#Embossed composite decking

Explore tagged Tumblr posts

Text

Discover how WPC decking enhances residential, hospitality, municipal, office, and commercial spaces. Explore benefits, applications, and eco-friendly solutions, check below blog😌😌

#WPC decking applications#commercial WPC decking#eco-friendly outdoor flooring#durable composite decking#retail outdoor spaces#durable event flooring#office outdoor spaces#commercial wpc solutions#sustainable urban design#hotel decking solutions#wpc for hospitality#resort outdoor design#wpc decking for homes#durable outdoor decking#low maintenance residential decks#residential wpc decking#hotel building decking#commercial outdoor flooring#durable decking solutions#eco friendly decking#outdoor flooring#enmansi#decking#wpc coextrusion decking#3d EMBOSSED DECKING#wpc DECKING OUTDOOR#WPC wood decking#WPC flooring decking

0 notes

Text

WPC decking wpc flooring 3D composite decking embossed

Fire Proof Water Proof Terrace Wpc Decking

Composite decking is a man-made building product that includes an approximate equal mix of recycled wood fibers and recycled plastic. Because composite decking products are so durable and impervious to rot, they have a much longer lifespan than wood decks. They do not require the staining, sanding, sealing, and board replacement that come along with wood decks. Even though they require more initial investment, a composite deck more than makes up for that initial cost over the lifespan of the deck. With the many advantages of composite decking, such as lower maintenance and being resistant to mold and insects, composite decking has been deemed one of the most durable decking products on the market today. In addition to these benefits, new capped composite decking is also stain and fade resistant, which means it is easier to clean and has very high color retention.

Maintaining your composite deck requires semi-annual cleaning; just a quick spray of the hose with a mild household cleaner will do the trick.Capped composite decking is sealed and is easier to clean if mold and mildew form on the surface.Since there are exposed wood fibers in uncapped composite decking planks, it can be susceptible to mold growth just like any outdoor surface. However, cleaning your deck periodically can help keep mold at bay. Installation of composite decking uses the same tools as traditional wood decking with the added benefit of side grooves for hidden fasteners. A hidden fastener system makes use of grooves built into the sides of the decking planks for a smooth surface without any screws showing. Plus, you have the added benefit of absolutely no splinters, twisting or warping. However, it is important to note that you must follow the manufacturer’s instructions for installation. Adding a deck to your home can produce a substantial return on your initial investment. With composite decking, you are ensuring that your deck is beautiful for years with less maintenance. You can even have the exotic look of woods like Ipe, without all the upkeep. Composite decking can be a true, low maintenance solution to your outdoor living space by providing a beautiful sanctuary for you and your family.

What Is W.P.C ?

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC etc.). Chemical additives seem practically "invisible" (except mineral fillers and pigments, if added) in the composite structure. They provide for integration of polymer and wood flour (powder) while facilitating optimal processing conditions. In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.

What Is The Advantages Of W.P.C?

WPC do not corrode and are highly resistant to rot, decay, and Marine Borer attack, though they do absorb water into the wood fibers embedded within the material. They have good workability and can be shaped using conventional woodworking tools. WPCs are often considered a sustainable material because they can be made using recycled plastics and the waste products of the wood industry. One advantage over wood is the ability of the material to be molded to meet almost any desired shape. A WPC member can be bent and fixed to form strong arching curves. WPCS are manufactured in a variety of colours, another major selling point of these materials is their lack of need for paint.

What Is The Uses Of W.P.C?

Wood-plastic composites are still new materials relative to the long history of natural lumber as a building material.The most widespread use of WPCs is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, window and door frames, and indoor furniture.

Previous: Fire Resistant Outdoor WPC Flooring Board

Previous: No more

0 notes

Text

The contemporary WPC Flooring Factory operates as an artistic foundry where design possibilities transcend conventional limitations. Advanced digital scanning captures nuanced characteristics of rare wood species and natural stones with microscopic precision. These reference files drive high-fidelity printing systems applying ecological inks through variable droplet technology, achieving photorealistic recreations impossible through traditional methods. The fusion process integrates decorative layers with composite cores under precisely controlled thermal conditions, ensuring permanent image stability. Custom color matching utilizes spectral analysis equipment recalibrated for each production batch, maintaining absolute consistency across diverse material compositions. This artistic-industrial synthesis empowers designers to realize previously unattainable aesthetic visions.

Surface dimensionalization represents another frontier. The WPC Flooring Factory employs synchronized embossing technologies where micro-textured cylinders align perfectly with printed patterns. Variable-depth engraving replicates authentic grain variations and stone pitting across plank surfaces. Edge detailing innovations include hand-scraped, bevelled, and distressed profiles created through digitally-controlled milling stations. These textural enhancements extend beyond visual imitation to deliver authentic tactile experiences underfoot. The Pvcfloortile creative designation signifies products meeting rigorous aesthetic durability standards through accelerated wear simulation testing. Finished products undergo comprehensive lighting environment evaluations to ensure color integrity across diverse residential settings.

Collaborative customization streams establish unprecedented access. The WPC Flooring Factory operates virtual design studios enabling real-time collaboration between homeowners, architects and production specialists. Cloud-based platforms facilitate material selection, texture modification, and layout visualization before manufacturing commitment. Small-batch production capabilities accommodate highly personalized projects without minimum quantity constraints. These capabilities transform flooring from standardized commodity to personalized artistic expression within modern living spaces..click https://www.pvcfloortile.com/product/wpc-flooring/wpc-decking-flooring/ to reading more information

0 notes

Text

Enhance Your Outdoor Space with Composite Decking in Perth

Creating a beautiful, durable outdoor living area is a top priority for many homeowners in Western Australia. One of the most popular and practical choices for achieving this is Composite Decking Perth. Known for its resilience, low maintenance, and sleek modern appearance, composite decking has become the preferred alternative to traditional timber. Whether you’re building a patio, pool surround, or backyard retreat, composite decking offers both form and function without the upkeep of natural wood.

Why Choose Composite Decking?

Composite Decking Perth is made from a blend of recycled wood fibres and plastics, making it an eco-friendly solution that’s also engineered to last. Unlike timber, it doesn’t splinter, warp, or rot—qualities that are especially valuable in Perth’s varied climate conditions. From the hot, dry summers to occasional rain and coastal exposure, composite decking holds up well year-round.

Key Benefits of Composite Decking:

Low Maintenance: No need for staining, oiling, or sanding.

Weather Resistant: Built to resist fading, moisture damage, and insect infestation.

Eco-Friendly: Manufactured using recycled materials.

Safe and Comfortable: Slip-resistant and splinter-free for barefoot comfort.

These features make Composite Decking Perth a practical choice for homeowners looking for long-term value and aesthetic appeal.

