#Fused Deposition Modelling

Explore tagged Tumblr posts

Text

Automotive 3D Printing Market Size, Share, Forecast, & Trends Analysis

Meticulous Research®—a leading global market research company, published a research report titled ‘Automotive 3D Printing Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the automotive 3D printing market is projected to reach $17.9 billion by 2032, at a CAGR of 22% from 2025–2032.

The automotive 3D printing market is experiencing growth driven by several factors, including the increasing adoption of fused deposition modeling (FDM) for manufacturing automotive components, the rising utilization of 3D printing for tooling and manufacturing aids, and the growing demand for polymers in automotive applications. However, the market growth is hindered by the high costs associated with 3D printing materials.

Furthermore, the increasing consumer demand for customized and personalized automotive parts, coupled with government initiatives promoting the adoption of 3D printing technologies, presents significant opportunities for market participants. However, this market also faces considerable challenges, including a lack of awareness and a shortage of skilled professionals. Moreover, the growing integration of artificial intelligence (AI) in design and production processes, along with the increasing use of sustainable and recyclable materials in 3D printing, represents a prominent trend in the automotive 3D printing market.

Key Players

The automotive 3D printing market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the automotive 3D printing market are 3D Systems Corporation (U.S.), Stratasys Ltd (U.S.), Desktop Metal, Inc. (ETEC) (U.S.), Dassault Systèmes S.E. (France), EOS GmbH (Germany), ExOne Operating, LLC (U.S.), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Proto Labs, Inc. (U.S.), Formlabs Inc. (U.S.), voxeljet AG (Germany), Markforged Holding Corporation (U.S.), MATERIALISE NV (Belgium), Ultimaker B.V. (Netherland), IC3D, Inc. (U.S.), Moog Inc. (U.S.), and Zortrax S.A. (Poland).

The automotive 3D printing market is segmented based on offering, technology, component, vehicle type, and application. The report also evaluates industry competitors and analyzes the market at the regional and country levels.

Among the offerings studied in this report, the hardware segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of the 3D printing hardware segment in the automotive market is driven by several key factors, including the rapid growth of 3D printing technology for creating complex part designs, an increased focus on reducing material waste and enhancing fuel efficiency through lightweight components, and the growing utilization of 3D printing hardware for tooling and manufacturing aids in vehicle production.

Among the technologies studied in this report, the fused deposition modeling (FDM) segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of Fused Deposition Modeling (FDM) in the automotive 3D printing market is attributed to its cost-effectiveness and capability to produce a diverse array of 3D-printed objects. The technology's rapid growth in reducing lead times and accelerating the prototyping process further enhances its appeal. Additionally, the increasing adoption of FDM is driven by its versatility in 3D printing with a wide range of materials, including polymers, metals, and ceramics.

Among the components studied in this report, the exterior components segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The segment's dominant position is boosted by the significant growth in manufacturing lightweight exterior body panels, which enhance vehicle performance. Additionally, the rising adoption of 3D printing for the production and prototyping of components such as mirror housings, tail lights, and headlights further contributes to this segment's dominance.

Among the vehicle types studied in this report, the ICE vehicles segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of 3D printing for internal combustion engine (ICE) vehicles in the automotive market is driven by several factors, including the flexibility in design it offers, a growing demand for aftermarket parts and custom components, and increased prototyping capabilities for ICE vehicles. Additionally, the established and widespread use of ICE vehicles, compared to electric or hybrid alternatives, further enhances the adoption of 3D printing in this segment.

Among the applications studied in this report, the prototyping segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of 3D printing in the automotive sector is supported by several factors, including its rapid ability to create prototypes of various components and test designs before full-scale production. The technology's capability to easily produce complex geometries and customized parts further enhances its appeal. Additionally, 3D printing contributes to more sustainable prototyping by minimizing material waste and reducing energy consumption, contributing to the automotive 3D printing market.

Geographic Review

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Sweden, Switzerland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Malaysia, Australia & New Zealand, Indonesia, Vietnam, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Israel, Saudi Arabia, and Rest of Middle East & Africa).

Among the geographies studied in this report, North America is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. This position is fueled by several key factors, including significant technological innovations from leading automotive manufacturers, increased investment in research and development within the sector, and rising demand for customized, high-performance vehicle components. Furthermore, the presence of an established supply chain infrastructure enhances the market's growth potential.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6038

Key Questions Answered in the Report:

What is the value of revenue generated by the sale offering, technology, component, vehicle type, and application?

At what rate is the global demand for automotive 3D printing projected to grow for the next five to seven years?

What is the historical market size and growth rate for the automotive 3D printing market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the automotive 3D printing market?

Who are the major players in the automotive 3D printing market? What are their specific product offerings in this market?

What recent developments have taken place in the automotive 3D printing market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Automotive 3D Printing Market#Fused Deposition Modeling. Automotive 3D Printing#Polymers#Selective Laser Sintering#Interior Components#Exterior Components#Prototyping

0 notes

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing#3D printing maintenance

1 note

·

View note

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Text

Welding materials on the moon

Before humans can colonize the moon or Mars, scientists and engineers must first develop techniques for building permanent structures and pressurized habitats in harsh, thin-atmosphere and low-gravity environments.

Dr. Wei Li, an assistant professor of mechanical engineering in the Erik Jonsson School of Engineering and Computer Science at The University of Texas at Dallas, is developing a virtual lunar welding platform to troubleshoot assembling large structures in such conditions.

