints, and why are they becoming so popular in the UK? This blog post will explore the ins and outs of DTF printing, its benefits, and why it might just be the perfect solution for your printing needs.

What is DTF Printing?

Direct to Film (DTF) printing is a revolutionary printing method that involves transferring a design onto a specialised film before pressing it onto fabric. Unlike traditional printing techniques such as Direct-to-Garment (DTG) or screen printing, DTF allows designs to be printed on a range of fabrics with ease, including cotton, polyester, blends, and more. This makes it a versatile solution for creating custom clothing, accessories, and promotional items.

The DTF printing process involves five key steps:

Design Creation: Artwork is created digitally and prepared for printing.

Printing on Film: The design is printed onto a PET film using special water-based inks.

Powder Application: A hot melt adhesive powder is applied to the wet ink.

Curing: The powder is cured using heat to prepare it for transfer.

Heat Pressing: The design is transferred to the fabric using a heat press machine.

Once completed, the result is a durable, vibrant, and high-quality print that adheres beautifully to the fabric.

Why is DTF Printing Gaining Popularity in the UK?

The UK market for customised garments and promotional products is booming. From small businesses offering personalised t-shirts to large-scale manufacturers, the demand for affordable yet high-quality printing solutions has never been higher. DTF printing fills this gap perfectly. Here are a few reasons why it is making waves across the country:

1. Versatility

One of the standout features of DTF printing is its ability to work on a wide variety of fabrics. Whether you’re printing on cotton, polyester, denim, canvas, or even leather, DTF prints offer exceptional results. This flexibility is particularly attractive to UK businesses catering to diverse customer demands.

2. Superior Print Quality

DTF prints boast vibrant colours, crisp details, and excellent durability. Unlike other methods, the designs do not crack or fade easily, even after multiple washes. This makes DTF perfect for both fashion and workwear, where longevity is crucial.

3. Cost-Effective Solution

Compared to other printing methods like screen printing, DTF is far more cost-effective, particularly for small to medium-sized orders. This affordability allows businesses and individuals to experiment with custom designs without the fear of high upfront costs.

4. Eco-Friendly Approach

With the rising importance of sustainability in the UK, DTF printing offers an eco-friendly advantage. The water-based inks and reduced waste involved in the process align with the values of environmentally conscious businesses and consumers.

5. No Minimum Orders

DTF printing removes the barrier of minimum order quantities, making it ideal for small businesses, hobbyists, and one-off custom projects. Whether you need one custom t-shirt or a batch of 100, DTF printing can accommodate your needs with ease.

DTF vs DTG Printing: What’s the Difference?

While both DTF and DTG (Direct-to-Garment) are popular printing methods, they cater to slightly different needs. DTG is ideal for printing directly onto cotton fabrics but struggles with other materials like polyester. In contrast, DTF can print on nearly any fabric type, making it a more versatile option.

Moreover, DTG often requires pre-treating fabrics to achieve optimal results, whereas DTF skips this step, saving both time and effort. For UK businesses seeking greater flexibility and efficiency, DTF printing is emerging as the clear winner.

Who Can Benefit from DTF Printing?

The beauty of DTF printing lies in its ability to cater to various sectors and individuals. Some of the key beneficiaries include:

Small Businesses: Whether you’re a startup offering custom t-shirts or a promotional merchandise company, DTF printing helps you deliver high-quality products without the need for expensive equipment.

Independent Designers: Artists and graphic designers can bring their creations to life with vibrant and detailed prints that showcase their work beautifully.

Workwear Suppliers: Businesses requiring durable uniforms and workwear benefit from DTF’s ability to withstand wear and tear.

Event Planners: From personalised wedding favours to branded corporate gifts, DTF allows event planners to create memorable, customised items.

Hobbyists: For individuals exploring creative hobbies like DIY printing, DTF offers an easy, affordable, and fun way to print custom designs at home.

How to Get Started with DTF Printing in the UK

If you’re considering adopting DTF printing for your business or personal projects, here’s how to get started:

Choose the Right Equipment: Invest in a DTF printer, PET films, adhesive powders, and a heat press machine. While the initial setup costs are affordable, ensure you choose quality products from trusted UK suppliers.

