#Fiber Optic Cable Connectors

Explore tagged Tumblr posts

Text

Common Applications of Multi-Core Fiber Coupling Connectors

Multi-core fiber coupling connectors let you bundle dozens of individual fibers into a single, compact module. Forget about messy, sprawling fiber panels—these connectors keep everything neat and scalable.

Top Use Cases:

Data Centers & Enterprise Networks • Spine-leaf architectures (100G, 400G) • High-density patch panels that reduce cable runs

Telco & 5G Deployments • Fiber to the Antenna (FTTA) for multiple RRUs in one shot • DAS systems inside stadiums and large venues

HPC & Research • Supercomputers, university clusters, and scientific labs • Parallel I/O links for storage arrays and compute nodes

Industrial & Automation • Smart factories—linking sensors, PLCs, and robots • Rugged, EMI-resistant assemblies for extreme conditions

Broadcast & Media • Live production rigs and OB vans carrying multiple SDI/HDMI signals • Reducing bulk when transmitting multi-camera feeds

Medical Devices • Diagnostic imaging (OCT, endoscopes) needing multi-wavelength fibers • Minimizing footprint inside medical carts

Military & Aerospace • Avionics fiber buses with tight space constraints • Ruggedized battlefield communications requiring secure, strain-relieved connections

Multi-core fiber coupling connectors aren’t just about saving space—they also simplify maintenance, cut installation time, and future-proof your network as speeds and densities increase.

1 note

·

View note

Text

Enhancing Network Speed and Security: Division 27’s Expertise in Fiber Optic Cable Installation

In today’s digital landscape, reliable connectivity is the backbone of any business. At Division 27 Telecommunications, Inc, we understand the critical role that high-speed, secure data transmission plays in mission-critical communications. Our team specializes in Fiber Optic Cable Installation, offering comprehensive services that support robust and scalable network infrastructures. From design to post-installation support, Division 27 is committed to delivering quality solutions that are custom-built to support current needs while preparing for future growth.

With the increasing demand for rapid data exchange, Fiber Optic Cable has become the preferred medium for high-performance networking. Unlike traditional copper cabling, fibre optics deliver significantly higher bandwidth and transmit data over longer distances with minimal signal loss. Our projects often involve complex installations such as Distributed Antenna Systems (DAS), Wi-Fi, and next-generation 5G infrastructure. Division 27’s specialization in both air-blown and conventional Fiber Optic Cable systems sets us apart in the telecommunications industry.

What distinguishes Division 27 Telecommunications, Inc. is our coordinated and technology-driven approach. Every installation is carried out with precision and guided by detailed planning to meet performance, budget, and timeline expectations. Our team brings a wealth of expertise in the low-voltage cabling field and possesses a deep knowledge of the intricacies involved in Fiber Optic Cable Installation. This includes the use of premium Fiber Optic Connectors that are crucial for achieving seamless data transmission and maintaining the integrity of the signal throughout the network.

We are not only installers—we are strategic partners who provide long-term infrastructure technology solutions. Our work supports major wireless carriers, tower owners, and fiber optic infrastructure providers across the country. The result is a secure and efficient network environment that supports the flow of critical information in real-time. Our highly trained technicians and engineers are dedicated to completing each project to the highest standards, reflecting our reputation for quality and dependability.

As a veteran-owned business, Division 27 Telecommunications, Inc. has earned recognition for both its service excellence and commitment to innovation. Our accreditation by the US Department of Veterans Affairs and our role as an authorized training centre for The Fiber Optic Association, Inc. are a testament to our industry credibility. Since our founding in 2013 by Rick Christopher—who brings over 25 years of experience in the field—we have prioritized staying ahead of the curve in technological advancements and installation techniques.

At Division 27, we believe that secure, fast, and future-proof connectivity is not just a goal—it is a necessity. Our expertise in Fiber Optic Cable Installation, our use of high-quality Fiber Optic Connectors, and our deep understanding of Fiber Optic Cable systems allow us to deliver network infrastructures that support today’s data demands and tomorrow’s innovations. Whether supporting a commercial facility or an entire campus network, Division 27 delivers solutions that perform with precision and reliability.

For high-quality telecommunications services grounded in technical excellence and long-term reliability, Division 27 Telecommunications, Inc. is your trusted partner.

0 notes

Text

https://www.futureelectronics.com/p/interconnect--connector-tools-contacts-accessories/dt04-3p-te-connectivity-7076061

Electrical connector Accessories, Cable assembly, crimping tool, USB connectors

DT Series Contact Size 16 3 Way Gray Receptacle Housing

#TE Connectivity#DT04-3P#Connectors#Tooling and Accessories#Electrical#Cable assembly#crimping tool#USB#Fiber optic#crimp#IC socket#Wire crimp#cable crimper#receptacle housing connector#Cable connectors#rf connector adapter

1 note

·

View note

Text

Fiber Optic Adapter - SC Female to SC Female

A Fiber Optic Adapter (also known as a coupler or connector adapter) is a passive device used to connect two optical fibers with the same or compatible connectors. In this case, an SC Female to SC Female adapter would be designed to connect two SC-terminated fiber optic cables together.

