#FlexographicPrinting

Explore tagged Tumblr posts

Text

Which Paper Bag-Making Machine Is Best for Kraft Paper Bags?

Kraft paper bags have become a symbol of eco-friendliness, strength, and sustainability. Whether it's for groceries, apparel, food delivery, or retail packaging, kraft paper bags are in high demand due to their durability and biodegradable nature. As the global push toward banning single-use plastics continues, starting a kraft paper bag manufacturing unit is not just a sustainable choice—it’s a smart business move.

But one of the most important questions we’re often asked at Prakash Machineries Pvt. Ltd. is “Which paper bag-making machine is best for kraft paper bags?”

In this article, we’ll walk you through the different types of kraft paper bag machines, what to look for, and how to choose the perfect model based on your business needs.

📦 Why Choose Kraft Paper for Bags?

Before diving into machines, let’s understand why kraft paper is a top choice:

High strength and tear resistance

Biodegradable and recyclable

Suitable for food-grade and non-food applications

Available in brown (natural) and white options

Compatible with printing and branding

Its versatility makes kraft paper suitable for grocery bags, pharmacy bags, takeaway bags, fashion shopping bags, and more.

🏭 Types of Kraft Paper Bags

Kraft paper can be used to produce various bag types:

V-Bottom Bags

Simple and lightweight

Suitable for groceries, medicines, and general packaging

High-speed production

Square Bottom Bags

Flat base, premium look

Ideal for clothing, bakery, and takeaway packaging

Can be enhanced with handles

Handle Bags (Flat or Twisted)

Used for retail, food delivery, and luxury packaging

Convenient for carrying heavy items

Requires handle pasting unit (inline or offline)

The type of bag you want to produce determines the best machine for your needs.

🏆 Best Paper Bag-Making Machines for Kraft Paper

At Prakash Machineries Pvt. Ltd., we manufacture machines optimized specifically for kraft paper rolls. Here are the top choices:

✅ 1. V-Bottom Paper Bag Machine

Ideal For: Groceries, pharmacies, sweets, and lightweight items Material: Kraft paper (brown or white), recycled paper Speed: 60–400 bags per minute Bag Size Range: Small to medium Features:

High-speed roll feeding

PLC-controlled for accuracy

Adjustable size settings

Why it’s great for kraft paper: Kraft paper feeds smoothly and can be processed at high speed with precision-cutting rollers. Perfect for businesses producing high volumes at low cost.

✅ 2. Square Bottom Paper Bag Machine

Ideal For: Clothing stores, food delivery, shoe boxes, etc. Material: Kraft paper, laminated paper, coated or printed sheets Speed: 100–200 bags per minute Bag Size Range: Medium to large Features:

Flat-bottom folding mechanism

Precision gluing system

Optional inline printing & handle pasting

Why it’s great for kraft paper: Kraft paper provides strong creases and folds, resulting in a rigid and elegant bag shape. These machines are best suited for premium packaging needs.

✅ 3. Inline Handle Bag-Making Machine

Ideal For: Premium retail packaging, branded shopping bags Handle Types: Flat paper or twisted paper handles Speed: 60–120 bags per minute Bag Type: Square bottom kraft bags with handles Features:

Fully automated process, including handle making

Servo control and glue pasting unit

Touchscreen interface

Why it’s great for kraft paper: Kraft paper bags with handles are in high demand. This machine adds convenience and value to your product with minimal labor.

✅ 4. Handle Pasting Machine (Offline)

Ideal For: Attaching handles to pre-made kraft paper bags Speed: 30–60 bags per minute Bag Type: Square bottom kraft bags Handle Types: Flat or twisted Use Case: For businesses that want to start small and upgrade later

Why it’s great for kraft paper: Offline handle pasting allows flexibility. Kraft paper bags are strong enough to support glued handles, making them perfect for multi-use shopping bags.

💰 Kraft Paper Bag Business Profitability

With kraft paper’s rising popularity, businesses can earn attractive margins:

Production Cost (medium bag): ₹--- – ₹---

Selling Price (with handle): ₹---- – ₹----

Daily Output (100 BPM × 8 hours): ---- bags

Monthly Profit Potential: ₹-–- lakhs (depending on size and branding)

A fully automatic kraft paper bag line can pay for itself in 6–12 months with consistent orders.

