#Fused Deposition Modeling (FDM)

Explore tagged Tumblr posts

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing#3D printing maintenance

1 note

·

View note

Text

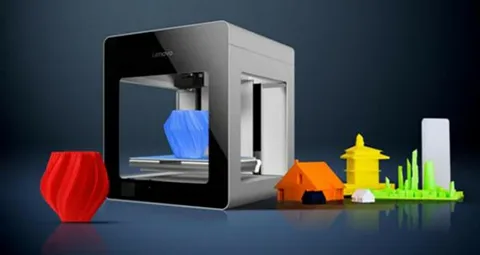

The Future in Layers: Understanding 3D Printing

3D printing, also known as additive manufacturing, is transforming how we design, create, and innovate. What once belonged to the realm of science fiction is now a powerful tool used in industries ranging from healthcare to aerospace. By building objects layer by layer from digital models, 3D printing offers flexibility, customization, and speed that traditional manufacturing often can’t match. 3D Printing

How 3D Printing Works At its core, 3D printing begins with a digital design, usually created using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers. The 3D printer reads these slices and deposits material — usually plastic, resin, metal, or even food — layer by layer until the final object takes shape.

There are several types of 3D printing technologies, including:

Fused Deposition Modeling (FDM) — Melts plastic filament and extrudes it layer by layer.

Stereolithography (SLA) — Uses UV light to cure liquid resin into solid layers.

Selective Laser Sintering (SLS) — Uses lasers to fuse powdered material, often metals or plastics.

Applications of 3D Printing

Healthcare: 3D printers are used to create prosthetics, dental implants, and even bioprinted tissues. Customization is key — no two patients are the same, and 3D printing makes it possible to tailor medical devices to individual needs.

Manufacturing: Prototyping with 3D printing is faster and more cost-effective than traditional methods. Companies can test and modify designs before full-scale production.

Education: Schools and universities use 3D printing to bring concepts to life in science, engineering, and art.

Architecture: Architects can produce detailed models and even explore 3D-printed housing for rapid, affordable construction.

Fashion & Art: Designers use 3D printing to create unique jewelry, clothing, and sculptures, often unachievable by hand.

Advantages of 3D Printing

Customization: Easily adapt designs for specific users or needs.

Speed: Rapid prototyping accelerates product development.

Reduced Waste: Additive processes use only the material needed.

Accessibility: Desktop 3D printers make production possible at home or in small businesses.

Challenges and Limitations Despite its promise, 3D printing faces challenges. Materials can be expensive or limited in strength and durability. Printing large objects can be time-consuming, and the technology still requires skilled operators for optimal results. Regulatory and safety standards are also developing to catch up with rapid innovation.

The Future of 3D Printing Looking ahead, 3D printing is poised to revolutionize supply chains, reduce environmental impact, and even explore new frontiers like space manufacturing. As the technology matures, we may see everyday products — from shoes to electronics — custom-printed just for us.

0 notes

Text

Discover the Future of Manufacturing with Online 3D Printing in India and Cheap 3D Printer Options

In recent years, technology has redefined how businesses and individuals approach manufacturing and design. One innovation that stands out is 3D printing—a tool that turns digital designs into physical objects with precision. Today,Online 3d Printing India has become not only accessible but also affordable, thanks to a growing market and advancements in printer technology. Whether you're a student, hobbyist, startup founder, or engineer, there's never been a better time to explore cheap 3D printer options in India.

Embracing Online 3D Printing in India

Online 3D printing services have revolutionized the Indian manufacturing ecosystem. Traditional prototyping was once time-consuming and expensive, often requiring large-scale industrial machinery. Now, with just a few clicks, users can upload CAD files and receive custom parts delivered to their doorstep—often within days.

This rapid shift to online 3D printing in India has empowered a wide range of users. Entrepreneurs and product designers now have the ability to test prototypes affordably. Architecture firms can produce intricate scale models without outsourcing abroad. Even medical professionals are exploring custom prosthetics and dental models—all enabled by accessible 3D printing platforms.

Some of the most popular online 3D printing services in India include:

think3D

Printo

Ethical 3D

3Ding

Fracktal Works

These platforms allow users to select materials, define dimensions, and choose between different printing technologies such as FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

Affordable Innovation: Cheap 3D Printer Options in India

While online services are excellent for occasional use, many people and businesses are opting to invest in their own machines. Fortunately, the cost barrier has dropped significantly, making it easier to own a 3D printer without spending a fortune. The market for cheap 3D printers in India is growing rapidly, with reliable models available for as little as ₹15,000–₹30,000.

Some of the top affordable 3D printer brands include:

Creality Ender Series (Ender 3, Ender 3 V2) Highly rated for hobbyists and beginners, these models offer excellent print quality at a low price.

Anycubic i3 Mega / Photon Series Popular for resin printing and detailed work, Anycubic is a go-to for those interested in finer resolution.

WOL3D An Indian brand offering budget-friendly options tailored to Indian consumers with solid after-sales service.

FlashForge Finder A user-friendly 3D printer ideal for educational and home use, particularly popular in schools.

These budget printers provide great value for money and are capable of producing professional-grade models, miniatures, mechanical parts, and more. Most of them come semi-assembled with user-friendly software like Cura, simplifying the learning curve for new users.

Key Benefits of Using Online 3D Printing in India

Convenience With online services, you don’t need to own a printer or invest in materials. Upload your design, choose the specs, and let the service provider handle the rest.

Material Variety Online platforms offer multiple printing materials—from standard PLA and ABS to advanced options like carbon fiber, nylon, or metal composites.

No Maintenance Hassles Maintenance and calibration are handled by experts, so you don’t have to worry about machine downtime.

Scalability Whether you're printing a one-off prototype or a short production run, online platforms scale easily to fit your needs.

Technical Expertise Many services also offer design consultations, helping clients optimize their models for better print quality and cost-effectiveness.

Why More Indians Are Buying Cheap 3D Printers

Cost-Efficient Prototyping For startups and freelancers, owning a 3D printer cuts prototyping costs drastically over time.

