#EMCSolutions

Explore tagged Tumblr posts

Text

#EMIS#EMCSolutions#ProductCatalogue#ElectronicsDesign#EngineeringResources#Innovation#electronicsnews#technologynews

0 notes

Text

Robots' Body --- Why Does the Mechanical Arm "Malfunction"? The Invisible Pit of Electromagnetic Interference, and Leiditech's Solution to Fix It!

High-speed robotic operations generate heat that risks controller crashes. Leiditech’s solution integrates:

l Intelligent temperature-controlled fan drives with real-time speed adjustment, reducing noise by 30% and energy consumption by 20%.

Flickering LEDs cause operational errors. Leiditech’s design ensures:

l A low-power drive circuit paired with the SM5819WS diode to stabilize display signals and reduce power waste.

Delayed or muffled alarms waste critical response time. Leiditech’s solution delivers:

l An optimized PWM-driven circuit with the SM5819WS diode, enabling 0.1-second alarm response.

Industrial EMI often causes RS485 packet loss. Leiditech’s dual-protection design includes:

l The PCI0420T-142-N common-mode choke to suppress differential-mode noise.

Gigabit Ethernet stability is critical for robotic control. Leiditech’s solution features:

l The 3R090–5S gas discharge tube (≤2pF capacitance) for surge protection, ensuring gigabit compatibility.

Static discharge during UART hot-plugging risks MCU failure. Leiditech’s protection includes:

l 3.3V lines: ESDA33CP30 (22kV contact/25kV air discharge, 12pF capacitance).

Core Value: Precision Engineering

With 15 years of industrial EMC expertise, Leiditech optimizes component selection and circuit design to minimize faults, extend service life, and boost operational efficiency. From thermal management to communication, every module is engineered for rugged EMI resilience.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

#Leiditech #RoboticAutomation #EMCsolutions #IndustrialElectronics #ESDProtection #FactoryAutomation #MechanicalArm #EngineeringInnovation #RS485 #EthernetStability #ElectromagneticInterference #SmartManufacturing #TechBlog #IndustrialSolutions

0 notes

Text

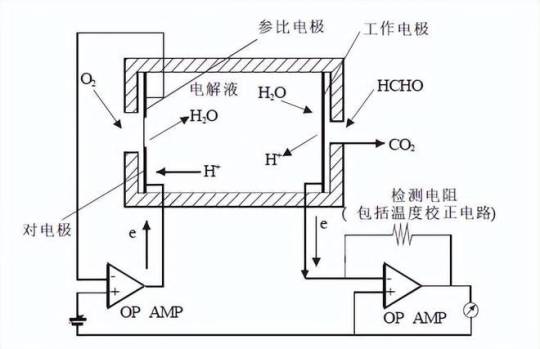

Robot's Nose- Electrochemical Gas Sensor ESD and Surge Protection Solution

Electrochemical gas sensors are devices that measure gas concentration by detecting the current signal generated from oxidation or reduction reactions of target gases on the electrode surface. They play a crucial role in industrial safety, environmental monitoring, indoor air quality assessment, and portable gas detection equipment.

Core Principle

Leiditech’s ESD and Surge Protection Guidelines for Electrochemical Sensor Circuits

1. Sensor Interfaces (WE/CE/RE)

A low-capacitance ESD device (Leiditech SD05C) is connected in parallel. Its bidirectional protection characteristic is compatible with the signal range of the three electrodes, and its low capacitance of 11pF minimizes attenuation of nanoampere-level weak current signals. It ensures that under IEC 61000–4–2 Level 4 tests (±8kV contact discharge, ±15kV air discharge), the clamping voltage remains within 13V, which is lower than the power supply voltage withstand limit of the downstream ADA4505–2 operational amplifier.

2. Potentiostatic Control Module and Transimpedance Amplifier

It is recommended to connect an ESDA05CC (SOD-523 package) in parallel across the feedback network (100kΩ resistor) of the transimpedance amplifier. Its 39pF capacitance matches the circuit’s capacitive reactance characteristics, and its 20A current handling capacity copes with sudden surges, protecting the high-impedance feedback node from ESD breakdown.