🔧 Why Choose Prakash Machineries Pvt. Ltd.?

🏭 30+ years of experience in machinery manufacturing

⚙️ Heavy-duty machines built for kraft paper handling

🛠️ In-house production of rollers, cylinders, and electronics

🌍 500+ installations across India and 30+ countries

📦 Spare parts and training support available nationwide

We build machines that are easy to operate, maintain, and scale as your business grows.

Final Thoughts

Kraft paper bags are not only strong and sustainable but also in high demand. Choosing the right paper bag-making machine—whether V-bottom, square bottom, or handle-attached—is essential for building a reliable and profitable packaging business.

If you’re planning to start or upgrade your kraft paper bag production, Prakash Machineries Pvt. Ltd. has the right machine, training, and support to ensure your success.

📞 Ready to invest in a kraft paper bag machine? 👉 Visit Prakash Machineries Pvt Ltd or 📩 Request a Free Quote and let our experts guide you to the perfect machine for your business.

#paper bag manufacturer#manufacturer#square bottom#v bottom#flexo#paper bag#machines#bags#paper#flexographicprinting#alien stage#cake#baking#chris sturniolo#breakfast#cooking#coa tinta flexo#delicious#chocolate#dan and phil#critical role

0 notes

Text

Transform your surfaces with Tridev Resins’ Water-Based Acrylic Emulsions! Built for durability, washability, and resistance to fungi and algae, our emulsions keep your paints fresh and long-lasting. Perfect for varnishes and paints that face the test of time.

For more details, visit- https://www.tridevresins.com/products/water-base-acrylic-emulsion

#Tridevresinsindia#waterbaseacrylic#highsolidcontent#Washability#printing#coatbridge#flexographic#printingindustry#flexoprinting#flexographicprinting

0 notes

Text

Commercial Printing Market Insights: Detailed Overview of Market Size, Share, Projected Growth

The global commercial printing market size is estimated to reach USD 598.06 billion by 2030, registering a CAGR of 3.2% from 2025 to 2030, according to a new report by Grand View Research, Inc. The rising demand for commercial printing for producing promotional material such as brochures, flyers, newspaper inserts, and pamphlets, among others, is expected to be one of the driving factors for the target market growth. The demand for commercial printing spans several industries, including manufacturing, advertising, food and beverage, retail, and healthcare.

The growing advertising needs of businesses contribute significantly to the demand for commercial printing of advertising materials. Commercial printing primarily involves printing on different types of paper and canvas for packaging, publishing, or advertising needs. Typesetting, bookbinding, fulfillment services, designing services, and finishing, which include folding, cutting, and binding, are some of the ancillary services provided by the market players, along with printing services. The fulfillment services include packaging, storage, and delivery of the printed material services.

The growth of online shopping and the demand for personalized experiences have boosted the demand for commercial printing from the packaging sector. Packaging is considered one of the most important marketing tools, and hence businesses are utilizing packaging to display products’ best features. Also, the packaging is being used as a tool to create an unboxing experience for the users.

As a result, many packaging companies are investing in high-technology commercial printing solutions. For instance, in October 2022, Comexi, a flexible packaging service provider, announced the launch of Digiflex, a machine designed for flexible packaging and label converters to print variable data such as QR codes, data matrix variable codes, barcodes, alphanumeric text, and other numbering & marking applications.

The COVID-19 pandemic severely impacted the commercial printing market. The pandemic led to reduced demand for commercial printing as businesses, and their operations were halted. Furthermore, the outbreak disrupted the supply chain and led to an increase in costs of raw materials and labor, and also severely impacted the distribution, which in turn impacted the growth of the target market negatively.

The advent of digital media is restricting the growth of the target market as it continues to replace print media with digital media. Users are adopting the digital form of books and magazines instead of the printed medium. Also, businesses are utilizing digital media for advertising purposes. Despite the impact of digitization, the print industry is, however, pivoting its business models by taking into account the changing needs, trends, and new realities of the market.

For More Details or Sample Copy please visit link @: Commercial Printing Market Report

Commercial Painting Market Report Highlights

The digital printing segment is expected to grow at the fastest CAGR of 4.4% over the forecast period. The growth is attributed to the rapid adoption of inkjet and laser printing solutions across the paper and packaging printing sector due to the cost-efficient and flexible nature of the technology.