Learn the Process: Familiarise yourself with the steps involved in DTF printing. There are plenty of online tutorials and resources to help you perfect your technique.

Source Quality Supplies: Use high-quality inks, powders, and films to achieve professional results. Many UK-based suppliers offer bundles and starter kits for beginners.

Start Small: Begin with small orders or personal projects to refine your skills before scaling up.

Market Your Services: If you’re a business, showcase your DTF printing capabilities through social media, local events, and online marketplaces to attract customers.

The Future of DTF Printing in the UK

As the custom printing industry continues to grow, DTF printing is poised to play a significant role in shaping its future. With advancements in technology and increasing demand for sustainable and versatile printing solutions, it’s no wonder DTF is quickly becoming the preferred choice for businesses and individuals alike.

From fashion designers to small-scale entrepreneurs, the UK market is embracing the endless possibilities that DTF printing has to offer. Its combination of quality, affordability, and flexibility ensures that it will remain a cornerstone of the printing industry for years to come.

Final Thoughts

DTF printing is revolutionising the world of custom printing in the UK. With its ability to produce vibrant, durable, and versatile designs on a wide range of fabrics, it’s no surprise that businesses and creatives are turning to DTF for their printing needs. Whether you’re looking to start a printing business, customise your workwear, or explore a creative hobby, DTF printing offers endless opportunities to bring your ideas to life.

So, if you haven’t already considered DTF printing, now is the time to explore this innovative solution and see how it can transform your projects. The future of printing is here, and it’s Direct to Film.

0 notes

Text

The Best Men’s Striped Polo T-Shirt for a Smart-Casual Look

When it comes to versatile wardrobe staples for men, the striped polo t-shirt is a clear winner. It effortlessly bridges the gap between formal and casual, making it a perfect choice for almost any occasion. Let’s explore everything you need to know about this timeless garment and how to make it your go-to for a smart-casual look.

Why Men’s Striped Polo T-Shirts Are a Wardrobe Essential

The Evolution of Polo T-Shirts

Originally designed for sports like tennis and polo, these shirts quickly transitioned into everyday fashion. Their structured collars and short sleeves made them an instant classic.

Why Stripes Never Go Out of Style

Stripes add character without overwhelming the outfit. They are both contemporary and traditional, offering a balance that appeals to men of all ages.

Key Features of a Good Striped Polo T-Shirt

Fabric Matters: Breathable and Durable Materials

Cotton remains a favorite for its softness and breathability. For a touch of luxury, look for blends that include silk or merino wool.

Fit for Style: Slim Fit vs. Classic Fit

Slim fits accentuate the body’s natural shape, while classic fits provide a relaxed and comfortable look.

Color Combinations That Work

Navy and white, black and gray, or even bold hues like red and blue can elevate your style game. Choose according to your personality and occasion.

Styling Your Men’s Striped Polo T-Shirt for a Smart-Casual Look

Pairing with Chinos or Trousers

Chinos in neutral tones like beige or khaki pair seamlessly with striped polos, adding a refined touch to your outfit.

Perfect Layering Ideas

Throw on a blazer for semi-formal events or a lightweight cardigan for cooler days. Layering can instantly elevate the aesthetic.

Shoes That Complement Your Striped Polo

Leather loafers, sneakers, or even boat shoes work wonderfully depending on the event.

Top Occasions to Wear a Men’s Striped Polo T-Shirt

Casual Outings with Friends

Pair your mens striped polo t shirt with jeans and sneakers for a laid-back yet stylish vibe.

Office-Friendly Casual Fridays

Opt for darker stripes with formal trousers to keep the look professional.

Evening Parties or Casual Dates

Add a jacket to your striped polo for an effortlessly chic ensemble.

Choosing the Right Striped Polo T-Shirt for Your Body Type

Tips for Tall and Slim Men

Go for horizontal stripes to add visual width and create a balanced appearance.

Suggestions for Broader Physiques

Vertical or thinner stripes work best as they elongate the silhouette and create a slimming effect.

Popular Brands Offering Men’s Striped Polo T-Shirts

High-End Designer Brands

Luxury brands like Ralph Lauren and Lacoste are known for their premium quality striped polos.