“As we try to return to the moon and reach Mars, keeping astronauts safe while achieving the missions is very important,” said Dr. Edward White, professor and department head of mechanical engineering and holder of a Jonsson School Chair. “Being in Earth’s orbit is a lot easier knowing that when things go wrong, we can make repairs and return safely. I’m really excited that Dr. Li’s research will help play an important role in making space travel safer and will enable us to successfully complete space missions.”

Li recently received an Early Stage Innovations three-year grant from NASA for up to $750,000 to support his study of welding on the surface of the moon. He was one of six researchers nationwide selected to receive the 2024 annual award, which is designed to accelerate the development of groundbreaking, high-risk/high-payoff space technologies.

“There are three main challenges for the astronauts working on the moon’s surface,” Li said. “The moon has a very thin atmosphere, so there are steep temperature changes, from around minus 387 degrees Fahrenheit to 260 degrees Fahrenheit. There is also an extreme vacuum environment due to the thin atmosphere. Finally, the gravity on the moon’s surface is only about one-sixth that of the Earth. The extreme environment can complicate the reliable implementation of building or manufacturing large structures on the moon’s surface and can lead to manufacturing defects.”

Welding metal in such an environment can cause defects that impact the material’s load-bearing capability, leading to fractures and ductile cracks; nevertheless, in-space assembly is vital to NASA’s long-term exploration goals, Li said.

“It would be very hard to establish regular machine shops on the moon’s surface to manufacture metal structures as we do on Earth,” Li said. “However, it could be possible to use spacecraft to ship metal components from the Earth to the moon, then deploy welding technology there to assemble the components into large structures that could enable the establishment of a human community.”

Li’s project will simulate lunar conditions to test the processes of electrical arc, laser and electron-beam welding in that type of environment. His virtual lunar welding platform simulates the welding process and welding-joint mechanical properties with a multiple-physics modeling approach. Among the equipment he is using is a custom-built, directed energy deposition machine, a technology typically used for additive manufacturing of metals. Li said the research also could be applied to fused deposition modeling, a type of 3D-printing process that can print nonmetallic parts in space.

Li, who directs the Comprehensive Advanced Manufacturing Lab in the Jonsson School, will work with his team to create the simulated environment at UT Dallas while working directly with NASA researchers, including Dr. Fredrick Michael from NASA’s Marshall Space Flight Center.

Li said his team will validate the simulation framework and modeling results with both space-based and on-the-ground experiments, as well as with historical experimental flight data from Skylab, the first U.S. space station. He said the model could be developed further for other space environments, including Mars and the International Space Station.

Dr. Wei Li received a grant from NASA to develop a platform that could overcome some of the challenges in building permanent structures in harsh, thin-atmosphere and low-gravity environments. Credit The University of Texas

2 notes

·

View notes

Text

Unieke 3D-ontwerpen en creatieve printideeën: geef jezelf de vrijheid

In de wereld van exclusieve 3D-ontwerpen hebben creativiteit en functionaliteit de manier veranderd waarop producten tot stand komen. Van op maat gemaakte sieraden tot ingewikkelde architectonische modellen, 3D-ontwerpen bieden makers de mogelijkheid om hun fantasie te stretchen. Het gaat hierbij niet alleen om het maken van prototypes, maar ook om het realiseren van een visie die zich onderscheidt. Of het nu voor persoonlijke projecten of zakelijke ondernemingen is, moderne tools en software maken het voor iedereen mogelijk om gedetailleerde en originele ontwerpen te creëren die volledig aansluiten bij hun behoeften.

De opkomst van creatieve 3D-printideeën

Creatieve 3D print ideeën zijn een pijler geworden in veel sectoren sinds 3D-printing breed toegankelijk is. Deze ideeën variëren van interieurdecoratie en geavanceerde technologie tot educatieve materialen die jonge geesten inspireren. De veelzijdigheid van 3D-printing heeft een explosie van ideeën aangewakkerd die alleen worden beperkt door de verbeelding. Of u nu unieke telefoonhouders of complexe sculpturen ontwerpt, het medium biedt de mogelijkheid om ideeën tot leven te brengen. Zowel professionals als hobbyisten waarderen creatieve 3D-projecten omdat deze een uiting zijn van persoonlijkheid en passie.

Technologie achter exclusieve 3D-creaties

Exclusieve 3D ontwerpen worden aangedreven door technologie die net zo intrigerend is als de objecten zelf. Moderne 3D-printers gebruiken geavanceerde technieken zoals stereolithografie, selective laser sintering en fused deposition modeling om een ongelooflijk niveau van detail en nauwkeurigheid te bereiken. Deze ontwikkelingen hebben 3D-printing toegankelijker gemaakt voor particulieren en kleine bedrijven. Hierdoor kunnen ontwerpers complexe geometrieën en texturen verkennen die moeilijk met de hand te realiseren zijn.

Inspiratie voor uw volgende 3D-project

Op zoek naar creatieve 3D-printideeën? Inspiratie kan uit veel bronnen komen. Dagelijkse uitdagingen bieden vaak een perfecte basis voor praktische ontwerpen. Heeft uw bureau bijvoorbeeld een organizer nodig? Of bent u op zoek naar een gepersonaliseerd cadeau? Met 3D-printing kunt u oplossingen op maat maken die bij uw stijl passen. Bovendien bieden online communities en ontwerpplatforms volop ideeën en bevorderen zij samenwerking.