The packaging segment accounted for the largest revenue share of over 54.2% in 2024. The packaging segment includes printing on labels, tags, and flexible packaging.

North America held the second-largest share in the commercial printing market in 2024 and accounted for a revenue share of over 33.2% of the global revenue.

Asia Pacific is expected to grow at the highest CAGR of 3.7% over the forecast period, and it was also the dominant region in the global market in 2024. The regional growth is attributed primarily to advancements in the print industry, such as digital technologies, particularly in China and India.

#CommercialPrinting#PrintingIndustry#PrintSolutions#OffsetPrinting#DigitalPrinting#FlexographicPrinting#GravurePrinting#ScreenPrinting

0 notes

Text

The Ultimate Guide to Doctor Blades: Micron Carbon Steel, Stainless Steel, Blue Steel, Golden Steel, and Polymer/UV Blades

In the world of professional printing, the quality of your tools directly impacts the final product. Among the most critical tools in the printing process are doctor blades. These blades control the amount of ink applied to a printing surface, ensuring that each print is sharp, clean, and consistent. But not all doctor blades are created equal. In this guide, we’ll explore the unique characteristics and benefits of various types of doctor blades, including Micron Carbon Steel, Stainless Steel, Blue Steel, Golden Steel, and Polymer/UV blades.

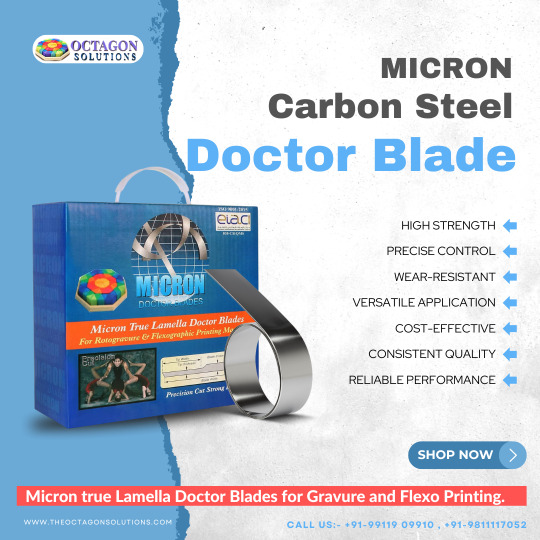

1. Micron Carbon Steel Doctor Blade

Strength and Durability Micron Carbon Steel Doctor Blades are known for their exceptional strength and durability. These blades are made from high-quality carbon steel, which provides a perfect balance of flexibility and toughness. This makes them ideal for high-pressure printing environments where consistent performance is crucial. The micron-level precision ensures that the blade delivers accurate and reliable ink metering, resulting in crisp and detailed prints every time.

Best Use Cases Micron Carbon Steel blades are particularly well-suited for flexographic and gravure printing, where maintaining sharpness and precision is essential for high-quality output.

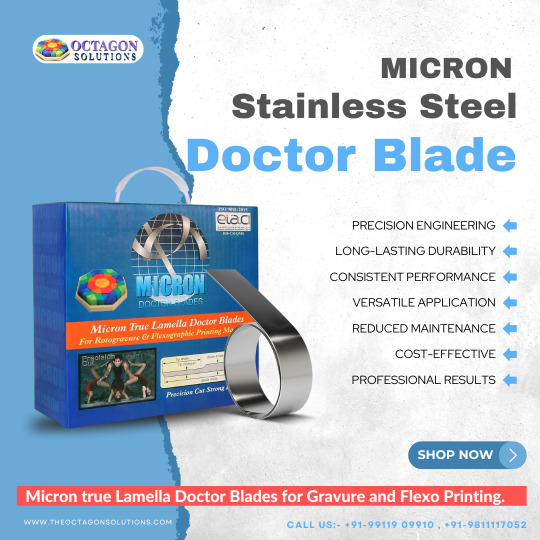

2. Stainless Steel Doctor Blade

Corrosion Resistance and Longevity Stainless Steel Doctor Blades are prized for their resistance to corrosion and wear, making them an excellent choice for environments where moisture or aggressive inks are present. The stainless steel material ensures that the blade remains sharp and effective over long periods, reducing the frequency of replacements and minimizing downtime.