Affordable Yet Stylish Options

Brands like Uniqlo, H&M, and Zara offer budget-friendly options without compromising style.

Caring for Your Striped Polo T-Shirts

Washing and Drying Tips

Always use cold water to maintain the fabric’s integrity and avoid fading.

How to Maintain the Vibrancy of Stripes

Turn the shirt inside out before washing and avoid direct sunlight while drying.

Sustainable Options in Striped Polo T-Shirts

Why Go for Organic Fabrics?

Organic cotton reduces environmental impact and feels equally comfortable on the skin.

Popular Eco-Friendly Brands

Brands like Patagonia and Everlane are pioneers in creating sustainable fashion.

Striped Polo T-Shirts in Pop Culture

From sports legends to Hollywood actors, striped polo t-shirts have been a fashion favorite. Think of James Bond or preppy college films—the striped polo is a recurring theme.

Shopping Tips for the Best Deals

Online vs. Offline Shopping Advantages

Online stores often have a wider range, but trying a shirt in-store helps ensure the perfect fit.

FAQs

What makes striped polo t-shirts versatile for men? Their blend of formal and casual elements makes them suitable for various occasions.

How can I style a striped polo t-shirt for an office setting? Pair it with dark trousers and polished shoes for a business-casual look.

Are there any specific fabrics to look for in a striped polo t-shirt? Cotton and cotton blends are ideal for their comfort and breathability.

What’s the best way to care for striped polo t-shirts to maintain their quality? Wash in cold water, avoid harsh detergents, and air-dry whenever possible.

Can striped polo t-shirts be worn year-round? Absolutely! They’re perfect on their own in summer and as a layering piece in winter.

Conclusion

A mens striped polo t shirt is more than just clothing—it’s a fashion statement that combines comfort, versatility, and timeless appeal. Whether you're heading to a brunch or a casual business meeting, this piece can effortlessly adapt to your needs. Invest in quality, care for it well, and watch it become your wardrobe MVP.

0 notes

Text

DTF STATION-DTGPRO

Before diving into the specific advantages of the DTF Station-DTGPRO, it’s essential to understand the differences between DTF and DTG printing. While Direct-to-Garment (DTG) printing involves applying ink directly onto the fabric, Direct-to-Film (DTF) printing involves printing designs onto a film, which is then transferred onto the garment using a heat press. The result is a versatile, durable print that adheres to a wide range of materials, including cotton, polyester, blends, and even synthetic fabrics. Click Here For More Information:

0 notes

Text

Exploring the Revolutionary Printing Technique Transforming Custom Apparel

DTF (Direct to Film) printing is rapidly gaining popularity in the UK's custom printing industry. This innovative method allows for high-quality, durable designs on various fabrics, offering an alternative to traditional techniques like screen printing or heat transfer vinyl. In this article, we will delve into what Dtf Printing UK is, its advantages, and why it's becoming a go-to solution for businesses and hobbyists across the UK.

What is DTF Printing?

Direct to Film printing is a process where designs are printed onto a special film, which is then transferred to the fabric using heat and pressure. Unlike Direct to Garment (DTG) printing, which directly prints ink onto fabric, DTF offers more versatility by allowing the T-Shirt Printing UK applied to multiple surfaces, including cotton, polyester, and blends.

The DTF Printing Process

Design Creation: The process begins with the creation of the artwork, often using design software like Adobe Illustrator or Photoshop.

Printing on Film: The design is printed onto a special PET film using a DTF printer and high-quality ink. The printed image is then coated with adhesive powder.

Heat Transfer: The film with the powdered design is transferred onto the fabric using a heat press at a specific temperature and pressure.

Final Result: Once the film is removed, the design is embedded into the fabric, creating a vibrant, long-lasting image.

Why DTF Printing is Revolutionizing the UK Market

The growing popularity of DTF printing in the UK can be attributed to several factors:

Versatility: DTF can be applied to a wide range of materials, making it ideal for both large-scale businesses and individual creators looking to offer a variety of products.

High Durability: DTF prints are known for their durability, wash resistance, and ability to withstand wear and tear, making them ideal for everyday apparel.

Vibrant Colours: The printing technique allows for vibrant colours and intricate designs, which can be difficult to achieve with traditional methods.