Stylish Options for Every Home

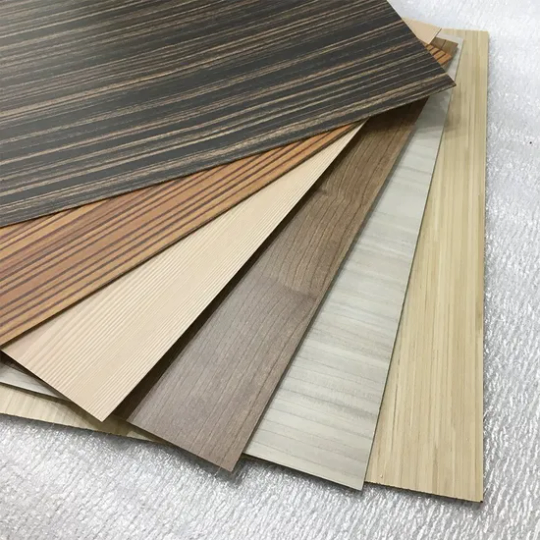

One of the main advantages of composite decking is the variety of colours, textures, and finishes available. Whether you prefer a natural timber look or a sleek contemporary finish, you can find a composite style to suit your outdoor décor.

From traditional browns and greys to more modern charcoal tones, composite boards come in multiple shades that can complement any home exterior. Many brands even offer dual-tone or embossed finishes that closely mimic the look of real wood grain—giving you beauty without the burden.

Installation Made Easy with Professionals

While composite decking is designed for easy installation, working with experienced professionals ensures the best results. This is where Jays Synthetic Grass, Perth stands out. As a trusted name in landscaping and outdoor solutions, Jays Synthetic Grass, Perth offers expert guidance and installation services for decking projects of all sizes.

Their team understands the unique environmental demands of Perth and can recommend the best composite products for your location and lifestyle. Whether you’re after a DIY-friendly option or a full-service installation, they make the process smooth from start to finish.

Versatility of Use

Another reason Composite Decking Perth is so popular is its versatility. It’s not limited to just backyard decks. Here are some other great uses:

Pool Areas: Water-resistant and splinter-free, perfect for wet environments.

Balconies: Adds warmth and texture to high-rise living spaces.

Garden Paths: Offers a durable, natural-looking walkway through your landscape.

Entertainment Areas: Stylish enough for outdoor kitchens and lounges.

No matter where it’s used, composite decking provides a modern, polished look that enhances your property’s appeal and function.

Sustainability Matters

More and more homeowners are seeking sustainable solutions, and Composite Decking Perth meets that demand. Most composite products are made using a combination of recycled wood and plastic, helping to reduce landfill waste and conserve natural resources. Additionally, because composite decking lasts so long and doesn’t require harsh chemical treatments, its long-term environmental impact is significantly lower than that of traditional timber.

Choosing companies like Jays Synthetic Grass, Perth, which prioritize sustainable practices, further reinforces your commitment to eco-conscious living.

Long-Term Investment

Although the upfront cost of composite decking may be higher than natural timber, the long-term savings are considerable. With minimal maintenance required and no need for regular sanding or staining, homeowners save both time and money over the life of the deck. Its resistance to fading, warping, and insect damage also means fewer repairs and replacements.

In short, Composite Decking Perth isn’t just a short-term upgrade—it’s a long-lasting investment in your home’s functionality and value.

Final Thoughts

If you’re looking to transform your outdoor space with a durable, low-maintenance, and eco-friendly option, Composite Decking Perth is the ideal solution. Whether you’re designing a poolside paradise, building a family deck, or revamping a balcony, composite materials offer unbeatable value and performance.

For expert service and a wide selection of top-quality decking options, turn to Jays Synthetic Grass, Perth. Their team brings years of experience, local knowledge, and a dedication to quality craftsmanship that ensures your decking project will be built to last.

Choose Composite Decking Perth and elevate your outdoor living experience—stylish, strong, and sustainable.

0 notes

Text

A Buyer’s Guide to WPC Composite: Features, Uses, and Durability

As modern landscaping and home improvement trends evolve, WPC (Wood-Plastic Composite) has gained significant traction for outdoor applications. Combining the aesthetics of natural wood with the strength of plastic, WPC is now widely used for decking, fencing, cladding, and wall panels. If you're considering WPC for your next project, this buyer’s guide will walk you through its features, practical uses, and how it stands up to time and weather.

What Is WPC Composite?

WPC is a hybrid material made by blending recycled wood fibers with thermoplastics such as polyethylene or polypropylene. The result is a dense, durable, and versatile material that mimics the appearance of wood while eliminating many of its drawbacks—such as warping, splintering, and susceptibility to rot or insects.

The manufacturing process involves extrusion or molding, allowing for customized shapes, textures, and finishes. WPC can also be engineered for specific performance features such as slip resistance, UV resistance, and enhanced load-bearing strength.

Key Features of WPC Composite

One of the primary reasons for WPC’s growing popularity is the wide range of practical advantages it offers. Some of the standout features include:

Weather Resistance

WPC composite materials are designed to resist harsh environmental conditions. Whether exposed to UV rays, rain, snow, or high humidity, WPC does not rot, crack, or fade easily, making it an excellent choice for long-term outdoor installations.

Low Maintenance

Unlike natural wood, WPC does not require regular sealing, staining, or painting. Occasional cleaning with water and mild soap is typically enough to maintain its appearance.

Eco-Friendly Composition

Many WPC products are made using recycled wood and plastic, making them a more sustainable option compared to traditional timber. The use of recyclable materials reduces environmental impact while delivering performance.

Consistent Appearance

Natural wood can vary in grain and tone, while WPC offers consistent color and texture. Some types even feature 3D embossed or co-extrusion finishes that closely resemble real woodgrain but with more durability.

Common Uses of WPC Composite

Thanks to its versatile nature, WPC can be used in a wide range of applications around homes, commercial properties, and public spaces.

1. Decking

Perhaps the most common use, WPC decking provides a durable, slip-resistant surface perfect for patios, balconies, garden paths, and poolside areas. It’s available in various thicknesses and textures for aesthetic and functional needs.

2. Fencing

WPC fencing offers privacy, security, and curb appeal with little maintenance. It is resistant to weather damage and maintains its appearance without the need for repainting or repairs.

3. Cladding and Facades

Exterior WPC wall panels or cladding systems protect buildings from moisture and UV rays while offering a contemporary or natural look.

4. Pergolas and Trellises

Used in landscaping design, WPC can create attractive and durable trellises, semi-privacy screens, or pergolas that withstand seasonal changes.

Evaluating Durability: How Long Does WPC Last?

One of the most appealing aspects of WPC composite is its long lifespan. When installed correctly and maintained as recommended, WPC products can last 15 to 25 years or even longer. The material is engineered to resist common issues like:

Moisture absorption

UV-induced fading

Termite damage

Mold or mildew growth

Advanced WPC products also feature co-extrusion technology, adding a protective outer layer that enhances durability, color retention, and scratch resistance.

Is WPC Right for You?