Learning and Education Schools and colleges are investing in low-cost 3D printers to introduce students to design thinking, CAD, and manufacturing.

Creative Freedom Artists, hobbyists, and makers use home printers to create custom toys, jewelry, cosplay items, and household gadgets.

Entrepreneurial Opportunities Many have turned 3D printing into a side hustle—offering local printing services, selling models online, or even creating niche products for e-commerce.

Tips for Choosing the Right Cheap 3D Printer in India

Know Your Use Case: Are you printing prototypes, models, toys, or functional parts? Choose the technology accordingly (FDM for general use, SLA for detail).

Check Community Support: Go for models with large user communities for easy troubleshooting and mods.

Look for After-Sales Service: Ensure the brand has support centers or easy access to replacement parts in India.

The Road Ahead: 3D Printing in India

India’s 3D printing ecosystem is just getting started. With government initiatives supporting Atmanirbhar Bharat and Make in India, there's a strong push to integrate advanced manufacturing technologies. As awareness spreads and costs decline further, online 3D printing in India and cheap 3D printers will become even more commonplace.

In fields like healthcare, education, architecture, and fashion, we can expect a rise in demand for personalized and on-demand manufacturing. From Jaipur’s prosthetic development labs to Bengaluru’s tech startups, India is steadily becoming a global player in 3D printing innovation.

Conclusion

The fusion of online convenience and affordability has made 3D printing a game-changer in India. Whether you need a one-time print job or are ready to explore the endless possibilities of home manufacturing, both online 3D printing in India and the growing range of Cheap 3d Printer Indiaoffer practical solutions for every level of user. As the technology evolves, it's clear that the future of fabrication is already within reach—layer by layer.

0 notes

Text

ANH: Cutting-edge Rapid Prototyping and 3D Printing Services in India

What We Offer: Precision at Every Layer

We harness a variety of industry-leading 3D printing technologies to bring your designs to life with unmatched quality:

SLA (Stereolithography) — Perfect for highly detailed, smooth surface parts.

SLS (Selective Laser Sintering) — Ideal for durable, functional prototypes without the need for support structures.

MJF (Multi Jet Fusion) — Great for producing strong, complex geometries at scale.

FDM (Fused Deposition Modeling) — A cost-effective method for both prototypes and end-use parts.

Each of these technologies caters to different needs — whether it’s fine detailing, structural strength, or low-cost prototyping. At ANH, our team helps you choose the best-fit solution tailored to your project goals.

Why Choose ANH for Rapid Prototyping?

✅ Quick Turnaround — We understand deadlines. Our agile processes ensure you receive your prototype faster, without compromising on quality.

✅ Industry Expertise — From automotive to aerospace, medical to consumer goods — we’ve worked across industries and understand their unique prototyping demands.

✅ In-House Experts — Our skilled engineers and technicians guide you throughout the journey , from design consultation to final delivery.

✅ Quality Assurance — Every print undergoes strict quality checks to meet precision, durability, and functionality standards.

Applications Across Industries

Automotive — Test parts, functional assemblies, or ergonomic models.

Aerospace — Lightweight components, complex geometries, and performance testing.

Medical — Custom devices, surgical tools, and anatomical models.

Consumer Goods — Product design validation, packaging mockups, and quick market testing.

Whether it’s a one-off prototype or a low-volume production run, we’re ready to deliver excellence.

From Concept to Creation — Seamlessly

Prototyping isn’t just about printing parts — it’s about accelerating innovation. At ANH, we partner with you to reduce development costs, shorten lead times, and improve product performance through effective prototyping strategies.

We don’t just deliver prints. We deliver solutions.

Ready to Innovate?

If you’re looking to test a concept, refine a design, or scale up with functional parts, ANH is your trusted partner for rapid prototyping and 3D printing services in India.

Let’s bring your ideas to life — faster, better, and smarter.

📞 Contact us today to learn how we can support your next big idea!

0 notes

Text

Automotive 3D Printing Market Size, Share, Forecast, & Trends Analysis

Meticulous Research®—a leading global market research company, published a research report titled ‘Automotive 3D Printing Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the automotive 3D printing market is projected to reach $17.9 billion by 2032, at a CAGR of 22% from 2025–2032.

The automotive 3D printing market is experiencing growth driven by several factors, including the increasing adoption of fused deposition modeling (FDM) for manufacturing automotive components, the rising utilization of 3D printing for tooling and manufacturing aids, and the growing demand for polymers in automotive applications. However, the market growth is hindered by the high costs associated with 3D printing materials.

Furthermore, the increasing consumer demand for customized and personalized automotive parts, coupled with government initiatives promoting the adoption of 3D printing technologies, presents significant opportunities for market participants. However, this market also faces considerable challenges, including a lack of awareness and a shortage of skilled professionals. Moreover, the growing integration of artificial intelligence (AI) in design and production processes, along with the increasing use of sustainable and recyclable materials in 3D printing, represents a prominent trend in the automotive 3D printing market.

Key Players

The automotive 3D printing market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the automotive 3D printing market are 3D Systems Corporation (U.S.), Stratasys Ltd (U.S.), Desktop Metal, Inc. (ETEC) (U.S.), Dassault Systèmes S.E. (France), EOS GmbH (Germany), ExOne Operating, LLC (U.S.), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Proto Labs, Inc. (U.S.), Formlabs Inc. (U.S.), voxeljet AG (Germany), Markforged Holding Corporation (U.S.), MATERIALISE NV (Belgium), Ultimaker B.V. (Netherland), IC3D, Inc. (U.S.), Moog Inc. (U.S.), and Zortrax S.A. (Poland).

The automotive 3D printing market is segmented based on offering, technology, component, vehicle type, and application. The report also evaluates industry competitors and analyzes the market at the regional and country levels.

Among the offerings studied in this report, the hardware segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of the 3D printing hardware segment in the automotive market is driven by several key factors, including the rapid growth of 3D printing technology for creating complex part designs, an increased focus on reducing material waste and enhancing fuel efficiency through lightweight components, and the growing utilization of 3D printing hardware for tooling and manufacturing aids in vehicle production.

