#Flex Circuits

Explore tagged Tumblr posts

Text

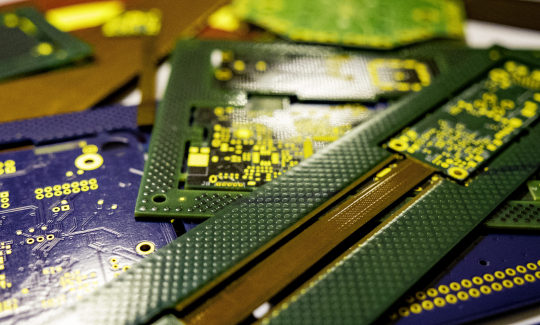

Custom Rigid Flex Circuits

Explore custom rigid flex circuits designed for precision, flexibility, and seamless integration in high-performance environments. Browse the visuals to find the right rigid flex solution tailored to your design specifications.

0 notes

Text

#stanford pines#stanley pines#gravity falls#god i dont know what im doing anymore...#forgot how time consuming making these things were#they are so tiny and look so dumb LMAO#stan doesnt even have blinking animations yet#blink mf blink!!!#dont mind my thd background and undertale cursor (i say while flexing)#also dont expect anything to come from this im just fucking around with it...#i do really wanna finish and release them tho.. at some point..... maybe..........#circuit to my brain

25 notes

·

View notes

Text

Miraculously…

#computer#computing#flex circuit pcb#astethic#laincore#dreamcore aesthetic#mental health#positivity#quote#gothy#strangecore#freaky#still here#insomnies#drink bleach#eat glass <3#y2k aesthetic#eerie aesthetic#not op#cool look#2000s web#webcore#web finds#sillyposting#ni ni

52 notes

·

View notes

Text

PCB schematic/design/fabrication/assembly

MPN TECH Pte Ltd provides One-Stop PCBA Solutions in Singapore, which support from R&D prototype to mass production. We have built long-term collaborations with many local startups, SIMES, MNCS, etc. We also have lots of overseas PCBA projects in Europe and the US. If any questions feel free to let me know.

Our Solutions:

PCB Design;

PCB Fabrication;

Components souring;

PCB Assembly;(SG Local machine Assembly)

3 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

For flexible printed boards with a large number of components and complex wiring relationships, consider the design of mounting retention positions to increase product reliability during structural design.

#pcb#flex pcb#rigid-flex pcb#flex circuit pcb#flexible pcb board#flexible circuit board#fpcway#fpcway.com#www.fpcway.com#today on tumblr#art#artwork#artists on tumblr#digital art

2 notes

·

View notes

Text

https://x-pcb.hashnode.dev/accelerate-product-development-with-quick-turn-flex-circuits-from-xpcb?showSharer=true

Accelerate Product Development with Quick Turn Flex Circuits from XPCB

The primary advantage of XPCB’s quick turn flex circuits service is speed. XPCB can deliver prototypes in as little as 24 hours, drastically reducing development cycles and enabling rapid testing and iteration.

0 notes

Text

Navigating the Future of Electronics with Rigid-Flex and Taconic PCB Manufacturers

Today’s Printed Circuit Boards (PCBs) are much more flexible and advanced than the first rigid versions. Compact devices with great capabilities and multiple features have earned popularity in the electronics industry, leading to the rise of Rigid-Flex PCBs and Taconic PCBs. The use of these technologies enables unique designs, improves how long the device works, and maintains good electricity flow. Rigid-flex PCB Manufacturers can move and also keep their form, similar to how rigid boards function. They particularly shine in high-speed or RF and microwave applications. Dependable and effective products rely greatly on what electronics do.

Rigid-Flex PCBs: Hybrid Structure with High Functionality

Rigid-Flex PCBs take attributes from both stiff and flexible PCBs and merge them into one board. As a result, rigid and flexible boards no longer need connectors and cables, letting us make assemblies that are lighter and more space-saving. You can find these boards in smartphones, medical devices used on patients, military systems and aerospace devices. They are suited for use in places that require resistance to vibration and bending due to machines. In manufacturing, various layers are made and bonded together using very accurate methods. Therefore, it is only experienced manufacturing companies that can keep products of constant quality and performance.