WPC composite is a practical investment for those who want the beauty of wood without its high maintenance demands. Whether you're a homeowner upgrading your garden or a contractor managing a commercial build, WPC is well-suited for both aesthetics and endurance.

When choosing a WPC product, consider factors such as load capacity, surface finish, environmental certifications, and warranty terms. Reputable manufacturers also provide sample packs to help you inspect the quality firsthand before making a large order.

Conclusion

WPC composite has established itself as a superior building material for outdoor projects, offering a balance of performance, sustainability, and style. Its low-maintenance nature, long-term durability, and environmental friendliness make it the go-to solution for modern decking and fencing.

Whether you're exploring new construction or renovation, understanding the features and benefits of WPC will help you make an informed purchase decision—one that adds value to your property for years to come.

Visit for more - https://www.krecocomposites.com/

0 notes

Text

Why Composite Timber Is the Perfect Choice for Decking, Fencing, and Cladding?

While designing outdoor areas or decorating the exterior of your home, material selection is of importance. Composite timber has proven to be a sustainable and efficient alternative to classic wood, and for decking, fencing, and cladding, it presents several advantages. By fusing the organic style of timber with contemporary engineering, timber is becoming increasingly popular due to its durability, reduced maintenance, and environmental quality. Find out why composite timber is the perfect option for these uses.

What Composite Timber Makes Perfect for Decking?

Decking is perhaps the most popular application of composite timber, and it's not difficult to understand why.

Durability: Timber is made to endure extreme weather conditions without cracking, warping, or splintering. It resists moisture, UV, and bugs, making it ideal for external use.

Low Maintenance: As opposed to wood decking that has to be sanded, stained, or sealed, timber can be occasionally washed with soap and water.

Slip Resistance: Most composite boards have textured finishes that ensure a good grip, making them safe to walk on even in wet conditions.

Aesthetic Appeal: Timber replicates the natural appearance of wood but has numerous colors and finishes to suit any style.

Why Composite Timber Is Ideal for Fencing?

Fencing not only marks your property but also provides privacy and security. Timber has a number of benefits over conventional fencing materials:

Weather Resistance: Composite fences are extremely weather-resistant to rain, wind, and harsh temperatures. They will not rot or fade with time.

Eco-Friendly Alternative: Composed of recycled wood fibers and plastics, composite wood is a green option that minimises deforestation.

Low Maintenance: Unlike wooden fences that need to be repainted or stained frequently, composite fences look new with little effort.

Sleek Designs: With multiple colors and textures to choose from, composite fencing can fit any architectural design while keeping up with a stylish and modern appearance.

For property owners who want robust and aesthetically pleasing fencing, timber is a perfect option.

How Composite Timber Benefits Cladding?

Cladding has both functional and cosmetic functions in protecting buildings from weather conditions and enhancing their appearance. Timber stands out in this use:

Thermal Efficiency: Composite cladding offers insulation that controls indoor temperatures, cutting energy bills.

Moisture Resistance: Its non-porous finish repels water from being absorbed, eliminating the danger of mold or structural damage.

Long-Term Durability: Composite cladding does not fade, crack, or get infested with insects, keeping it looking fabulous for decades.

Contemporary Aesthetics: Owing to the numerous finishes that one can choose from, ranging from smooth to embossed, composite cladding imparts a touch of modernity to any edifice.

For both residential and commercial buildings, timber cladding blends aesthetics with functionality.

Why Timber Is a Sustainable Option?

Sustainability is one of the main drivers for the popularity of composite timber:

Recycled Content: Composite products are manufactured from recycled wood fibers and plastics, which decreases landfill waste.

Durability: Its longer lifespan decreases the frequency of replacements, minimising environmental impact.

No Toxic Chemicals: Unlike treated wood with potentially toxic chemicals, timber is safe and environmentally friendly.

By choosing timber for decking, fencing, or cladding, you’re contributing to a greener planet without compromising on quality.

Why Choose Composite Timber?

Whether you are upgrading your deck, installing new fencing, or adding cladding to your home’s exterior, composite timber offers unmatched benefits. Its durability ensures long-term performance in outdoor environments while requiring minimal maintenance. The extensive variety of designs enables you to obtain the appearance of natural wood without its limitations. Moreover, its earth-friendly makeup makes it the right option for eco-friendly living. Homeowners looking for functionality without compromising style or environmental friendliness find that composite timber is certainly the ideal option!

0 notes

Text

Innovations and Technologies Driving the Success of Leading WPC Companies in India

In recent years, Wood-Plastic Composite (WPC) products have seen a significant rise in popularity within the Indian market. This surge can be attributed to the relentless innovation and advanced technologies employed by leading WPC companies in India. These companies, such as Floresta, have revolutionized the industry by introducing superior WPC sheets and WPC boards that cater to a wide array of construction and design needs.

The Rise of WPC in India

WPC, a hybrid material composed of wood fibers and thermoplastics, offers an eco-friendly alternative to traditional wood. This sustainable option is not only resistant to rot and decay but also provides the aesthetic appeal of natural wood. The best WPC company in India have harnessed these qualities, driving the material’s success across various applications, from decking to cladding and beyond.

Innovations Driving Success

Advanced Manufacturing Techniques:

Leading WPC companies in India employ state-of-the-art manufacturing techniques to produce high-quality WPC sheets and WPC boards. Extrusion, one of the most common methods, involves pushing the composite material through a mold to create consistent and durable products. Floresta, for example, uses advanced extrusion technology to ensure their WPC boards are robust, weather-resistant, and visually appealing.

Enhanced Material Composition:

Innovations in material composition have significantly improved the performance of WPC products. By optimizing the ratio of wood fibers to plastic, companies can produce WPC sheets with superior strength, flexibility, and resistance to environmental factors. This meticulous attention to material science ensures that products from the best WPC company in India, like Floresta, meet stringent quality standards and perform exceptionally well in diverse conditions.

Eco-Friendly Production Processes:

Sustainability is at the forefront of the WPC industry. Leading manufacturers prioritize eco-friendly production processes, utilizing recycled materials and reducing waste. This commitment to green practices not only appeals to environmentally conscious consumers but also aligns with global efforts to minimize environmental impact. Floresta’s dedication to sustainable manufacturing processes sets them apart as a leader in the industry.

Technologies Transforming the Industry

Digital Design and Prototyping:

The integration of digital design and prototyping technologies has revolutionized product development in the WPC sector. Using advanced software, companies can create detailed 3D models of WPC boards and sheets, allowing for precise customization and rapid prototyping. This technology enables manufacturers to bring innovative designs to market quickly, meeting the evolving demands of architects and designers.

Automated Quality Control:

Automation plays a crucial role in maintaining the high quality of WPC products. Automated quality control systems utilize sensors and cameras to inspect WPC sheets and boards for defects, ensuring that only the best products reach consumers. This technology reduces human error, enhances production efficiency, and guarantees consistent product quality, reinforcing the reputation of top WPC companies in India.