Conclusie

Voor iedereen die exclusieve 3D-ontwerpen wil ontdekken en creatieve 3D-printideeën wil realiseren, is het hebben van de juiste tools essentieel. Ongeacht uw ervaring als ontwerper is het vinden van een betrouwbaar platform zoals 3dbende.nl een geweldige start. Met moderne apparatuur en expertise kunt u deze wereld betreden en uw artistieke visie tot leven brengen!

2 notes

·

View notes

Text

Argentinosaurus huinculensis

(temporal range: 96.2-92.19 mio. years ago)

[text from the Wikipedia article, see also link above]

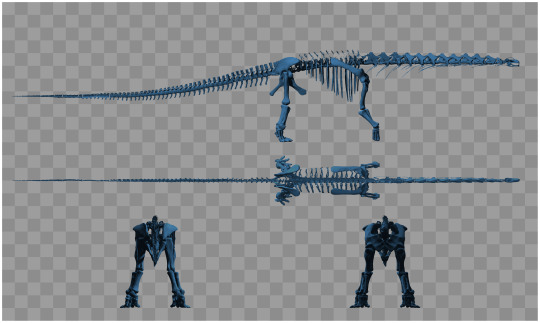

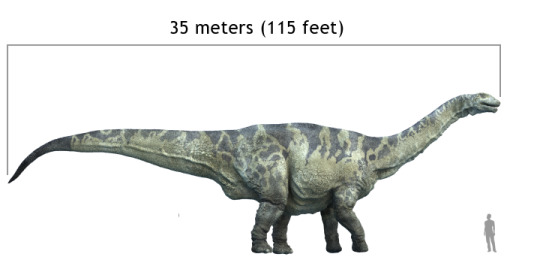

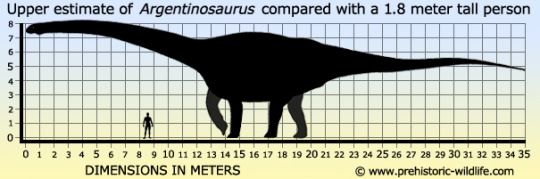

Argentinosaurus is a genus of giant sauropod dinosaur that lived during the Late Cretaceous period in what is now Argentina. Although it is only known from fragmentary remains, Argentinosaurus is one of the largest known land animals of all time, perhaps the largest, measuring 30–35 metres (98–115 ft) long and weighing 65–80 tonnes (72–88 short tons). It was a member of Titanosauria, the dominant group of sauropods during the Cretaceous. It is widely regarded by many paleontologists as the biggest dinosaur ever, and perhaps lengthwise the longest animal ever, though both claims have no concrete evidence yet.

The first Argentinosaurus bone was discovered in 1987 by a farmer on his farm near the city of Plaza Huincul. A scientific excavation of the site led by the Argentine palaeontologist José Bonaparte was conducted in 1989, yielding several back vertebrae and parts of a sacrum—fused vertebrae between the back and tail vertebrae. Additional specimens include a complete femur (thigh bone) and the shaft of another. Argentinosaurus was named by Bonaparte and the Argentine palaeontologist Rodolfo Coria in 1993; the genus contains a single species, A. huinculensis. The generic name Argentinosaurus means "Argentine lizard", and the specific name huinculensis refers to its place of discovery, Plaza Huincul.

The fragmentary nature of Argentinosaurus remains makes their interpretation difficult. Arguments revolve around the position of the recovered vertebrae within the vertebral column and the presence of accessory articulations between the vertebrae that would have strengthened the spine. A computer model of the skeleton and muscles estimated this dinosaur had a maximum speed of 7 km/h (5 mph) with a pace, a gait where the fore and hind limb of the same side of the body move simultaneously. The fossils of Argentinosaurus were recovered from the Huincul Formation, which was deposited in the middle Cenomanian to early Turonian ages (about 96 to 92 million years ago) and contains a diverse dinosaur fauna including the giant theropod Mapusaurus.

8 notes

·

View notes

Text

The Future in Layers: Understanding 3D Printing

3D printing, also known as additive manufacturing, is transforming how we design, create, and innovate. What once belonged to the realm of science fiction is now a powerful tool used in industries ranging from healthcare to aerospace. By building objects layer by layer from digital models, 3D printing offers flexibility, customization, and speed that traditional manufacturing often can’t match. 3D Printing

How 3D Printing Works At its core, 3D printing begins with a digital design, usually created using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers. The 3D printer reads these slices and deposits material — usually plastic, resin, metal, or even food — layer by layer until the final object takes shape.

There are several types of 3D printing technologies, including:

Fused Deposition Modeling (FDM) — Melts plastic filament and extrudes it layer by layer.

Stereolithography (SLA) — Uses UV light to cure liquid resin into solid layers.

Selective Laser Sintering (SLS) — Uses lasers to fuse powdered material, often metals or plastics.

Applications of 3D Printing

Healthcare: 3D printers are used to create prosthetics, dental implants, and even bioprinted tissues. Customization is key — no two patients are the same, and 3D printing makes it possible to tailor medical devices to individual needs.

Manufacturing: Prototyping with 3D printing is faster and more cost-effective than traditional methods. Companies can test and modify designs before full-scale production.

Education: Schools and universities use 3D printing to bring concepts to life in science, engineering, and art.

Architecture: Architects can produce detailed models and even explore 3D-printed housing for rapid, affordable construction.

Fashion & Art: Designers use 3D printing to create unique jewelry, clothing, and sculptures, often unachievable by hand.

Advantages of 3D Printing

Customization: Easily adapt designs for specific users or needs.

Speed: Rapid prototyping accelerates product development.