Key Advantages of Rigid-Flex PCB Manufacturers

Important benefits of using well-known Rigid-flex PCB Manufacturers are their excellent design aid and advanced methodologies. They depend on laser direct imaging for precise work and optical inspection that finds problems in the early stage. Tests using temperature fluctuation and electrical overload guarantee that the product will function in any extreme condition. Manufacturers typically boost efficiency by assisting with design changes that lower the number of components and simplify assembly. In addition, they guarantee that flexible circuit boards meet all IPC standards for quality. Because they are involved in developing products and moving them into mass production, they help make the process more efficient.

Taconic PCBs: High-Frequency Performance Excellence

Taconic PCB Manufacturers are produced from proprietary PTFE-based laminates designed by Taconic with low dielectric loss and thermal stability. These boards are the preferred option for RF, microwave, and high-speed digital designs. They are most prevalent in satellite communications, radar systems, 5G base stations, and aerospace communication modules. Taconic laminates have low signal attenuation and superior dimensional stability. They exhibit moisture resistance as well as heat tolerance, which makes them dependable in extreme working environments. Production using these laminates demands proficiency in drilling, plating, and multilayer bonding because of their special properties.

What to Expect from a Taconic PCB Manufacturers

The best Taconic PCB Manufacturers must possess extensive experience in working with high-frequency laminate material. It involves strict impedance control, surface preparation, and low-loss transmission line engineering. Cleanroom facilities, specially designed PTFE-compatible equipment, and precise lamination procedures are necessary for high-quality output. The producers may perform RF testing and thermal profiling to ensure circuit integrity. They also guide customers on stack-up selection as well as PCB layout according to end-use frequency requirements. By maintaining compliance with IPC and MIL-spec specifications, these companies ensure the critical applications' performance and safety.

Comparing Rigid-Flex and Taconic PCBs

Although both are sophisticated PCBs, Rigid-Flex and Taconic PCBs are for different technical applications. Rigid-Flex is prized for mechanical flexibility, whereas Taconic leads for signal transmission at high speeds. Rigid-Flex boards simplify systems and minimize space utilization in cramped enclosures, while Taconic boards maintain signal purity in communication networks. The components and manufacturing methods are quite different, as are the final-use applications. The two are chosen based on physical space, frequency range, and exposure to the environment. Designers will often talk to both varieties of manufacturers to match their circuit requirements with the appropriate solution.

Conclusion

As innovation speeds up in electronics, the need for Rigid-flex PCB Manufacturers and Taconic PCBs keeps increasing. Such technologies facilitate the development of lighter, faster, and more efficient devices across industries. With increasingly sophisticated design challenges, collaborating with an experienced manufacturer is crucial. BS Interconn Hong Kong Co., LIMITED differentiates itself by providing quality-oriented, customer-centric PCB manufacturing services. Whether you're creating a next-generation medical wearable or a state-of-the-art RF device, selecting a reliable Rigid-Flex or Taconic PCB producer guarantees that your product will outperform and outlast the competition.

#Rigid-flex PCB Manufacturers#Taconic PCB Manufacturers#flexible circuit boards#high-frequency PCB#RF PCB solutions#microwave PCBs#PTFE laminates#hybrid PCB design#aerospace PCB#medical device PCBs#5G PCB manufacturer#signal integrity PCB#low dielectric PCB#high-speed PCB#multilayer PCB assembly#IPC compliant PCBs#MIL-spec PCBs#advanced PCB manufacturing#Taconic laminate PCB#Rigid-Flex technology

1 note

·

View note

Text

How to Design Efficient and Reliable Rigid-Flex Circuit Boards?

Rigid-Flex Circuit Boards combine the best highlights of rigid and flexible PCBs into a single bound together structure, advertising creators effective focal points for complex and space-constrained applications. These hybrid Boards are composed of rigid layers that give mechanical soundness and flexible areas that permit energetic development or collapsing. To accomplish both proficiency and unwavering quality in rigid-flex circuit board plan, engineers must take after a set of best hones that consider mechanical, electrical, and fabricating aspects.