Here's a breakdown of the components:

SC Connector: The SC (Subscriber Connector) is a common type of fiber optic connector with a square-shaped snap-in coupling mechanism. It is widely used in data communication and telecommunication networks. The connector has a push-pull design that ensures a secure connection.

Female Connector: The "Female" designation indicates that the connector has a socket or receptor to accept a male connector. In the case of an SC Female connector, it means that the adapter has an SC port with a socket to accept the male end of an SC-terminated fiber optic cable.

SC Female to SC Female Adapter: This adapter is designed to connect two SC-terminated fiber optic cables that have male SC connectors at their ends. Each side of the adapter has an SC Female port (socket) where the SC connectors from the cables can be inserted. This creates a continuous optical connection between the two cables, allowing light signals to pass from one fiber to another.

These adapters are useful in scenarios where you need to extend the length of a fiber optic cable or connect two cables with SC connectors that are too short to reach each other directly. Fiber optic adapters are commonly used in networking, data centers, telecommunications, and other applications where high-speed and reliable data transmission is crucial.

When choosing a fiber optic adapter, it's important to ensure compatibility between the connector types and the mode of the fiber (single-mode or multi-mode) being used. Additionally, make sure to handle and install fiber optic components with care to avoid damage to the delicate optical fibers and connectors.

#Fiber Optic Adapter#Buy Fiber Optic Cable Adapter Coupler#Fiber Optic Adapter SC to LC Singlemode Simplex#SC Male to LC Female UPC Fiber Optical#Fiber Optic Adapters#Fiber Adapters#Fiber Optic Connector Adapters

0 notes

Text

What are Industrial Cable Connectors?

Introduction:

Industrial cable connectors play a vital role in establishing reliable and secure connections in various industrial applications. From power transmission to data communication, these connectors ensure seamless connectivity and efficient performance. In this comprehensive guide, we will explore the ins and outs of industrial cable connectors, their types, applications, and key considerations. So, let's dive in and understand the importance of industrial cable connectors in modern industries.

Understanding Industrial Cable Connectors:

Industrial cable connectors are specialized devices designed to facilitate secure and reliable connections between cables, wires, and other electrical components in industrial environments. These connectors are engineered to withstand harsh conditions, provide efficient transmission of power or data signals, and ensure safe and durable connections.

Types of Industrial Cable Connectors:

a. Circular Connectors:

These connectors feature a cylindrical shape and are commonly used in applications where robustness and durability are crucial, such as heavy machinery, automation systems, and outdoor installations.

b. Rectangular Connectors:

Rectangular connectors are versatile and widely used in industrial settings. They offer a wide range of configurations and can accommodate multiple contacts for power, signal, and data transmission.

c. Fiber Optic Connectors:

Fiber optic connectors are specifically designed for high-speed data transmission over long distances. They use optical fibers to transmit light signals, providing excellent bandwidth and immunity to electromagnetic interference.

d. Coaxial Connectors:

Coaxial connectors are primarily used for RF (radio frequency) applications. They feature a central conductor surrounded by insulation, a metallic shield, and an outer insulating layer, ensuring proper impedance matching and minimal signal loss.

Key Features and Specifications:

Industrial cable connectors come with various features and specifications that are crucial for their optimal performance. These include:

Connector housing material: Robust and durable materials such as metal or high-grade engineering plastics are commonly used to withstand harsh environmental conditions.

IP rating: The IP (Ingress Protection) rating indicates the connector's resistance to dust and water intrusion. Higher IP ratings signify better protection against environmental elements.

Contact configuration: Connectors can have different contact arrangements, such as pin-and-socket or plug-and-jack, depending on the application requirements.

Voltage and current rating: Industrial cable connectors are designed to handle specific voltage and current levels, ensuring safe and reliable power transmission.

Locking mechanisms: Many connectors incorporate locking mechanisms to ensure secure connections and prevent accidental disconnection due to vibrations or movements.

Applications of Industrial Cable Connectors:

a. Automation and Robotics:

Industrial cable connectors are extensively used in automation and robotics applications to connect various sensors, actuators, and control systems, enabling seamless communication and power transfer.

b. Automotive Industry:

Cable connectors play a crucial role in the automotive industry, facilitating connections between electrical systems, sensors, and components in vehicles.

c. Energy Sector:

In the energy sector, industrial cable connectors are utilized in power generation, transmission, and distribution systems, ensuring reliable and efficient electricity transfer.

d. Telecommunications:

Industrial connectors are integral to telecommunication networks, providing reliable connections for data transmission, telephony, and networking equipment.

e. Aerospace and Defense:

In aerospace and defense applications, industrial connectors are essential for reliable communication, power distribution, and signal transmission in challenging environments.

Factors to Consider when Choosing Industrial Cable Connectors:

a. Environment and Operating Conditions:

Consider the temperature range, moisture levels, dust exposure, and other environmental factors to select connectors that can withstand these conditions.

b. Electrical and Mechanical Specifications:

Evaluate the voltage and current ratings, contact resistance, insulation resistance, and mechanical durability to ensure compatibility with your application requirements.

c. Signal and Power Requirements:

Determine the type and bandwidth of signals or power being transmitted to choose connectors that offer the necessary performance and compatibility.

d. Industry Standards and Certifications:

Look for connectors that comply with industry standards and certifications to ensure quality, reliability, and compatibility with other equipment.