Reduced Waste: Additive processes use only the material needed.

Accessibility: Desktop 3D printers make production possible at home or in small businesses.

Challenges and Limitations Despite its promise, 3D printing faces challenges. Materials can be expensive or limited in strength and durability. Printing large objects can be time-consuming, and the technology still requires skilled operators for optimal results. Regulatory and safety standards are also developing to catch up with rapid innovation.

The Future of 3D Printing Looking ahead, 3D printing is poised to revolutionize supply chains, reduce environmental impact, and even explore new frontiers like space manufacturing. As the technology matures, we may see everyday products — from shoes to electronics — custom-printed just for us.

0 notes

Text

The Zortrax M200 Plus 3D Printer machine is a durable workhorse, engineered to handle even the most demanding printing jobs. This capacity to 3D Print long hour jobs with utmost accuracy is very important for a 3D Printer machine, which standout in rapid prototyping, with Layer Plastic Deposition (LPD) 3D Printing technology (similar to fused deposition modelling a.k a Fused Filament Fabrication, FFF technology) for addressing various 3D printing applications. With its robust build quality, this is a highly durable 3D Printing machine with less cost to maintain and at the same time it supports various inhouse and open source 3D Printing filaments.

#3d printers#types of 3d printers#best 3d printers#3d printers india#3d printers near me#3d printers in india#3d printers in bangalore#industrial 3d printers#different types of 3d printers#3d printers for sale#best 3d printers in india#what are 3d printers#3d printers cost#3d printers bangalore#3d scanners#types of 3d scanners#handheld 3d scanners#3d scanners for 3d printers#artec 3d scanners#top 3d scanners#3d scanners for reverse engineering#industrial 3d scanners#how do 3d scanners work#cheap 3d scanners#3d scanners for 3d printing#best 3d scanners#3d printers and scanners#3d scanners near me#3d scanners in india

0 notes

Text

Automotive 3D Printing Market to be Worth $17.9 Billion by 2032

Meticulous Research®—a leading global market research company, published a research report titled ‘Automotive 3D Printing Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication, the automotive 3D printing market is projected to reach $17.9 billion by 2032, at a CAGR of 22% from 2025–2032.

The automotive 3D printing market is experiencing growth driven by several factors, including the increasing adoption of fused deposition modeling (FDM) for manufacturing automotive components, the rising utilization of 3D printing for tooling and manufacturing aids, and the growing demand for polymers in automotive applications. However, the market growth is hindered by the high costs associated with 3D printing materials.

Furthermore, the increasing consumer demand for customized and personalized automotive parts, coupled with government initiatives promoting the adoption of 3D printing technologies, presents significant opportunities for market participants. However, this market also faces considerable challenges, including a lack of awareness and a shortage of skilled professionals. Moreover, the growing integration of artificial intelligence (AI) in design and production processes, along with the increasing use of sustainable and recyclable materials in 3D printing, represents a prominent trend in the automotive 3D printing market.

Key Players

The automotive 3D printing market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the automotive 3D printing market are 3D Systems Corporation (U.S.), Stratasys Ltd (U.S.), Desktop Metal, Inc. (ETEC) (U.S.), Dassault Systèmes S.E. (France), EOS GmbH (Germany), ExOne Operating, LLC (U.S.), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Proto Labs, Inc. (U.S.), Formlabs Inc. (U.S.), voxeljet AG (Germany), Markforged Holding Corporation (U.S.), MATERIALISE NV (Belgium), Ultimaker B.V. (Netherland), IC3D, Inc. (U.S.), Moog Inc. (U.S.), and Zortrax S.A. (Poland).

The automotive 3D printing market is segmented based on offering, technology, component, vehicle type, and application. The report also evaluates industry competitors and analyzes the market at the regional and country levels.

Among the offerings studied in this report, the hardware segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of the 3D printing hardware segment in the automotive market is driven by several key factors, including the rapid growth of 3D printing technology for creating complex part designs, an increased focus on reducing material waste and enhancing fuel efficiency through lightweight components, and the growing utilization of 3D printing hardware for tooling and manufacturing aids in vehicle production.

Among the technologies studied in this report, the fused deposition modeling (FDM) segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of Fused Deposition Modeling (FDM) in the automotive 3D printing market is attributed to its cost-effectiveness and capability to produce a diverse array of 3D-printed objects. The technology's rapid growth in reducing lead times and accelerating the prototyping process further enhances its appeal. Additionally, the increasing adoption of FDM is driven by its versatility in 3D printing with a wide range of materials, including polymers, metals, and ceramics.

Among the components studied in this report, the exterior components segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The segment's dominant position is boosted by the significant growth in manufacturing lightweight exterior body panels, which enhance vehicle performance. Additionally, the rising adoption of 3D printing for the production and prototyping of components such as mirror housings, tail lights, and headlights further contributes to this segment's dominance.

Among the vehicle types studied in this report, the ICE vehicles segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of 3D printing for internal combustion engine (ICE) vehicles in the automotive market is driven by several factors, including the flexibility in design it offers, a growing demand for aftermarket parts and custom components, and increased prototyping capabilities for ICE vehicles. Additionally, the established and widespread use of ICE vehicles, compared to electric or hybrid alternatives, further enhances the adoption of 3D printing in this segment.

Among the applications studied in this report, the prototyping segment is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. The dominant position of 3D printing in the automotive sector is supported by several factors, including its rapid ability to create prototypes of various components and test designs before full-scale production. The technology's capability to easily produce complex geometries and customized parts further enhances its appeal. Additionally, 3D printing contributes to more sustainable prototyping by minimizing material waste and reducing energy consumption, contributing to the automotive 3D printing market.