Understand the Application Requirements

Before starting the format, it's basic to get it the particular needs of the application. Rigid Flex Circuit Boards are frequently utilized in aviation, military, therapeutic gadgets, and progressed shopper hardware — all situations that request tall unwavering quality. Architects must consider space limitations, mechanical stretch, electrical execution, and natural introduction to guarantee that the board meets execution and solidness expectations.

Use Legitimate Layer Stack-Up Planning

A well-structured layer stack-up is key to accomplishing flag keenness and mechanical quality. In rigid-flex circuit Boards, the move between the unbending and flexible areas must be smooth and free of push concentration. Legitimate stack-up arranging incorporates deciding the number of layers, copper weight, dielectric materials, and the twist span of flexible locales. Dodging as well numerous layers in the flex range makes a difference avoid delamination and splitting over time.

Maintain Controlled Twist Areas

One of the most common focuses of disappointment in rigid-flex plans is the twist zone. To guarantee long-term unwavering quality, the twist span ought to be at slightest 10 times the thickness of the flex fabric. Twists ought to never happen at the interface between unbending and flexible segments. Moreover, dodge putting vias, cushions, or sharp points in the twist region to decrease mechanical stretch. Utilize bended follows and stunned vias to upgrade adaptability and decrease the hazard of cracking.

Optimize Follow Routing

Efficient directing is fundamental for flag keenness and control dissemination. In rigid-flex circuit Boards, follows ought to be directed opposite to the twist pivot in flexible areas. Parallel follows in a twist range are more likely to break over time. Keep up steady follow widths and dividing, and maintain a strategic distance from 90-degree points in steering, as they can cause flag reflections and push focuses. Controlled impedance plan is moreover imperative for high-speed flag transmission.

Design for Manufacturability (DFM)

Working closely with your PCB manufacturer amid the plan stage can avoid expensive modifications. Utilize standard materials and take after industry rules like IPC-2223 for rigid-flex board plan. Indicate clear mechanical diagrams, resistances, and stack-up subtle elements in the manufacture drawings. Too, incorporate fiducials and test focuses to help in get together and review processes.

Include Intensive Testing and Validation

To guarantee the long-term unwavering quality of rigid-flex circuit Boards, intensive testing is basic. This may incorporate warm cycling, vibration tests, and electrical testing beneath stack. Early approval makes a difference capture plan blemishes and guarantees the board can perform in real-world conditions.

Conclusion

Designing effective and dependable rigid-flex circuit Boards requires a mindful approach that equalizations electrical execution with mechanical judgment. By carefully arranging the layer stack-up, overseeing twist ranges, optimizing follow steering, and centring on manufacturability, engineers can make progressed gadgets that are both compact and tough. With legitimate testing and adherence to plan benchmarks, rigid-flex Boards gotten to be a trusted arrangement for today’s most requesting electronic applications.

0 notes

Text

Um guia completo de PCB flexível de dupla face

Este artigo apresentará de forma abrangente a definição de PCB flexível de dupla face e o empilhamento, as vantagens, os materiais, as aplicações de PCB flexível de duas camadas e a diferença entre PCB flexível de um lado, PCB flexível de dois lados e PCB flexível de várias camadas.

O que é uma PCB flexível de dupla face?

Uma PCB flexível é um tipo de placa de circuito impresso, também chamada de circuito impresso flexível, ou FPC. O FPC é feito de material adesivo ou não adesivo. O cobre usado no processo de produção de FPC é dividido em cobre eletrolítico e cobre laminado, e o cobre laminado antiaderente é mais flexível e dobrável.

Uma PCB flexível de camada dupla consiste em duas camadas condutoras com uma camada isolante entre elas. Uma PCB flexível de camada dupla é um produto ideal que requer densidade de circuito.

Material de PCB flexível de dupla face

Há muitas opções diferentes de materiais para a fabricação de PCB flexível de dupla face, como PI, PET, PEN, LCP, etc. De acordo com os diferentes requisitos de aplicação, podemos ajudá-lo a pesquisar quais opções são mais adequadas para você. Também fornecemos cobre em diferentes espessuras para atender a todas as suas expectativas e necessidades.