Among the technologies studied in this report, the fused deposition modeling (FDM) segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of Fused Deposition Modeling (FDM) in the automotive 3D printing market is attributed to its cost-effectiveness and capability to produce a diverse array of 3D-printed objects. The technology's rapid growth in reducing lead times and accelerating the prototyping process further enhances its appeal. Additionally, the increasing adoption of FDM is driven by its versatility in 3D printing with a wide range of materials, including polymers, metals, and ceramics.

Among the components studied in this report, the exterior components segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The segment's dominant position is boosted by the significant growth in manufacturing lightweight exterior body panels, which enhance vehicle performance. Additionally, the rising adoption of 3D printing for the production and prototyping of components such as mirror housings, tail lights, and headlights further contributes to this segment's dominance.

Among the vehicle types studied in this report, the ICE vehicles segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of 3D printing for internal combustion engine (ICE) vehicles in the automotive market is driven by several factors, including the flexibility in design it offers, a growing demand for aftermarket parts and custom components, and increased prototyping capabilities for ICE vehicles. Additionally, the established and widespread use of ICE vehicles, compared to electric or hybrid alternatives, further enhances the adoption of 3D printing in this segment.

Among the applications studied in this report, the prototyping segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of 3D printing in the automotive sector is supported by several factors, including its rapid ability to create prototypes of various components and test designs before full-scale production. The technology's capability to easily produce complex geometries and customized parts further enhances its appeal. Additionally, 3D printing contributes to more sustainable prototyping by minimizing material waste and reducing energy consumption, contributing to the automotive 3D printing market.

Geographic Review

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Sweden, Switzerland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Malaysia, Australia & New Zealand, Indonesia, Vietnam, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Israel, Saudi Arabia, and Rest of Middle East & Africa).

Among the geographies studied in this report, North America is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. This position is fueled by several key factors, including significant technological innovations from leading automotive manufacturers, increased investment in research and development within the sector, and rising demand for customized, high-performance vehicle components. Furthermore, the presence of an established supply chain infrastructure enhances the market's growth potential.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6038

Key Questions Answered in the Report:

What is the value of revenue generated by the sale offering, technology, component, vehicle type, and application?

At what rate is the global demand for automotive 3D printing projected to grow for the next five to seven years?

What is the historical market size and growth rate for the automotive 3D printing market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the automotive 3D printing market?

Who are the major players in the automotive 3D printing market? What are their specific product offerings in this market?

What recent developments have taken place in the automotive 3D printing market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Automotive 3D Printing Market#Fused Deposition Modeling. Automotive 3D Printing#Polymers#Selective Laser Sintering#Interior Components#Exterior Components#Prototyping

0 notes

Text

How fast is 3D printing?

How fast can 3D printing be? In what scenarios can it really bring the dual advantages of speed and cost? This article will compare mainstream 3D printing technologies (such as FDM, SLA, SLS, MJF) with traditional processes (such as CNC, injection molding, casting), combined with typical production scenarios, to dismantle the technical core and commercial significance of "3D printing speed" for you.

I believe that after reading this article, you will have a clearer answer to "when to use 3D printing and why it is so fast and meaningful".

Fast 3D Printing vs. Traditional Crafts: Which is Faster?

Before we compare specific technologies, let's clarify a basic issue: FDM (fused deposition modeling), SLA (stereolithography), MJF (multi-jet fusion), these names are all different molding principles of 3D printing. They each have their own unique printing methods, material adaptability and speed performance, so they have their own advantages in efficiency. In sharp contrast to them, traditional manufacturing processes such as CNC, injection molding, and casting also have completely different production capacity structures and response rhythms. Let's disassemble them one by one to see whether 3D printing technology can catch up in terms of speed.

FDM vs. CNC

When you need to make a small tool sample urgently (for example, wThe advantage of this technology lies not only in its speed, but also in its flexibility. In particular, after adjusting the nozzle diameter (such as above 0.6mm), the nozzle speed can reach 150 mm/s, and a medium-complex part with a height of 100mm can be printed within 1 hour. FDM has obvious advantages in printing speed, which can significantly improve molding efficiency and is suitable for rapid prototyping and testing of medium-complexity prototypes.hen the design is completed at 3 pm and the installation verification is required in the evening), FDM (fused deposition modeling) technology will be the best solution.

But if it is changed to CNC, the delivery time is often measured in days due to the preparation of process documents, debugging of tool fixtures, and cutting process.

SLA/DLP vs. Injection Molding

SLA (stereolithography) is known for its high precision, with a layer thickness of 0.025–0.1 mm, an accuracy of up to ±25μm, and a molding speed of about 10–30 mm/h. The advantage of SLA printing speed is not its high speed, but its ability to output stably while maintaining surface quality, which is suitable for scenes with high requirements for process consistency.

DLP (digital light processing) is more efficient in printing. It increases the printing speed to 50-100 mm per hour by exposing the entire layer of the image at the same time, which is particularly efficient in the production of small-sized and large-quantity parts. The advantage of DLP printing speed is that it can quickly respond to batch requirements. It keeps a certain degree of accuracy while minimizing the unit molding time.

In contrast, although injection molding is very fast in single-piece molding speed, its overall delivery cycle is often extended by the pre-process of "mold development", which usually takes several days or even weeks and is accompanied by high costs. If the product design is frequently adjusted, the trial and error cost of repeated mold changes will also be very high.

SLM vs. Metal Casting

The biggest feature of SLM is that it can print complex structures in one go - for example, parts with through holes, buckles, and grids, without any support. Since SLM does not require mold opening and prefabrication processes, it can significantly speed up the overall delivery speed in the early stages of product development.

In contrast, although metal casting has cost advantages in mass production, the preparation process is long - mold design, casting cooling, and deburring often take several days or even a week. If you encounter a business scenario that requires rapid iteration, metal casting technology is basically unsolvable.