Installation and Maintenance Tips:

a. Proper Cable Termination:

Follow manufacturer guidelines for cable termination to ensure a secure and reliable connection. Use appropriate tools and techniques to achieve proper insulation and strain relief.

b. Secure Connection Techniques:

Employ locking mechanisms, such as threaded couplings or bayonet-style locks, to prevent accidental disconnection and ensure stable connections.

c. Regular Inspection and Maintenance:

Regularly inspect connectors for signs of wear, damage, or contamination. Clean connectors using recommended methods and replace any faulty or damaged components promptly.

Future Trends in Industrial Cable Connectors:

The industrial cable connector industry is continually evolving to meet the demands of advancing technology and changing industrial requirements. Some emerging trends include miniaturization, increased data transmission speeds, and improved resistance to extreme temperatures and vibrations.

Conclusion:

Industrial cable connectors are indispensable components in modern industrial applications, enabling secure and reliable connections for power transmission and data communication. Understanding the types, features, applications, and key considerations when choosing these connectors is crucial to ensure optimal performance and long-term reliability. By selecting the right industrial cable connectors and following proper installation and maintenance practices, industries can enhance efficiency, safety, and overall productivity.

#Industrial Cable Connectors#cable connectors#Types of Industrial Cable Connectors#Coaxial Connectors#Fiber Optic Connectors#Applications of Industrial Cable Connectors

0 notes

Text

How to Pick Your Next 10G SFP+ Optical Transceiver

Whether you’re running a campus backbone or a high-density data center, getting the right 10G SFP+ transceiver can save you headaches (and cash). Here’s your cheat sheet:

Distance:

SR (850 nm): up to ~300 m over multimode fiber

LR (1310 nm): up to ~10 km over single-mode

ER (1550 nm): up to ~40 km, plus DCM options

Cable & Connector: Make sure your fiber type (OM3/OM4 vs. OS2) and LC connectors match.

Compatibility: Check OEM vs. 3rd-party support, firmware updates, and warranty.

Cost vs. Performance: Don’t overpay for ER when SR does the job—or underbuy and end up replacing sooner.

Ready to level up your network? 🚀

2 notes

·

View notes

Text

Get a Clear Picture of Fiber Optic Pigtail

A fiber optic pigtail is a fiber optic cable that has one end terminated with a factory-installed connector while leaving the other end unterminated. As a result, the connector side may be connected to equipment, while the other side is melted with optical fiber cables. Pigtail patch cords terminate fiber optic cables via fusion or mechanical splicing. High-quality pigtail cables, along with…

View On WordPress

2 notes

·

View notes

Text

What is an AOC cable used for?

Hey there, tech enthusiasts! Today, we’re diving into the world of AOC cables—those sleek, futuristic connectors that are quietly transforming how we experience our devices. If you’ve ever marveled at a crystal-clear 4K movie, dominated an online gaming session, or set up a clutter-free workspace, chances are an AOC cable was working its magic behind the scenes. With Fibrecross leading the charge in innovative connectivity, let’s unpack what these cables are, why they’re awesome, and how they’re making your digital life better.

So, what exactly is an AOC cable? AOC stands for Active Optical Cable, and it’s a game-changer in the world of data transfer. Unlike the old-school copper cables we’re used to, AOC cables use optical fiber to carry data as light signals. Sounds sci-fi, right? But here’s the practical part: they’ve got tiny transceivers at each end that convert electrical signals into light and back again. This lets them transmit massive amounts of data—like ultra-high-definition video or lightning-fast gaming inputs—over long distances without losing quality. Fibrecross AOC cables are designed to make this tech accessible, whether you’re a casual user or a tech pro.

Picture this: you’re setting up a home entertainment system. Your TV is mounted on one wall, and your streaming device or console is tucked away in a cabinet 20 feet across the room. A traditional copper HDMI cable might struggle to keep the signal strong over that distance, leaving you with glitches or a fuzzy picture. Enter Fibrecross AOC cables. They can stretch up to 100 meters (that’s over 300 feet!) while delivering pristine 4K or even 8K video, plus buttery-smooth 120Hz refresh rates for gaming. No signal loss, no drama—just pure performance. It’s like having a superpower for your home theater.

But AOC cables aren’t just for movie nights. Gamers, you’re gonna love this. If you’re rocking a high-end PC with multiple monitors or a VR headset, Fibrecross AOC cables are your secret weapon. They handle high-bandwidth demands like 144Hz or 240Hz refresh rates with ease, ensuring your gameplay stays lag-free. Ever been sniped in a shooter because your screen stuttered? Yeah, AOC cables help keep that from happening. For VR, where every millisecond counts to avoid motion sickness, these cables deliver the speed and reliability you need to stay immersed.

Let’s talk aesthetics, too, because who doesn’t want a clean setup? AOC cables are thinner and more flexible than their copper cousins, which means less bulk and easier cable management. Whether you’re curating a minimalist desk or a glowing RGB gaming station, Fibrecross AOC cables slide into your setup without ruining the vibe. Plus, they’re lightweight, so you’re not lugging around a brick of wires when you rearrange your space.