3. Signal Output and MCU Interfaces

l On the path where the sensor signal, after amplification, is transmitted to the MCU (e.g., AIN1± pin of AD7798), an RC filter network (1kΩ+100pF) is connected in series. The cutoff frequency of 1.6MHz is compatible with the sensor’s signal bandwidth (≤10Hz). Meanwhile, an ESDA33CP30 (3.3V) or SMDA05CCN (5V) is connected in parallel, both meeting IEC 61000–4–2 Level 4 protection requirements.

4. Power Module

For 3.3V VCC: Leiditech uses ESD0321CW (DFN0603 package, 30pF capacitance, 21A discharge current).

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#GasSensorProtection #ElectrochemicalSensors #ESDProtection #SurgeProtection #Leiditech #CircuitDesign #IndustrialSafety #EMCsolutions #TechBlog #SensorDesign #IoTDesign #SmartSensors #EmbeddedEngineering #PCBDesignTips

0 notes

Text

The Inspiration from Why Electric Bicycles Are Prone to Catching Fire

Electric bicycles occasionally catch fire. Shanghai Leiditech’s EMC Brother analyzes the reasons, which may provide some inspiration for you.

The reason why electric bicycles are prone to catching fire may be due to insufficient protection functions of the battery management system (BMS) or battery quality issues. To enhance the BMS protection functions and reduce the risk of fire, consider the following points:

Battery quality control: Select high-quality battery suppliers, and strictly control raw materials and production processes to ensure the safety and stability of batteries.

Overcharge and discharge protection: The BMS needs an accurate overcharge and discharge protection function to prevent the battery from overheating or even catching fire due to improper charging and discharging. Consider adopting more advanced voltage and temperature monitoring technologies to cut off the charging and discharging circuit in a timely manner.

Temperature monitoring and control: The BMS should be able to monitor the battery temperature in real-time and take protective measures when the temperature exceeds the safe range, such as stopping charging/discharging or reducing the charging/discharging rate.

Short circuit protection: Strengthen the monitoring and protection against short circuits to ensure that the circuit can be cut off promptly in case of an internal short circuit in the battery, thus avoiding fire risks.

Overload protection: The BMS should be able to promptly detect and handle battery overload conditions to prevent battery damage caused by prolonged high-load operation.

Through the above improvements, the safety of electric bicycles can be enhanced, and the risk of fire can be reduced. Meanwhile, users should also pay attention to reasonable use and charging in daily use, avoiding over-discharging and over-charging to ensure the safety of electric bicycles.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#EBikeSafety #BatteryManagement #ElectricBike #Leiditech #FirePrevention #SmartCharging #TechSolutions #SustainableTransport #BatterySafety #EMCSolutions #GreenMobility

0 notes

Text

Causes and Solutions for Frequent Damage to Automotive Sensors

Reasons for frequent Damage to Automotive Sensors?

During the rectification of issues for automotive customers, Leiditech’s EMC specialist found that the main common cause of frequent damage to in-vehicle sensors is unstable voltage.

During vehicle operation, voltage fluctuations are unavoidable. These fluctuations can stem from engine startup, the operating status of the alternator, and the use of other electrical equipment, posing significant challenges to in-vehicle sensors. Unstable voltage is particularly problematic for sensors because they require extremely high voltage stability.

1. Solutions Proposed by Leiditech’s EMC Specialist

Leiditech’s EMC specialist has identified a feasible solution: using small-sized, high-current TVS (Transient Voltage Suppressor) protection devices.

By integrating TVS protection devices into vehicle circuits, we can effectively address the issue of frequent sensor damage. This not only extends sensor lifespan, reduces the costs of sensor replacement and maintenance, but also ensures the reliability and stability of the vehicle.

Protecting the stable operation of in-vehicle sensors and enhancing vehicle performance and reliability is our shared goal. Let’s work together to adopt TVS protection solutions, bringing more reliable and stable sensor performance to vehicles and making travel safer and smoother.