Best Use Cases These blades are ideal for applications where longevity and consistent performance are critical, such as in packaging, label printing, and other industrial printing processes.

3. Blue Steel Doctor Blade

Versatility and Precision Blue Steel Doctor Blades are a popular choice for their versatility and precision. The unique composition of blue steel allows for a balance between flexibility and hardness, making it suitable for a wide range of printing applications. These blades are designed to provide smooth ink transfer and minimize streaking, ensuring high-quality results.

Best Use Cases Blue Steel blades are well-suited for printers who require a versatile tool that can adapt to different inks and substrates, particularly in flexographic and gravure printing.

4. Golden Steel Doctor Blade

Premium Quality and Enhanced Performance Golden Steel Doctor Blades represent the premium segment of doctor blades. These blades are engineered for superior performance, offering enhanced wear resistance and longer service life. The golden steel material provides a unique combination of hardness and flexibility, ensuring that the blade delivers precise and consistent results even in the most demanding printing conditions.

Best Use Cases Golden Steel blades are ideal for high-end printing applications where quality and consistency are non-negotiable, such as in fine art reproduction, specialty packaging, and other premium print jobs.

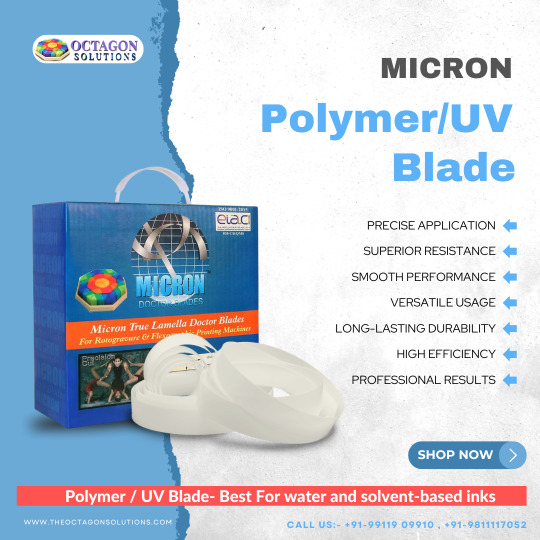

5. Polymer/UV Doctor Blade

Specialized for UV and Polymer Inks Polymer/UV Doctor Blades are specially designed for use with UV-curable and polymer-based inks. These blades offer exceptional resistance to the chemical properties of these inks, ensuring that they maintain their integrity and performance over time. The polymer construction also allows for greater flexibility, which helps in achieving smooth and even ink application.

Best Use Cases These blades are particularly effective in applications where UV or polymer inks are used, such as in screen printing, digital printing, and other specialized printing processes.

For More info Visit here:- Octagon Solutions

Conclusion

Choosing the right doctor blade for your printing needs can make a significant difference in the quality and efficiency of your work. Whether you need the strength and durability of Micron Carbon Steel, the corrosion resistance of Stainless Steel, the versatility of Blue Steel, the premium quality of Golden Steel, or the specialized performance of Polymer/UV blades, there’s a doctor blade designed to meet your specific requirements. By understanding the unique properties and best use cases of each type of blade, you can make an informed decision that will enhance your printing process and deliver superior results.

#PrintingQuality#DoctorBlade#MicronBlade#CarbonSteelBlade#StainlessSteelBlade#BlueSteelBlade#GoldenSteelBlade#PolymerBlade#UVBlade#PrecisionPrinting#PrintIndustry#ProfessionalPrinting#FlexographicPrinting#GravurePrinting#InkControl#PrintingSolutions#HighQualityPrints#PrintingTools#IndustrialPrinting#PrintShopTools#PrintTechnologies#PrintIndustryPros#GraphicPrinting#DurableBlades#PrintingInnovation#AdvancedPrinting

0 notes

Text

Explore The Magic Of Foil Stamping in The Printing Industry!

Have you ever thought about how some packaging gets its golden shine? Foil stamping might be the answer you have been looking for.

If you are looking to give your custom boxes a classy and perfect look that others are missing, then it is the right time to consider foil stamping & embossing techniques. Thisis also known as hot foil stamping or foil printing. It is an amazing printing method where a desired visual finish is attained by applying foil to another material.