Beyond home use, AOC cables shine in professional settings. Think data centers, where servers need to talk to each other without interference, or medical imaging systems that demand pixel-perfect clarity. Fibrecross AOC cables are immune to electromagnetic noise—something copper cables can’t dodge—which makes them ideal for these high-stakes environments. Even in live events, like concerts or sports broadcasts, AOC cables ensure video feeds stay flawless over long runs.

Oh, and here’s a bonus: they’re kind of eco-friendly. AOC cables use less power than copper ones, which is great for your electric bill and the planet. Fibrecross builds theirs to last, so you’re not tossing out frayed cables every year. It’s a small win for sustainability in a world of constant tech upgrades.

In short, Fibrecross AOC cables are your go-to for connecting today’s high-tech world. From epic gaming sessions to binge-worthy streams to pro-grade setups, they’re the backbone of seamless, high-speed performance. Next time you plug in, give a nod to Fibrecross for making it all possible.

2 notes

·

View notes

Text

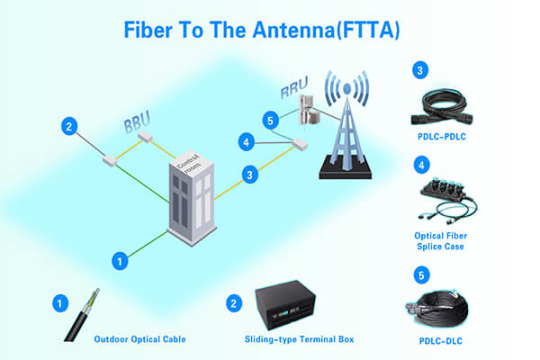

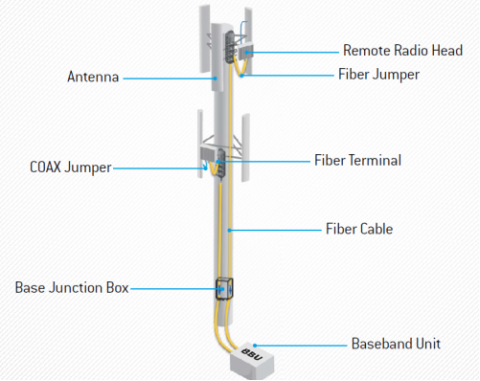

FTTA: High-Performance Solution for Integrated Optical Fiber and 5G Networks

There is a huge demand for high-speed data transfers in today’s mobile telecommunications networks. FTTA (Fiber-to-the-Antenna) is an essential element of 5G networks and ensures reliable, robust, and future-proof installation, improves user experience and reduces costs. This article helps you to understand FTTA.

What is FTTA?

FTTA is a broadband network architecture to connect the building baseband unit (BBU) to the remote radio unit (RRU) at the top of the tower by using optical fibers to replace all or part of the coaxial network. FTTA can reduce the loss of signal power. And up to 20km's maximum transmission distance helps realize centralized placement of base stations (BS) in lower-cost telecommunication rooms and more flexible and modularized network planning.

FTTA Solution

FTTA solution reduces installation time and saves the cost of installation and maintenance. FTTA solution includes outdoor optic fibers, PDLC outdoor waterproof patch cords, terminal boxes, etc.

Benefits of FTTA

Perhaps the most benefit of FTTA stems from the physical content of the cable itself. The smaller diameter and lighter weight allow many fiber optic cables to occupy the same amount of space as a single coax cable. Because cellular towers are naturally subject to the elements, the physical size and properties of optical cabling are much less susceptible to damage from gusts of wind.

Other benefits of FTTA relate to the shift from analog to digital. Due to signal losses, the coax cable limited the distance between the antenna and the base station to as low as around 100m. Optical cabling can span up to 20 km with minimal losses.

FTTA provides improved energy consumption and signal integrity. Tower amplifiers are no longer required to combat the inherent noise floor of extended coax runs. The cooling of power amplifiers through air conditioning in a traditional base unit is replaced by ambient air cooling of the RRH, which significantly reduces the electrical power consumption of the system.

FTTA also provides flexible deployment, reduced complexity, saves installation time and space on the tower, lower investment, and high reliability.

Typical FTTA Scenario

Fiber optic networks aim to perform high-speed, error-free data transmission. Adequate testing during each phase of the network deployment guarantees that products meet specifications. It minimizes costly and time-consuming troubleshooting efforts, including locating dirty/damaged connectors, questionable splices, and other faulty components before they disrupt service.

One of the most crucial factors in ensuring proper transmission is controlling power loss in the network against the link loss-budget specifications from the network design recommendation, which establishes a total end-to-end loss budget with sufficient margin while reducing back reflection to a minimum.

What is the Future of FTTA?

Consumer demand and technological advancement will continue to challenge the broadband infrastructure and necessitate more innovation. As incremental improvements such as active antennas integrated with the RRH to eliminate the need for all coax, small cell technology, and tower construction continues to evolve, it is safe to assume the future of FTTA may hold a few more surprises.

5G network provides speeds up to 100 times faster than 4G, which requires more small cell sites/DAS and improvements in conventional antenna tower bandwidth. Fiber optics will continue to provide the lifeblood to this ever-evolving network because only fiber can support the backhaul of these small cell sites produced by this intense proliferation of traffic.