Leiditech Electronics has launched small-sized, high-current TVS devices that help customers improve product quality. Validated through automotive surge testing, these devices ensure safer operation.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#AutomotiveTech #SensorProtection #TVSDevices #VehicleElectronics #Leiditech #CarMaintenance #AutoRepair #VoltageProtection #EMCSolutions #CarTech #AutomotiveInnovation #VehicleSensors #SmartDriving #AutoParts #AutomotiveElectronics

0 notes

Text

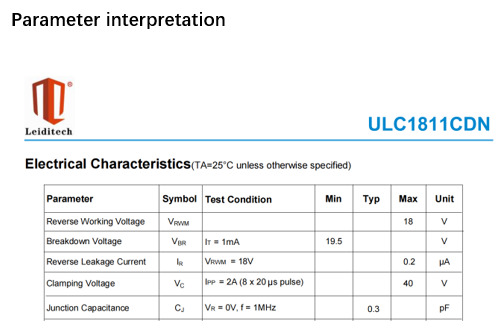

How to Choose the Right Device for NFC Interface Protection?

Applications

In the era of the Internet of Things, especially with the ongoing spread of Omicron, many of our products now use near-field communication (NFC) or other wireless methods for communication. All wireless products are equipped with antennas, and how to implement interface protection in small-sized products has troubled many engineers.

Selection Criteria

First, to meet the requirements of such electronic products — thin, small, and portable — the ESD protection component must be sufficiently compact. For example, a 0402 package, or even a 0201 package, can achieve the advantages of high integration and high flexibility in PCB design.

Second, the parasitic capacitance of the ESD protection component’s pins must be small to avoid signal interference. For instance, when using an ESD protection component in an antenna, the frequency band of the antenna and the minimum acceptable parasitic capacitance for different frequency bands must be considered. Typically, the parasitic capacitance of ESD protection components used in antennas should be less than 1pF, or even lower.

Third, when selecting the maximum operating voltage and unidirectional/bidirectional characteristics of ESD protection components, the highest and lowest voltages of the signal swing must be considered to prevent signal interference. For example, in an NFC antenna, the maximum signal voltage typically reaches 18V, and negative voltages may also occur, so a bidirectional ESD protection component suitable for this signal voltage range must be selected. In a GPS antenna, the maximum voltage is usually less than 5V and the minimum voltage is no less than 0V, so a 5V unidirectional ESD protection component can be used.

Fourth, the ESD protection component must have high tolerance to ESD events, at least capable of withstanding 8kV ESD attacks in contact mode as per IEC 61000–4–2.

Fifth, and most importantly, the clamping voltage of the ESD protection component during an ESD event must be low enough. This not only protects the circuit from permanent damage caused by electrostatic discharge but also ensures that signal transmission is not interfered with by the ESD.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#ESDProtection #NFC #IoTDevices #WirelessTech #EMCsolutions #PCBDesign #ElectronicsEngineering #Leiditech #TechInnovation #ClampingVoltage #ElectrostaticProtection #TechTips #CircuitProtection

0 notes

Text

USB PD Fast Charger Static Surge Protection with TVS

USB PD fast chargers have become ubiquitous essentials in daily life, providing fast and convenient charging for electronic devices like smartphones, tablets, laptops, wearable devices, cameras, car chargers, and emerging IoT smart home products. Common output voltages include 5V, 9V, 12V, 15V, and 20V.

The output interface of USB PD chargers requires anti-static and surge protection to safeguard devices and circuit boards. This prevents damage from static electricity or surge currents during charging (e.g., hot-plugging), reducing equipment failure risks and enhancing charger stability/safety.

Shanghai Leiditech offers a USB PD fast-charging interface static surge protection scheme:

l Input Range: 90VAC ~ 265VAC, Output Range: 5V ~ 20V, Max Power: 65W.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#USBPD #FastCharging #TVSProtection #SurgeProtection #Leiditech #ESDProtection #TechSafety #ChargerDesign #EMCSolutions #SmartElectronics #IoTDevices #PowerProtection #ElectronicsDesign #CircuitProtection

0 notes

Text

ESD Tube: ESD0321CW Can Replace uClamp3331ZA, AZ5A83-01B, and AZ8523-01B

Several points to note when judging whether ESD diodes can be replaced:

o Is VRWM close?

o Is the anti-static ability close?

o Is VBR close?

o Is IPP close?

o Is CJ close?