Geographic Review

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Sweden, Switzerland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Malaysia, Australia & New Zealand, Indonesia, Vietnam, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Israel, Saudi Arabia, and Rest of Middle East & Africa).

Among the geographies studied in this report, North America is anticipated to hold the dominant position, with a large share of the automotive 3D printing market in 2025. This position is fueled by several key factors, including significant technological innovations from leading automotive manufacturers, increased investment in research and development within the sector, and rising demand for customized, high-performance vehicle components. Furthermore, the presence of an established supply chain infrastructure enhances the market's growth potential.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6038

Key Questions Answered in the Report:

What is the value of revenue generated by the sale offering, technology, component, vehicle type, and application?

At what rate is the global demand for automotive 3D printing projected to grow for the next five to seven years?

What is the historical market size and growth rate for the automotive 3D printing market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the automotive 3D printing market?

Who are the major players in the automotive 3D printing market? What are their specific product offerings in this market?

What recent developments have taken place in the automotive 3D printing market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Automotive 3D Printing Market#Fused Deposition Modeling. Automotive 3D Printing#Polymers#Selective Laser Sintering#Interior Components#Exterior Components#Prototyping#Production Parts#Tooling and Manufacturing Aids

0 notes

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing

1 note

·

View note

Text

Discover the Future of Manufacturing with Online 3D Printing in India and Cheap 3D Printer Options

In recent years, technology has redefined how businesses and individuals approach manufacturing and design. One innovation that stands out is 3D printing—a tool that turns digital designs into physical objects with precision. Today,Online 3d Printing India has become not only accessible but also affordable, thanks to a growing market and advancements in printer technology. Whether you're a student, hobbyist, startup founder, or engineer, there's never been a better time to explore cheap 3D printer options in India.

Embracing Online 3D Printing in India

Online 3D printing services have revolutionized the Indian manufacturing ecosystem. Traditional prototyping was once time-consuming and expensive, often requiring large-scale industrial machinery. Now, with just a few clicks, users can upload CAD files and receive custom parts delivered to their doorstep—often within days.

This rapid shift to online 3D printing in India has empowered a wide range of users. Entrepreneurs and product designers now have the ability to test prototypes affordably. Architecture firms can produce intricate scale models without outsourcing abroad. Even medical professionals are exploring custom prosthetics and dental models—all enabled by accessible 3D printing platforms.

Some of the most popular online 3D printing services in India include:

think3D

Printo

Ethical 3D

3Ding

Fracktal Works

These platforms allow users to select materials, define dimensions, and choose between different printing technologies such as FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering).

Affordable Innovation: Cheap 3D Printer Options in India

While online services are excellent for occasional use, many people and businesses are opting to invest in their own machines. Fortunately, the cost barrier has dropped significantly, making it easier to own a 3D printer without spending a fortune. The market for cheap 3D printers in India is growing rapidly, with reliable models available for as little as ₹15,000–₹30,000.

Some of the top affordable 3D printer brands include:

Creality Ender Series (Ender 3, Ender 3 V2) Highly rated for hobbyists and beginners, these models offer excellent print quality at a low price.

Anycubic i3 Mega / Photon Series Popular for resin printing and detailed work, Anycubic is a go-to for those interested in finer resolution.

WOL3D An Indian brand offering budget-friendly options tailored to Indian consumers with solid after-sales service.

FlashForge Finder A user-friendly 3D printer ideal for educational and home use, particularly popular in schools.

These budget printers provide great value for money and are capable of producing professional-grade models, miniatures, mechanical parts, and more. Most of them come semi-assembled with user-friendly software like Cura, simplifying the learning curve for new users.

Key Benefits of Using Online 3D Printing in India

Convenience With online services, you don’t need to own a printer or invest in materials. Upload your design, choose the specs, and let the service provider handle the rest.

Material Variety Online platforms offer multiple printing materials—from standard PLA and ABS to advanced options like carbon fiber, nylon, or metal composites.

No Maintenance Hassles Maintenance and calibration are handled by experts, so you don’t have to worry about machine downtime.

Scalability Whether you're printing a one-off prototype or a short production run, online platforms scale easily to fit your needs.

Technical Expertise Many services also offer design consultations, helping clients optimize their models for better print quality and cost-effectiveness.

Why More Indians Are Buying Cheap 3D Printers

Cost-Efficient Prototyping For startups and freelancers, owning a 3D printer cuts prototyping costs drastically over time.

Learning and Education Schools and colleges are investing in low-cost 3D printers to introduce students to design thinking, CAD, and manufacturing.

Creative Freedom Artists, hobbyists, and makers use home printers to create custom toys, jewelry, cosplay items, and household gadgets.

Entrepreneurial Opportunities Many have turned 3D printing into a side hustle—offering local printing services, selling models online, or even creating niche products for e-commerce.

Tips for Choosing the Right Cheap 3D Printer in India

Know Your Use Case: Are you printing prototypes, models, toys, or functional parts? Choose the technology accordingly (FDM for general use, SLA for detail).

Check Community Support: Go for models with large user communities for easy troubleshooting and mods.

Look for After-Sales Service: Ensure the brand has support centers or easy access to replacement parts in India.