Você também pode escolher poliimida, FR-4, chapa de aço, chapa de alumínio, etc., para o reforço para PCB flexível de dupla face.

Quais são as aplicações da PCB flexível de dupla face?

A PCB flexível de dupla face tem sido amplamente utilizada devido ao seu excelente desempenho, como

Comunicações

Eletrônicos de consumo

Automotivo

Medicina

Industrial

Aeroespacial

Militar

Transporte, etc.

PCB flexível de um lado versus PCB flexível de dois lados. PCB flexível de dupla face versus PCB flexível multicamada.

O Flex PCB de um lado ou o Flex PCB de camada única instala o original em um lado da placa e há um padrão condutor no outro. Uma PCB flexível de camada única tem apenas uma camada de material condutor. A PCB flexível de camada única tem as vantagens de custo mais baixo, design mais fácil, produção, produção em massa e tempo de entrega.

A PCB flexível de dupla face tem mais camadas do que a PCB flexível de camada única, mas menos do que a PCB flexível de várias camadas; a PCB flexível de camada dupla tem uma camada de metal condutor em ambos os lados, o que aumenta a densidade da fiação por unidade de área e é mais adequada para roteamento.

Os circuitos e componentes em ambos os lados da PCB flexível de dupla face podem ser conectados eletricamente por meio de montagem através de orifícios e montagem em superfície.

Três ou mais PCBs flexíveis de dupla face são laminadas em uma PCB flexível de múltiplas camadas. Cada camada de substrato em uma PCB multicamada tem metal condutor em ambos os lados. Esses substratos são colados com um adesivo exclusivo, mas um material isolante separa cada substrato.

A conexão elétrica entre cada camada da PCB flexível multicamada é obtida por meio de orifícios, orifícios cegos ou orifícios enterrados.

As vantagens da PCB flexível multicamada são:

Mais adequada para projetos complexos;

Maior qualidade e confiabilidade;

A densidade dos circuitos de PCB flexível multicamadas é maior, com maior capacidade e velocidade de operação, e o desempenho geral do produto é aprimorado;

Maior durabilidade. Quanto maior o número de camadas da placa de circuito, maior a espessura, portanto, mais durável do que a PCB flexível de um lado ou a PCB flexível de dois lados;

Tamanho menor e peso mais leve: A placa de circuito impresso flexível multicamada apresenta um design de circuito mais compacto, que pode comprimir ainda mais o tamanho e o volume da placa de circuito, reduzindo assim o peso.

Capacidades de fabricação de PCB flexível

Hitech Circuits oferece serviços de fabricação de protótipos de PCB flexível de giro rápido: podemos entregar seu pedido de fabricação de PCB flexível em até 24 horas.

Se você estiver procurando por uma PCB flexível de um lado, um circuito flexível de dois lados ou um fabricante e parceiro de PCB flexível multicamada complexa, todos nós seremos sua escolha certa.

Há também muitas opções para o processo de tratamento de superfície de PCB flexível de dupla face:

Ouro de imersão

Estanho de imersão

Prata de imersão

ENEPIG

OSP

Nós Hitech Circuits estamos sempre dedicados a fornecer preços competitivos, boa qualidade e prazo de entrega rápido para nossos clientes. Se você tiver alguma necessidade de PCI, não hesite em contactar-me.

0 notes

Text

Cutting-Edge Rigid Flex PCB Solutions for Modern Electronics

ASC provides advanced rigid flex PCB solutions, blending rigid and flexible circuit technologies for enhanced durability and performance. Ideal for complex applications in industries such as aerospace, medical, and consumer electronics, our rigid flex PCBs offer exceptional reliability, compact design, and cost-efficiency. Trust ASC for high-quality, custom rigid flex PCBs tailored to meet the specific demands of your electronic projects.

#rigid flex pcb#rigid flex pcbs#flex circuit manufacturer#flex pcb manufacturer#flex circuit board manufacturers#flexible pcb manufacturers#flex rigid pcb manufacturer#rigid flex pcb manufacturers#rigid flex pcb supplier#fast turn rigid flex pcb#rigid flex pcb manufacturer#flexible printed circuit board manufacturers#flex rigid pcb

0 notes

Text

Important Ohm’s Law Problems for Competitive Exams

A circuit has a resistance of 10 Ω and a current of 2 A. What is the voltage across the circuit?