Low Setup Costs: Unlike screen printing, which requires extensive setup, DTF is relatively easy to implement with fewer materials and equipment.

Comparing DTF with Other Printing Techniques

When compared to traditional methods such as DTG or sublimation, DTF offers unique advantages:

DTF vs. DTG: While DTG is ideal for cotton-based fabrics, DTF works well on a wider range of materials. Additionally, DTF can print on darker fabrics without the need for pre-treatment.

DTF vs. Sublimation: Sublimation printing is often limited to polyester fabrics and lighter colours, whereas DTF can be used on cotton and darker materials, giving it more flexibility.

Challenges and Considerations

While DTF printing offers numerous benefits, there are a few considerations to keep in mind:

Equipment Costs: While setup is simpler than screen printing, the specialized printers and consumables can still be costly for small businesses or hobbyists.

Learning Curve: Mastering the DTF process can take time, especially when it comes to perfecting heat and pressure settings for different materials.

0 notes

Text

How to Print DTF Transfers: Tips for Long-Lasting Designs

DTF (direct-to-film) printing is revolutionizing the printing industry, offering vibrant and durable designs on various materials, including cotton, nylon, and leather. Unlike sublimation, which is limited to polyester, DTF can handle a broader range of fabrics. If you're ready to dive into DTF transfers, this guide will walk you through the process step-by-step, ensuring your designs last.

What You’ll Need for DTF Printing

Before you start, gather these essential tools:

Best DTF Printer: Choose a printer specifically designed for DTF, or consider converting an existing inkjet printer.

DTF Transfer Film: This is the medium where your design will be printed.

DTF Ink: Specialized ink that adheres to the film and bonds with the fabric.

Curing Powder: This adhesive ensures your design stays on the fabric during the transfer process.

Heating Press or DTF Oven: These apply the necessary heat and pressure to bond your design to the fabric.

RIP Software: This software prepares your designs for printing, ensuring accurate color layering.

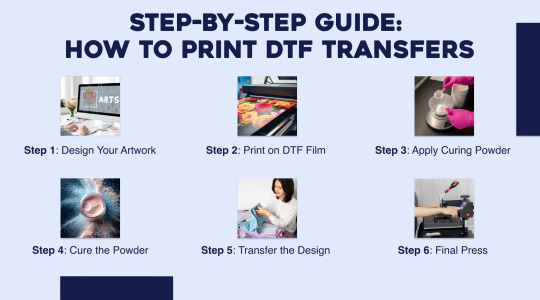

Step-by-Step Guide to Print DTF Transfers

Step 1: Design Your Artwork

Use graphic design software like Adobe Illustrator or Photoshop to create your design. For dark fabrics, ensure to include a white layer when printing. Once you're satisfied with the design, it's time to print.

Step 2: Print on DTF Film

Load the DTF transfer film into your printer. Print your artwork using DTF ink, following the order: colors first, then an uncolored layer. If using a converted inkjet printer, make sure it’s properly set up for DTF printing.

Step 3: Apply Curing Powder

Also Read: What Does DTF Transfer Mean?

While the ink is still damp, sprinkle curing powder evenly over the design. This step is crucial for ensuring the image adheres to the fabric.

Step 4: Cure the Powder

Using a DTF oven or heat press, heat the printed film at about 325°F (163°C) for 2 to 3 minutes. This step transforms the curing powder into an effective adhesive.

Step 5: Transfer the Design

Once the powder is cured, place the design on your garment. Set your heat press to around 320°F and apply pressure for 15-20 seconds. Allow the fabric to cool slightly before peeling off the film.

Step 6: Final Press

For added durability, give your fabric another press. Place a piece of parchment over the design and press for an additional 10-15 seconds. This helps embed the design into the fabric, enhancing its longevity.

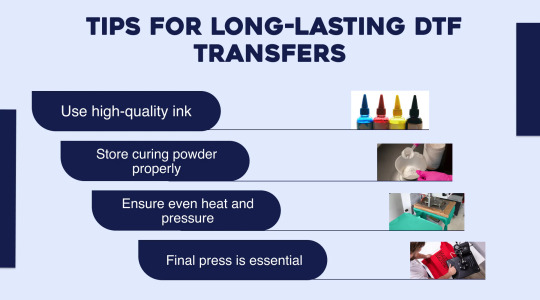

Tips for Long-Lasting DTF Transfers

Use High-Quality Ink: Invest in DTF-specific ink to prevent faded colors and ensure vibrant prints.