How fast 3D printing wins in three major scenarios with speed

In addition to the differences in the technology itself, the advantages of 3D printing speed also vary in different practical scenarios. From R&D proofing to mass production, we take a panoramic look at its actual performance at the application level.

Rapid prototyping

In the early stages of hardware product development, whether or not samples can be produced within a day often determines the efficiency of project iteration. Compared with traditional manufacturing that requires production scheduling, mold making, and debugging, 3D printing can achieve same-day design and same-day delivery. FDM printing is suitable for structural verification and preliminary testing, while SLA can achieve high-quality appearance models with a resolution of ±25μm. No mold is required, and samples can be produced directly, which is the biggest speed advantage of 3D printing in the prototype stage.

3D printing technology understands that prototype verification is not a one-time delivery, but a cycle mode of rapid trial and error-instant correction to promote continuous product evolution. Making trial and error fast and low-cost is the key force that 3D printing technology gives to the rhythm of product development.

Small batch custom production

When products pursue personalization and frequent iterations, the mold development and assembly processes of traditional manufacturing often cannot keep up with the pace. 3D printing technologies such as MJF and SLM do not require mold opening and can directly print finished parts. Taking MJF as an example, the industrial model has an hourly output of more than 3,000 cm⊃3;, which is suitable for typical scenarios such as orthopedic brackets and customized shells.

The key to small-batch customization is not the unit cost, but the response speed of delivery and the freedom of design. 3D printing provides a new generation of flexible manufacturing path.

Large-scale standardized production

Although injection molding and CNC still dominate in mass manufacturing, 3D printing is becoming an accelerator for early verification. In the stages of new product trial sales and regional testing, 3D printing can deliver hundreds of samples within a few days, seize the market time window, and reduce the risk of repeated mold modifications.

In mass manufacturing, 3D printing is not a substitute, but an accelerator. It helps companies quickly try and fail in uncertainty and make more informed judgments before formal mass production.

In an era where manufacturing efficiency has become a competitive threshold, the speed dividend of 3D printing has moved from prototypes to mass production, from innovation to profits. It can not only fill the response window of traditional processes, but also provide a decision buffer in uncertainty. The question is not whether 3D printing can be used, but when it is most cost-effective to use it. The following table summarizes the performance of various manufacturing methods in terms of speed, flexibility and cost under different production goals, helping you to judge at a glance:

3D printing is not the opposite of traditional manufacturing, but a powerful complement to it. From rapid prototyping, flexible trial production to product verification, it allows companies to conduct trial and error quickly and at low cost, speeding up the pace of every idea to implementation. This is exactly the key point mentioned at the beginning of the article: the real manufacturing advantage does not lie in how fast the machine runs, but in whether you can use "speed" on the blade of innovation at the right time.

Want to learn more about which 3D printing solution is best for your product design or production line? Contact us for a free consultation.

1 note

·

View note

Text

Japan Healthcare 3D Printing Market Reset: Analyzing Economic Stressors and Trade Policy Shocks

Introduction: The latest research study from Prophecy Market Insights offers a thorough analysis of the Healthcare 3D Printing Market , focusing on risk assessment, opportunities, and strategic decision-making support. This report provides insights into market development, trends, growth factors, and investment structures, aiding businesses in navigating the evolving landscape of Healthcare 3D Printing Market. Report Sample: A brief overview of the research report. Graphical presentation of regional analysis. Revenue analysis of top players in the market. Selected illustrations of market insights and trends. Example pages from the report. Healthcare 3D Printing Market Overview: The research provides a systematic approach to gathering, evaluating, and interpreting market data, including customer preferences, competitor analysis, and sectoral trends. It helps companies understand customer needs, assess market demand, and identify growth opportunities. Market research offers valuable insights through surveys, interviews, and data analysis, guiding product development, marketing strategies, and decision-making processes. Request a Sample Strategic Report in PDF Format: https://www.prophecymarketinsights.com/market_insight/Insight/request-pdf/5028 Leading Key Players Operating in the Healthcare 3D Printing Market 3D Systems Inc. Formlabs Inc. Materialise NV. The ExOne Company General Electric Company Bio3D Technologies Organovo Holdings Inc. Stratasys Ltd. Proto Labs Inc. SLM SOLUTIONS GROUP AG. and others. Key players are well-known, powerful businesses that have a big impact on a certain market or sector. Finding the important companies is essential to comprehending the dynamics of the industry or the competitive environment. Please be aware that changes in the industry, mergers, acquisitions, or the entry of new competitors may cause the status of important players to alter over timeHealthcare 3D Printing Market: Demand Analysis & Opportunity Outlook 2034 Healthcare 3D Printing Market analyzes customer preferences, economic trends, and industry dynamics to predict demand patterns and identify new opportunities. By leveraging data-driven research and predictive modeling, businesses can anticipate changes in market demand, plan product development, and position themselves proactively in the evolving business landscape of 2034. Major Market Analysis Findings: Consumer preferences: Businesses can better understand their target audience’s preferences by conducting market research, which can reveal things like preferred product features, pricing, and branding. The most crucial product characteristics, the most alluring pricing points, and the most effective brand messaging are just a few examples of key findings. Market size and growth potential: Businesses can evaluate the size of the market and its growth potential with the use of market research. The size of the market overall, the size of particular market segments, and the market’s anticipated growth rate are just a few examples of key findings. Market trends: Businesses can use market research to spot new market trends, such as alterations in customer behavior, adjustments to industry rules, or the arrival of new technologies. The most important market trends, the causes influencing those trends, and their possible effects on the company may be some of the key findings. Get a free sample of the report: https://www.prophecymarketinsights.com/market_insight/Insight/request-sample/5028 (The sample of this report is readily available on request) The segments and sub-section of Healthcare 3D Printing Market is shown below: Market Segmentation: Healthcare 3D Printing Market, By Product (Laser Based, Syringe Based, Inkjet Based, Magnetic Levitation), By Technology (Stereo-lithography, Selective Laser Sintering (SLS), Fused Deposition Modelling (FDM)), By Application (Implants, Tissue Engineering, Clinical Study Devices, External Wearable Devices, and Others) and By Region