V= I × R = 2A × 10Ω = 20V

A 24V battery is connected to a resistor of 6 Ω. Find the current flowing through the circuit.

youtube

GET MORE FREE SOLUTION 👈.

#digital learning#online education#online courses#online tutoring#online learning#hesi a2 test#hesi a2 test prep#hesi online classes#electronics manufacturing#electronics industry#electronics components#electronics store#electronics design#vlsi design#electronics#materials#connectivity#computing#ohm's law#flexible circuit board#flex circuit pcb#circuit breaker#electric switch#Youtube

0 notes

Text

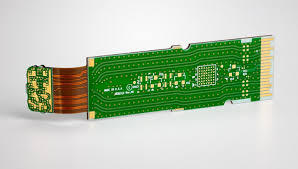

Polyimide Flex Circuits

Enhance performance and durability with polyimide flex circuits, designed for high-temperature resistance and superior flexibility. Explore the circuit image showcasing space-saving design and high reliability for demanding applications.

0 notes

Text

https://mydvc.in/jkenterprises

We are offering electronic all type charger /Adapter Refresh PCB board our client

REGARD

J K Enterprises

8700096979

0 notes

Text

you flirt back for the first time:

sylus

you say something like, “you keep looking at me like that, sylus… you’re gonna have to do something about it,” with a shy little smile.

he completely malfunctions. his eyes grow wide, he swallows hard, his heart visibly skipping a beat.

sylus stares at you like he’s trying to determine if you’re possessed. then, quietly, with his voice a little huskier than usual, “that’s new.”

he recovers fast, though. steps closer and gently brushes your hair behind your ear. “is this your way of telling me you want me to kiss you? because i’m listening.”

bonus:

… sylus.exe has crashed.

his lips part and his eyes darken. he stares for a moment, like he’s trying to decide between kissing you soft or ruining your life. eventually, he just breathes, “say that again. i dare you.”

zayne

you casually murmur, “if you’re gonna keep biting your lip like that, at least let me do it for you,” while scrolling your phone.

dead silent. zayne stops breathing. his jaw flexes, his pupils dilate.

“…excuse me?” his voice drops an octave and he looks at you like you just kicked open the doors to a side of you he definitely wants to explore.

he walks over real slow, tilts your chin up and says, “say that again. no, no—i need it word for word, baby. because if i heard what i think i heard…”

bonus:

zayne chokes on air. his head snaps around so fast, his whole brain reboots. “wait. what? you never—?!” he chuckles lowly. “okay, okay. who are you and what did you do with my sweet, shy angel?”

caleb

you’re teasing him during one of his gym sessions and say, “keep showing off like that and i might have to reward you. privately.”

caleb drops the dumbbell. literal pause. he stares at you with wide eyes, mouth slightly open like a golden retriever who just got called a bad boy.

“wait. wait. wait, back up. say that again?” he starts laughing, but it’s nervous, like he doesn’t know how to process it.

he immediately gets 10x more flirty and tries to re-assert dominance with a grin. “okay, but only if you’re the reward too.”

bonus:

his jaw clenches, breath catches and you can feel the tension shift. like something in him just snapped. he leans back, clears his throat and gives a tiny smirk. “you’re playing with fire, and i’m not the type to pull away when i get burned.”

xavier

you’re both deep into a high-risk deepspace operation. he’s focused, assessing potential threats, guns calibrated, his hud flickering with tactical readouts. you, cool as ever, lean in behind him and murmur through the comms. “you look sexy when you’re in control like this. makes me want to follow your every order… after hours.”

immediate system crash. xavier stops walking, literally halts mid-movement in zero gravity like his whole code just corrupted.