The encapsulation of ESD0321CW is DFN0603 (0.6x0.3x0.3mm), which is the same as that of uClamp3331ZA, AZ5A83–01B, and AZ8523–01B.

The main parameters of ESD0321CW, including VRWM, VBR, IPP, CJ, and ESD (air and contact), are almost identical to those of uClamp3331ZA, AZ5A83–01B, and AZ8523–01B. Therefore, ESD0321CW is fully replaceable.

Advantages of ESD0321CW:

o Small package (DFN0603)

o Large current (IPP 21A)

o Low clamping voltage when scanning VCC

o High anti-static performance (±30kV)

o Better protection for 3V products against large surges and voltage spikes

Applications of ESD0321CW:

ESD0321CW is mainly used for electrostatic protection of 3.3V power supplies. Its main application scenarios include:

o Mobile phones and handheld devices

o Industrial equipment

o Computer interface protection

o Processors

o Serial-parallel interface protection

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#ESDProtection #TVSDiodes #ElectronicsDesign #EMCSolutions #Semiconductor #CircuitProtection #IoTDesign #MobileElectronics #IndustrialAutomation #Leiditech #TechInnovation #ElectronicsEngineer #ComponentReplacement #3VProtection

0 notes

Text

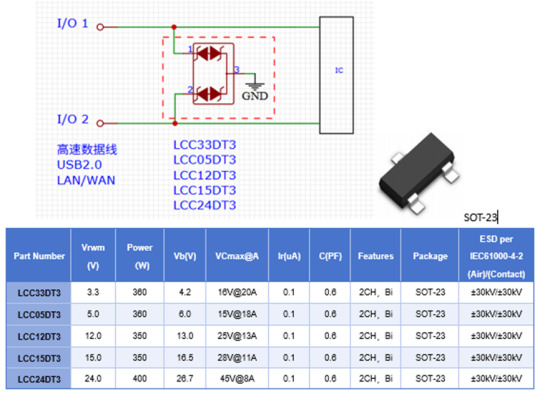

High-Speed Signal Dual-Channel SOT-23 Low Capacitance ESD Protection

Shanghai Leiditech often receives inquiries from new and existing customers: “Do you have dual-channel bidirectional 3.3V or 5V… ESD diodes for high-speed signals? We need to protect two I/O ports from ESD, preferably in SOT-23 package.”

l The LCC33DT3, LCC05DT3, LCC12DT3, LCC15DT3, and LCC24DT3 series can meet customers’ ESD protection requirements for 3.3V, 5V, 12V, 15V, and 24V signal voltages, which are the conventional signal voltages required by customers.

l Dual-channel bidirectional ESD protection: One device is sufficient to meet the requirement, saving space and facilitating PCB layout.

l Complies with IEC61000–4–2 (ESD) with ±30kV (air) and ±30kV (contact), meeting ESD Level 4 (±8kV/15kV) protection.

l All models in this series have a peak power of over 300W, featuring not only high ESD protection but also strong surge resistance to protect against surges caused by hot-swapping.

l Low clamping voltage (VCmax@A) under peak current conditions.

l Low junction capacitance (approximately 0.6pF), suitable for high-speed signal applications.

l Low leakage current (0.1μA).

For high-speed dual-channel ESD protection and other interface ESD/surge protection requirements, please contact Leiditech’s sales team or the EMC specialist.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#ESDProtection #HighSpeedDesign #PCBDesign #USB3 #HDMI #LAN #IoTDesign #EMCsolutions #SOT23 #TVSdiode #ElectronicsDesign #SurgeProtection #Leiditech #SignalIntegrity #ESDdiodes

0 notes

Text

D-U-N-S® Certified: Leiditech — Your Trusted Chinese Partner for Electronic Components

For overseas enterprises seeking reliable Chinese suppliers, the D-U-N-S® Number serves as a critical benchmark for evaluating partner credibility. Shanghai Leiditech has successfully completed the Dun & Bradstreet (D&B) global certification process, and the following four dimensions highlight our collaborative advantages:

I. Why Is the D-U-N-S® Number the “Trust Passport” for International Business?

1. A Globally Recognized Business Identifier

l As an authoritative identifier used in over 200 countries and trusted by 90% of Fortune 500 companies, the D-U-N-S® Number acts as a “Digital Credit Passport” for enterprises.

l Enterprise profiles can be queried via D&B Hoovers, revealing core data such as establishment year, ownership structure, and credit ratings.