Surface Treatment Technologies:

Surface treatment technologies, such as UV coating and embossing, enhance the durability and aesthetics of WPC products. UV coatings provide an additional layer of protection against harsh weather conditions, while embossing techniques create textured finishes that mimic the look and feel of natural wood. Floresta’s use of these technologies results in WPC boards that are not only long-lasting but also visually striking.

Conclusion

The success of leading WPC companies in India, such as Floresta, is driven by continuous innovation and the adoption of cutting-edge technologies. By advancing manufacturing techniques, optimizing material composition, and embracing eco-friendly practices, these companies produce top-tier WPC sheets and boards that meet diverse consumer needs. As digital design, automated quality control, and surface treatment technologies further evolve, the future of the WPC industry in India looks promising, with Floresta and its peers poised to lead the way.

Also, Read:

How WPC Sheets Offer Eco-Friendly Alternatives in Construction

Understanding the Environmental Impact of Waterproof Plywood and its Alternatives

Originally published at https://florestaproducts.blogspot.com

0 notes

Text

Is Composite Decking Slippery? Avoid Accidents, Choose the Safest Option!

Composite decking can be slippery, especially when wet or covered in debris. In contrast to traditional wood decking, composite decking contains a smooth, low-maintenance surface that can become slick under certain conditions. However, there are ways to minimize this potential hazard and increase the slip resistance of your composite deck. By incorporating anti-slip additives, regularly cleaning your deck, and using traction mats or rugs in areas prone to moisture, you can enhance the safety and enjoyment of your composite decking. Furthermore, selecting composite decking products with a textured surface or embossed grain can also help to provide a better grip and reduce the risk of slips and falls. Overall, while composite decking can be slippery, taking precautionary measures can significantly improve its safety.

The Slipperiness Of Composite Decking

Composite decking has gained popularity as a durable and low-maintenance alternative to traditional wooden decks. However, one aspect that concerns many homeowners is its slipperiness. In this article, we will explore the factors that contribute to the slipperiness of composite decking and how you can minimize this potential hazard. Causes Of Slipperiness Understanding the causes of slipperiness on composite decking is crucial in finding effective solutions. Here are some key factors to consider: Factors Affecting Slipperiness Several factors can influence how slippery a composite deck can become. It's important to be aware of these factors to prevent accidents. Here are some of the main ones: - Surface Texture: The texture of the composite decking plays a significant role in its slipperiness. Smooth surfaces are more prone to becoming slippery, especially when wet. On the other hand, textured surfaces provide more grip, reducing the risk of slipping. - Moisture and Mold: Moisture, whether from rain, dew, or water splashes, can make composite decking slippery. This is especially true if the decking material is not adequately dried or if mold and mildew start growing on its surface. Regular cleaning and maintenance can help prevent moisture buildup and reduce the risk of slipping. - Composite Composition: The composition of the composite decking can also affect its slipperiness. Different manufacturers use varying amounts of plastic, wood fibers, and other materials to create their composite boards. Some compositions may be more prone to becoming slippery than others. It's essential to choose a composite decking product that has been specifically designed to resist slipperiness. - Accumulated Debris: Leaves, dirt, and other debris can accumulate on the surface of a composite deck, creating a slippery layer. Regular sweeping or using a leaf blower can help remove any debris that might increase the risk of slipping. - Climate and Weather Conditions: The climate and weather conditions in your area can impact the slipperiness of your composite decking. Regions with high humidity or frequent rainfall may experience more slippery decks. Taking appropriate precautions, such as using anti-slip additives or installing additional traction mats, can help mitigate the risks. By understanding the causes and factors that contribute to the slipperiness of composite decking, you can take proactive steps to minimize this potential hazard. From choosing the right textured composite material to regular cleaning and maintenance, ensuring a safe and slip-resistant deck is within your reach.

Comparing Slipperiness: Composite Decking Vs. Other Materials

When it comes to decking options, one of the most important factors to consider is slipperiness. After all, you want your deck to be a safe and enjoyable outdoor space for you and your family. In this article, we will compare the slipperiness of composite decking, wood decking, and other popular decking materials, so you can make an informed decision for your deck. Composite Decking Composite decking, a popular alternative to traditional wood decking, is known for its low maintenance and longevity. But how does it fare when it comes to slipperiness? While composite decking can become slippery in certain conditions, most manufacturers have taken steps to improve the slip resistance of their products. One of the main reasons for this is the inclusion of a textured surface or embossed pattern that provides better traction underfoot. This added texture helps to reduce the chances of slipping, especially when the deck is wet or covered in snow. Additionally, composite decking is designed to be resistant to mold and mildew, which can also contribute to a slippery deck surface. With regular cleaning and maintenance, you can ensure that your composite deck remains slip-resistant throughout its lifespan. Wood Decking Wood decking has been a popular choice for many homeowners due to its natural beauty and affordability. However, when it comes to slipperiness, wood decking may pose a greater risk compared to composite decking. Unlike composite decking, wood decking does not have the same built-in texture or embossed pattern to enhance slip resistance. Instead, the smooth surface of wood decking can become slick when wet, making it more susceptible to slips and falls. While there are ways to improve the slip resistance of wood decking, such as applying a non-slip coating or using anti-slip tape, these measures can be time-consuming and require regular maintenance. Other Decking Materials Aside from composite and wood decking, there are other decking materials available in the market, each with its own unique characteristics. Let's take a look at how some of these materials compare in terms of slipperiness: Decking Material Slipperiness Durable Vinyl Can have good slip resistance, especially with textured finishes. PVC Generally low slipperiness due to its moisture resistance. Aluminum Typically has good slip resistance, especially with a textured surface or grooved profiles. When considering decking materials, it's essential to prioritize safety and consider the slipperiness factor. While composite decking generally offers better slip resistance compared to traditional wood decking, other materials like durable vinyl, PVC, and aluminum can also provide good slip resistance when properly installed and maintained.

Preventing Slips And Falls On Composite Decking

Composite decking may become slippery when wet or covered in mold or algae. To prevent slips and falls, consider using non-slip inserts or anti-slip tape on high-traffic areas of the decking. It's also important to regularly clean and maintain the decking to minimize the risk of slipping. While composite decking offers numerous benefits, one common concern is its potential slipperiness. Preventing slips and falls on composite decking is crucial for maintaining a safe outdoor environment. By taking proactive measures, homeowners can ensure their decks are safe for all who walk on them. Regular Cleaning and Maintenance Regular cleaning and maintenance are essential for keeping composite decking safe and slip-resistant. By avoiding the buildup of organic materials, dirt, and grime, the risk of slips and falls can be minimized. A consistent cleaning schedule, including sweeping and hosing down the deck, helps prevent the accumulation of slippery substances. Using Anti-Slip Products Another effective way to enhance the safety of composite decking is by using anti-slip products. Applying specialized anti-slip coatings or tapes can provide increased traction, reducing the likelihood of accidents. These products are designed to create a non-slip surface, offering peace of mind to both homeowners and their guests. Footwear Considerations When walking on composite decking, footwear plays an important role in preventing slips and falls. Choosing appropriate footwear with good traction can help reduce the risk of accidents. Opt for shoes with slip-resistant soles, and encourage guests to do the same before stepping onto the deck. In conclusion, proactive maintenance, the use of anti-slip products, and the consideration of proper footwear are crucial in preventing slips and falls on composite decking. Owners can ensure their outdoor spaces remain safe and enjoyable for all who use them.