(North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) - Trends, Analysis and Forecast till 2032 Regional Analysis for Healthcare 3D Printing Market: This section of the report includes comprehensive information on Healthcare 3D Printing Market that is accessible in several fields. Each region offers a distinct Healthcare 3D Printing Market length as each state has its own executive insurance laws and components. North America - U.S., Canada Europe - UK, Germany, Spain, France, Italy, Russia, Rest of Europe Asia Pacific - Japan, India, China, South Korea, Australia, Rest of Asia-Pacific Latin America - Brazil, Mexico, Argentina, Rest of Latin America Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa Research Methodology The research methodology employed by Prophecy Market Insights for market research involves a systematic approach that integrates primary and secondary research techniques. Through direct interactions with industry experts and stakeholders, as well as comprehensive analysis of secondary sources, we gather valuable data on market trends, consumer behavior, and competitive landscape. Advanced data analysis techniques are then applied to interpret this data accurately, providing clients with actionable insights to make informed decisions and strategies in today's dynamic marketplaces. Author: Shweta.R is a market research analyst with deep expertise in the food and nutrition sector. Passionate about data-driven insights, She focuses on identifying emerging trends and growth opportunities. About Us: Prophecy Market Insights is a leading provider of market research services, offering insightful and actionable reports to clients across various industries. With a team of experienced analysts and researchers, Prophecy Market Insights provides accurate and reliable market intelligence, helping businesses make informed decisions and stay ahead of the competition. The company's research reports cover a wide range of topics, including industry trends, market size, growth opportunities, competitive landscape, and more. Prophecy Market Insights is committed to delivering high-quality research services that help clients achieve their strategic goals and objectives. Contact Us: Prophecy Market Insights Website- https://www.prophecymarketinsights.com US toll free: +16893053270

0 notes

Text

Your Guide to Professional 3D Printing Services in Riyadh

As innovation continues to thrive in Saudi Arabia’s capital, 3D printing services in Riyadh are becoming essential for businesses, engineers, architects, and creators seeking advanced, cost-effective manufacturing solutions. Whether you're a startup needing a prototype or an established company exploring customized production, understanding the 3D printing landscape in Riyadh is key to staying competitive—and providers like 3DWorksME are leading the way.

What Is 3D Printing and Why Is It Important?

3D printing, or additive manufacturing, is the process of creating physical objects directly from digital designs. Unlike traditional manufacturing, which often involves cutting away material, 3D printing builds objects layer by layer—saving time, reducing waste, and allowing for high levels of customization. This makes it a powerful tool for industries like architecture, automotive, aerospace, healthcare, and education.

Types of 3D Printing Services in Riyadh

Riyadh’s 3D printing service providers, such as 3DWorksME, offer a range of technologies to suit various needs:

FDM (Fused Deposition Modeling) for durable plastic parts

SLA (Stereolithography) for high-resolution prototypes

SLS (Selective Laser Sintering) for functional, load-bearing components

Metal 3D Printing for end-use parts in industries like aerospace or medical

These options allow customers to choose the best material and technique for their application—be it prototyping, tooling, architectural models, or production-grade parts.

Why Choose a Professional 3D Printing Partner in Riyadh?

Working with a local expert like 3DWorksME comes with many advantages:

Faster turnaround times due to local production

Direct communication for better customization and quality assurance

Expertise in CAD design, reverse engineering, and prototyping

On-demand production, reducing the need for large inventories

Local 3D printing services also align with Saudi Arabia’s Vision 2030 by promoting digital transformation, localized manufacturing, and sustainable practices.

Industries Benefiting from 3D Printing in Riyadh

Construction: Custom architectural models and building components

Healthcare: Surgical guides, dental molds, and prosthetics

Education: Engineering and design schools use 3D printing for hands-on learning

Product Design: Rapid prototyping to test and refine concepts

Aerospace/Automotive: Lightweight, complex components produced faster and cheaper

These applications show how 3D printing enables smarter design, rapid innovation, and cost savings across sectors.

How to Get Started

If you're ready to explore 3D printing in Riyadh, start with a consultation. Providers like 3DWorksME help assess your design files, suggest the right material and process, and guide you through prototyping or production. Whether you're producing a single item or scaling up for small-batch manufacturing, they ensure top-tier quality and support every step of the way.

Conclusion: Professional 3D printing services in Riyadh are transforming the way ideas come to life. With experienced providers like 3DWorksME, businesses can innovate faster, reduce costs, and create complex, customized products like never before. Whether you're an entrepreneur, engineer, or architect, now is the perfect time to leverage the power of 3D printing in the heart of Saudi Arabia.

0 notes

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing

1 note

·

View note

Link

0 notes

Text

Accelerate Prototyping with Fast and Flexible FDM Printing by Ruban Master

Fast and dependable FDM printing from Ruban Master can help you to realize your 3D creations. Perfect for functional prototypes and parts ready for manufacturing, our Fused Deposition Modeling technique provides strength, accuracy, and economy. Whether you are finishing a functional model or iterating a fresh idea, FDM printing provides the flexibility to move fast and keep on budget. High-grade thermoplastics allow Ruban Master to guarantee real-world performance and longevity. Our staff closely coordinates with you to satisfy every need and dimension. Under one professional roof, choose FDM for detailed models, speedier development, and a flawless mix of form and function.

0 notes

Text

Dental 3D Printer Market Share Analysis and Leading Companies 2032

The global dental 3D printer market was worth USD 158.6 million in 2024. It’s expected to grow from USD 174.1 million in 2025 to USD 345.2 million by 2032, with a healthy CAGR of 10.3% over that period. North America led the market in 2024, holding a 39.6% share.

The dental 3D printer market is witnessing significant advancements, driven by increasing demand for precision, customization, and faster turnaround times in dental procedures. 3D printing technology is revolutionizing the dental industry by enabling the rapid production of crowns, bridges, implants, and dental models with greater accuracy. With ongoing innovations in materials and the ability to create personalized dental solutions, this market is becoming more accessible to dental professionals around the globe.