Conclusion

FTTA is an innovative, flexible, and future-oriented way to install the network. It secures your network connectivity today and in the future.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

#suntelecom#fiberoptic#telecommunications#fttx#telecomengineering#cabling#osp#fiberopticcable#catv#telecomconsult

2 notes

·

View notes

Text

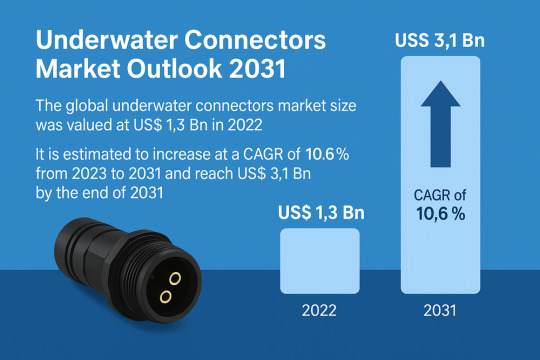

Underwater Connectors Market Gears Up for 10.6% Annual Growth

The global underwater connectors market is poised for significant growth, with industry analysts projecting a robust CAGR of 10.6% from 2023 to 2031. Valued at US$ 1.3 Bn in 2022, the market is expected to cross US$ 3.1 Bn by the end of 2031. A confluence of technological innovation, expanding maritime activity, and growing demand for autonomous and remotely operated underwater vehicles is fueling this expansion.

Market Overview: Underwater connectors play a vital role in ensuring power transmission, signal transfer, and data communication in submerged environments. These connectors are integral to applications across oil & gas exploration, defense, marine science, and renewable offshore energy. Wet-mateable and dry-mateable connectors continue to evolve to meet deep-sea operational challenges, with innovations in materials and design further driving their adoption.

Market Drivers & Trends

The surge in global data consumption has led to rapid expansion in subsea fiber optic cable networks, creating a sustained demand for reliable and high-performance underwater connectors. These systems support internet backbone infrastructure and intercontinental connectivity, relying on connectors to manage complex transmission needs over long oceanic distances.

Additionally, increased deployment of autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs) across commercial and defense sectors has propelled the need for high-quality, wet-mateable connectors that enable real-time control, data relay, and power distribution.

The growing emphasis on oceanographic research, renewable energy (especially offshore wind farms), and undersea exploration has created new avenues for underwater connectors across global waters.

Recent Developments

CRE expanded its Aberdeen facility with a custom connector manufacturing cell to meet growing demand for metal shell connectors.

Fischer Connectors enhanced its UltiMate series with new ultra-rugged models suitable for harsh environments.

Hydro Group introduced advanced rubber-molded subsea connectors under its Hydro Rubber Moulded (HRM) series.

Northrop Grumman signed a non-exclusive agreement to manufacture NiobiCon niobium-based connectors, specially designed for challenging underwater environments.

Key Players and Industry Leaders

The underwater connectors landscape is marked by innovation-driven competition. Key companies leading the charge include:

AMETEK Inc.

Amphenol Corporation

Fischer Connectors SA

GISMA Steckverbinder GmbH

Hydro Group

TE Connectivity

Teledyne Technologies Inc.

MacArtney A/S

OTAQ Group

Eaton

Siemens AG

Amissiontech Co., Ltd.

These firms are heavily investing in R&D, leveraging materials like stainless steel, Inconel, and titanium to develop ruggedized connectors tailored to meet the demands of both shallow and deep-sea operations.

Latest Market Trends

Customization and Modularity: Manufacturers are responding to market needs with customizable connector designs that suit application-specific parameters.

Material Innovation: Adoption of corrosion-resistant materials such as niobium and titanium to ensure durability and safety in high-pressure underwater environments.

Hybrid Connection Technologies: The market is seeing a growing demand for connectors that can simultaneously handle electrical, optical, and fluidic signals.

Increased Use of Wet-Mateable Connectors: Their ability to be connected and disconnected underwater has made them vital in oil & gas and offshore energy applications.

Market Opportunities

Expansion of Offshore Wind Farms: As countries prioritize renewable energy, underwater connectors are critical components for energy transmission from ocean-based turbines to onshore facilities.

Defense Modernization Programs: Increasing investments in unmanned maritime surveillance and combat platforms are opening up significant opportunities in the defense sector.

Scientific Exploration and Monitoring: Deep-sea observatories and underwater communication infrastructures require robust connectivity solutions, presenting new use cases for undersea connectors.

Emerging Markets in Asia and Africa: Rapid industrialization and offshore resource exploration in these regions are fueling demand for underwater infrastructure, including connectors.

Explore the highlights and essential data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=38582

Future Outlook

Analysts predict steady growth in underwater connectors market share across defense, scientific research, oil & gas, and renewable energy sectors. Key to this outlook is the anticipated rise in remote operations via AUVs and ROVs, increased data demand via undersea fiber networks, and development of robust subsea communication infrastructure.

North America, particularly the U.S., is expected to dominate the market through 2031 due to its established oil & gas sector and naval modernization programs. Europe and Asia Pacific will also exhibit high growth, driven by technological advancements, renewable energy initiatives, and increased maritime research activities.