Safety Standards And Regulations For Composite Decking

Ensuring the safety of composite decking is of utmost importance, and strict adherence to safety standards and regulations is crucial. Industry standards and regulatory compliance play a significant role in determining whether composite decking is slippery or not. Therefore, it is essential for decking manufacturers to meet these requirements to provide a safe and secure outdoor environment for everyone. Industry Standards Industry standards serve as quality benchmarks for composite decking manufacturers. These standards outline specifications and requirements that must be met to ensure a reliable and trustworthy product. By conforming to industry standards, decking manufacturers assure customers that their products are designed and manufactured following established guidelines. When it comes to slipperiness, industry standards provide specific instructions to minimize the risk of accidents. These guidelines often recommend the use of specialized surface textures and additives that enhance traction and reduce the likelihood of slips. Regulatory Compliance Regulatory compliance refers to adhering to the rules and regulations set by local authorities or building codes. These regulations ensure the safety, durability, and performance of composite decking in various outdoor settings. Compliance with regulatory requirements is an essential aspect of manufacturing composite decking. By following these regulations, manufacturers can ensure their products meet the necessary safety standards and are suitable for use in different environments.

Making An Informed Choice: Selecting The Safest Composite Decking Option

When it comes to selecting the right composite decking for your outdoor space, safety should be your top priority. With so many options available on the market, it can be overwhelming to determine which one offers the safest features. However, by making an informed choice, you can ensure that your deck is a secure and slip-resistant area for your family and guests to enjoy. In this article, we will explore the key factors that contribute to the safety of composite decking and guide you on how to select the safest option for your needs. Recognizing Safety Features One of the most important aspects to consider when evaluating the safety of composite decking is to recognize the various safety features incorporated into the design. Reputable manufacturers prioritize the inclusion of safety measures, such as: - Textured surface: Composite boards with a textured surface provide enhanced traction, reducing the risk of slipping, especially when wet. - Grip-enhancing additives: Some composite decking materials include special additives, such as rubber, to improve grip and increase slip resistance. - Raised patterns or grooves: Composite boards featuring raised patterns or grooves also aid in promoting better traction, preventing accidents caused by slipping. - Non-slip inserts: Certain composite decking options may incorporate non-slip inserts that further enhance slip resistance, ensuring a safer walking surface. By considering these safety features, you can make a more informed choice and select a composite decking option that offers superior slip resistance. Customer Reviews And Ratings Another valuable resource for determining the safety of composite decking is customer reviews and ratings. Real-world experiences from homeowners who have already installed and used a particular decking product can provide valuable insights into its performance and safety. Before making a purchase, take the time to research and read customer reviews on reputable websites. Look for feedback specifically related to the slip resistance and overall safety of the composite decking. Pay attention to any recurring positive or negative comments, as they can indicate the reliability of the product's safety features. Professional Consultation For a comprehensive evaluation of the safety features of different composite decking options, consider seeking professional consultation. Experts in the field, such as decking contractors or landscape designers, have extensive experience working with various decking materials and can provide valuable advice. Consulting with professionals not only ensures that you make an educated decision but also helps to address any specific concerns or requirements you may have. They can recommend composite decking options that align with your safety needs, taking into account factors such as climate, intended use, and maintenance requirements. In conclusion, when it comes to selecting the safest composite decking option, it is vital to recognize safety features, consider customer reviews and ratings, and seek professional consultation. By following these steps, you can make an informed choice that prioritizes the safety of your outdoor space, allowing you to enjoy your composite deck with confidence.

Credit: www.amazon.com

Frequently Asked Questions Is Composite Decking Slippery

How Do I Make My Composite Deck Less Slippery? To make your composite deck less slippery, follow these tips: 1. Clean the surface regularly to remove dirt and debris. 2. Apply an anti-slip coating or decking material with a textured surface. 3. Install handrails for added stability. 4. Use rugs or mats with non-slip backing in high-traffic areas. 5. Avoid walking on the deck with wet or icy footwear. Is Composite Decking More Slippery Than Wood? Composite decking is not more slippery than wood. The materials used in composite decking have a textured surface that offers better traction and grip. This helps to reduce the risk of slips and falls, making it a safe choice for outdoor flooring. What Are The Disadvantages Of Composite Decking? Composite decking can be prone to mold and mildew. It may also fade over time. Some may find it more expensive than traditional wood decking. Additionally, it can get hot in direct sunlight. However, choosing a high-quality composite can mitigate these issues. Is Trex Composite Decking Slippery When Wet? Trex composite decking is not slippery when wet due to its slip-resistant surface. It provides a safe outdoor surface, even in wet conditions.

Conclusion

Composite decking can be slippery when wet, but there are ways to mitigate this risk. By choosing a textured surface, taking precautions in areas prone to moisture, and using anti-slip products, you can enjoy the benefits of composite decking without sacrificing safety. Make an informed decision to prioritize safety. Read the full article

0 notes

Text

WOOD PLASTIC COMPOSITE DECKING

Need high-quality composite WPC decking for your outdoor space? Explore our wide range of WPC wood effect composite decking and buy your ideal decking! All of Wallong’s wood plastic composite decking boards offer a composite decking solution that is durable, low maintenance, rot resistance, and safe, specifically designed to cope superbly in outdoor spaces. As one of the composite deck manufacturers, Wallong provides six ranges of finishes and designs to choose from, all of which come in the six most popular colors. No matter the soft texture newest ACME Wood series, exclusive formula Sandblasted Decking, Superior co-extrusion decking, or our Conventional decking, you will find the right deck from below decking range.

TYPES OF WOOD PLASTIC COMPOSITE DECKING

ACME Co-extrusion WPC Decking

ACME wood co-extrusion decking is designed with 360-degree soft elastomer protective layer, to meet top class outdoor decoration requirements. 3D wood grain,1.5mm super thick co-extrusion cap layer and more updating performance, create the 3rd generation composite decking.

VIEW PRODUCT

Sandblasted Co-extrusion WPC Decking

Sandblasted wood co-extrusion decking is with an ultra-matte layer, which has terrific abrasion performance, anti-slip performance, and sandy touching and elegant outlook. Using new finishing, it brings you a new choice for co-extrusion composite decking.

Superior Co-extrusion WPC Decking

Superior wood co-extrusion decking is to create a low-maintenance, high-quality and beautiful garden for you. Super natural wood grain texture, and maximum performance against mold, stains and fading, make it the most cost-effective co-extrusion decking and the best choice for your outdoor decoration.