Tariff Impact Analysis For Dental 3D Printer Market:

Market Overview

The Dental 3D Printer Market is witnessing strong momentum driven by the increasing adoption of digital dentistry and advancements in 3D printing technology. Market growth is propelled by the rising demand for customized dental prosthetics and appliances, which enhance patient outcomes and reduce turnaround times. The efficiency and precision offered by dental 3D printers have made them essential tools in modern dental practices and laboratories, contributing to steady expansion.

Market Trend

The Dental 3D Printer Market is experiencing remarkable momentum, driven by the rising adoption of digital dentistry and the increasing demand for customized dental solutions. Major trends shaping the market include the shift towards chairside 3D printing, the use of advanced materials for better biocompatibility, and the integration of AI in dental CAD/CAM workflows. Furthermore, the growing popularity of cosmetic dentistry procedures and the need for quick, precise dental restorations are fueling innovations within the Dental 3D Printer Market.

Market Segmentation

Market segmentation in the Dental 3D Printer Market is primarily based on technology, application, and end-user. Technologies such as stereolithography (SLA), digital light processing (DLP), selective laser sintering (SLS), fused deposition modeling (FDM), and PolyJet are widely utilized. Each technology serves different needs, from high precision models to cost-effective prototypes. Applications span orthodontics, prosthodontics, implantology, and surgical guides, reflecting the versatility of dental 3D printers in producing various dental devices and components. End-users include dental laboratories, clinics, and research institutes, each leveraging the technology for specific purposes such as rapid production or innovation development.

List of Top Dental 3D Printer Market Companies:

Asiga (Australia)

Stratasys (Israel)

Prodways (France)

Formlabs (U.S.)

3D Systems, Inc. ( U.S.)

Dentsply Sirona (U.S.)

Amann Girrbach AG (Germany)

DWS S.r.l. (Italy)

Roland DG Corporation (Japan)

Desktop Metal, Inc. (U.S.)

Market Growth

Despite its promising growth, the Dental 3D Printer Market faces several restraining factors. High initial costs for advanced 3D printing equipment can limit adoption, especially in smaller practices. Additionally, the stringent regulatory environment for dental medical devices requires manufacturers to comply with rigorous standards, which can delay product launches. Material limitations related to biocompatibility and durability also pose challenges, as ongoing research is needed to expand the portfolio of suitable printing materials. Furthermore, a shortage of skilled operators familiar with dental 3D printing technology hampers faster integration in some regions.

Regional Analysis

Regionally, the Dental 3D Printer Market shows varied growth patterns. North America dominates the market due to its established healthcare infrastructure, technological innovation, and high patient awareness. Europe follows closely, with countries emphasizing research and regulatory compliance. The Asia-Pacific region is emerging as a fast-growing market, fueled by increasing healthcare expenditures and rising dental care demand in populous countries. Latin America, the Middle East, and Africa represent emerging markets where growing awareness and investments in dental healthcare are gradually driving demand for dental 3D printers.

Key Industry Developments

In 2023 and 2024, the Dental 3D Printer Market saw major advancements with the launch of faster, more precise 3D printers designed specifically for chairside use, enabling same-day dental restorations. Leading companies introduced new biocompatible resins and hybrid materials to improve the quality and durability of printed dental appliances. Strategic collaborations between dental clinics and 3D printing firms expanded access to advanced technologies, while regulatory approvals for new dental 3D printing systems in North America and Europe accelerated market adoption. Additionally, growing investments in AI-integrated dental workflows and cloud-based printing solutions further fueled innovation in the Dental 3D Printer Market.

Contact us:

Fortune Business Insights™ Pvt.

Phone: USA: +1 833 909 2966 (Toll-Free),

United Kingdom: +44 808 502 0280 (Toll-Free)

APAC: +91 744 740 1245

Email: [email protected]

0 notes

Text

Discover How 3D Print Services and Cheap 3D Printer India Solutions Are Transforming Innovation

In recent years, 3D printing technology has emerged as a powerful tool across industries—from prototyping and manufacturing to healthcare and education. Businesses and individuals alike are reaping the benefits of rapid, cost-effective production using modern 3D printers. With increasing accessibility, more Indians are turning to 3D print services and exploring options for a cheap 3D printer in India to bring their ideas to life.

Why 3D Printing Is Gaining Momentum

3D printing, also known as additive manufacturing, creates physical objects by layering material based on a digital model. This process dramatically reduces waste, speeds up prototyping, and allows for the customization of products that traditional manufacturing struggles to offer.

Designers, architects, engineers, hobbyists, and students are now using 3D printing for projects ranging from miniatures and machine parts to architectural models and medical implants. The rising interest has spurred the growth of reliable and affordable 3D print services and a market boom for cheap 3D printer India options.

What Are 3D Print Services?

3D print services allow you to print a design without owning a 3D printer yourself. You simply upload your CAD file to an online portal or visit a local 3D printing center, choose your preferred material, and let experts do the rest. These services are ideal for those who need professional prints occasionally or want high-quality output without investing in expensive machines.

In India, the demand for professional 3D printing has surged across metro cities like Bangalore, Delhi, Mumbai, and Hyderabad. Companies offer services like rapid prototyping, industrial modeling, product design, and even small-batch production. Whether you're a student working on a science fair project or a startup developing a new prototype, 3D print services provide flexible, on-demand solutions.

Exploring the Market for a Cheap 3D Printer in India

While outsourcing printing to professional services is convenient, many hobbyists and startups prefer owning a machine for hands-on experience and long-term savings. The good news is that the Indian market offers a wide range of options for those seeking a cheap 3D printer in India without compromising on performance.

Entry-level FDM (Fused Deposition Modeling) printers are now available at affordable prices, starting as low as ₹15,000 to ₹30,000. Brands like Creality, Anycubic, Wanhao, and Indian-made Pramaan 3D have released budget-friendly models that cater to both beginners and advanced users.

These machines support common filament types like PLA, ABS, and PETG, and some even come with open-source firmware for customization. With online tutorials and active user communities, it’s easier than ever to set up and operate a cheap 3D printer in India from your home or workshop.