Market Segmentation

By Type:

Dry-Mateable Connectors

Wet-Mateable Connectors

Others

By Sealing Technology:

Rubber-molded

Rigid shell

Fluid-filled

Inductive Couplings

By Connection Type:

Electrical

Optical

Hybrid

By Material:

Stainless Steel

Inconel

Titanium

By Application:

Oil & Gas Exploration Equipment

Offshore Wind Energy

Submarine Systems

ROV/AUV

Underwater Communication Infrastructure

Underwater Observatories

Others

By End-use Industry:

Oil & Gas

Renewable Energy

Military & Defense

Scientific Research

Telecommunications

Regional Insights

North America: Leads the market, fueled by oil & gas exploration, military investments, and a robust scientific ecosystem.

Europe: Advanced defense activities and presence of leading electronics manufacturers position it as a high-growth region.

Asia Pacific: Rapidly developing infrastructure in China, Japan, South Korea, and ASEAN countries offers significant future potential.

Middle East & Africa: Offshore oil activities and increasing fiber optic connectivity offer promising growth.

South America: Brazil’s deepwater oil reserves are driving demand for subsea infrastructure, including connectors.

Why Buy This Report?

Comprehensive Market Insights: Understand key trends, growth drivers, and challenges shaping the underwater connectors market.

Strategic Forecasting: Get reliable projections up to 2031, including quantitative and qualitative assessments.

Competitive Landscape Analysis: Evaluate the positioning, capabilities, and strategies of leading market players.

Regional Breakdown: Gain insight into regional performance and emerging geographic opportunities.

Technology Trends: Track the evolution of materials, design innovations, and connector technology advancements.

Investment Insights: Identify high-opportunity segments, application areas, and potential investment avenues.

0 notes

Text

Loopback testing made easy.

FiberLife offers Fiber Loopback Cables/Modules in LC, SC, and MTP/MPO connector styles, available in both singlemode and multimode options. Choose from simplex, duplex, or high-density multi-fiber modules (8/12/24 cores) to simulate a complete optical signal path for accurate validation. Perfect for verifying port functionality and troubleshooting fiber networks in data centers, telecom setups, and equipment production lines.

0 notes

Text

SFP Modules: The Essential Guide for Network Engineers

Living in the ever-evolving scene of networking advancement, standing ahead of the loop is critical for network engineers and IT professionals. The lone important component that frequently makes its way into their toolkit is the SFP modules. Small-sized yet highly potent, these compact devices play a huge part in the connectivity and efficiency of modern networks.

For almost two decades, we at AE Connect have witnessed the evolution of this tiny, indispensable device, and are here to guide you through everything you need to know about SFP modules, from their basics to troubleshooting issues.

What is an SFP Module?

Let’s start with the fundamentals. SFP stands for Small Form-factor Pluggable. It’s a compact, hot-swappable transceiver used in data communication and telecommunication applications. These modules are often called mini-GBICs (Gigabit Interface Converters) due to their ability to convert electrical signals to optical or vice versa.

An SFP module resembles a small metal box with a connector on one end, making it easy to insert and remove from compatible network devices such as networking switches, routers, and network interface cards (NICs). These modules come in various types, including SFP and SFP+, each designed for specific data rates and distances.

What is the Function of the SFP Module?

The primary function of an SFP module is to enable data transmission across different types of media, including fiber optic cables and copper cables. It serves as the link between the optical and electrical domains in a network, converting digital signals into optical signals for long-distance transmission or vice versa for shorter distances.

SFP transceivers play a pivotal role in ensuring network flexibility and scalability. Network engineers can select the appropriate SFP module type based on their specific needs, allowing them to customize their network infrastructure.

How Do You Choose the Right SFP Module?

Selecting the right SFP module is critical to ensure optimal network performance. Here are some key factors to consider:

Data Rate:

Determine the required data rate for your network. SFP modules come in various speeds, from 100Mbps to 100Gbps.

Distance:

Keep in view the distance over which you need to pass on data. Distinct SFP modules are developed for short-range, intermediate-range, and long-range applications.

Fiber Type:

Choose the appropriate SFP module depending on whether you’re working with single-mode (for long distances) or multi-mode (for short distances) fiber optic cable.

Compatibility:

Make sure your networking hardware is compatible with the SFP module. Not all modules work with all devices, so check compatibility lists provided by manufacturers.

Is SFP Better than RJ45?

This one is a popular question in the networking field. SFP and RJ45 are two different innovations, each with its own strengths.

SFP modules are generally preferred for:

Long-distance, high-speed connections.

Fiber optic networks.

Scalable and flexible network designs.

On the other hand, RJ45 (Ethernet) is preferred for:

Shorter-distance connections within a building.

Cost-effective solutions.

Compatibility with existing infrastructure.

The choice between SFP and RJ45 depends on your network’s specific requirements and your budget.

What are the Components of the SFP Module?

Inside the seemingly unassuming SFP module, you’ll find a complex set of components working together to facilitate data transmission. The key components include:

Transmitter: This element converts electrical signals into optical signals for transmission.

Receiver: It receives incoming optical signals and converts them back into electrical signals.

Microcontroller: This controls and monitors the module’s functions, ensuring optimal performance.

LC Connector: This modest, latching connector is put to use to connect the SFP module to optical fiber or copper cabling.