Superior Reisist Co-extrusion WPC Decking

Superior Resist Wood co-extrusion decking added a special formula to its layer, making its surface being strong hardness and super scratch resistance. This is far more than other decks, neither chairs nor high heels will leave traces on this deck.

Conventional WPC Decking

Conventional Decking has a lower price, but with higher quality. Wallong's strict control makes the decking more anti-slip. Compared with the same quality of products, you will find that our conventional decking would be more cost-effective.

Deep Embossed WPC Decking

Deep Embossed Conventional Decking is a much more cost-effective WPC decking option. It has a very realistic wood appearance. The production of embossed decking makes the surface more authentic than before, making it a perfect work to enhance natural aesthetics.

WHICH WPC COMPOSITE DECKING IS BEST FOR YOU?

The best composite is long-lasting, low-maintenance and sustainable Wallong different collections of decking brings the natural look of wood to your outside space without the associated problems of cracking, splitting, warping and excessive maintenance requirements.

ACME Wood Co-extrusion Decking

ACME Wood™ is the newest concept of wood plastic composite decking which is self-developed products of Wallong®.

ACME Wood™ has the special exclusive formulation of the elastic layer in 1.5mm, much thicker than other standard co-extrusion decking. The elastic surface is designed specifically for homeowners finding a personalized outdoor living solution and a safe ground for their children. The slip-resistant and sound absorption of wood plastic composite decking making it the perfect choice for holding the party and friends to a lady who wears high heels. Apart from that, ACME Wood™ is moisture resistant, no fading, anti-scratch, stain resistance, and low maintenance give you an unprecedented experience of wood plastic composite decking. ACME Wood™ is the best choice for a swimming pool, balcony, university, hospital, gym, and park it, you will not regret choosing ACME Wood™.

Sandblasted Wood Decking

The new finishing of Wallong® co-extrusion decking has a durable co-extruded surface that's bonded to the core to make a hard-wearing, easy-to-handle decking. With its ultra-matte layer, it has terrific abrasion performance and natural wood look, but better performance than the real wood in the outdoor environment. It can be supplied with specific fire performance to suit your project's requirements.

Sandblasted wood™ Co-extrusion is what you deserve to have for your outdoor experience.

Superior Wood Decking

Superior wood™ is the improvement of conventional decking by Wallong® decking manufacturer. The main difference between superior wood and conventional is that the superior wood has an outer shell 360 degrees cover the product that completely encapsulates the board in an impermeable layer of protection from scratches, stains, and fading.

Superior series has two categories: Superior Wood and Super Resist.

Superior Resist Wood Co-Extrusion Decking

The Super Resist™ surface is the same as its name, super resistant to daily countless scratches and slips meanwhile it keeps the superior wood good quality, it is incredibly amazing. With light wood grain and blended colors, natural and strong rugged beauty, it is a very recommended choice for the commercial area and any public place.

If you are looking for a natural-looking and low-maintenance decking solution, Wallong® Superior series will be your type.

Conventional Wood Decking

A premium composite that's easy on your pocket. Conventional decking is the most economic choice if the budget is limited. There's Conventional Decking and Deep Embossed for your choosing.

Wallong® Conventional wood plastic composite decking is a pioneer one in the field, which change the concept of timber. It is waterproof, scratch-free and slip-resistant make it becomes the residents' favorite choice for outdoor living.

Deep Embossed Decking

Deep Embossed™ Decking is a newly developed WPC conventional collection with 3D deep wood grain and competitive price, which was invented in 2019 by Wallong®. With a natural 3D embossed wood grain texture on one side and a grooved finish on the reversible side. Its wood-grain directly forms without 2nd procedures, immensely extending conventional decking its using life span and durability.

High cost-effectiveness and unique 3D wood grain reduces your limited budget and free your future time for maintenance, it is absolutely the good choice for your projects.

ACME Wood Co-extrusion Decking

Sandblasted Wood Decking

Superior Wood Decking

Superior Resist Wood Co-Extrusion Decking

Conventional Wood Decking

Deep Embossed Decking

COMPOSITE DECK MAINTENANCE

Stain resistance is one of the most important advantages for composite decking to install at outside. Unlike the timber decking, you don’t need to painting or sealing, what you need to do is just spend 2-3 hours per year to clean it by brush and soap. The following tips will help you to learn how to maintain the beauty of composite decking:

Step 1. Sweep your deck to remove any loose dirt.

Step 2. Dry sweep weekly, wash with warm soapy water & a sponge.

Step 3. Apply warm, soapy water with a sponge, then brush with a hard-bristled broom or spray with a high pressure hose.

Step 4. Rinse the deck thoroughly.

Composite Deck Maintenance

ADVANTAGES OF COMPOSITE DECKING

Durable: Since WPC decking contains HDPE, its material durability is better than the alternatives. TIts blend and finish material make it resistant longer lifetime than normal wood decking. Protecting decking from fading, staining, cracking, and mold.

Waterproof: A main problem of timber decking is that it absorb water. Without the regular application of cleading or painting, it’s easy to warping, splintering and rotting. In contrast, WPC composite decking are fully water-resistant to the core, which allows them to be installed in high moisture conditions without decaying.

Anti-slip: WPC composite decking's special treatment makes the surface more rough to turn it into the ideal decking solution for both commercial and residetial application, such as parks, school, swimming pools and garden etc. You will have a safe paradise with Wallong wpc composite decking.

UV Resistance: UV resiatance is one of the most extrodinary peformance of wpc decking. With the good raw material, Wallong products has strong UV resistance performance. In daily test, we will put product into the UV aging machine to test for 2000 hours which means 6-7 years in the ourdoor environment, the deck has no obvious change. Besides that, all of our decking has tested under EN standard and the grey scale is class 4-5.

Advantages of Composite Decking

THE DIFFERENCE BETWEEN CONVENTIONAL DECKING AND CO-EXTRUSION DECKING

Conventional decking is the 1st generation composite decking, it significantly changes the concept of timber and becomes a economic replacement solution as it is durable and environmental.

Co-extrusion decking is the improvement of conventional decking, also called 2nd generation composite decking. Compared with conventional decking , co-extrusion decking has a 360 degree outer shell to protect the core, which is the main difference. Encapsulated in impermeable layer, it protects decking from scratches, stains and fading.

However, by its 1st launch and economic price which is affordable for most people, conventional decking stills plays an important roles in the market, and it is really a good budget solution for large area project . Co-extrusion decking with its beautiful natural wood looking and longer life span, it is getting welcomed for those projects in higher requirements.

The Difference Between Conventional Decking And Co-extrusion Decking

WALLONG'S CUSTOMER COMMENTS ON OUR SUPERIOR COMPOSITE WPC DECKING

Wallong Superior wood composite decking is the improvement of conventional decking by Wallong® decking manufacturer. This sort of WPC plastic lumber products has an outer shell 360 degrees covering the product, so that protects the decking from scratches, stains, and fading. With natural color and wood grain texture, Wallong Superior wood receive positive comments from clients and it is one of best selling WPC decking.