Benefits of Using 3D Print Services and Owning a Cheap 3D Printer

Both 3D print services and affordable personal printers offer distinct benefits, depending on your needs:

Advantages of 3D Print Services:

Professional Quality: Get access to high-resolution industrial-grade printers.

Variety of Materials: Choose from advanced resins, metals, and composites.

No Maintenance Hassle: Avoid the setup, calibration, and upkeep involved in running your own printer.

Expert Guidance: Collaborate with technicians who can help optimize your design for the best results.

Advantages of Cheap 3D Printers in India:

Affordability: Entry-level printers are budget-friendly and easily available online and offline.

Learning Opportunity: Great for students and makers to understand the nuances of 3D modeling and printing.

Creative Control: Make quick iterations and modifications in real time without relying on a third party.

Business Potential: Entrepreneurs can start small-scale manufacturing or offer local 3D print services in their area.

Who Can Benefit from 3D Printing?

The applications of 3D printing extend far beyond engineering and manufacturing. Here’s a look at some key users:

Students and Educators: Ideal for STEM education, science models, and project-based learning.

Architects: Use 3D printing for scale models, elevation designs, and visual presentations.

Healthcare Professionals: Print prosthetics, surgical tools, and anatomical models.

Artists and Designers: Bring creative ideas to life with customized jewelry, home decor, and wearable tech.

Entrepreneurs: Launch product-based businesses with minimal initial investment using a cheap 3D printer India setup.

Final Thoughts: Embrace the Future with 3D Printing

The 3D printing landscape in India is rapidly evolving. As awareness grows, both 3D print services and affordable home-use machines are making innovation more accessible than ever. Whether you want to prototype a new invention, create personalized items, or enter the world of digital manufacturing, now is the perfect time to explore your options.

Investing in a cheap 3D printer in India or partnering with a local 3D print service can unlock endless possibilities for your creativity or business. As technology continues to advance, those who adopt 3D printing today will lead the way in shaping the products and solutions of tomorrow.

0 notes

Text

3D Printing Materials Market to Thrive with Growing Applications in Construction and Architecture

Market Overview

The 3D printing materials market is witnessing dynamic growth, driven by technological advancements, evolving industry needs, and increasing adoption across diverse end-use sectors. Valued in billions, this market is projected to continue expanding significantly through 2034. 3D printing, also known as additive manufacturing, relies heavily on materials ranging from polymers to metals to create functional and complex objects layer by layer. These materials are integral to the production of everything from aerospace components and automotive parts to medical devices and fashion accessories.

With industries focusing on efficiency, customization, and sustainability, the demand for high-performance and application-specific materials is surging. As businesses recognize the value of 3D printing for rapid prototyping, tooling, and even end-use manufacturing, the market for compatible materials is evolving rapidly, making this a crucial segment within the broader additive manufacturing ecosystem.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS22349

Market Dynamics

The primary driver of the 3D printing materials market is the increasing demand for rapid, cost-effective, and customizable production processes across various industries. In sectors like aerospace, healthcare, and automotive, the ability to produce lightweight, complex parts without traditional tooling is revolutionizing design and manufacturing processes. This shift is amplifying the need for advanced materials that meet specific strength, flexibility, and heat resistance requirements.

Polymers, especially thermoplastics, continue to dominate the market due to their versatility and affordability. However, metals like titanium and aluminum are gaining momentum in aerospace and defense applications for their strength-to-weight ratio. Ceramics and biomaterials are also emerging, particularly in dental and orthopedic applications.

Additionally, the evolution of technologies such as Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA) is influencing material development. Each technology has unique material requirements, fostering innovation in powders, filaments, liquids, and resins. Moreover, the increasing use of 3D printing in construction with materials like concrete and sand is opening new market segments.

Challenges such as high material costs, limited material availability for specific applications, and stringent regulatory standards in the healthcare and aerospace sectors still persist. Nonetheless, ongoing R&D and strategic partnerships are addressing these issues, leading to material innovations with broader applications and lower costs.

Key Players Analysis

Several key players are shaping the global 3D printing materials landscape through innovation and strategic expansion. Industry leaders such as Stratasys, 3D Systems Corporation, EOS GmbH, HP Inc., and Materialise NV are known for their comprehensive portfolios and strong R&D investments. These companies are focusing on developing proprietary materials that align with their respective 3D printing platforms.

Emerging firms like Markforged, Desktop Metal, and Carbon, Inc. are making waves with high-strength composites and metal powders. Partnerships between material suppliers and printer manufacturers are becoming common to ensure compatibility and performance optimization.

Many players are also venturing into sustainable solutions, including recyclable and bio-based materials. This focus not only meets regulatory and consumer demands but also positions companies favorably in a market leaning increasingly toward environmental responsibility.

Regional Analysis

North America currently holds the largest share of the 3D printing materials market, with the United States being a major hub for aerospace, defense, and healthcare innovation. The region benefits from advanced manufacturing infrastructure, significant R&D funding, and early technology adoption.

Europe follows closely, led by Germany, the UK, and France. The European Union's focus on industrial modernization and sustainability is pushing demand for advanced and eco-friendly materials.

The Asia-Pacific region is experiencing the fastest growth, particularly in China, Japan, and South Korea. The region’s strong electronics and automotive industries, combined with supportive government initiatives, are contributing to robust market expansion.

In Latin America, the Middle East, and Africa, the market is still emerging but is expected to grow steadily due to increasing awareness, education initiatives, and infrastructure development.

Recent News & Developments

Recent years have seen significant investments and collaborations in the 3D printing materials space. Major players are launching new lines of high-performance resins, metal powders, and composite filaments. For instance, HP expanded its Metal Jet production platform, introducing materials suited for mass production of complex metal parts.

Startups are also introducing biodegradable materials and waste-reducing alternatives. Notably, there has been an increase in government-funded research to develop 3D printing materials for national defense and healthcare needs.

The emergence of service bureaus offering material consulting, training, and maintenance services is a notable trend, helping smaller firms access expertise and reduce entry barriers.