This technique also applies heat, foil, metal, and pressure just like embossing or debossing in order to create unique printed designs.

Applications of Foil Stamping

Labels

Product packaging

Holiday cards

Stationery

Pocket folders

Postcards

Certificates

Seals

This modern hot stamping technique was first comprehended in the late 19th century. These days, it's used to enhance the perceived value of goods and add visual intrigue.

Process of Foil Stamping

A foil is a thin film layered with the colors that are applied to a product with the help of the foil stamping process. The pigment is applied to a clear film, which serves as a vehicle for the color to be transferred to the product. Pigmented sediments make up a second layer of the foil, and a heat-activated adhesive adheres the sediments to the product in a third layer. You can also apply foil stamping to all kinds of paper stocks, like embossing and Spot UV.

Types of Foil Stamping

There are different hot stamping techniques that give you ultimate results. You can choose any one according to your substrate and the type of finish you want.

Flat Foil Stamping: It is a very simple and economical process where a metal stamp transfers the foil onto the substrate. It produces a foil pattern that appears to rise somewhat above the surface.

Vertical Foil Stamping: This effective technique is highly used specifically for printing foil designs on flat substrates and cylindrical shaped areas.

Sculpted Foil Stamping: This technique uses brass dies to create a high-quality image that offers a clearly defined and carved look.

Peripheral Foil Stamping: This is the process where foil heat transfers are applied to the outer layer of the product throughout the whole perimeter.

Benefits of Foil Stamping

Here are some incredible benefits that you can enjoy after foil stamping. Let’s take a glance:

It helps to make your product packaging stand out from the competition.

The different colored foil adds an elegant touch of brilliance and beauty to any package to give it a luxurious style.

If you combine it with other effects like raised or embossed designs, it can take your packaging to a whole new level of sophistication.

It is highly known for its versatile nature. It is not only ideal for metallic lettering, but it can be used on different types of corrugated boxes and carton boxes.

Final Words:

If you love the attraction and exceptionality of foil stamping and are interested in using this effective process to add enhancement to your packaging, contact PlateCrafters today. We are one of the best flexographic printing companies andhave years of experience and knowledge in creating a wide variety of packaging products to ensure that your packaging captures your brand, your message, and so much more.

#FoilStamping#Embossing#FlexographicPrinting#PrintingTech#PrintDesign#FoilPrinting#EmbossedDesigns#PrintSolutions#PrintingServices#CustomPrinting#PrintIndustry#FoilEmbossing#PrintInnovation#PrintingExperts

0 notes

Text

Explore a Wide Range of Printing Services at Sec-Print in Ghana

Are you in search of top-notch printing services in Ghana? Look no further than Sec-Print! We offer a comprehensive array of printing solutions tailored to meet your diverse needs. From Flexographic Printing to Security Printing, we've got it all covered.

Flexographic Printing in Ghana

Our Flexo Printing services are designed to deliver high-quality and cost-effective results. Whether you need flexible packaging, labels, or other printing products, our Flexographic Printing in Ghana can meet your demands with precision.

Security Printing in Ghana

Security is a top concern for various industries, and our Security Printing services are here to address those concerns. We specialize in producing secure documents and materials that safeguard your valuable information and assets.

Offset Printing in Ghana

When it comes to Offset Printing in Ghana, Sec-Print is a trusted name. We excel in delivering sharp and consistent prints, making it an ideal choice for magazines, brochures, and more.

Digital Printing in Ghana

Our Digital Printing services in Accra, Ghana, offer speed and flexibility without compromising on quality. Whether it's short-run projects or personalized prints, our digital printing services are up to the task.

Explore Printing Services in Ghana

At Sec-Print, we take pride in being one of the leading printing companies in Ghana. Our commitment to excellence and customer satisfaction sets us apart in the industry. Whether you're in Accra or elsewhere in Ghana, you can count on us for all your printing needs.

Don't hesitate to reach out to us at Sec-Print for top-notch printing in Ghana. We're here to bring your printing projects to life with precision and professionalism.