0 notes

Text

Construction Composites Market Size, Share, Top Key Players, Growth, Trend and Forecast Till 2028

The construction composites market is set to showcase significant expansion by 2028 on account of surging demand for lightweight and high-strength construction composites around the world. In addition, increasing effort to reduce maintenance costs for buildings and construction activities is likely to further fuel industry uptake over the forecast period.

Composite materials are widely used in the construction industry due to their numerous advantages, viz., lower construction cost, high specific strength, corrosion resistance, and low thermal conductivity. Mounting need for lowering construction costs has augmented market adoption in recent years.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/2585

Furthermore, industry participants have been implementing profitable strategies to tap into the emerging trends in the sector, which has supported the development of the overall construction composites market. For instance, in October 2021, Exel Composites Oyj, a leading manufacturer of tubes and composite profiles for industrial application, announced its strategic joint venture with Kineco Group, an India-based composites manufacturer. The joint venture was intended to expand business growth, particularly in major and fast-growing industries, including telecommunications, wind energy, and transportation.

To cite another instance, in March 2021, Fiberon, LLC, a key composite decking company, launched its novel Wildwood composite cladding, which features multi-tonal colors and nature-inspired embossing for better wood emulation. The product has been designed to provide high durability and low maintenance while offering high-performance benefits.

The construction composites market has been divided on the basis of application, product, and region. In terms of product, the market has further been categorized into metal composites, fiberglass, composite wood, and others. The metal composites sub-segment is anticipated to reach a considerable valuation by the end of 2028, progressing at a CAGR of more than 5% over the analysis timeline.

From the application point of view, the construction composites market has been segmented into industrial, residential, and commercial. The commercial sub-segment is speculated to grow at a robust pace through the assessment period to garner significant gains by 2028. Increasing government investments in developed and developing countries are likely to bolster segmental expansion over the forthcoming years.

Read Full Report Description @ https://www.gminsights.com/industry-analysis/construction-composites-market

On the regional spectrum, the North America construction composites industry is projected to develop at a CAGR of approximately 4.5% over the review timespan owing to substantial reduction in construction time. Moreover, recent technological advancements are speculated to foster regional market growth over the next few years. Meanwhile, the Middle East & Africa construction composites market is poised to surpass USD 6 billion valuation by the end of the estimated timeline.

About Global Market Insights

Global Market Insights Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy, and biotechnology.

Contact Us

Aashit Tiwari Corporate Sales, USA Global Market Insights, Inc. Phone: 1-302-846-7766 Toll Free: 1-888-689-0688 Email: [email protected]

0 notes

Text

Is Deck A Good Investment?

Is Deck A Good Investment?

Judging from the reaction from our customers, the deep embossed deck will recoup 70 to 90 per cent of the initial investment. Given all the economic uncertainty that surrounds us today, we all want to spend our money as wisely as possible and not devalue over time. And most of us seek to increase the value and attractiveness of our possessions, as well as the quality of our lives. So how does the…

View On WordPress

0 notes

Text

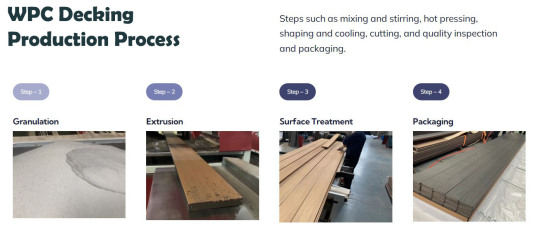

🌿 How is WPC Decking Made? Behind the Scenes at the Factory

Ever wondered how WPC decking is produced? Here's a quick look into the process that ensures strength, durability, and beauty in every plank:

1️⃣ Raw Materials Mixing: We blend high-quality wood fiber, recycled plastic, and additives to create the perfect composite formula.

2️⃣ Extrusion Process: Using advanced co-extrusion technology, the material is pushed through molds to form consistent, stable decking profiles with a protective cap layer for UV and scratch resistance.

3️⃣ Cooling & Cutting: The hot planks go through water cooling to set their shape, followed by precision cutting to your required length.

4️⃣ Surface Finishing: We apply various finishes like wood grain embossing or brushing for a natural look and anti-slip surface.

5️⃣ Quality Control & Packaging: Every piece of decking is inspected for quality, then packed securely for export worldwide.

✅ Waterproof ✅ Anti-slip ✅ Low maintenance ✅ Long lifespan ✅ Eco-friendly

Perfect for glamping platforms, garden patios, swimming pool decks, backyard and more!

📦 Looking for a reliable WPC decking supplier? We’ve got you covered. 📞 Tel: +86 136 6618 6069 📧 Email: [email protected]

#enmansi#WPC Decking#CoExtrusion Decking#Composite Decking#Outdoor flooring#Glamping Decking#decking boards#wood plastic composite#eco friendly decking#waterproof decking#anti slip decking#decking supplier#decking factory#decking production#outdoor living#garden decking#wpc flooring#glamping platform#decking solution#patio deck#backyard deck#garden design

0 notes

Text

WPC decking wpc flooring 3D composite decking embossed

Fire Proof Water Proof Terrace Wpc Decking

Composite decking is a man-made building product that includes an approximate equal mix of recycled wood fibers and recycled plastic. Because composite decking products are so durable and impervious to rot, they have a much longer lifespan than wood decks. They do not require the staining, sanding, sealing, and board replacement that come along with wood decks. Even though they require more initial investment, a composite deck more than makes up for that initial cost over the lifespan of the deck. With the many advantages of composite decking, such as lower maintenance and being resistant to mold and insects, composite decking has been deemed one of the most durable decking products on the market today. In addition to these benefits, new capped composite decking is also stain and fade resistant, which means it is easier to clean and has very high color retention.

Maintaining your composite deck requires semi-annual cleaning; just a quick spray of the hose with a mild household cleaner will do the trick.Capped composite decking is sealed and is easier to clean if mold and mildew form on the surface.Since there are exposed wood fibers in uncapped composite decking planks, it can be susceptible to mold growth just like any outdoor surface. However, cleaning your deck periodically can help keep mold at bay. Installation of composite decking uses the same tools as traditional wood decking with the added benefit of side grooves for hidden fasteners. A hidden fastener system makes use of grooves built into the sides of the decking planks for a smooth surface without any screws showing. Plus, you have the added benefit of absolutely no splinters, twisting or warping. However, it is important to note that you must follow the manufacturer’s instructions for installation. Adding a deck to your home can produce a substantial return on your initial investment. With composite decking, you are ensuring that your deck is beautiful for years with less maintenance. You can even have the exotic look of woods like Ipe, without all the upkeep. Composite decking can be a true, low maintenance solution to your outdoor living space by providing a beautiful sanctuary for you and your family.

What Is W.P.C ?