Browse Full Report @ https://www.globalinsightservices.com/reports/3d-printing-materials-market/

Scope of the Report

This report provides an in-depth analysis of the 3D printing materials market, covering material types such as polymers, metals, ceramics, composites, biomaterials, wax, concrete, and sand. It categorizes products into filaments, powders, resins, liquids, and pellets and includes associated services such as design, consulting, training, and maintenance.

Technologies considered in the report range from FDM, SLS, SLA, DLP, and EBM to newer processes like Binder Jetting and Directed Energy Deposition (DED). Applications analyzed span from prototyping and tooling to aerospace, automotive, education, and fashion.

End-users include healthcare, defense, electronics, and construction industries, segmented further by production modes such as in-house manufacturing and outsourced service bureaus.

This comprehensive approach ensures a holistic understanding of the market’s trajectory, offering insights for stakeholders to navigate and capitalize on growth opportunities in this rapidly evolving industry.

Discover Additional Market Insights from Global Insight Services:

Silica Sand for Glass Making Market: https://www.globalinsightservices.com/reports/silica-sand-for-glass-making-market/

Copper Foil Market: https://www.globalinsightservices.com/press-releases/copper-foil-market/

Textile Flooring Market: https://www.globalinsightservices.com/reports/textile-flooring-market/

Wood Charcoal Market: https://www.globalinsightservices.com/reports/wood-charcoal-market/

Carbon Capture Concrete Market: https://www.globalinsightservices.com/reports/carbon-capture-concrete-market/

0 notes

Text

Desktop 3D Printer Market Growth Drivers Transforming Additive Manufacturing Industry Globally

The desktop 3D printer market has witnessed remarkable growth over recent years, revolutionizing how products are designed, prototyped, and even manufactured. As additive manufacturing technology continues to advance, the demand for desktop-sized 3D printers has surged among hobbyists, educators, small businesses, and professionals. Understanding the primary drivers behind this market growth is essential for stakeholders aiming to capitalize on the expanding opportunities. This article delves into the key factors propelling the desktop 3D printer market forward.

1. Technological Advancements and Innovation

One of the most significant drivers behind the desktop 3D printer market is ongoing technological innovation. Improvements in printer hardware, including better precision, faster print speeds, and enhanced reliability, have made desktop 3D printers more accessible and capable. The evolution from basic fused deposition modeling (FDM) to more sophisticated technologies such as stereolithography (SLA) and digital light processing (DLP) has broadened application possibilities, encouraging more users to adopt desktop 3D printing.

Moreover, advances in printing materials—from plastics to composites and even metal-infused filaments—have expanded the functional range of desktop 3D printers. These improvements enable users to create durable, high-quality prototypes and end-use parts, making desktop 3D printing a viable option across many industries.

2. Decreasing Costs and Increasing Affordability

Cost reduction is another powerful driver for the desktop 3D printer market. Early 3D printers were prohibitively expensive for individual users and small businesses. However, economies of scale, increased competition among manufacturers, and technological maturity have drastically lowered prices. Today, entry-level desktop 3D printers are available at affordable prices, opening the market to hobbyists, students, and startups.

Alongside hardware costs, the decreasing price of printing materials and software solutions further contributes to affordability. This overall reduction in total cost of ownership encourages wider adoption and frequent usage of desktop 3D printers.

3. Growing Demand for Rapid Prototyping and Customization

Industries increasingly demand rapid prototyping to accelerate product development cycles. Desktop 3D printers allow designers and engineers to quickly iterate designs without relying on costly third-party manufacturing. This on-demand prototyping significantly reduces lead times, lowers development costs, and enables faster time-to-market.

Additionally, the rise of mass customization in sectors like healthcare, fashion, and consumer goods boosts the need for flexible manufacturing solutions. Desktop 3D printers empower small-scale production of customized items tailored to individual specifications, meeting customer demands for uniqueness and personalization.

4. Expansion of Educational and DIY Markets

Educational institutions and maker communities play an influential role in expanding the desktop 3D printer market. Schools and universities integrate 3D printing into STEM curricula to provide students hands-on experience with emerging technologies. This exposure cultivates future professionals familiar with additive manufacturing, thereby sustaining market growth.

The DIY and maker movement thrives on accessible, affordable desktop 3D printers, enabling enthusiasts to create prototypes, replacement parts, and artistic projects. Online communities sharing designs and knowledge stimulate further interest and innovation, broadening the user base.

5. Enhanced Software and User-Friendly Interfaces

User experience improvements drive the market by making 3D printing less intimidating for new users. Advanced software with intuitive interfaces, pre-configured print profiles, and automated calibration simplify the printing process. Cloud-based platforms and mobile apps offer seamless remote management, design sharing, and collaboration.

Such user-friendly solutions lower the entry barriers and increase productivity, encouraging adoption by non-technical users and businesses alike.

6. Increasing Adoption in Healthcare and Other Key Industries

The healthcare industry’s adoption of desktop 3D printing significantly influences market growth. Customized implants, surgical guides, prosthetics, and anatomical models are increasingly produced using desktop printers for personalized patient care. This sector’s expanding use cases highlight the practical benefits of desktop 3D printing technology.

Similarly, industries like automotive, aerospace, consumer electronics, and architecture are leveraging desktop 3D printers for prototyping, tooling, and small-batch production, driving broader market demand.

7. Government Initiatives and Investments

Government policies and initiatives promoting innovation and advanced manufacturing also act as growth drivers. Funding for research, subsidies for equipment acquisition, and support for technological education encourage adoption of desktop 3D printing. Such measures foster an ecosystem conducive to market expansion.

Conclusion

The desktop 3D printer market is propelled by a combination of technological innovations, cost reductions, and growing demand for rapid prototyping and customization. Expanding applications in education, healthcare, and industry further amplify growth prospects. As software becomes more user-friendly and governments support advanced manufacturing initiatives, the desktop 3D printer market is set to continue its dynamic growth trajectory, reshaping traditional manufacturing paradigms and enabling creativity across sectors.

0 notes