EEPROM: An Electrically Erasable Programmable Read-Only Memory (EEPROM) stores vital information about the module, such as manufacturer details, serial number, and compatibility data.

Diagnostic Features: Some advanced SFP modules include diagnostics and monitoring features, such as Digital Optical Monitoring (DOM) to track performance and troubleshoot issues.

What is the Input Voltage of SFP?

SFP modules typically operate on low voltage, usually around 3.3 volts. This low voltage requirement makes them energy-efficient and suitable for a wide range of network devices.

How to Troubleshoot SFP Module Issues?

Even the most reliable SFP modules can encounter issues over time. Here are some troubleshooting steps to help you diagnose and resolve common SFP module problems:

Check Physical Connections:

Ensure that the module is properly inserted into its slot and that the fiber optic cable is securely connected.

Inspect Fiber Optic Cables:

Examine the cables for damage, bends, or kinks that could affect signal transmission.

Verify Compatibility:

Confirm that the SFP module is compatible with your network equipment. Mismatched modules can lead to connectivity problems.

Use Diagnostic Tools:

Many SFP modules come with diagnostic features. Utilize these tools to monitor the module’s performance and detect issues.

Update Firmware:

Be sure that your network equipment’s firmware is updated. Manufacturers often introduce firmware upgrades that can enhance compatibility and functionality.

Replace Faulty Modules:

If all else fails, consider replacing the SFP module. Over time, these modules can wear out, leading to degraded performance.

Unlocking Connectivity: AE Connect for Reliable SFP Modules

In the dynamic sphere of networking and connectivity, the request for high-performance solutions is ever on the rise. As setups and industries continue to advance, the need for trusted, effective, and economical networking equipment has never been truly more critical.

Here is where AE Connect, your trusted companion, takes action, bridging the gap between innovation and connectivity.

At AE Connect, we take pride in being at the forefront of networking technology. With great care and commitment to superior quality and innovation, we have placed ourselves as a reputable manufacturer of Small Form-factor Pluggable (SFP) modules, providing groundbreaking solutions that empower networks all around the world.

Our SFP modules are manufactured in India, ascertaining that they satisfy the top standards of quality and reliability. We take advantage of the latest advancements in networking technology to create SFP modules that deliver solid gold performance.

Every AE Connect SFP module undergoes rigorous testing to ensure it meets or exceeds industry standards. Whether you need high-speed data transmission or long-distance connectivity, our modules are engineered to meet your specific needs.

You can trust our products to perform consistently and reliably at reasonable pricing.

Conclusion

SFP modules are vital for modern networking. When choosing one, consider the data rate, distance, fiber type, and compatibility with your devices. Inside an SFP module, multiple components work together, and they typically operate on low voltage.

Troubleshooting SFP issues involves checking connections, inspecting cables, verifying compatibility, using diagnostics, updating firmware, and replacing faulty modules. Trust AE Connect for top-quality, rigorously tested SFP modules, ensuring reliable performance for various networking requirements.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Digital Audio Optical Cable Thinner Optical Cable Make Wires Easier to Conceal Before purchasing, make sure this is the optical audio cable thickness you need.If you want a thicker cable, you can see if another digital optical audio cable Fiber Optic Audio Cable Wide Compatibility: Works for devices with a Toslink (S/PDIF or Optical) port, like: CableCreation Optical Audio Cable is compatible with Multiple brand Soundbars, CD / DVD / Blu-Ray players, Home / Audio theater receivers CableCreation Digital Optical Audio Cable Compatible with Multiple brand TVs; Preamplifiers; Digital satellites; Audio processors; CableCreation Toslink cable compatible with Game Consoles/PlayStation; Digital-to-analog converters (DACs). Gold-Plated Connector 24K gold-plated connectors resist corrosion and make sure a tight connection as well as offer a clear, smooth-flowing optimal signal. High quality PVC Jacket With high quality PVC jacket, this toslink optical digital audio cable is flexible and strong enough for your daily use. Removable Protective Cover 【Ultra-thin Design】The digital optical audio cable applys 0.08 inch (2.2mm) super slim and lighter cord for neater your space and easy to rearrangement. 【Professional Sound】The optical cable pefects for 3D surround sound, supporting PCM sound, 5.1 and 7.1 of Dolby and DTS sound. Let you enjoy the perfect music world. 【Excellent Quality】The digital audio optical cable enjoy24K gold-plated interface and premium pof-inner material fiber optic cable to promise the sound quality. 【Wide Compatibility】The digital optical cable meets the standard of Toslink S/PDIF optical audio signals, compatible with sound bar to a TV, a blue ray player to a home theater ect. 【Long Warranty】We provide up to 2 months warranty service and customer service. If you have any problems, please contact us in time, we will serve you wholeheartedly. [ad_2]

0 notes

Text

Why Should You Rely on Connector Wrenches for Precision and Safety?

Introduction to Connector Wrenches

Connector wrenches are essential tools engineered to simplify the tightening and loosening of connectors in a wide variety of electrical, electronic, and mechanical assemblies. Unlike generic wrenches, connector wrenches are specially designed to provide optimal torque control, ensuring secure connections without damaging delicate components. Their role is increasingly important in precision-driven industries, from telecommunications and aerospace to electronics manufacturing and data centers. The compact design and compatibility with hard-to-reach spaces make these tools a must-have for technicians and engineers working with connectors, sensors, cables, microcontrollers, and other sensitive components.