The Road Ahead: 3D Printing in India

India’s 3D printing ecosystem is just getting started. With government initiatives supporting Atmanirbhar Bharat and Make in India, there's a strong push to integrate advanced manufacturing technologies. As awareness spreads and costs decline further, online 3D printing in India and cheap 3D printers will become even more commonplace.

In fields like healthcare, education, architecture, and fashion, we can expect a rise in demand for personalized and on-demand manufacturing. From Jaipur’s prosthetic development labs to Bengaluru’s tech startups, India is steadily becoming a global player in 3D printing innovation.

Conclusion

The fusion of online convenience and affordability has made 3D printing a game-changer in India. Whether you need a one-time print job or are ready to explore the endless possibilities of home manufacturing, both online 3D printing in India and the growing range of Cheap 3d Printer Indiaoffer practical solutions for every level of user. As the technology evolves, it's clear that the future of fabrication is already within reach—layer by layer.

0 notes

Text

ANH: Cutting-edge Rapid Prototyping and 3D Printing Services in India

What We Offer: Precision at Every Layer

We harness a variety of industry-leading 3D printing technologies to bring your designs to life with unmatched quality:

SLA (Stereolithography) — Perfect for highly detailed, smooth surface parts.

SLS (Selective Laser Sintering) — Ideal for durable, functional prototypes without the need for support structures.

MJF (Multi Jet Fusion) — Great for producing strong, complex geometries at scale.

FDM (Fused Deposition Modeling) — A cost-effective method for both prototypes and end-use parts.

Each of these technologies caters to different needs — whether it’s fine detailing, structural strength, or low-cost prototyping. At ANH, our team helps you choose the best-fit solution tailored to your project goals.

Why Choose ANH for Rapid Prototyping?

✅ Quick Turnaround — We understand deadlines. Our agile processes ensure you receive your prototype faster, without compromising on quality.

✅ Industry Expertise — From automotive to aerospace, medical to consumer goods — we’ve worked across industries and understand their unique prototyping demands.

✅ In-House Experts — Our skilled engineers and technicians guide you throughout the journey , from design consultation to final delivery.

✅ Quality Assurance — Every print undergoes strict quality checks to meet precision, durability, and functionality standards.

Applications Across Industries

Automotive — Test parts, functional assemblies, or ergonomic models.

Aerospace — Lightweight components, complex geometries, and performance testing.

Medical — Custom devices, surgical tools, and anatomical models.

Consumer Goods — Product design validation, packaging mockups, and quick market testing.

Whether it’s a one-off prototype or a low-volume production run, we’re ready to deliver excellence.

From Concept to Creation — Seamlessly

Prototyping isn’t just about printing parts — it’s about accelerating innovation. At ANH, we partner with you to reduce development costs, shorten lead times, and improve product performance through effective prototyping strategies.

We don’t just deliver prints. We deliver solutions.

Ready to Innovate?

If you’re looking to test a concept, refine a design, or scale up with functional parts, ANH is your trusted partner for rapid prototyping and 3D printing services in India.

Let’s bring your ideas to life — faster, better, and smarter.

📞 Contact us today to learn how we can support your next big idea!

0 notes

Text

3D and 4D Printing Technology Market - Strategic Developments

Business Market Insights recently announced the release of the market research titled 3D and 4D Printing Technology Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the 3D and 4D Printing Technology market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. 3D and 4D Printing Technology Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the 3D and 4D Printing Technology market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated 3D and 4D Printing Technology market research has all that you need.

What are Key Offerings Under this 3D and 4D Printing Technology Market Research?

Global 3D and 4D Printing Technology market summary, current and future 3D and 4D Printing Technology market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global 3D and 4D Printing Technology Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the 3D and 4D Printing Technology Market?

3D and 4D Printing Technology market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. 3D and 4D Printing Technology market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their 3D and 4D Printing Technology market share.

Report Attributes

Details

Segmental Coverage

Technology

Stereolithography

Fused Deposition Modelling

Selective Laser Sintering

Direct Metal Laser Sintering

Polyjet/Multijet Printing

Electron Beam Melting

Digital Light Processing

Material

Plastics

Metal

Ceramics

Composites

Resins

Bio-Metals

Hybrid Metals

Application

Prototyping

Manufacturing

Research & Development

End Use Industry

Aerospace & Defence

Automotive

Healthcare

Consumer Goods

Construction

Education & Research

Electronics

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Stratasys Ltd.

3D Systems Corporation

Materialise NV

Autodesk, Inc.

Hewlett Packard Enterprise (HP)

EOS GmbH

Desktop Metal, Inc.

Organovo Holdings, Inc.

Dassault Syst?mes SE

Nano Dimension Ltd.

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective 3D and 4D Printing Technology market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The 3D and 4D Printing Technology market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

Business Market Insights is a market research platform that provides subscription services for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductors, Aerospace & Defense, Automotive & Transportation, Energy & Power, Healthcare, Manufacturing & Construction, Food & Beverages, Chemicals & Materials, and Technology, Media & Telecommunications.

Contact Us:

If you have any questions about this report or would like further information, please contact us:

Contact person: Ankit Mathur

Email: [email protected]

Phone: +16467917070

#3D and 4D Printing Technology Market#3D and 4D Printing Technology Market Size#3D and 4D Printing Technology Market Trends#3D and 4D Printing Technology Market Shares#3D and 4D Printing Technology Market Growth

0 notes

Text

How fast is 3D printing?

How fast can 3D printing be? In what scenarios can it really bring the dual advantages of speed and cost? This article will compare mainstream 3D printing technologies (such as FDM, SLA, SLS, MJF) with traditional processes (such as CNC, injection molding, casting), combined with typical production scenarios, to dismantle the technical core and commercial significance of "3D printing speed" for you.