“…repeat that,” he says into the comm, voice a little rough, a lot lower than usual. he doesn’t turn to face you. he’s trying to regain composure while actively calculating threat levels.

he doesn’t miss a beat on the mission afterward, but the tight grip on his weapon and the way he refuses to look at you say everything: you broke him.

bonus:

he stammers, short-circuits, then just covers his face and laughs into his hands quietly. “okay. that’s unfair. you can’t just… out-flirt me like that.”

rafayel

you’re watching him get dressed and casually comment, “if you’re going to tease me with that shirt unbuttoned, the least you can do is let me take it off for you.”

rafayel blinks, twice. “what did you just say?” not offended, not teasing. he’s actually stunned.

a slow, devilish smile starts to curl on his lips as he puts down whatever he was holding. he steps toward you and murmurs, “are you seducing me? because i have to warn you… i’m very easy to seduce.”

bonus:

rafayel freezes. for one glorious second there’s silence. then he smiles a bit mischievously. “oh? okay, i see you. someone’s been hiding from me the whole time.” he never lets it go, but he wants more of your flirty side. “you gonna flirt like that again, or was i just blessed once?”

author’s note: sometimes i can’t decide in which direction i want to go with a headcanon, so, i went with a little bonus 😊

#lads x reader#lads x you#love and deepspace#love and deepspace x reader#lads sylus#sylus#sylus x non mc#sylus x reader#sylus x you#lads Caleb#caleb x non!mc reader#caleb x you#caleb x reader#lads zayne#zayne x you#zayne x reader#lads xavier#xavier x non mc#xavier x you#xavier x reader#lads rafayel#rafayel x you#rafayel x reader#lads x non!mc reader#lads

6K notes

·

View notes

Text

Rigid Circuits: An Overview

Rigid circuits are a fundamental component of modern electronic devices, widely used across industries such as telecommunications, consumer electronics, automotive, and aerospace. These circuits are made using rigid materials as their base substrate, providing mechanical stability and durability. This article explores the key characteristics, advantages, and applications of rigid circuits, providing a comprehensive understanding of their significance in electronics manufacturing.

What are Rigid Circuits? Rigid circuits are printed circuit boards (PCBs) fabricated on solid and inflexible substrates. Unlike flexible or hybrid PCBs, rigid circuits maintain their shape and cannot be bent or flexed. Key features of rigid circuits include:

Electrical Insulation: Excellent dielectric properties ensure effective insulation between conductive layers.

Mechanical Strength: High tensile strength and durability, suitable for multilayer and high-density designs.

Thermal Resistance: Can withstand elevated temperatures, making them suitable for heat-intensive applications.

Longevity: Designed for long-term reliability in various environments.

Advantages of Rigid Circuits

Structural Stability: Rigid circuits provide a robust framework that protects components from physical stress and mechanical damage.

Cost-Effectiveness: The manufacturing processes for rigid PCBs are well-established, allowing for efficient mass production at a reasonable cost.

Versatility: Compatible with a variety of designs, including single-sided, double-sided, and multilayer configurations.

Enhanced Performance: Rigid circuits offer stable performance in high-speed and high-power applications.

Applications of Rigid Circuits

Consumer Electronics: Used in smartphones, tablets, laptops, and other devices for compact and efficient designs.

Telecommunications: Found in routers, network equipment, and signal transmission systems due to their reliable electrical properties.

Automotive: Essential for engine control units, infotainment systems, and advanced driver-assistance systems (ADAS).

Aerospace and Defense: Trusted for avionics, radar systems, and other critical equipment due to their durability and reliability.

Industrial Equipment: Incorporated in control panels, robotics, and precision machinery for high-performance operations.

Limitations of Rigid Circuits While rigid circuits are versatile and reliable, they have certain limitations:

Lack of Flexibility: Rigid circuits cannot be bent or shaped to fit unconventional enclosures, limiting their use in some applications.

Weight: Heavier compared to flexible PCBs, which may be a disadvantage in weight-sensitive designs.

Thermal Challenges: Although thermally resistant, advanced heat dissipation requirements may require additional cooling solutions or alternative materials.

Conclusion Rigid circuits are a cornerstone of the electronics industry, offering durability, reliability, and high performance across a range of applications. Their robust design and adaptability make them a preferred choice for countless industries. However, as technology progresses, alternative circuit types like flexible and rigid-flex PCBs may complement or replace traditional rigid circuits in specific use cases.

0 notes