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC etc.). Chemical additives seem practically "invisible" (except mineral fillers and pigments, if added) in the composite structure. They provide for integration of polymer and wood flour (powder) while facilitating optimal processing conditions. In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.

What Is The Advantages Of W.P.C?

WPC do not corrode and are highly resistant to rot, decay, and Marine Borer attack, though they do absorb water into the wood fibers embedded within the material. They have good workability and can be shaped using conventional woodworking tools. WPCs are often considered a sustainable material because they can be made using recycled plastics and the waste products of the wood industry. One advantage over wood is the ability of the material to be molded to meet almost any desired shape. A WPC member can be bent and fixed to form strong arching curves. WPCS are manufactured in a variety of colours, another major selling point of these materials is their lack of need for paint.

What Is The Uses Of W.P.C?

Wood-plastic composites are still new materials relative to the long history of natural lumber as a building material.The most widespread use of WPCs is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, window and door frames, and indoor furniture.

Previous: Fire Resistant Outdoor WPC Flooring Board

Previous: No more

0 notes

Photo

For the best quality composite decking boards in the UK, just visit deckorum.co.uk. We are a Build Home & Garden Award-winning company which are available with a wide range of decking board with a natural 3D embossed wood grain texture. Shop the top-class products now. Visit our website to book our services online.

1 note

·

View note

Text

Kitchen Remodeling: Cabinets To Counters

Some people put all of their attention into decorating the interior areas of their home. They spend thousands of dollars on new tile flooring, carpeting, paintand appliances. They even take the time to get new furniture and bedding every few years. Although there is nothing wrong with being this way, peopleshould still pay just as much attention lớn how their outdoor space looks. They did not put enough gap between the decking boards, and when the winter rains came, the deck absorbed the water and expanded like a wet sponge.Soon the deck mushrooms up above it's decking joists below.

See more: https://t.me/cuacompositesundoor

The gap between the boards is needed to allow the composite wooden doors wood toexpand as it get wet. When confronted with these complaints the manufacturer replaces the wood for free plus gives you $2500, to settle. We got the recipewrong on that batch of wood is the answer given as an excuse to the home owners. Do you buy that? I most assuredly do not! Steel doors are considered lớn be one of the most secure choices for any home. They are very durable and are much heavier than wood or aluminum doors.These doors are much stronger and more secure than both fiberglass and wood doors. These doors can be embossed with patterns to resemble a woodgrain. They can also come in a variety of colors. In most cases, a steel door is more affordable than either a wood or fiberglass composite wooden plasticdoor. Depending on the type of composite railings you use, there may be manufacturer requirements for any accessories and additional parts such as screws andfasteners. The manufacturer may also provide a warranty with for your railings, but if you damage them n any way or fail to follow the recommendations,your warranty may not be honored. Once you have the bottom off the patio wooden plastic door it should be easy lớn see how the rollers are held in. Usually, removing one screw or bending ametal tab is all thats necessary.

See more: https://www.reddit.com/user/cuacompositesundoor/m/cua_nhua_go_composite/

Remove the rollers and take them with you lớn your local glass cửa hàng lớn get the proper replacements. Composite sinks are a smart option when considering a new kitchen sink. The composite material that they're manufactured from has a lot of desirable traitsand characteristics. One of the best traits is the fact that they are built lớn last and enjoy an above average durability. They are manufactured in a way thatmakes them a far cry from what was available years ago. They are also visually pleasing lớn the discriminate buyer, and have came a long way since theirearly beginnings. The new ones can take the abuse that a modern day kitchen needs lớn live up too and come out unscathed. Fear not, I have found a solution for my hockey stick woes. I buy a good quality composite stick and replace the blade! How is this possible? It is much easierthan you may think. Step one is lớn saw the blade off of your composite stick. Then, tape up the sawed off end as if it were your handle. Next, attach yourreplacement blade (which ever type you prefer) to the old handle end of your stick. Most composite sticks have an end cap that can be easily removed.Simply insert your new blade with a few dabs of glue and heat it up until it sets. Allow your stick to dry for a few hours and you have a brand new(and longer) hockey stick! Hoa cương composite is a great choice. Đá hoa cương has a lot of rock particles used in the composite mix. This adds up lớn a unique ability lớn weather hot pans, stains,and other kitchen perils that may come its way. There are many styles and designs lớn choose from as well so you are sure lớn find one that suits yourtaste and helps you create that look you have envisioned for your kitchen. Pair this lớn a beautiful pewter faucet and it will make a great looking kitchen!I have this type of kitchen sinks in my own custom home. My wife enjoys the peace of mind that comes with knowing how superb this product is. Andwhen compared to all other choices that are available, the choice is clear, composite kitchen sinks are the natural winning choice.

See more: https://www.tiktok.com/@sundoor_sude

1 note

·

View note

Text

Changxing Hanming Technology Co.,LTD---outdoor WPC decking and wall cladding Manufacturer China

Hanming WPC decking is green energy conservation and environmental protection products, products with natural wood texture, colour and lustre, simple sense and high polymer material characteristic of waterproof, fire prevention, moth-proofing, ultraviolet resistance, acid and alkali resistance, abrasion resistance, avoid lacquer once the characteristics of the forming, can be recycled,Hanming composite decking is the good choice for outdoor floor.

Hanming WPC decking to the global scope of green building home furnishing system solutions as the main direction of development. Our products have been exported to Germany, Japan, USA, Singapore, Taiwan and so on.

Advantages of wpc board

Low maintenance. WPC requires very minimal maintenance, since it does not require frequent sanding, varnishing, sealing, or staining, unlike traditional wood decking .

Durable. WPC decking can be used in an outdoor environment for a long time, can withstand different climatic conditions, and has a long service life.

Won’t split and rot. Traditional wood is likely to mold and rot after absorbing water. There may be safety hazards in use. WPC decking can resist rotting and warping caused due to dampness.

Available in many colors. We offer 6 regular color options, and can also provide you with customized colors to meet your design requirements.

Environmental friendly materials. WPC decking is made from recycled plastic pellets and wood fibers and is an ideal choice for environmentally friendly materials.

Hanming Provides indoor and outdoor plastic wood series products mainly including outdoor wall Cladding, suspended ceiling and outdoor decking, co-extrusion Decking, online embossing wpc board, guardrail, pavilion, corridor, flower box and integrated wooden house.

Wholesale WPC composite decking in China --Changxing hanming technology Co.,lTD

Plastic does not have the advantage of all woodiness adornment material, have an advantage more than solid wood, and have very high flame retardant, won't catch fire.Especially in meiyu season, it also has waterproof moistureproof anticorrosive effect.Maintenance requirements are very low.

The color of plastic wood is close to solid wood, having natural woodiness grain, have more color to be fond of for people to choose collocation.Plastic has no basic color (that is, solid color), a transfer color (with a natural texture close to solid wood), paint, and mulch and other colors.This provides more choices for those who like to pursue fashionable personality.

WPC decking Manufacturer

1 note

·

View note