#FlexographicPrinting #SecurityPrinting #OffsetPrinting #DigitalPrinting #PrintingServices #PrintinginGhana #PrintingCompanies #AccraPrinting #SecPrint

#FlexographicPrinting#SecurityPrinting#OffsetPrinting#DigitalPrinting#PrintingServices#PrintinginGhana#PrintingCompanies#AccraPrinting#SecPrint

0 notes

Text

The application of plate mounting tape in flexographic printing is a critical step that contributes to the overall quality of the printing process. This specialized adhesive tape is specifically designed to facilitate the precise alignment and secure attachment of printing plates onto cylinders or sleeves in flexographic printing machines.

Flexographic printing is a widely used high-speed printing method that is particularly popular for producing packaging materials, labels, and various flexible substrates. The plate mounting tape plays an indispensable role in this process by acting as a bonding agent between the printing plate and the cylinder. This secure attachment is vital to maintain accurate registration and to ensure that ink is transferred onto the substrate with utmost precision.

The distinctive characteristics of plate mounting tape are what make it an ideal choice for flexographic printing applications. Typically composed of a foam or film backing coated with a high-strength adhesive on both sides, this tape offers exceptional properties that enhance the printing process. The foam or film layer serves a dual purpose: it provides a cushioning effect and compensates for any potential irregularities present on the surface of the cylinder. This compensatory feature guarantees even contact between the printing plate and the substrate, resulting in consistent and high-quality printing results.

In essence, plate mounting tape is a vital component in the flexographic printing workflow. It ensures that printing plates are securely affixed to cylinders or sleeves, enabling precise registration and the accurate transfer of ink. Its specialized design, encompassing a foam or film backing along with high-strength adhesive properties, is tailored to meet the demands of the flexographic printing process. This tape's ability to accommodate surface irregularities and facilitate uniform contact makes it an indispensable tool in achieving optimal printing outcomes.

#FlexographicPrinting#PlateMountingTape#PrintingTechnology#HighSpeedPrinting#PackagingPrinting#LabelPrinting#PrintingInnovation#PrintQuality#PrintingProcess#PreciseRegistration#InkTransfer#FlexibleSubstrates#PrintIndustry#PrintingMaterials#PrintTechnology#PrintingMachinery#PrintSolutions#PrintExperts#PrintingInk#PrintedLabels#PrintingCylinders#PrintProduction#PrintFinishing#PrintingPress#PrintCraftsmanship#PrintingExcellence#PrintInnovation#PlateAttachment#PrintAccuracy#PrintResults

0 notes

Text

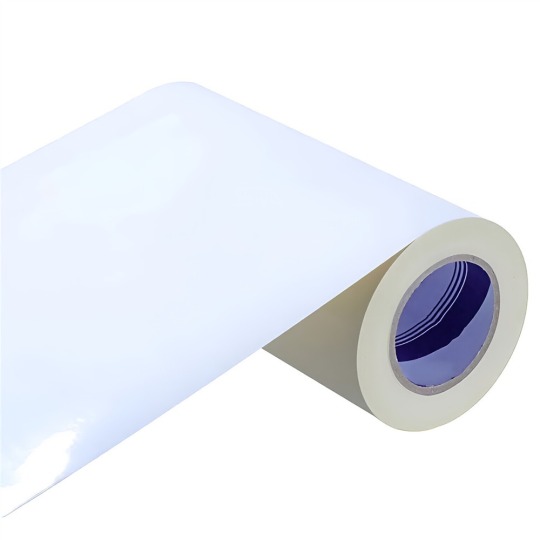

Semi Gloss Paper

Semi Gloss Paper is a versatile coated paper that offers a balance between a matte and glossy finish. This paper is designed to deliver high-quality printing with vibrant colors and sharp details, while minimizing glare. The semi gloss coating enhances color richness and provides a subtle sheen, making it ideal for a wide range of applications.

High-Quality Coating

The semigloss finish provides a refined look with enhanced print clarity, perfectfor both text and images.

Optimal Printability

Compatiblewith various printing methods, including digital, offset, and flexographicprinting, ensuring excellent print results.

Durability

Resistant tofingerprints, smudges, and moderate moisture, making it suitable for bothindoor and light outdoor use.

Versatility

Available in various weights and sizes to suit different printing needs and applications.

0 notes

Text

**Exciting News from WEBTECH!** 📣

We are thrilled to announce that WEBTECH International Machineries has secured yet another order for our latest generation 8 Colors Flexographic Label Printing Machine in 450 mm working width : LABELTECH X2 SERIES from - Nagpur City, Maharashtra! 🎉

This marks our second order from Nagpur in just the last five months, a testament to the growing trust and confidence in our cutting-edge technology and commitment to quality.