I believe that after reading this article, you will have a clearer answer to "when to use 3D printing and why it is so fast and meaningful".

Fast 3D Printing vs. Traditional Crafts: Which is Faster?

Before we compare specific technologies, let's clarify a basic issue: FDM (fused deposition modeling), SLA (stereolithography), MJF (multi-jet fusion), these names are all different molding principles of 3D printing. They each have their own unique printing methods, material adaptability and speed performance, so they have their own advantages in efficiency. In sharp contrast to them, traditional manufacturing processes such as CNC, injection molding, and casting also have completely different production capacity structures and response rhythms. Let's disassemble them one by one to see whether 3D printing technology can catch up in terms of speed.

FDM vs. CNC

When you need to make a small tool sample urgently (for example, wThe advantage of this technology lies not only in its speed, but also in its flexibility. In particular, after adjusting the nozzle diameter (such as above 0.6mm), the nozzle speed can reach 150 mm/s, and a medium-complex part with a height of 100mm can be printed within 1 hour. FDM has obvious advantages in printing speed, which can significantly improve molding efficiency and is suitable for rapid prototyping and testing of medium-complexity prototypes.hen the design is completed at 3 pm and the installation verification is required in the evening), FDM (fused deposition modeling) technology will be the best solution.

But if it is changed to CNC, the delivery time is often measured in days due to the preparation of process documents, debugging of tool fixtures, and cutting process.

SLA/DLP vs. Injection Molding

SLA (stereolithography) is known for its high precision, with a layer thickness of 0.025–0.1 mm, an accuracy of up to ±25μm, and a molding speed of about 10–30 mm/h. The advantage of SLA printing speed is not its high speed, but its ability to output stably while maintaining surface quality, which is suitable for scenes with high requirements for process consistency.

DLP (digital light processing) is more efficient in printing. It increases the printing speed to 50-100 mm per hour by exposing the entire layer of the image at the same time, which is particularly efficient in the production of small-sized and large-quantity parts. The advantage of DLP printing speed is that it can quickly respond to batch requirements. It keeps a certain degree of accuracy while minimizing the unit molding time.

In contrast, although injection molding is very fast in single-piece molding speed, its overall delivery cycle is often extended by the pre-process of "mold development", which usually takes several days or even weeks and is accompanied by high costs. If the product design is frequently adjusted, the trial and error cost of repeated mold changes will also be very high.

SLM vs. Metal Casting

The biggest feature of SLM is that it can print complex structures in one go - for example, parts with through holes, buckles, and grids, without any support. Since SLM does not require mold opening and prefabrication processes, it can significantly speed up the overall delivery speed in the early stages of product development.

In contrast, although metal casting has cost advantages in mass production, the preparation process is long - mold design, casting cooling, and deburring often take several days or even a week. If you encounter a business scenario that requires rapid iteration, metal casting technology is basically unsolvable.

How fast 3D printing wins in three major scenarios with speed

In addition to the differences in the technology itself, the advantages of 3D printing speed also vary in different practical scenarios. From R&D proofing to mass production, we take a panoramic look at its actual performance at the application level.

Rapid prototyping

In the early stages of hardware product development, whether or not samples can be produced within a day often determines the efficiency of project iteration. Compared with traditional manufacturing that requires production scheduling, mold making, and debugging, 3D printing can achieve same-day design and same-day delivery. FDM printing is suitable for structural verification and preliminary testing, while SLA can achieve high-quality appearance models with a resolution of ±25μm. No mold is required, and samples can be produced directly, which is the biggest speed advantage of 3D printing in the prototype stage.

3D printing technology understands that prototype verification is not a one-time delivery, but a cycle mode of rapid trial and error-instant correction to promote continuous product evolution. Making trial and error fast and low-cost is the key force that 3D printing technology gives to the rhythm of product development.

Small batch custom production

When products pursue personalization and frequent iterations, the mold development and assembly processes of traditional manufacturing often cannot keep up with the pace. 3D printing technologies such as MJF and SLM do not require mold opening and can directly print finished parts. Taking MJF as an example, the industrial model has an hourly output of more than 3,000 cm⊃3;, which is suitable for typical scenarios such as orthopedic brackets and customized shells.

The key to small-batch customization is not the unit cost, but the response speed of delivery and the freedom of design. 3D printing provides a new generation of flexible manufacturing path.

Large-scale standardized production

Although injection molding and CNC still dominate in mass manufacturing, 3D printing is becoming an accelerator for early verification. In the stages of new product trial sales and regional testing, 3D printing can deliver hundreds of samples within a few days, seize the market time window, and reduce the risk of repeated mold modifications.

In mass manufacturing, 3D printing is not a substitute, but an accelerator. It helps companies quickly try and fail in uncertainty and make more informed judgments before formal mass production.

In an era where manufacturing efficiency has become a competitive threshold, the speed dividend of 3D printing has moved from prototypes to mass production, from innovation to profits. It can not only fill the response window of traditional processes, but also provide a decision buffer in uncertainty. The question is not whether 3D printing can be used, but when it is most cost-effective to use it. The following table summarizes the performance of various manufacturing methods in terms of speed, flexibility and cost under different production goals, helping you to judge at a glance:

3D printing is not the opposite of traditional manufacturing, but a powerful complement to it. From rapid prototyping, flexible trial production to product verification, it allows companies to conduct trial and error quickly and at low cost, speeding up the pace of every idea to implementation. This is exactly the key point mentioned at the beginning of the article: the real manufacturing advantage does not lie in how fast the machine runs, but in whether you can use "speed" on the blade of innovation at the right time.