Why Are Connector Wrenches So Important?

Connector wrenches serve as the interface between quality installation and long-lasting performance. Whether assembling fiber optic cables or tightening RF connectors in communication equipment, these wrenches ensure a perfect fit and torque consistency, reducing the risk of signal loss or component failure.

Their significance extends across multiple fields:

In electronics, they provide careful application of pressure, preserving internal components.

In safety-critical environments, they prevent under-tightening or over-tightening, which can compromise functionality.

In thermal and high-frequency environments, they help maintain signal integrity and reduce potential system malfunctions.

With the rise in automated systems, robotics, and microelectronic devices, connector wrenches have become more refined, precise, and essential.

What Are the Key Features of a Connector Wrench?

Connector wrenches are built with attention to detail, functionality, and durability. The best models are manufactured using high-grade materials like stainless steel or anodized aluminum, and are compatible with various connector types and industry standards.

Key features include:

Ergonomic handles that provide a comfortable, anti-slip grip during repetitive tasks

Torque-limiting designs to prevent damage to sensitive terminals or threaded connectors

Slim or angled profiles to access connectors in tight or obstructed areas

Interchangeable heads to work with different connector sizes or standards

Non-magnetic materials to ensure safety in environments with magnetic-sensitive components like capacitors, sensors, and microprocessors

These design features make connector wrenches versatile for professionals working with thermal pads, controllers, contactors, and other high-performance equipment.

How Are Connector Wrenches Used in Industry?

Connector wrenches are utilized across several technical sectors where precise connectivity is essential. In telecommunications, for example, connector wrenches are commonly used to install coaxial or fiber connectors. In the aviation and aerospace industry, they’re instrumental in ensuring vibration-resistant terminations. In electronics, especially during PCB assembly or repair, connector wrenches help technicians maintain uniform pressure on connector housings, cable grips, and solderless terminals.

They are also integral in:

Automotive electronics installation and diagnostics

Sensor placement in industrial automation systems

Power connector setup in energy distribution equipment

Secure mounting of thermal systems involving heatsinks or fans

Connector wrenches not only streamline workflows but also improve the longevity and safety of complex systems.

What Types of Connector Wrenches Are Available?

There is a wide range of connector wrenches, each tailored for specific applications or connector types. Selecting the right wrench ensures compatibility and precision.

Common types include:

Fixed-head connector wrenches for specific connector sizes and types

Adjustable connector wrenches for handling multiple dimensions with one tool

Torque-limiting connector wrenches with calibrated mechanisms for consistent tightness

T-handle and L-handle styles that enhance torque application in confined spaces

Ratcheting connector wrenches for high-efficiency repetitive tasks

Insulated connector wrenches designed for working with electrical connectors in live circuits

Selecting the correct type ensures compatibility with connectors in tools, switches, safety modules, microcontrollers, and more.

Where Are Connector Wrenches Most Commonly Applied?

Connector wrenches are ubiquitous in various high-tech and industrial environments. Their ability to handle components without risking deformation makes them especially useful in sensitive electrical and data systems.

Typical applications include:

Networking installations involving coaxial, SMA, or fiber connectors

Aerospace electronic equipment where vibration-resistant assembly is vital

Medical devices requiring delicate yet firm connection fittings

Industrial automation systems incorporating sensors, thermal components, and fuses

Consumer electronics involving microprocessors, LEDs, and compact controllers

Renewable energy systems for secure connection of high-power terminals and capacitors

These tools are ideal for use during both installation and maintenance phases.

What Are the Benefits of Using the Right Connector Wrench?

Using the right connector wrench can enhance performance, increase safety, and reduce rework. As systems become increasingly compact and complex, the precision offered by connector wrenches becomes even more valuable.

Key benefits include:

Enhanced reliability of electrical and mechanical connections

Minimization of torque-related connector damage

Efficient installation and maintenance of components such as switches, thermal pads, and cables

Reduction in installation time and human error

Compliance with technical standards in regulated industries

The result is a cleaner, more stable connection with increased system performance and reduced maintenance costs.

How to Choose the Ideal Connector Wrench?

Choosing the right connector wrench depends on various factors such as the type of connector, environment, access space, and required torque.

Consider the following criteria:

Material durability and resistance to wear

Ergonomic design suited for extended use

Compatibility with specific connector types (e.g., SMA, N-Type, DIN)

Availability of torque control if precision is critical

Magnetic safety when working near microelectronics

Size and weight for ease of transport in fieldwork

Investing in a quality wrench tailored to your workflow can make all the difference in precision and efficiency.

Final Thoughts

Connector wrenches play a vital role in ensuring reliable, secure, and professional-grade connectivity across electronics, automation, communications, and industrial applications. As the demand for high-performance systems increases, the importance of using precise tools like connector wrenches becomes evident. These tools enhance system performance, improve safety, and prolong the lifespan of critical components.

Whether you're an electronics technician working with sensors and microcontrollers or an engineer installing power connectors and thermal solutions, connector wrenches are your trusted companion for clean, secure, and efficient assembly. Explore quality options from trusted brands and elevate your toolkit for modern-day applications.

0 notes