We extend our heartfelt gratitude to all our customers and partners for your unwavering support. It is your trust in us that drives our continuous pursuit of excellence. Together, we strive to innovate and deliver even better solutions every day.

Thank you for being a part of our journey!

#WebtechInternational #PrintingMachinery #FlexographicPrinting #LabelPrinting #CustomerSuccess #Innovation #Nagpur #Maharashtra

#labeltechX2 #labelprinting #packaginglabels #flexolabelpress

#label printing#flexo innovation#flexo printing machine#packaging labels#flexo#label#webtech#branding

1 note

·

View note

Photo

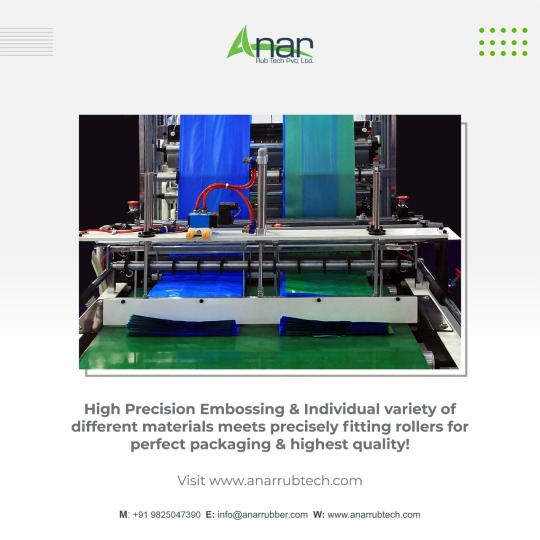

Services that fit in with your tailor-made checklists.

Precise outcomes and superior quality meets you at the final ground at Anar Rub Tech Pvt Ltd

To attain the desired packaging of highest quality, contact us at 9825047390

Or visit www.anarrubtech.com

#flexographicprinting#gravureprinting#flexiblepackagingindustry#wovensacksindustry#papercupindustry#textileindustry#BOPPtapeindustry#packaging#packagingindustry#anarrubtech#rubberroller#industrialrubberroller

5 notes

·

View notes

Photo

Made a polymer plate to mount to a flexographic press with my designs on it! I’m printing a series of elemental cats which I will be handing out at a Comic Con that I will be attending this year 😉 I’ll post details about the Con once it gets closer to March. #character #flexography #flexographic #flexographicprinting #flexographiclabels #design #graphicart #cat #elementals https://www.instagram.com/snuggiepug/p/Bt414Zeg-c2/?utm_source=ig_tumblr_share&igshid=1gvsq0fn97thk

#character#flexography#flexographic#flexographicprinting#flexographiclabels#design#graphicart#cat#elementals

2 notes

·

View notes

Text

Viscosity Cups with and Without Stands

Our Viscosity Cups are essential tools for measuring the viscosity of liquids such as paints, inks, and coatings. Available with or without stands, these cups are made of durable materials to ensure accurate and reliable results. The cups without stands are ideal for handheld use, while the cups with stands provide stability during the viscosity testing process.

The design of our Viscosity Cups allows for easy and precise measurement of flow times, making them suitable for a wide range of applications in various industries. Whether you are a professional painter, printer, or manufacturer, these cups will help you achieve consistent and high-quality results in your work. Invest in our Viscosity Cups today and experience the difference in your workflow and final product quality.

Why choose us? ✅ High-quality materials for durability and longevity ✅ Designed for ease of use and reliable results ✅ Trusted by professionals in labs worldwide

🛒 check now and elevate your viscosity measurement : [Viscosity Cups with and Without Stands]

Contact Us For More Details Call Us:- (+91) - 9911909910, (+91) -83476 46816 Mail Us:- [email protected]

#ViscosityCup#ViscosityMeasurement#QualityControl#IndustrialEquipment#LaboratoryEquipment#Manufacturing#ViscosityControl#RotogravurePrinting#FlexographicPrinting#PrintingIndustry#PrintedPackaging#OffsetPrinting

0 notes

Text

PlatesCrafters: Quality Flexographic Printing Plates

Are you looking for top best flexographic printing plates? Are you in need of flexographic printing plates for your packaging needs? PlatesCrafters is the only place to look! we provide accurate and long-lasting plates that guarantee consistently high-quality prints each and every time. Trust PlatesCrafters for your flexographic printing plate requirements.