Want to learn more about which 3D printing solution is best for your product design or production line? Contact us for a free consultation.

1 note

·

View note

Text

Japan Healthcare 3D Printing Market Reset: Analyzing Economic Stressors and Trade Policy Shocks

Introduction: The latest research study from Prophecy Market Insights offers a thorough analysis of the Healthcare 3D Printing Market , focusing on risk assessment, opportunities, and strategic decision-making support. This report provides insights into market development, trends, growth factors, and investment structures, aiding businesses in navigating the evolving landscape of Healthcare 3D Printing Market. Report Sample: A brief overview of the research report. Graphical presentation of regional analysis. Revenue analysis of top players in the market. Selected illustrations of market insights and trends. Example pages from the report. Healthcare 3D Printing Market Overview: The research provides a systematic approach to gathering, evaluating, and interpreting market data, including customer preferences, competitor analysis, and sectoral trends. It helps companies understand customer needs, assess market demand, and identify growth opportunities. Market research offers valuable insights through surveys, interviews, and data analysis, guiding product development, marketing strategies, and decision-making processes. Request a Sample Strategic Report in PDF Format: https://www.prophecymarketinsights.com/market_insight/Insight/request-pdf/5028 Leading Key Players Operating in the Healthcare 3D Printing Market 3D Systems Inc. Formlabs Inc. Materialise NV. The ExOne Company General Electric Company Bio3D Technologies Organovo Holdings Inc. Stratasys Ltd. Proto Labs Inc. SLM SOLUTIONS GROUP AG. and others. Key players are well-known, powerful businesses that have a big impact on a certain market or sector. Finding the important companies is essential to comprehending the dynamics of the industry or the competitive environment. Please be aware that changes in the industry, mergers, acquisitions, or the entry of new competitors may cause the status of important players to alter over timeHealthcare 3D Printing Market: Demand Analysis & Opportunity Outlook 2034 Healthcare 3D Printing Market analyzes customer preferences, economic trends, and industry dynamics to predict demand patterns and identify new opportunities. By leveraging data-driven research and predictive modeling, businesses can anticipate changes in market demand, plan product development, and position themselves proactively in the evolving business landscape of 2034. Major Market Analysis Findings: Consumer preferences: Businesses can better understand their target audience’s preferences by conducting market research, which can reveal things like preferred product features, pricing, and branding. The most crucial product characteristics, the most alluring pricing points, and the most effective brand messaging are just a few examples of key findings. Market size and growth potential: Businesses can evaluate the size of the market and its growth potential with the use of market research. The size of the market overall, the size of particular market segments, and the market’s anticipated growth rate are just a few examples of key findings. Market trends: Businesses can use market research to spot new market trends, such as alterations in customer behavior, adjustments to industry rules, or the arrival of new technologies. The most important market trends, the causes influencing those trends, and their possible effects on the company may be some of the key findings. Get a free sample of the report: https://www.prophecymarketinsights.com/market_insight/Insight/request-sample/5028 (The sample of this report is readily available on request) The segments and sub-section of Healthcare 3D Printing Market is shown below: Market Segmentation: Healthcare 3D Printing Market, By Product (Laser Based, Syringe Based, Inkjet Based, Magnetic Levitation), By Technology (Stereo-lithography, Selective Laser Sintering (SLS), Fused Deposition Modelling (FDM)), By Application (Implants, Tissue Engineering, Clinical Study Devices, External Wearable Devices, and Others) and By Region

(North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) - Trends, Analysis and Forecast till 2032 Regional Analysis for Healthcare 3D Printing Market: This section of the report includes comprehensive information on Healthcare 3D Printing Market that is accessible in several fields. Each region offers a distinct Healthcare 3D Printing Market length as each state has its own executive insurance laws and components. North America - U.S., Canada Europe - UK, Germany, Spain, France, Italy, Russia, Rest of Europe Asia Pacific - Japan, India, China, South Korea, Australia, Rest of Asia-Pacific Latin America - Brazil, Mexico, Argentina, Rest of Latin America Middle East & Africa - South Africa, Saudi Arabia, UAE, Rest of Middle East & Africa Research Methodology The research methodology employed by Prophecy Market Insights for market research involves a systematic approach that integrates primary and secondary research techniques. Through direct interactions with industry experts and stakeholders, as well as comprehensive analysis of secondary sources, we gather valuable data on market trends, consumer behavior, and competitive landscape. Advanced data analysis techniques are then applied to interpret this data accurately, providing clients with actionable insights to make informed decisions and strategies in today's dynamic marketplaces. Author: Shweta.R is a market research analyst with deep expertise in the food and nutrition sector. Passionate about data-driven insights, She focuses on identifying emerging trends and growth opportunities. About Us: Prophecy Market Insights is a leading provider of market research services, offering insightful and actionable reports to clients across various industries. With a team of experienced analysts and researchers, Prophecy Market Insights provides accurate and reliable market intelligence, helping businesses make informed decisions and stay ahead of the competition. The company's research reports cover a wide range of topics, including industry trends, market size, growth opportunities, competitive landscape, and more. Prophecy Market Insights is committed to delivering high-quality research services that help clients achieve their strategic goals and objectives. Contact Us: Prophecy Market Insights Website- https://www.prophecymarketinsights.com US toll free: +16893053270

0 notes