Store Curing Powder Properly: Keep it in a dry place to avoid clumping, which can affect adhesion.

Ensure Even Heat and Pressure: Consistent temperature and pressure are key to achieving smooth, durable designs.

Never Skip the Final Press: This step significantly boosts the durability of your design, helping it withstand multiple washes.

Choosing the Right DTF Printer

For beginners, selecting the right printer can be daunting. While dedicated DTF printers are available, many opt to convert existing inkjet printers like the Epson L1800 or P600. Ensure your chosen printer is compatible with DTF films and inks, and look for models with good customer support and availability of replacement parts.

DTF Printing vs. Other Methods

Also Read: What Kind of Printer Do I Need for DTF Transfers?

Screen Printing: Ideal for large orders but labor-intensive and costly for intricate designs. DTF allows for quick, smaller batches.

Sublimation Printing: Limited to polyester and lighter colors; DTF works on various fabrics and is effective on dark materials due to its white ink layer.

DTG Printing: While DTG offers a soft finish, it requires pre-treatment of fabric. DTF simplifies the process, making it more user-friendly for beginners. Also Read: How to Remove DTF from a Shirt Without Ruining the Fabric

DTF printing is a versatile, easy method for creating vibrant designs on various fabrics. Whether you’re a novice or a seasoned pro, with the right tools and a bit of practice, you can produce stunning, long-lasting transfers.

Ready to start creating your DTFIL transfers? Explore your options and bring your designs to life with ease!

0 notes

Text

The Ultimate Comparison: DTF vs. DTG Printing

Introduction to DTF and DTG Printing

Printing techniques have evolved tremendously over the years, leading to various methods that cater to different needs in the textile industry. Two of the most popular printing methods today are Direct to Film (DTF) and Direct to Garment (DTG) printing. Both techniques have their unique advantages, challenges, and suitable applications. In this article, we aim to provide a comprehensive comparison of DTF and DTG printing, exploring everything from their processes and equipment to the quality of prints they produce.

What Is DTF Printing?

DTF printing, or Direct to Film printing, involves transferring images onto a special film before applying them to garments. This method has gained popularity due to its versatility and high-quality output.

How Does DTF Printing Work?

The DTF here process consists of several essential steps:

Design Creation: Using graphic design software, artists create digital designs which are then sent to the printer. Film Printing: A direct-to-film printer prints designs onto a special film using eco-solvent or water-based inks. Powder Adhesive Application: After printing, an adhesive powder is sprinkled on the wet ink. Heat Curing: The printed film is heated in an oven so that the adhesive melts into the ink. Transfer Application: Finally, the film is placed on a garment and heat-pressed, transferring the design. What Is DTG Printing?

On the other hand, DTG printing, or Direct to Garment printing, involves directly applying ink onto fabric using specialized inkjet technology.

How Does DTG Printing Work?

The steps involved in DTG printing are as follows:

Pre-Treatment: Fabrics are pre-treated with a solution that helps the ink adhere better. Design Creation: Similar to DTF, designs are created digitally. Inkjet Printing: The garment is placed in a DTG printer where it is sprayed with inks directly onto the fabric. Curing Process: After printing, garments undergo curing through heat or UV light for durability. The Ultimate Comparison: DTF vs. DTG Printing

When comparing these two methods—DTF vs. DTG—you'll find that each has its strengths depending on your specific requirements.

youtube

Quality of Prints DTF: Produces vibrant colors and fine details due to its ability to print on various fabrics without compromising quality. DTG: Also offers high-quality prints but may struggle with darker fabrics unless pre-treated effectively. Versatility DTF: Can be used on multiple materials including cotton, polyester blends, and even leather. DTG: Primarily suited for 100% cotton fabrics; limitations exist when working with synthetic materials. Production Speed DTF: Offers faster production times since multiple transfers can be done simultaneously. DTG: Generally slower as each garment re

0 notes