#FlexographicPrinting#PrintingPlates#FlexoPlates#Flexography#PackagingPrinting#HighQualityPrints#PrintingIndustry#FlexoTechnology#FlexographicSolutions#PlatesCrafters

0 notes

Text

Exploring Flexographic Printing at Sec-Print: Custom Stickers Made Easy

Are you in search of top-notch flexographic printing services in Ghana? Look no further than Sec-Print, your trusted partner for all your custom sticker printing needs.

Why Choose Flexographic Printing in Ghana?

Flexographic printing is a versatile and cost-effective printing method known for its ability to produce high-quality prints on a variety of materials. Whether you need labels, stickers, or packaging materials, flexographic printing can deliver exceptional results.

Sec-Print: Your Premier Choice for Flexographic Printing in Ghana

At Sec-Print, we take pride in being one of the leading flexographic printing companies in Accra, Ghana. Our state-of-the-art equipment and experienced team ensure that your printing projects are handled with precision and care.

Custom Sticker Printing Made Easy

Custom sticker printing is one of our specialties. Whether you're a business looking to create branded labels or an individual in need of personalized stickers, we've got you covered. Our flexographic label printing services allow you to bring your creative ideas to life.

Why Choose Sec-Print for Flexographic Printing in Ghana?

Quality Assurance: We maintain strict quality control measures to ensure that every print meets your expectations.

Affordable Pricing: Our competitive pricing makes high-quality flexographic printing accessible to businesses of all sizes.

Quick Turnaround: We understand the importance of deadlines. Count on us for fast and reliable service.

Sustainability: We are committed to environmentally friendly printing practices.

Contact Us Today!

Ready to get started with flexographic printing in Ghana? Contact Sec-Print today, and let's bring your printing projects to life with precision, professionalism, and creativity.

Visit Sec-Print

#flexographicprinting #customstickers #labelprinting #Ghanaprinting #Accra #SecPrint

0 notes

Text

The Flexographic Printing Inks technique

Flexographic printing may be done on a variety of materials, including paper, cardboard, and plastic film. Printing is done with low viscosity liquid inks. Water-based inks, solvent inks, and UV-cured inks are some of the options.

Color-intensity variations in flexographic printing inks are mostly caused by changes in ink viscosity. Low viscosity flexographic printing fluids allow for optimal ink flow in the ink unit. On the other hand, if the printing ink has a low viscosity, it transfers poorly onto the printing plate, resulting in prints with insufficient colour intensity and optical density.

Flexography is a popular method for applying basic patterns and regions of colour to a broad range of packaging materials, including paper and plastic containers (including waxed-paper containers), corrugated-cardboard boxes, tape, envelopes, and metal foil.

Read more @ https://cmiinfoistic.blogspot.com/2021/10/everything-to-know-about-flexographic.html

#Specialty and fine chemicals#flexographicprinting#flexographic inks#flexographic printing inks#coherent market insights

0 notes

Link

Title: Anilox Rollers - The Heart Of Flexographic Printing

Description:

Anilox roller is the basis of the anilox rollers for the flexo printing /coating process. It's a measuring roller that accurately delivers liquid ink, varnish, or coating onto a print carrier.

This video explains the importance of Anilox Rollers in the printing Industry.

We, Anar Rub Tech Pvt Ltd, are the leading and eminent manufacturers of Anilox and ceramic Anilox rollers. Our primary idea is to create and manufacture quality materials to fulfill the requirements of our esteemed clients.

Our Anilox rollers accompany various benefits like better and Improved corrosion prevention, Long assistance life, Ideal, and easy handling.

You can contact us on +91 9825047390 or visit aniloxroller.in

#aniloxroller#aniloxrollers#ceramicaniloxroller#aniloxsleeve#ciflexo#flexographicprinting#gravureprinting#flexiblepackagingindustry#wovensacksindustry#papercupindustry#BOPPtapeindustry#offsetindustry#paperindustry#BOPPIndustry#PVDCcoatingIndustry

0 notes