2. An Essential Tool for Risk Management

l Enables overseas clients to verify business authenticity swiftly, preventing fraud from fake entities.

l Provides in-depth background checks on financial stability, legal compliance, and other critical dimensions.

II. Leiditech’s D-U-N-S® Number: Your Guarantee of Trust

1. Rigorously Certified Enterprise Qualifications

l Passed D&B’s triple audit system: verification of basic business information, operational premises, and credit records.

l Confirmed as an independent legal entity with a stable operational history and excellent business reputation.

2. Transparent and Verifiable Business Profiles

l Key information accessible via our D-U-N-S® Number: ▶ Founded in 2011, 14 years of expertise in electronic components. ▶ Core business: EMC protection solutions and component supply. ▶ Partner network: Serves clients in 20+ countries across Europe, America, Japan, and South Korea.

III. Our Commitment: Customer-Centric Quality Services

1. Product Excellence

l All products certified to international standards (RoHS/REACH/CE).

l Implemented IATF 16949 quality management system to ensure reliability of automotive-grade electronic components.

2. Long-Term Collaboration Assurance

l D-U-N-S®-linked business credit reports with dynamically updated operational status.

l Compliant international trade processes supporting TT payment terms.

IV. Contact Us Today to Start Your Trusted Partnership

Whether you need:

l Cost-effective electronic component procurement

l Customized ESD/surge protection solutions

l A stable long-term Chinese supply chain partner

Leiditech, backed by our D-U-N-S® certification, stands ready to be your reliable bridge to the Chinese market.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

#Leiditech #DUNSCertified #ElectronicComponents #TrustedSupplier #EMCsolutions #ChineseManufacturer #GlobalTrade #SupplyChainPartner #ESDProtection #B2BChina #RoHS #IATF16949 #ReliableSourcing #TechSolutions #ComponentSupply

0 notes

Text

MOSFET for Brushless Motor Drive

When a bladeless fan delivers gentle air, its internal 130,000 RPM brushless motor is precisely driven by MOSFET; when a floor sweeper maneuvers into a 7cm gap, 7 groups of motors collaborate to achieve millimeter-level edge cleaning; an electric toothbrush vibrates at 31,000 times per minute to clean tooth gaps, a fascia gun responds to force adjustment within 50μs, and a high-altitude operation drone uses high-pressure water to scrub skyscraper curtain walls — behind these seemingly ordinary devices lies a precise control system of brushless motor + electronic drive.

一、Technical Core of Motor Drive: From Mechanical Commutation to Electronic Revolution

Mechanical Commutation Era — Brushed Motor

Traditional brushed motors rely on physical contact between carbon brushes and commutators to conduct current. When current flows through carbon brushes into rotating commutator segments, the interaction between the coil magnetic field and permanent magnets generates torque. However, sparking causes electromagnetic interference, and mechanical wear requires regular carbon brush replacement. Advantages include simple structure and high starting torque, making them still applicable in scenarios such as car window lifting and children’s toy cars.

Electronic Commutation Era — Brushless Motor

一、Introduction to N+P Type MOS

N+P type (Complementary) MOSFET products integrate N-channel and P-channel MOSFETs into a single package with high/low-side configuration, greatly optimizing the product packaging structure. Such Complementary MOSFET products not only improve designers’ design efficiency but also optimize system architecture, providing lower-cost and more reliable solutions.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

MOSFET #BrushlessMotor #MotorDrive #ElectronicsDesign #TechInnovation #Leiditech #SmartDevices #PowerElectronics #PCBDesign #IoTDevices #DroneTech #EmbeddedSystems #ElectronicEngineering #EMCSolutions

0 notes